Method for performing hydrothemal regulation and control on refractory and fine-grained vulcanization slag to optimize flotation behavior thereof

A technology of sulfurized slag and fine particles, which is applied in the field of environmental engineering, can solve the problems of unsatisfactory flotation recovery rate, etc., achieve good hydrophobicity and floatability, good crystal form, and improve hydrophobicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

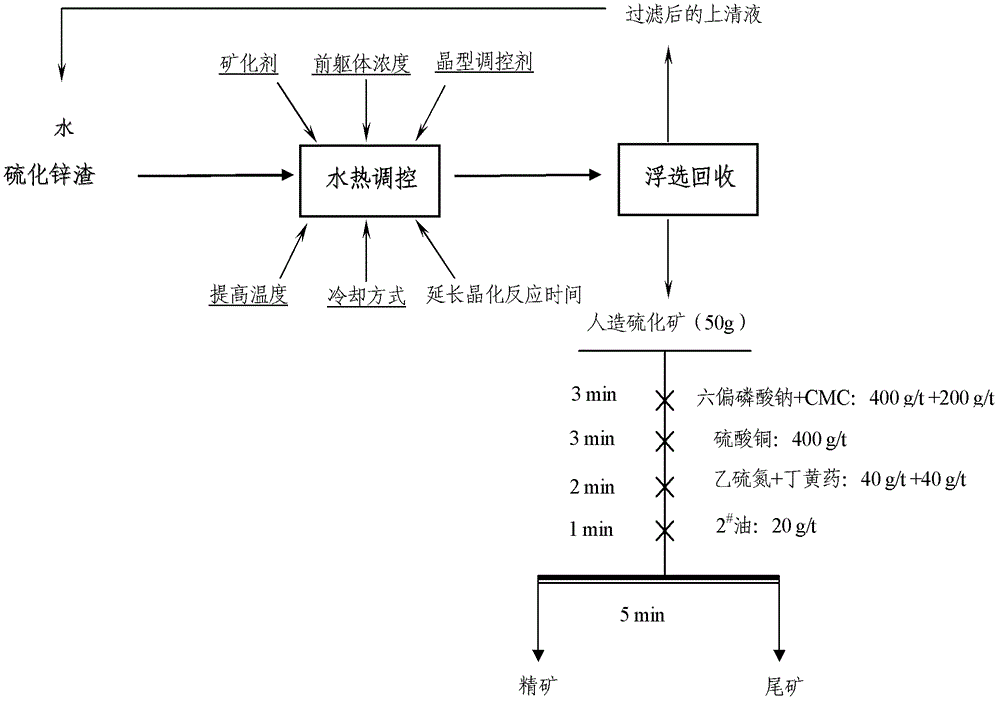

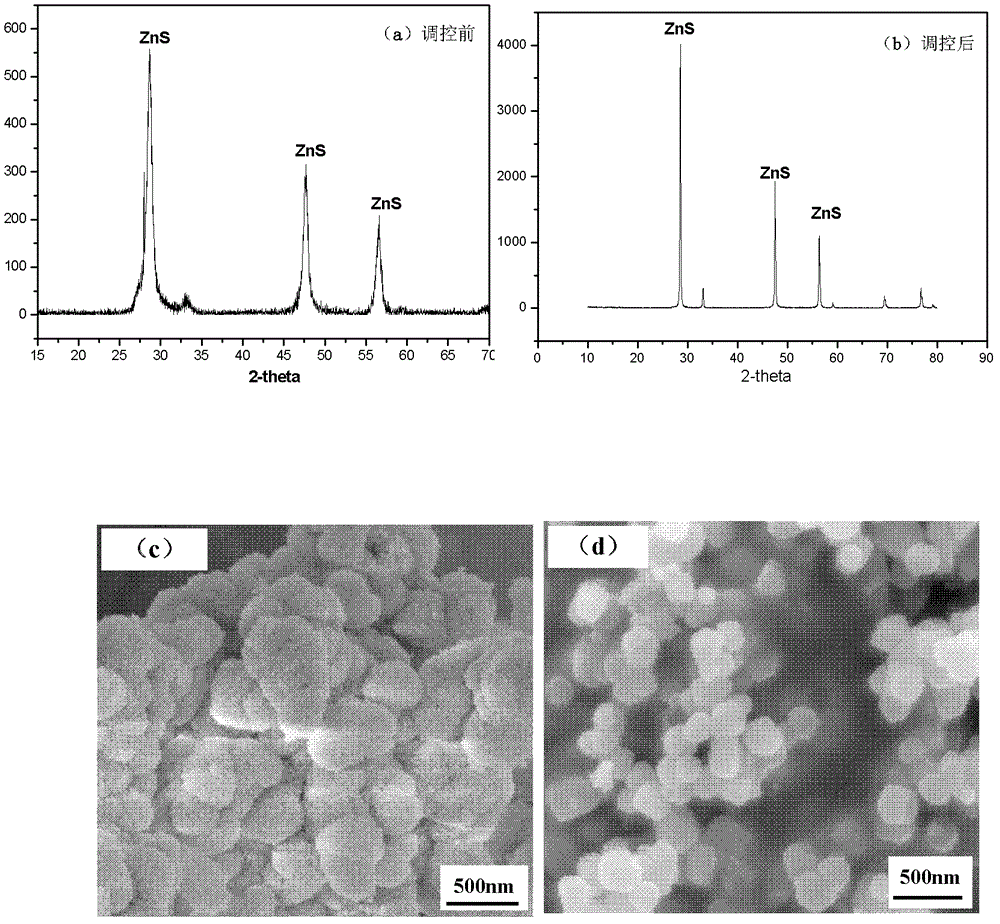

[0027] Hydrothermal control and flotation of pure compound zinc sulfide prepared by chemical precipitation method

[0028] Step 1: Take 30g of pure compound zinc sulfide prepared by chemical precipitation method, pass through a 150μm sieve, 2.5g of natural galena, add mineralizer KOH, make the reaction system pH 9 and place it in GCF-0.5L strong magnetic rotary stirring In the reaction kettle, add water at the same time to make the filling degree in the kettle 70%, the rotation speed is set to 200r / min, the temperature is set to 260°C, and the reaction is 4 hours. After the reaction is finished, cool naturally, take out the material, and filter with suction. The solid is the adjusted zinc sulfide.

[0029] Step 2: Take 50g of zinc sulfide after hydrothermal control and flotation recovery on a 0.5L-XFG hanging tank flotation machine. Set the flotation temperature to 60°C, the stirring speed to 2070r / min, and stir for 5 minutes; add the collector, Stir for 2 min; add foaming agent a...

Embodiment 2

[0034] Hydrothermal control and flotation of simulated zinc sulfide slag prepared by chemical precipitation method

[0035] Step 1: Simulate the zinc sulfide-containing sludge (the main impurity is calcium sulfate) produced by using sodium sulfide as a neutralizer in the treatment process of a certain smelting wastewater, and take Na 2 30g of zinc sulfide, 70g of calcium sulfate, 2.5g of natural galena prepared by S precipitation method through 150μm aperture sieve, adding mineralizer KOH to make the pH of the reaction system 9 and placing it in the GCF-0.5L strong magnetic rotary stirring reactor At the same time, add water to make the filling degree of the kettle 70%, set the rotation speed to 200r / min, set the temperature to 260°C, and react for 4 hours. After the reaction is finished, cool naturally, take out the materials, and filter with suction. The solid is the simulated zinc sulfide slag after adjustment.

[0036] Step 2: Take 50g of simulated zinc sulfide slag after hydro...

Embodiment 3

[0041] Hydrothermal control and flotation of slag containing zinc sulfide

[0042] Step 1: Take 100g of zinc sulfide residue (produced in a smelting wastewater treatment process using sodium sulfide as a neutralizer to produce zinc sulfide sludge), 2.5g of natural galena, and add mineralizer KOH. , Set the pH system to 9, place in a GCF-0.5L strong magnetic rotary stirring reactor, add water to make the filling degree of the kettle 70%, set the speed to 200r / min, set the temperature to 260°C, and react for 4 hours. After the reaction is over, cool naturally, take out the materials, and filter by suction. The solid is the adjusted zinc sulfide slag.

[0043] Step 2: Take 50g of zinc sulfide slag after hydrothermal control and flotation recovery on a 0.5L-XFG hanging tank flotation machine. Set the flotation temperature to 60°C, the stirring speed to 2070r / min, and stir for 5 minutes; add dispersant and Inhibitor, stir for 3min; add activator during zinc flotation and stir for 3min;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com