Combined reagent for medium and low temperature phosphate rock flotation and use method thereof

A combination of reagents and phosphate rock technology, applied in flotation, solid separation, etc., can solve problems such as poor low temperature resistance, achieve the effects of reducing production costs, improving flotation results, and improving flotation indicators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

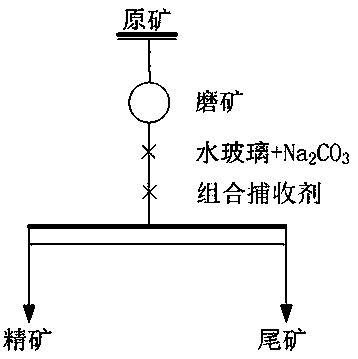

[0015] The processing object of this embodiment is: a phosphate ore raw ore P in Yunnan 2 o 5 Grade 23.56%, the specific method is (such as figure 1 Shown): Grind the raw ore until the fineness is -0.074mm, accounting for 40%. t, the temperature of the flotation pulp is 5°C, after a rough separation, the P in the phosphorus concentrate is finally obtained 2 o 5 The grade is 29.86%, and the recovery rate is 72.38%.

[0016] Using the combined medicament of the present invention as a collector (the addition amount is 20g / t) to replace the collector oxidized paraffin soap, under the same flotation conditions, P 2 o 5 The grade is 32.65%, the recovery rate is 89.72%, and the concentrate grade and recovery rate have been greatly improved; the raw materials and mass percentages of the combined agent are: α-amino acid 10wt%, oxidized paraffin wax soap 60wt%, lauryl Sodium sulfonate 25wt%, kerosene 5wt%.

Embodiment 2

[0018] The processing object of this embodiment is: a phosphate ore raw ore P in Guizhou 2 o 5 The grade is 21.32%. The specific method is: grind the raw ore until the fineness is -0.074mm, accounting for 60%. -Amino acid 150g / t, flotation pulp temperature is 15°C, after a rough separation, the P in the phosphorus concentrate is finally obtained 2 o 5 The grade is 31.86%, and the recovery rate is 85.61%.

[0019] Using the combined medicament described in the present invention as a collector (the addition amount is 150g / t) to replace the collector α-amino acid, under the same flotation conditions, P 2 o 5 The grade is 34.85%, and the recovery rate is 91.26%. The raw materials and mass percentages of the combined agent are: α-amino acid 30wt%, oxidized paraffin soap 25wt%, sodium dodecylsulfonate 5wt%, kerosene 40wt%.

Embodiment 3

[0021] The processing object of this embodiment is: a raw ore P mainly composed of a certain collophosphine in Hubei 2 o 5 The grade is 25.52%. The specific method is: grind the raw ore until the fineness is -0.074mm, accounting for 80%. Dialkyl sodium sulfonate 300g / t, flotation pulp temperature is 25 ℃, after a rough separation, finally get the P in the phosphorus concentrate 2 o 5 The grade is 28.46%, and the recovery rate is 75.21%.

[0022] Using the combined medicament of the present invention as a collector (the addition amount is 300g / t) to replace the collector sodium dodecylsulfonate, under the same flotation conditions, P 2 o 5 The grade is 33.65%, the recovery rate is 85.96%, and a good flotation index has been obtained; the raw materials and mass percentages of the combined agent are: α-amino acid 50wt%, oxidized paraffin wax soap 20wt%, sodium dodecylsulfonate 20wt% %, kerosene 10wt%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com