Mineral processing process for recovering copper from copper smelting slag through flotation

A technology for copper smelting slag and copper recovery, applied in flotation, solid separation, etc., can solve the problems of large loss of copper minerals, waste of resources, unsatisfactory recovery indicators, etc., achieve good mineral processing indicators, avoid sliming, and save chemicals cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

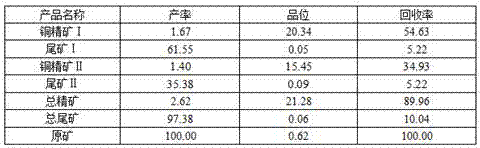

[0071] The copper content of copper slag in a smelter is 0.62%, which is slowly cooled slag.

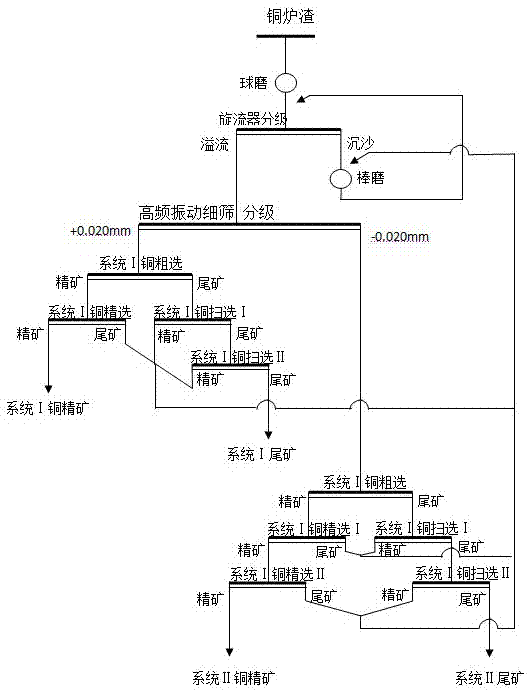

[0072] according to figure 1 As shown in the process flow, the copper slag is firstly ground, and the fineness of the ground product is -0.044mm, which accounts for 89%. System Ⅰ and system Ⅱ are processed separately to obtain copper concentrate Ⅰ and tailings Ⅰ, copper concentrate Ⅱ and tailings Ⅱ respectively. The copper concentrates are combined as the total copper concentrate, and the tailings are combined as the total tailings. The conditions are as follows:

[0073] System I:

[0074] Rough selection: collector butyl xanthate: 90g / t copper smelting slag, foaming agent 2 # Oil: 30g / t copper smelting slag, stirring for 2 minutes, flotation time: 6 minutes;

[0075] Selection: blank selection, flotation time 4min;

[0076] Sweeping Ⅰ: collector butyl xanthate: 30g / t copper smelting slag, foaming agent 2 # Oil: 5g / t copper smelting slag, stirring for 2min, flotation time: 3min...

Embodiment 2

[0088] The copper content of copper furnace slag in a smelter is 0.77%, which is water-quenched slag.

[0089] according to figure 1 In the process flow shown, the grinding fineness of the slag is -0.044mm, accounting for 84%, and the rest are the same as in Example 1. The closed circuit test indicators are shown in Table 2:

[0090] Table 2 Closed circuit test index / %

[0091]

Embodiment 3

[0093] The copper content of copper slag in a smelter is 0.89%, which is slow cooling slag.

[0094] according to figure 1 In the process flow shown, the grinding fineness of the slag is -0.044mm, accounting for 80%, and the rest are the same as in Example 1. The closed-circuit test indicators are shown in Table 3:

[0095] Table 3 Closed circuit test index / %

[0096]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com