High-efficiency pulp modifying machine for molybdenum tungsten ore flotation technology and implementation method thereof

An implementation method and pulp technology, applied in flotation, chemical instruments and methods, mixers, etc., can solve the problems of not realizing high-efficiency pulping technology, chaotic flotation process, and easy precipitation, and improve hydrophobicity and reliability. Floatability, improve flotation separation accuracy and mineral yield, and save chemicals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

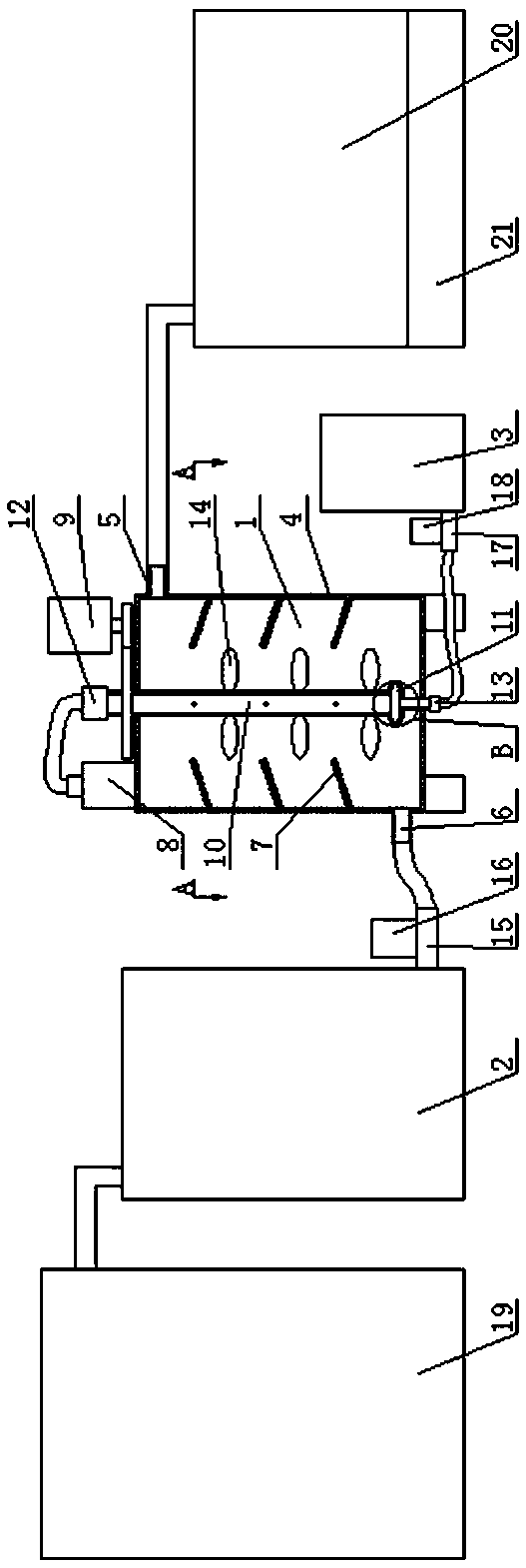

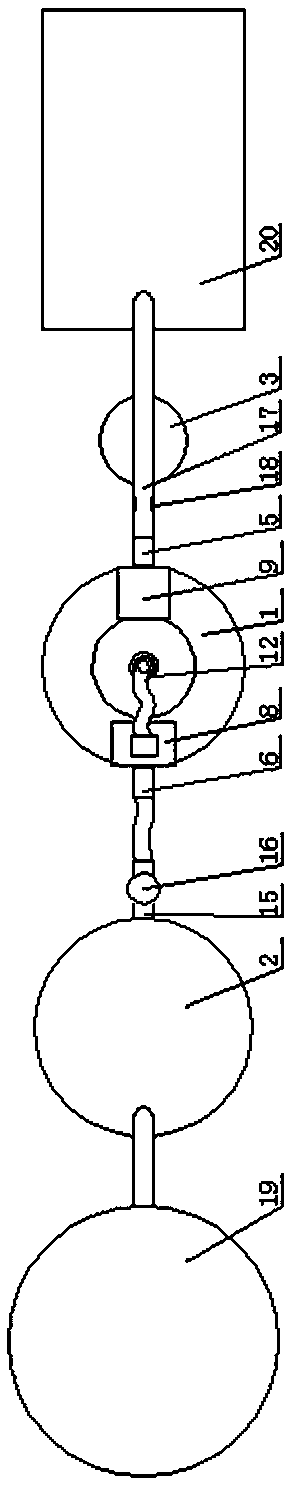

[0043] The implementation method of the high-efficiency pulp reformer used in the molybdenum-tungsten ore flotation process includes the following steps:

[0044] (a) Take the raw ore and pass it through the ore grinding system 19 to crush, grind, screen and classify the raw ore, and grind the raw ore until it reaches the dissociated fineness of the mineral to obtain a qualified grinding product;

[0045] (b) Transport the ground minerals in step (a) to the raw material bin 2, and then add water for uniform mixing;

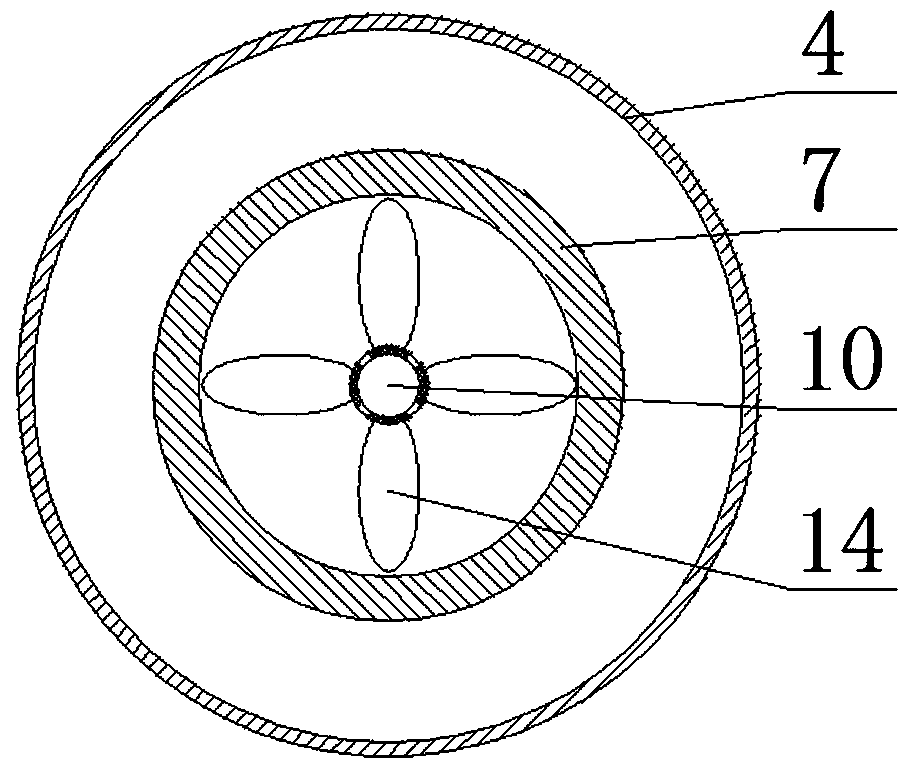

[0046] (c) The ore pulp blended in step (b) is input to the lower part of the slurry mixing box 1 through the first feeding pump 16, and the air compressor 8 and the second feeding pump 18 respectively connect the compressed air and the medicament through the air intake The pipe 12 and the feeding connecting pipe 13 enter the spray chamber 11 at the lower part of the main body of the rotating shaft 10, and the compressed air and the chemical are sprayed out from the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com