Patents

Literature

56results about How to "Improve flotation index" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

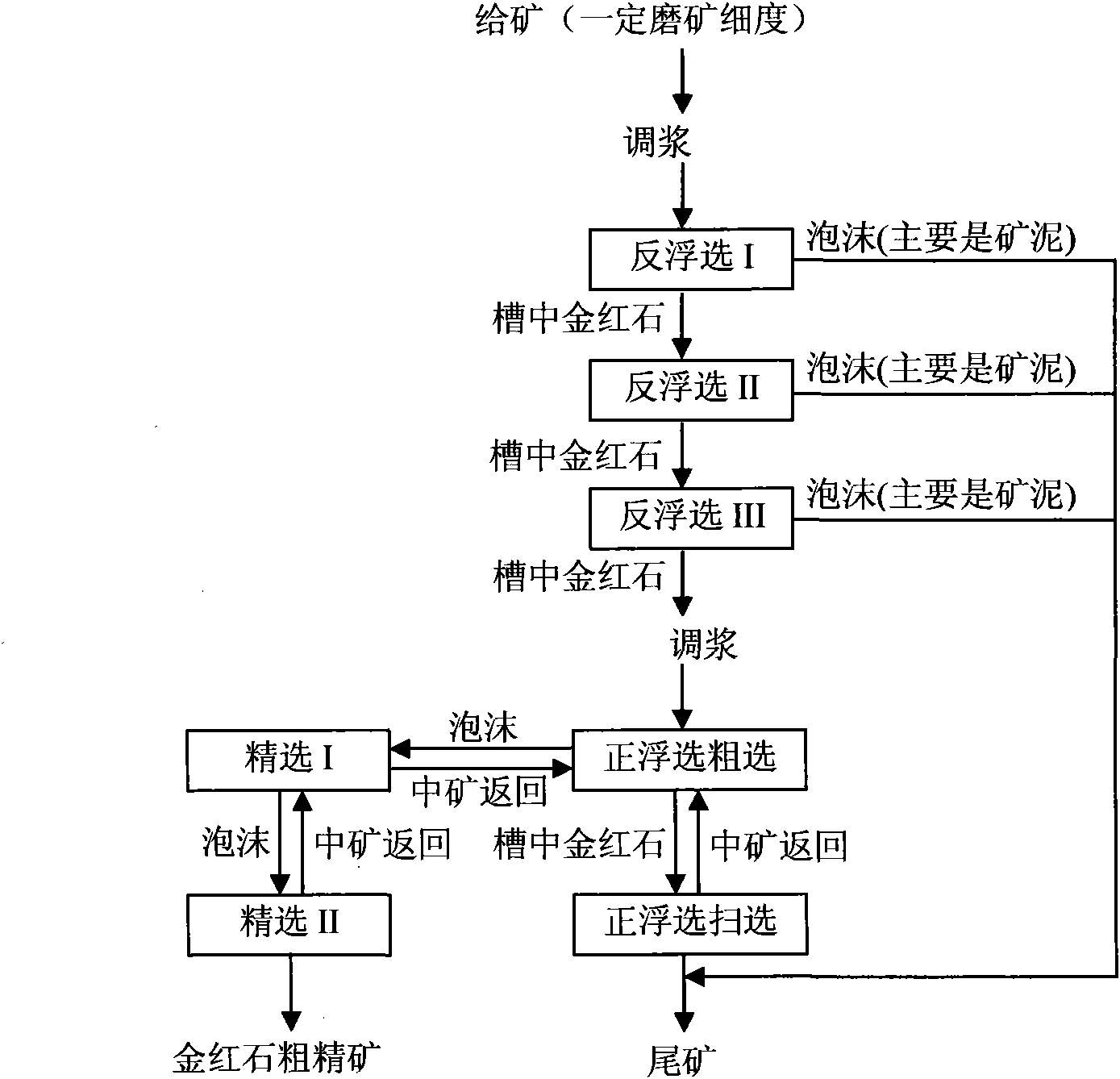

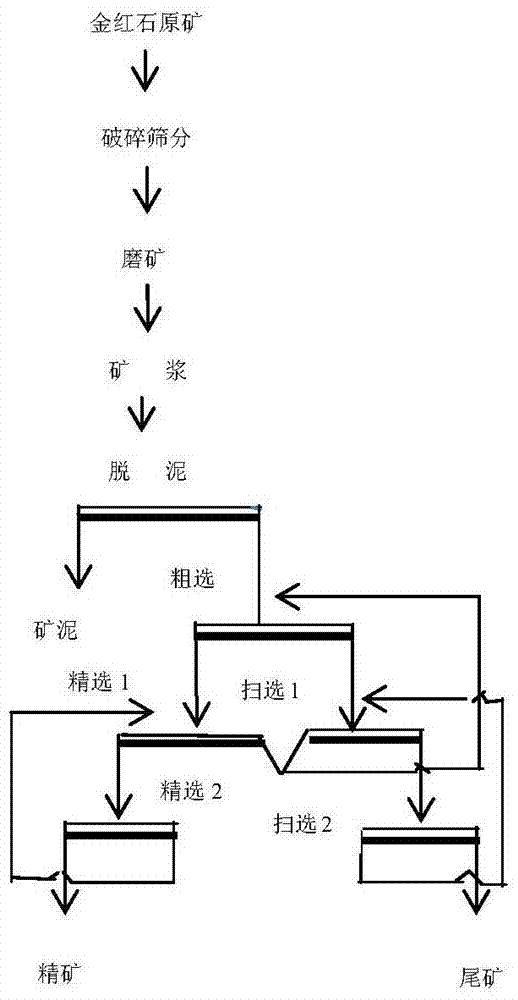

Method for roughing and tailings-discarding of fine rutile ore by multi-stage floatation

The invention provides a method for roughing and tailings-discarding of fine rutile ore by multi-stage floatation, relating to the technique for roughing and tailings-discarding of fine rutile ore by multi-stage floatation and belonging to the technical field of mineral processing engineering. The method of the invention comprises the following steps: firstly, conducting the reverse floatation of rutile by using sodium oleate as a collector according to the characteristics that aluminum sulfate can inhibit the rutile and activate silicate minerals in varying degrees, so as to effectively deslime in the process of reverse floatation; and then, conducting the forward floatation of rutile by using lead nitrate (or lead acetate) as an activator of rutile and using sodium alkyl hydroxamate and benzyl arsonic acid (or styryl phosphonic acid) as a combined collector according to the characteristic that gangue minerals can be inhibited on a combined basis under the synergistic action of sodium fluorosilicate, carboxymethylcellulose and the residual aluminum sulfate in the ore pulp, briefly, the method of the invention can realize the roughing and tailings-discarding of fine rutile by the multi-stage floatation comprising the following steps: firstly, conducting the reverse floatation by inhibiting the rutile; and then, conducting the forward floatation by activating the rutile. The method of the invention has the advantages that the enrichment ratio and recovery rate of rutile are high, the tailings of rutile ore can be discarded thoroughly and the mineral processing cost of rutile can be greatly reduced.

Owner:KUNMING UNIV OF SCI & TECH

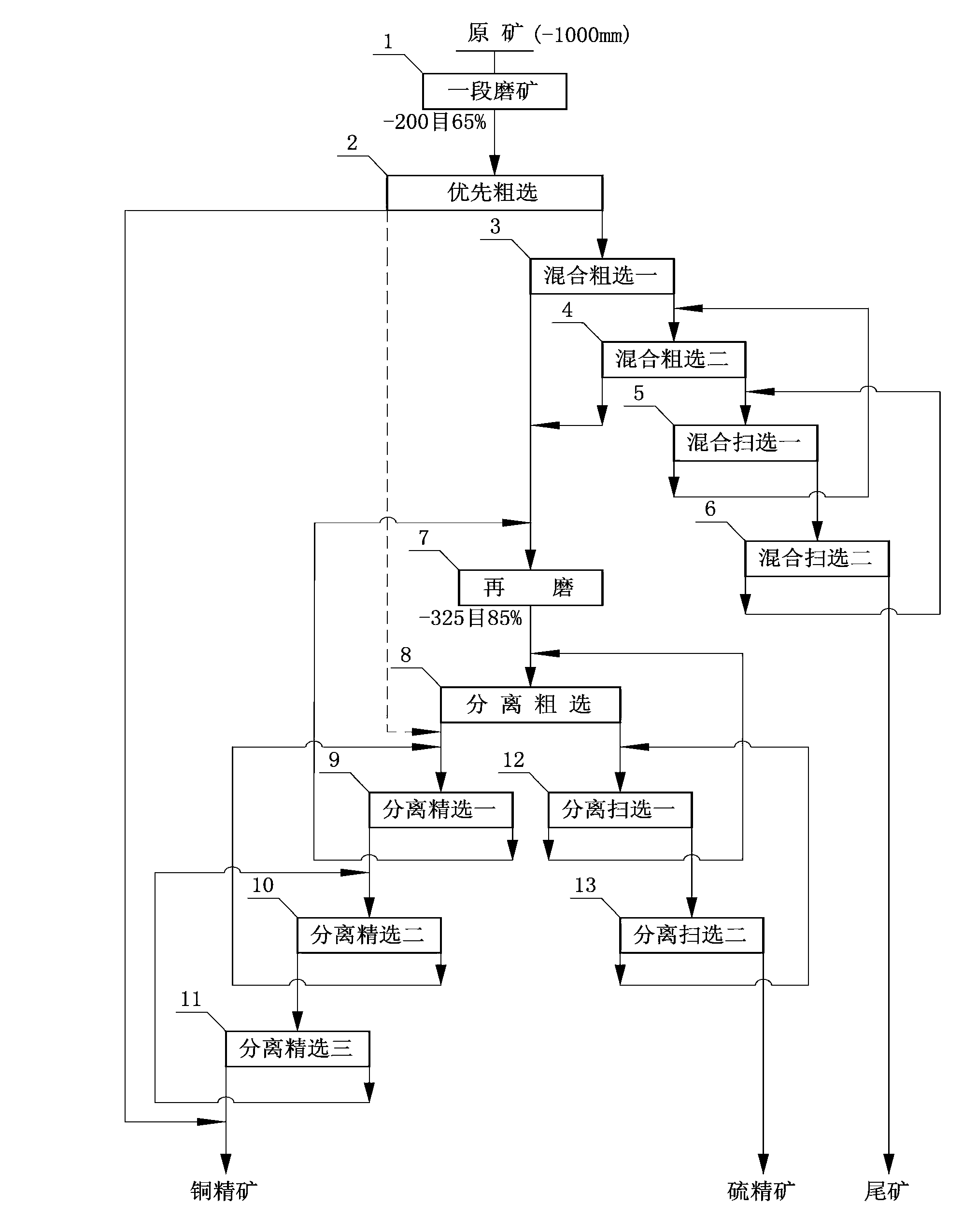

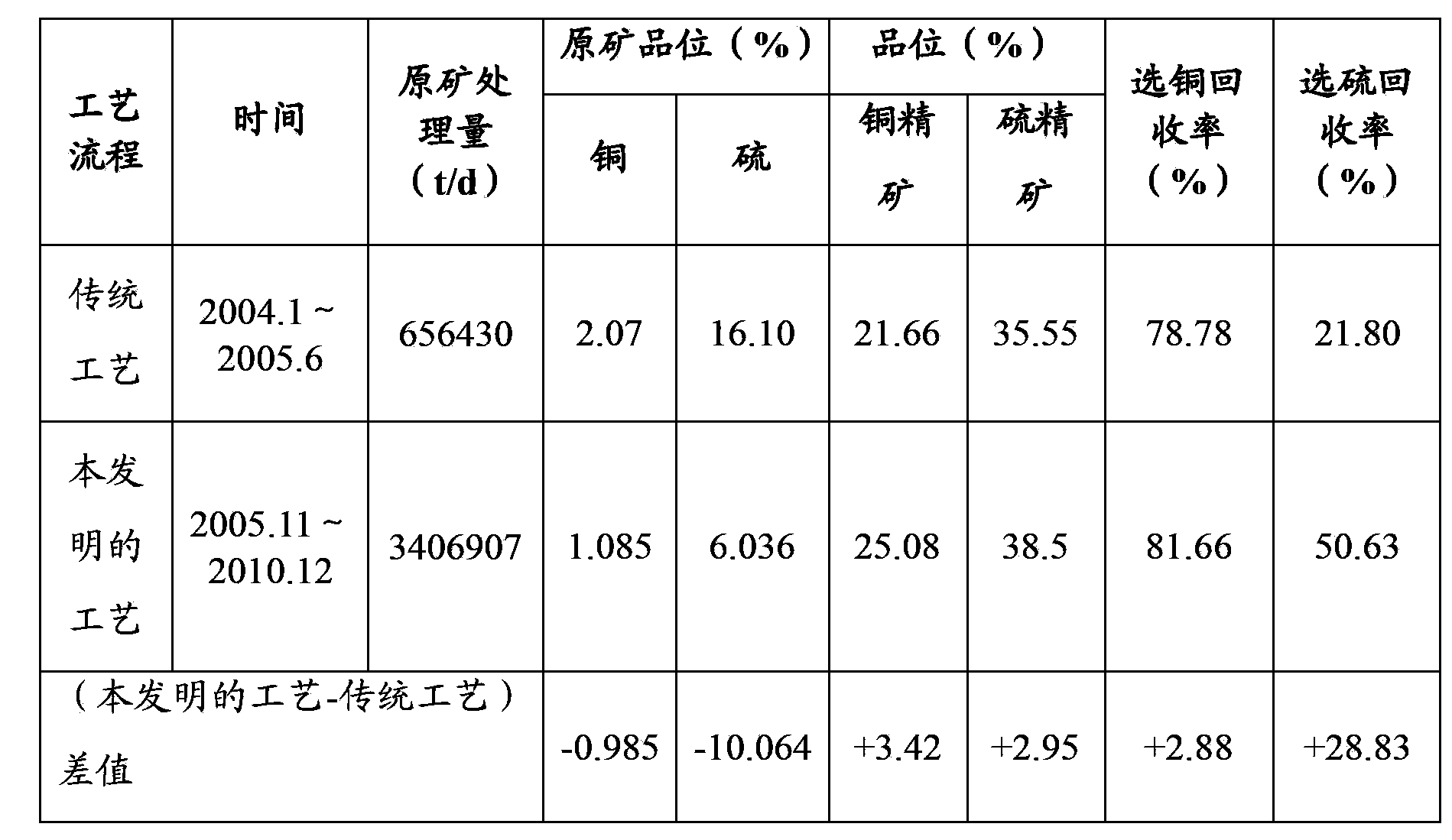

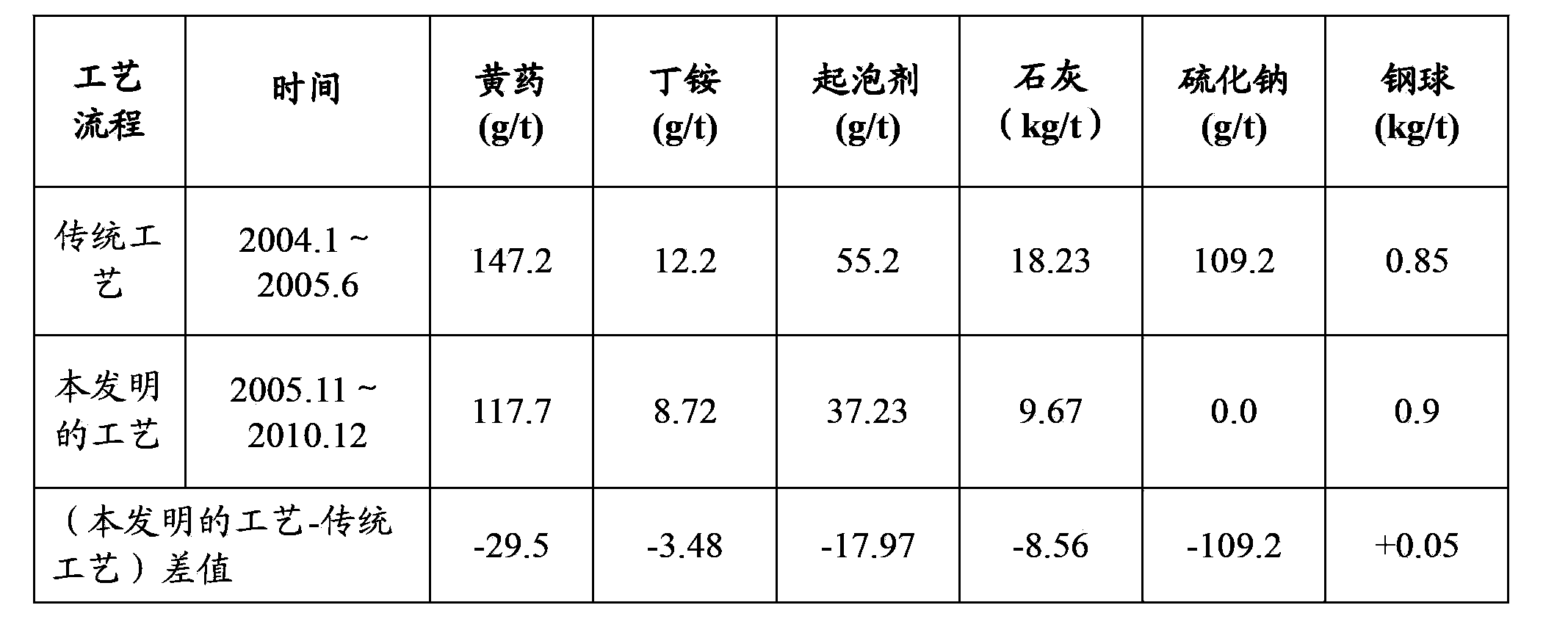

Flotation method for copper sulphide ore

The invention relates to a flotation method for copper sulphide ore. The method comprises the following steps of (1) performing primary grinding on the copper sulphide ore so as to obtain a primary grinding product; (2) performing first flotation on the primary grinding product by utilizing a first trapping agent so as to obtain a monomer copper mineral and secondary copper-rich mineral intergrowth-contained first flotation product and first flotation residues; (3) performing second flotation on the first flotation residues by utilizing a second trapping agent so as to obtain copper-poor intergrowth, complex copper mineral and free sulfur-contained a second flotation product and second flotation tailings; (4) performing secondary grinding on the second flotation product so as to obtain a secondary grinding product; and (5) performing copper-sulfur separation on the secondary grinding product in a strong caustic environment so as to obtain copper concentrate and sulfur concentrate. By utilizing the flotation method for the copper sulphide ore provided by the invention, copper-sulfur flotation can be effectively performed on the complex and refractory copper sulphide ore.

Owner:CHINA NERIN ENG

Method for recovering rutile

The invention relates to a method for recovering rutile. According to the method for recovering the rutile, desliming is conducted after raw ore is subjected to ore grinding, lead nitrate serves as an activator, sodium fluosilicate and water glass serve as inhibitors, styrene phosphoric acid and 1-capryl alcohol serve as collecting agents, second oil serves as a foaming agent, flotation separation is conducted, and rutile concentrate is obtained. The technical scheme of the method for recovering the rutile has the following technical effects that (1) the flotation index of the rutile is greatly increased to enable the grade of the rutile to be improved by over 80% and the recovering rate to be about 60% in roughing, then one-time medicating concentration, one-time blank concentration and two-time scavenging are conducted, finally, the TiO2 content in the concentrate reaches 92%, the concentration ratio is over 20, the recovering rate is between 80% and 85%, the TiO2 content in tailings is reduced to 0.5-0.7%; and (2) the pH of ore pulp does not need to be adjusted, operation is easy, a flotation foam layer is thick, control is easy, and the flotation velocity is high.

Owner:WUHAN UNIV OF TECH

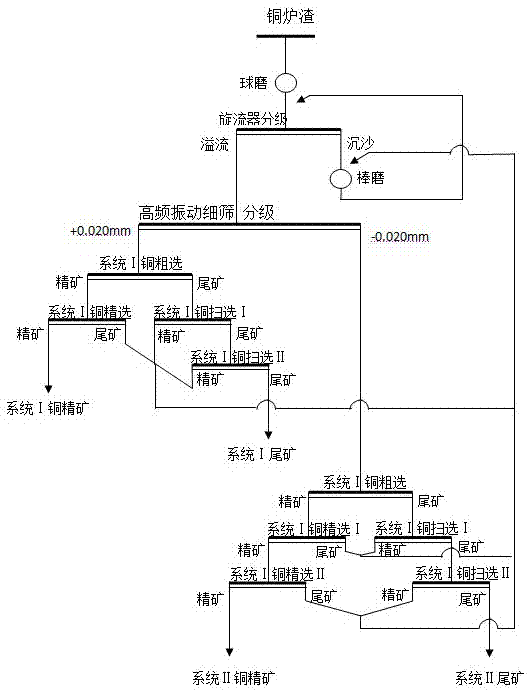

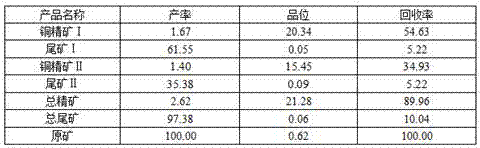

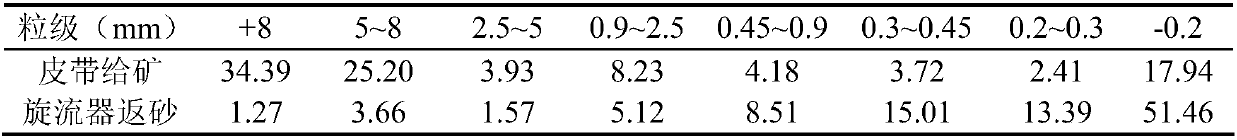

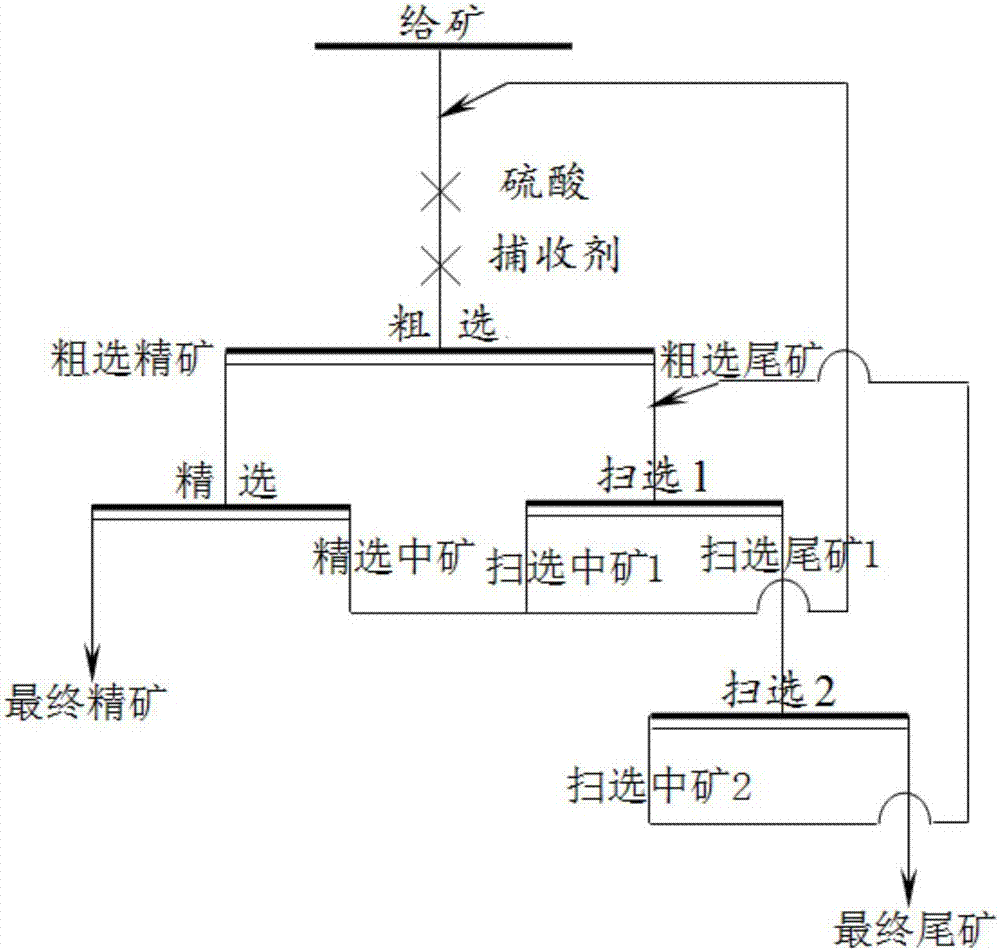

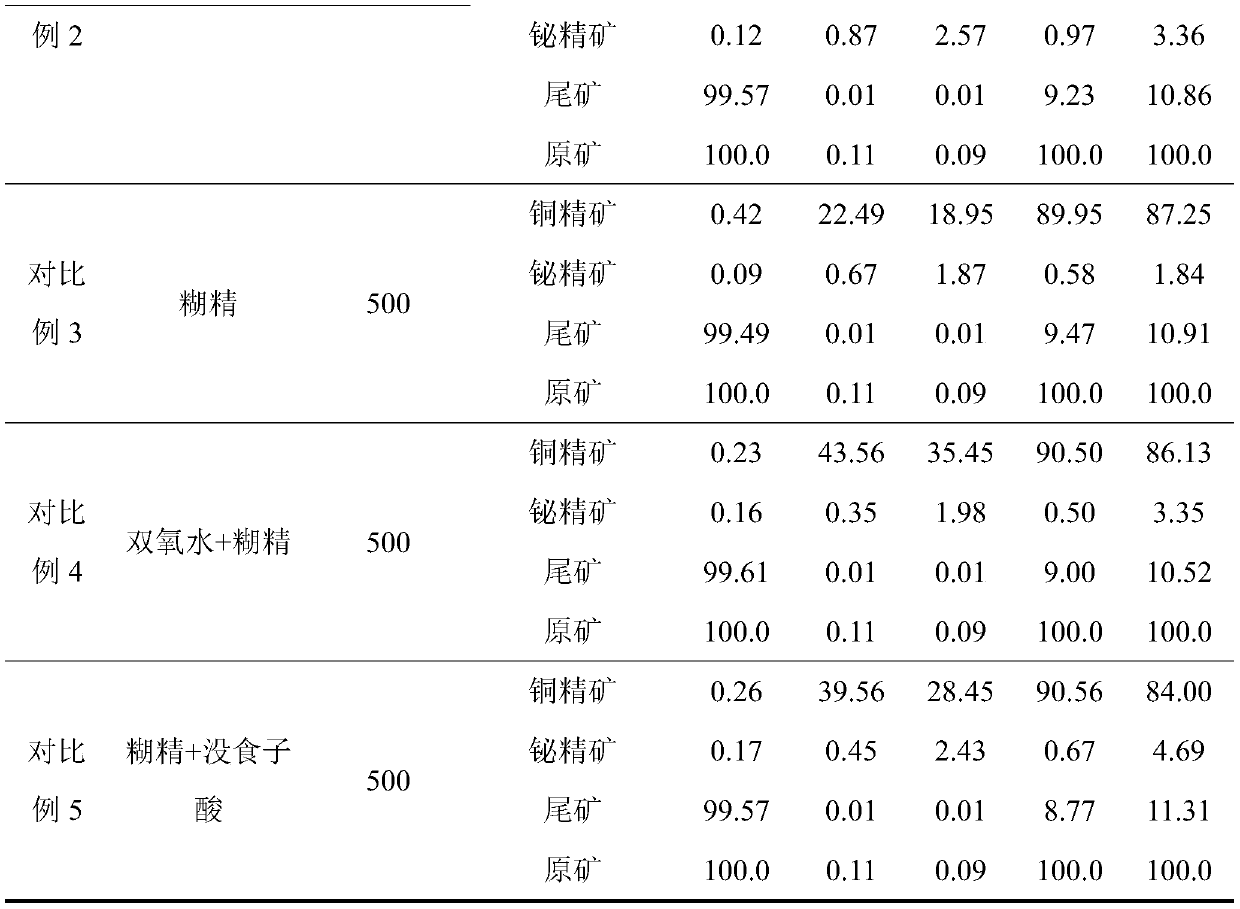

Mineral processing process for recovering copper from copper smelting slag through flotation

The invention discloses a mineral processing process for classifying recovery of copper from copper smelting slag. The mineral processing process adopts an ore grinding-grading-classifying separation process; a two-stage and one closed circuit grinding flow composed of a ball grinding mill, a rod mill and a hydrocyclone is used for the ore grinding of the copper smelting slag, and the occupancy of grinding products with granularity -0.044 mm is 80-90%; the grinding products are graded into +0.020 mm coarse products and -0.020 mm fine products by a high-frequency vibrating fine screen, the +0.020 mm coarse products are processed into copper concentrate I and gangue I through one-time roughing, one-time concentrating and twice scavenging flotation processes, and the -0.020 mm fine products are processed into copper concentrate II and gangue II through one-time roughing, twice concentrating and twice scavenging flotation processes. The flotation condition pertinence is improved, the reagent cost and energy consumption cost are lowered, and the purpose of effectively recovering the copper from the copper smelting slag is achieved.

Owner:KUNMING UNIV OF SCI & TECH

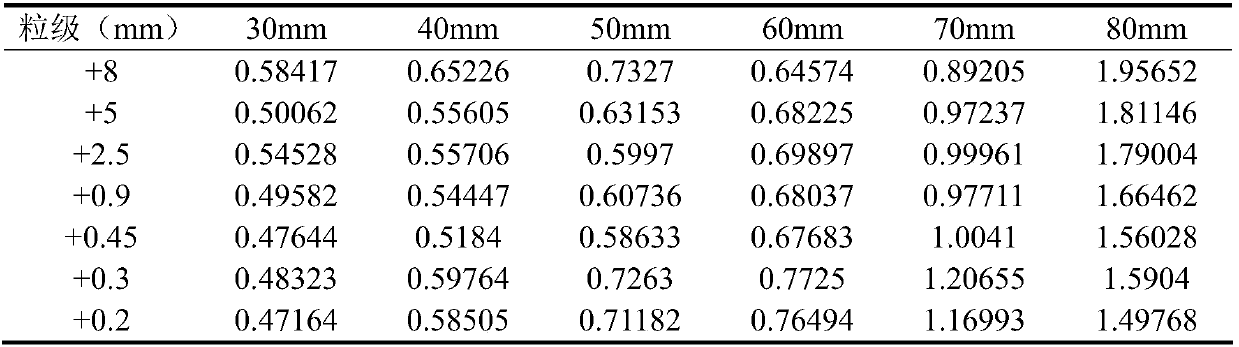

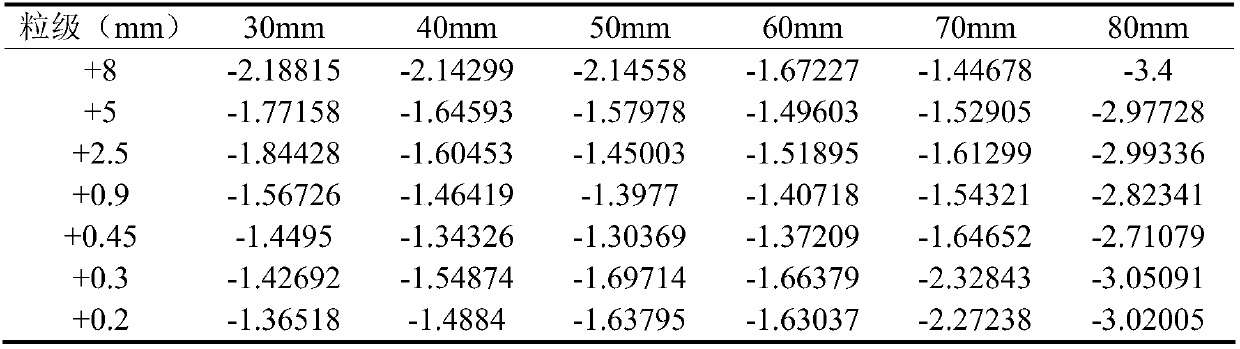

Method for determining steel ball ratio based on grinding kinetics

ActiveCN107597311AOvercome the shortcomings of incomplete consideration of influencing factors of diameterAvoid the risk of bias in mechanical property testingGrain treatmentsComplex mathematical operationsElectricitySteel ball

The invention discloses a method for determining the steel ball ratio based on grinding kinetics. The influence of the raw ore property on grinding work is indirectly reflected mainly by means of thegrinding kinetic parameter K values and the grinding kinetic parameter m values; by calculating the K values and the m values, the optimal steel ball diameter is determined, and finally the steel ballratio is obtained; and through industrial application, it is shown that in grinding products, the content of the products with the coarse grade is decreased by about five percentage points, the content of the products with the over-crushed grain size grade is decreased by about one percentage point, the content of the products with the intermediate easily-separated grain-grade is increased by about nine percentage points, the recycling rate is increased by about two percentage points, the unit steel consumption is decreased by about 10%, and the unit electricity consumption is decreased by about 6%. The method is practicable and high in applicability; the steel ball ratio can be calculated aiming at different types of ores; and in the actual application of a ball grinding mill, the treatment capacity of the ball grinding mill is increased, the grain-size composition of the obtained grinding products is more reasonable, and thus the flotation index is improved.

Owner:KUNMING UNIV OF SCI & TECH

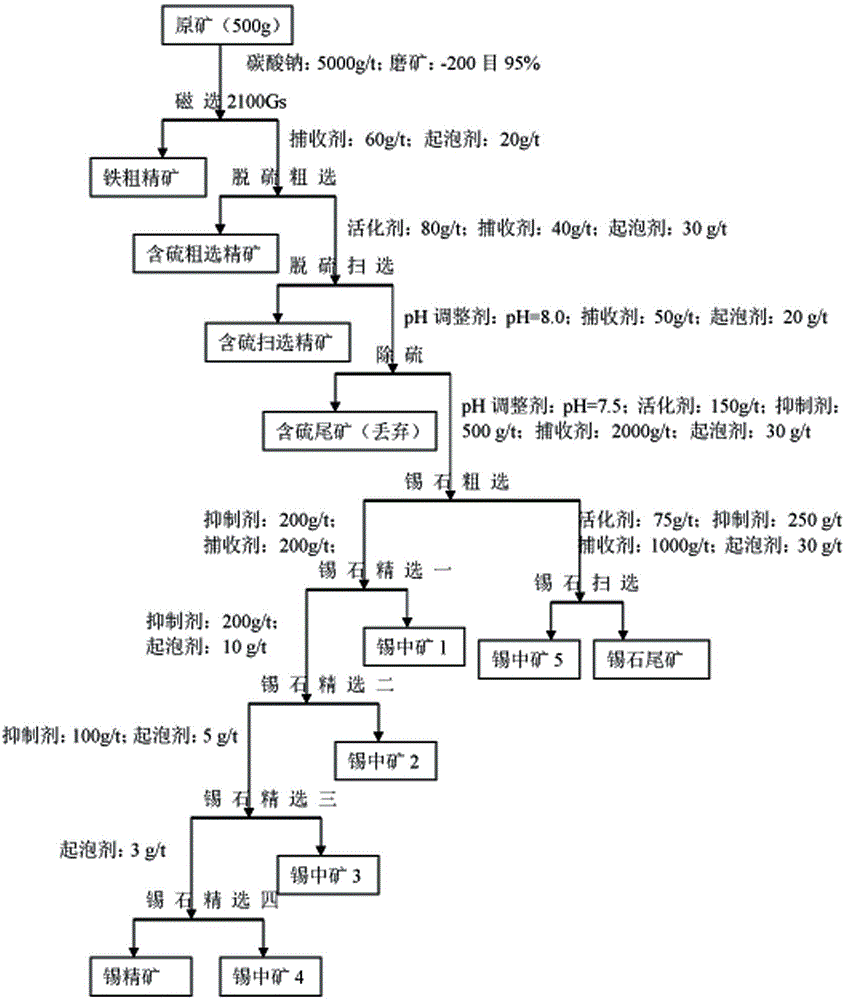

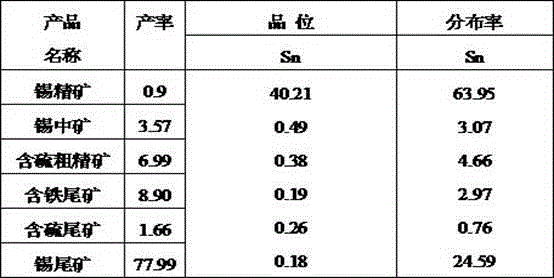

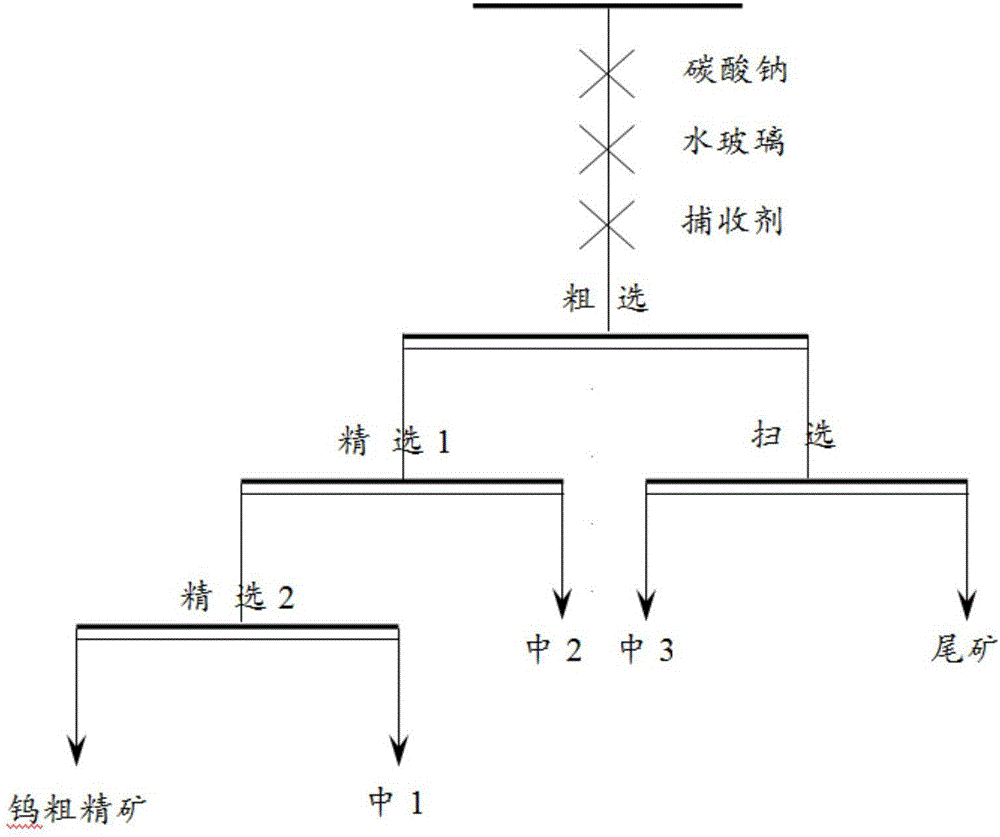

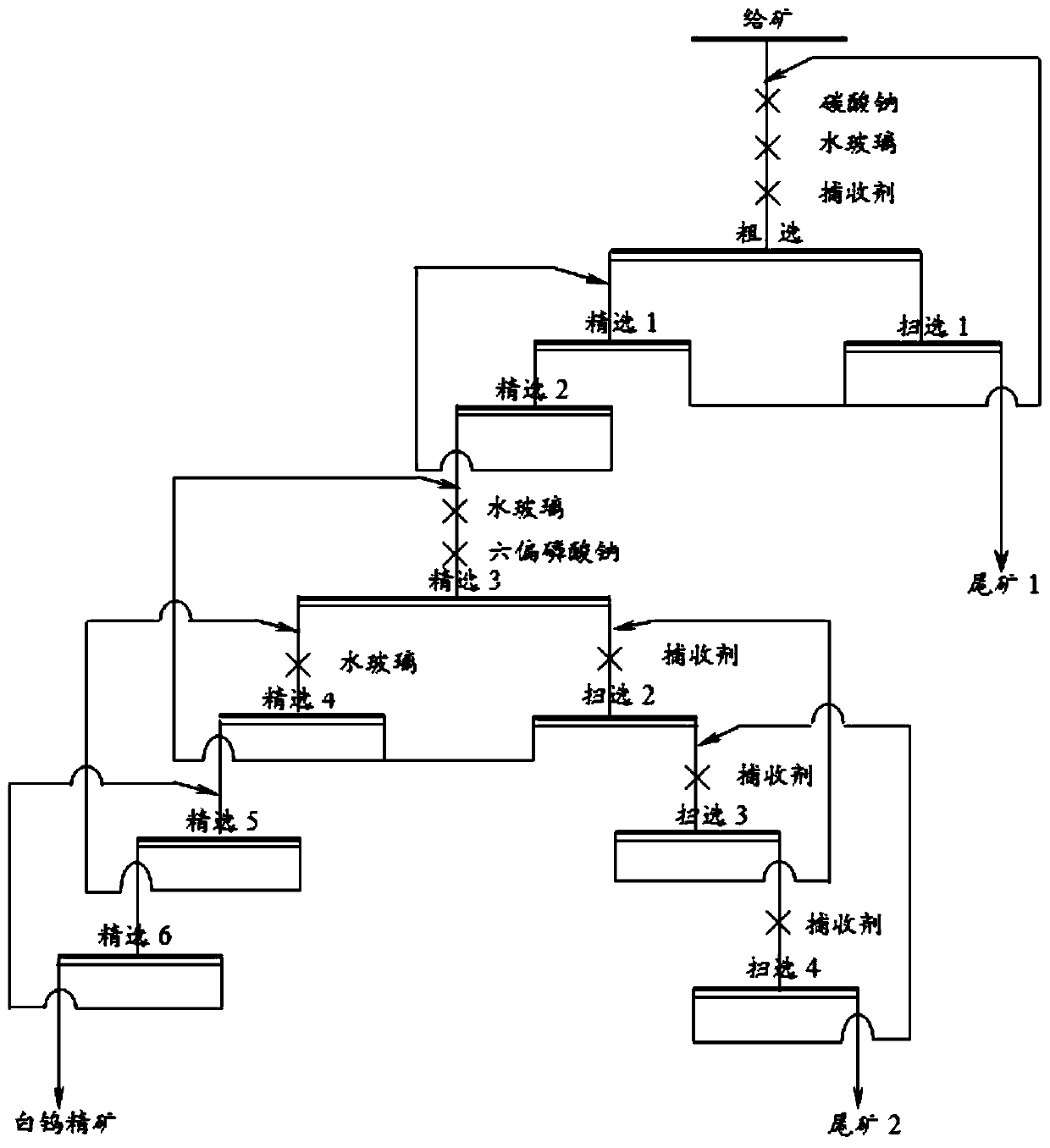

Beneficiation method for comprehensively reclaiming complex multi-metal micro-grain cassiterite sulphide ore

ActiveCN103551245AGuaranteed stabilityImprove flotation indexFlotationWet separationAutomatic controlSodium silicate

Owner:CINF ENG CO LTD

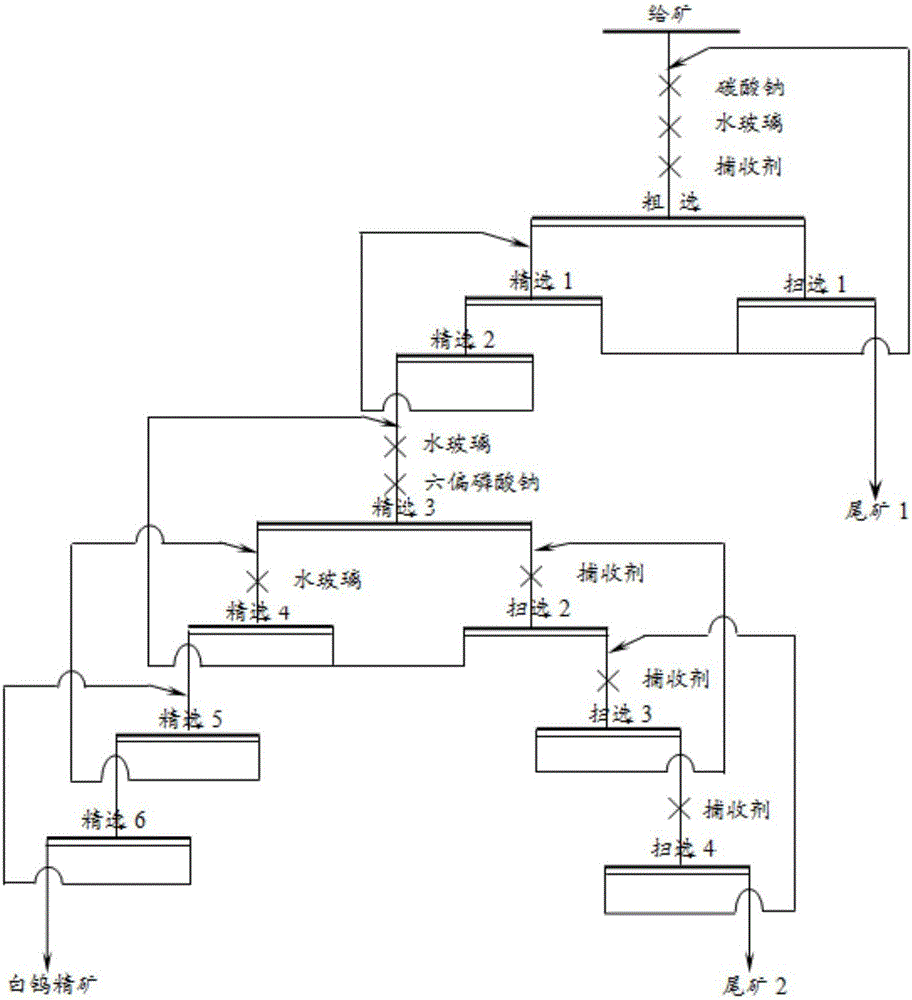

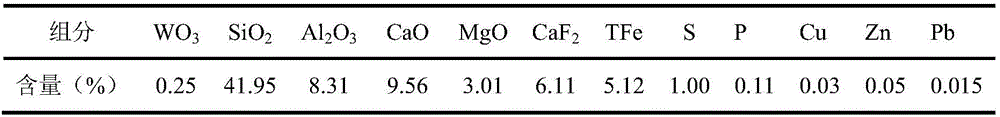

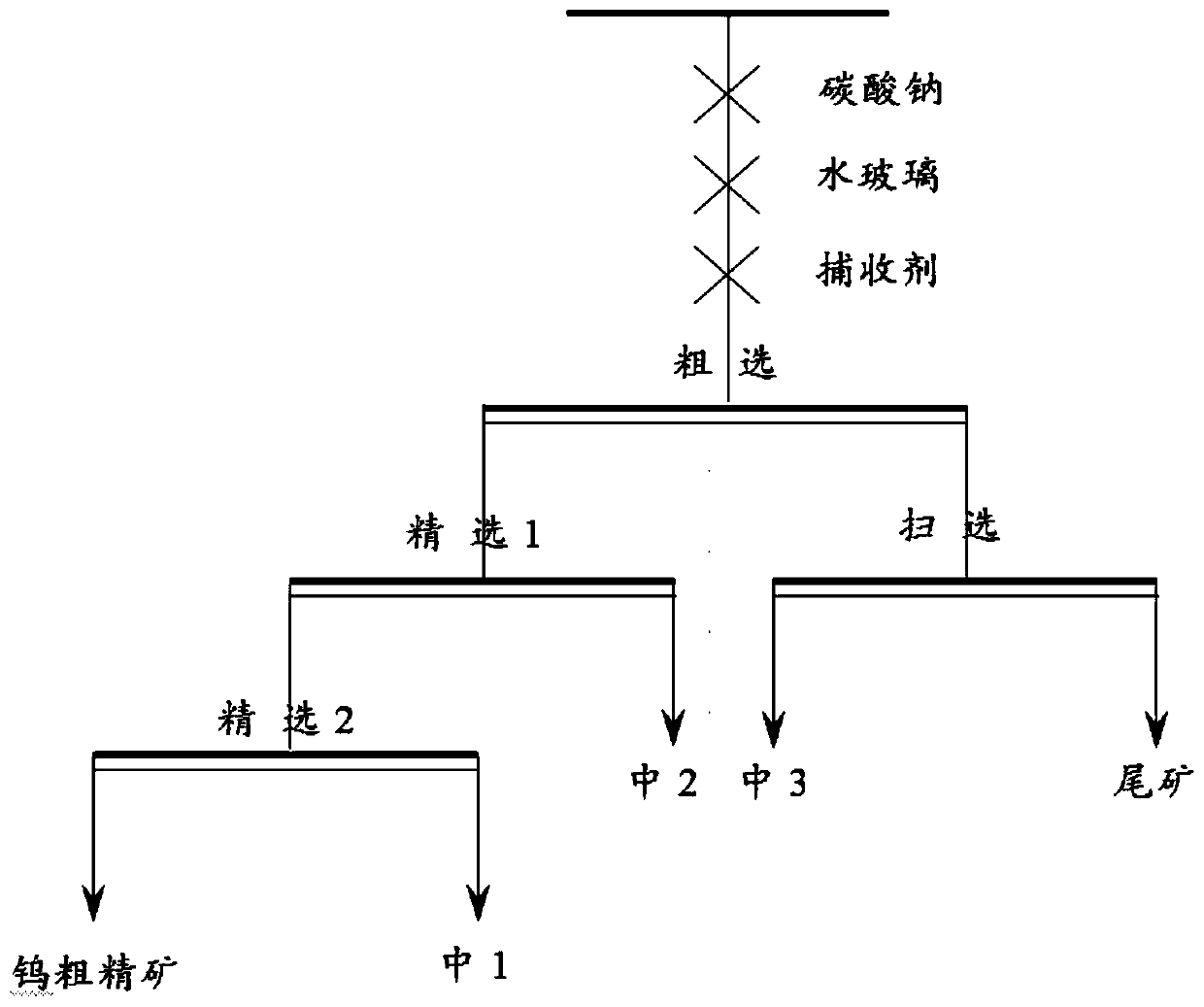

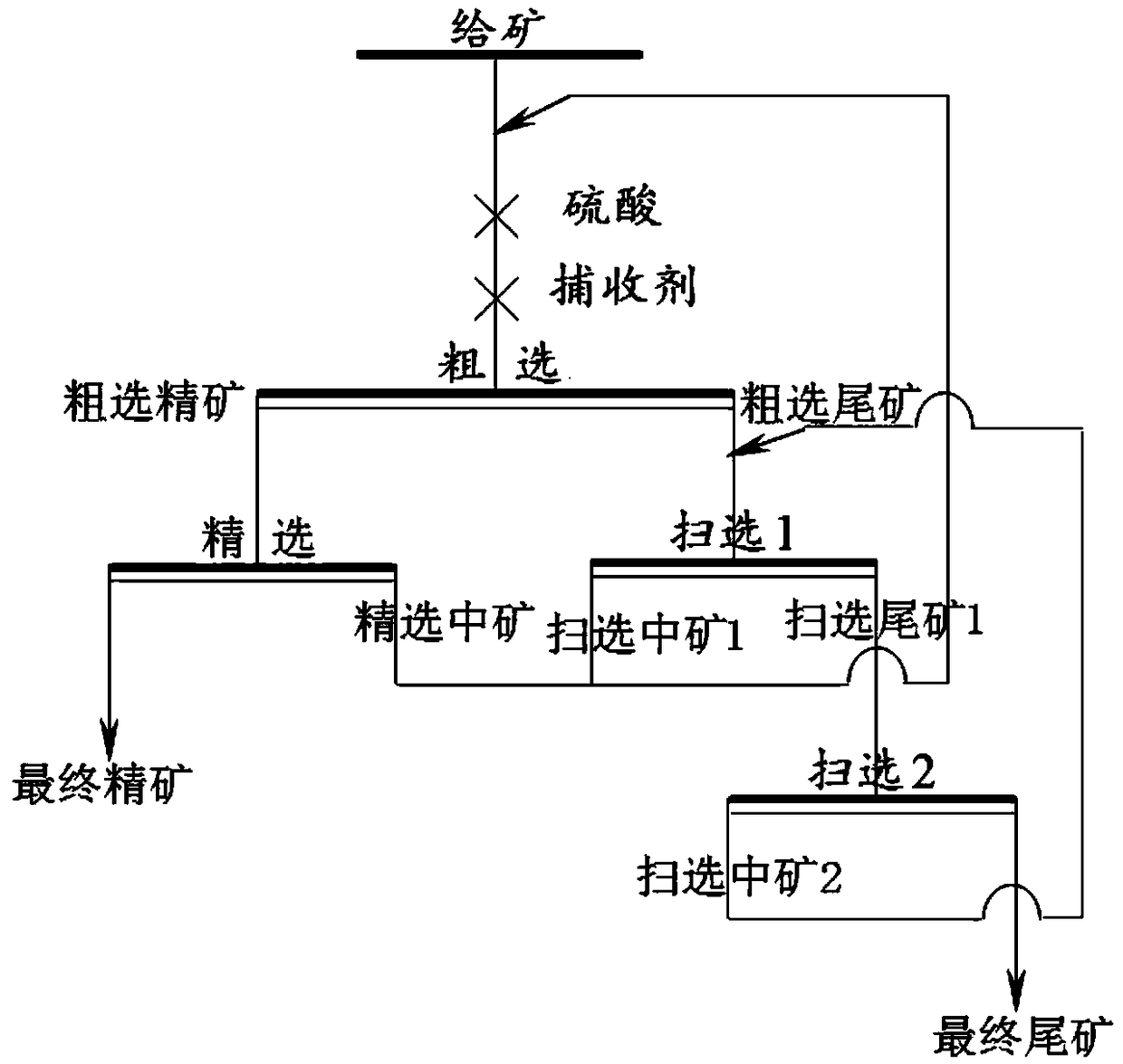

High-calcium scheelite flotation collector and preparation method and application method thereof

ActiveCN106733217ARaise the gradeHigh recovery rateFlotationCalcium in biologyAqueous sodium hydroxide

The invention discloses a high-calcium scheelite flotation collector and a preparation method and an application method thereof and belongs to the technical field of solid mineral resource sorting. The preparation method comprises the following steps of: by taking foots, hydroxylamine hydrochloride, sodium hydroxide, sulfuric acid and the like in a coconut oil refining process as raw materials, adding the treated foots in a certain molar ratio into a hydroxylamine hydrochloride aqueous solution at a certain temperature; then dropwise adding a sodium hydroxide aqueous solution with a certain concentration, and performing acidification after the dropwise adding reaction is finished; dehydrating and washing the acidified product to obtain coconut alkylhydroxyoxime acid; and then compounding the coconut alkylhydroxyoxime acid and soy acid in certain percentages by mass to obtain a mixture, and then saponifying the mixture to obtain the high-calcium scheelite flotation collector. The collector prepared by the preparation method disclosed by the invention is stable in property, good in floating index, stable in foam, high in adaptability, low in cost and non-toxic, and meanwhile, can efficiently separate scheelite from calcium-containing minerals in the high-calcium scheelite.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

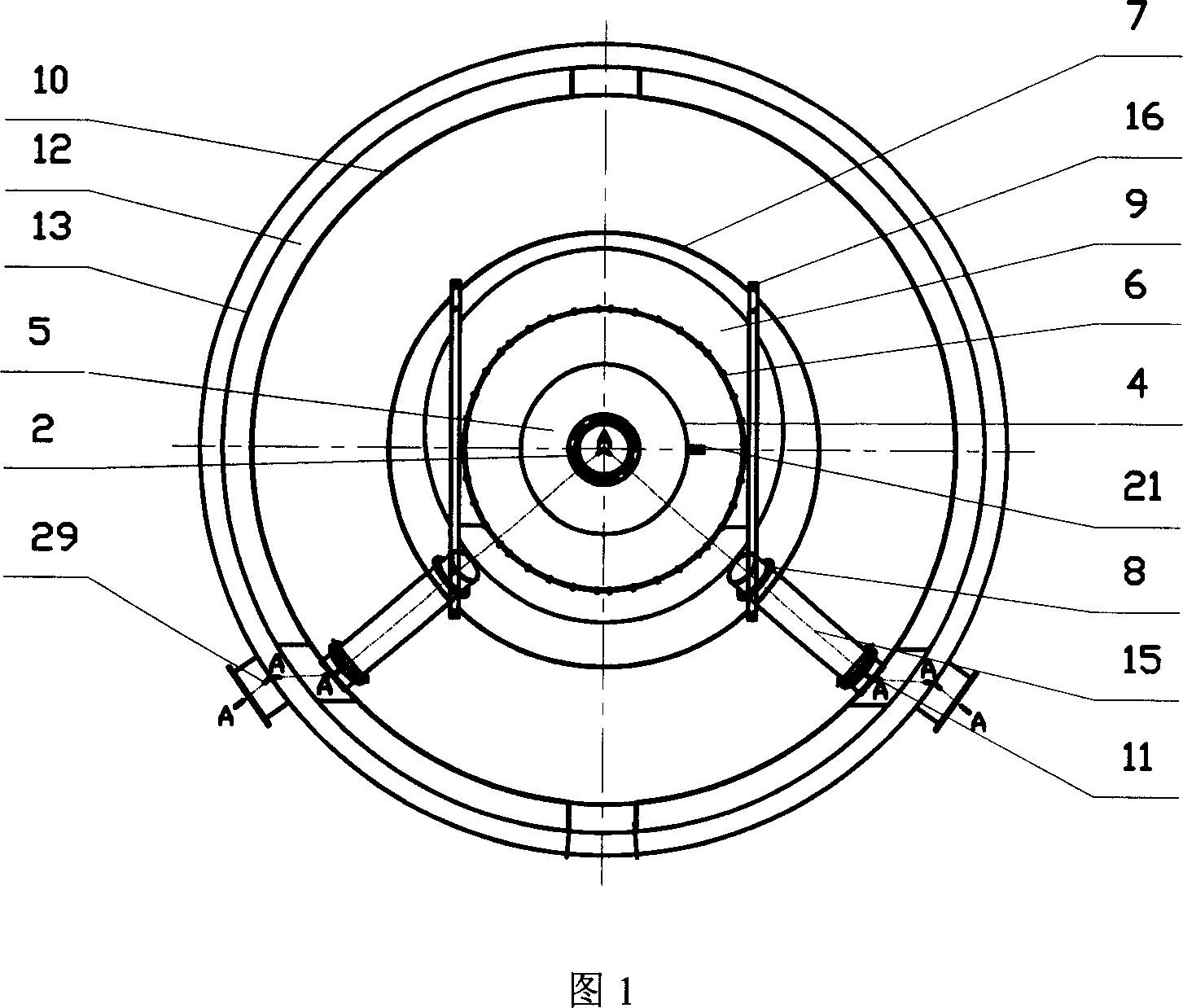

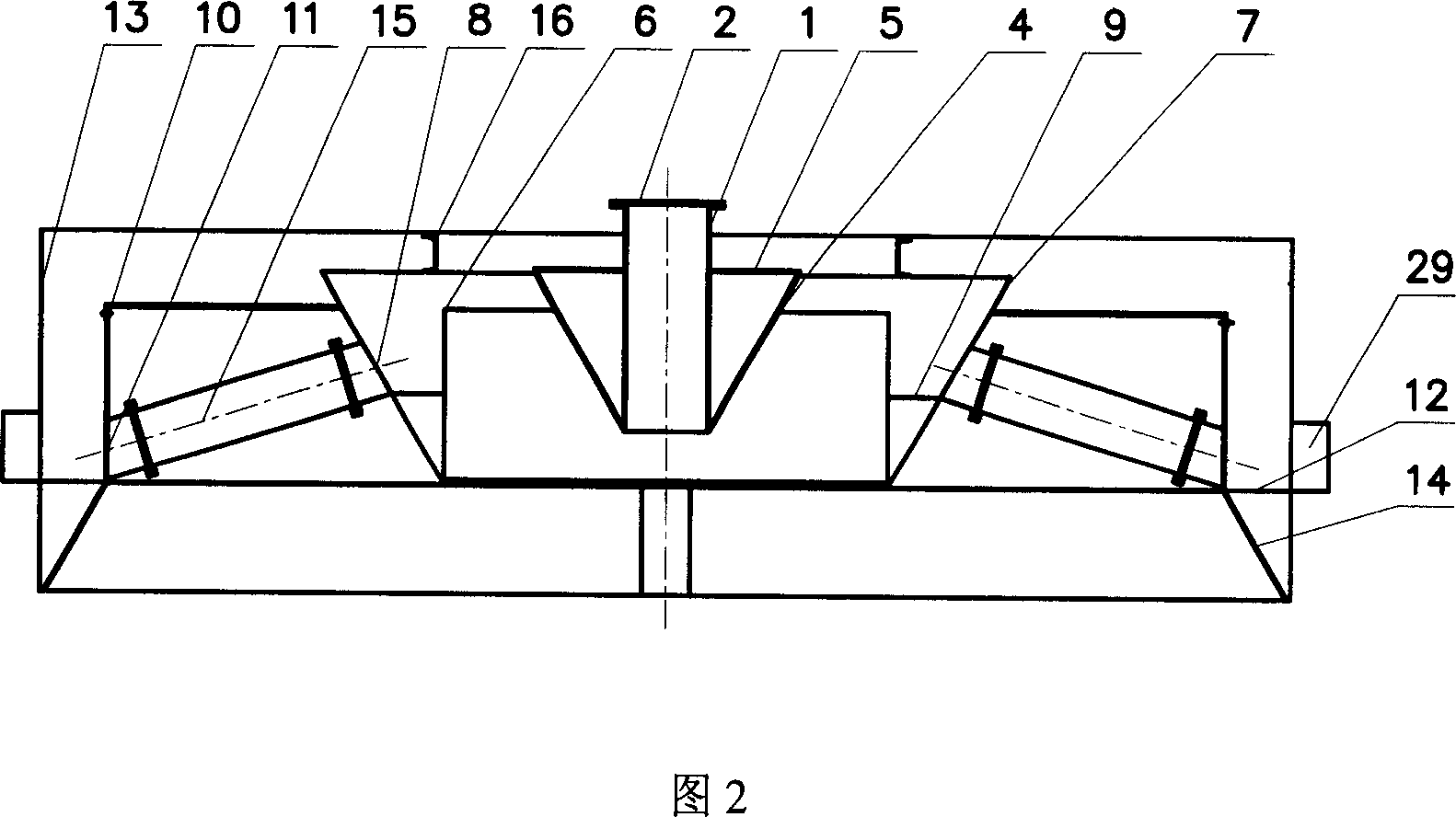

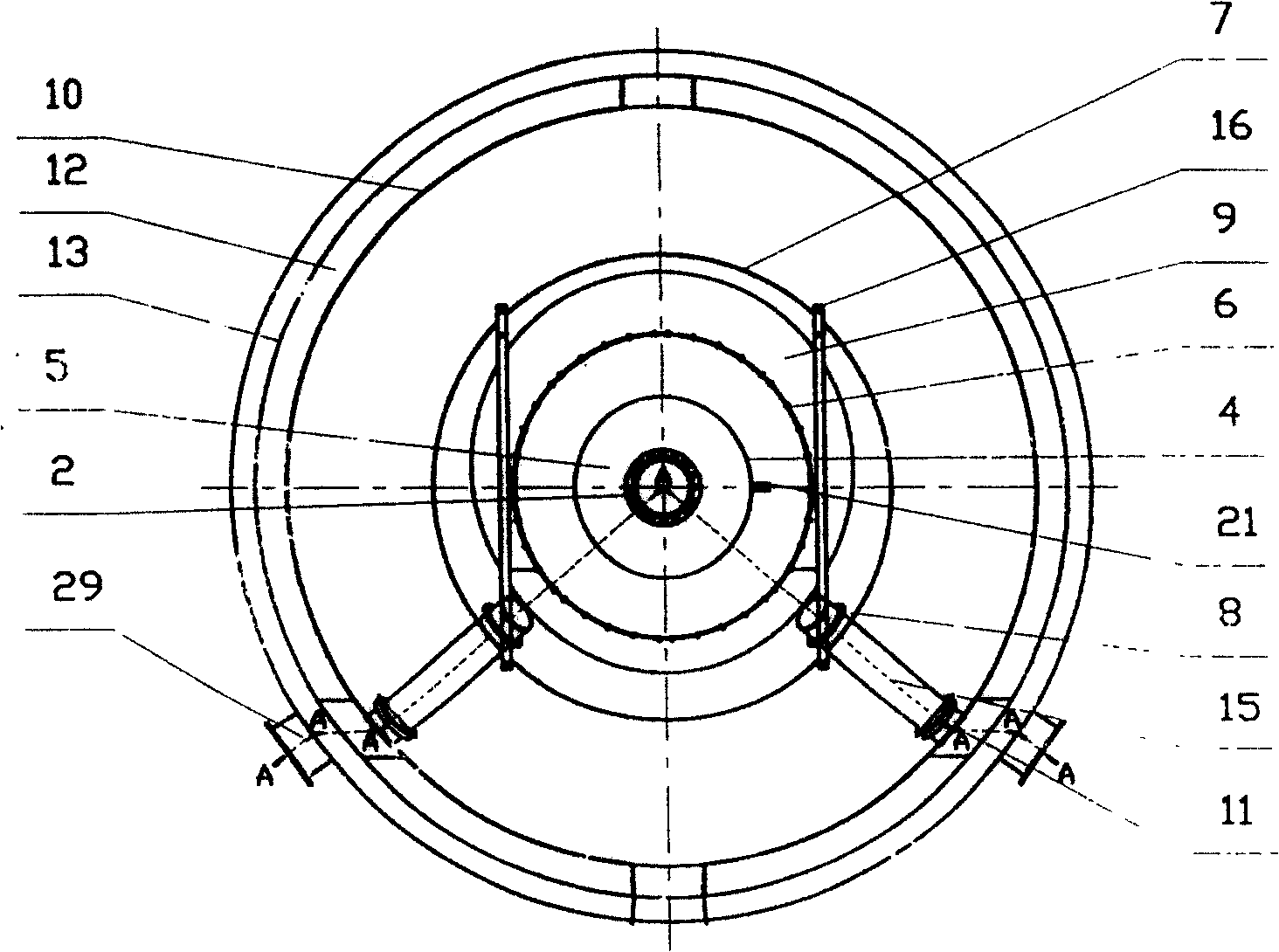

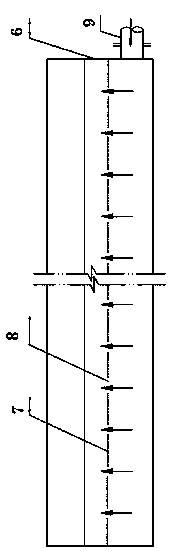

Foam pushing device of floatation machine

InactiveCN1931438AShorten the conveying distanceImprove flotation indexFlotationNon-ferrous metalEngineering

The present invention relates to floatation equipment for separating non-ferrous metal mineral, ferrous metal mineral and non-metal mineral, and is especially foam pushing device for large floatation machine. The foam pushing device is one double foam pushing cone structure comprising an inner foam pushing cone, an inner foam channel, outer foam pushing cone and outer foam channel. The foam pushing device separates the foams inside the floatation tank into two parts, the marginal part exhausted through the outer foam channel and the middle part exhausted through the inner foam channel, and the shortened foam conveying distance ensures the fluent exhaustion of floatation foam and is favorable to the floatation process.

Owner:BEIJING GENERAL RES INSITUTE OF MINING & METALLURGY GUAN MACHINERY +1

Method for using collector prepared from illegal cooking oil in fluorite flotation

The invention relates to a method for using a collector prepared from illegal cooking oil in fluorite flotation. The collector is prepared by the following steps: (a) purifying and extracting illegal cooking oil; and (b) subjecting the purified and extracted illegal cooking oil obtained by the step (a) to a hydrolysis reaction and thus obtaining the collector for use in ore floatation. When the collector prepared from the illegal cooking oil, which is used in the invention, is used in fluorite flotation, the selectivity of the collector is improved, and the technical index and economic index of the flotation can be improved. As the illegal cooking oil is used as the raw material for preparing the collector, the technical scheme adopted by the invention has a great significance for avoiding environment pollution, simplifying production process, reducing food safety threats and the like.

Owner:BEIJING JUNZHIQING SCI & TECH

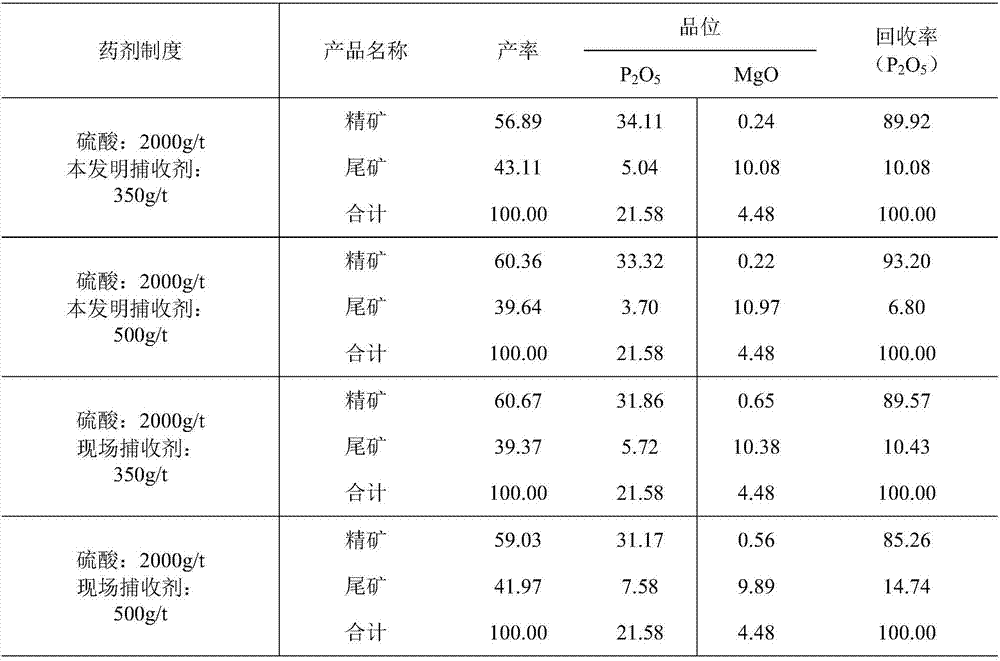

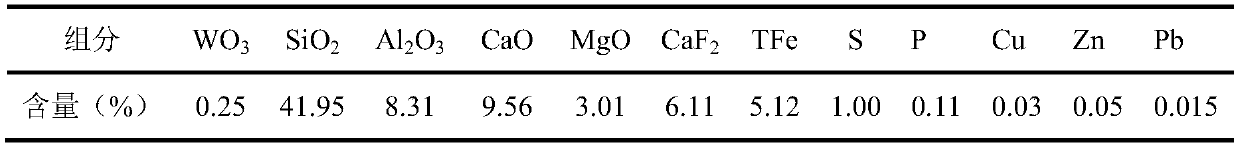

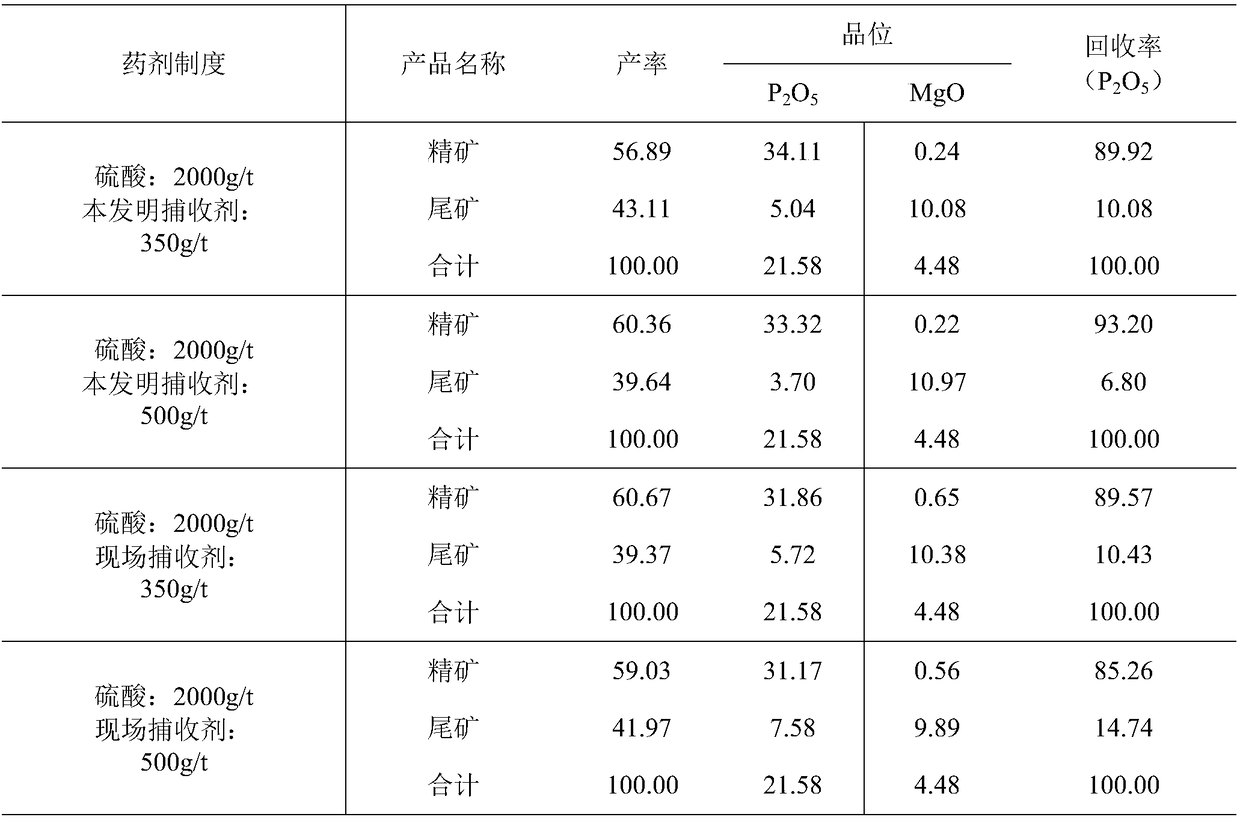

Collophanite reverse flotation collector and preparation method and application method thereof

ActiveCN106944263AGood mud resistanceThe flotation index is stableFlotationHigh phosphateOrganic layer

The invention discloses a collophanite reverse flotation collector and a preparation method and an application method thereof, and belongs to the technical field of solid mineral resource separation. Vacuum five-line phenol extract oil, a diluent, fuming sulphuric acid, sodium hydroxide and the like are used as raw materials, after raw oil and the diluent are mixed according to a certain mass percent, the fuming sulphuric acid is fed into a reaction still for sulfonation, stirring and washing are conducted after a sulfonation reaction is completed, still standing is conducted for layering, an organic layer is taken for primary saponification in a saponification reaction still, and sulphonate is obtained; and the obtained sulphonate and soy acid are compounded into a mixture according to a certain mass percent, the mixture is subjected to secondary saponification, and the anionic high-calcium (high-magnesium) collophanite reverse flotation collector is obtained. The collector is simple in preparation process, high in adaptability (such as the temperature and the ore pulp pH), good in mud resistance, high and stable in flotation index, low in cost and free of toxicity; and when the collector is applied to high-calcium (high-magnesium) collophanite flotation, the high-phosphate concentrate grade (P2O5) can be remarkably improved, the recovery rate of high-phosphate concentrate can be remarkably increased, and the impurity content of the concentrate is lowered.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

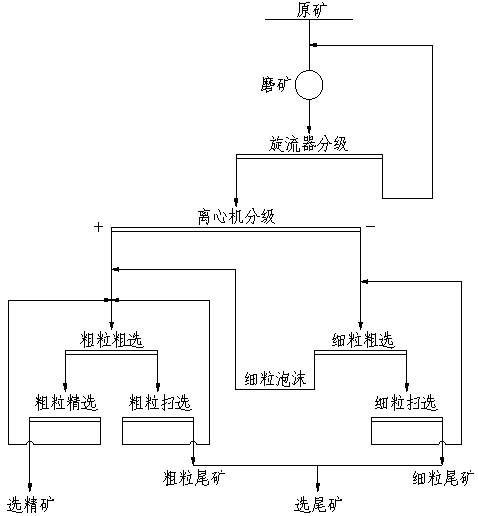

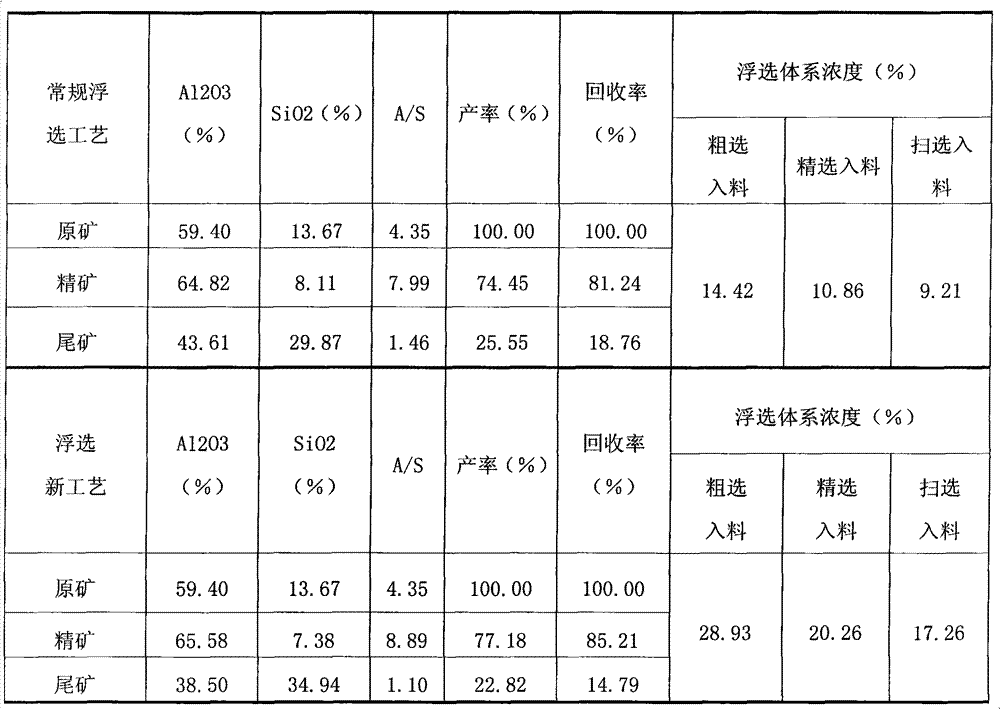

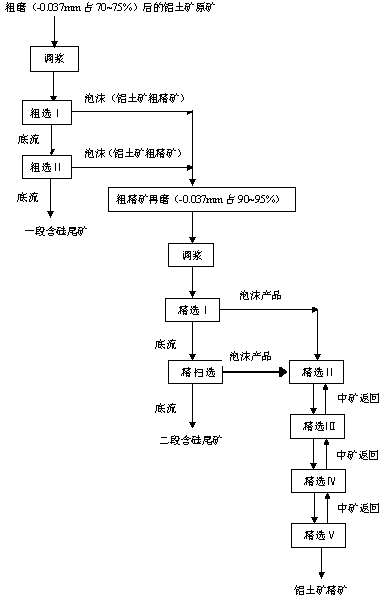

A kind of bauxite graded flotation desiliconization method

ActiveCN106964479BSolve the problem of mixed selectionEasy to handleFlotationWet separationTyping ClassificationResource recovery

The invention relates to a bauxite classification and floatation desilication method, in particular to a bauxite high-speed disc type classification-positive floatation desilication method. The bauxite high-speed disc type classification-positive floatation desilication method is characterized in that ore grinding products are subjected to two-stage classification, and obtained coarse grain ore pulp and fine grain ore pulp enter a floatation system to be floated. According to the bauxite high-speed disc type classification-positive floatation desilication method, the bauxite ore pulp is efficiently classified through a high-speed disc type classifier, and the classified ore pulp is floated. The problem that fine particles and coarse particles in bauxite difficult to float are mixed and are difficult to float is effectively solved, the treatment capacity of the floatation system is improved, the floatation index of the floatation system is increased, production cost is reduced, the resource recovery rate is high, and economic benefits are good.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

Lead-antimony-zinc sulfide ore bulk flotation collecting agent and preparation and application thereof

InactiveCN106423581AThe amount of blowing agent is reducedReduce drug costsFlotationSingle useKerosene

The invention relates to a lead-antimony-zinc sulfide ore bulk flotation collecting agent and preparation and application thereof. The gearbox left box body shell is prepared by mixing tert-dodecyl mercaptan and emulsified kerosene. The mass ratio of the tert-dodecyl mercaptan to the emulsified kerosene is 1:(0.9-1.2). The lead-antimony-zinc sulfide ore bulk flotation collecting agent has the better collecting effect on sulfide, and can be applied to lead-antimony-zinc sulfide ore bulk flotation. The lead-antimony-zinc sulfide ore bulk flotation collecting agent has the good foaming property, can adopt a small amount or no foaming agent, and can decrease the consumption of an activating agent copper sulfate; compared with traditional MA or single use of emulsified kerosene and tert-dodecyl mercaptan, the grade and recycling rate of sulfide can be increased, and types and consumption of medicament are reduced.

Owner:CENT SOUTH UNIV +1

Improved chemical for increasing flotation target of powellite ore and its preparing method

A modified chemical for increasing the floatation quality of Mo-W ore is an inorganic adjusting agent composed of sulfuric acid and water glass proportionally. Its preparing process includes such steps as adding the sulfuric acid solution to water glass solution proportionally while stirring, and post-stirring for several minutes.

Owner:青海西部矿业科技有限公司

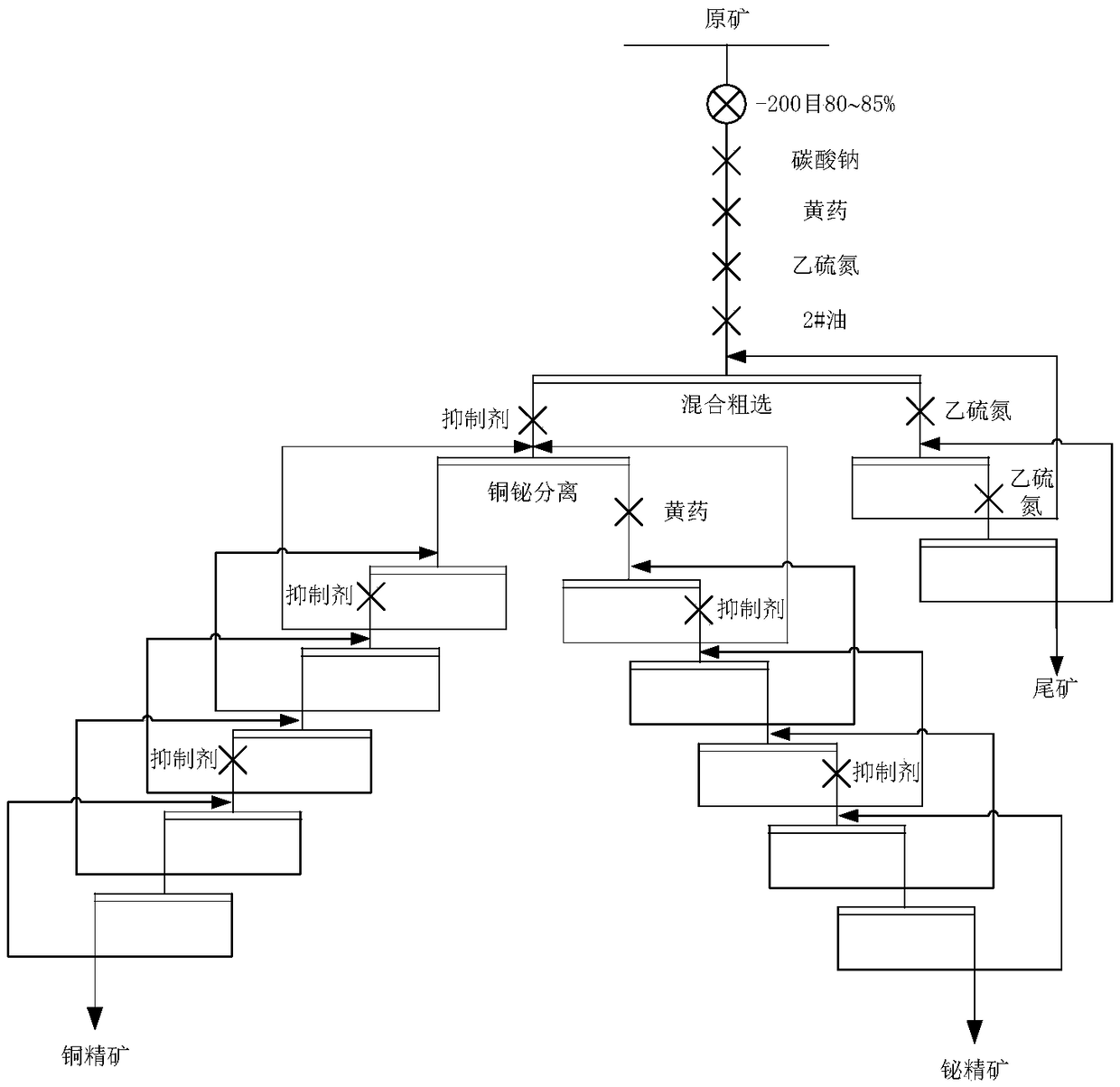

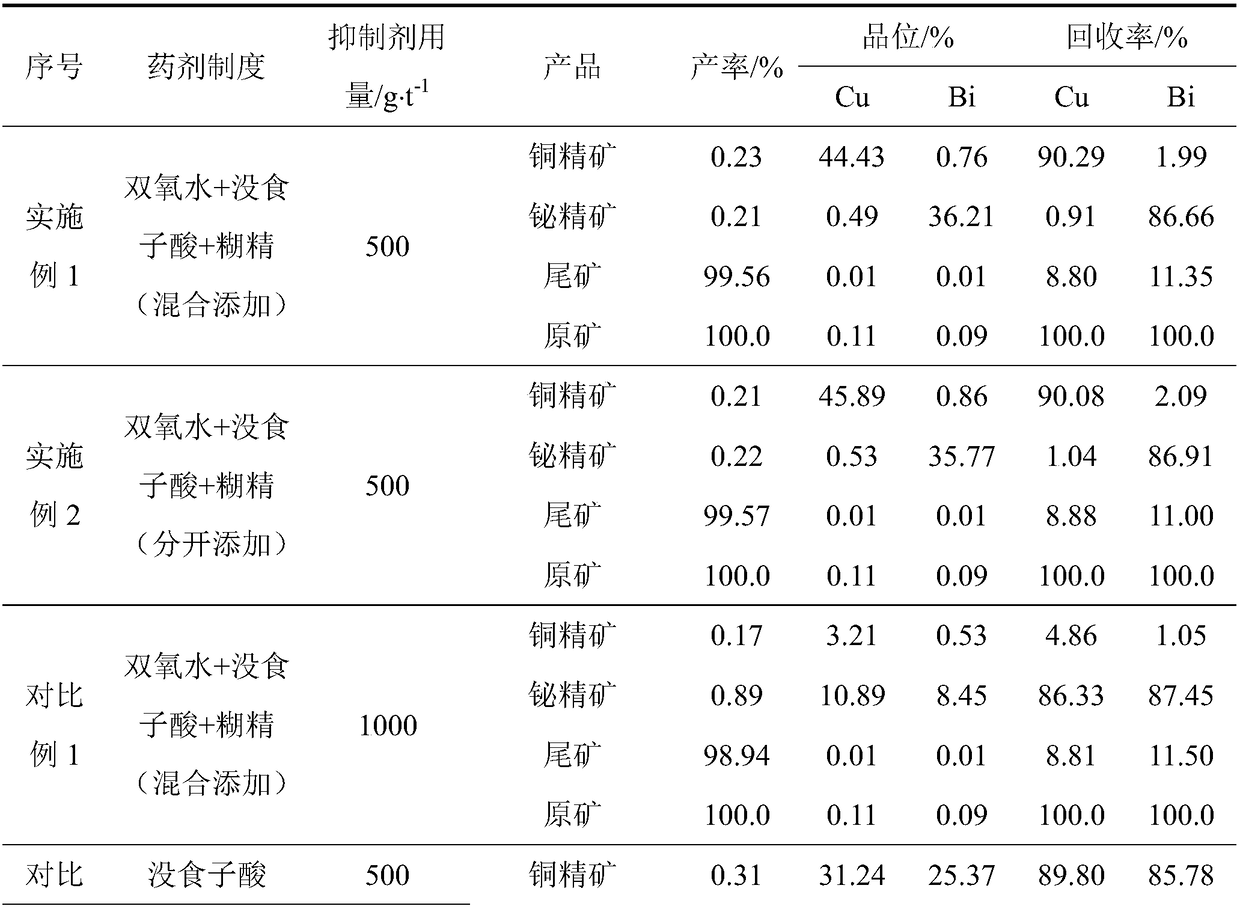

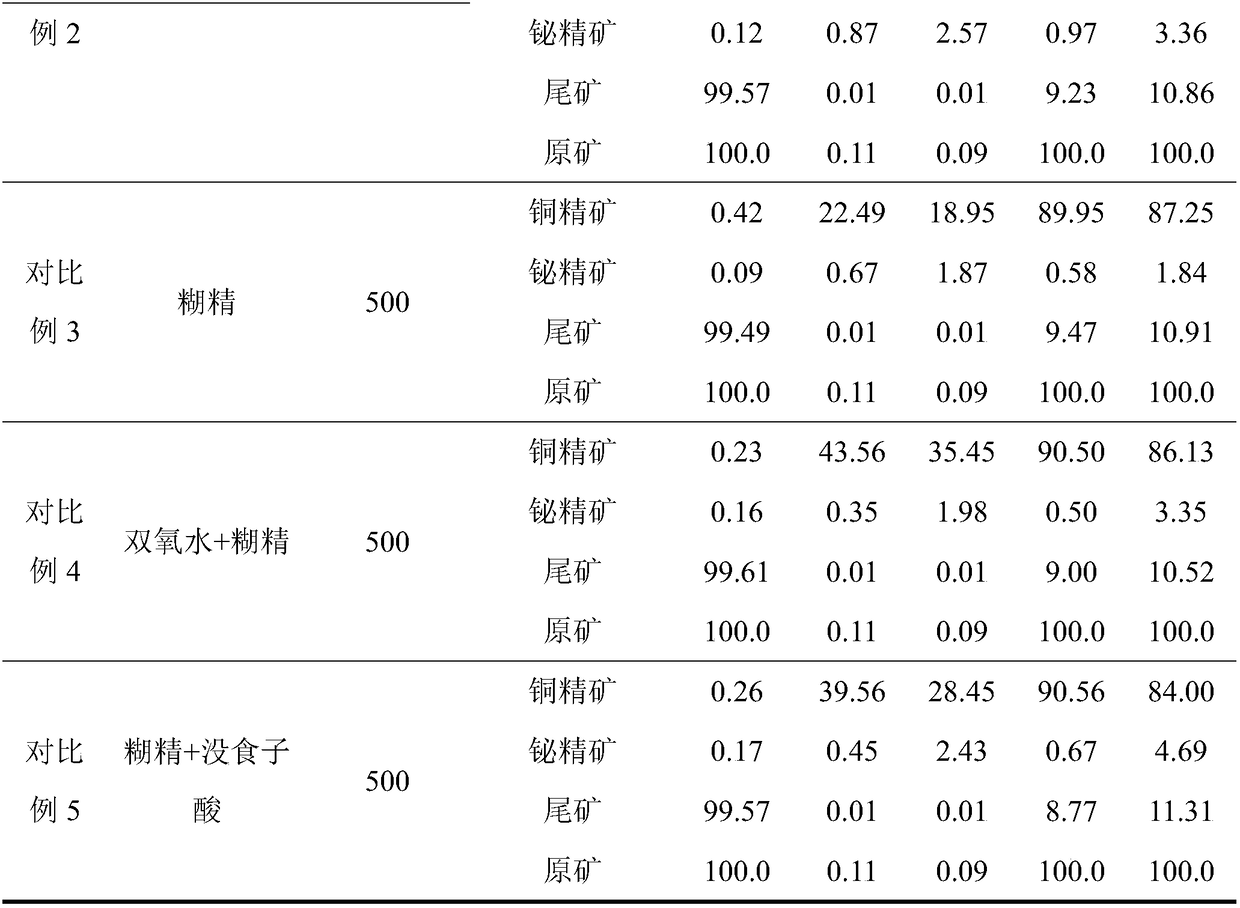

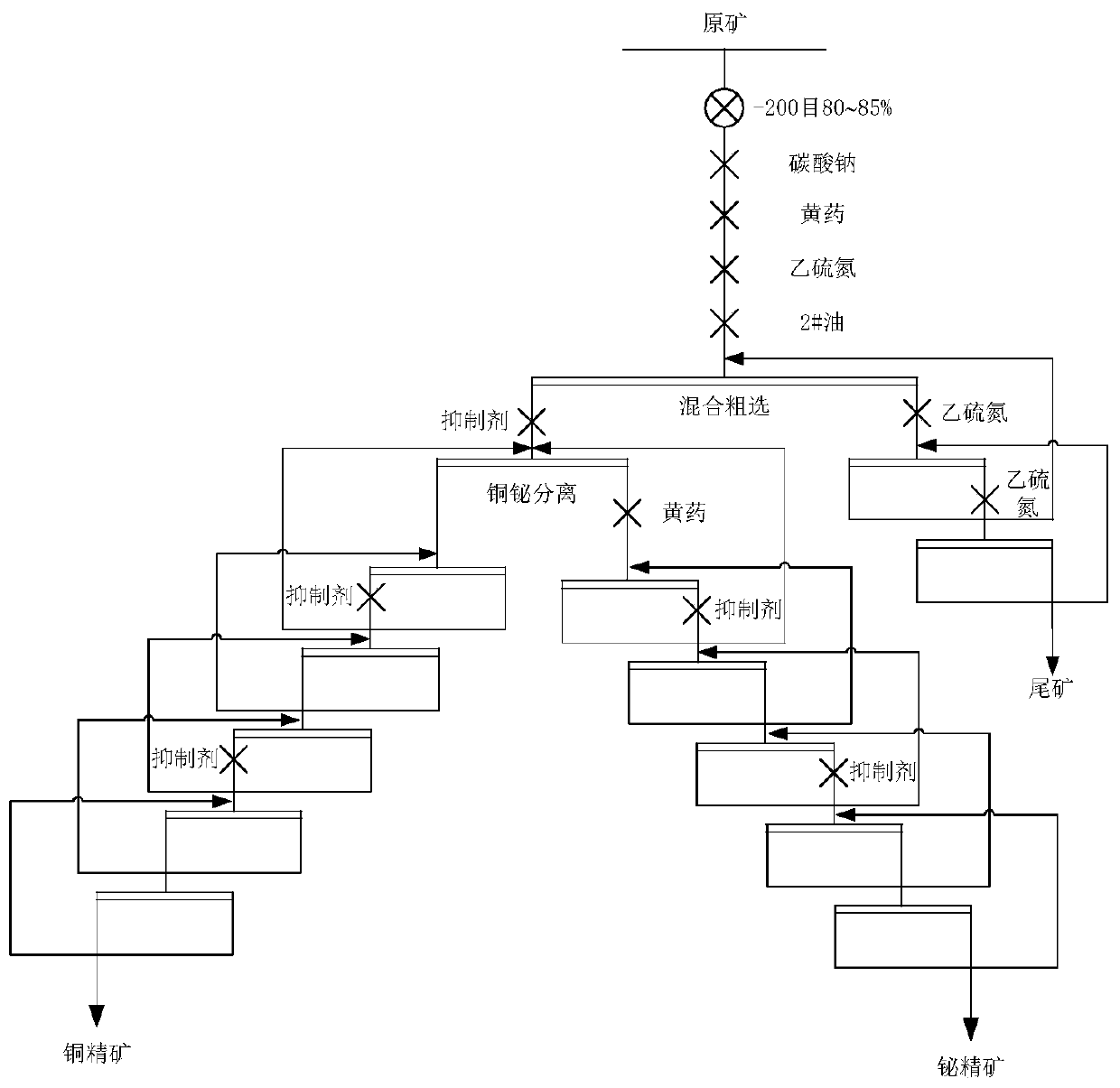

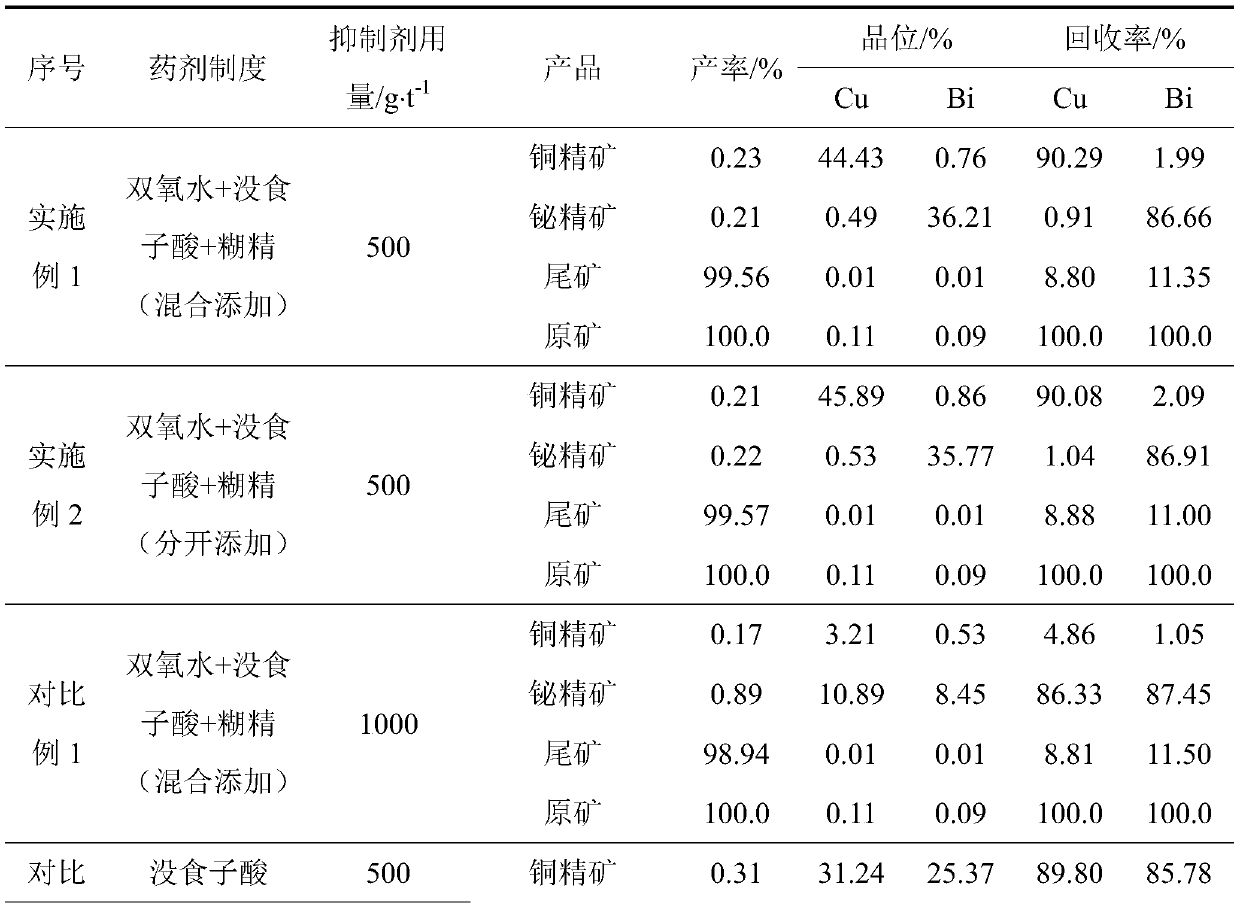

Bismuth sulfide mineral inhibiting agent and application thereof

ActiveCN108620240AImprove adsorption capacityImprove ionic interactionFlotationBismuth sulfideGallic acid ester

The invention discloses a bismuth sulfide mineral inhibiting agent and application thereof. The inhibiting agent comprises the following components in parts by mass: 2-5 parts of hydrogen peroxide, 3-4 parts of gallic acid, and 1-2 parts of dextrin. In a flotation process of sulfide minerals containing bismuth, 50-500 g / t combined inhibiting agent is added in each flotation according to each tonnage of raw ore minerals, so that the inhibition of the sulfide minerals containing bismuth can be realized. The bismuth sulfide mineral inhibiting agent has the advantages of high acting effect, low use level and the like, is free of using such high-consumption medicaments as poisonous cyanides, lime and sodium sulfide to reduce environmental pollution, meanwhile, reduces the beneficiation cost, and improves the sorting index.

Owner:CENT SOUTH UNIV

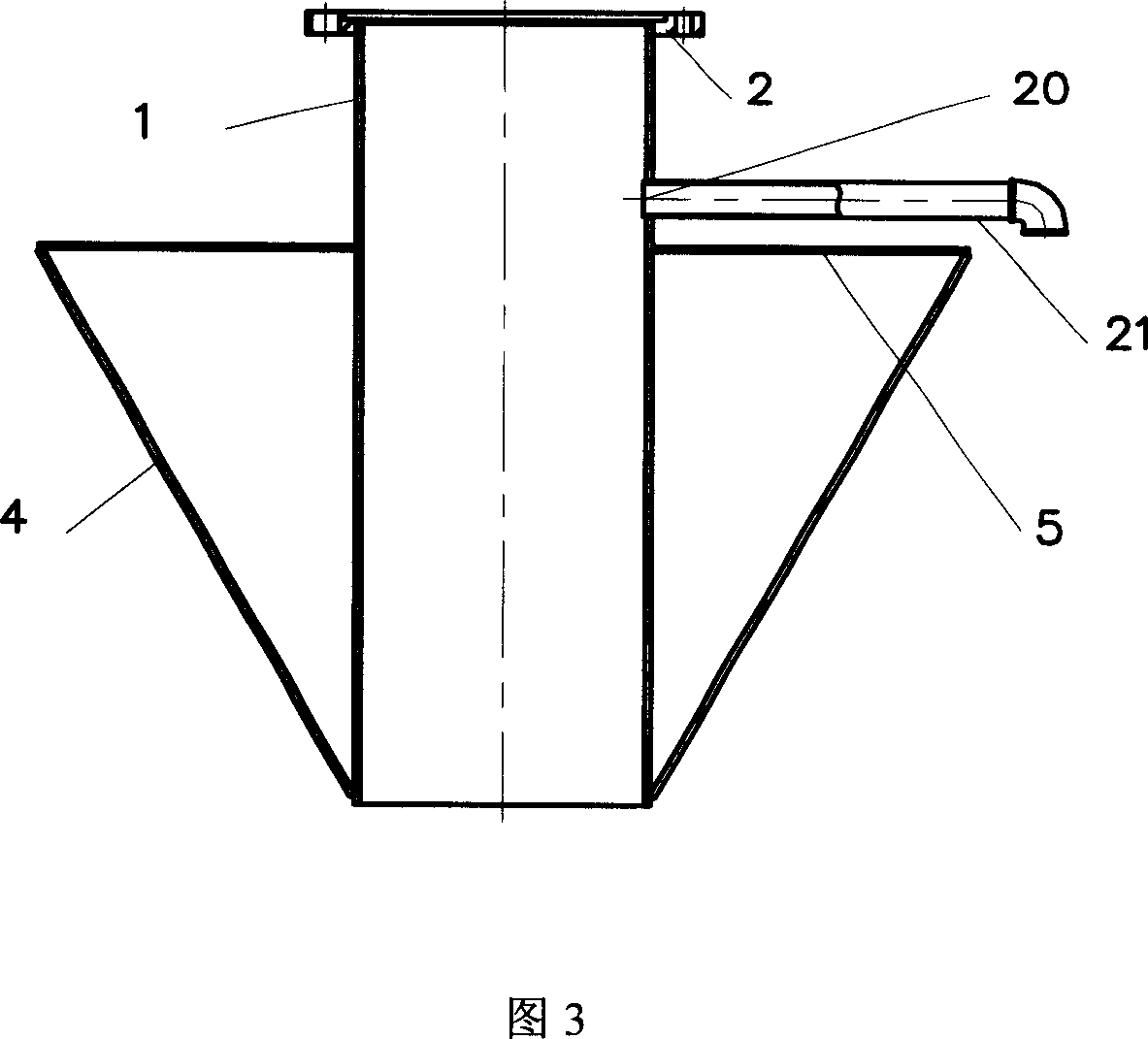

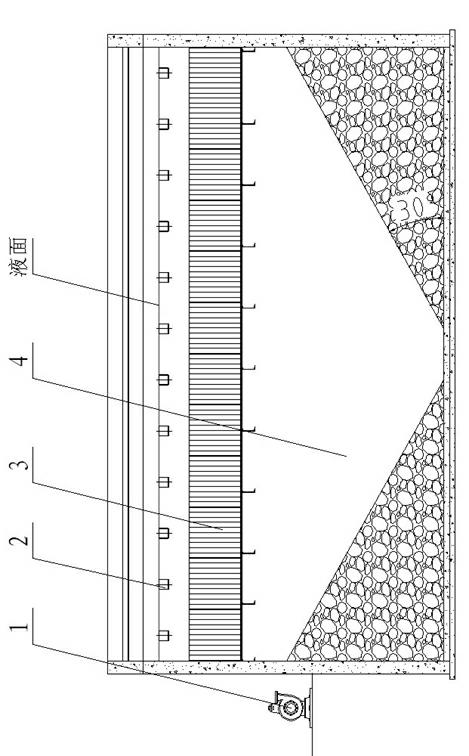

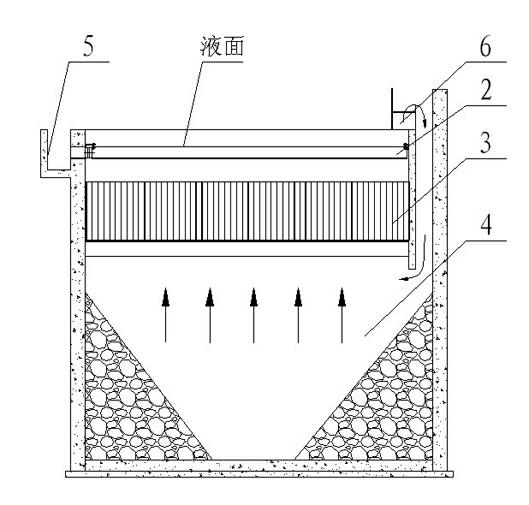

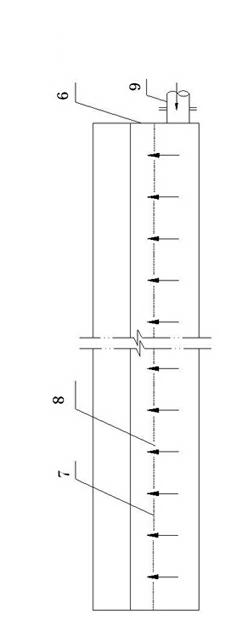

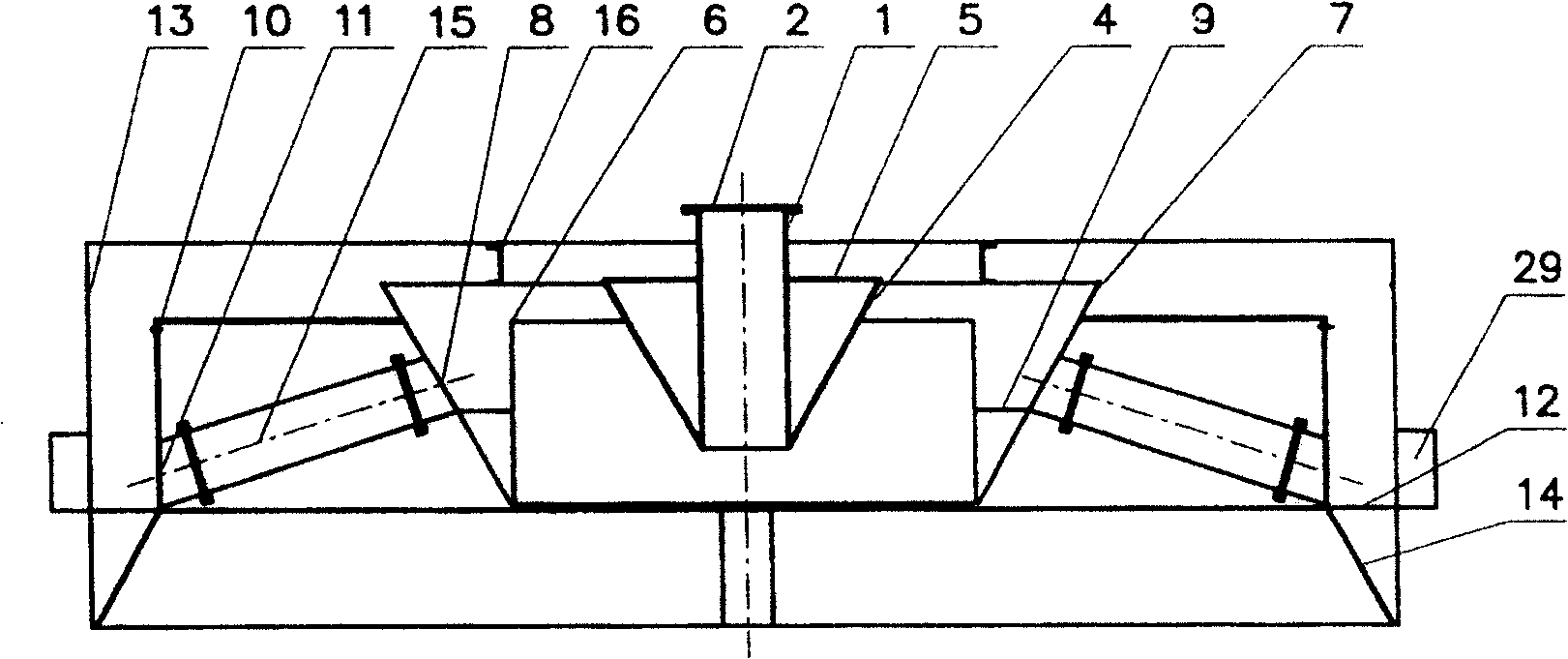

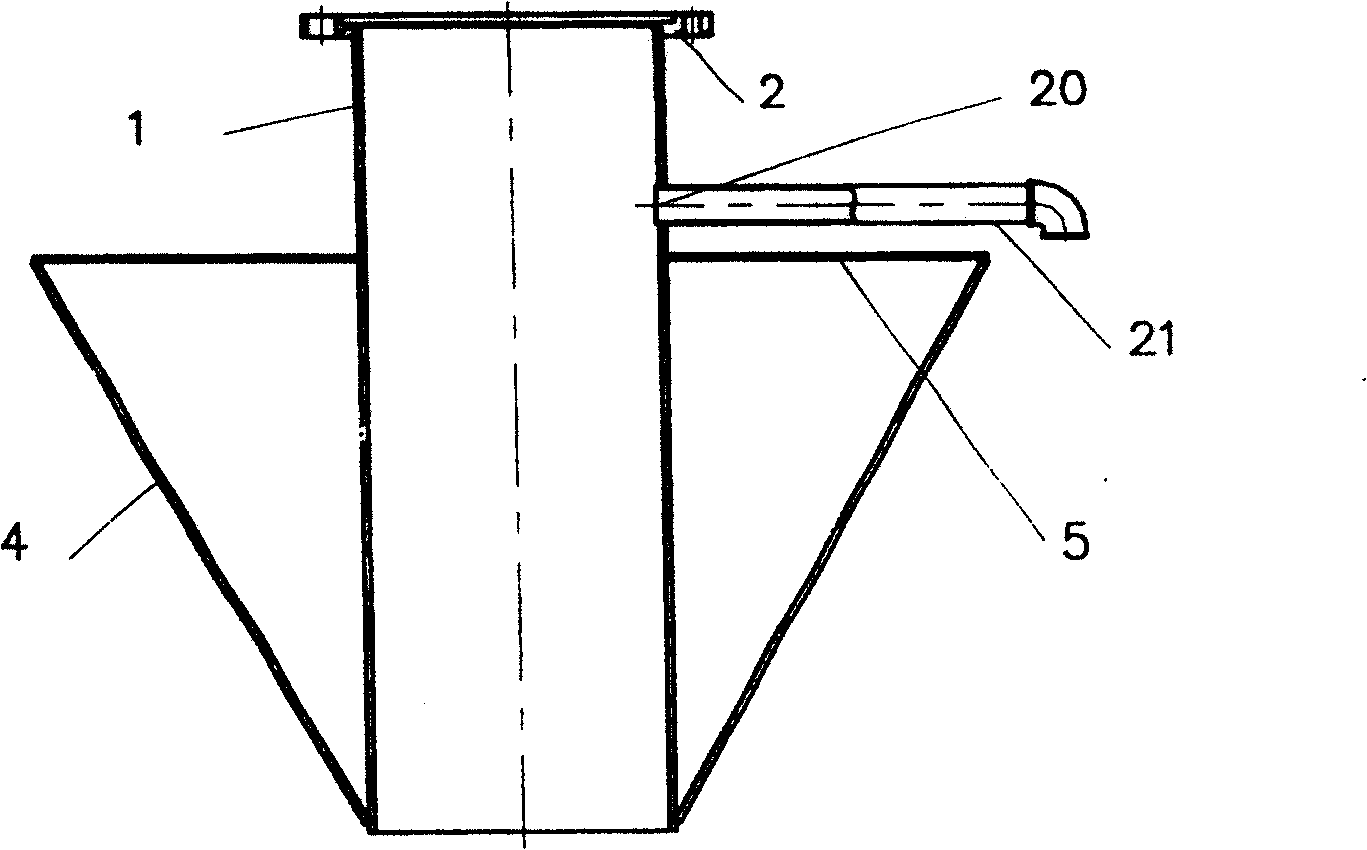

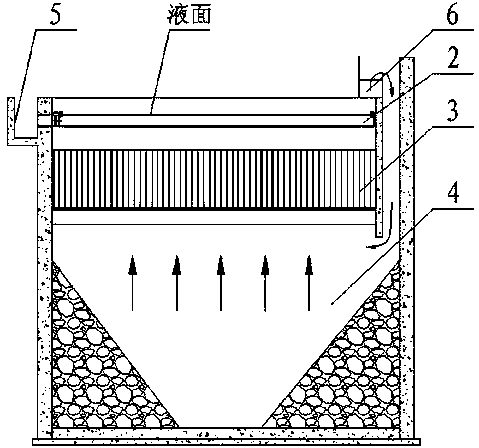

Flotation feed desliming pool

ActiveCN102614687AReduce power consumptionSimple structureSedimentation settling tanksEngineeringFeeding pumps

A flotation feed desliming pool comprises a feeding pipe, a flotation feeding pump, a feeding distribution tank, an overflow tank and a flow distribution area, wherein the feeding distribution tank, the overflow tank and the flow distribution area are disposed above the desliming pool. The feeding distribution tank is arranged above the desliming pool and connected with the feeding pipe, and a plurality of through holes are uniformly distributed on a transverse partition which is arranged in the middle of the feeding distribution tank. The flow distribution area comprises a vertical pipe combination unit arranged above the middle of the desliming pool, the vertical pipe combination unit consists of a plurality of vertically arranged pipelines which are formed by mutually stacking a plurality of glass epoxies bent by compression, and the cross section of each pipeline is regular hexagonal. A gap of coal dressing equipment is filled by the flotation feed desliming pool by means of innovative measures, desliming process of flotation feed is realized by the aid of the hydraulic classification principle, and the flotation feed desliming pool is simple in structure, convenient in operation, effective in desliming and high in operating efficiency. Further, underflow of the desliming pool is conveyed by the feeding pump to floatation operation, the flotation feed desliming pool integrates functions of desliming and feed buffering and is low in investment and quick in effectiveness.

Owner:唐山国华科技国际工程有限公司

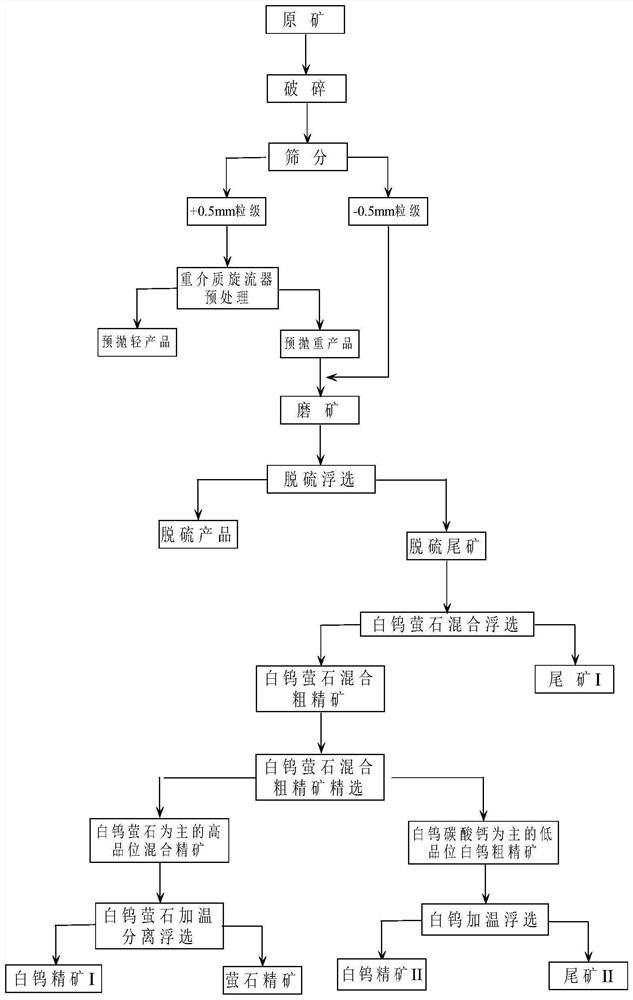

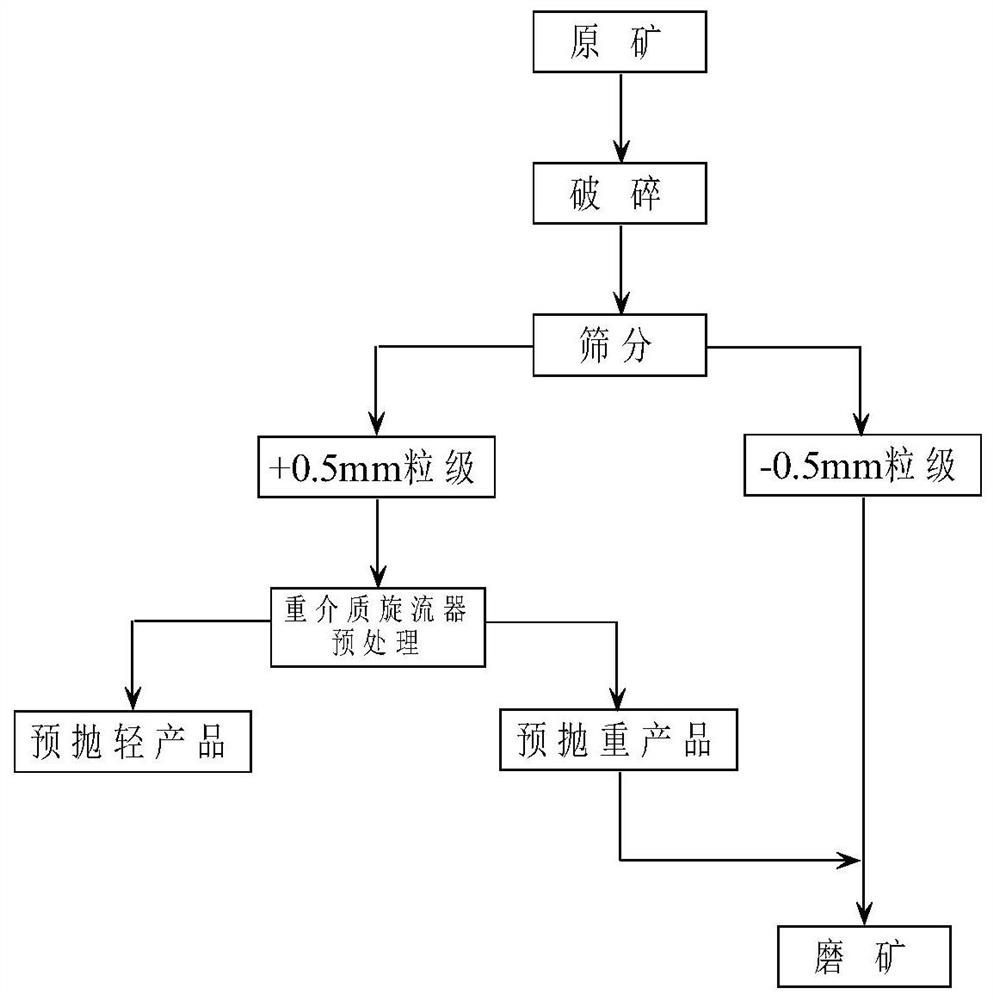

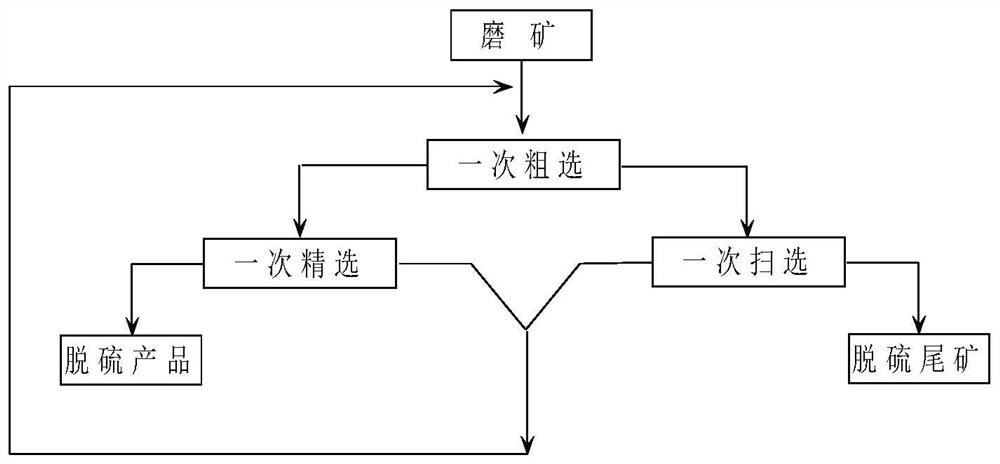

Beneficiation method for high-calcium-carbonate low-grade scheelite

ActiveCN111841826AReduce storage capacityRealize step-by-step recyclingVortex flow apparatusFlotationEngineeringMineralogy

The invention provides a beneficiation method for high-calcium-carbonate low-grade scheelite. The method includes the steps: discarding low-specific-gravity minerals with the specific gravity lower than that of scheelite and fluorite in ore before feeding the raw ore into a mill; firstly, performing scheelite-fluorite bulk flotation on ore pulp obtained after ore milling to obtain rough scheelite-fluorite bulk concentrate and tailings I; then, performing fine separation on the rough scheelite-fluorite bulk concentrate to obtain high-grade bulk concentrate with scheelite-fluorite as the main component and low-grade rough scheelite concentrate with scheelite-calcium carbonate as the main component; then, performing heating flotation separation on the high-grade bulk concentrate with the scheelite-fluorite as the main component to obtain scheelite concentrate I and fluorite concentrate; and performing heating flotation separation on the low-grade rough scheelite concentrate with the scheelite-calcium carbonate as the main component to obtain scheelite concentrate II and tailings II. The method avoids the situation that a lot of easy-to-float fluorite is lost in scheelite heating flotation tailings in a conventional scheelite preferential flotation process, and stepwise recovery of the scheelite and comprehensive recovery of the fluorite are achieved.

Owner:BEIJING MINING & METALLURGICAL TECH GRP CO LTD

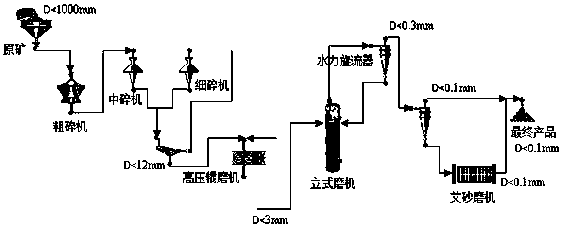

Ultralow-energy-consumption grinding technology for non-ferrous metal ore

InactiveCN109127076AUniform particle size distributionImprove flotation indexGrain treatmentsNon-ferrous metalHigh pressure

The invention provides an ultralow-energy-consumption grinding technology for non-ferrous metal ore and belongs to the field of ore selection. The technology is mainly composed of grinding processes such as rough crushing, middle crushing, fine crushing, high-pressure rolling, stirring grinding and sand grinding. The technology aims at most non-ferrous metal ore with medium rigidity, and the totalenergy consumption of the ultralow-energy-consumption grinding technology can be controlled below 15 kwh / t; compared with a traditional three-segment one-closed-circuit ore crushing and two-segment full-closed-circuit ore grinding technology and a traditional rough crushing and SAB technology, the technology has the advantages that the total energy consumption is lowered by 30% or above, the operation technology is compact and low in cost, industrial production and allocation are easily achieved, and the technology is suitable for application and popularization.

Owner:JIANGXI UNIV OF SCI & TECH

Combined reagent for zinc-containing ore flotation and using method thereof

The invention discloses a combined reagent for zinc-containing ore flotation and a using method thereof, and belongs to the field of mineral flotation reagents. The combined reagent comprises, by mass, 5-40% of hydroxamic acid (the length of a carbon chain is C6-C8), 10-50% of ethidene diamine, 10-60% of xanthate (the length of a carbon chain is C2-C5) and 5-40% of palmitoyl glycine. The reagent is soluble at normal temperature, free of toxins, efficient and environmentally friendly. The zinc-containing ore flotation index can be improved. Compared with a conventional zinc oxide flotation collector, the combined reagent has the advantages of being small in reagent consumption and low in price, zinc sulfide and zinc oxide do not need to be separately graded in the flotation technology, zincsulfide ore and zinc oxide ore can be recycled at the same time, and the combined reagent especially has a good flotation effect on low-grade zinc oxide ore with a relatively high sludge content.

Owner:KUNMING UNIV OF SCI & TECH

Foam pushing device of floatation machine

Owner:BEIJING GENERAL RES INSITUTE OF MINING & METALLURGY GUAN MACHINERY +1

Method for activating calamine in flotation process

InactiveCN102489412AHigh recovery rateImprove flotation indexFlotationTest sampleSodium acid carbonate

The invention provides a method for activating calamine in the flotation process and belongs to the technical field of ore benefication. The method comprises the following steps of: dry-milling calamine pure mineral to obtain test samples which comprise 80 to 90 weight percent of 320 meshes qualified particles; adding the test samples into a flotation machine, wherein the flotation pulp volume is 50 ml and the test mineral samples at each time is 0.5 g; and adding a combined regulator of sodium hydroxamate, sodium carbonate and sodium sulfide into pulp which is stirred uniformly and taking the combined regulator as an activating agent of the calamine, wherein the total adding amount is 80 to 140 mg / L per ton of the calamine and the action time is 4 to 5 minutes, the using amount of a collector dodecylamine is 30 to 40 mg / L and the action time is 4 to 5 minutes, and the flotation time is 5 to 7 minutes. The activation effect of the method is more excellent than the conventional activation effect; the total using amount of the sodium sulfide is reduced by 20 to 30 percent; and compared with the conventional activation method of the calamine, the activation method has the advantage that: the flotation recovery rate of the calamine can be increased by 6 to 12 percent.

Owner:KUNMING UNIV OF SCI & TECH

Magnesium-silicate-rich mineral floatation inhibitor as well as preparation method and application thereof

The invention provides a magnesium-silicate-rich mineral floatation inhibitor. The inhibitor comprises the following ingredients in part by weight: 2 to 30 parts of mannan, 5 to 25 parts of sodium gluconate and 5 to 15 parts of sodium tripolyphosphate. The mannan is one of konjac glucomannan and aloe mannan. The invention also provides a method of preparing the inhibitor. The invention also provides application of the inhibitor in inhibiting the magnesium-silicate-rich minerals in a floatation process.

Owner:INST OF MULTIPURPOSE UTILIZATION OF MINERAL RESOURCES CHINESE ACAD OF GEOLOGICAL SCI

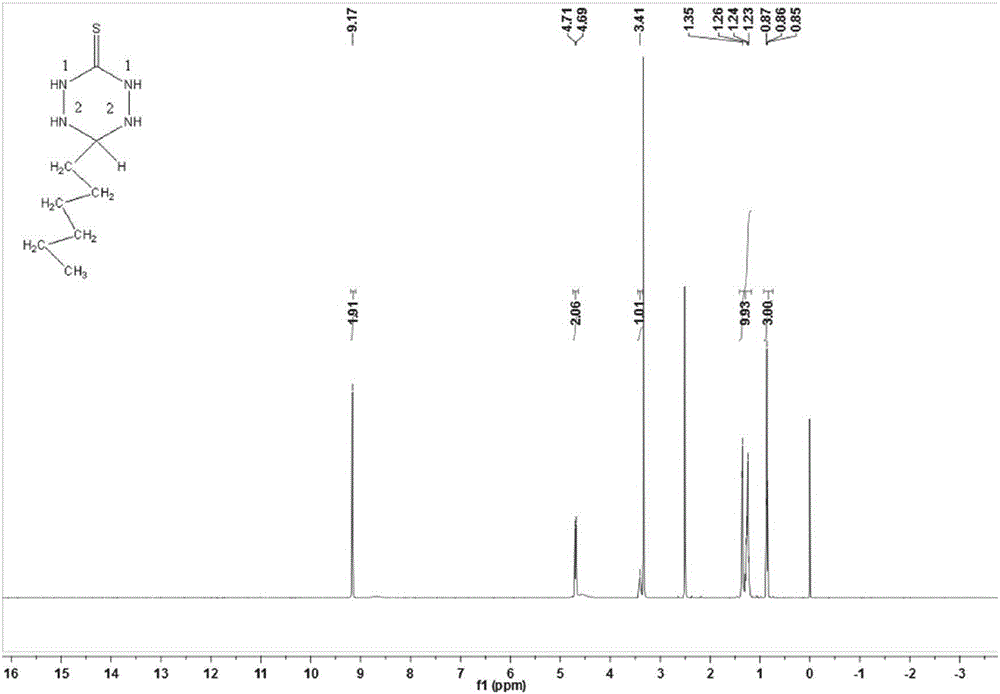

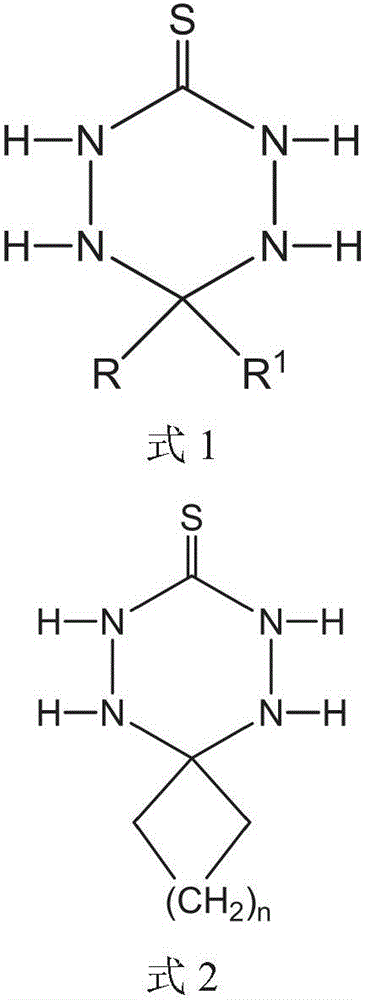

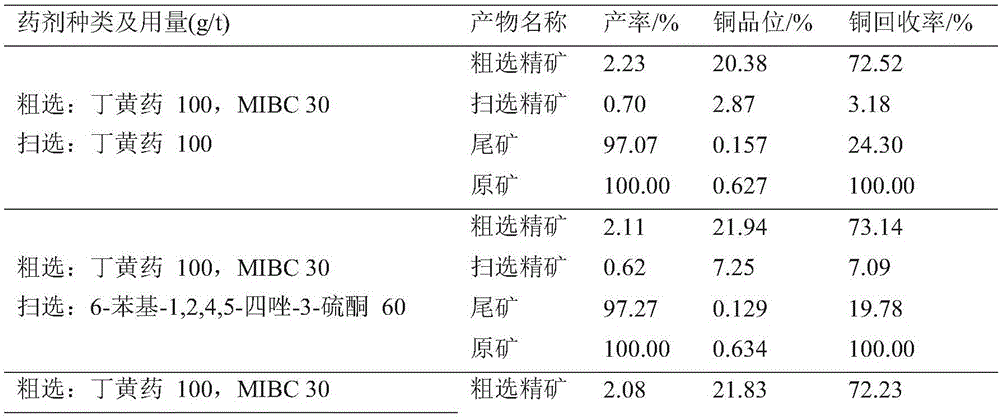

Application of 1,2,4,5-tetrazole-3-thioketone flotation collecting agent

ActiveCN106391323AImprove flotation indexImproved flotation recoveryFlotationMineral flotationCopper

The invention discloses application of a 1,2,4,5-tetrazole-3-thioketone flotation collecting agent. The application is characterized in that a 1,2,4,5-tetrazole-3-thioketone compound as a mineral flotation collecting agent is applied to minerals containing copper, silver or gold to recycle valuable metal in a flotation manner, and compared with a common flotation collecting agent in prior art, enriching and recycle of copper, silver or gold minerals can be effectively improved.

Owner:CENT SOUTH UNIV

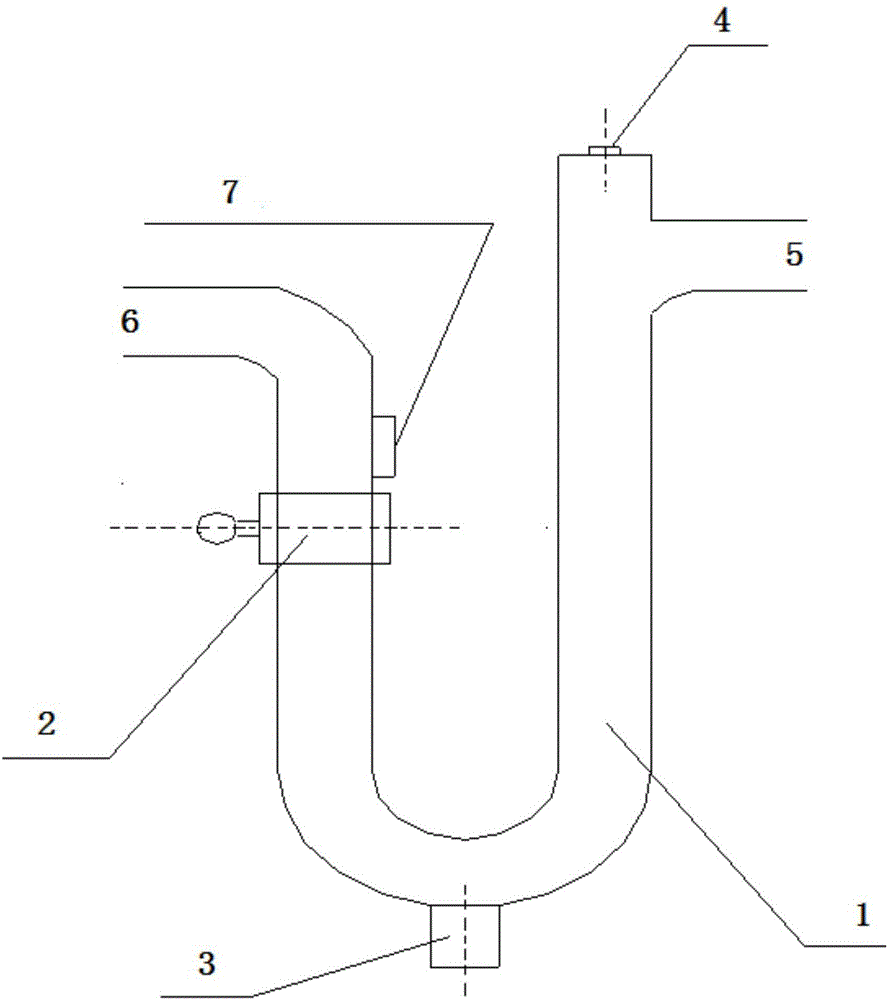

Hydroclone overflow ore feeding pipeline

InactiveCN106269220AAccurate measurementImprove stabilitySolid separationExhaust valveWorking environment

The invention relates to a hydroclone overflow ore feeding pipeline which comprises a U-shaped pipe, an electromagnetic flowmeter, a blowdown valve and an exhaust valve, wherein a discharge port and a feed port are formed in the left and right sides of the upper end of the U-shaped pipe respectively; the electromagnetic flowmeter is mounted below the discharge port; the blowdown valve is mounted at the bottom of the U-shaped pipe; the exhaust valve is mounted above the feed port; the U-shaped pipe is connected with a measured ore pulp pipeline; the hydroclone overflow ore pulp flows into the U-shaped pipe through the measured ore pulp pipeline via the feed port; the electromagnetic flowmeter measures the ore pulp flow; and the ore pulp is subjected to flotation operation through the discharge port. The hydroclone overflow ore feeding pipeline provided by the invention has the advantages of simple structure, easiness in operation, accurate flow measurement and strong practicability, and can realize stable hydroclone overflow ore feeding while providing a stable working environment for the electromagnetic flowmeter.

Owner:CHANGCHUN GOLD RES INST

A kind of high calcium scheelite flotation collector and its preparation method and application method

The invention discloses a high-calcium scheelite flotation collector and a preparation method and an application method thereof and belongs to the technical field of solid mineral resource sorting. The preparation method comprises the following steps of: by taking foots, hydroxylamine hydrochloride, sodium hydroxide, sulfuric acid and the like in a coconut oil refining process as raw materials, adding the treated foots in a certain molar ratio into a hydroxylamine hydrochloride aqueous solution at a certain temperature; then dropwise adding a sodium hydroxide aqueous solution with a certain concentration, and performing acidification after the dropwise adding reaction is finished; dehydrating and washing the acidified product to obtain coconut alkylhydroxyoxime acid; and then compounding the coconut alkylhydroxyoxime acid and soy acid in certain percentages by mass to obtain a mixture, and then saponifying the mixture to obtain the high-calcium scheelite flotation collector. The collector prepared by the preparation method disclosed by the invention is stable in property, good in floating index, stable in foam, high in adaptability, low in cost and non-toxic, and meanwhile, can efficiently separate scheelite from calcium-containing minerals in the high-calcium scheelite.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

A mixed flotation collector of lead-antimony-zinc sulfide ore, its preparation and application

The invention relates to a lead-antimony-zinc sulfide ore bulk flotation collecting agent and preparation and application thereof. The gearbox left box body shell is prepared by mixing tert-dodecyl mercaptan and emulsified kerosene. The mass ratio of the tert-dodecyl mercaptan to the emulsified kerosene is 1:(0.9-1.2). The lead-antimony-zinc sulfide ore bulk flotation collecting agent has the better collecting effect on sulfide, and can be applied to lead-antimony-zinc sulfide ore bulk flotation. The lead-antimony-zinc sulfide ore bulk flotation collecting agent has the good foaming property, can adopt a small amount or no foaming agent, and can decrease the consumption of an activating agent copper sulfate; compared with traditional MA or single use of emulsified kerosene and tert-dodecyl mercaptan, the grade and recycling rate of sulfide can be increased, and types and consumption of medicament are reduced.

Owner:CENT SOUTH UNIV +1

A collophosite reverse flotation collector and its preparation method and application method

The invention discloses a collophanite reverse flotation collector and a preparation method and an application method thereof, and belongs to the technical field of solid mineral resource separation. Vacuum five-line phenol extract oil, a diluent, fuming sulphuric acid, sodium hydroxide and the like are used as raw materials, after raw oil and the diluent are mixed according to a certain mass percent, the fuming sulphuric acid is fed into a reaction still for sulfonation, stirring and washing are conducted after a sulfonation reaction is completed, still standing is conducted for layering, an organic layer is taken for primary saponification in a saponification reaction still, and sulphonate is obtained; and the obtained sulphonate and soy acid are compounded into a mixture according to a certain mass percent, the mixture is subjected to secondary saponification, and the anionic high-calcium (high-magnesium) collophanite reverse flotation collector is obtained. The collector is simple in preparation process, high in adaptability (such as the temperature and the ore pulp pH), good in mud resistance, high and stable in flotation index, low in cost and free of toxicity; and when the collector is applied to high-calcium (high-magnesium) collophanite flotation, the high-phosphate concentrate grade (P2O5) can be remarkably improved, the recovery rate of high-phosphate concentrate can be remarkably increased, and the impurity content of the concentrate is lowered.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

A kind of bismuth sulfide mineral suppressor and application thereof

ActiveCN108620240BImprove adsorption capacityImprove chelation abilityFlotationBismuth sulfideGallic acid ester

The invention discloses a bismuth sulfide mineral inhibiting agent and application thereof. The inhibiting agent comprises the following components in parts by mass: 2-5 parts of hydrogen peroxide, 3-4 parts of gallic acid, and 1-2 parts of dextrin. In a flotation process of sulfide minerals containing bismuth, 50-500 g / t combined inhibiting agent is added in each flotation according to each tonnage of raw ore minerals, so that the inhibition of the sulfide minerals containing bismuth can be realized. The bismuth sulfide mineral inhibiting agent has the advantages of high acting effect, low use level and the like, is free of using such high-consumption medicaments as poisonous cyanides, lime and sodium sulfide to reduce environmental pollution, meanwhile, reduces the beneficiation cost, and improves the sorting index.

Owner:CENT SOUTH UNIV

Positive flotation method for bauxite

Owner:中铝郑州有色金属研究院有限公司 +1

Flotation feed desliming pool

ActiveCN102614687BReduce power consumptionSimple structureSedimentation settling tanksEngineeringCoal

A flotation feed desliming pool comprises a feeding pipe, a flotation feeding pump, a feeding distribution tank, an overflow tank and a flow distribution area, wherein the feeding distribution tank, the overflow tank and the flow distribution area are disposed above the desliming pool. The feeding distribution tank is arranged above the desliming pool and connected with the feeding pipe, and a plurality of through holes are uniformly distributed on a transverse partition which is arranged in the middle of the feeding distribution tank. The flow distribution area comprises a vertical pipe combination unit arranged above the middle of the desliming pool, the vertical pipe combination unit consists of a plurality of vertically arranged pipelines which are formed by mutually stacking a plurality of glass epoxies bent by compression, and the cross section of each pipeline is regular hexagonal. A gap of coal dressing equipment is filled by the flotation feed desliming pool by means of innovative measures, desliming process of flotation feed is realized by the aid of the hydraulic classification principle, and the flotation feed desliming pool is simple in structure, convenient in operation, effective in desliming and high in operating efficiency. Further, underflow of the desliming pool is conveyed by the feeding pump to floatation operation, the flotation feed desliming pool integrates functions of desliming and feed buffering and is low in investment and quick in effectiveness.

Owner:唐山国华科技国际工程有限公司

Flotation two-stage desiliconization method for high-silicon bauxite

ActiveCN102489411BGood desiliconization effectAvoid the effects of the desiliconization processFlotationSodium phosphatesEngineering

The invention relates to a flotation two-stage desiliconization method for high-silicon bauxite, which is a flotation desiliconization technology for bauxite and belongs to the technical field of mineral processing engineering. The method comprises the following steps of: coarsely grinding the bauxite into particles with certain fine granularity; under the condition of a certain ore pulp concentration, performing flotation first-stage desiliconization by using sodium carbonate as a pH regulator and a dispersing agent of the ore pulp, water glass and sodium hexametaphosphate as a combined inhibitor of gangue mineral, lead acetate as an activating agent of the bauxite, sodium oleate as a collector of the bauxite and pine oil as a foaming agent, wherein the base flow in a flotation groove is a section of silicon-containing tailings; allowing foam products to enter a grinding machine and grinding the foam products into particles with fine granularity; adding the medicaments sequentially and mixing pulp; performing flotation second-stage desiliconization, wherein the base flow in the flotation groove is a section of silicon-containing tailings; and selecting the foaming products for multiple times to form bauxite concentrate. The sectional desiliconization method for 'flotation first-stage desiliconization after coarse grinding and flotation second-stage desiliconization after regrinding rough concentrate' is utilized, so the influence of ore argillization phenomenon on desiliconization is greatly reduced, the flotation desiliconization effect on the high-silicon bauxite is obvious, the silicon dioxide content of the bauxite concentrate can be reduced greatly, the ratio of aluminum to silicon of the bauxite concentrate is increased, and the recovery rate is high.

Owner:山西道尔铝业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com