Synchronous reverse flotation process for low-magnesium high-magnification semi-collophanite

A technology of reverse flotation and colloidal phosphate rock, applied in flotation, solid separation and other directions, can solve the problems of complex beneficiation process, complex symbiotic relationship, low sorting efficiency, etc., to overcome the complex flotation process and simple flotation process. , the effect of strong operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

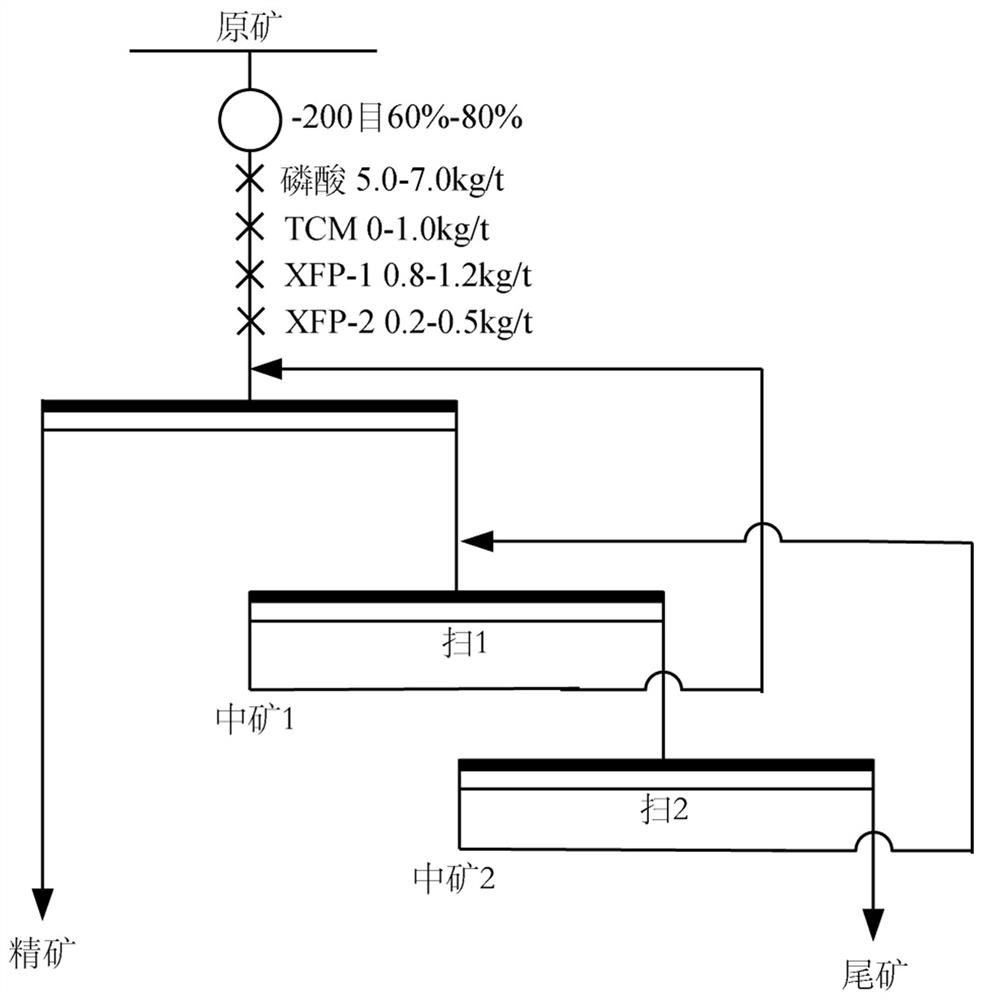

[0025] In this example, P 2 o 5 The grade is 26.46%, sesquioxide Al 2 o 3 Content 3.67%, Fe 2 o 3 Content 1.21%, MgO content 1.56%, SiO 2 15.3wt%, CaO 37.37wt% low-magnesium colloidal phosphate rock was subjected to synchronous reverse flotation dealumination and magnesium flotation, the process flow see figure 1 , the specific process steps are as follows:

[0026](1) Add water to crush and grind the low-magnesium and high-sesquitylic phosphate rock (the content of -0.074mm is 70%) to obtain a pulp with a mass concentration of 26%. Add a pH regulator phosphoric acid to the pulp to adjust the pulp and stir to adjust the pH to 5.8 , and then add regulator TCM (aluminum chloride, sodium chloride and polyacrylamide with a mass ratio of 1:1:0.0003) to adjust the pulp flotation system, and finally add anion collectors and cationic collectors to stir evenly, and inflate the flotation The resulting foam product is tailings, and the product in the flotation tank is reverse flo...

Embodiment 2

[0029] In this example, P 2 o 5 The grade is 26.47%, sesquioxide Al 2 o 3 Content 3.47%, Fe 2 o 3 Content 1.23%, MgO content 1.86%, SiO 2 16.4wt%, CaO 36.74wt% low-magnesium colloidal phosphate rock was subjected to synchronous reverse flotation dealumination and magnesium flotation, the process flow see figure 1 , the specific process steps are as follows:

[0030] (1) Add water to crush and grind the low-magnesium and high-sesquivalent colloidal phosphate rock (-0.074mm70%) to obtain a pulp with a mass concentration of 26%, add a pH regulator phosphoric acid to the pulp to adjust the pulp and stir, adjust the pH to 5.8, and then add Regulator TCM (aluminum chloride, sodium chloride and polyacrylamide with a mass ratio of 1:1:0.0005) adjusts the pulp flotation system, and finally add anion collectors and cationic collectors to stir evenly, aerate flotation, and the obtained The foam product is tailings, and the product in the flotation tank is reverse flotation dealum...

Embodiment 3

[0033] In this example, P 2 o 5 The grade is 26.67%, sesquioxide Al 2 o 3 Content 3.47%, Fe 2 o 3 Content 1.04%, MgO content 2.36%, SiO 2 14.45 wt%, CaO 37.85 wt% low-magnesium colloidal phosphate rock was subjected to synchronous reverse flotation dealumination and magnesium flotation. figure 1 , the specific process steps are as follows:

[0034] (1) Add water to crush and grind the low-magnesium and high-sesquivalent colloidal phosphate rock (-0.074mm70%) to obtain a pulp with a mass concentration of 26%, add a pH regulator phosphoric acid to the pulp to adjust the pulp and stir, adjust the pH to 5.8, and then add Regulator TCM (aluminum chloride, sodium chloride and polyacrylamide with a mass ratio of 0.6:1:0.0004) to adjust the slurry flotation system, and finally add anion collectors and cationic collectors to stir evenly, aerated flotation, and the obtained The foam product is tailings, and the product in the flotation tank is reverse flotation dealumination and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com