A collophosite reverse flotation collector and its preparation method and application method

A collector and reverse flotation technology, applied in flotation, solid separation, etc., can solve problems such as difficult to meet the use requirements, large amount of collector used, poor low-temperature flotation effect, etc., to achieve good collection effect, The effect of stable flotation index and less chemical usage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

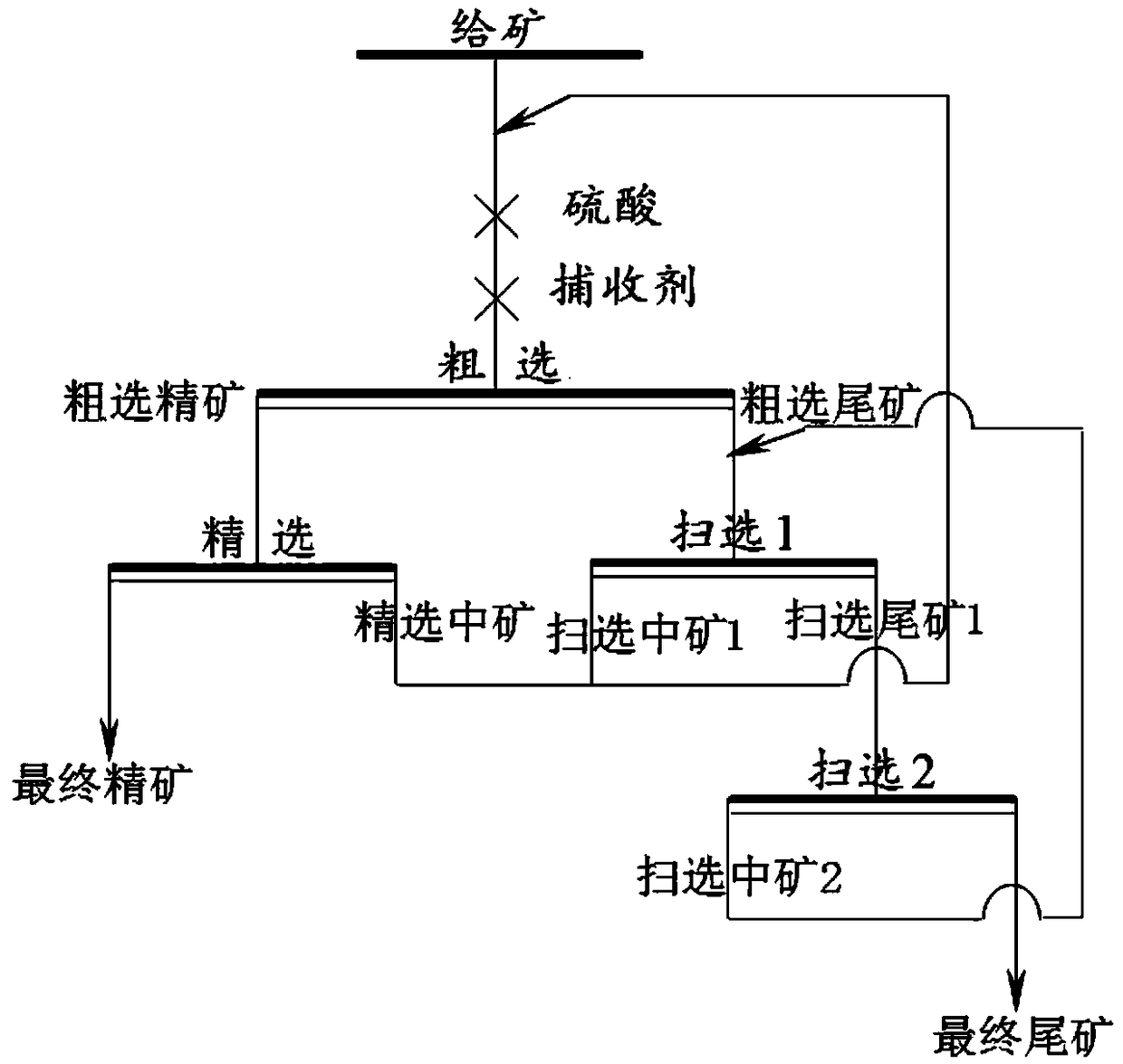

Method used

Image

Examples

preparation example Construction

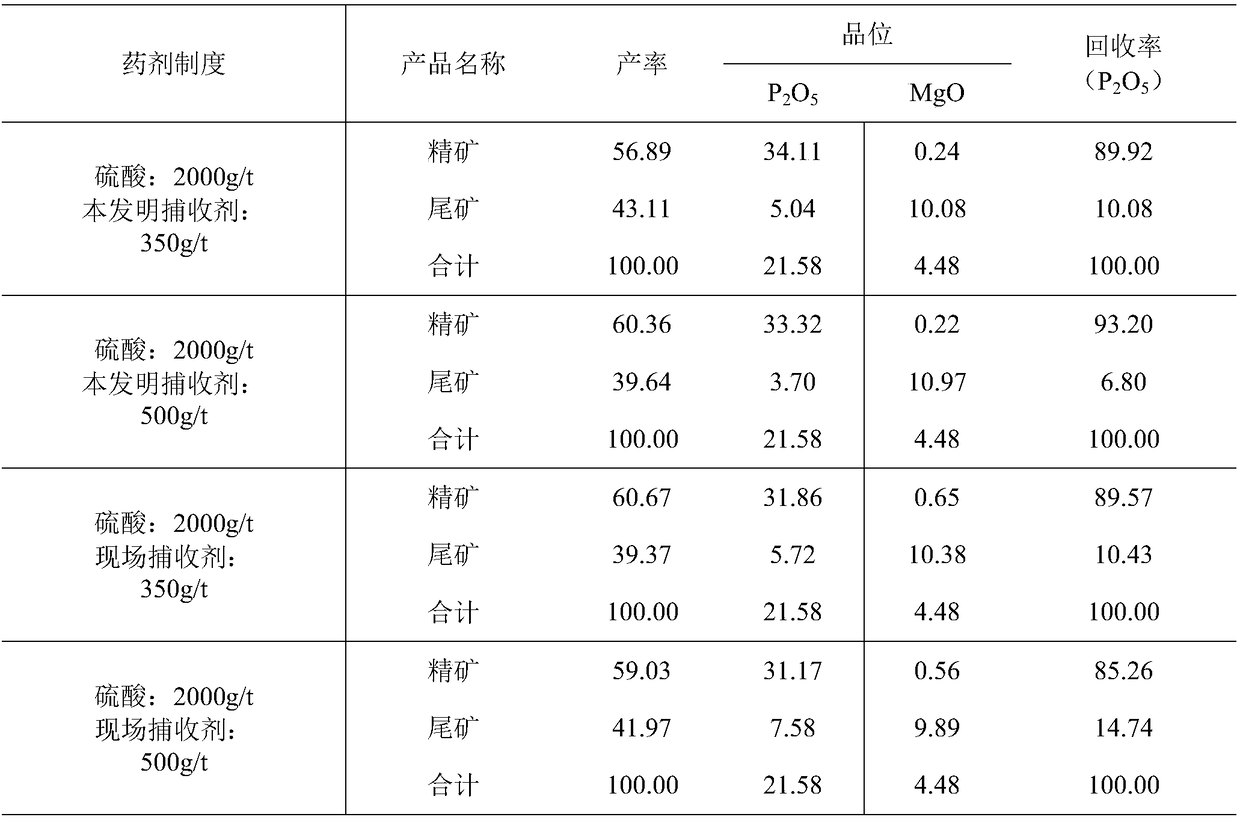

[0048] In view of the above problems existing in the existing collectors, the inventors optimized the design of the reaction raw materials and their proportions and reaction process parameters through a large number of experimental studies. High-efficiency separation of limestone and carbonate minerals, and the collector has good mud resistance, strong foaming ability, strong collection ability, strong adaptability, low synthesis cost, etc., high and stable flotation index, and at the same time Its preparation process is simple, low in cost and non-toxic. Using the collector obtained in the present invention in combination with an anionic surfactant or a nonionic surfactant greatly improves the low temperature resistance of the collector, and at the same time, the selectivity is also greatly improved. The preparation method of the high-calcium (magnesium) quality collophosphate reverse flotation collector of the present invention specifically comprises the following steps:

...

Embodiment 1

[0064] The preparation method of a kind of collophanite reverse flotation collector of the present embodiment comprises the following steps:

[0065] (1) Mix the extracted oil of decompressed pentanophenol with gasoline at a mass ratio of 1:2 and place it in a reactor, stir and heat at 25°C, and then add fuming sulfuric acid into the reactor for sulfonation agent for sulfonation, SO in the oleum used 3 The mass fraction is 15wt%, the sulfonation temperature is 50°C, and the sulfonation time is 1h to obtain a sulfonated product with an oil content of 57wt%.

[0066] (2) The obtained sulfonated product is stirred and washed with water and left to stand for stratification, and the organic layer is saponified using NaOH solution as a saponification agent to obtain a sulfonate, the mass ratio of the organic layer to the NaOH solution is 4:2, and Saponification pH=8.

[0067] (3) The obtained sulfonate and soybean oleic acid are compounded into a mixture at a mass ratio of 10:1, a...

Embodiment 2

[0078] The preparation method of a kind of collophanite reverse flotation collector of the present embodiment comprises the following steps:

[0079] (1) Mix the extracted oil of decompressed pentanophenol with gasoline at a mass ratio of 4:1 and place in a reactor, stir and heat at 20°C, and then add fuming sulfuric acid into the reactor for sulfonation agent for sulfonation, SO in the oleum used 3 The mass fraction is 25wt%, the sulfonation temperature is 65°C, and the sulfonation time is 2h to obtain a sulfonated product with an oil content of 55wt%.

[0080] (2) The obtained sulfonated product is stirred and washed with water and allowed to stand for stratification, and the organic layer is saponified using NaOH solution as a saponification agent to obtain a sulfonate, and the mass ratio of the organic layer to the NaOH solution is 10:1, and Saponification pH=11.

[0081] (3) Compound the obtained sulfonate and soybean oleic acid in a mass ratio of 4:1 to form a mixture,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com