Mud resistant type water reducing agent and preparation method therefor

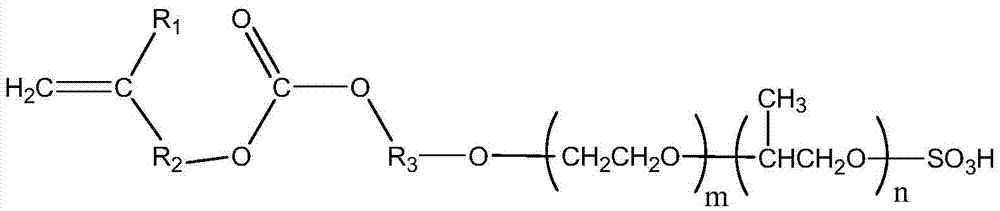

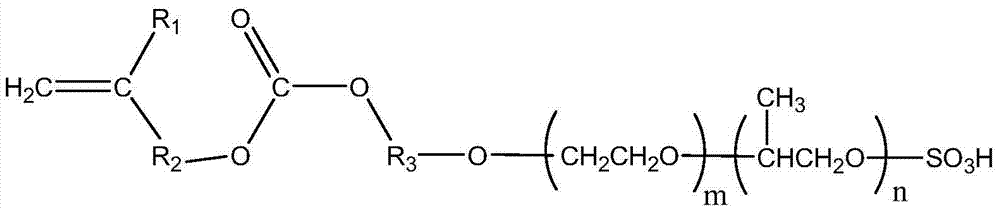

A water-reducing agent and anti-mud type technology, which is applied in the field of anti-mud-type water reducing agent and its preparation, can solve the problems of high price of cationic monomer, influence on the performance of water reducing agent, and increasing the comprehensive cost of concrete admixtures, etc. The effect of using less monomer, increasing steric hindrance, and good mud resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

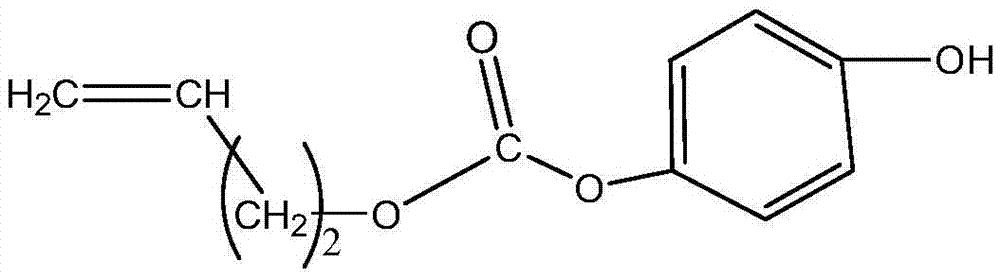

Embodiment 1

[0046] In the reaction kettle with negative pressure conditions, start stirring, add dimethyl carbonate and sulfuric acid, slowly raise the temperature to 80-90°C, and double drop 1-butenol and hydroquinone into the reaction kettle. Wherein, the feeding molar ratio of the three reactants is: dimethyl carbonate: 1-butenol: hydroquinone = 1: 1.5: 1.5, and the catalyst addition is 0.2% of the total feeding mass. As the reaction proceeds, the product methanol is continuously discharged from the system. When the methanol no longer flows out, the temperature is lowered for 20 minutes and the material is discharged. According to the difference in boiling point, the product is subjected to vacuum distillation to separate by-products to obtain the starting agent.

[0047] 207 g of starter and 1.0 g of KOH were added to the high pressure reactor. Seal the device and replace it with nitrogen 3 times. Start stirring, heat up, and when the temperature reaches 110°C, feed 10g of ethylene ...

Embodiment 2

[0053] In the reaction kettle with negative pressure conditions, start stirring, add dimethyl carbonate and sulfuric acid, slowly raise the temperature to 80-90°C, and double drop 1-butenol and hydroquinone into the reaction kettle. Wherein, the feeding molar ratio of the three reactants is: dimethyl carbonate: 1-butenol: hydroquinone = 1: 1.5: 1.5, and the catalyst addition is 0.2% of the total feeding mass. As the reaction proceeds, the product methanol is continuously discharged from the system. When the methanol no longer flows out, the temperature is lowered for 20 minutes and the material is discharged. According to the difference in boiling point, the product is subjected to vacuum distillation to separate by-products to obtain the starting agent.

[0054] 207 g of starter and 1.0 g of KOH were added to the high pressure reactor. Seal the device and replace it with nitrogen 3 times. Start stirring, heat up, and when the temperature reaches 110°C, feed 10g of ethylene ...

Embodiment 3

[0060] In a reaction kettle with negative pressure conditions, start stirring, add dimethyl carbonate and sulfuric acid, slowly raise the temperature to 80-90°C, and double drop 2-methyl-heptenol and p-hydroxybenzyl alcohol into the reaction kettle. Wherein, the molar ratio of the three reactants is: dimethyl carbonate: 2-methyl-heptenol: p-hydroxybenzyl alcohol = 1:1.5:1.5, and the catalyst addition is 0.2% of the total mass of the feed. As the reaction proceeds, the product methanol is continuously discharged from the system. When the methanol no longer flows out, the temperature is lowered for 20 minutes and the material is discharged. According to the difference in boiling point, the product is subjected to vacuum distillation to separate by-products to obtain the starting agent.

[0061] 277 g of starter and 1.0 g of KOH were added to the high pressure reactor. Seal the device and replace it with nitrogen 3 times. Start stirring, heat up, and when the temperature reache...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com