Beneficiation method for producing multi-product nickel concentrate

A beneficiation method and multi-product technology, applied in the beneficiation field of pentlandite and nickel-containing pyrrhotite, to achieve the effect of improving the comprehensive recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0038] (1) The raw ore may be a mixed ore of pentlandite and nickel-containing pyrrhotite.

[0039] (2) The ore grinding can be carried out by using a vertical mill or a wet ball mill according to the method in the prior art.

[0040] (3) A mixture of sodium metabisulfite and diethylene triamine is added to at least one of the one-time roughing described in step a, the one-time beneficiation described in step b, and the one or more beneficiation described in step c As a pyrrhotite inhibitor.

[0041] (4) For each flotation (including rough selection, selection, sweep selection, low-nickel selection, low-nickel fine sweeping), collectors, foaming agents, activators, pulses can be added according to the existing technology. Stone inhibitors and modifiers; for example, terpineol oil can be used as foaming agent, copper sulfate can be used as pyrrhotite activator, guar gum and starch can be used as gangue inhibitors.

[0042] Specifically, the beneficiation method for producing multi-pro...

Embodiment 1

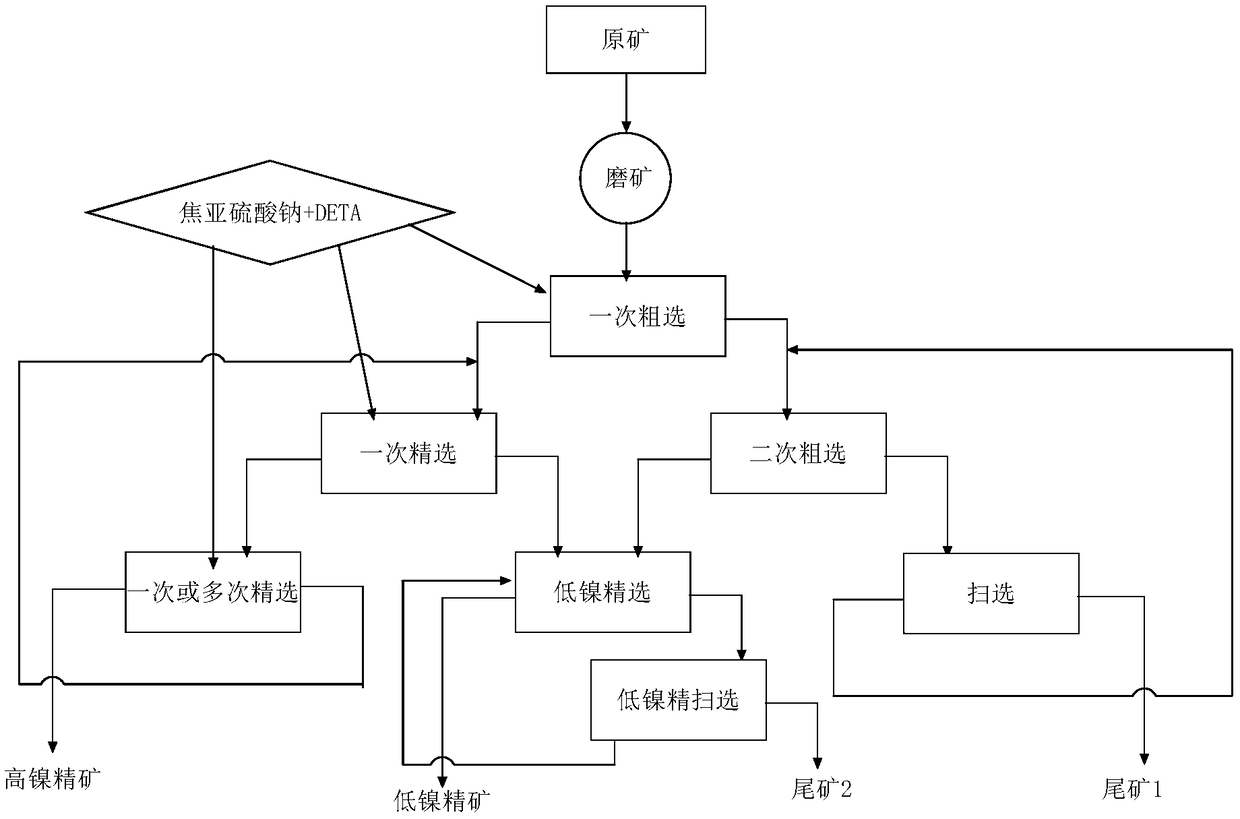

[0051] Such as figure 1 As shown, a beneficiation method for producing multi-product nickel concentrate can be used for flotation of mixed ore of pentlandite and nickel-containing pyrrhotite, which specifically may include the following steps:

[0052] Step a1. Grind the raw ore to prepare raw ore slurry, and add gangue mineral inhibitor addition, collector and foaming agent to the raw ore slurry for a rough separation, thereby obtaining a rough concentrate and a rough concentrate. Select tailings. Among them, gangue mineral inhibitor uses carboxymethyl cellulose (CMC) 500g / t, collector uses butyl xanthate 60g / t, and foaming agent uses methyl isobutyl carbinol (MIBC) 40g / t.

[0053] Step b1: Adding gangue mineral inhibitor and pyrrhotite inhibitor to the primary coarse beneficiation concentrate to perform primary beneficiation, thereby obtaining primary beneficiation concentrate and primary beneficiation tailings. Wherein, the gangue mineral inhibitor adopts carboxymethyl cellulo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com