Positive flotation method for bauxite

A technology of positive flotation and bauxite, applied in flotation, solid separation, etc., can solve the index deterioration of fine tailings yield and recovery rate in flotation system, reduce the processing capacity of flotation single equipment, flotation system Reduced processing capacity and other issues, to achieve the effects of easy promotion, improved flotation index, and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

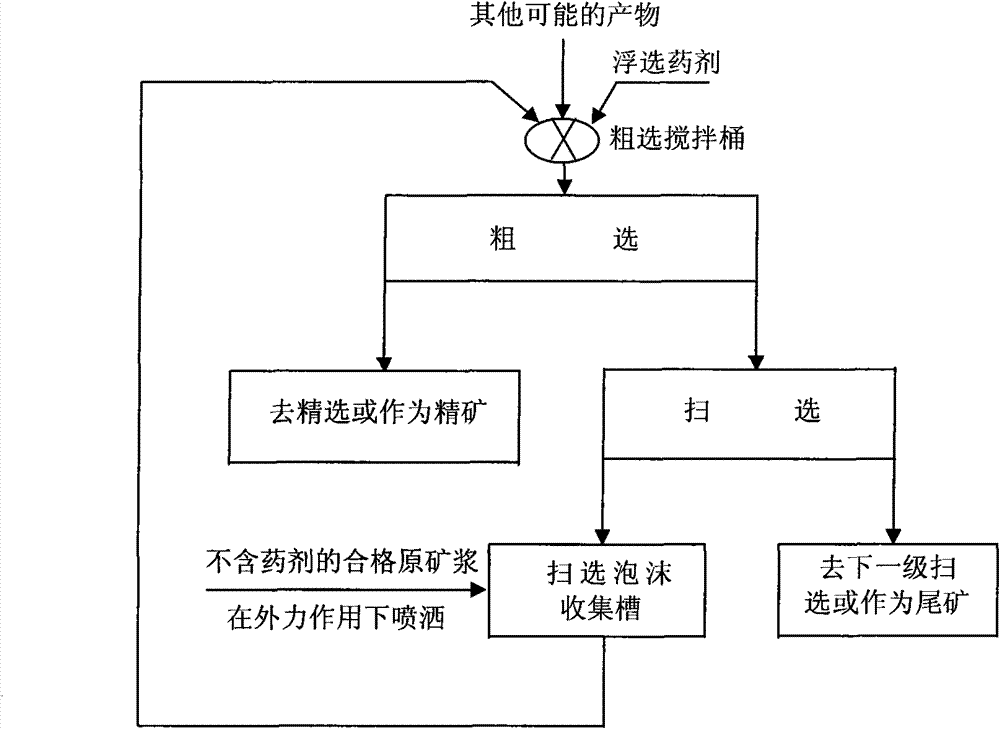

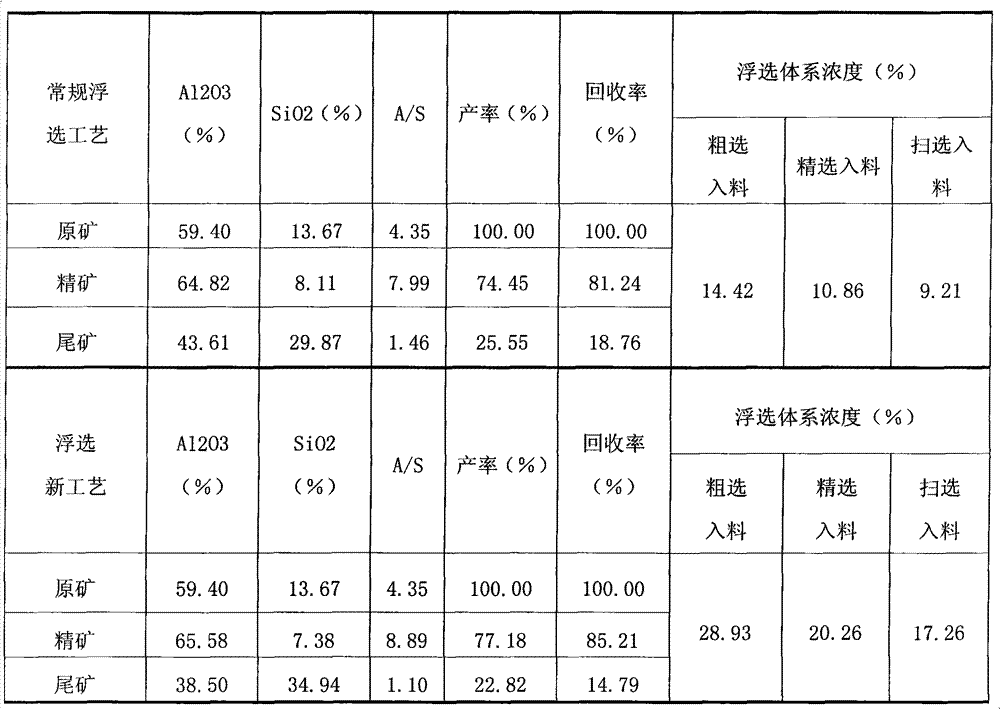

[0011] Taking Henan bauxite as the test ore sample, the raw ore Al2O3 is 59.40%, SiO2 is 13.67%, the aluminum-silicon ratio is 4.35, and the concentration of the raw ore pulp is 40.17%. The principle process flow chart adopted is shown in the attachment figure 1 , the specific flotation process is as follows:

[0012] Low-grade bauxite in Henan with a processing capacity of 1.7t / h After grinding in the ball mill and grading by the spiral classifier, the qualified raw ore pulp obtained is first transported under a certain external force and sprayed to the scavenging foam collection tank, after the scavenging foam is completely washed away, it is transported through the scavenging foam The tube returns to the coarser mixing drum. In the roughing mixing tank, it directly enters the roughing operation after interacting with flotation agents (pH value adjusters, dispersants, collectors, inhibitors) and other products of the flotation operation. After the beneficiation operation,...

Embodiment 2

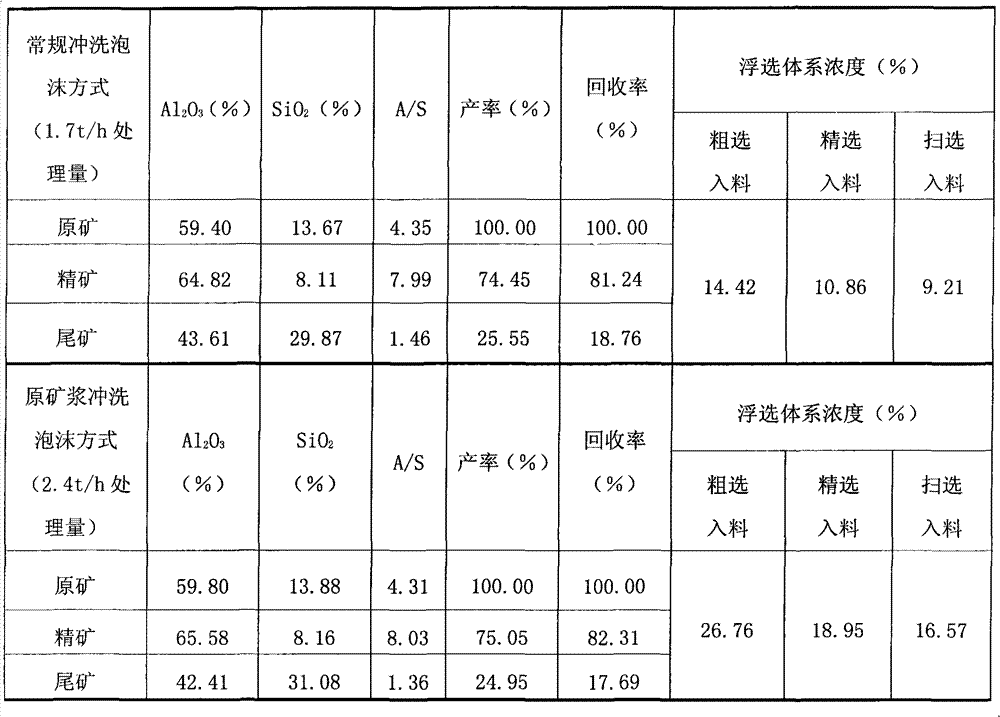

[0017] Taking Henan bauxite as the test ore sample, the raw ore Al2O3 is 59.80%, SiO2 is 13.88%, the aluminum-silicon ratio is 4.31, and the concentration of the raw ore pulp is 42.34%. The principle process flow chart adopted is shown in the attachment figure 1 , the specific flotation process is as follows:

[0018] Low-grade bauxite in Henan with a processing capacity of 2.4t / h After grinding in the ball mill and grading by hydrocyclone, the qualified raw ore slurry obtained is first transported and sprayed to the scavenging foam collection tank under a certain external force, and after the scavenging foam is completely washed away, it passes through the scavenging foam The transfer pipe returns to the coarser mixing drum. In the roughing mixing tank, it directly enters the roughing operation after interacting with flotation agents (pH value adjusters, dispersants, collectors, inhibitors) and other products of the flotation operation. After the beneficiation operation, i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com