Polycarboxylate mother liquor with high water-reducing, slump-retaining and sludge-resisting properties and manufacturing method thereof

A polycarboxylic acid and three-high technology, applied in the field of building materials and cement additives, can solve the problems of incompatibility at the same time, and achieve the effects of long-distance transportation and pumping construction, low process cost, and low preparation process cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

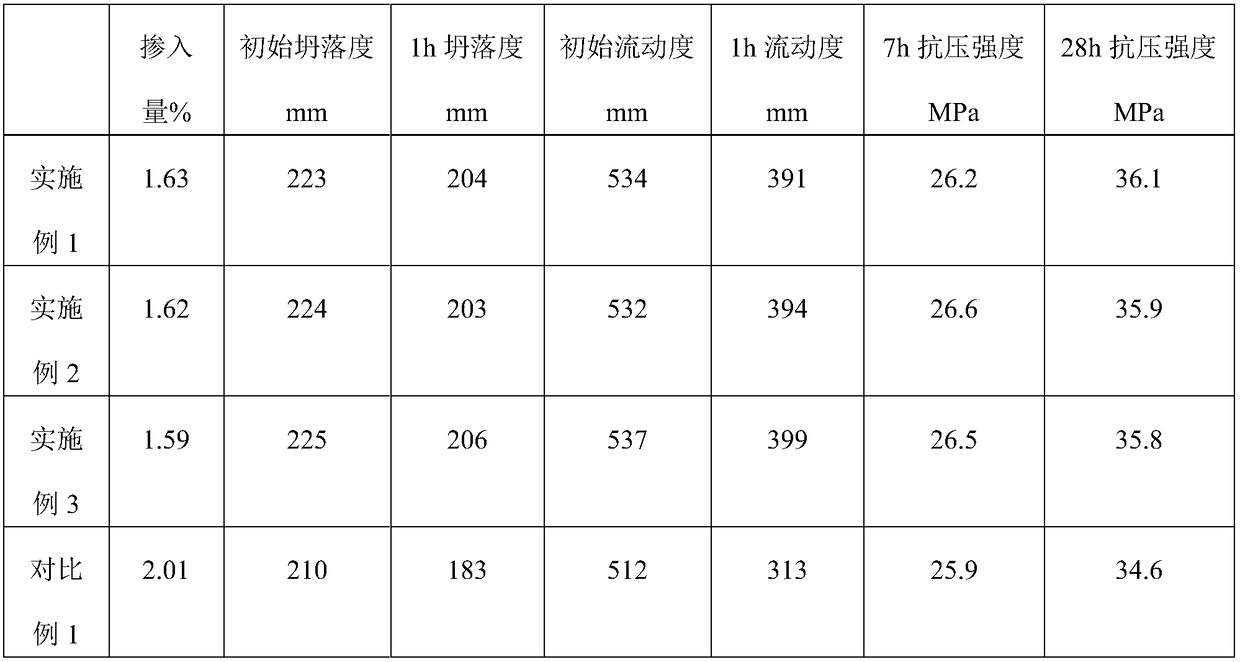

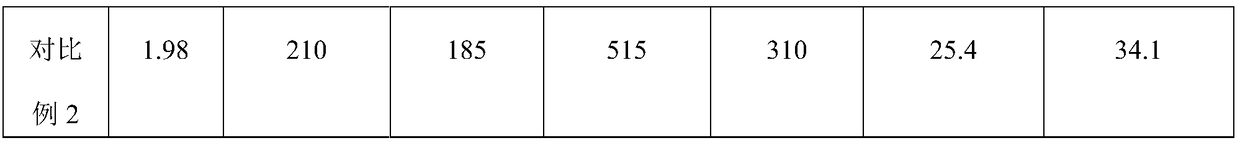

Embodiment 1

[0028] According to the formula of polycarboxylate three-high mother liquor, including 34 parts of methallyl polyoxyethylene ether, 4 parts of acrylic acid, 0.55 parts of sodium hypophosphite, 0.25 parts of 30% hydrogen peroxide, 0.15 parts of ammonium persulfate, 0.14 parts of vitamin C, 61.6 parts of deionized water. Mix water and polyether superplasticizer macromonomer evenly; heat up the base material; put hydrogen peroxide into the base material, put sodium phosphate and ammonium persulfate into the base material again, add acrylic acid and vitamin C to dissolve in water respectively to obtain dripping material ; drop the dripping material into the heated bottom material respectively, carry out the heat preservation reaction, add water and dilute to obtain the polycarboxylic acid mother liquor, and store it further.

Embodiment 2

[0030] According to the formula of polycarboxylate three-high mother liquor, including 31 parts of methallyl polyoxyethylene ether, 4.8 parts of acrylic acid, 0.6 parts of sodium hypophosphite, 0.4 parts of 30% hydrogen peroxide, 0.1 parts of ammonium persulfate, 0.15 parts of vitamin C, 61 parts of deionized water. Mix water and polyether superplasticizer macromonomer evenly; heat up the base material; put hydrogen peroxide into the base material, put sodium phosphate and ammonium persulfate into the base material again, add acrylic acid and vitamin C to dissolve in water respectively to obtain dripping material ; drop the dripping material into the heated bottom material respectively, carry out the heat preservation reaction, add water and dilute to obtain the polycarboxylic acid mother liquor, and store it further.

Embodiment 3

[0032] According to the formula of polycarboxylate three-high mother liquor, including 33 parts of methallyl polyoxyethylene ether, 4.5 parts of acrylic acid, 0.6 parts of sodium hypophosphite, 0.3 parts of 30% hydrogen peroxide, 0.2 parts of ammonium persulfate, 0.12 parts of vitamin C, 61.28 parts of deionized water. Mix water and polyether superplasticizer macromonomer evenly; heat up the base material; put hydrogen peroxide into the base material, put sodium phosphate and ammonium persulfate into the base material again, add acrylic acid and vitamin C to dissolve in water respectively to obtain dripping material ; drop the dripping material into the heated bottom material respectively, carry out the heat preservation reaction, add water and dilute to obtain the polycarboxylic acid mother liquor, and store it further.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com