Preparation and application of copper oxide ore flotation composite collecting agent

A composite collector and a technology for copper oxide ore, which are applied in the fields of copper oxide ore flotation composite collector, copper oxide ore flotation, and composite collector, can solve the problem of difficulty in forming economic benefits, large consumption of chemicals, and beneficiation. Long process and other problems, to achieve the effect of facilitating the monitoring of the production process, increasing the adsorption capacity, and reducing the inclusion of copper concentrates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] The composite collector described in this example is firstly mixed according to the mass ratio of butyl xanthate: aviation kerosene: transformer oil = 80:1:1, and then adding water with a mass percentage of 95% for ultrasonic emulsification for 2 minutes. made.

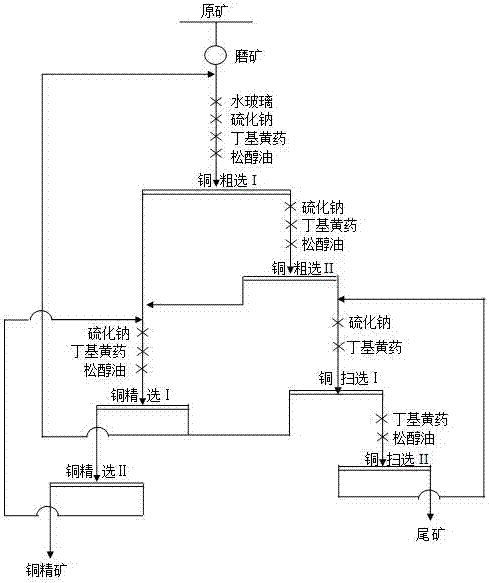

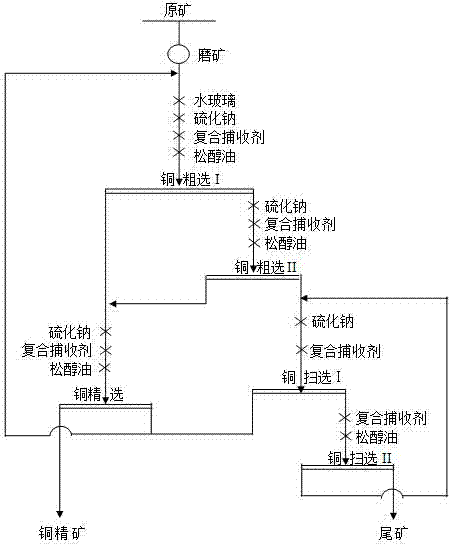

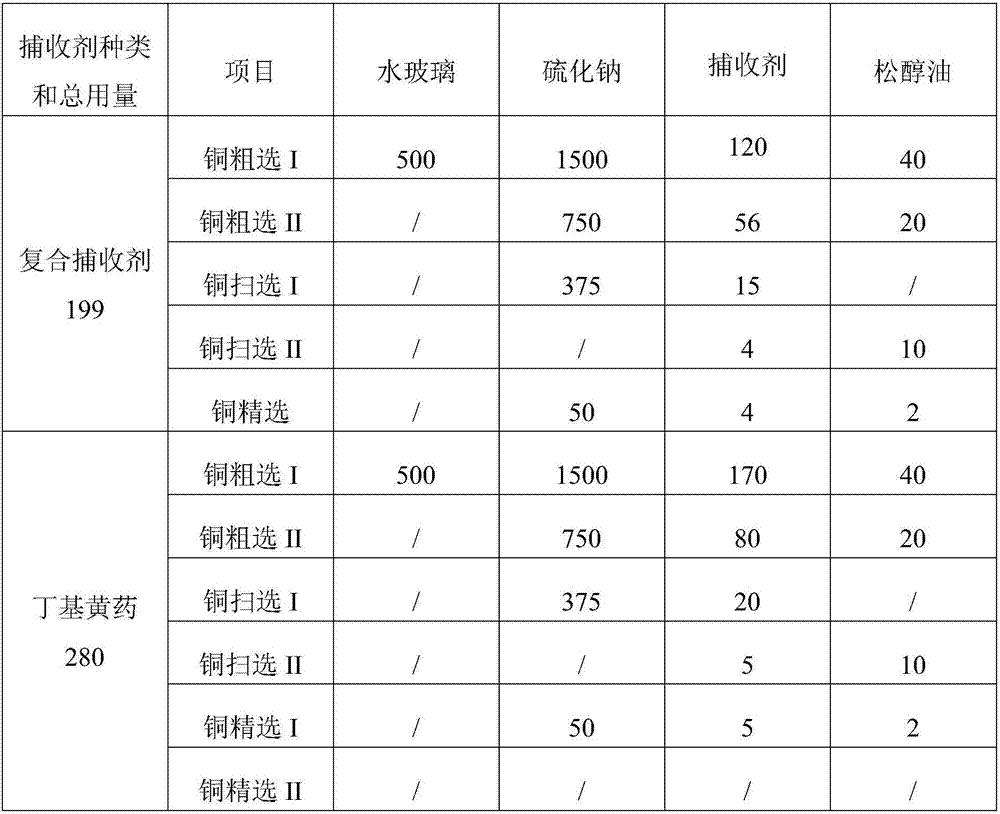

[0029] In this example, a copper oxide ore in Yunnan Province has a grade of Cu0.95% and a copper oxidation rate of 31.13%. The raw ore is ground to -0.074mm (200 mesh / inch), and the sieved material accounts for 70% of the raw ore quality, and the sieved material is added to adopt the traditional collector butyl xanthate and the composite collector prepared by the present embodiment respectively. In the flotation operation, the respective preferred dosages of the two collectors, and under the same conditions of other technological conditions (such as the amount of sodium sulfide, etc.) (see Table 1 for details), carried out the comparative test of the closed-circuit flotation process, and the process is shown i...

Embodiment 2

[0036] The composite collector described in this example is pre-mixed according to the mass ratio of butyl xanthate: aviation kerosene: transformer oil = 80:1:1, and then adding water with a mass percentage of 92% for ultrasonic emulsification and solubilization treatment 2 prepared in minutes.

[0037] In this example, the scale of the flotation plant is 2,000 tons / day, the annual production is 300 days, the butyl xanthate is 8,000 yuan / ton, and the composite collector is 8,500 yuan / ton. A copper oxide ore in Yunnan Province has a selected grade of Cu0.85%, a copper oxidation rate of 42.20%, and the raw ore is ground to -0.074mm. The sieved material accounts for 80% of the raw ore quality. The traditional collector butyl xanthate and this example are used respectively. Prepared composite collector, under the same situation (see Table 3 for details) of two kinds of collectors in each flotation operation, and other technical conditions (such as sodium sulfide consumption, etc.)...

Embodiment 3

[0044] The composite collector described in this example is pre-mixed according to the mass ratio of butyl xanthate: aviation kerosene: transformer oil = 80:1:1, and then add water with a mass percentage of 90% for ultrasonic emulsification and solubilization treatment Prepared in 3 minutes.

[0045] In this example, a copper oxide ore in Sichuan Province has a grade of Cu of 1.32% and a copper oxidation rate of 64%. The raw ore is ground to -0.074mm, and the sieved material accounts for 70%-90% of the raw ore quality. The traditional collector butyl xanthate and the composite collector prepared in this embodiment are respectively used in each flotation operation. The respective preferred dosages of the collectors, and under the same conditions of other technological conditions (such as the amount of sodium sulfide, etc.) (see Table 5 for details), a comparative test of the closed-circuit flotation process was carried out, and the results of the comparative tests of the two co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com