Production technology of high-efficiency and high-concentration polyaluminum chloride

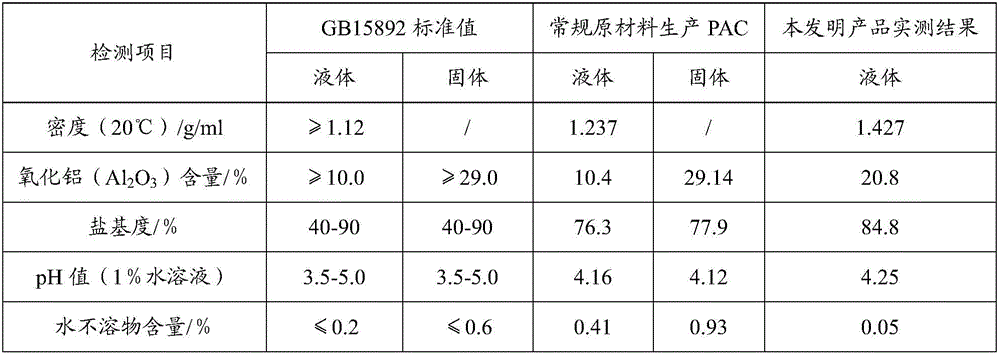

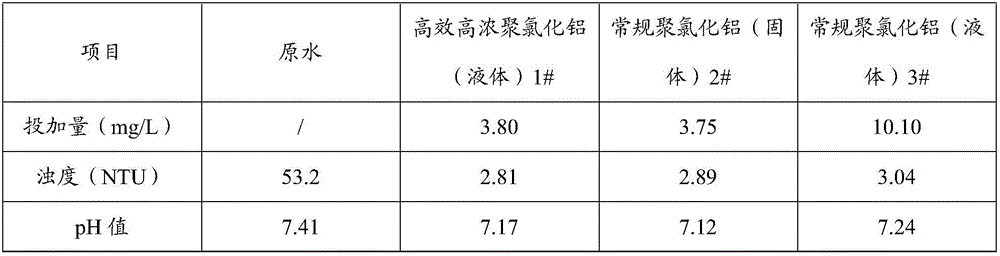

A polyaluminum chloride, production process technology, applied in the direction of aluminum chloride, aluminum halide, etc., can solve the problems of high cost performance and lack of promotion of liquid products, and achieve the effect of improving product quality indicators and increasing the degree of polymerization of products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

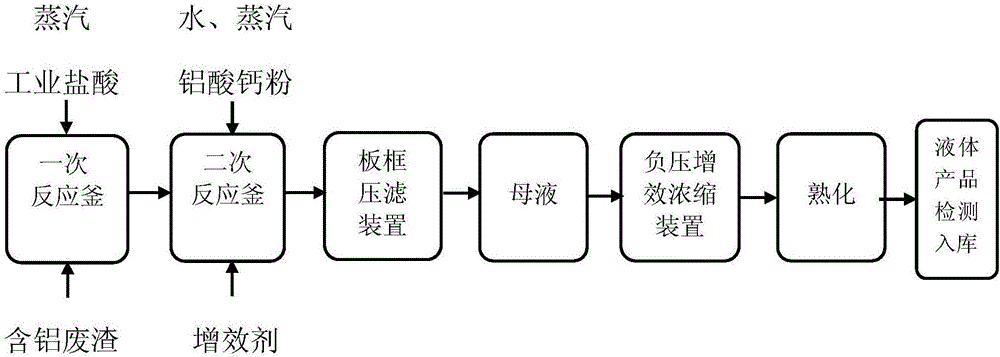

Method used

Image

Examples

Embodiment 1

[0037] Step 1: In an acid-resistant primary reaction kettle heated by steam with a stirring device, add appropriate amount of water and 175 parts of industrial hydrochloric acid while stirring to prepare a hydrochloric acid solution with a volume concentration of 22.8%; Add 138 parts of aluminum-containing waste slag, stir until dissolved; then continue to heat up until the temperature of the reaction system is controlled at 100-125°C, and react for 3 hours under normal pressure; sampling and testing;

[0038] Step 2: Pump the primary feed liquid obtained in Step 1 into an acid-resistant polymerization secondary reaction kettle with a stirring device heated by steam, start stirring, add an appropriate amount of water, start adding 46 parts of calcium aluminate powder, and add After the completion, adjust the density of the feed liquid to 1.24g / ml with water, then add 6 parts of synergist trisodium phosphate, raise the temperature until the temperature of the reaction system is ...

Embodiment 2

[0043] Step 1: In an acid-resistant primary reaction kettle heated by steam with a stirring device, add appropriate amount of water and 209 parts of industrial hydrochloric acid while stirring to prepare a hydrochloric acid solution with a volume concentration of 24%; Add 157 parts of aluminum-containing waste slag, stir until dissolved; then continue to heat up until the temperature of the reaction system is controlled at 100-125°C, and react for 4.5 hours under normal pressure; sampling and testing;

[0044] Step 2: Pump the primary feed liquid obtained in Step 1 into an acid-resistant polymerization secondary reaction kettle with a stirring device heated by steam, start stirring, add an appropriate amount of water, start adding 61 parts of calcium aluminate powder, and add After the completion, adjust the density of the feed liquid to 1.26g / ml with water, then add 8 parts of synergist trisodium phosphate, raise the temperature until the temperature of the reaction system is ...

Embodiment 3

[0049] Step 1: In an acid-resistant primary reaction kettle with a stirring device heated by steam, add appropriate amount of water and 188 parts of industrial hydrochloric acid while stirring to prepare a hydrochloric acid solution with a volume concentration of 23.5%; Add 149 parts of aluminum-containing waste slag to the mixture, stir until dissolved; then continue to heat up until the temperature of the reaction system is controlled at 100-125°C, and react for 4 hours under normal pressure; sampling and testing;

[0050] Step 2: Pump the primary feed liquid obtained in Step 1 into an acid-resistant polymerization secondary reactor with a stirring device heated by steam, start stirring, add an appropriate amount of water, start adding 54 parts of calcium aluminate powder, and add After the completion, adjust the density of the feed liquid to 1.25g / ml with water, then add 7 parts of synergist trisodium phosphate, raise the temperature until the temperature of the reaction sys...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com