A kind of high calcium scheelite flotation collector and its preparation method and application method

A collector, scheelite technology, applied in flotation, solid separation and other directions, can solve the problem that the separation effect of high calcium scheelite is difficult to meet production needs, and achieve stable flotation index, high concentrate grade and high efficiency separation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

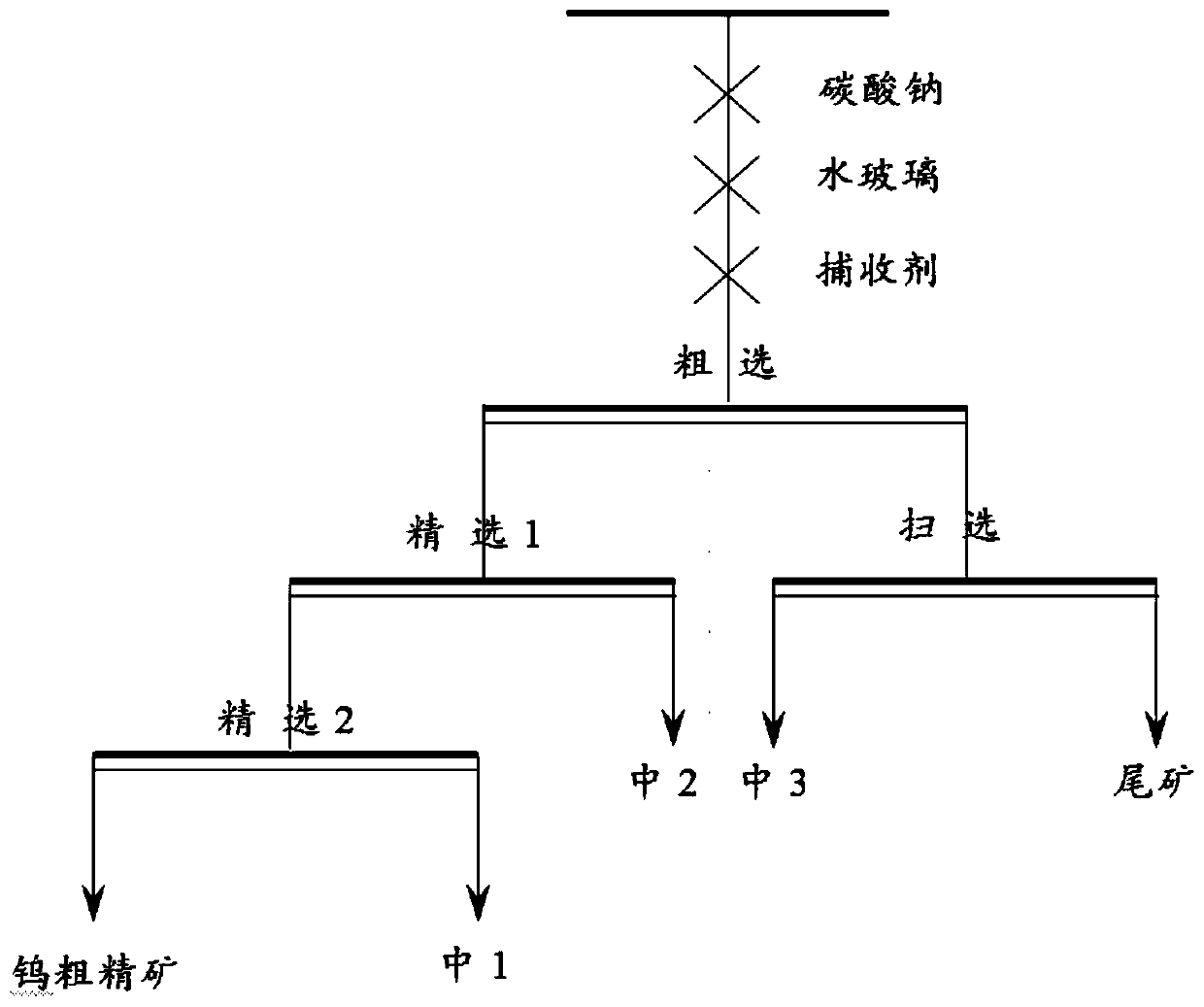

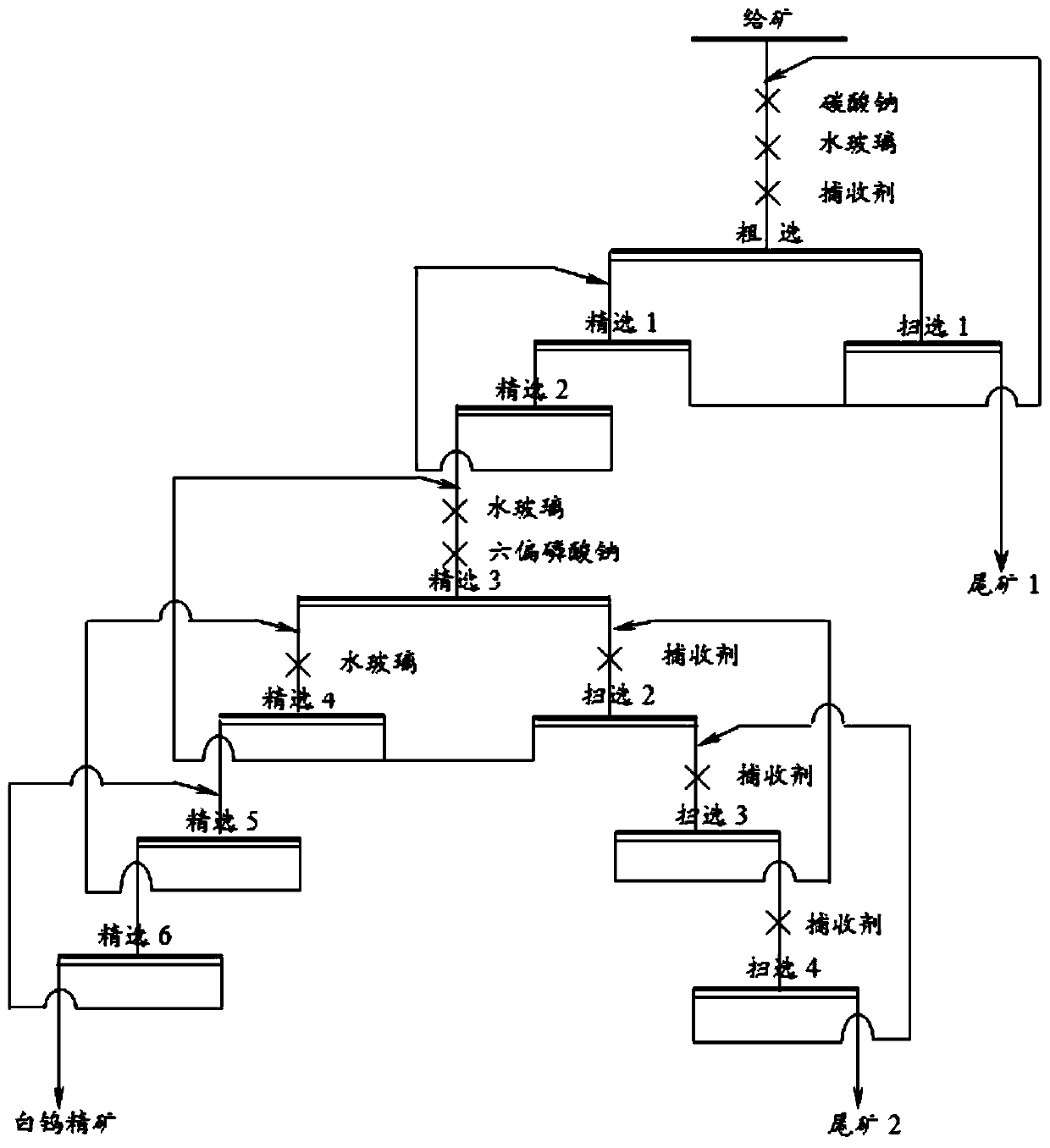

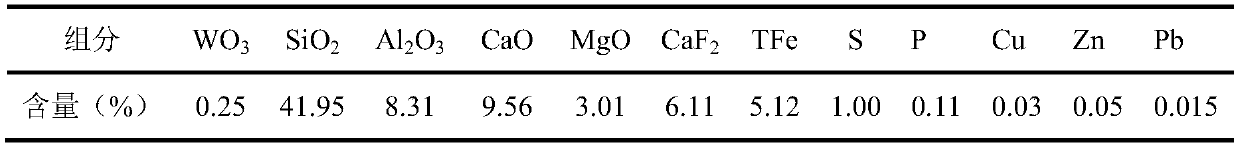

Method used

Image

Examples

preparation example Construction

[0053] The preparation method of a kind of high-calcium scheelite flotation collector of the present invention is to react with oil bottoms, hydroxylamine hydrochloride, sodium hydroxide, sulfuric acid, etc. in the coconut oil refining process, and react with soybean oleic acid After compounding, the collector is treated with saponification, the preparation process is simple, and the obtained collector abandons the shortcomings of the existing scheelite flotation collector, the product performance is stable, and the collection capacity of scheelite is remarkable enhanced. The concrete steps of this preparation method are as follows:

[0054] (1) add the hydroxylamine hydrochloride aqueous solution to the oil bottom in the coconut oil refining process, then add dropwise sodium hydroxide solution to react, the mol ratio n of each material 1 (oil foot): n 2 (Hydroxylamine hydrochloride): n 3 (NaOH) is (1-3): (0.8-2.2): (1.5-3.5), the main components of the used oil bottoms are...

Embodiment 1

[0074]A kind of preparation method of high calcium scheelite flotation collector of the present embodiment, its steps are as follows:

[0075] (1) adding mass concentration to the oil foot in the coconut oil refining process is the hydroxylamine hydrochloride aqueous solution of 10%, and the rear dripping mass concentration is that the sodium hydroxide solution of 50wt% reacts, and the mol ratio of each reactant is n 1 (oil foot): n 2 (Hydroxylamine hydrochloride): n 3 (NaOH) is 1: 2.2: 3.5, and the main components of the oil foot used in the present embodiment are medium-chain fatty acid caprylic acid and capric acid, and calculate the average oil foot mole number with the molecular weight of the capric acid fat in the oil foot, control simultaneously The reaction temperature is 50° C., and the reaction time is 4 hours. After the reaction, acidification treatment is carried out with a sulfuric acid solution with a mass fraction of 5 wt %. The pH of the acidification end poin...

Embodiment 2

[0099] A kind of preparation method of high calcium scheelite flotation collector of the present embodiment, its steps are as follows:

[0100] (1) the oil bottom in the coconut oil refining process is added the hydroxylamine hydrochloride aqueous solution that mass concentration is 15wt%, and the sodium hydroxide solution that rear drop mass concentration is 30wt% reacts, and the mol ratio n of each reactant 1 (oil foot): n 2 (Hydroxylamine hydrochloride): n 3 (NaOH) is 3: 0.8: 1.5, and the main component of used oil foot in the present embodiment is medium-chain fatty acid octanoic acid and capric acid, and calculates average oil foot molar number with the molecular weight of capric acid fat in oil foot, controls simultaneously The reaction temperature is 40° C., and the reaction time is 6 hours. After the reaction, a sulfuric acid solution with a mass fraction of 15 wt % is used for acidification treatment, and the pH of the acidification end point is 4. Then, coconut oil ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com