Method for recovering rutile

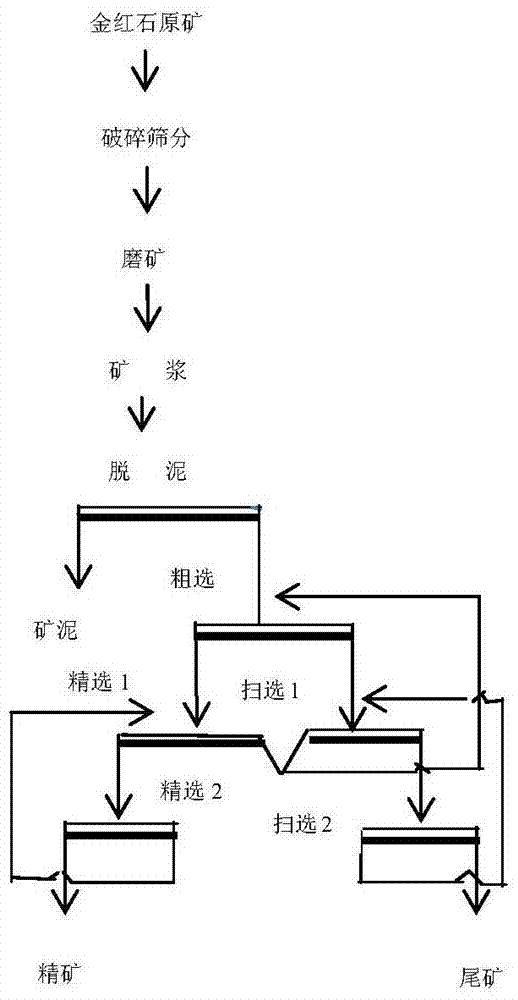

A technology of styrene phosphonic acid and lead nitrate, applied in the field of rutile recovery, can solve the problems of large loss of rutile, poor selectivity, complex process, etc., and achieve the effects of fast flotation rate, easy control and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A certain rutile in Jiangsu is used, the ore body is eclogite, and the whole rock is mineralized. The main constituent minerals are garnet, omphacite and a small amount of quartz, mica and other minerals. According to the nature of the ore, the mine is considered to be eclogite type rutile ore. The main titanium-containing minerals in the ore are rutile and a small amount of ilmenite. Microscopic observation shows that the rutile in the ore is mainly disseminated. Rutile is mostly allomorphic granular or semi-euhedral granular crystal form. Most of the rutile in the ore is distributed among mineral particles such as garnet and omphacite, and part of it is wrapped by minerals such as garnet, which has a certain impact on the recovery of rutile. The particle size of rutile in the ore is relatively coarse, and some rutile and ilmenite are closely symbiotic. MLA analysis results show that -0.074mm accounts for 30% of the original ore, and the dissociation degree of ruti...

Embodiment 2

[0027] A rutile mine in Hubei is used. The rutile ore is green-black, dense and hard, and has a flaky structure with gray stripes (bands). Titanium minerals include rutile, ilmenite and titanite, and gangue minerals include white (sericic) mica. , oblique zoisite-epidedite, calcite, chlorite and pyrite, among which the useful minerals are rutile and garnet.

[0028] The ore sample is ground to a content of -0.074mm of 60%. Flotation is carried out after sedimentation desliming. Rough selection: 700g / t of lead nitrate, 1300g / t of sodium fluorosilicate, 500g / t of water glass, 700g / t of styrene phosphonic acid, 300g / t of n-octanol, rough selection after pulping. The rough selection scraping time is 90 seconds. Sweeping 1: lead nitrate 500g / t, styrene phosphonic acid 300g / t, n-octanol 200g / t. Sweep 2: lead nitrate 300g / t, sodium fluorosilicate 300g / t, styrene phosphonic acid 200g / t, n-octanol 150g / t; selection 1: sodium fluorosilicate 400g / t, styrene phosphonic acid 200g / t. ...

Embodiment 3

[0030]A complex low-grade rutile mine in Shaanxi is used. The useful minerals of this mine are mainly rutile, other main metal minerals include pyrrhotite and pyrite, and a small amount of siderite and monazite; gangue minerals include quartz and chlorite Stone, iron dolomite, feldspar, muscovite, followed by a small amount of apatite, sphene, biotite, hornblende, barite, etc.

[0031] The embedded particle size of rutile in the ore is relatively fine, which belongs to the ore with evenly distributed fine particles, and the particle size is roughly between 0.01-0.3mm. shape, rutile and gangue minerals are closely embedded, and more than 85% are embedded in gangue minerals such as chlorite. The ore sample is ground to a content of -0.074mm of 60%. Flotation is carried out after desliming by sedimentation desliming method. Rough selection: 500g / t of lead nitrate, 1000g / t of sodium fluorosilicate, 300g / t of water glass, 500g / t of styrene phosphonic acid, 200g / t of n-octanol, ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com