Patents

Literature

65results about How to "Improve floatability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Collophanite flotation collector and method for preparing same

ActiveCN101797536AStable chemical propertiesGood water solubilityFatty acids production/refiningFlotationSolubilityFatty acid

The invention relates to a collophanite normal-temperature flotation collector, in particular to collophanite flotation collector prepared from natural rubber seed oil fatty acid, belonging to the collector. The invention also relates to a method for preparing the collophanite flotation collector. The collophanite flotation collector comprises natural rubber seed oil fatty acid, tall oil, tributyl phosphate, tween 80, dodecyl benzene sulfonic acid, inorganic base and water. The collophanite flotation collector has stable chemical performance, good water solubility, high flotation speed, suitable viscosity and strong selectivity and collection performance, is easy to diffuse in collophanite pulp, can be used for obverse floatation and reverse flotation and can generate uniform bubbles, obviously shorten the floatation time, improve the concentrate grade and reduce the content of impurities in the concentrate product.

Owner:YUNNAN CHEM RES INST

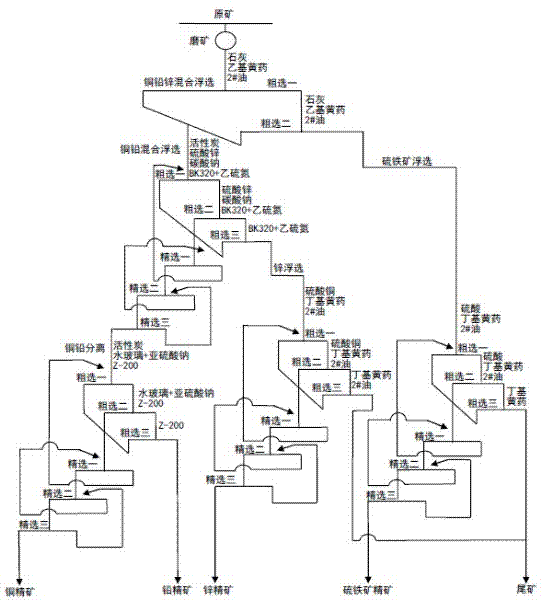

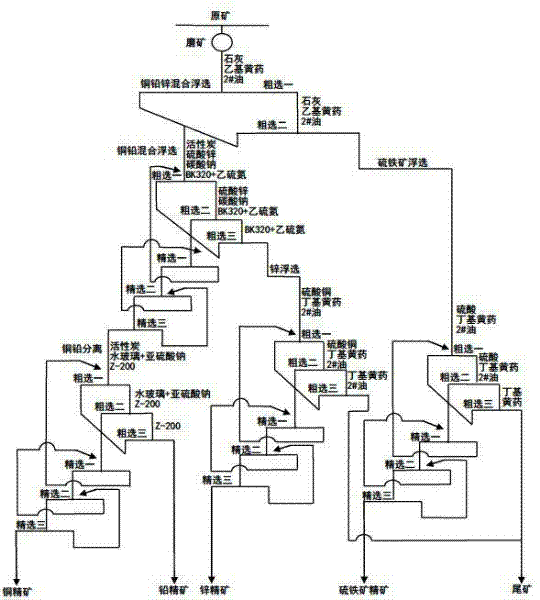

Mineral dressing method for separating Cu-Pb-Zn-Fe multi-metal sulfide mineral

The invention discloses a mineral dressing method for separating a Cu-Pb-Zn-Fe multi-metal sulfide mineral, which comprises the following steps: selecting a raw mineral, grinding the mineral, carrying out mixed flotation to Cu, Pb and Zn, carrying out mixed flotation to Cu and Pb, separating Cu and Pb, carrying out Zn flotation and pyrite flotation, and finally obtaining a Cu, Pb, Zn and pyrite concentrate. The method has the advantages of good metal sulfide mineral effect and high metal recovery rate, is simple to operate and is suitable to popularize and apply.

Owner:KUNMING UNIV OF SCI & TECH

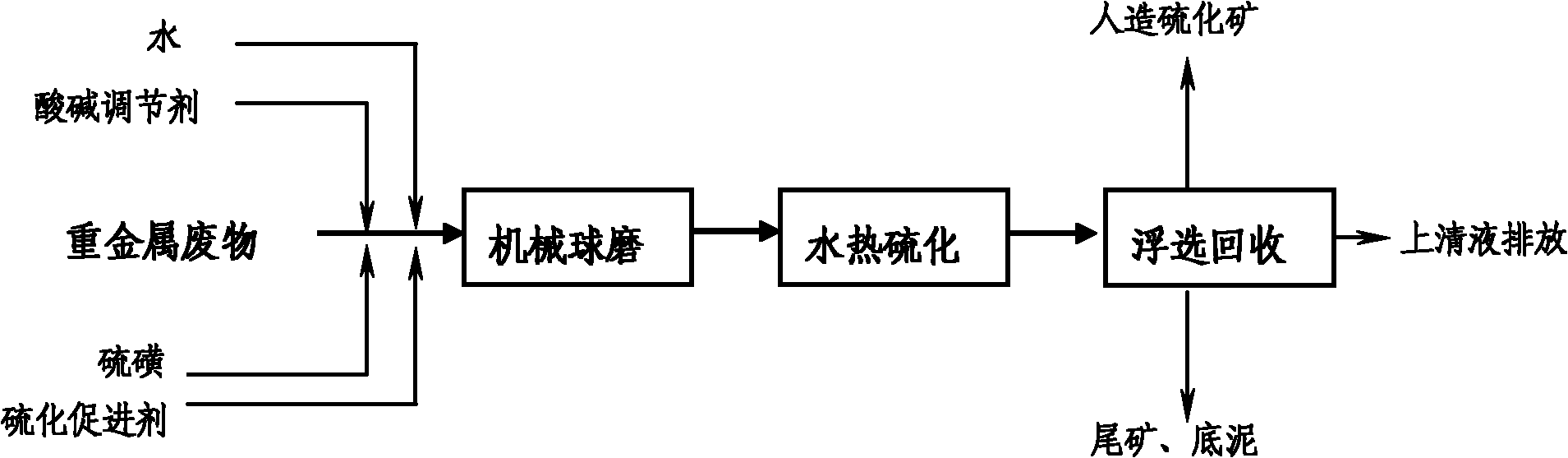

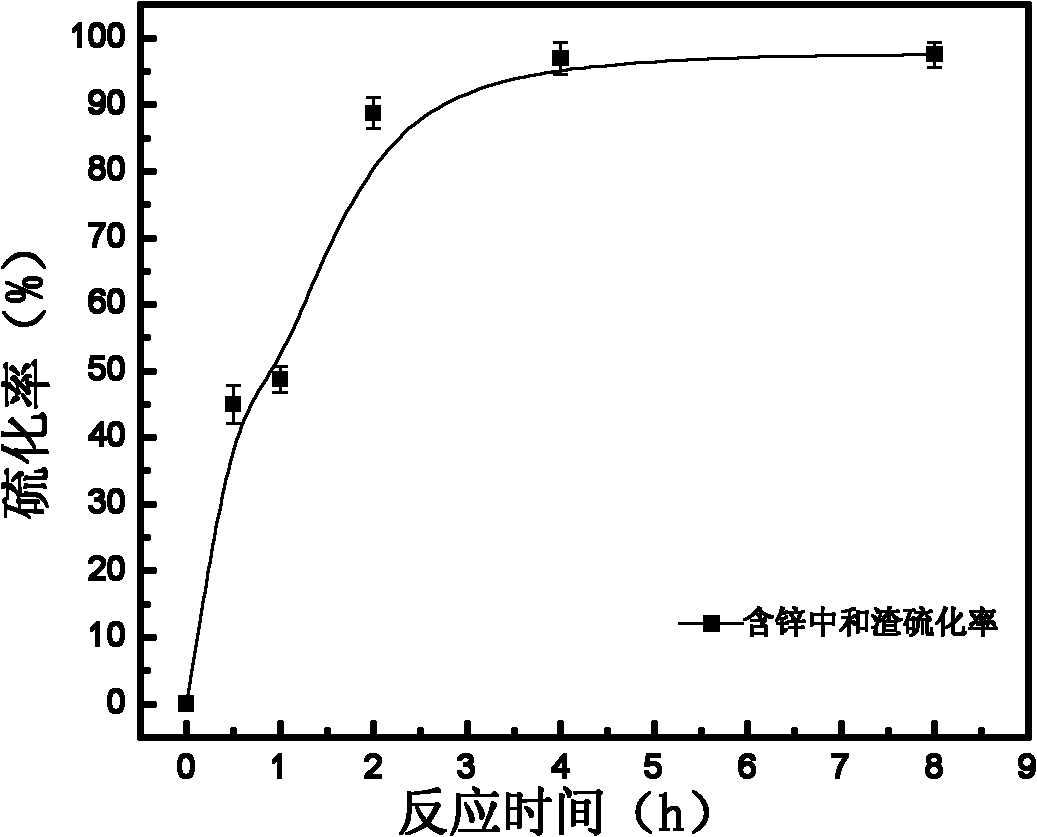

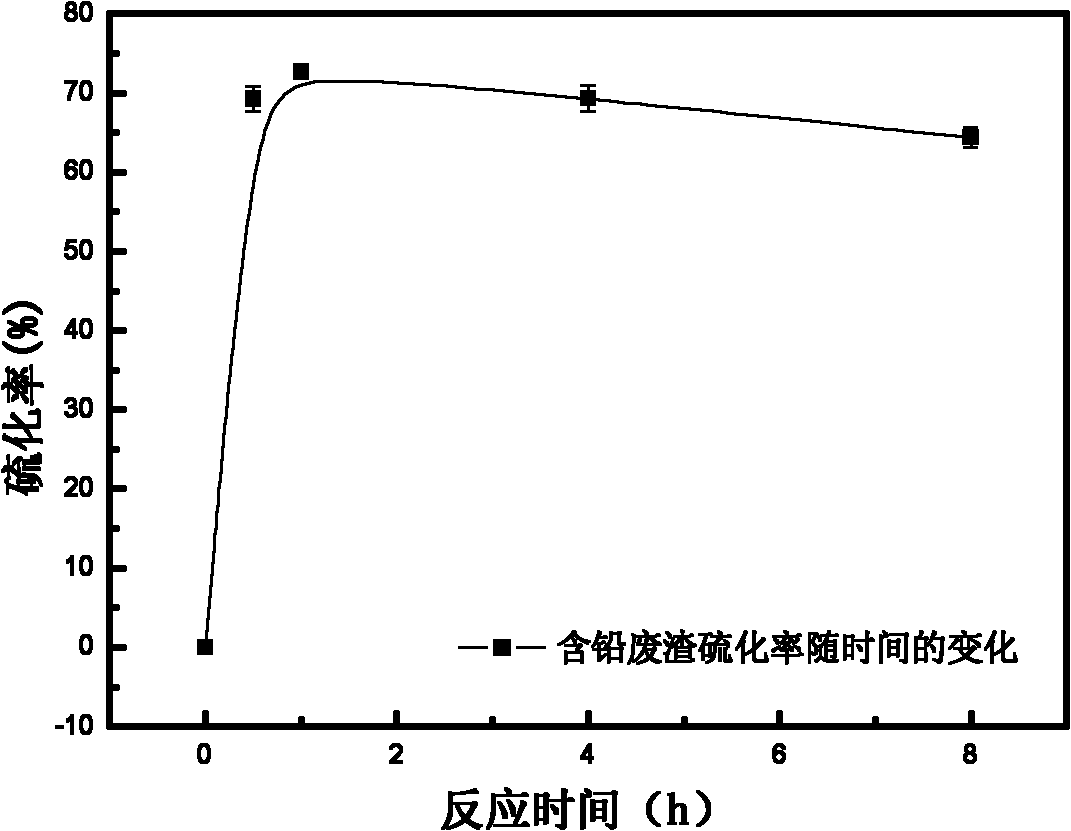

Method for sulfidizing heavy metal waste and recovering valuable metals in heavy metal waste

ActiveCN101824543ASave raw materialsHigh crystallinityProcess efficiency improvementVulcanizationMetallic sulfide

The invention discloses a method for sulfidizing heavy metal waste and recovering valuable metals in the heavy metal waste, comprising the following steps of: crushing the heavy metal waste, and ball-milling mixing the crushed heavy metal waste with sulphur simple substance and corresponding vulcanizing accelerator; after further fine grinding and activating, putting activated fine residue into a reaction kettle, and using sulphur disproportionation reaction to lead heavy metal in the waste into stable metal sulfide under the condition that the temperature is 160-240 DEG C, and the pressure is 1.8-2.2MPa; completing the process of hydrothermal vulcanization reaction; and then, recovering metals in a way of sulphide ore flotation. By adopting the hydrothermal vulcanization way, the method leads the sulphuration rate of the heavy metal in the residue to reach more than 90%, and secondary pollution is not caused in the sulphuration process. The method is not only used for sulfidizing and recovering the valuable metals in the waste residue, but also used for sulfidizing and stabilizing treatment of heavy metal waste residue.

Owner:CENT SOUTH UNIV

Gastric remaining preparation, swollen molding, and production process

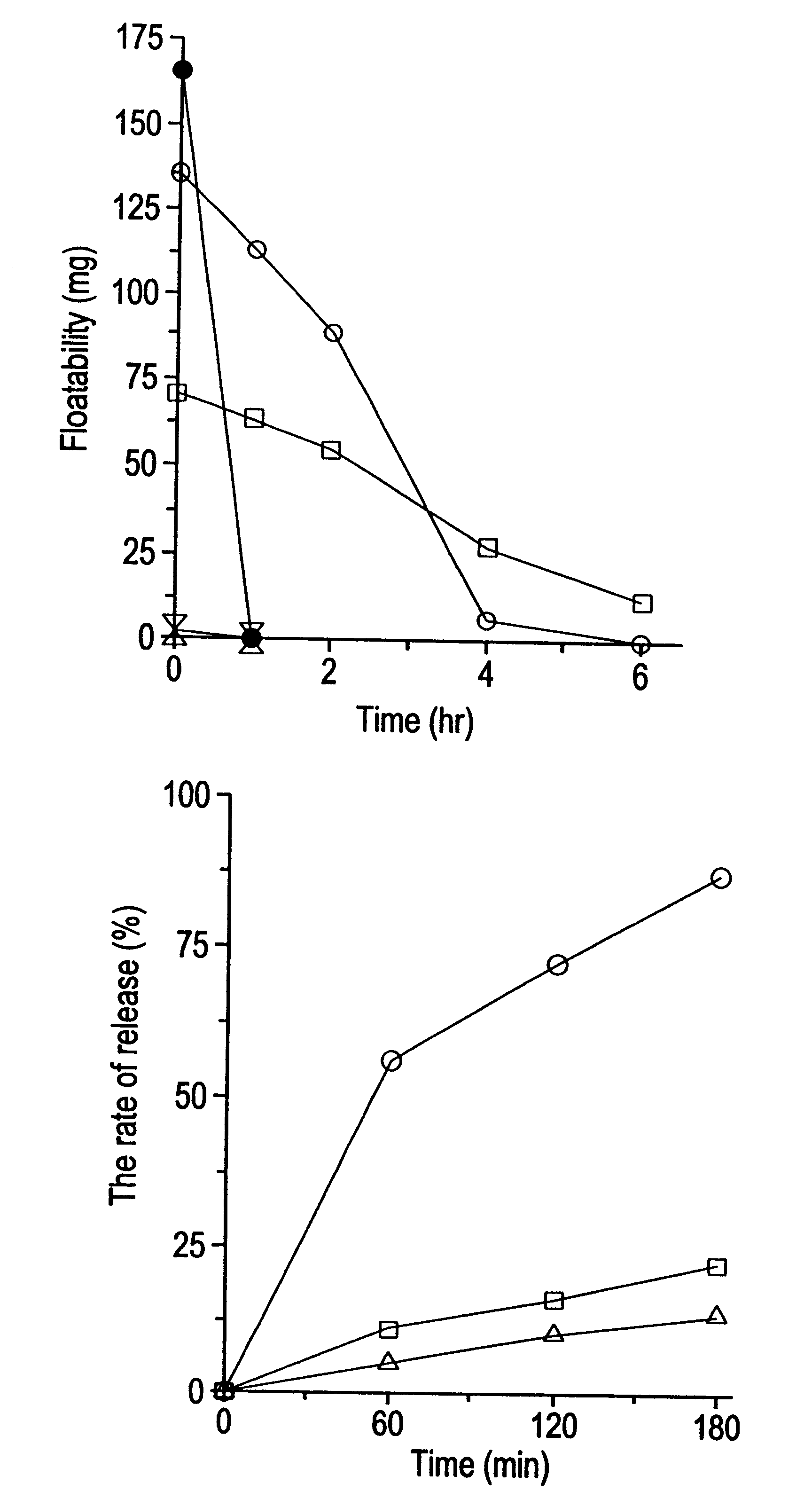

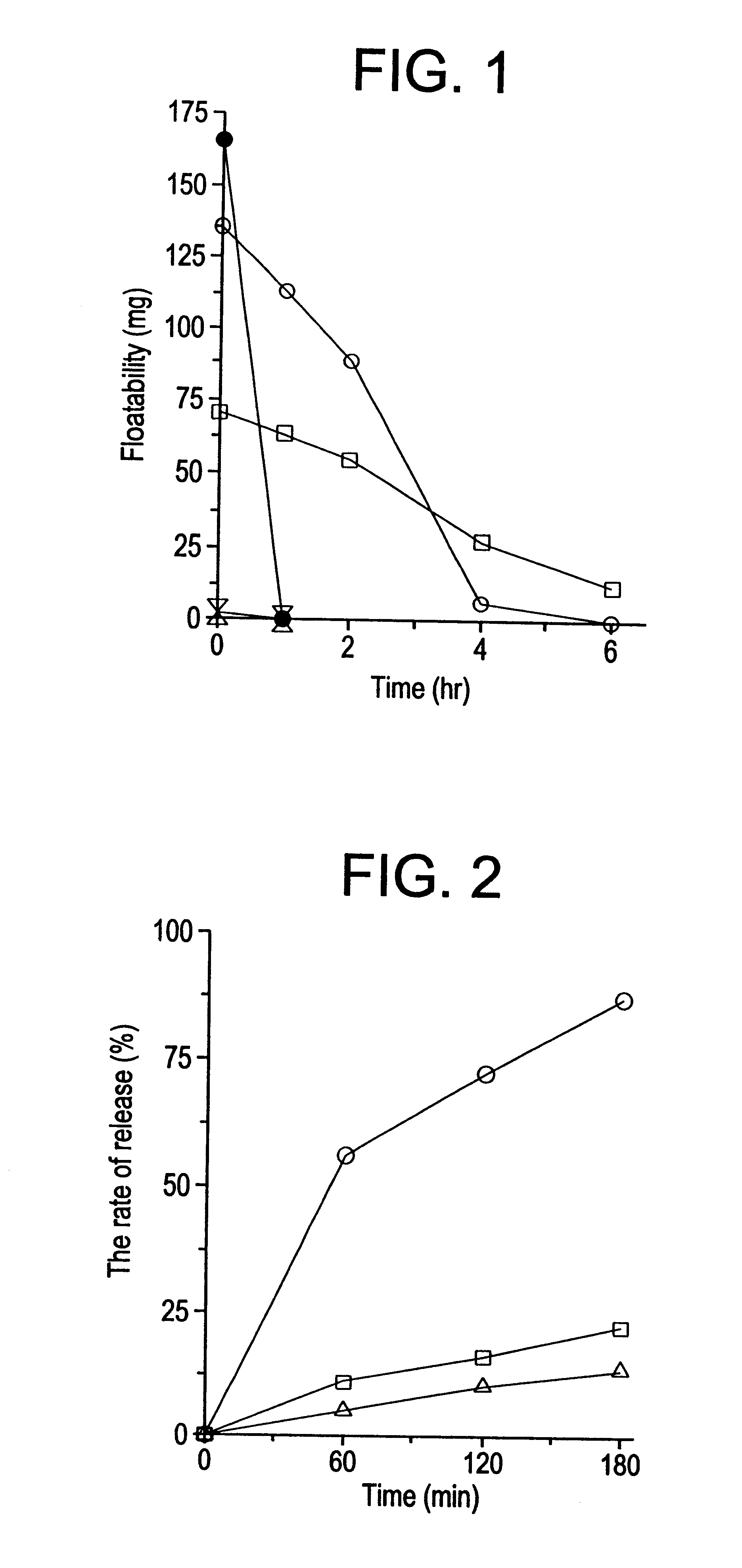

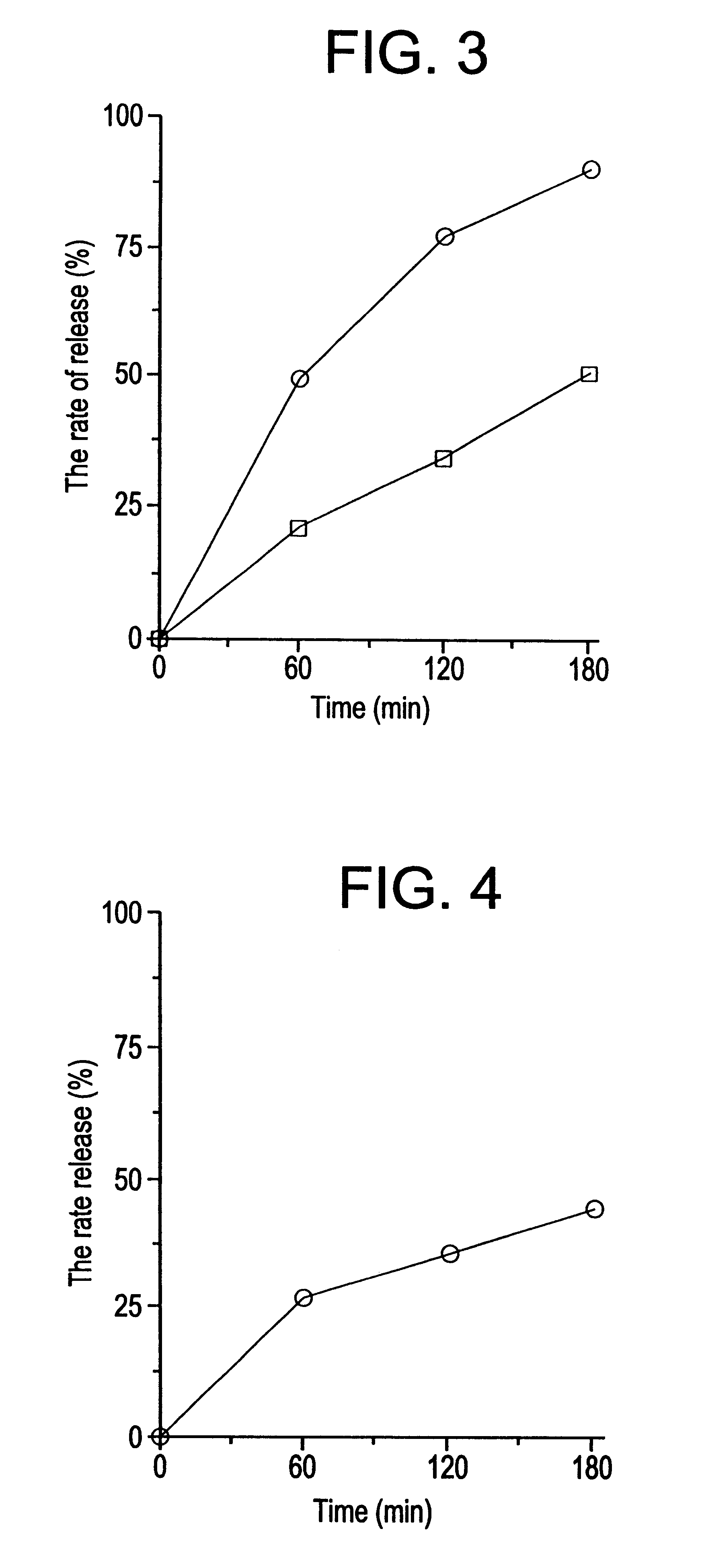

InactiveUS6312726B1Improve floatabilityHigh mechanical strengthPowder deliveryPharmaceutical non-active ingredientsApparent densityBlowing agent

A gastric remaining preparation having a configuration entirely different from that of the conventional ones. It comprises a swollen molding having a mesh-like cross-section and an apparent density of less than 1, containing an acid-resistant polymer compound as a predominant component as well as at least an auxiliary blowing agent and a drug substance. The molding can be produced by using a multi-screw extruder.

Owner:NIPPON SHINYAKU CO LTD

Preparation method of copper based sliding plate material

InactiveCN104911382ALess componentsEasy to implementLiquid/solution decomposition chemical coatingElectrolysisCopper plating

The invention provides a preparation method of a copper based sliding plate material, and belongs to the functional material preparation technical field. According to the method, copper is used as a base material, carbon nanotubes and titanium silicon carbide are used as reinforcing materials, graphite is used as a self-lubricating wear-resistant material, and chemical copper plating is carried out after pretreatment by a wet chemical method. The content of copper plated carbon nanotubes is 2.5-90%, the content of copper plated graphite is 2.5-90%, the content of copper plated titanium silicon carbide is 2.5-90%, and the content of an electrolytic copper powder is 5-90%. The components of the obtained four raw materials are subjected to ball milling in a ball mill according to the proportion, so as to achieve the purpose of uniform mixing; finally, the four materials are subjected to mixed hot pressing sintering into an organic whole body by adopting a vacuum hot pressing sintering furnace at high temperature and high pressure; heat preservation treatment at a certain temperature is carried out, so that the purpose of structural stability is achieved, the material has the performance of high electrical conductivity, high lubricity, high wear resistance and the like, and ultimately, the copper based sliding plate material with excellent performance is obtained. The copper based sliding plate material is mainly used for manufacture of track traffic equipment.

Owner:SOUTHWEST JIAOTONG UNIV

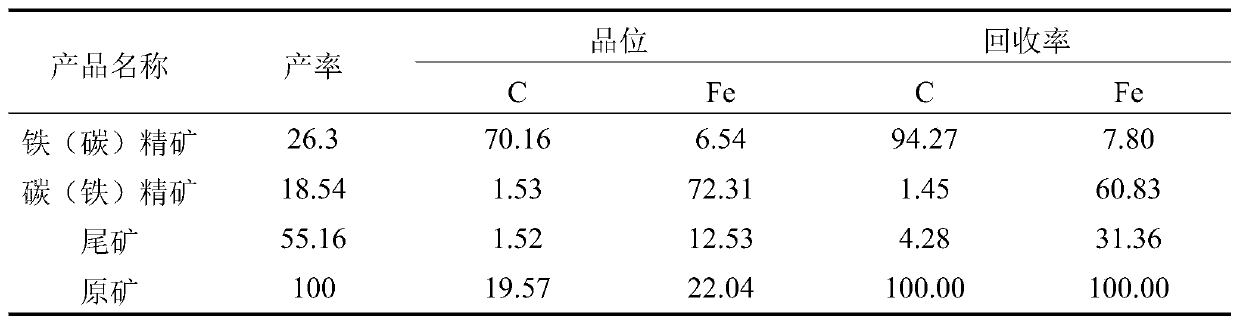

Harmless dressing and smelting method for recycling lead, zinc, carbon, iron and tailings from water quenching slag

InactiveCN109825718AThe process steps are simpleReduce hardnessProcess efficiency improvementQuenchingReducing agent

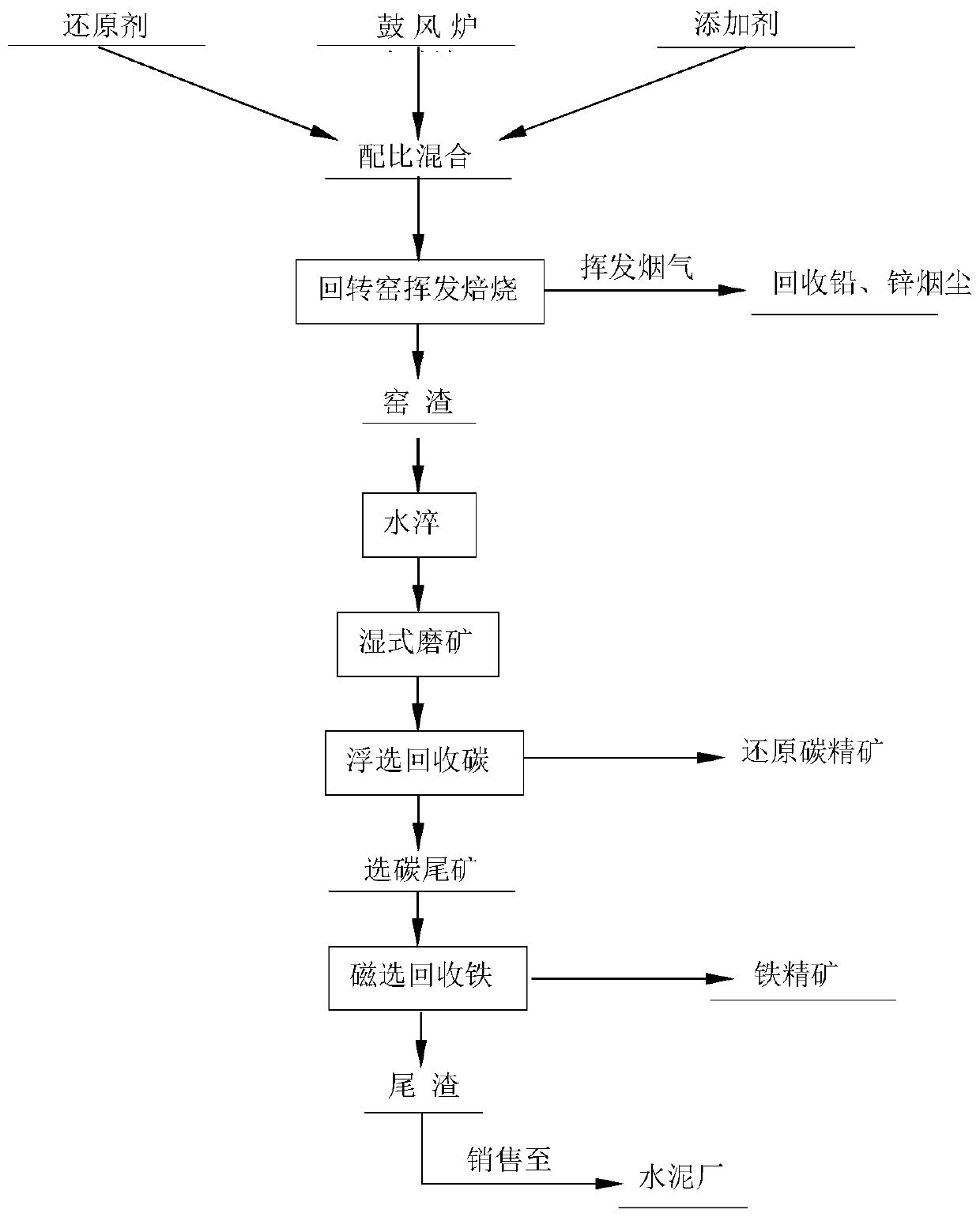

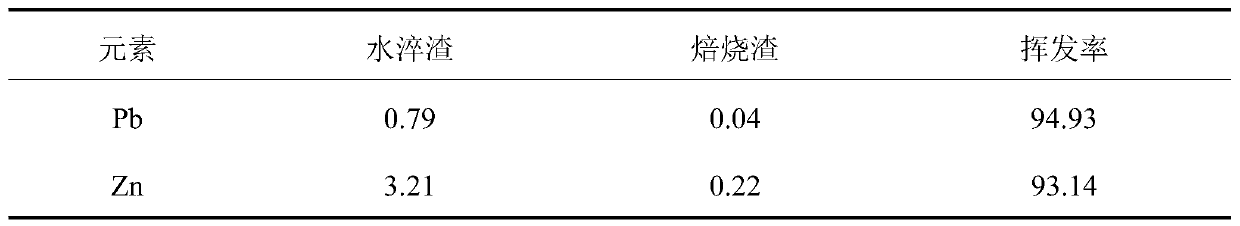

The invention belongs to the technical field of fire metallurgy and mineral processing, and discloses a harmless dressing and smelting method for recycling lead, zinc, carbon, iron and tailings from water quenching slag. The harmless dressing and smelting method is characterized in that a metallurgy process of high-temperature reducing (volatilizing) roasting and a mineral processing process of flotation and magnetic separation are adopted, and a rotary kiln is applied to perform the metallurgy process of high-temperature reducing (volatilizing) roasting to recycle components lead and zinc from the water quenching slag of a blast furnace; the kiln slag of the rotary kiln is grinded to certain thickness, and coke and iron minerals in the slag can be recycled through the mineral processing process of flotation and magnetic separation; and tailings with valuable constituents recycled mainly contain nonmetal minerals such as silicate, and can be used as ingredients for cement production for being sold, so that harmless treatment on the tailings is realized. While lead and zinc are volatilized and recycled, characteristics of slag are changed, so that beneficial conditions are providedfor subsequently recycling carbon and iron from kiln slag, and therefore, comprehensive recycling is realized; and the floated and recycled carbon can be taken as a reducing agent for being reused forreducing roasting of the water quenching slag of the blast furnace, so that production cost is reduced.

Owner:JIANGXI UNIV OF SCI & TECH

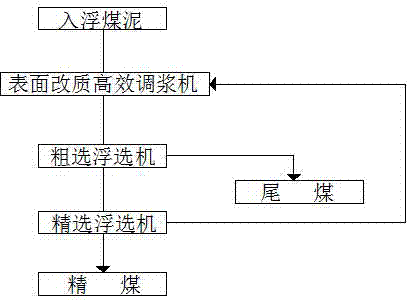

Pulp mixing reinforced deep flotation technology process

InactiveCN103752414AImprove floatabilityFully contactedFlotationSocial benefitsPulp and paper industry

The invention discloses a pulp mixing reinforced deep flotation technology process for fine coal slime and particularly for coal slime with special characteristics of large high-ash fine slime content, difficulty in floatation and the like. The process includes: pumping floatation coal slime into a surface modification pulp mixer for pulping and adding an agent, allowing mixed pulp to flow into a roughing flotation machine (column), and performing separation to obtain roughed cleaned coal and roughed tailing; taking the roughed tailing as final tailing, allowing the roughed cleaned coal to immediately flow into a primary cleaning flotation machine (column) for cleaning to obtain recleaning cleaned coal and recleaning tailing, and returning the recleaning tailing to the efficient surface modification pulp mixer for second pulp mixing and floatation so as to increase cleaned coal recovery rate. If ash content is still high after primary cleaning, secondary cleaning is performed. By the adoption of the efficient surface modification pulp mixer, floatability of particle surfaces of the floatation coal slime can be improved, particles and the agent act fully, cleaned coal recovery rate and separation efficiency are high, and agent usage amount is small; economic and social benefits are remarkable.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

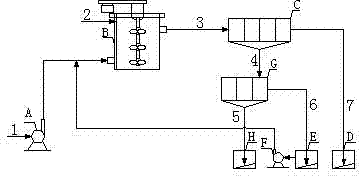

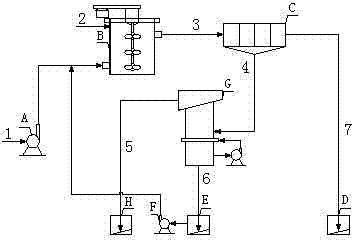

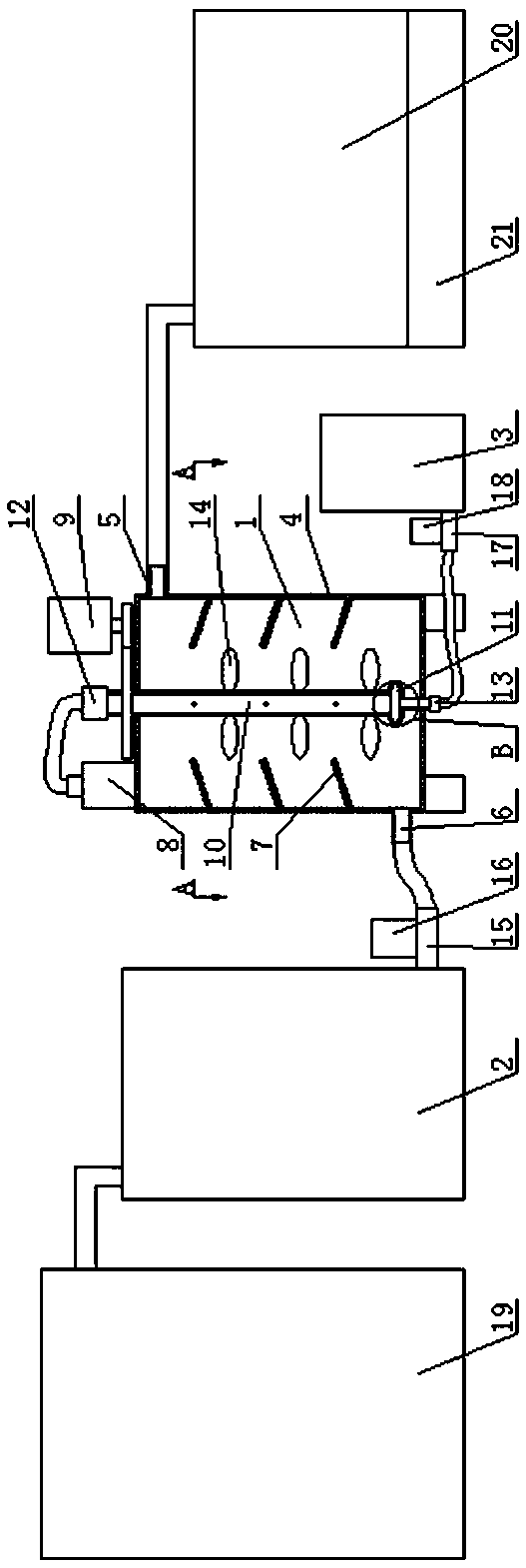

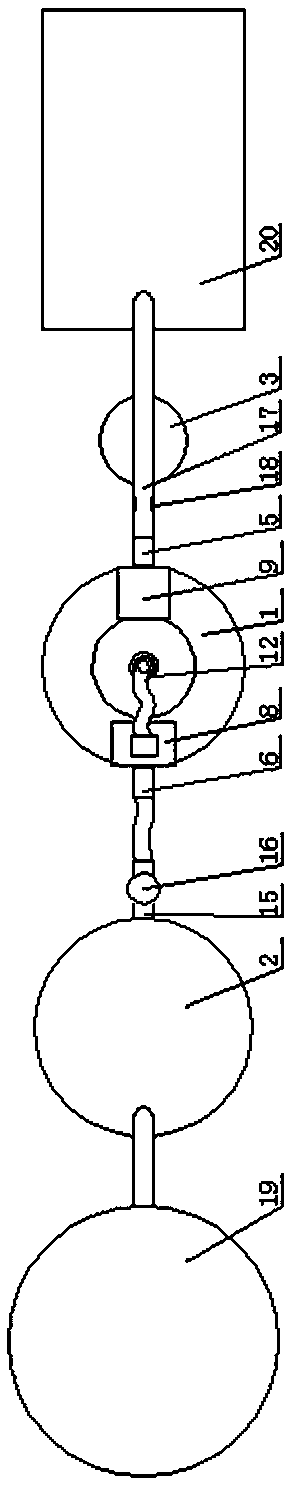

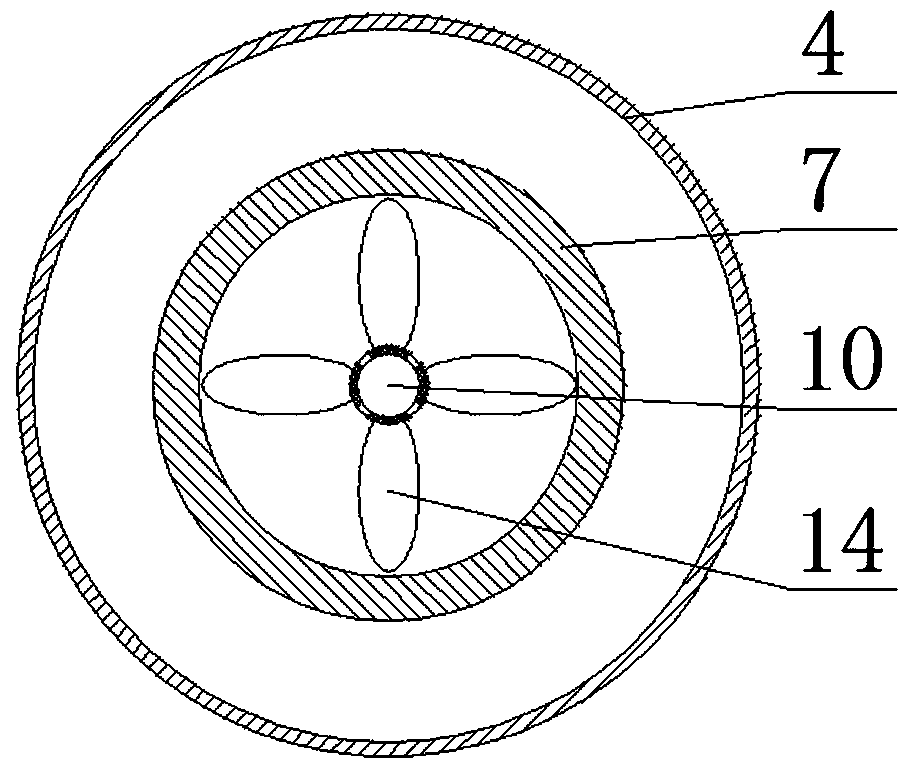

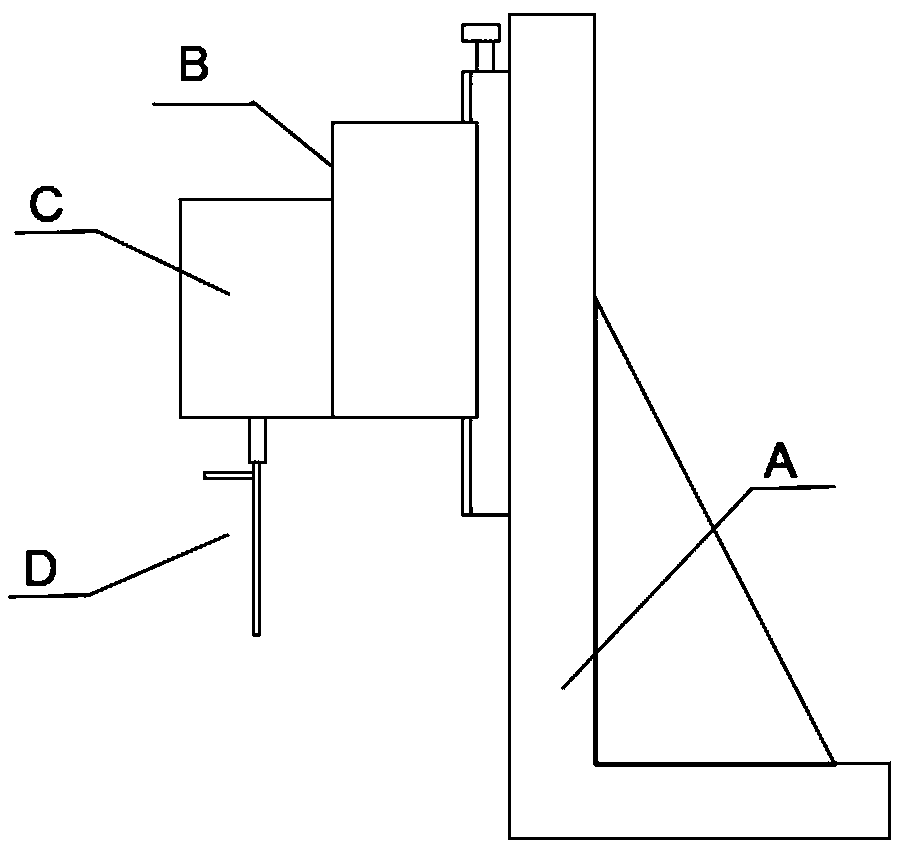

High-efficiency pulp modifying machine for molybdenum tungsten ore flotation technology and implementation method thereof

PendingCN107913629AWell mixedConvenient ascentTransportation and packagingMixer accessoriesPulp and paper industry

The invention relates to a high-efficiency pulp modifying machine, which comprises a pulp mixing box, a material silo connected to the lower part of a side surface of the pulp mixing box and a medicament barrel connected to the bottom of the pulp mixing box. The pulp mixing box comprises a box body and a rotating shaft assembly which is rotatably connected to the box body. An air compressor and amotor are arranged on the upper surface of the box body. The rotating shaft assembly comprises a rotating shaft body, a drug spray bin arranged below the rotating shaft body, and an air inlet connecting pipe and a drug inlet connecting pipe which are respectively arranged at the upper end and lower end of the rotating shaft body. A discharging pipe is arranged at the lower part of a side surface of the material silo. The discharging pipe is provided with a first feed pump. A drug outlet pipe is arranged at the lower part of a side surface of the medicament barrel. The drug outlet pipe is provided with a second feed pump. The invention also provides an implementation method of the high-efficiency pulp modifying machine for the molybdenum tungsten ore flotation technology, comprising the following steps: mineral grinding; pulp blending; pulp modification; and pulp flotation. The high-efficiency pulp modifying machine of the invention has strong reliability. By the adoption of the high-efficiency pulp modifying machine, pulp and a medicament are fully mixed, cost is saved, and flotation precision and yield of mineral are raised.

Owner:中国黄金集团中原矿业有限公司

Efficient adhesion type high-titanium furnace protection stemming

The invention discloses efficient adhesion type high-titanium furnace protection stemming, which is prepared from the following ingredients in percentage by weight: 8 to 12 percent of bauxite, 3 to 7 percent of brown fused alumina, 22 to 32 percent of titanium-containing materials, 10 to 14 percent of iron silicon nitride, 6 to 10 percent of silicon carbide, 10 to 15 percent of coke, 6 to 12 percent of tar, 0.5 to 3 percent of pyrophillite, 2 to 5 percent of asphalt, 1 to 5 percent of cyanite, 3 to 7 percent of sericite, 0.5 to 4 percent of resin and a certain amount of crystalline flake graphite. Compared with a conventional titanium-containing stemming, the efficient adhesion type high-titanium furnace protection stemming has the advantages that the titanium content is high; the titanium-containing materials, particularly titanium pigments have good reaction activity, and can sufficiently react with other substances for forming caulking substances; due to the ultrafine granularity, the stemming can easily float up to a furnace cylinder erosion region in a furnace cylinder; flake graphite is introduced; good floating performance, lubricating performance and plasticity are realized; the stemming can be combined with generated high-temperature-resistant caulking particles such a TiC, TiN and Ti(C,N); the particles are carried for better entering the erosion region to be effectively filled into the seams; the effective furnace protection effect is achieved.

Owner:畲云锋

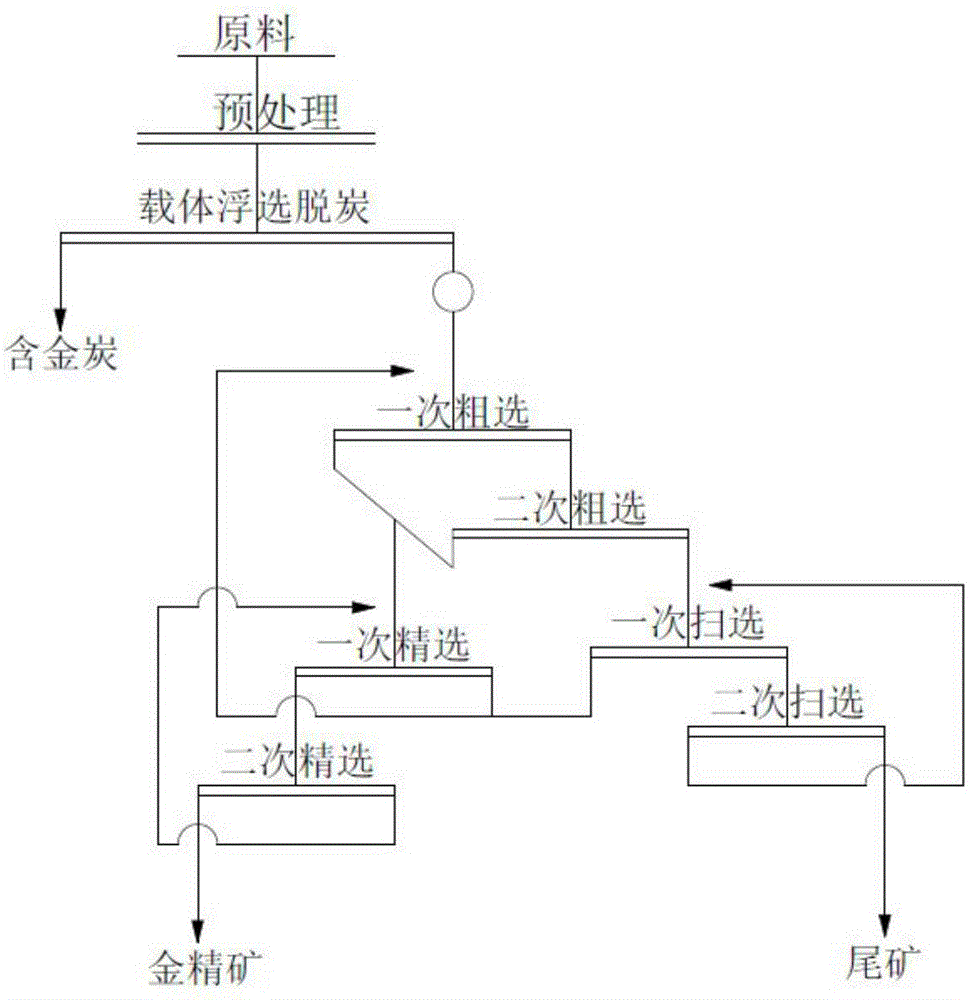

Method for flotation recovery of gold from gold-extracting tailings obtained from preliminary biooxidation-carbon-in-pulp process

ActiveCN104451173AHigh recovery rateImprove floatabilityFlotationProcess efficiency improvementArsenateJarosite

The method provides a method for flotation recovery of gold from gold-extracting tailings obtained from a preliminary biooxidation-carbon-in-pulp process, and belongs to the technical field of comprehensive utilization of resources. The method comprises the following steps: firstly, preprocessing gold-extracting tailings obtained from a preliminary biooxidation-carbon-in-pulp process by virtue of nano copper / iron-loaded modified active carbon so as to remove residual cyanide which can inhibit the flotation of pyrite in the tailings; and netting ferric arsenate and jarosite colloids by virtue of colloidal substances generated from the nano copper / iron-loaded modified active carbon such as ferric hydroxide and adsorbing organic colloidal substances so as to eliminate a harmful effect on the flotation; meanwhile, carrying out carrier flotation on micro / fine-grained gold-containing carbon in the tailings by taking the nano copper- and iron-loaded modified active carbon as a carrier, so as to greatly improve the floatability of the micro / fine-grained gold-containing carbon. After flotation and decarburization, and after ore grinding, roughing, scavenging and concentrating are respectively carried out twice, so that gold concentrate is finally obtained. Materials and agents adopted by the method in the preprocessing and flotation processes are environmental friendly, easy to prepare and low in cost, so that the method disclosed by the invention is applicable to industrial production.

Owner:JIANGXI YIYUAN REGENERATION RESOURCE CO LTD

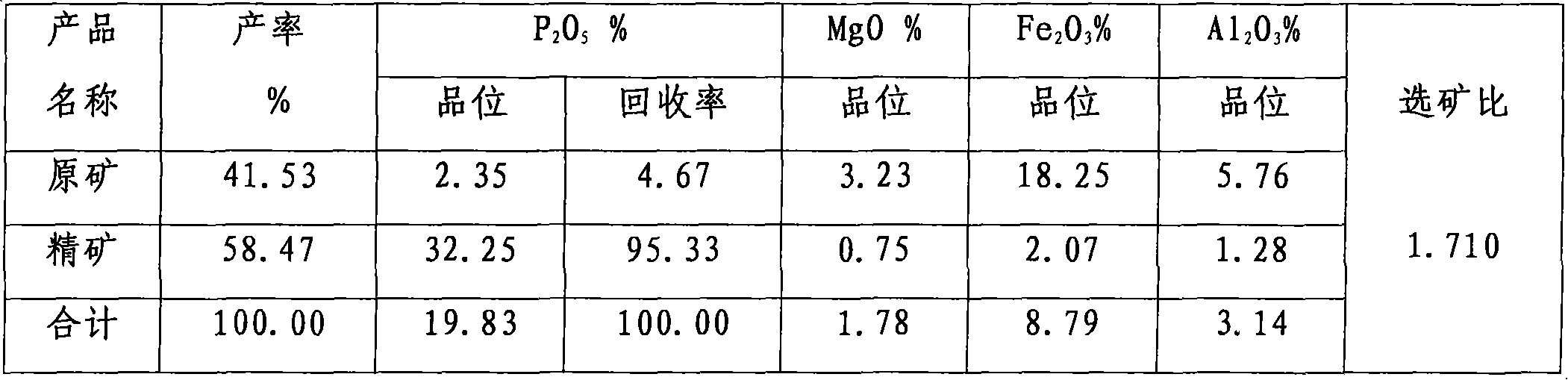

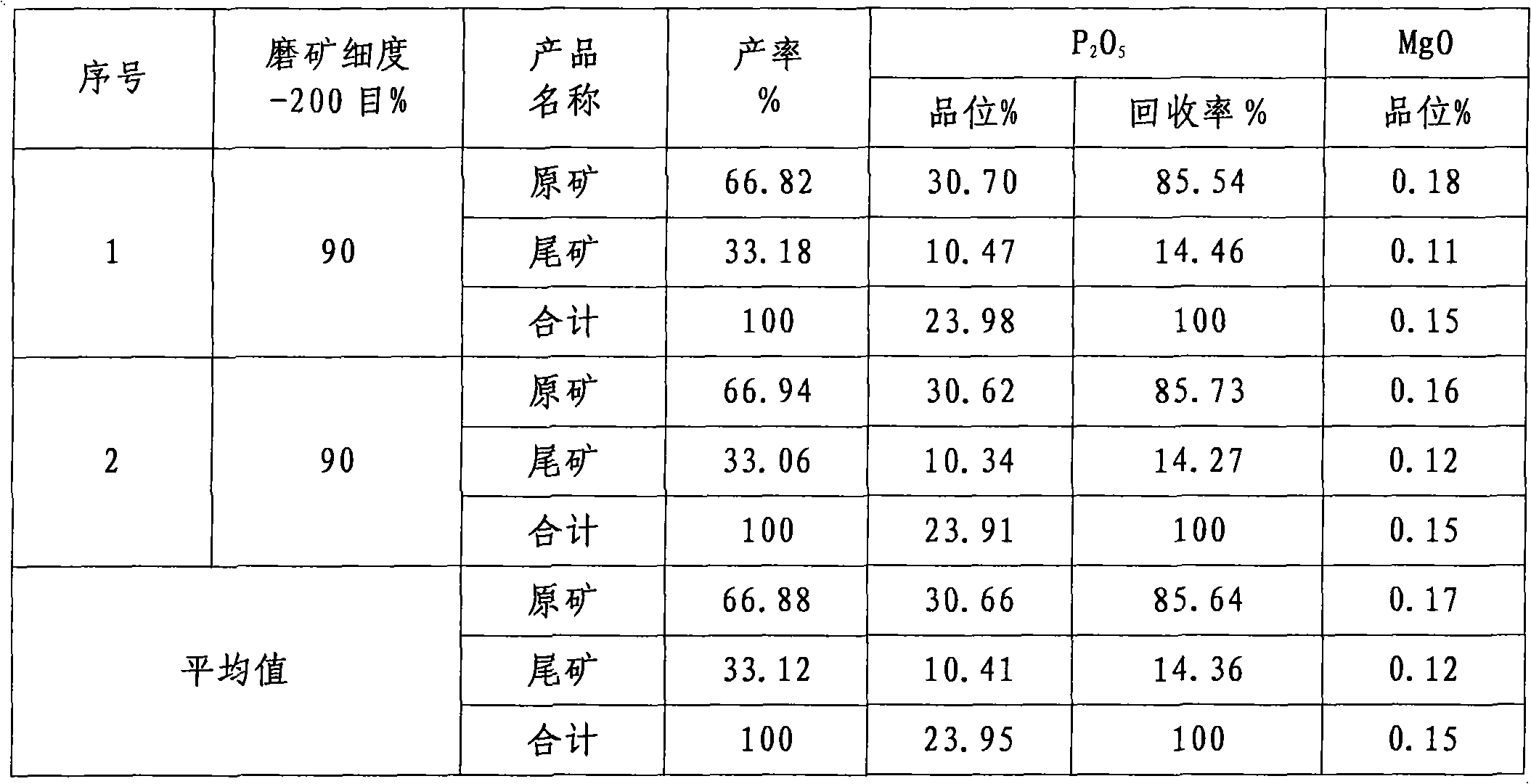

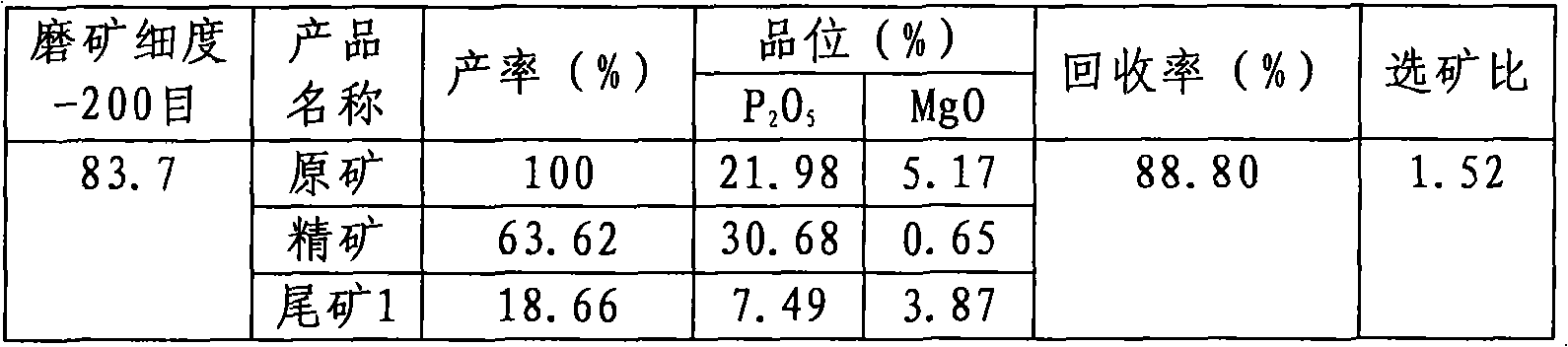

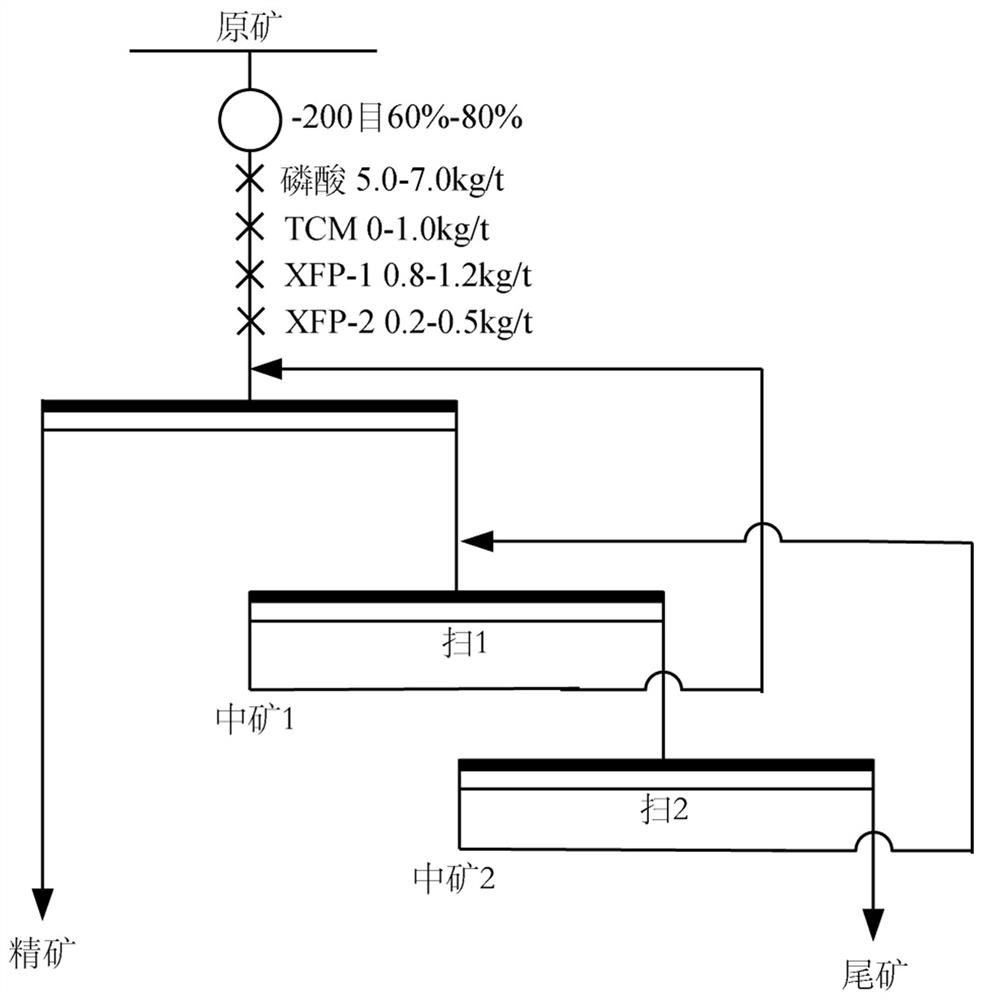

Synchronous reverse flotation process for low-magnesium high-magnification semi-collophanite

The invention belongs to the technical field of phosphate ore beneficiation, and particularly relates to a synchronous reverse flotation process for low-magnesium high-magnification semi-collophanite.According to the technical scheme, a 'one-step method' flotation process is adopted, namely, water is added for size mixing, an ore pulp flotation system is adjusted through an adjusting agent underthe condition that the pH ranges from 4 to 6, and then an anion collecting agent and a cation collecting agent are added for desilicication and magnesium removal synchronous reverse flotation. The process has the advantages that useful minerals in the ore are effectively enriched through reasonable utilization of a combined reagent based on the fact that the proportions of gangue minerals in collophanite are different, the phosphate ore flotation technological process is simplified, the cost of the flotation reagent is remarkably reduced, the capacity of recovering useful minerals from phosphate ore is effectively improved, and a new thought is provided for the flotation technology of the low-magnesium high-power semi-collophanite.

Owner:YIDU XINGFA CHEM COMPANY

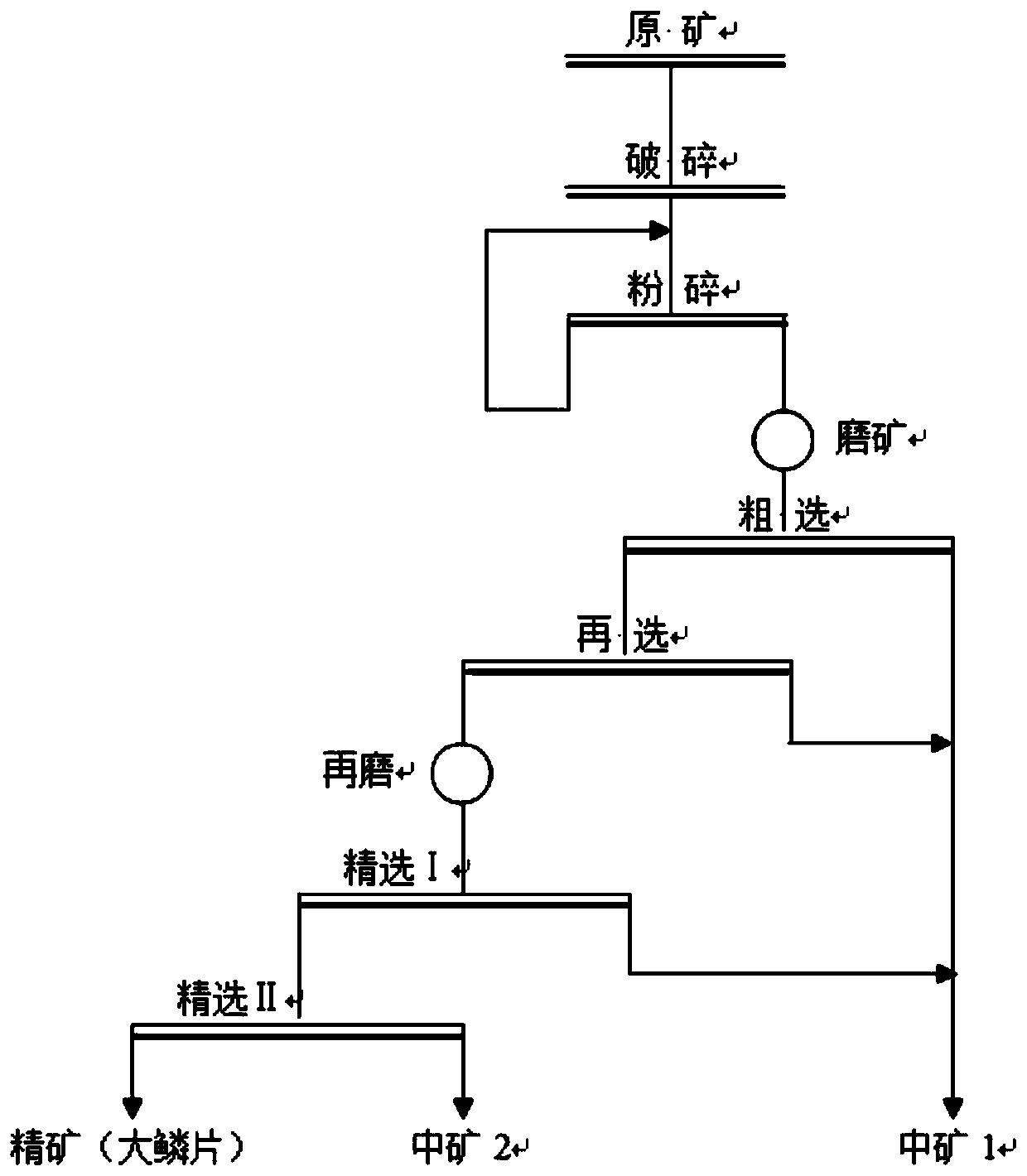

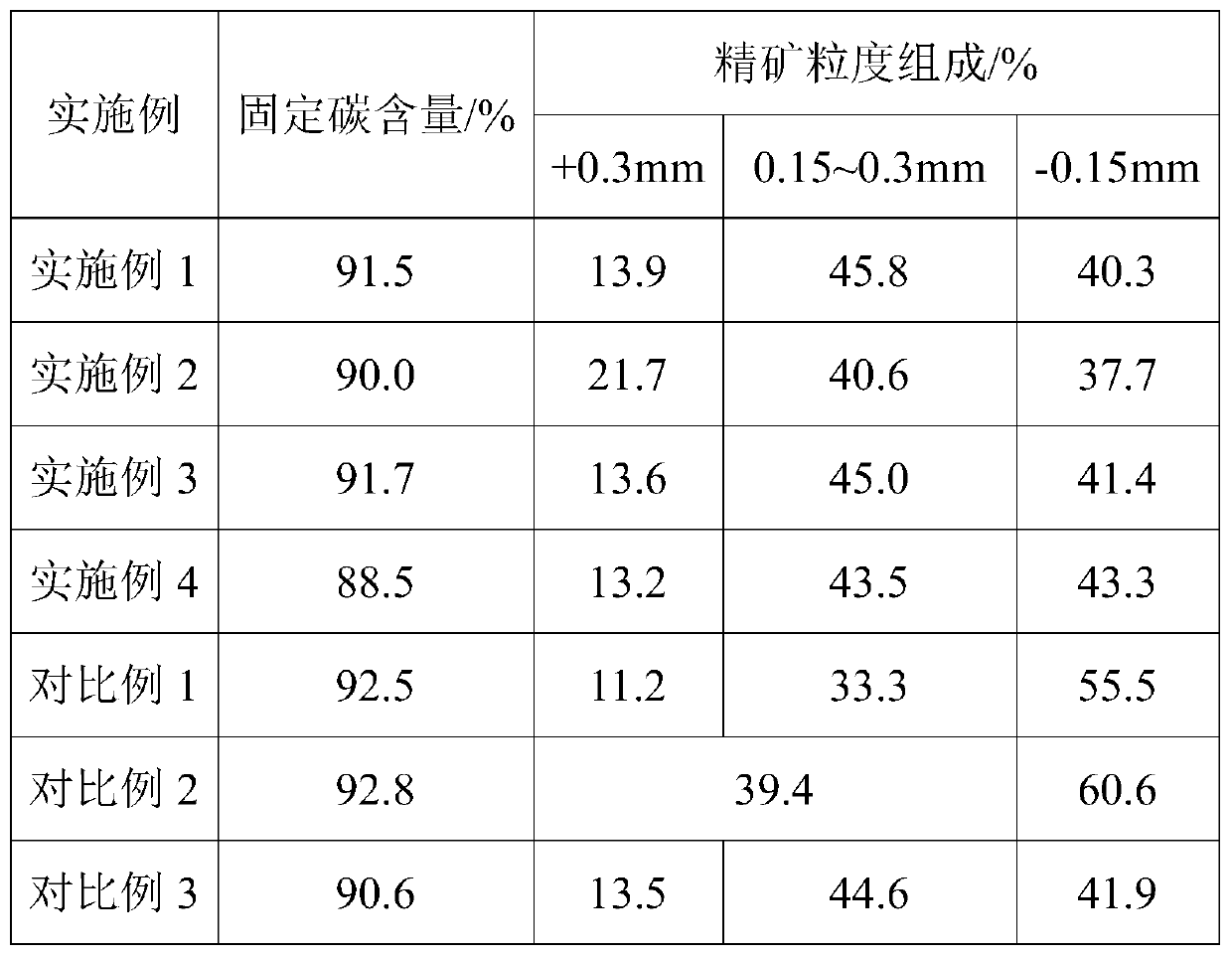

Low-quality and low-concentration protection extraction process for graphite squama

The invention provides a low-quality and low-concentration protection extraction process for graphite squama. The low-quality and low-concentration protection extraction process of the graphite squamacomprises the following steps: (1) pulverization, (2) wet grinding, (3) rough selection, (4) re-grinding, and (5) fine selection: performing first fine selection on re-ground materials, performing flotation overflow, then performing second fine selection, merging a bottom current into a middling product 1, performing dehydration on the second-selected overflow, and performing drying so as to obtain ore concentrate, wherein the bottom current is a middling product 2. Large-squama graphite can be separated from gangue in a reasonable selective pulverization mode, so that damage to the graphitesquama is reduced greatly; meanwhile, the large-squama graphite can be extracted preferentially through the low-quality low-concentration flotation process, then the separated part of the large-squamagraphite can be treated separately, and therefore the graphite concentrate with high squama content can be obtained under the condition of the shortened flotation process; and the final ore concentrate product has a content of not less than 58% at +0.15 mm, and the content of fixed carbon is not less than 90%.

Owner:苏州中材非金属矿工业设计研究院有限公司

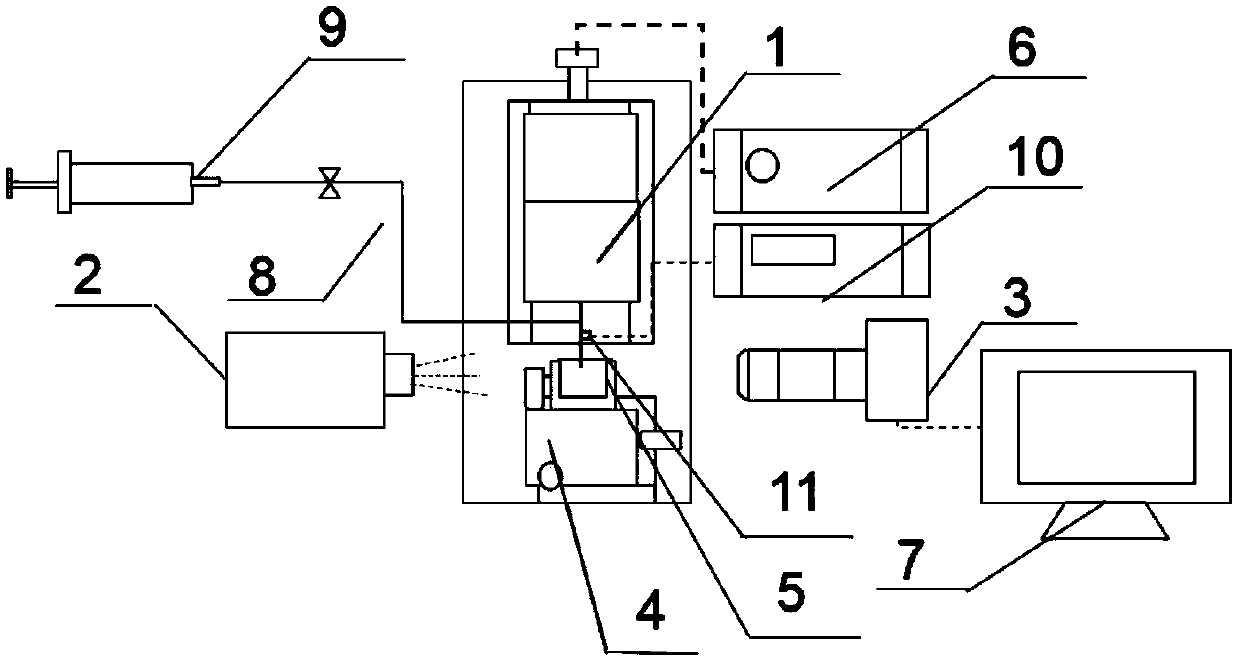

System and method for evaluating floatability of particles

ActiveCN109580438AImprove floatabilityRealize quantitative evaluationIndividual particle analysisVideo monitoringDesorption

The invention relates to a system and method for evaluating the floatability of particles, and belongs to the technical field of particle floatation. The problem that inaccurate evaluation is caused due to the fact that the floatability of samples can be judged only by induction time in the prior art is solved. The measurement system of floatation particle bubbles comprises a motion drive unit, avideo monitoring unit and a displacement acquisition unit; the displacement acquisition unit is used for measuring the critical desorption amplitude of the particles falling off from the bubbles; themotion drive unit is used for driving particle bubble flocs to perform simple harmonic vibration; the video monitoring unit is used for monitoring the adhesion state of the particles and the bubbles,and when the particles and the bubbles are desorbed, a data acquisition system collects the critical desorption amplitude. The test method comprises the steps that the bubbles are generated, the bubbles approach the samples, the data of inducing time is acquired, the samples, the bubbles and the flocs perform the simple harmonic vibration, and the data acquisition system acquires the amplitude. The system and method for evaluating the floatability of the particles realize the joint characterization of the particle floatability through the adhesion and desorption behavior between the particlesand the bubbles, and improve the accuracy of a test.

Owner:CHINA UNIV OF MINING & TECH

Combined reagent for medium and low temperature phosphate rock flotation and use method thereof

The invention discloses a combined reagent for medium and low temperature phosphate rock flotation and a use method thereof, and belongs to that field of mineral flotation reagents. The combined reagent comprises 10-50 wt% of alpha-amino acid, 20-60 wt% of oxidized paraffin soap, 5-40 wt% of sodium dodecyl sulfonate and 5-40 wt% of kerosene. The combined reagent is mixed according to a certain proportion, the collecting ability and low-temperature resistance of the phosphate rock are improved through the synergistic effect among the reagents, and the combined reagent has the advantages of lessreagent consumption and low price compared with a single phosphate rock flotation collector and is soluble at normal temperature, nontoxic, efficient and environment-friendly. In particular, the combined reagent has a good flotation effect on the refractory collophanite and plays an important role in improving the recovery and utilization of phosphate rock resources.

Owner:KUNMING UNIV OF SCI & TECH

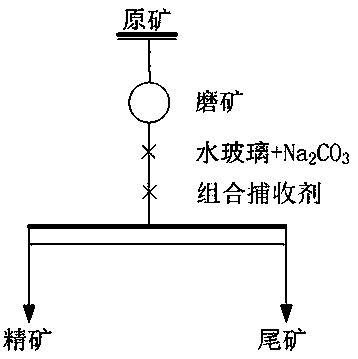

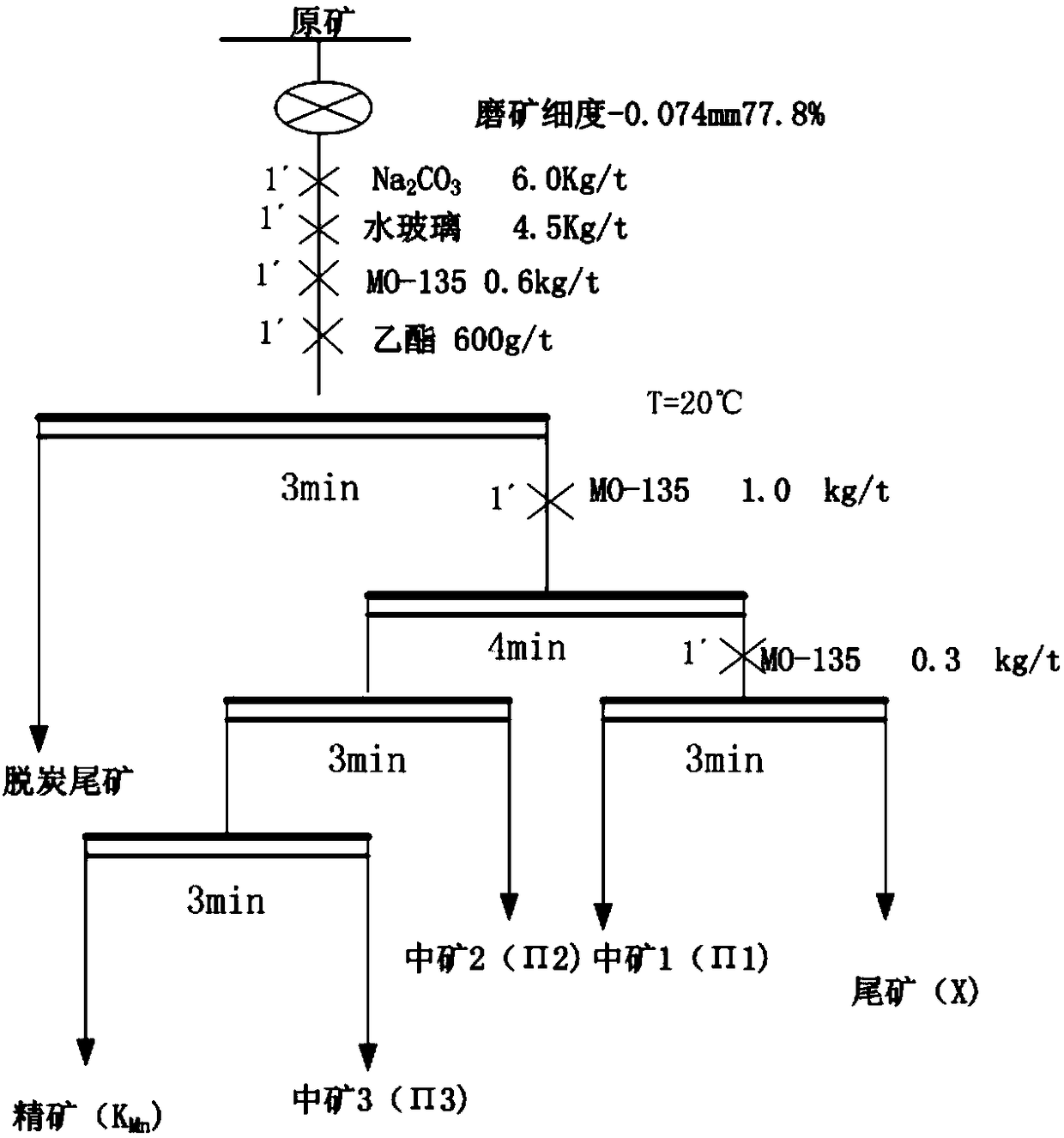

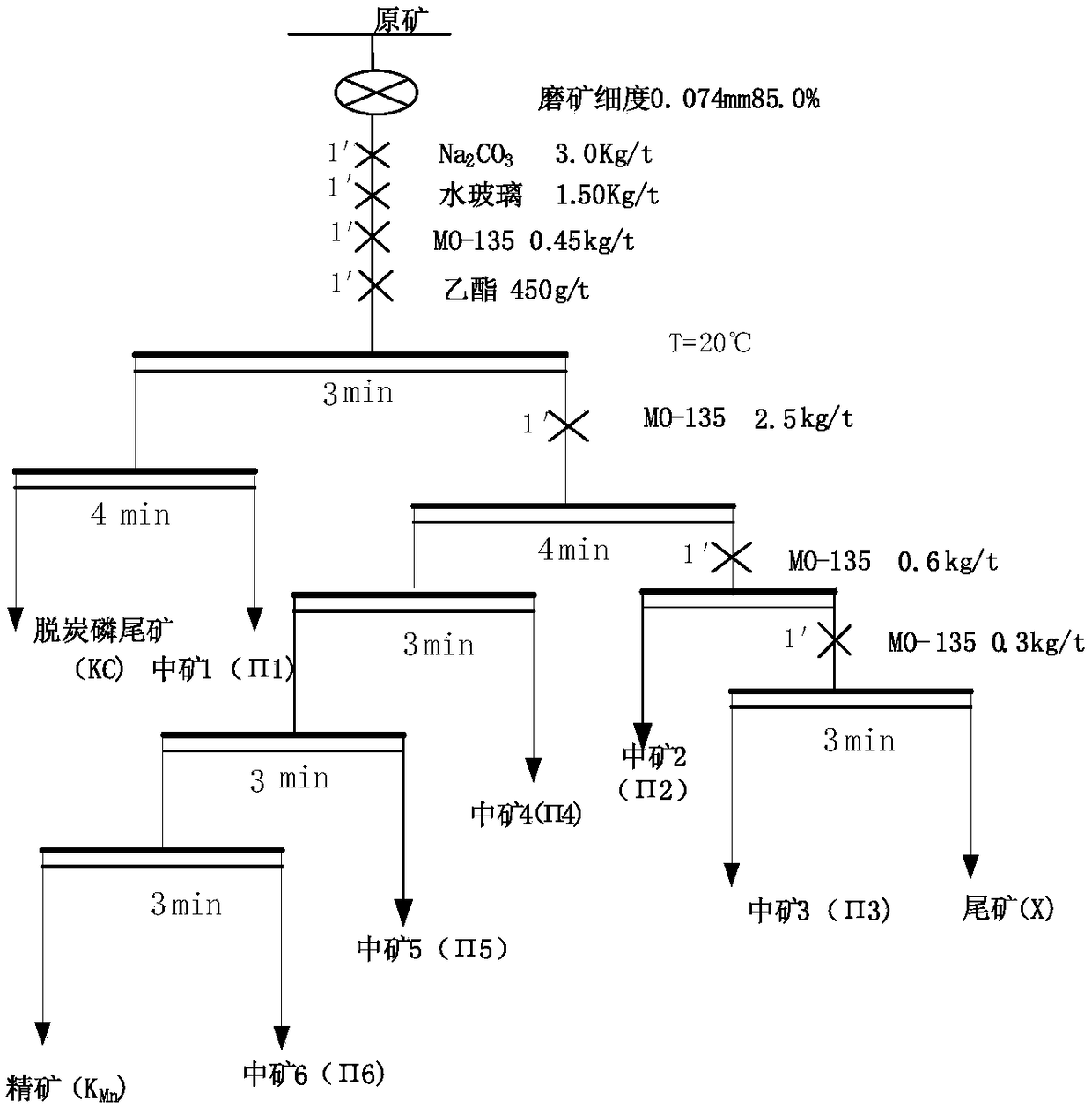

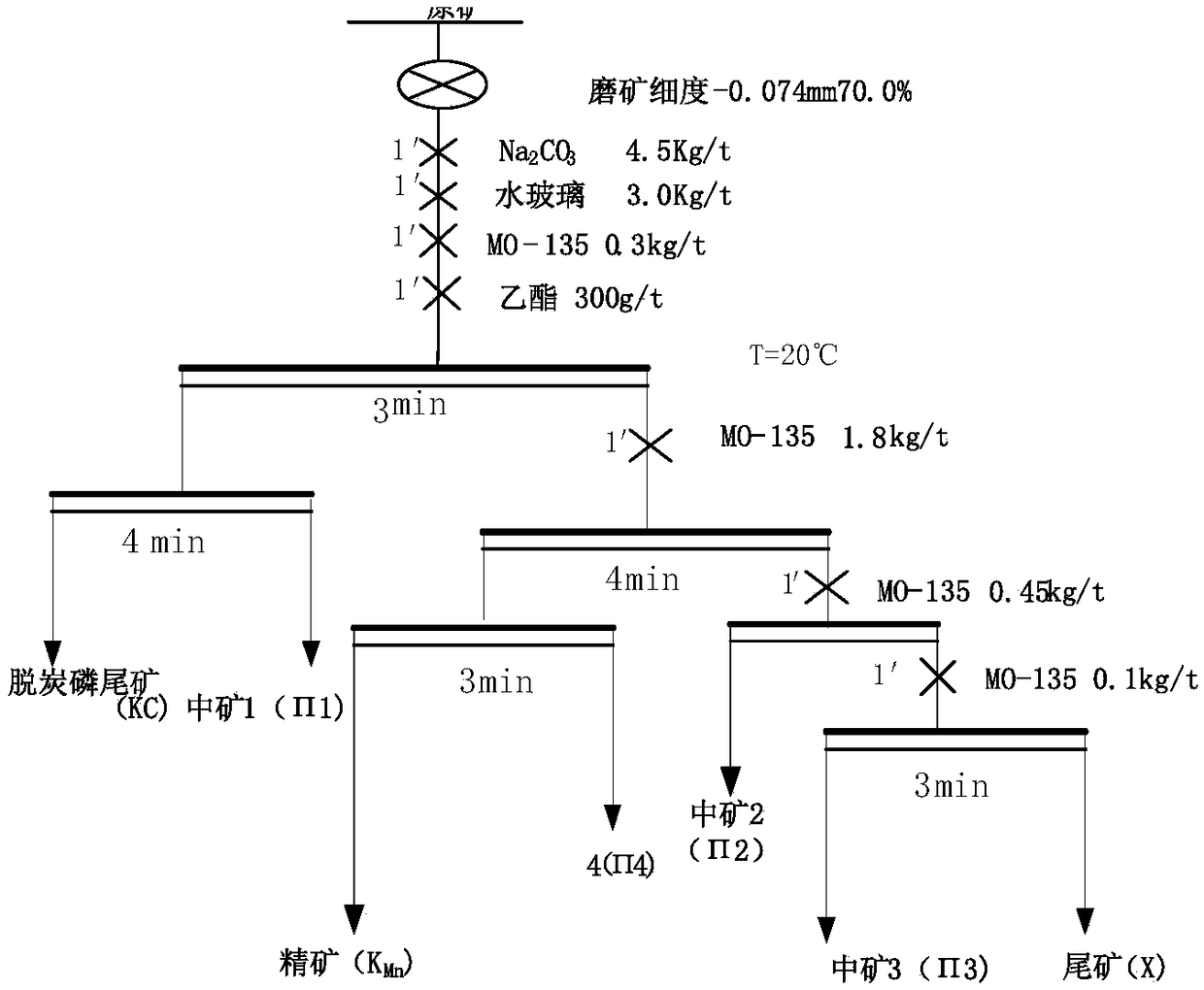

Carbon organic matter deposited low grade manganese ore flotation technology

The invention belongs to the technical field of manganese ore beneficiation and discloses a carbon organic matter deposited low grade manganese ore flotation technology. By adopting a reverse and direct flotation process, an anionic fatty acid collecting agent and a foaming agent diethyl phthalate are used for decarburization and dephosphorization by floatation first, so that the content of carbonorganic matters in ore pulp is reduced, and the dosage of the collecting agent is reduced effectively, and moreover, the foam amount in the follow-up direct floatation process is reduced, the floating selectivity is improved, and mechanical entrainment and conveying difficulty of foam are avoided, so that the floating process is easily controlled and stabilized, and meanwhile, the beneficiation cost is lowered to a great extent, thereby providing a new concept for the carbon organic matter deposited low grade manganese ore flotation technology.

Owner:WUHAN INSTITUTE OF TECHNOLOGY +1

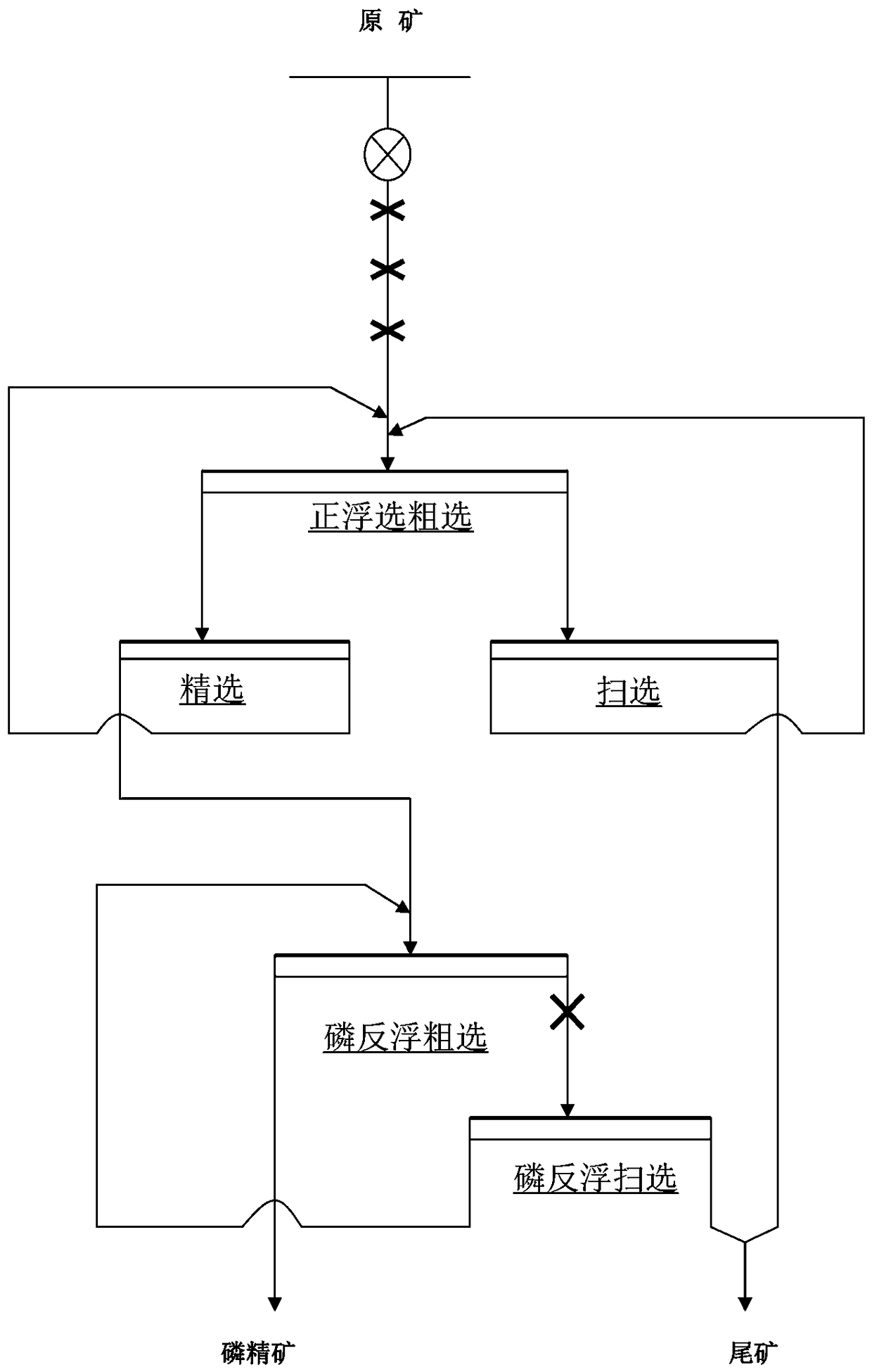

Demagging and manganese reducing phosphorus direct-reverse flotation technology of low-grade manganic phosphorite ore

InactiveCN108993779AImprove mineral processing recovery rateQuality assuranceFlotationManganesePhosphoric acid

The invention provides a demagging and manganese reducing phosphorus direct-reverse flotation technology of low-grade manganic phosphorite ore. The technology comprises the steps that the low-grade manganic phosphorite ore is crushed and ground to obtain ore pulp, sodium carbonate is added into a direct flotation ore pulp tank, the pH value of the ore pulp is adjusted, then water glass, a phosphorus direct flotation collecting agent and a foaming agent are added into the tank and mixed, air flotation is performed, an obtained froth product is phosphorus rough concentrate, the phosphorus roughconcentrate is transferred into a concentrating tank for concentrating, an obtained froth product is direct flotation phosphorus concentrate, and a product in the tank is direct flotation tailings; and the direct flotation phosphorus concentrate is placed in a reverse flotation ore pulp stirring tank, sulfuric acid and phosphoric acid are added, the pH value of the ore pulp is adjusted, then a phosphorus reverse flotation collecting agent is added, stirring and pulp adjusting are performed, air flotation is performed, an obtained froth product is tailings containing magnesium and manganese, and a product in the tank is phosphorus concentrate. In alkalescent medium ore pulp, the phosphorus ore has the good floatability. In weakly acidic ore pulp, dolomite carbonate minerals have the good floatability while the floatability of phosphorus minerals is poor, and the phosphorus minerals and the dolomite carbonate minerals are effectively separated.

Owner:湖北省黄麦岭磷化工有限责任公司

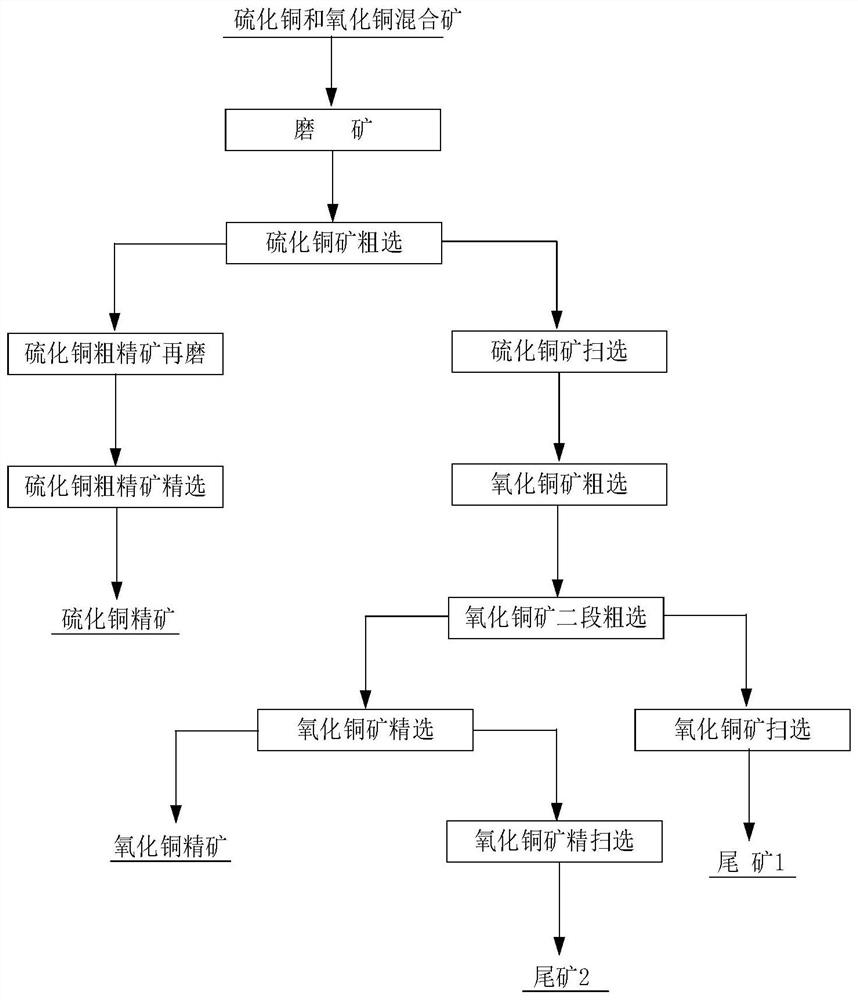

Separation method for cupric oxide and copper sulfide mixed ore

The invention discloses a separation method for cupric oxide and copper sulfide mixed ore. The separation method comprises the following steps: S1, grinding the cupric oxide and copper sulfide mixed ore to below the grade of 0.074mm accounting for 60 to 70 percent of fineness; S2, adding a regulator, a collector and a foaming agent for floating copper sulfide ore into ore pulp obtained from S1; S3, grinding copper sulfide rough concentrate obtained from S2, and carrying out aeration floatation to obtain copper sulfide concentrate; S4, adding a vulcanizing agent, the regulator, the collector and the foaming agent into copper sulfide rougher tailings obtain from S2 and carrying out floatation to obtain cupric oxide rough concentrate; and S5, adding the vulcanizing agent, the regulator, the collector and the foaming agent into the cupric oxide rough concentrate obtained from S4, carrying out floatation to obtain cupric oxide concentrate and cleaner tailings, scavenging the cleaner tailings and outputting the cleaner tailings. By use of the separation method disclosed by the invention, the copper sulfide concentrate and the cupric oxide concentrate with higher grade and higher recoveryrate can be obtained, so that the investment is saved; and the separation method can be applied to industrial production.

Owner:CHINA ENFI ENGINEERING CORPORATION

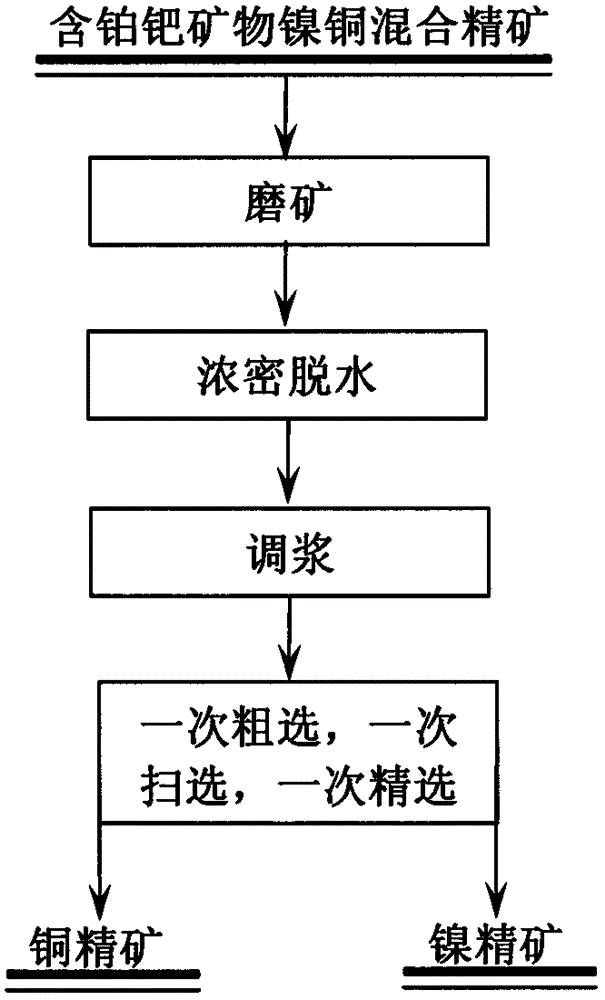

Separation method of nickel-copper mixed concentrate containing platinum-palladium mineral

The invention relates to a separation method of nickel-copper mixed concentrates containing platinum-palladium minerals. The separation method is characterized by comprising the following steps of: adding active carbon to the nickel-copper mixed concentrates containing the platinum-palladium minerals for ore grinding; mixing size; and adding an ore pulp regulating agent, an inhibiting agent, a collecting agent and a foaming agent to carry out nickel-copper flotation separation to obtain copper concentrates and nickel concentrates. The copper concentrates obtained through the separation method contain copper with a grade more than 20 percent and nickel with the grade lower than 2 percent; the nickel concentrates contain the nickel with the grade more than 3 percent, and the recovery rate of the nickel is more than 95 percent; platinum-palladium elements are gathered into the nickel concentrates, the recovery rate of platinum is more than 86 percent, and the recovery rate of palladium is more than 93 percent. The separation method has the advantages of simple process, good separation effect, high sorting index and economic rationality.

Owner:GUANGZHOU RES INST OF NON FERROUS METALS

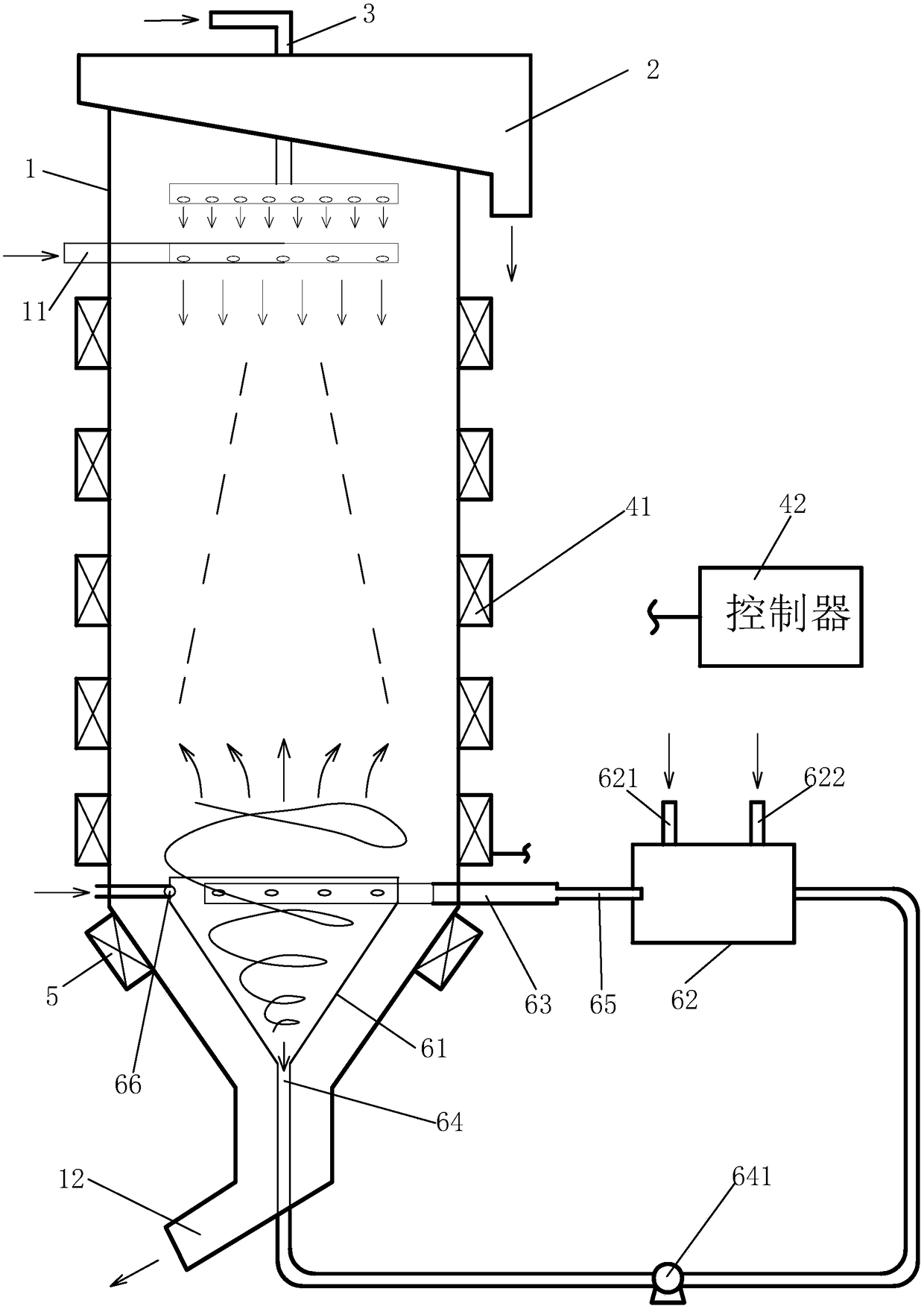

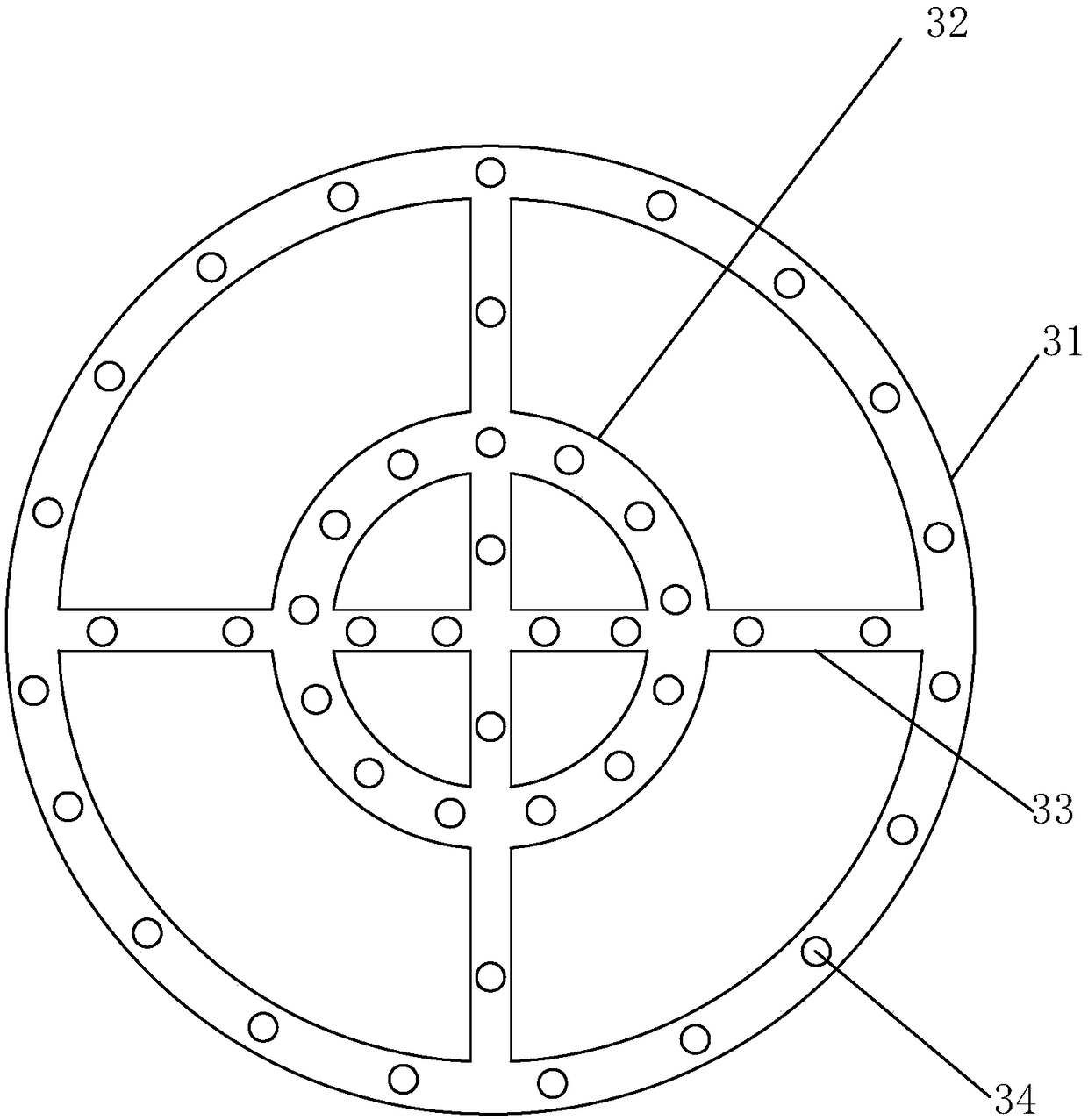

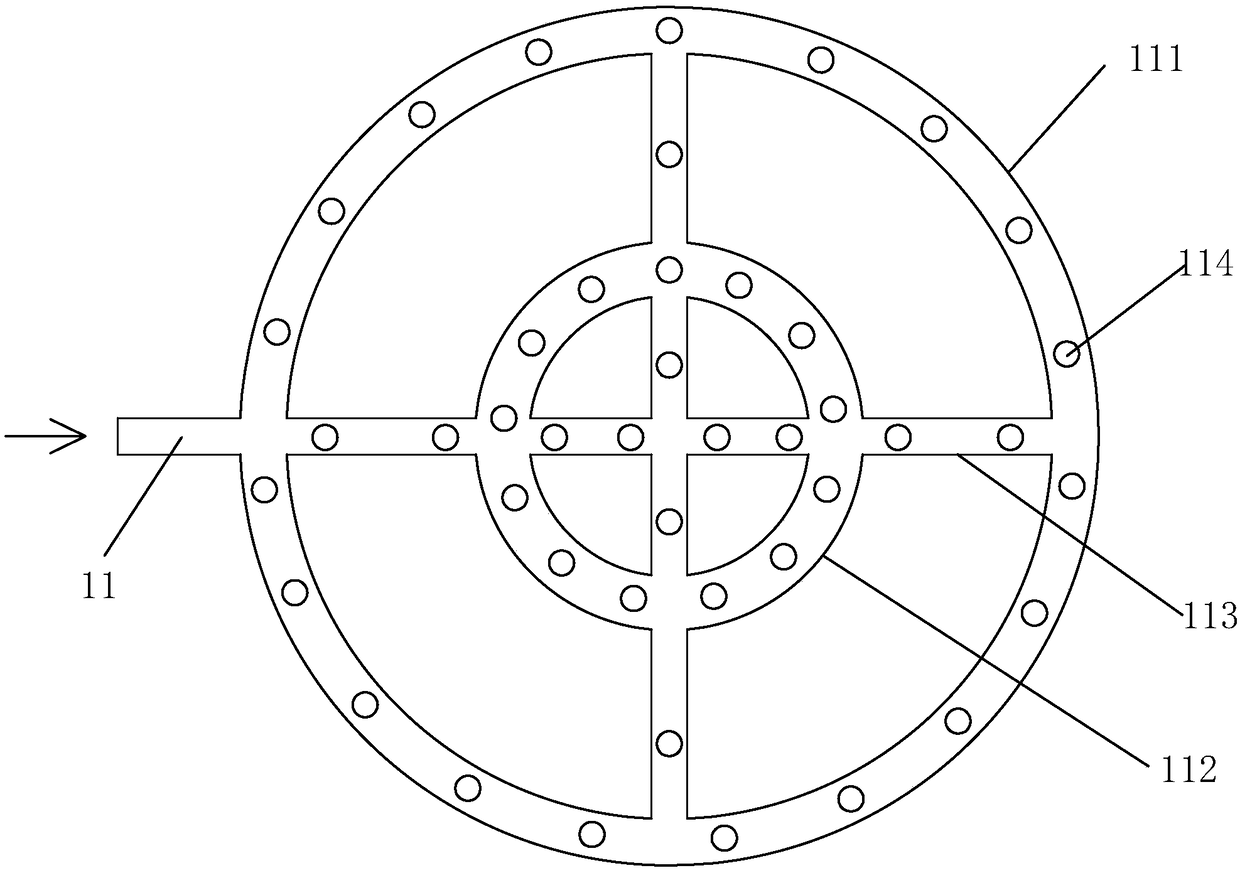

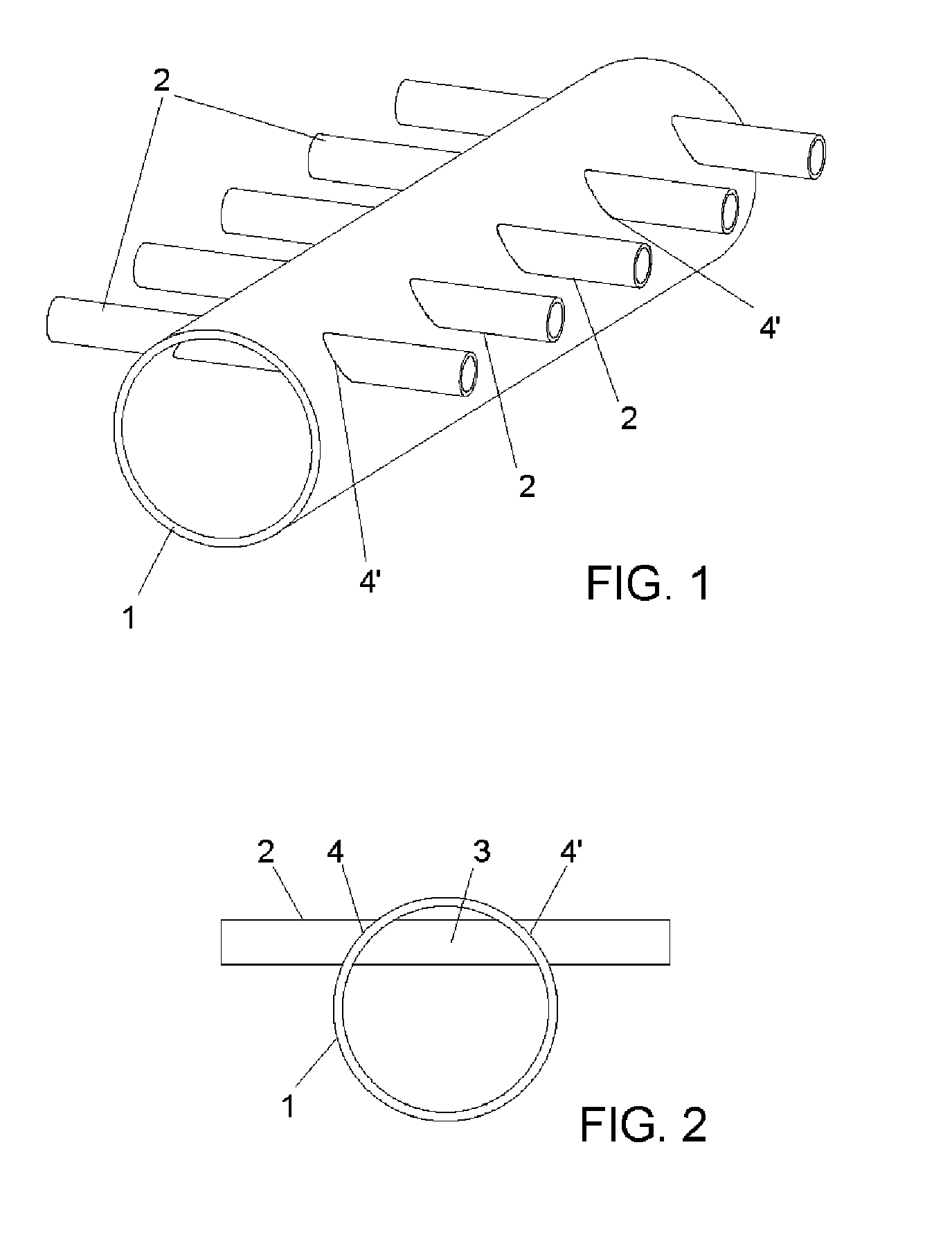

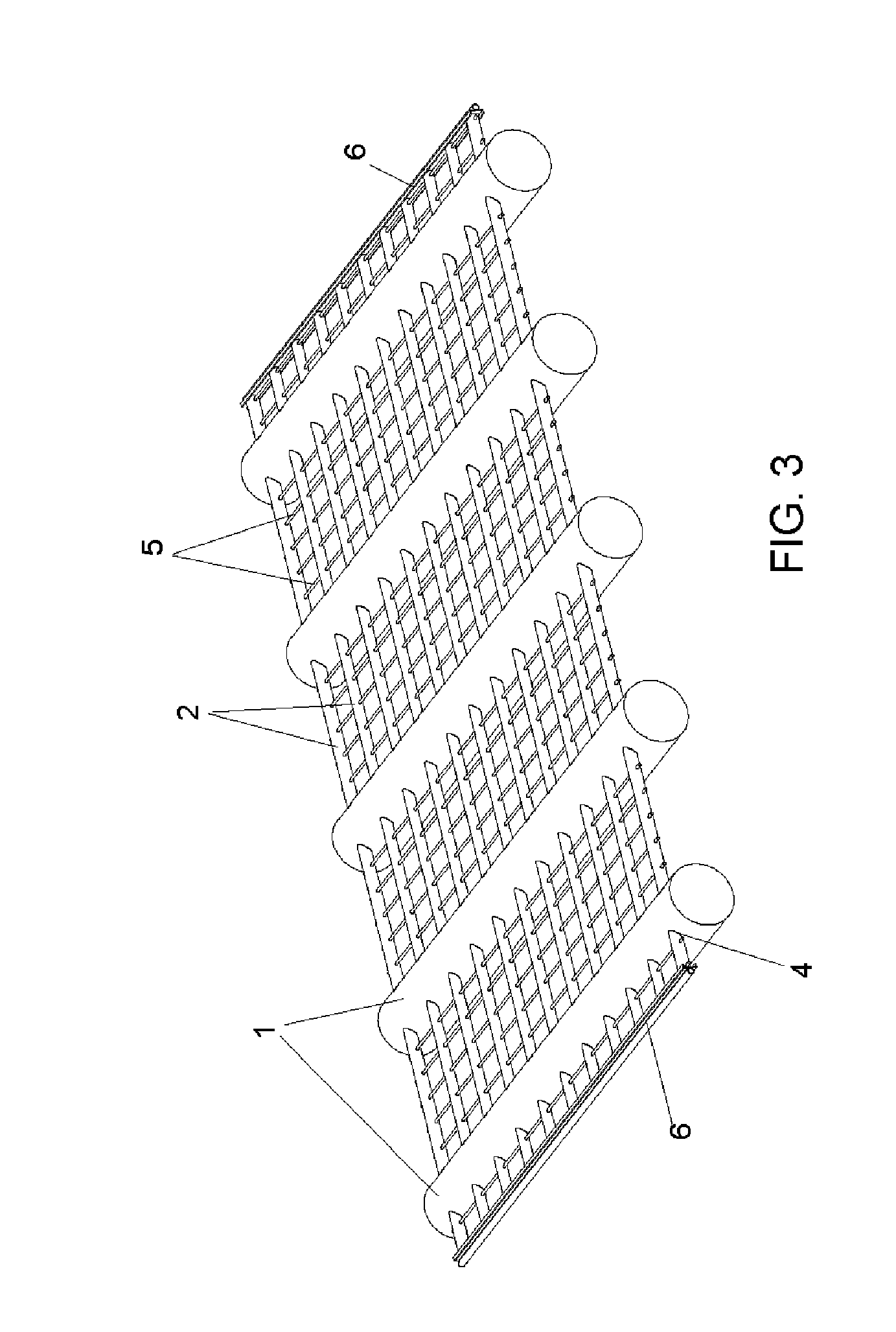

Floatation magnetic separation column device and combined type bubble generator

The invention discloses a floatation magnetic separation column device. The top of a column casing is provided with an overflow groove. The upper portion inside the column casing is provided with a spray device and an ore inlet. A pulsed magnet field and a demagnetizing device are mounted outside the column casing. The bottom of the column casing is provided with an iron ore concentrate outlet anda combined type bubble generator, wherein the combined type bubble generator comprises a conical barrel and a suction chamber. The conical barrel is arranged in the column casing in a sleeved manner,and a gap is reserved. The top of the column casing is open and communicates with the interior of the column casing. A tangential water pipe and a feeding pipe are arranged at the positions, on the upper portion of the conical barrel, inside the column casing. The bottom of the conical barrel is provided with a discharging pipe which extends out of the bottom of the column casing. The dischargingpipe is provided with a pump. The other end of the discharging pipe is connected to one side of the suction chamber. The suction chamber is provided with a gas inlet and an auxiliary agent addition opening. The other side of the suction chamber is connected with the feeding pipe of the conical barrel through a small-diameter throat pipe. The floatation magnetic separation column device is simplein structure, high in separation index and easy to operate; the grade of concrete can be remarkably raised; and by means of the combined type bubble generator, the generation quality of bubbles can beimproved, and the number of the generated bubbles can be increased; and the floatation treatment effect is improved.

Owner:JIANGSU DAFENG XINANDE MINING CO LTD

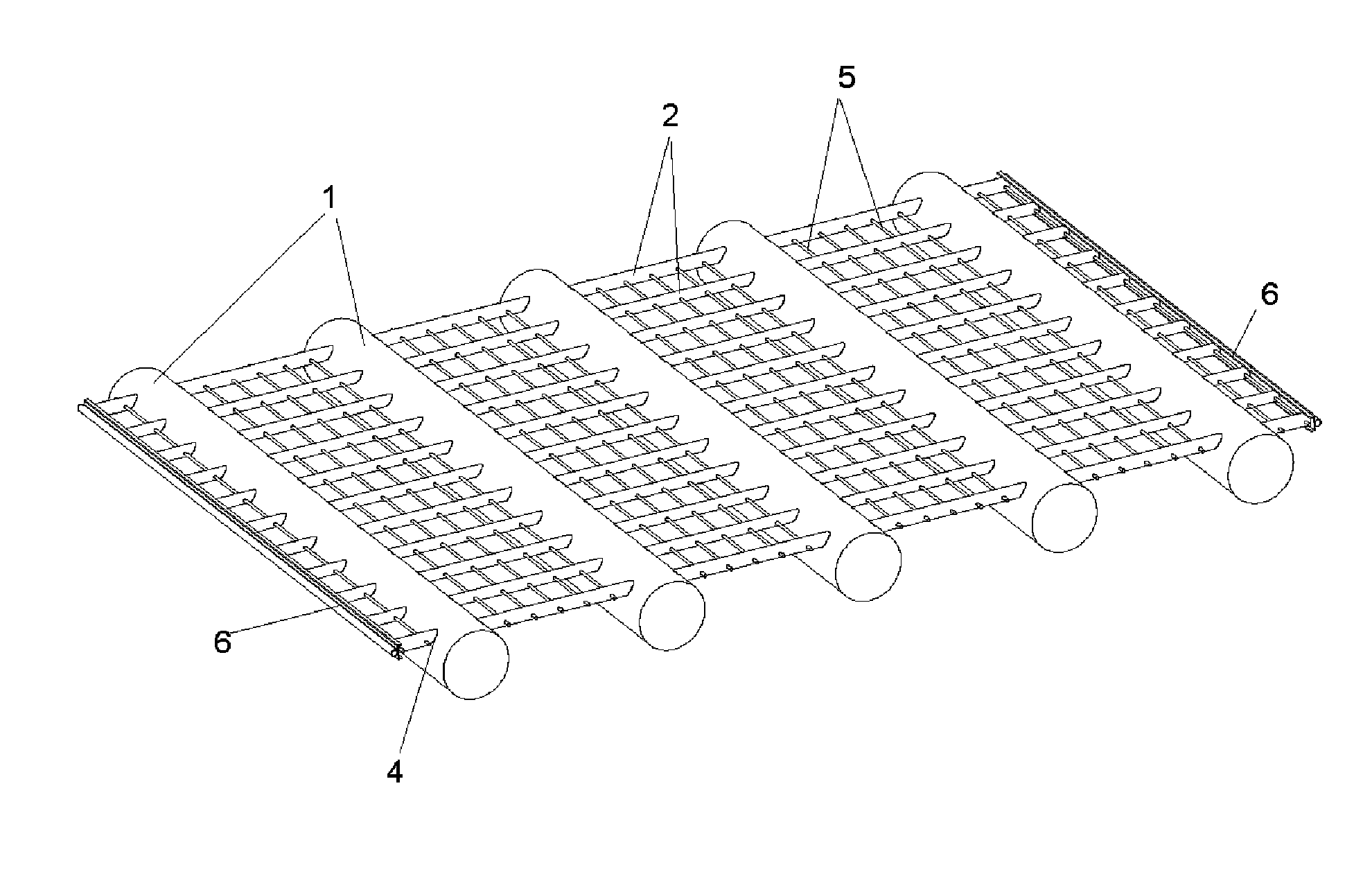

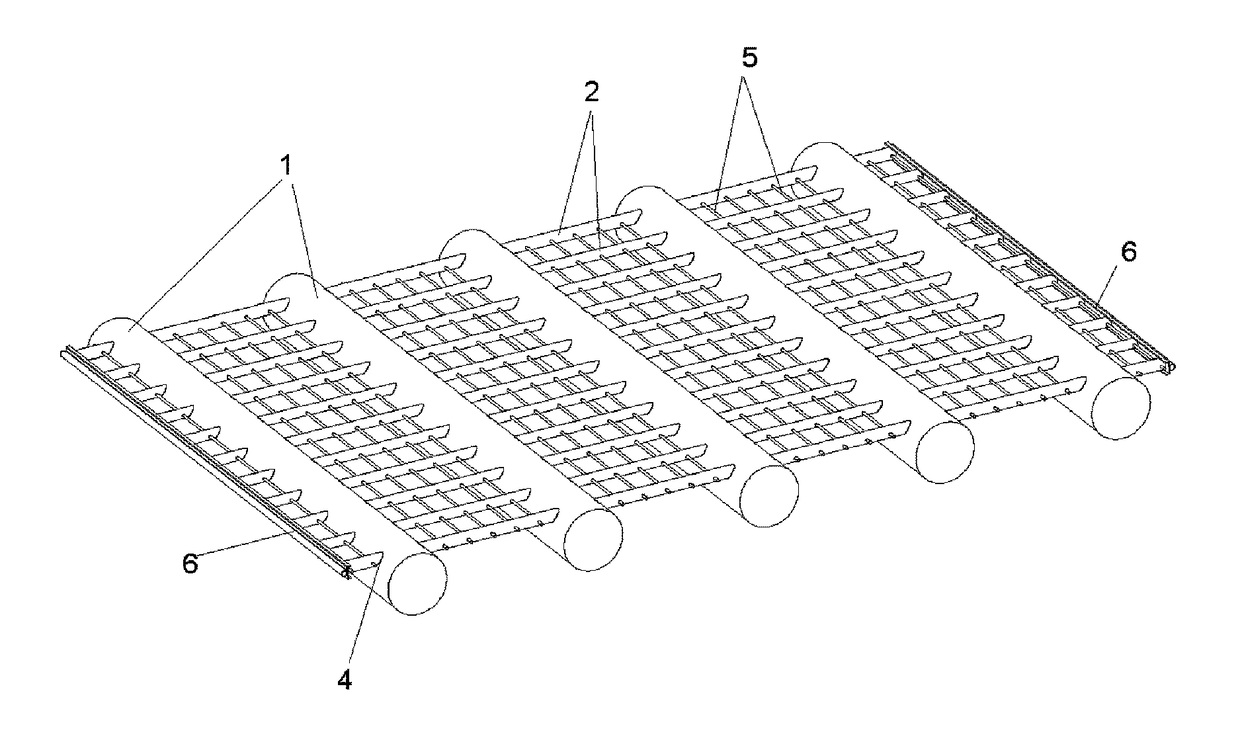

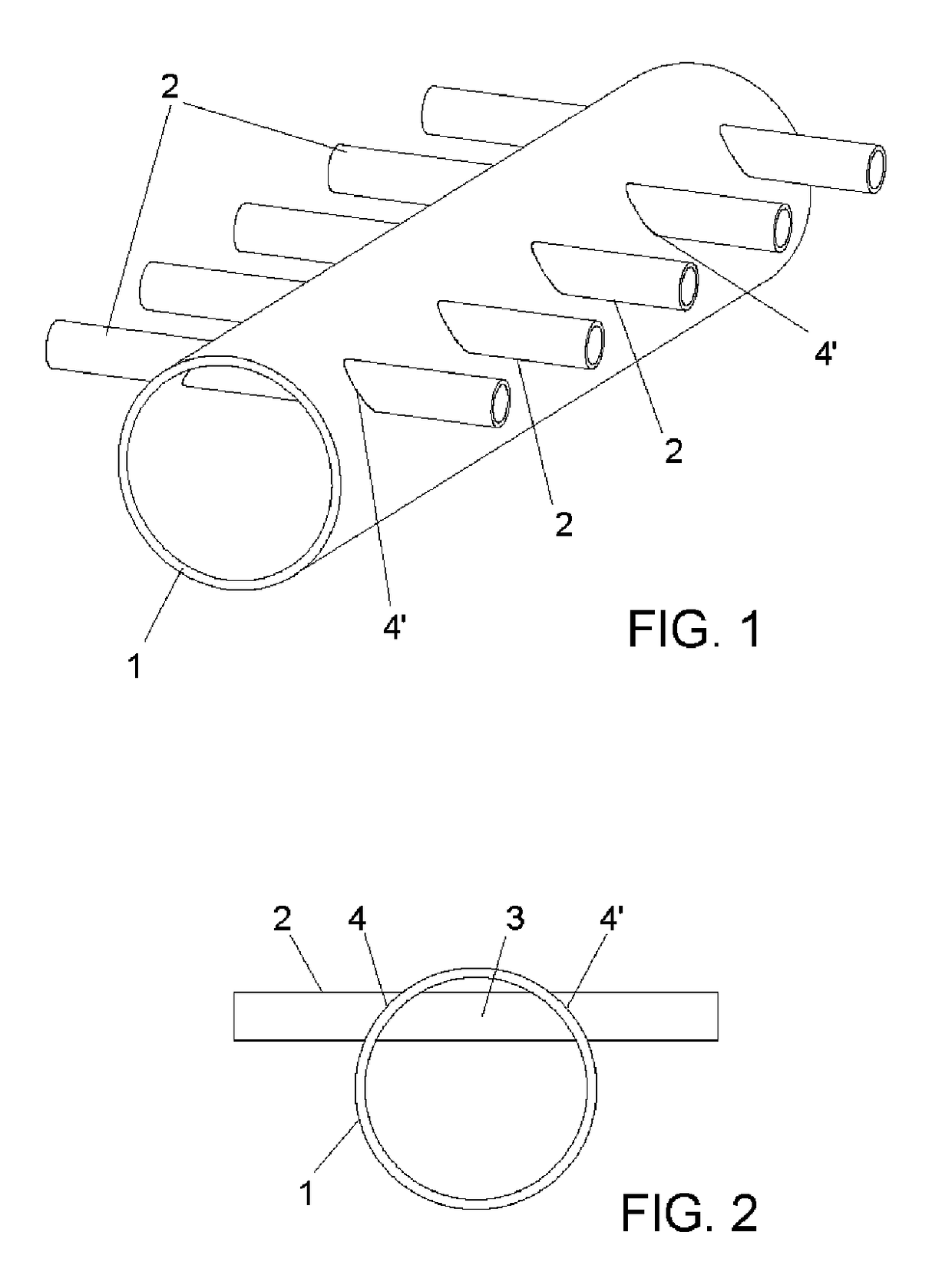

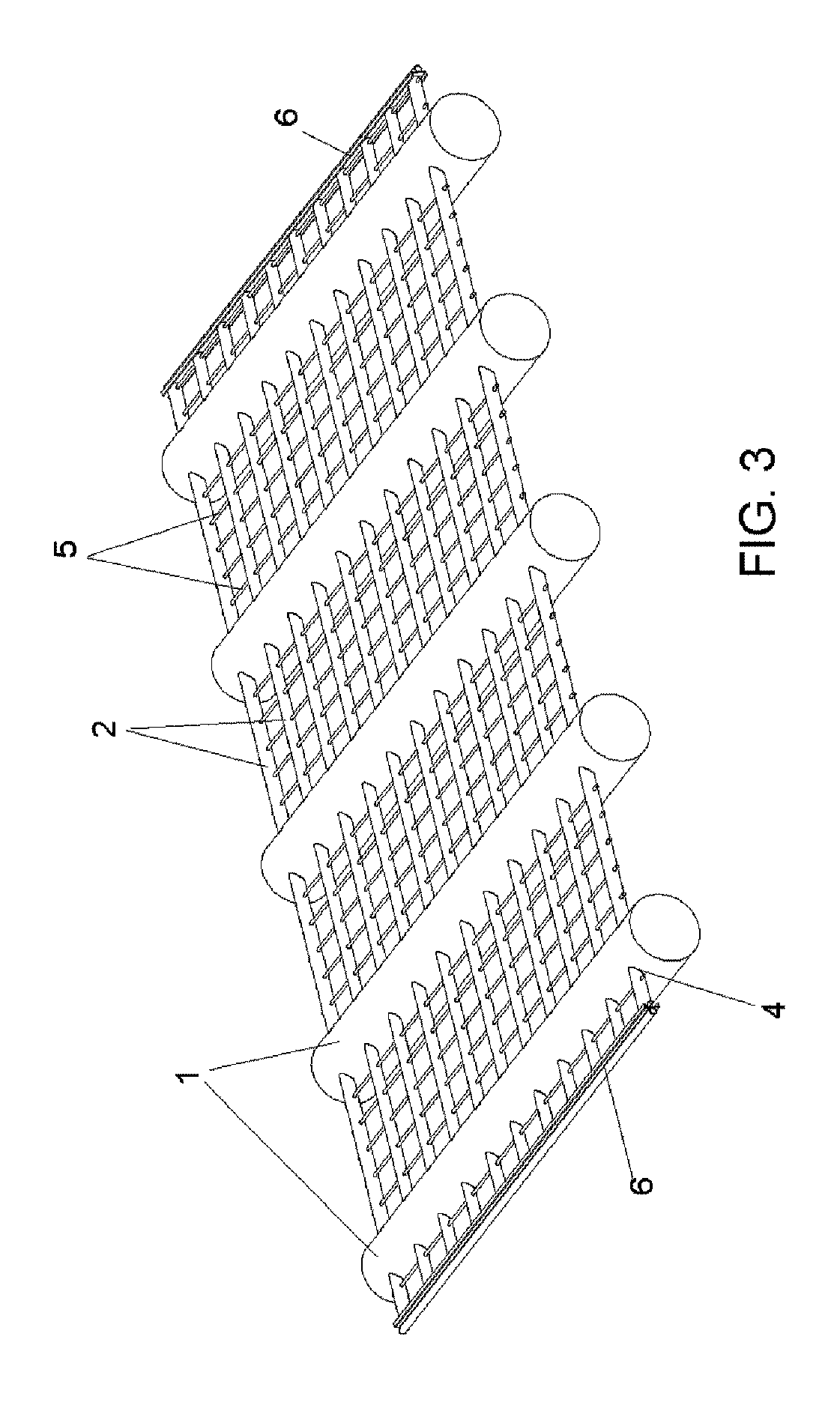

Floating structure and method for obtaining same

ActiveUS20150144068A1Increase resistanceImprove floatabilityClimate change adaptationPisciculture and aquariaEngineering

Owner:ESPANOLA DE PLATAFORMAS MARINAS SL

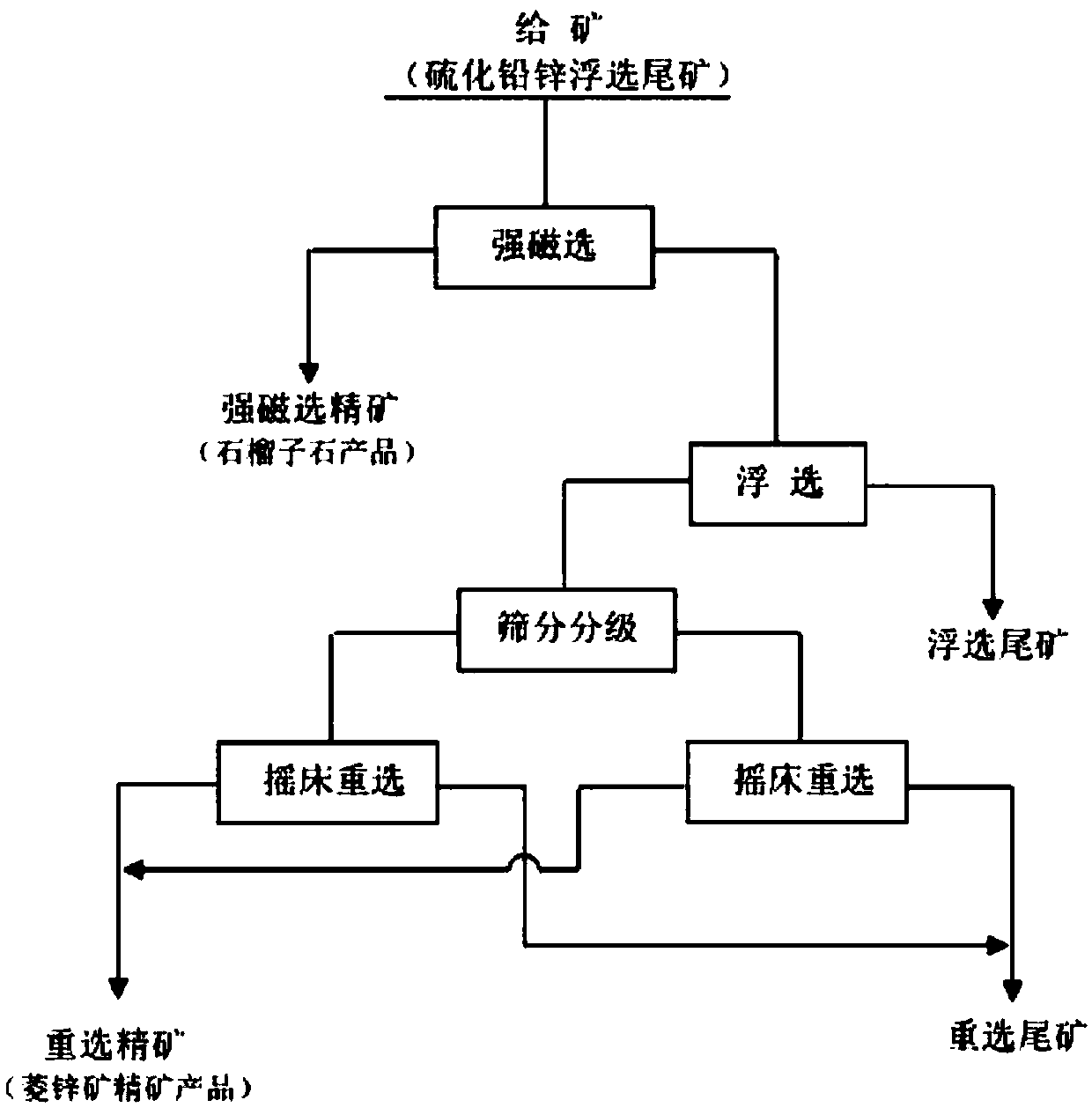

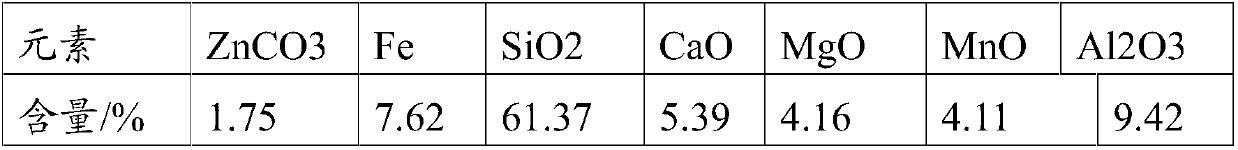

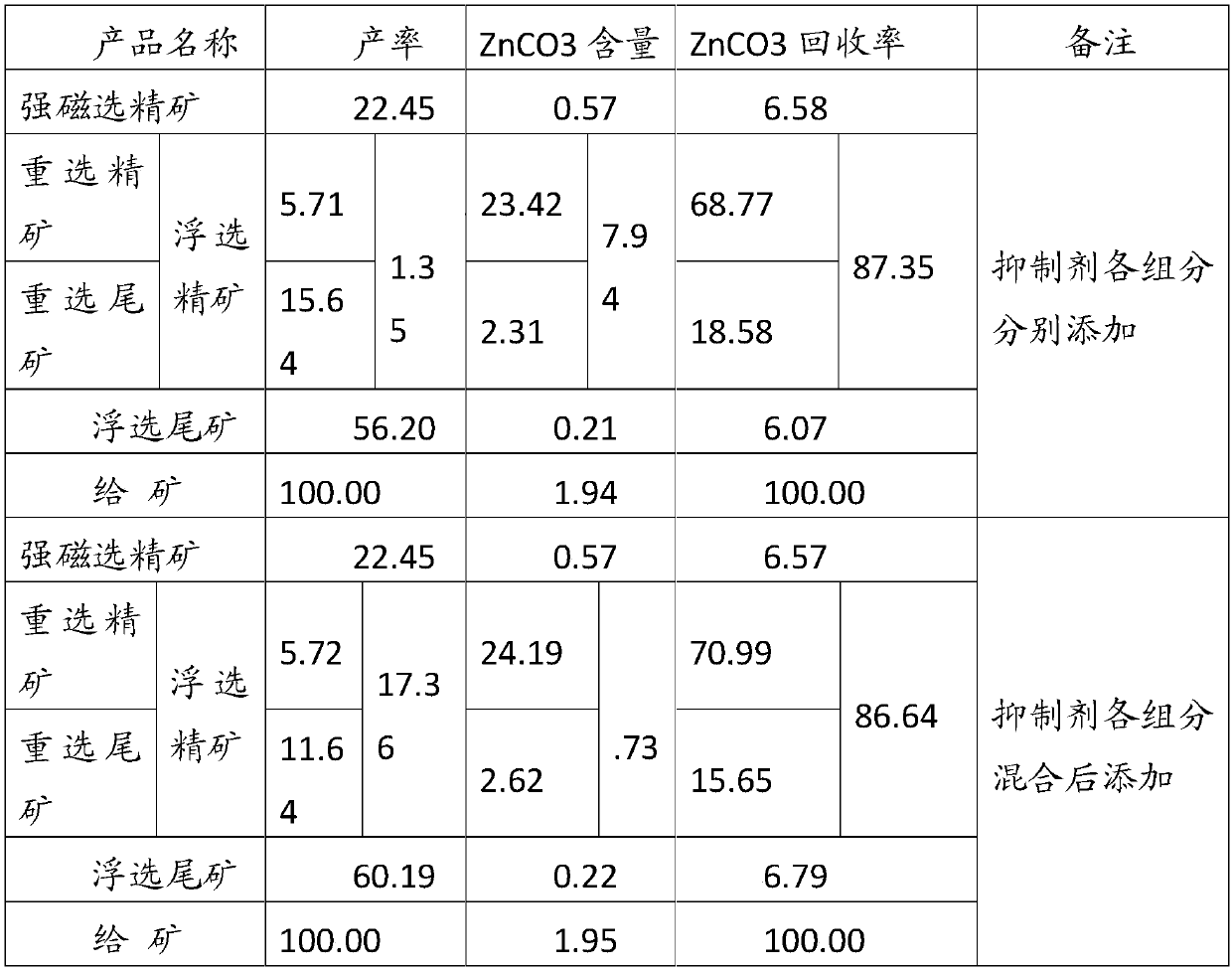

Ore separation method for reverse flotation of smithsonite from lead-zinc sulphide flotation tailings

InactiveCN107694740AReduce consumptionImprove enrichment effectFlotationMagnetic separationSmithsoniteEngineering

The invention discloses an ore separation method for the reverse flotation of smithsonite from sulphide lead-zinc flotation tailings. According to the ore separation method, tailings obtained after the flotation of lead sulphide and zinc sulphide from high-garnet-type lead-zinc sulphide are fed. The ore separation method comprises the following steps: step 1, carrying out strong magnetic separation on the fed tailings by adopting a high-gradient pulsating strong magnetic separation machine, so as to obtain strong magnetic separation concentrate and strong magnetic separation tailings; step 2,carrying out flotation on the strong magnetic separation tailings by adopting a flotation machine, so as to obtain flotation concentrate and flotation tailings; and step 3, carrying out wet screeningand classification on the flotation concentrate to obtain materials in two different size fractions, and carrying out separation on the materials in two different size fractions again, so as to obtainconcentrates in two size fractions and tailings in two size fractions. By adoption of the ore separation method, the smithsonite can be separated from the fed tailings. Besides, the agent consumptionis low, the enrichment effect is good, and the recovery rate is relatively ideal.

Owner:HUNAN RES INST FOR NONFERROUS METALS

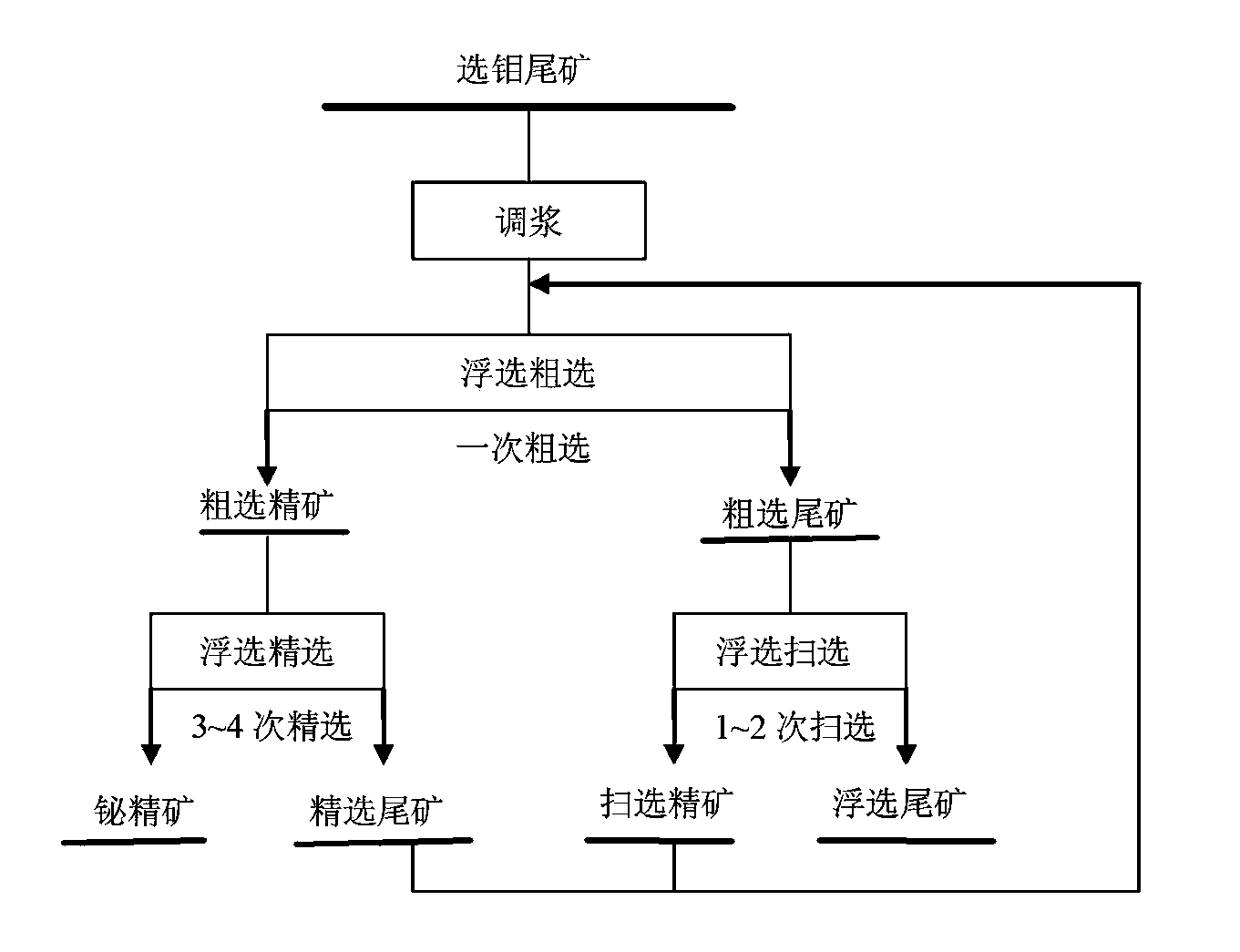

Beneficiation method for recycling bismuth from molybdenum selecting tailings

A beneficiation method for recycling bismuth from molybdenum selecting tailings is characterized by including the following steps that grout is mixed, in the step, concentrated sulfuric acid is added into the molybdenum selecting tailings; flotation roughing is performed, in the step, activator lead nitrate, collecting agent butyl xanthate and foaming agent terpenic oil are added to perform primary roughing to obtain roughed concentrate and roughed tailings; floating scavenging is performed, in the step, the butyl xanthate and the foaming agent terpenic oil are added in the primary scavenging of the roughed tailings, and the butyl xanthate and the foaming agent terpenic oil are added in the secondary scavenging or blank scavenging is performed to obtain scavenged concentrate and flotation tailings; flotation fine selection is performed, in the step, three to four times of blank fine selection is performed on the roughed concentrate to obtain bismuth concentrate and fine selected tailings; the fine selected tailings and the scavenged concentrate are made to return to the flotation roughing operation. According to the beneficiation method, bismuth is recycled from the molybdenum selecting tailings under the faintly acid condition in order to solve the problems that under the alkaline condition, activation of bismuthinite is poor and the recycling efficiency is low. According to the method, the recycling rate of the bismuth is larger than 85%, the Bi content in the bismuth concentrate is larger than 20%, and the method is applicable to molybdenum ore mines containing bismuth.

Owner:GUANGZHOU RES INST OF NON FERROUS METALS

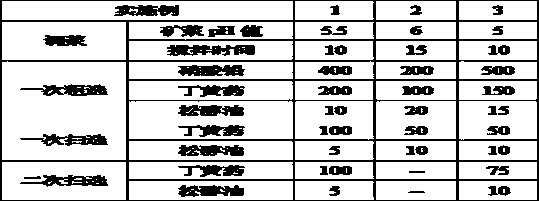

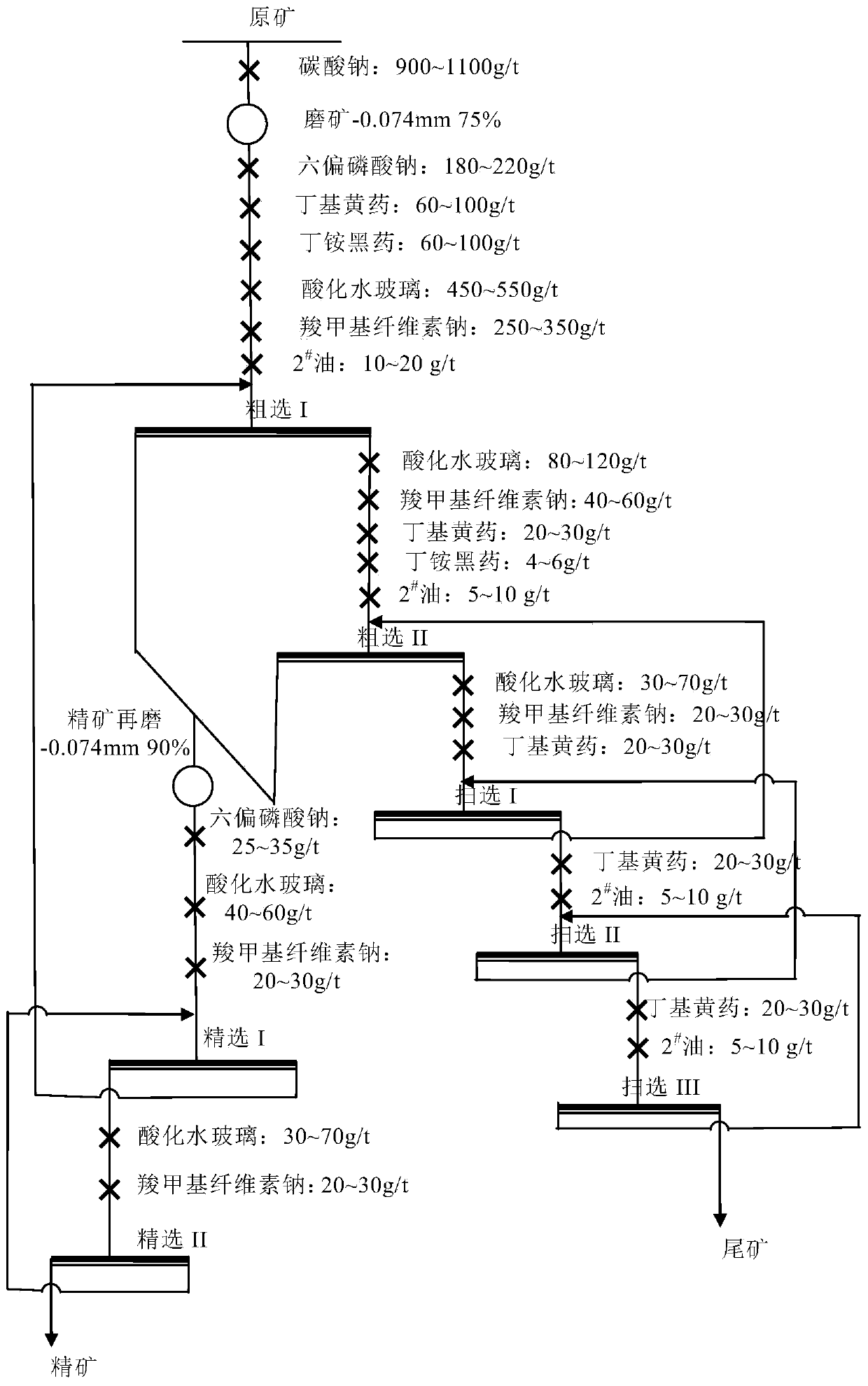

Method of flotation and magnesium reduction for talcum-type copper-nickel sulfide ore

The invention relates to a method of flotation and magnesium reduction for talcum-type copper-nickel sulfide ore. According to the beneficiation method, talcum-type copper nickel polymetallic ore is taken as a raw material, a flotation technology is adopted, and nickel ore concentrate is obtained. The method comprises the steps of ore grinding, size mixing, roughing, scavenging and concentration operation. After ore grinding, sodium hexametaphosphate, butyl xanthate, ammonium dibutyl dithiophosphate, acidified water glass, sodium carboxymethylcellulose and 2#oil are added in sequence, the added sodium carboxymethylcellulose inhibits talcum which easily floats, and the acidified water glass enhances the selectivity of the inhibiting agent. The acidified water glass can form colloidal particles in the ore pulp system, the colloidal particles are selectively adsorbed on the surfaces of gangue mineral particles to make the gangue mineral particles hydrophilic and enhances the selectivity of the inhibiting agent sodium carboxymethylcellulose, and on the basis of not influencing the grade and recovery rate of copper and nickel concentrate, the content of MgO in the copper and nickel concentrate can be significantly reduced by 3% or above. According to the method, the content of MgO in the copper and nickel concentrate can be effectively reduced, and indicators in beneficiation for the talcum-type copper-nickel sulfide ore are improved.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

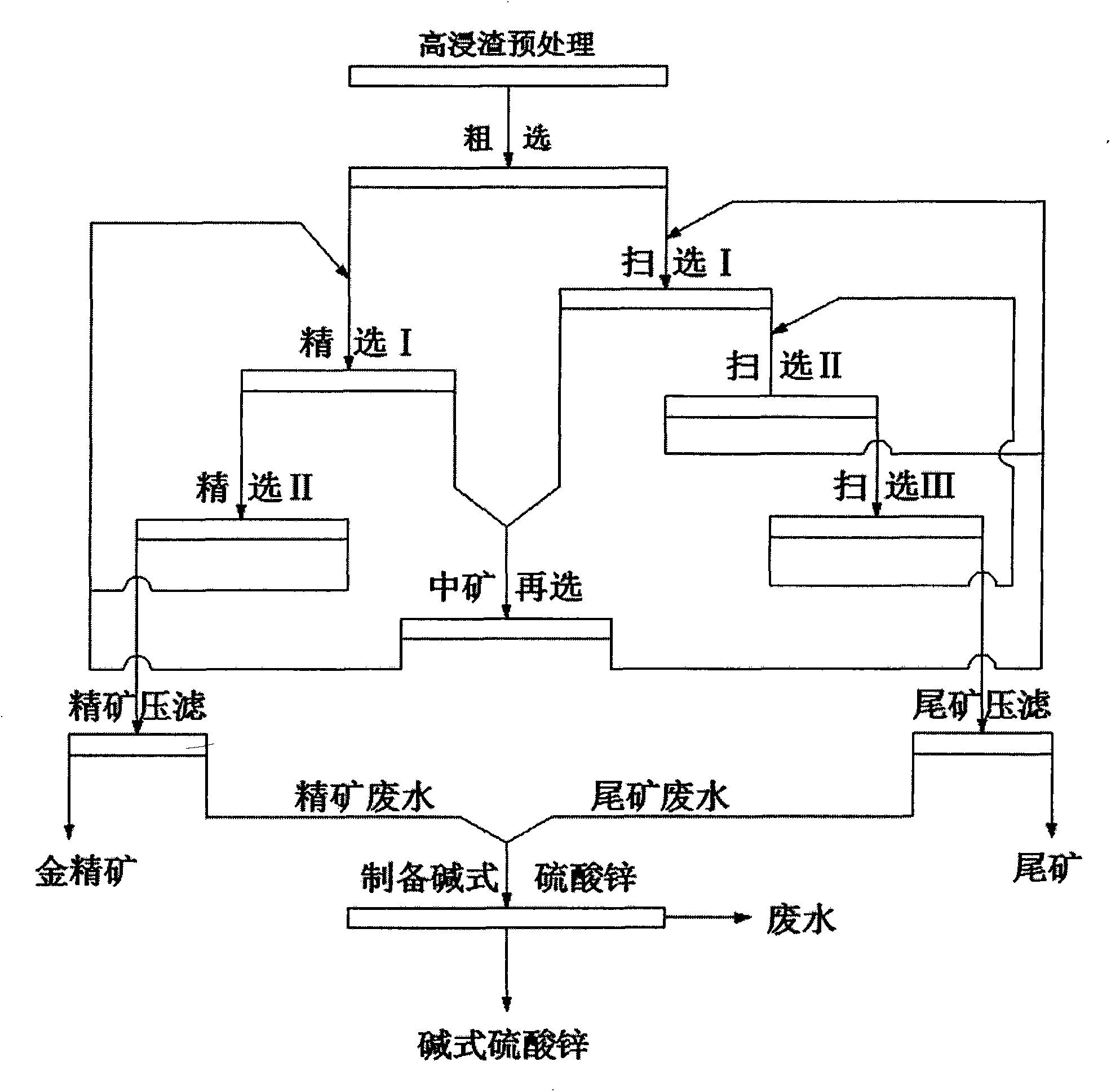

Method for comprehensively recovering gold and zinc from high leaching residue and recycling wastewater

InactiveCN103521504AImprove protectionImprove resource utilizationSolid waste disposalProcess efficiency improvementResource utilizationSulfate

The invention discloses a method for comprehensively recovering gold and zinc from high leaching residue and recycling wastewater. The method comprises nine process steps of pre-treating the high leaching residue, carrying out rough concentration once, carrying out fine concentration twice, carrying out scavenging for three times, carrying out middling re-concentration once and preparing basic zinc sulfate. The method is the best process route which is selected aiming at the mineral characteristics of the high leaching residue. The gold recovery rate is increased through carrying out rough concentration once, fine concentration twice, scavenging for three times and middling re-concentration once on pretreated high leaching residue ore slurry, the combined adding point and dosage of medicaments are selected scientifically and reasonably, the acting time of various medicaments is guaranteed, the dosage of the medicaments is reduced, and the recovery rate and grade of gold are further increased. Due to the step of preparing basic zinc sulfate from waste mineral water, zinc sulfate is recovered while mineral separation wastewater is purified, and the wastewater returns to floatation slurry mixing and is recycled; the wastewater can be recycled, so that the environmental protection is facilitated, and the resource utilization rate is increased.

Owner:CHIFENG ZHONGSE ZINC IND CO LTD

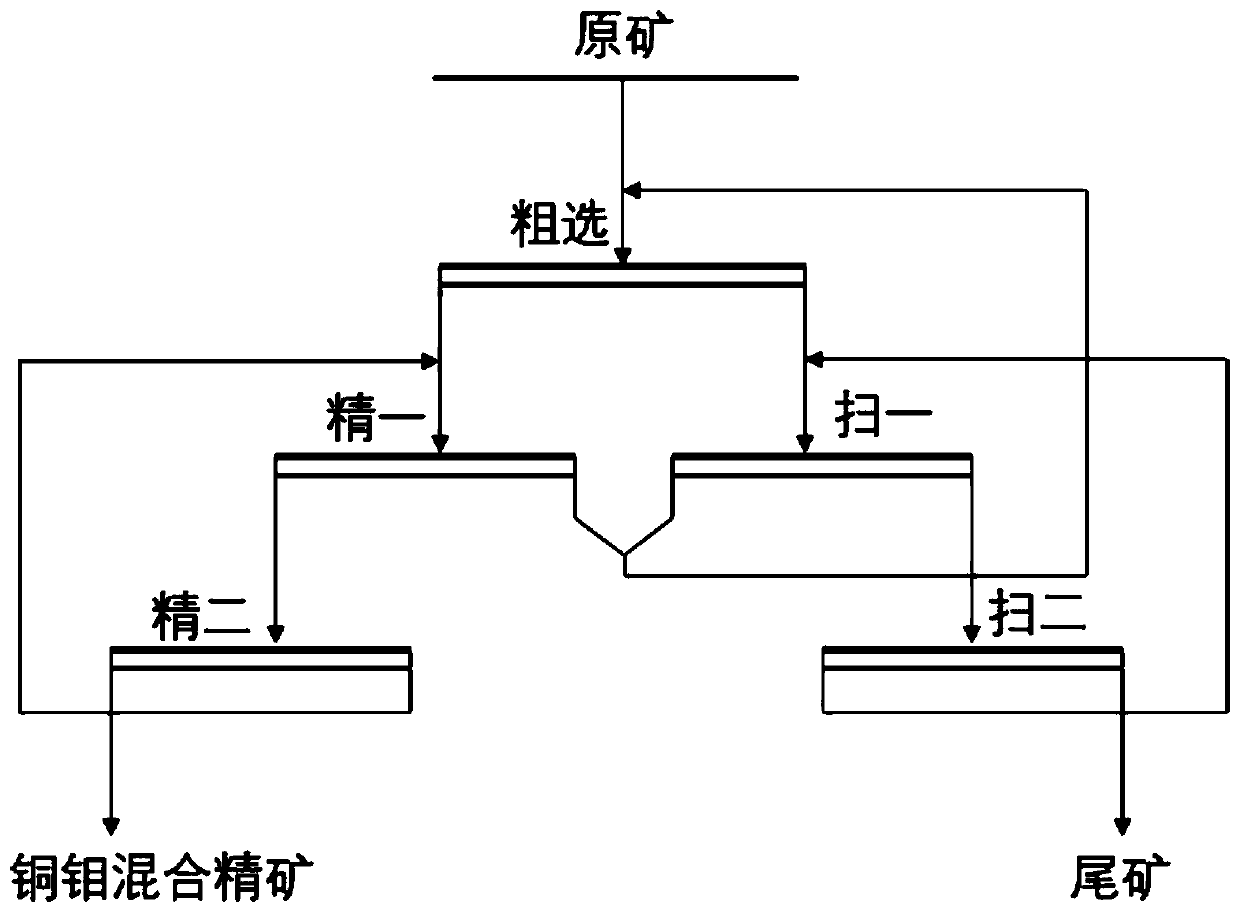

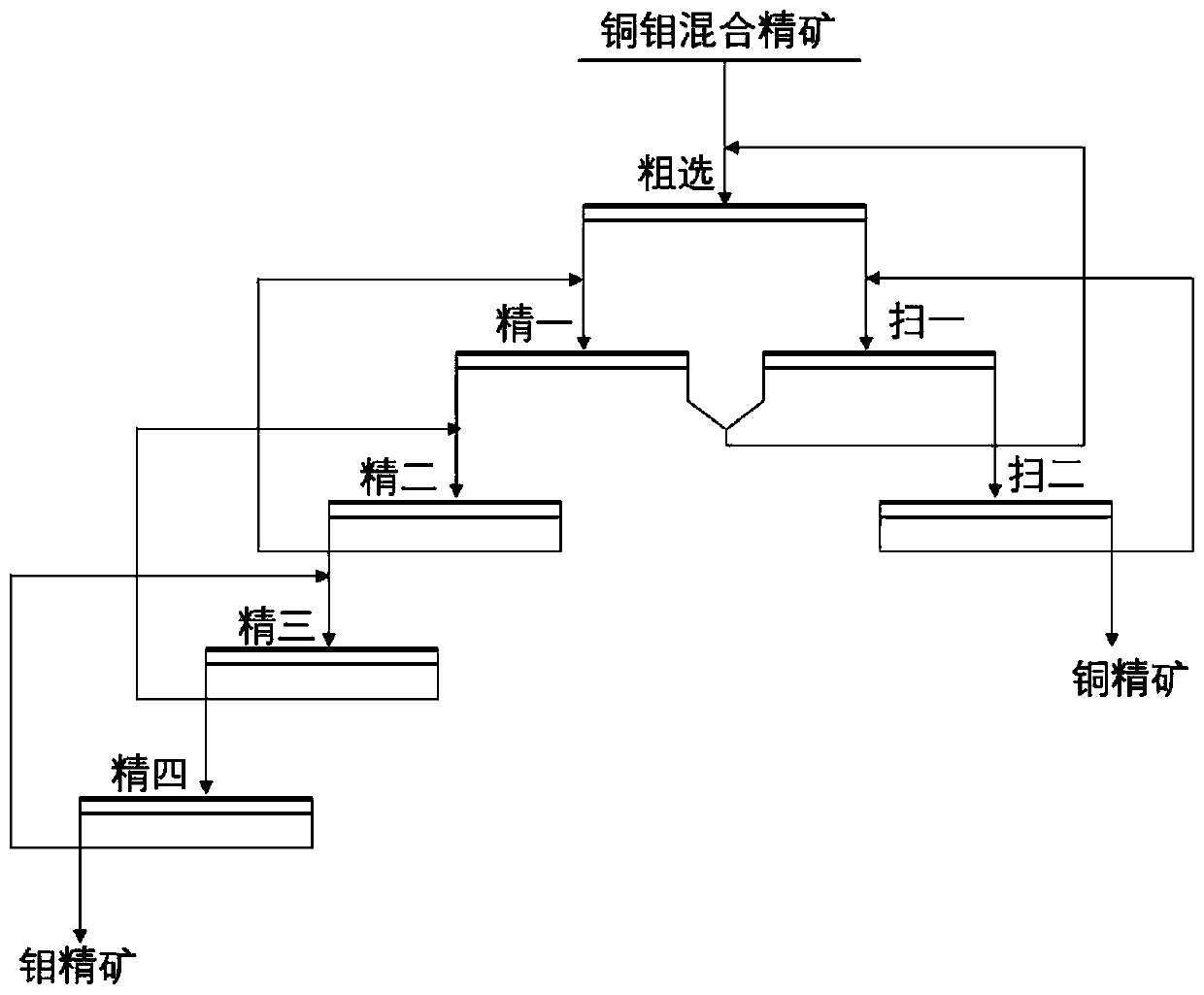

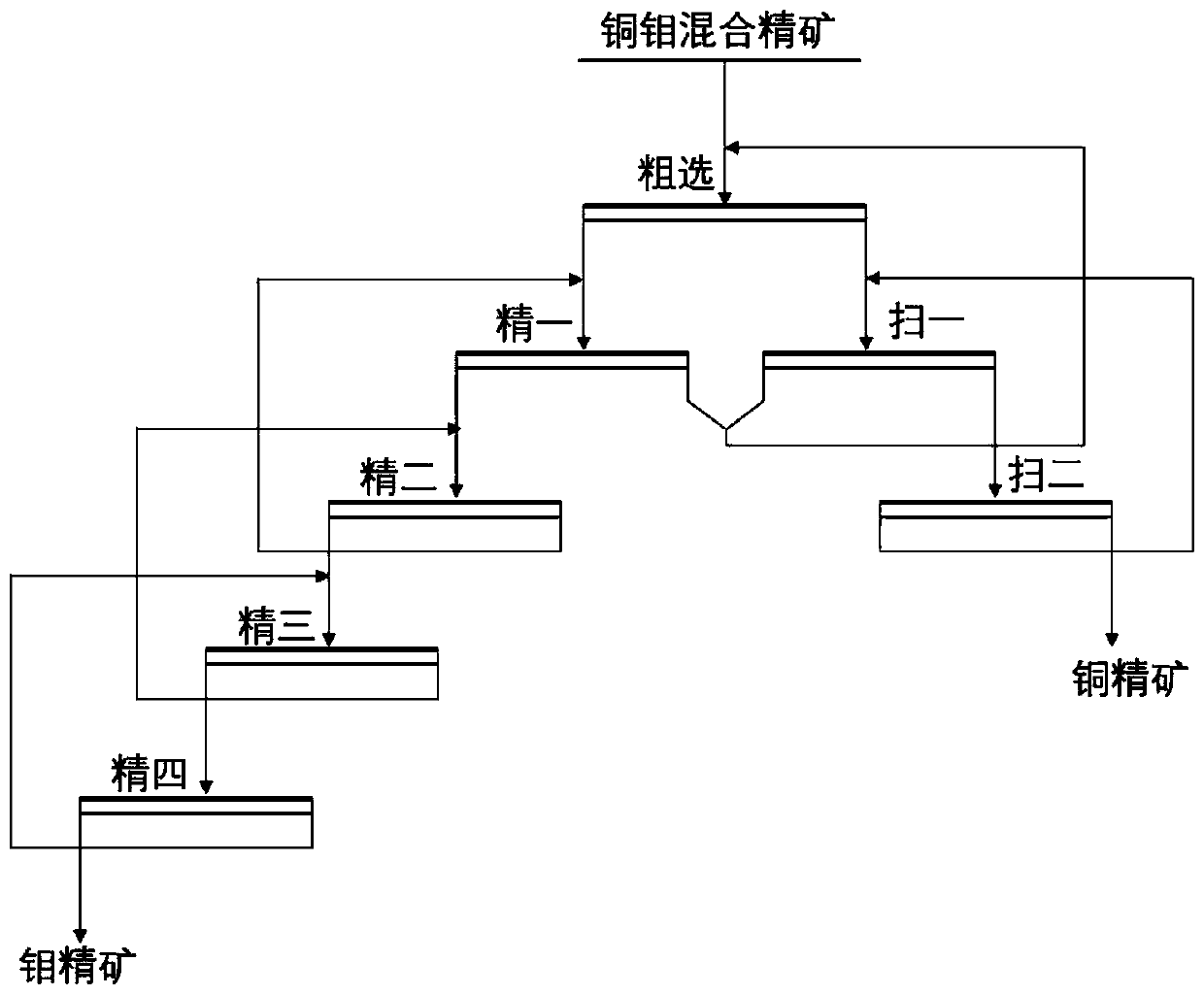

Flotation method for copper-molybdenum sulfide ore

The invention provides a flotation method for copper-molybdenum sulfide ore. The method comprises the following steps: carrying out crushing, ore grinding and desliming pretreatment on raw copper-molybdenum ore to prepare copper-molybdenum ore pulp with a concentration of 30-40%; adding the copper-molybdenum ore pulp into a flotation device, adding a collecting agent kerosene and a foaming agent terpenic oil under the condition of a preset pH value, and carrying out a bulk flotation process of sequentially returning middlings through first roughing, second concentration and second scavenging to obtain copper-molybdenum bulk concentrate; and finally preparing mixed ore pulp with a concentration of 25-35% from the copper-molybdenum bulk concentrate, adjusting to a preset pH value and a preset external control potential, adding a copper inhibitor and / or a collecting agent kerosene, and carrying out a flotation process of sequentially returning middlings through first roughing, fourth concentration and second scavenging, and separating to obtain copper concentrate and molybdenum concentrate. According to the method, the copper-molybdenum separation flotation process is carried out by combining an external control potential flotation mode with a copper inhibitor, so that the process is stable and controllable, the recovery rate of copper-molybdenum resources in raw ore is high, andthe copper-molybdenum separation effect is remarkable.

Owner:NANHUA UNIV

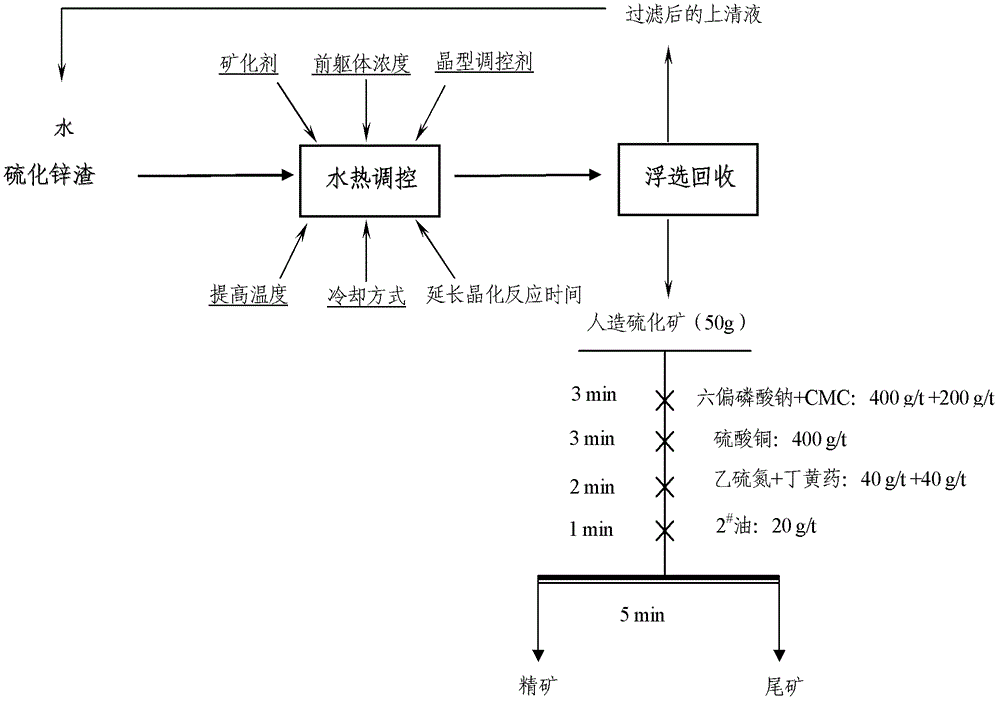

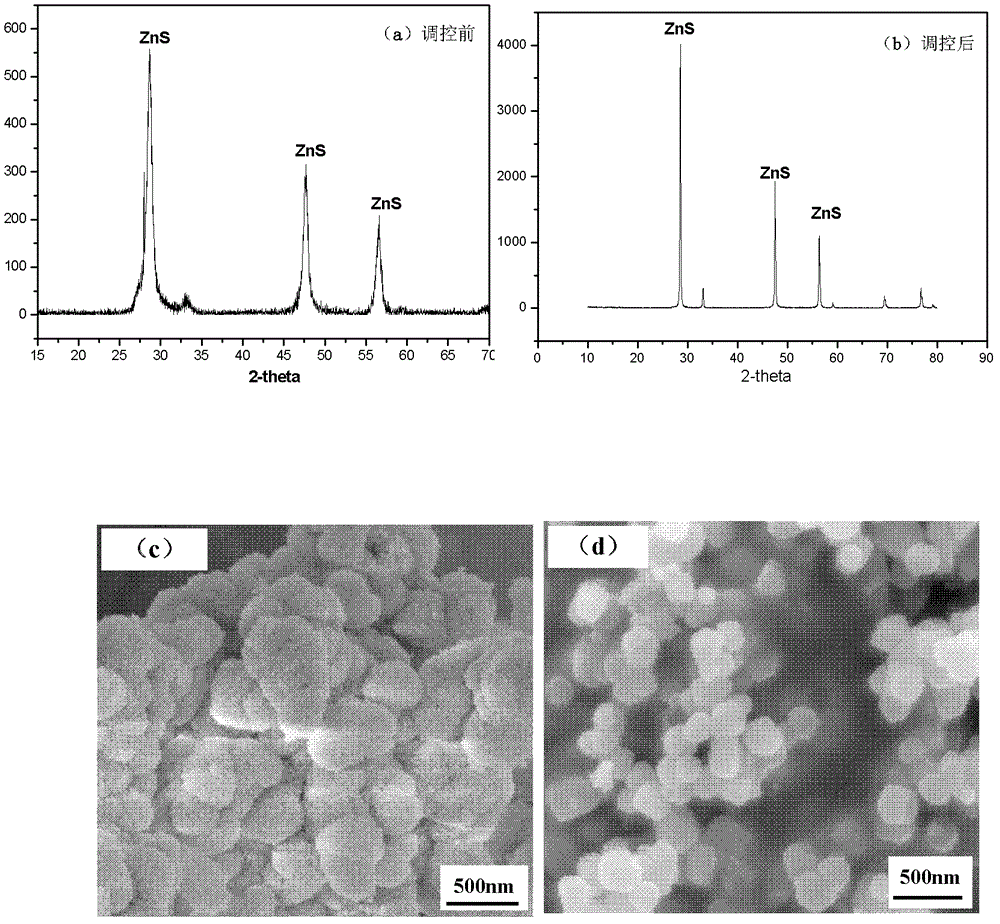

Method for performing hydrothemal regulation and control on refractory and fine-grained vulcanization slag to optimize flotation behavior thereof

ActiveCN102642862BEnhanced hydrothermal crystallizationImprove hydrophobicityZinc sulfidesVulcanizationSlag

Owner:CENT SOUTH UNIV

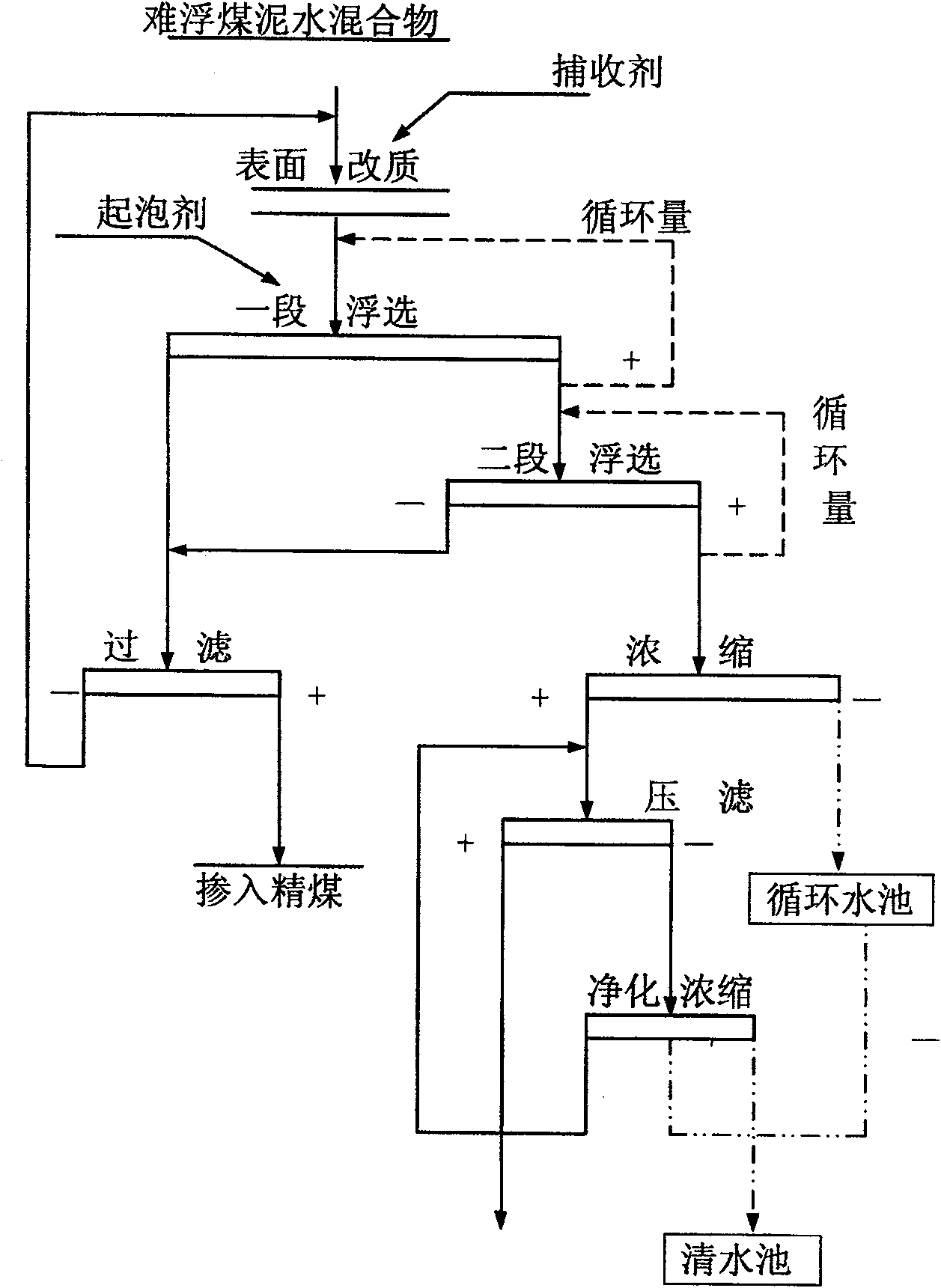

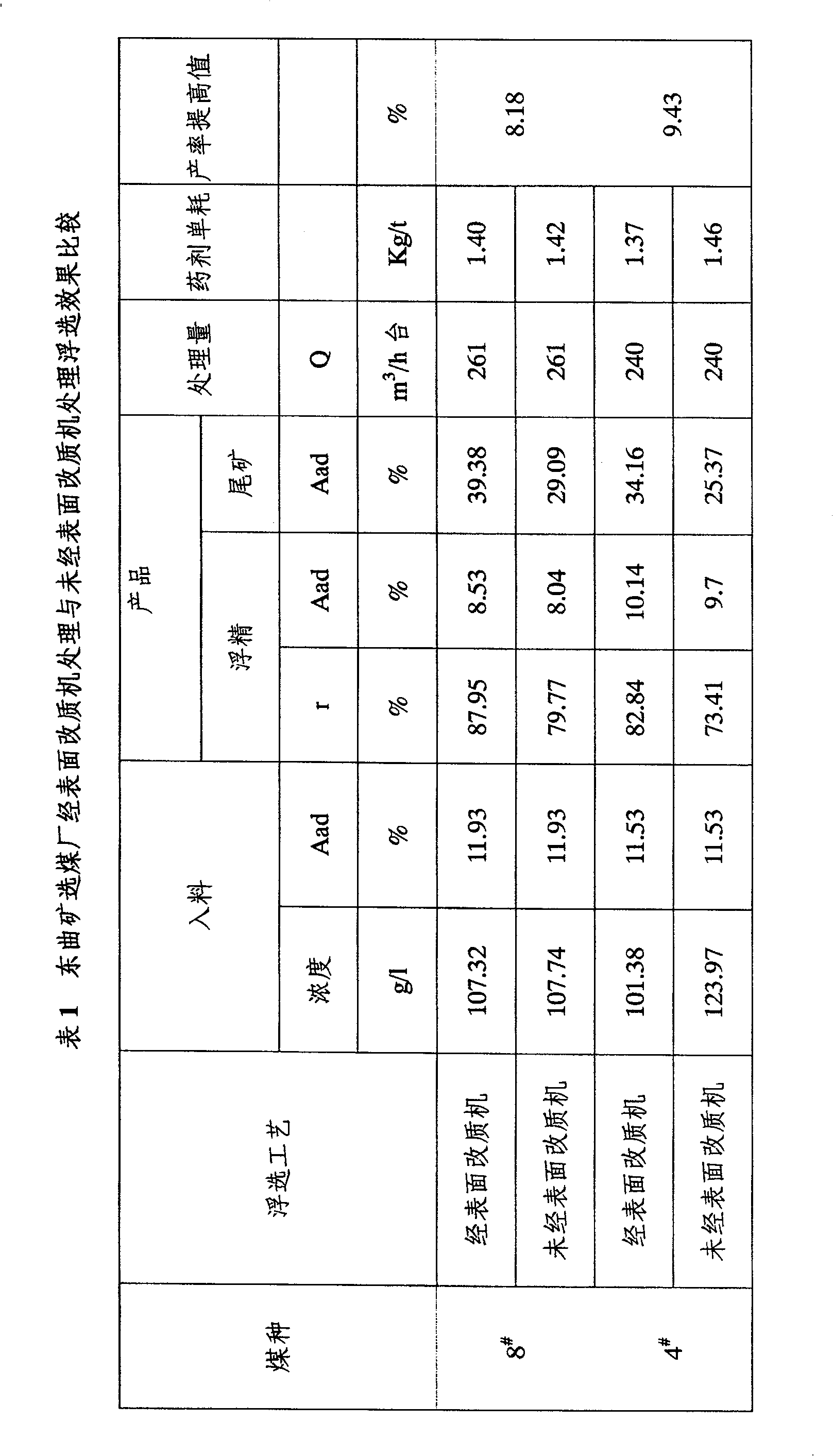

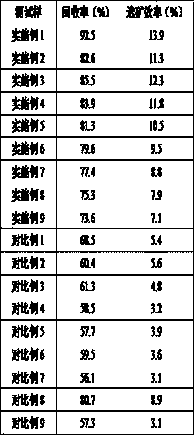

Floatation method of difficult-to-float coal

The invention provides a flotation method for difficult-to-float coal slime, which uses a surface modifier combined with a micro-bubble flotation machine. Both the flotation and flotation effects can be effectively guaranteed, which solves the problem that the difficult-to-float slime cannot wash out qualified float products and the float yield is low. Since the two mechanisms have some similarities, after joint use, they can guarantee On the basis of ash content, the unit consumption of chemicals (collectors and foaming agents) is reduced by 20%, and the extraction rate of floating semen is increased by more than 10%.

Owner:SHANXI COKING COAL GROUP

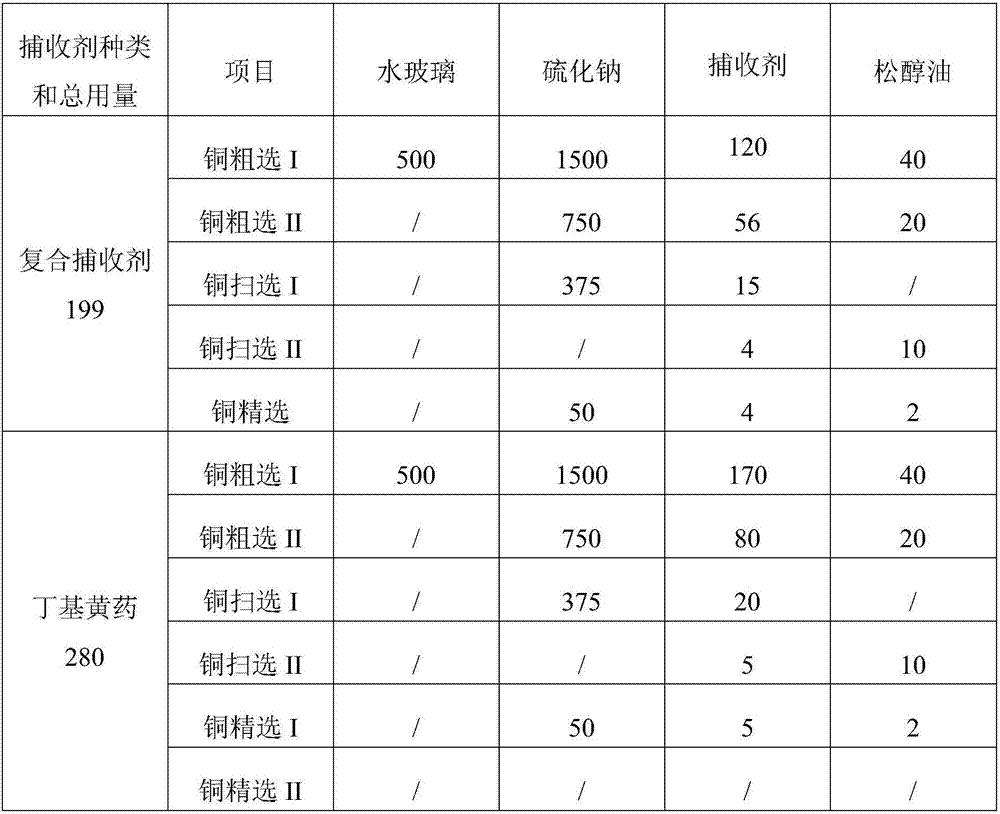

Preparation and application of copper oxide ore flotation composite collecting agent

The invention relates to preparation and application of a copper oxide ore flotation composite collecting agent. The composite collecting agent comprises sodium n-butylxanthate, aviation kerosene and transformer oil, and the mass ratio of the sodium n-butylxanthate to the aviation kerosene to the transformer oil is 80:1:1 through mixing. The composite collecting agent further comprises water, and the mass of the water accounts for 90%-95% of the mass of the composite collecting agent. According to the composite collecting agent, the original nature of components can be kept, and an efficient synergistic effect can be generated. The composite collecting agent is used for replacing sodium n-butylxanthate of a traditional collecting agent, the number of times of copper concentration operation can be shortened by one time, and the total quantity of the collecting agent is reduced by 20%-30%; the beneficial effects of shortening the beneficiation process and reducing reagent consumption are achieved; the aims of reducing the production cost and improving economic benefits are achieved; and the copper oxide ore flotation composite collecting agent is suitable for copper oxide ore flotation.

Owner:云南省地质矿产勘查开发局中心实验室

Floating structure and method for obtaining same

ActiveUS9902474B2Improve floatabilityIncrease resistanceClimate change adaptationPisciculture and aquariaEngineeringFitting-out

Owner:ESPANOLA DE PLATAFORMAS MARINAS SL

Preparation method of novel flotation collector

The invention discloses a preparation method of a novel flotation collector. The preparation method comprises the steps that cotton oil fatty acid is taken as a raw material and then subjected to saponification treatment to obtain cotton oil fatty acid soap, citric acid, sodium silicate, sodium carbonate, sodium oleate and phenoxyacetic acid composite products are added, and composite fatty acid citrate-based carboxylic acid containing multi-element carboxyl is obtained and applied to phosphate ore flotation by serving as a phosphate ore collector. The synthetic agent has the characteristics of being good in water solubility, high in collecting capability, good in selectivity and good in low temperature resistance, has the advantages of being low in agent dosage and production cost compared with unmodified fatty acid, and has the important significance for reducing the flotation cost and improving the flotation efficiency.

Owner:隆化县新村矿业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com