Flotation method for copper sulphide ore

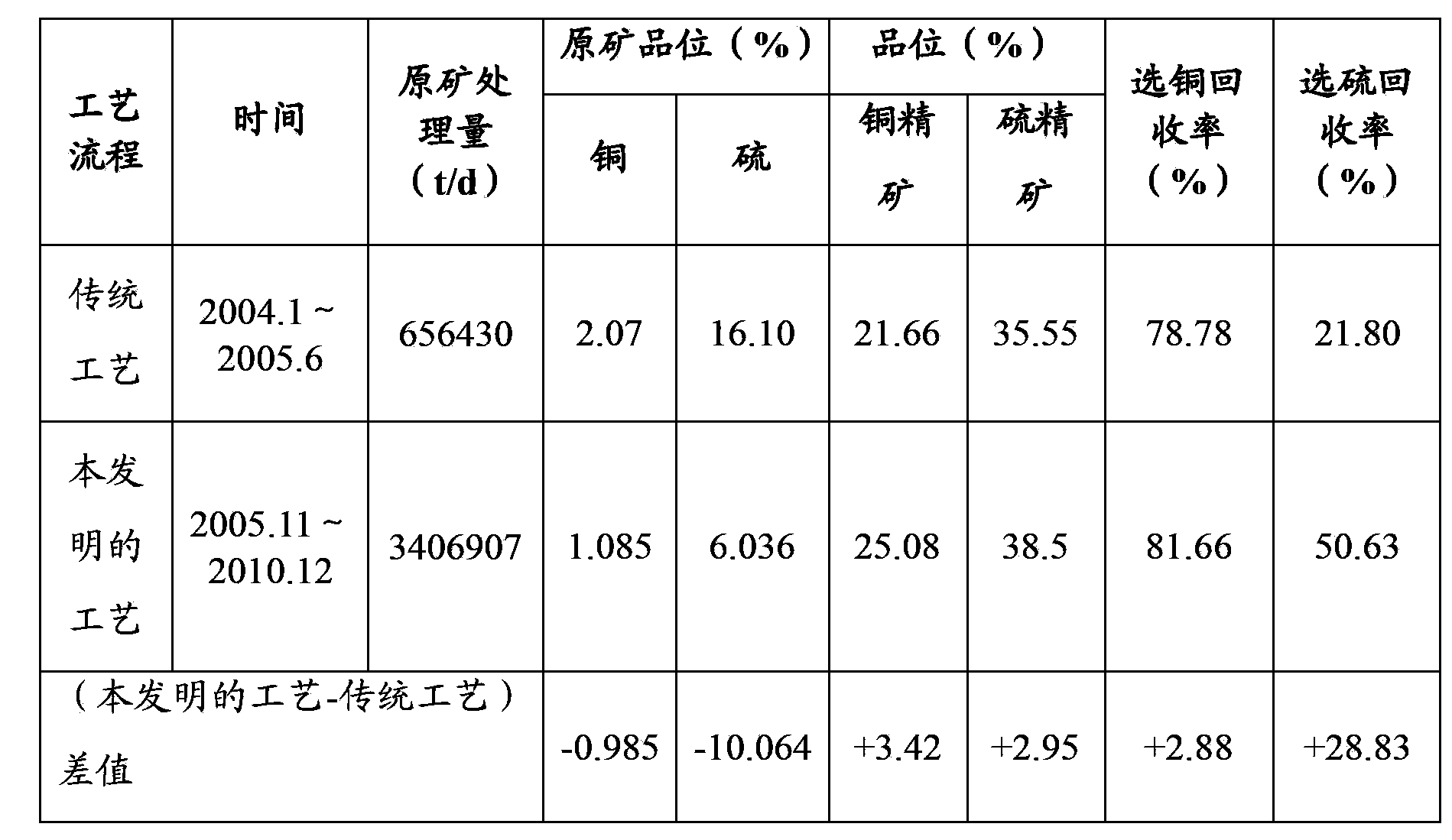

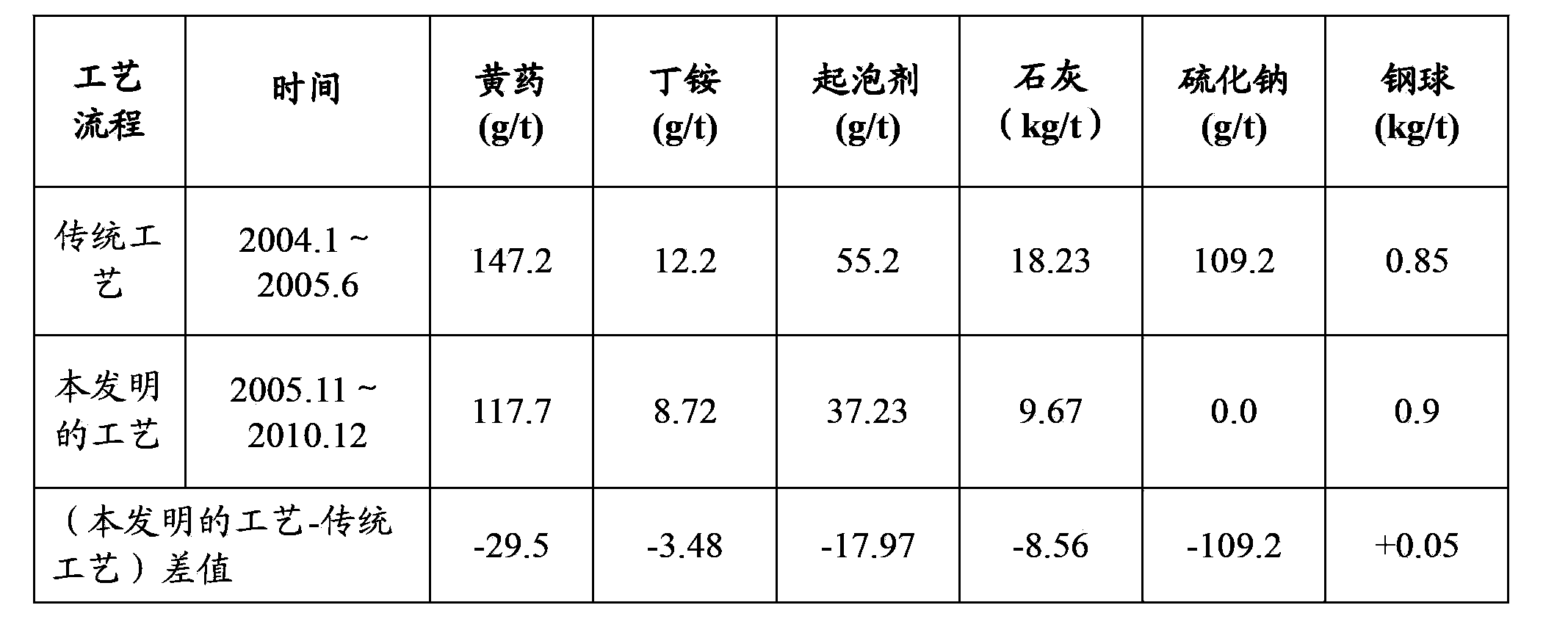

A copper sulfide and ore technology, applied in the metallurgical field, can solve the problems of only 34.20% recovery rate, clogging of tailings conveying pipe, low indicators and low efficiency, achieving strong guiding significance and reference value, reducing the amount of regrinding, economical Significant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

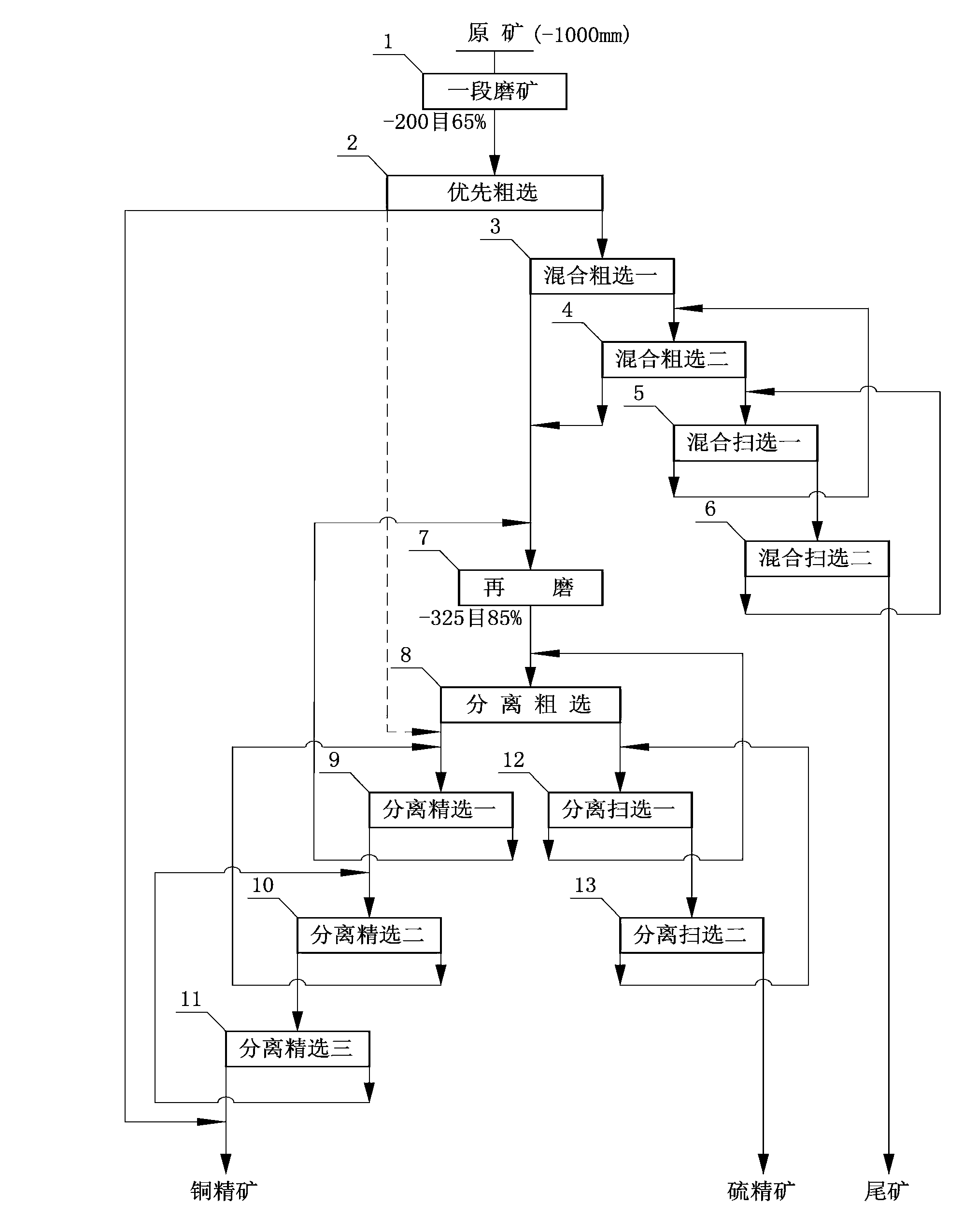

Method used

Image

Examples

Embodiment 1

[0032] (1) Utilize the flotation method of copper sulfide ore of the present invention (also referred to as technique of the present invention sometimes herein) to carry out copper sulfide ore flotation:

[0033] Firstly, the raw ore with a block size of less than 1000mm is transported from the mining field to the raw ore warehouse of the rough crushing workshop of the concentrator, and is crushed by a jaw crusher (PEJ-1215, NHI Group Co., Ltd.) to reduce the maximum block size to 350mm Next, use a wet semi-autogenous mill (φ6.4×3.3, NHI Group Co., Ltd.) and a wet overflow ball mill (φ4.8×7.0, NHI Group Co., Ltd.) to crush the coarsely crushed copper ore Grinding is carried out to prepare pulp.

[0034] Then use the cyclone group (FX660-GT×7, Weihai Haiwang Cyclone Co., Ltd.) to classify the pulp to obtain the overflow pulp with a concentration of 30% and a particle size of -200 mesh 65%. pH = 8) and add butyl ammonium black drug into the optimal roughing flotation machine (K...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com