Flotation feed desliming pool

A desliming tank and flotation technology, applied in the direction of settling tanks, etc., can solve the problems of increased ash content, polluted clean coal, and fast flotation speed of fine mud, so as to reduce the ash content of flotation clean coal, reduce the degree of interference, and improve the flotation rate. The effect of choosing indicators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] The present invention will be further described below in conjunction with the accompanying drawings.

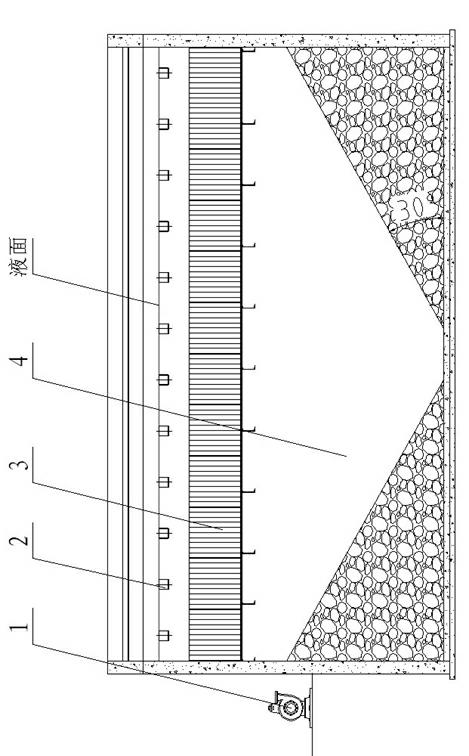

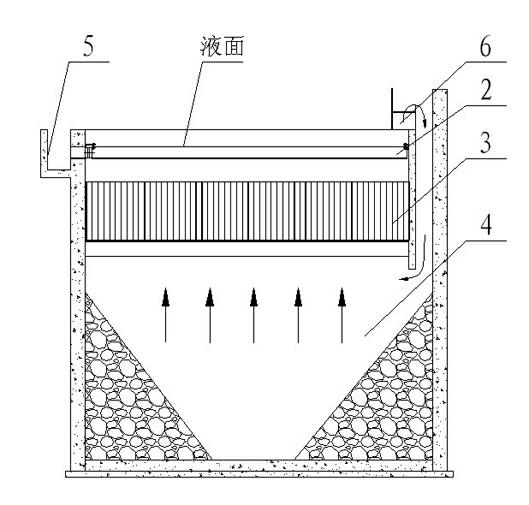

[0056] See attached Figure 1-6 , the flotation feeding and desliming tank disclosed in the present invention includes a feeding pipe, a flotation feeding pump 1, and a feeding distribution tank 6, an overflow Launder 2 and rectification area 3.

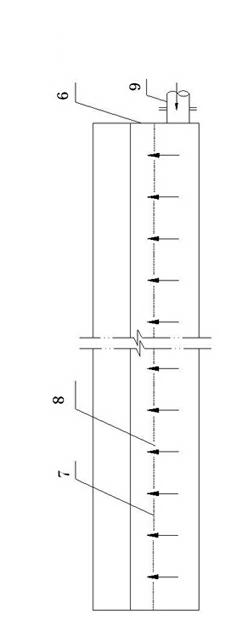

[0057] The feeding distribution tank 6 is arranged on the upper part of the desilting tank and is connected with the feeding pipe 9. The top of the feeding distribution tank 6 is open, and a transverse partition 7 is arranged in its middle, and a plurality of Through hole 8. The two side plates of the feed distribution tank 6 are one low and the other high, the high side plate is located near the center of the desilting tank, and the low side plate is located near the wall of the desilting tank. The flotation feeding material is evenly fed along the length of the desilting tank to maintain a uniform upward water flow on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com