Patents

Literature

66results about How to "Good beneficiation index" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

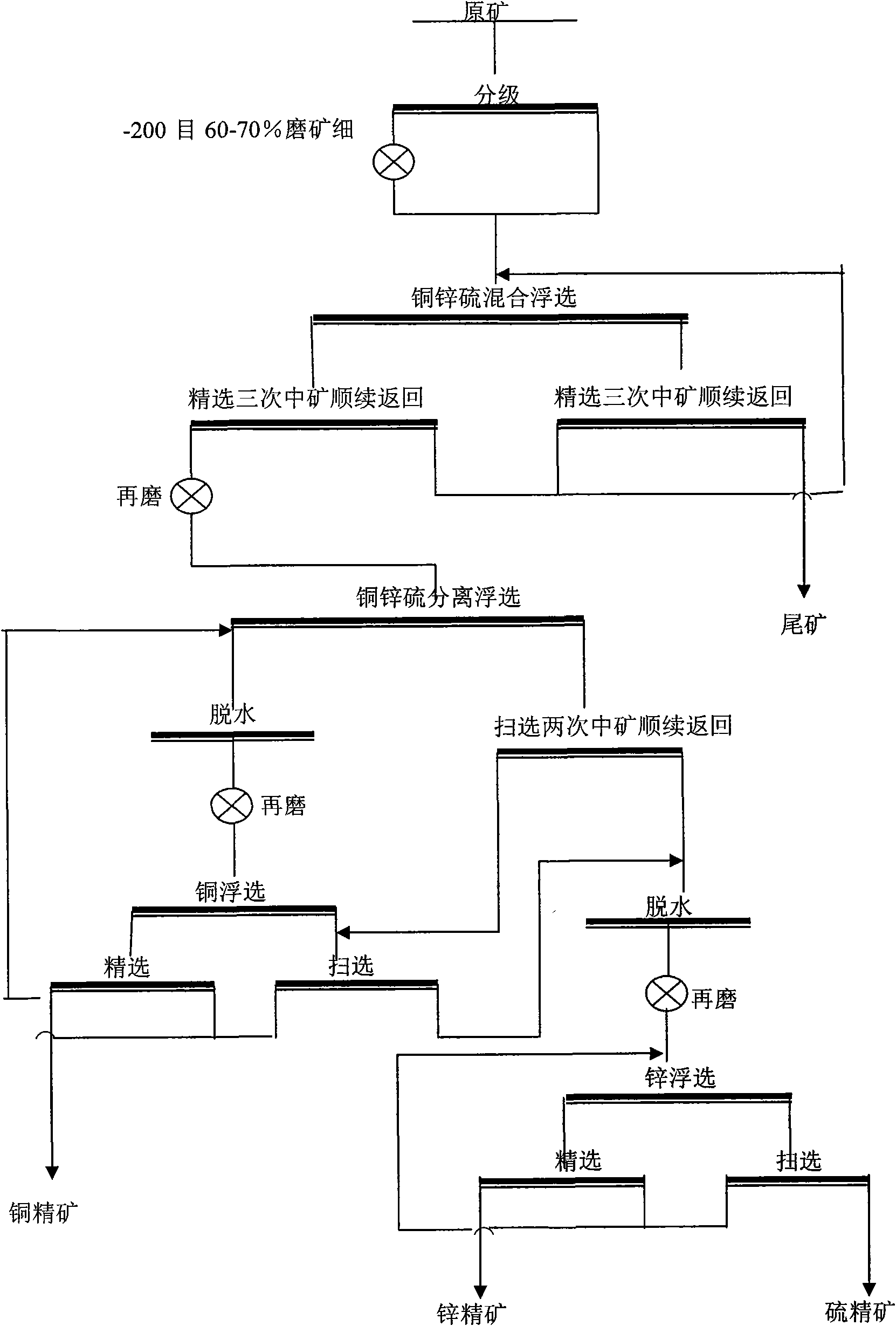

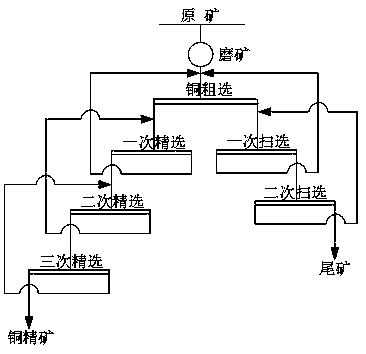

Ore-selecting method of difficultly-selected copper zinc sulphur ore

Owner:HUNAN RES INST FOR NONFERROUS METALS

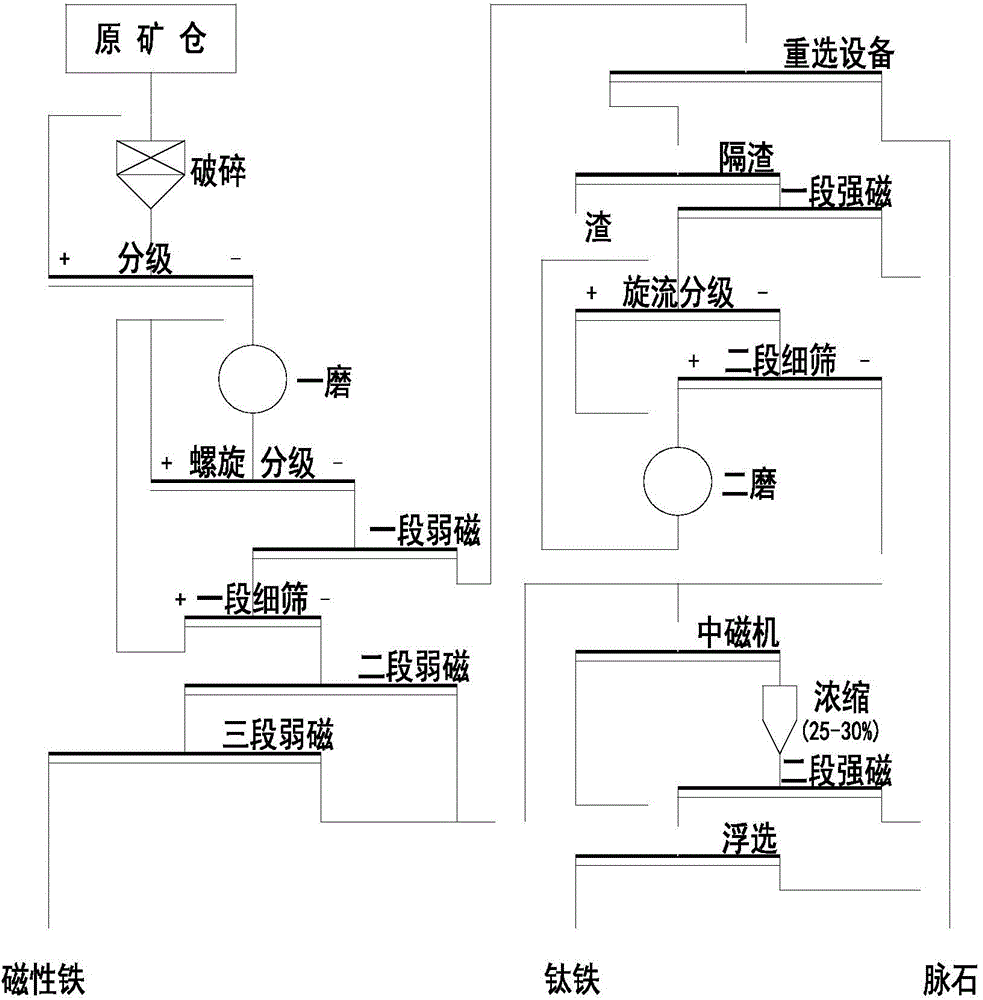

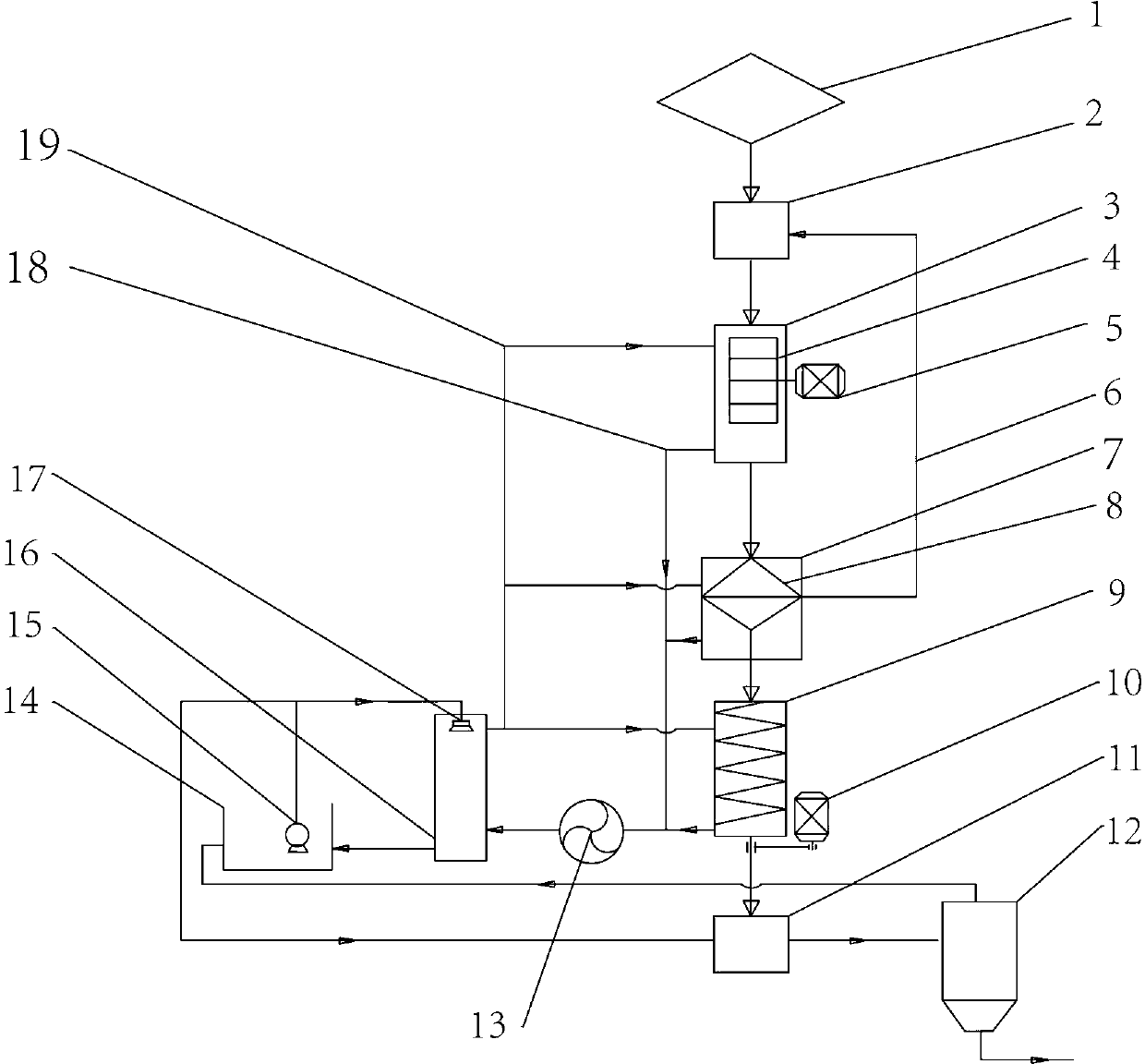

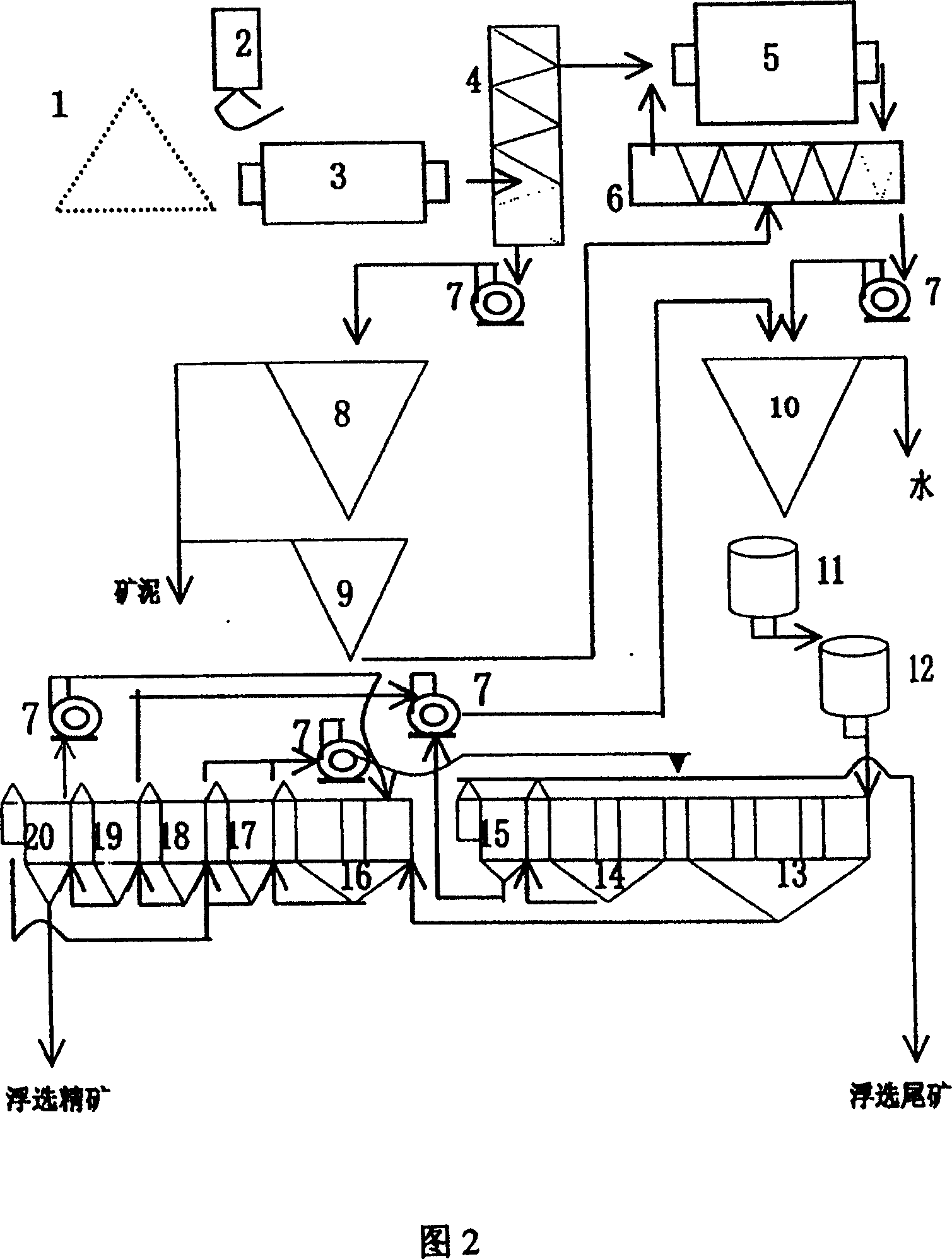

Ilmenite beneficiation method and equipment

InactiveCN104607296AGood beneficiation indexAlleviate the shortageGrain treatmentsWet separationIlmeniteEngineering

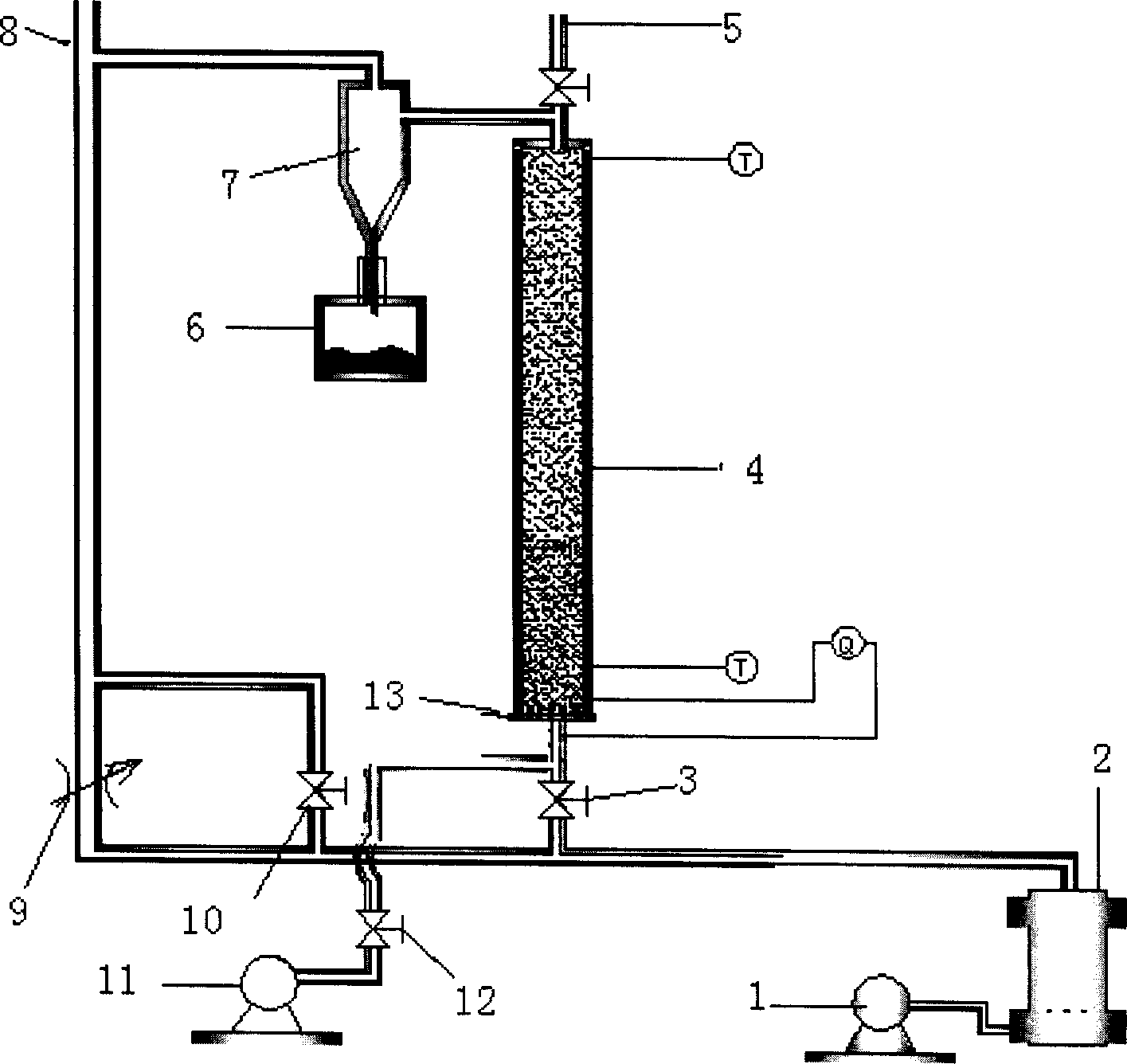

The invention provides an ilmenite beneficiation method and equipment, and is suitable for comprehensive utilization of low grade ilmenite resources. The method and the equipment provided by the invention can be used for separating materials by fully using three kinds of physical differences of useful components in ilmenite magnetic iron and ferrotitanium and useless gangues, such as magnetism, density and surface hydrophilicity, as well as the property of the stage degree of dissociation. In the whole separating process, by using a magnetic-gravity separation-flotation combined process, the magnetic iron which is the strongest in magnetism is separated by using a magnetic separating method firstly, and then the ferrotitanium is selected by using a method of gravity separation combined with strong magnetic combined flotation. In the whole separating process, a graded ore grinding and graded beneficiation method is adopted, and in the process of separating the ferrotitanium, ore is secondarily ground, so that the ferrotitanium containing part of impurities after strong magnetism in the first stage is further dissociated, and therefore, relatively good beneficiation indexes are obtained.

Owner:LONGI MAGNET CO LTD

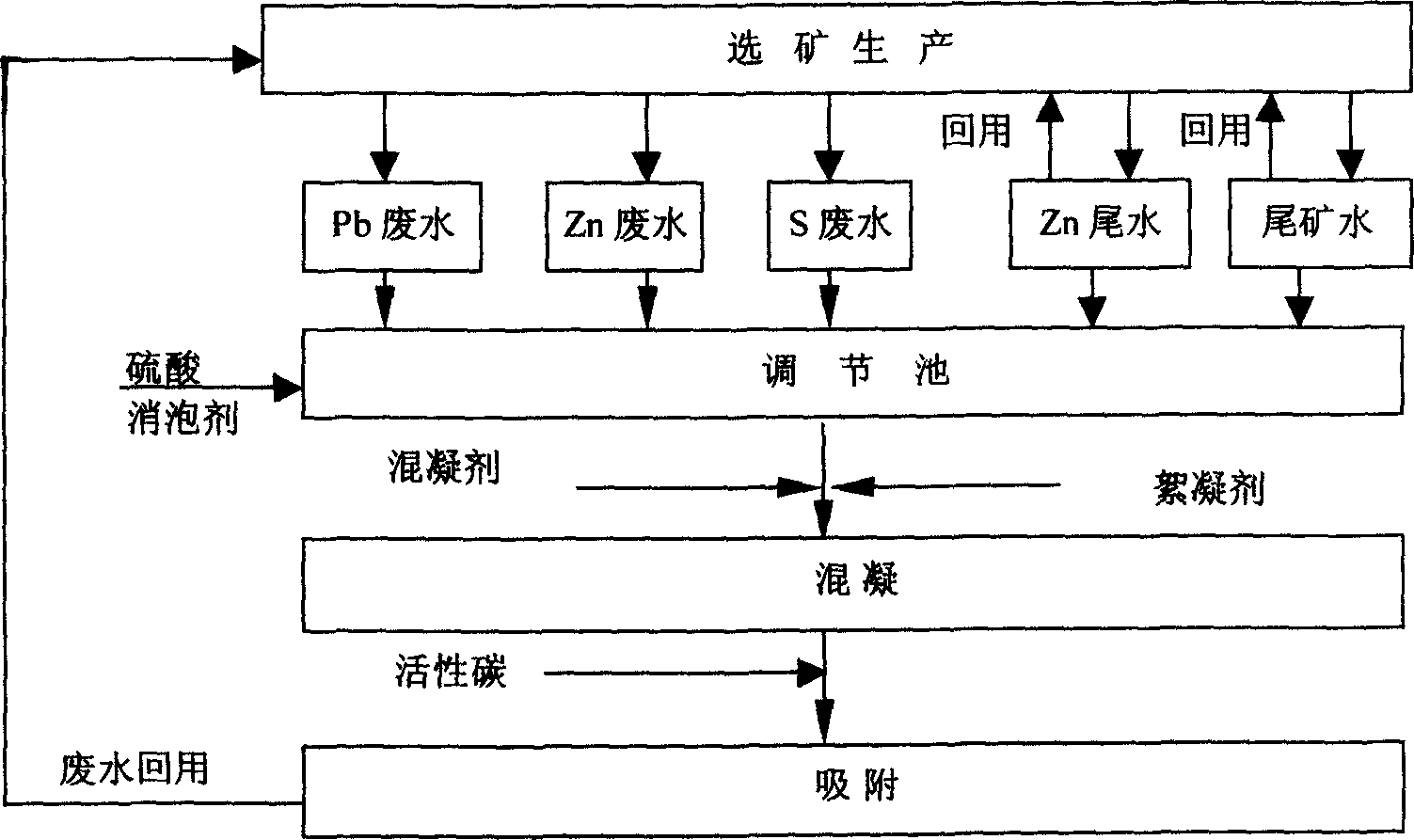

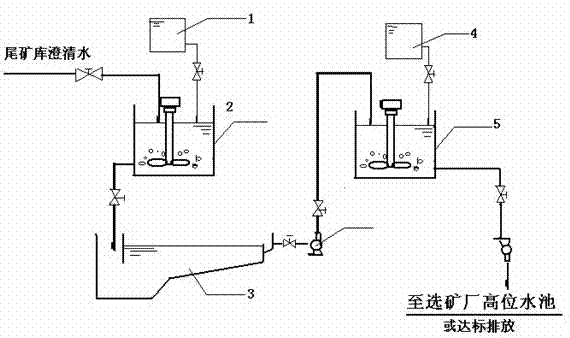

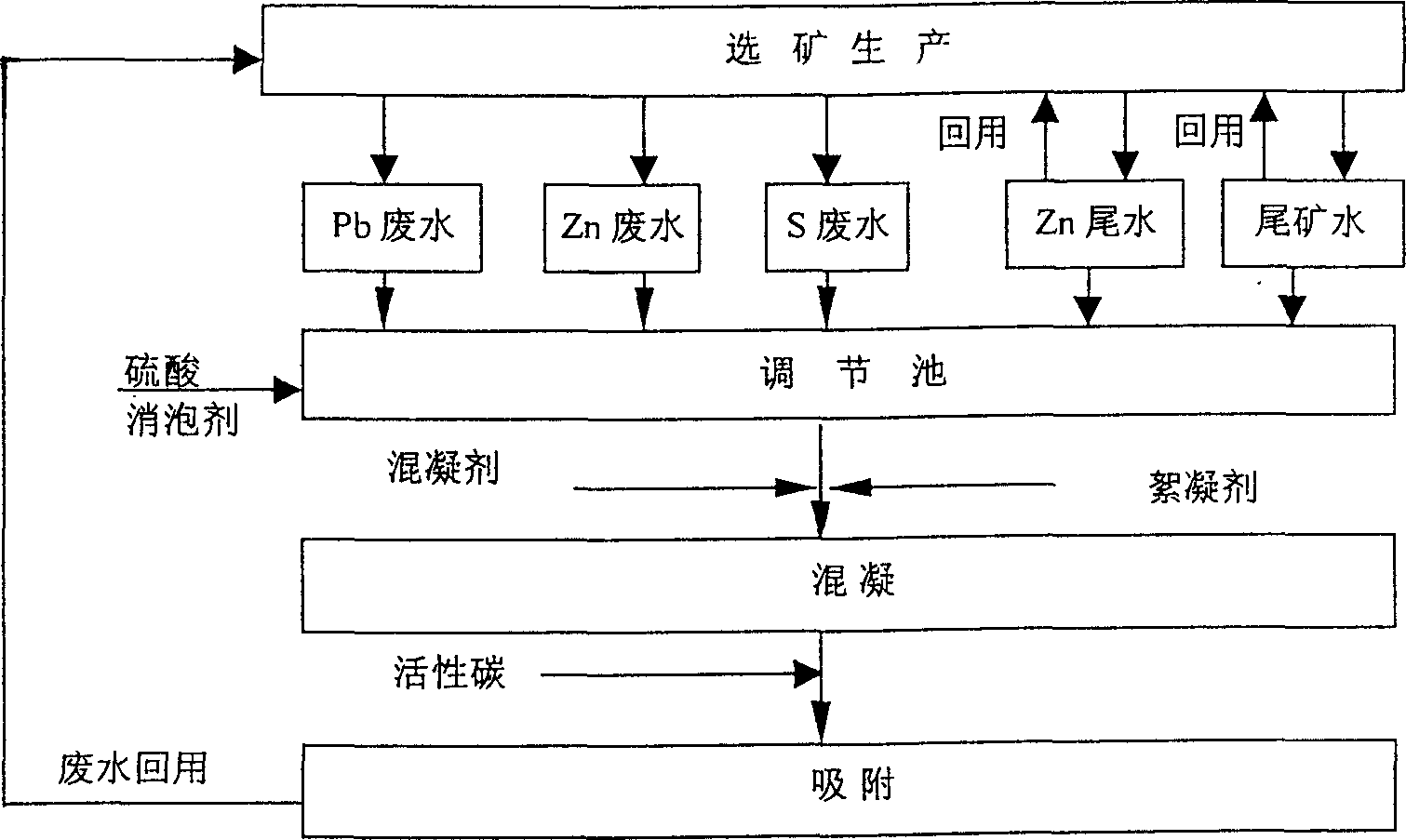

Method for cyclic utilizing mineral dressing waste water from sulphur ore of lead-zinc

InactiveCN1562794AEliminate the effects ofAvoid pollutionWater/sewage treatment by neutralisationWater/sewage treatment by flocculation/precipitationActivated carbonAluminium sulfate

The waste water circular utilization provided by this invention is to use mineral operation waste water for milling of ores prodn. zenc tail water can be direct reused to zenc selecting operation, flume water can be direct reused to sulphur selecting operation, mineral operation waste water can be reused for ore grinding, lead selecting and mineral operation after being processed suitably. Said processes include: to add sulphuric in mineral operation waste water to adjust pH value to 8-11, add flocculator and aluminum suffate to do coagulating sedimentation, then to do adsorption to the waste water being processed by coagulating sedimention by adding active carbon again, to add defoaming agent into the mineral operation waste water.

Owner:南京银茂铅锌矿业有限公司 +1

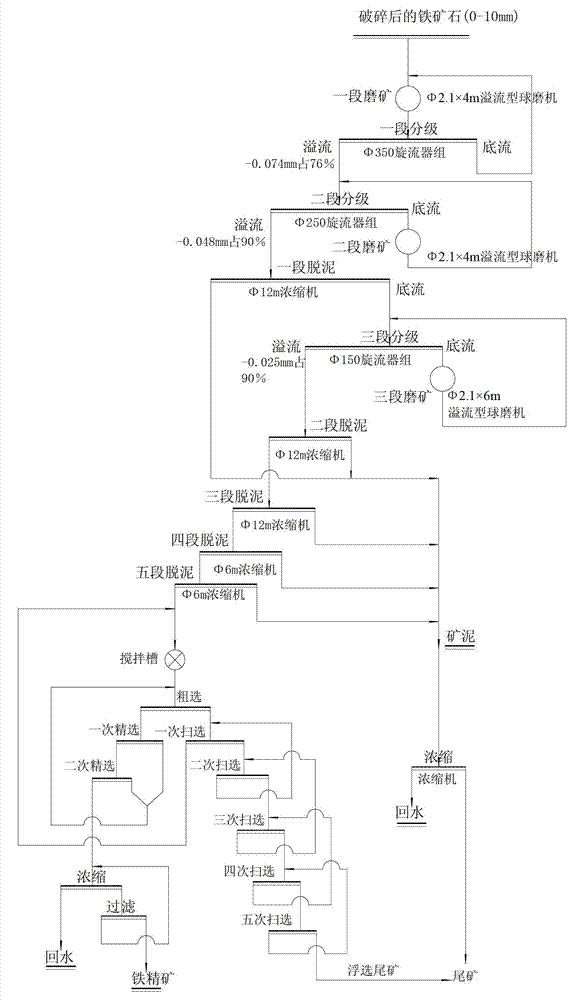

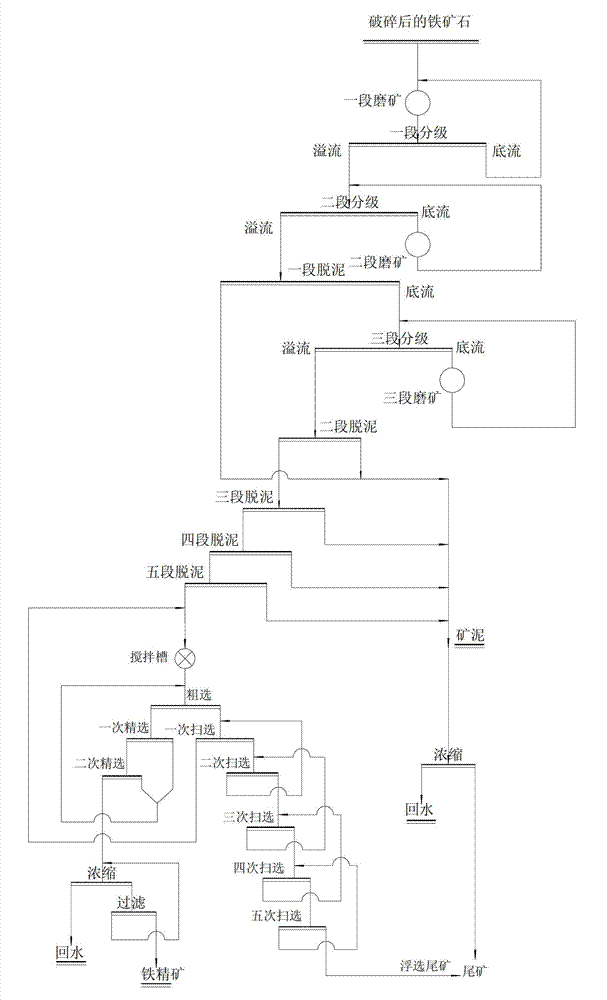

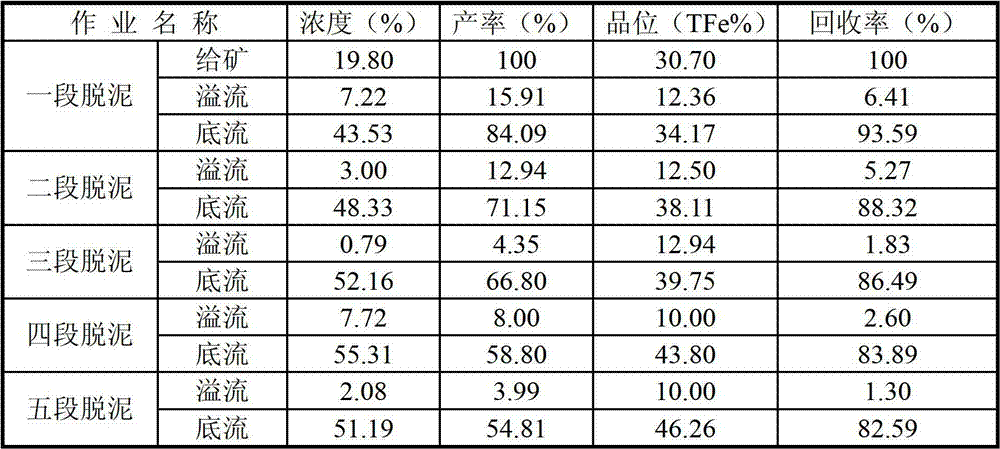

Ore benefication process for low-grade fine particle grade embedded distribution refractory iron ore

ActiveCN102806139AEliminate the effects ofGood desliming effectDifferential sedimentationGrain treatmentsFlocculationThree stage

The invention discloses an ore benefication process for low-grade fine particle grade embedded distribution refractory iron ore. The process comprises the following steps that crushed ore products are firstly subjected to one-stage ore grinding and one-stage grading, underflow after the grading is returned for re-grinding, and overflow is subjected to two-stage grading; underflow after the second-stage grading is subjected to second-stage ore grinding, ore grinding discharge materials are returned to the second-stage grading, and overflow is subjected to one-stage desliming; underflow after the desliming is subjected to three-stage grading and three-stage ore grinding, ore grading discharge materials are returned to three-stage grading, and overflow is subjected to second-stage desliming; next, three-section, four-section or five-section or more-section desliming is sequentially carried out; underflow after the desliming starts to be subjected to reverse flotation after the stirring, rougher flotation is firstly carried out, products in a groove after the rougher flotation are subjected to fine selection, foam products after the fine selection are returned to a rougher flotation groove, and products in a groove after the fine selection are concentrated and filtered to obtain ore concrete; and concentration machines and selective flocculation desliming processes are respectively adopted for each stage of desliming. The process provided by the invention has the advantages that the investment cost is low, the occupied area is small, the production and the maintenance are simple and convenient, the adaptability is high, the fine grinding desliming effect is good, and the like.

Owner:HUNAN SHIZHUYUAN NON FERROUS METAL

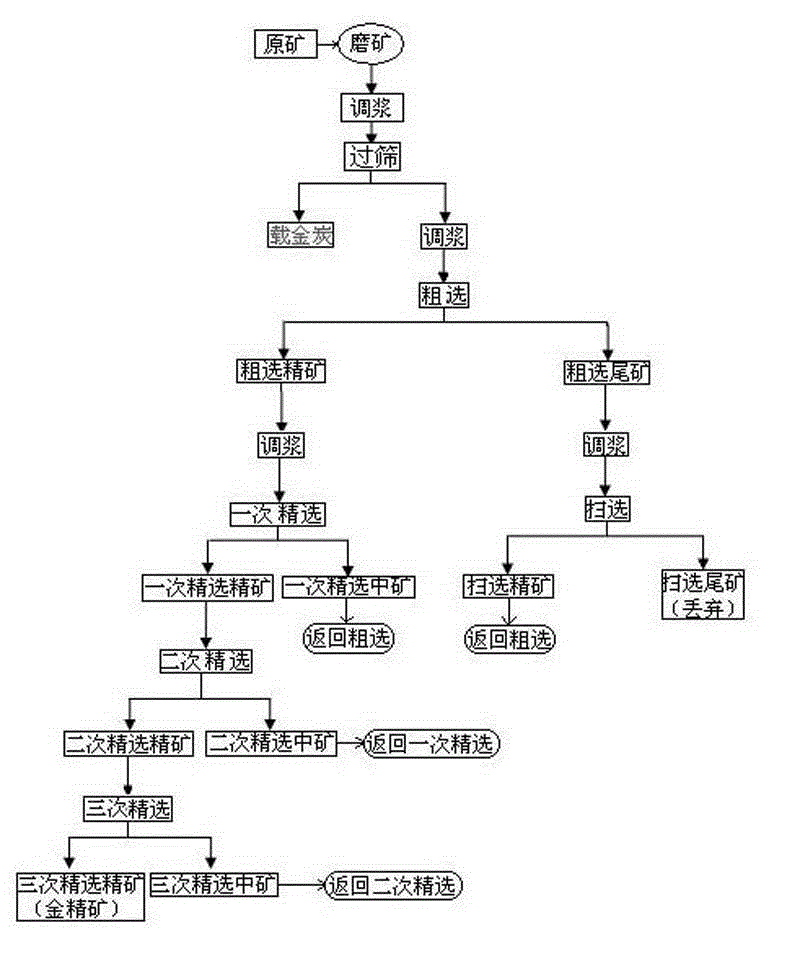

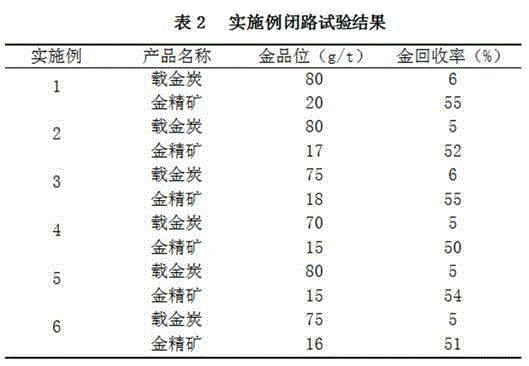

Method for selecting gold from gold ore leaching residue

ActiveCN103977881AAchieve recyclingProcess results are simpleFlotationWet separationDibutyl dithiophosphateFoaming agent

The method discloses a method for selecting gold from gold ore leaching residue. The method comprises the following steps: ore grinding, grid screening, roughing, scavenging, first selection, second selection and third selection. Active carbon is added during ore grinding, gold loaded carbon with higher gold content is firstly screened by adopting a 40-mesh grid screen at a ball-milling ore discharge port, then an inhibitor, a collecting agent and a foaming agent are added during the floatation process, and finally size mixing and stirring are carried out for roughing floatation work. The inhibitor is sodium fluosilicate, the collecting agent is Ammonium dibutyl dithiophosphate, and the foaming agent is terpenic oil. According to the method, through reasonable allocation of ore grinding and grid screening, the gold grade of the gold loaded carbon reaches to 70-80 g / T, the gold grade of floatation gold concentrate reaches to 15-20 g / T, the recovery rate of the gold loaded carbon reaches to 5-6%, the recovery rate of floatation gold reaches to 50-55%, and the total recovery rate of gold reaches to 55-61%. The ore dressing method is simple in technology and easy to operate on site.

Owner:NORTHWEST RES INST OF MINING & METALLURGY INST

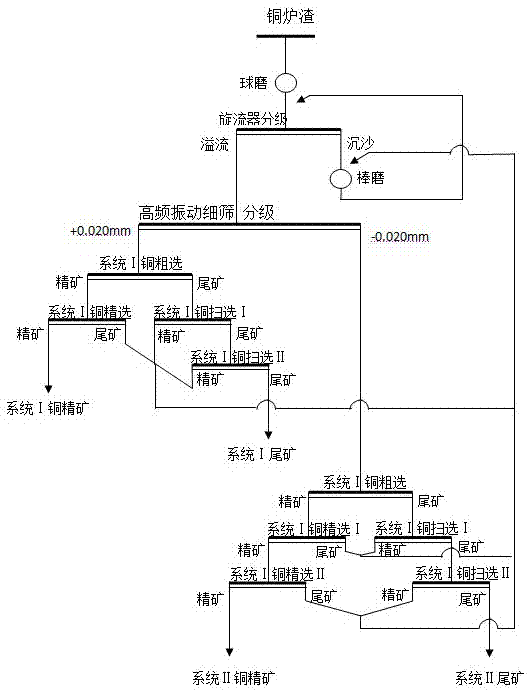

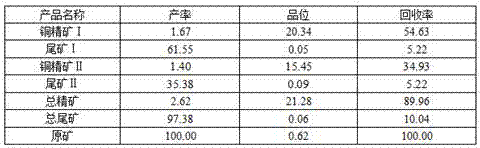

Mineral processing process for recovering copper from copper smelting slag through flotation

The invention discloses a mineral processing process for classifying recovery of copper from copper smelting slag. The mineral processing process adopts an ore grinding-grading-classifying separation process; a two-stage and one closed circuit grinding flow composed of a ball grinding mill, a rod mill and a hydrocyclone is used for the ore grinding of the copper smelting slag, and the occupancy of grinding products with granularity -0.044 mm is 80-90%; the grinding products are graded into +0.020 mm coarse products and -0.020 mm fine products by a high-frequency vibrating fine screen, the +0.020 mm coarse products are processed into copper concentrate I and gangue I through one-time roughing, one-time concentrating and twice scavenging flotation processes, and the -0.020 mm fine products are processed into copper concentrate II and gangue II through one-time roughing, twice concentrating and twice scavenging flotation processes. The flotation condition pertinence is improved, the reagent cost and energy consumption cost are lowered, and the purpose of effectively recovering the copper from the copper smelting slag is achieved.

Owner:KUNMING UNIV OF SCI & TECH

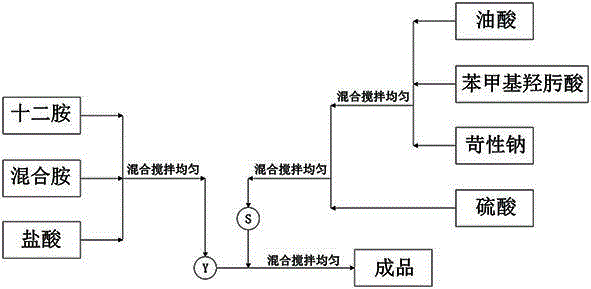

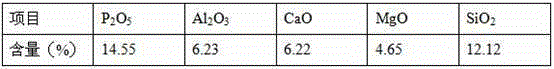

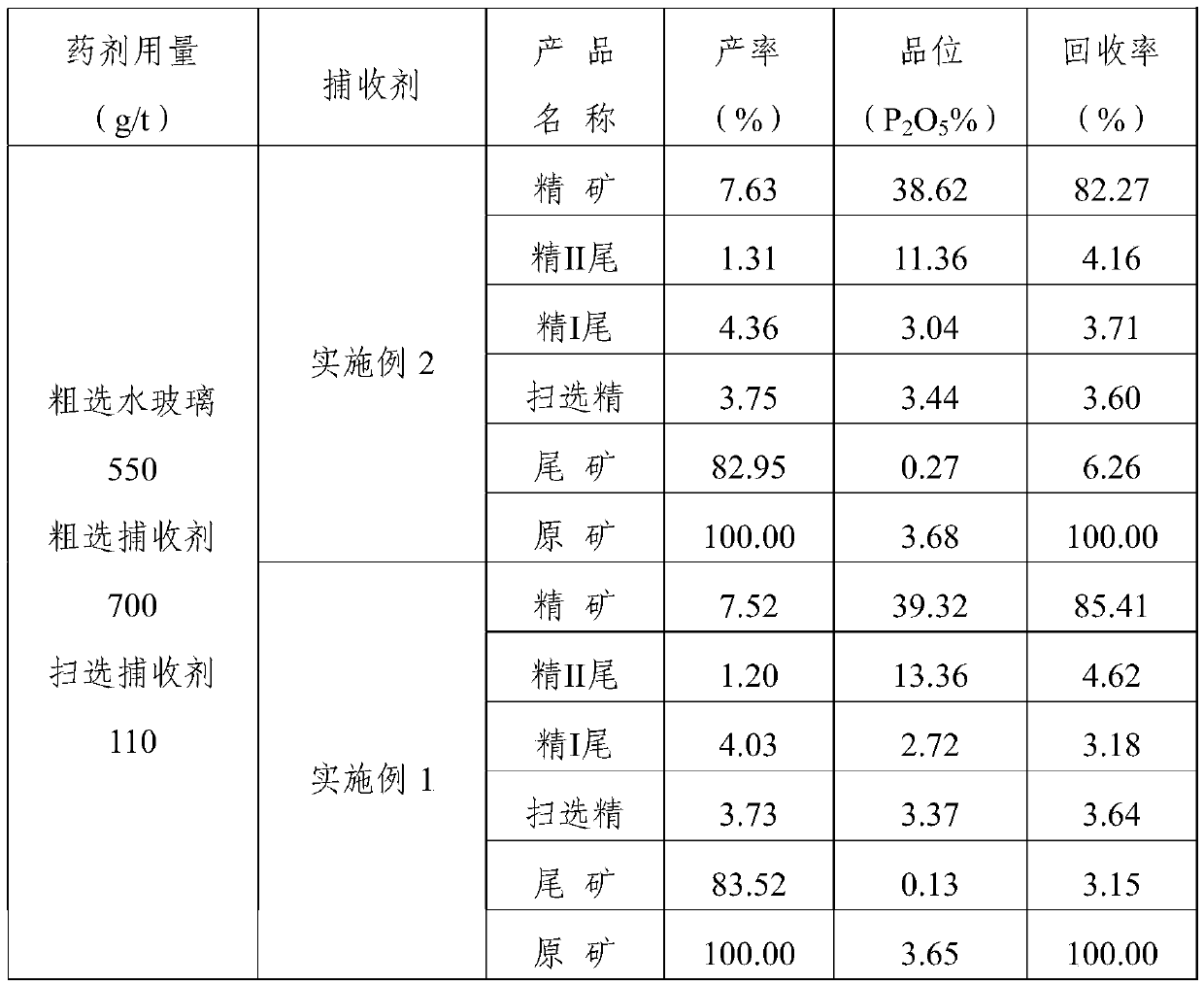

Phosphate rock flotation collector and preparation method thereof

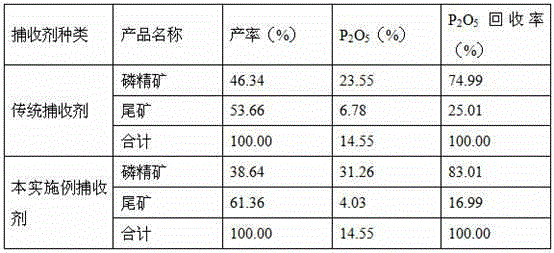

InactiveCN105013619AReduce distractionsImprove concentrate gradeFlotationPhosphatePhysical chemistry

The invention discloses a phosphate rock flotation collector. The phosphate rock flotation collector comprises, by weight ratio, 20-70 parts of Y and 30-80 parts of S; the Y comprises, by weight ratio, 60-30 parts of lauryl amine, 20-40 parts of mixed amine and 20-30 parts of hydrochloric acid; the S comprises, by weight ratio, 20-40 parts of oleic acid, 20-40 parts of phenmethyl hydroximic acid, 20-30 parts of caustic soda and 10-20 parts of sulfuric acid. The invention further discloses a preparation method of the phosphate rock flotation collector. The phosphate rock flotation collector and the preparation method have the beneficial effects that the selectivity and the collecting property are strong, the flotation time is short, the interference caused by other ions in pulp is small, the technological operation is simple, and the economic benefit is remarkable; the grade of P2O5 can be improved by about 5%, and the phosphorus comprehensive recovery rate can be improved by about 10%; poisonous and side effects do not exist, pollution to the environment can be avoided; and the raw material source channels are convenient, and the preparation method is simple.

Owner:四川有色金砂选矿药剂有限公司

Technique of adjusting and controlling electric potential for floatation of sulphide ore of lead and zinc

InactiveCN1562493ARealize the new process of potential control flotationHigh indexFlotationResource utilizationSludge

An electric level controlled floatation technology for lead zinc sulfuride ore features that in the step of floating lead, the electric level of ore sludge is regulated to 140-210 mv by adding lime into grinder while the capturer is added, and in the step of floating zinc the electric level of ore sledge is regulated to 150-170 mv by adding lime to lead tailings while adding capturer. Its odvantage is high recovery rate.

Owner:南京银茂铅锌矿业有限公司 +1

Device for measuring reaction rateof flash magnetized calcination for refractory iron oxide ore

InactiveCN1776421AFast feedingQuick unloadingMaterial heat developmentPreparing sample for investigationEngineeringReaction speed

Structure of the testing device is as following: blower fan, gas generator, separator and reaction furnace are connected to each other through pipe; adjustable valve and switch valve are setup at pipe connected between the gas generator and the separator; material receiver is at lower part of the separator; the gas generator and reaction furnace are connected through pipe with switch valve; being setup at upper, middle, and lower part of the reaction furnace, the test points are in use for thermocouple to measure reduction gas in the furnace, temperature in furnace chamber and temperature of tail gas; through pipe with control valve, the bottom part of the reaction furnace is connected to the blower fan, and test points are in use for measuring flux of coal gas and component. Features are: low energy consumption; the testing device can be added to furnace and demount from furnace quickly, measuring reaction change velocity from weak magnetism to strong magnetism, etc.

Owner:HUAZHONG UNIV OF SCI & TECH +1

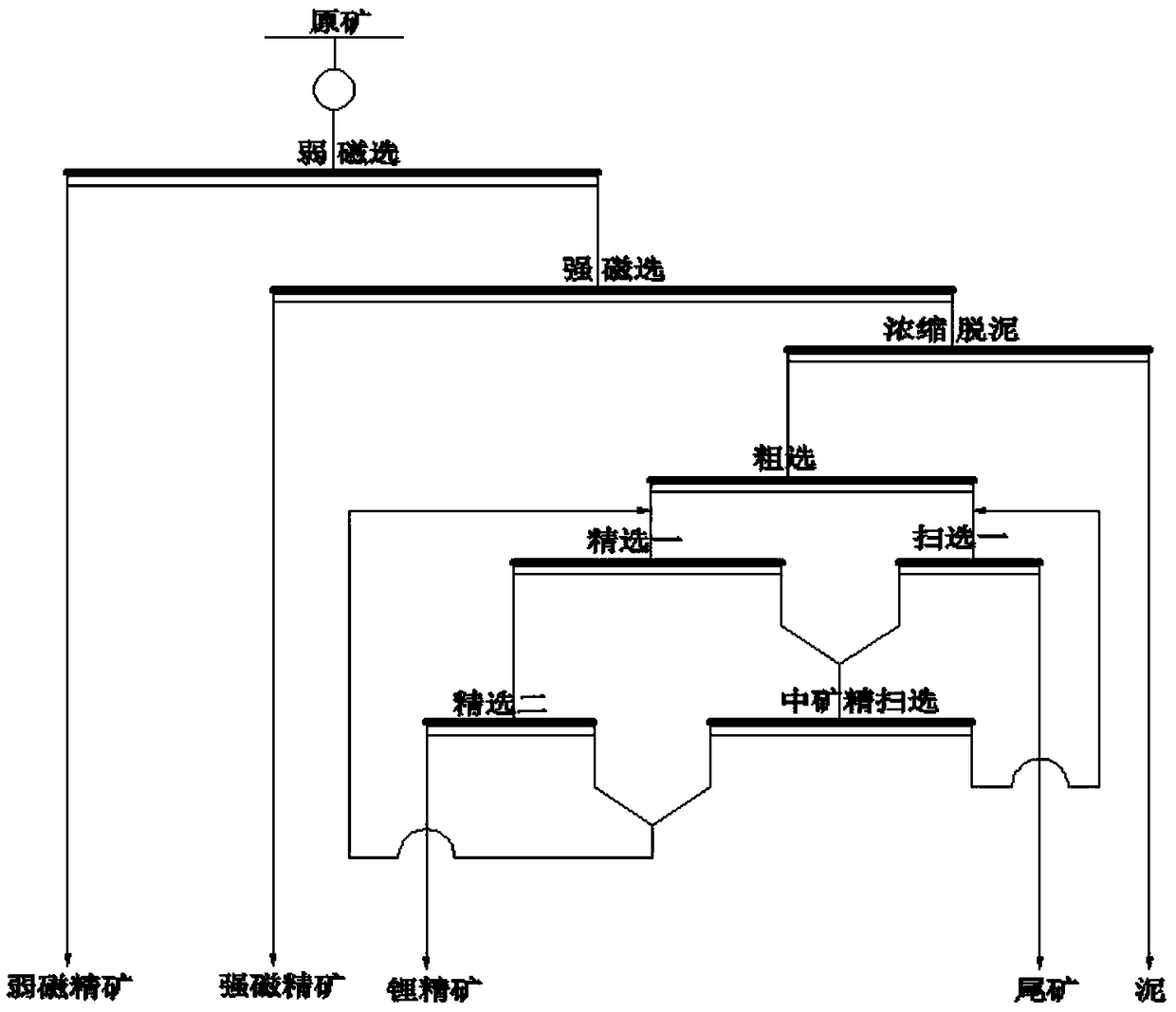

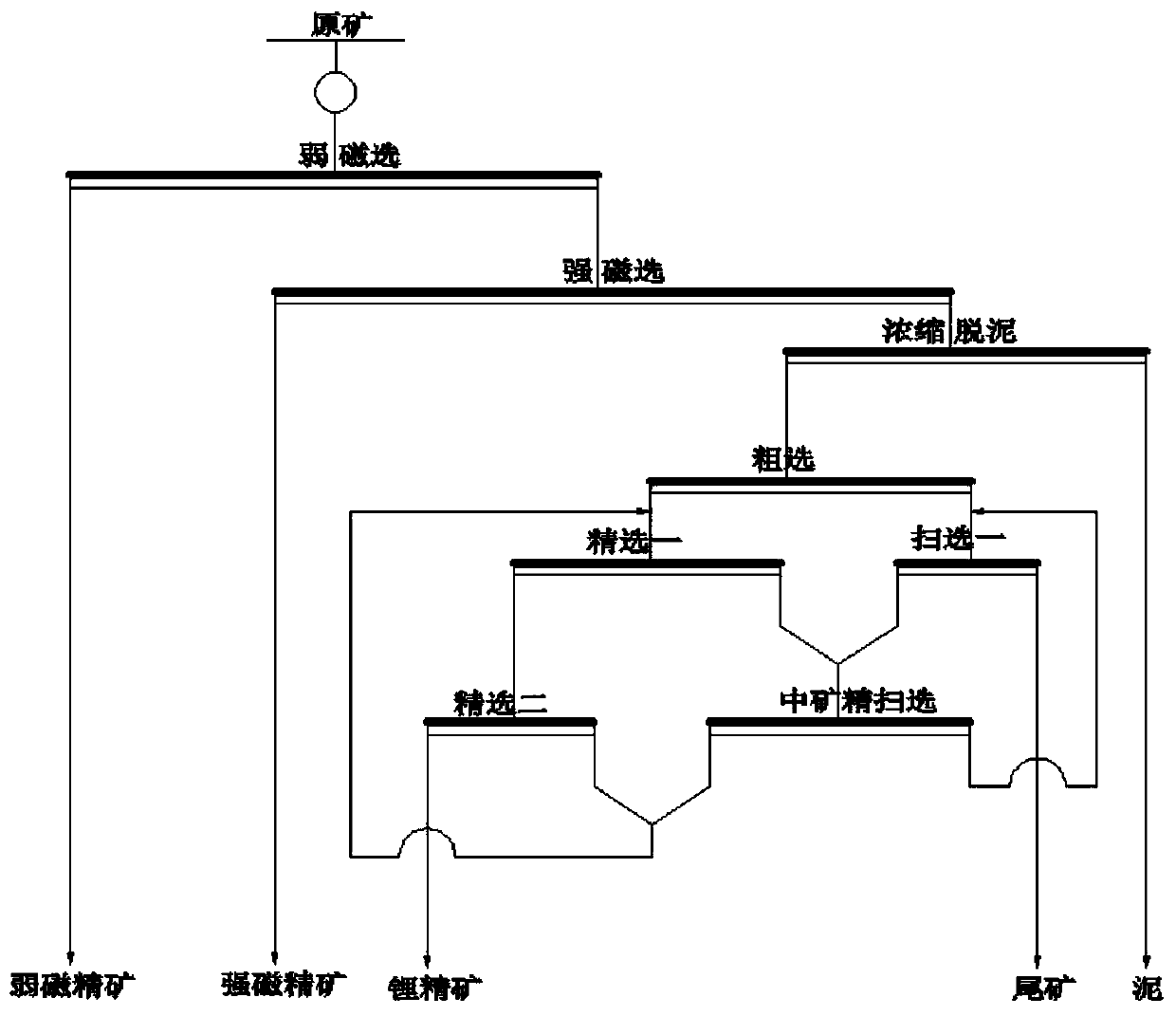

Magnet-flotation combined beneficiation technology of spodumene

ActiveCN109107754AThe flotation process is stableGood beneficiation indexWet separationOleic Acid TriglycerideMagnetic separation

The invention discloses a magnet-flotation combined beneficiation technology of spodumene. Spodumene ore is subjected to smashing and grinding. Ore pulp after grinding is sequentially subjected to lowintensity magnetic separation and high intensity magnetic separation to respectively obtain low intensity magnetic concentrated ore and high intensity magnetic concentrated ore. The discharged high intensity magnetic tailing ore is subjected to concentration and desliming, and is provided for flotation operation. Procedures of the flotation operation comprises one time of roughing, two times of scavenging and two times of concentrating. A collecting agent adopts compound of Fatty calcium, hydroxylamine compound and oleic acid, wherein the ratio is (6-7):(2.0-2.5):(1.0-1.5). The Li2O grade inthe final lithium concentrate is as high as 5.8-6.4%, and the recycling rate is 79.0-88%. The beneficiation technology is simple, stable and reliable, applicability is high, the laboratory index and the industrial application index are in agreement with each other, and the disadvantage of a big gap between the industrial application index and the laboratory index in the spodumene beneficiation technology is overcome. The collecting agent is excellent in selectivity, high in collecting performance, and is environmentally friendly.

Owner:SINOSTEEL MAANSHAN INST OF MINING RES +1

Treatment chemical for lead-zinc flotation tailing wastewater

InactiveCN102502934AQuick decalcificationReduce contentWaste water treatment from quariesWater/sewage treatment by flocculation/precipitationHigh concentrationPhosphate

The invention discloses a treatment chemical for lead-zinc flotation tailing wastewater, wherein the chemical comprises, in percentage by weight, 80-90% of carbonate, 9-19% of phosphate and 0.5-1% of non-ionic polyacrylamide; and the treatment chemical is suitable for treating lead-zinc flotation tailing wastewater with suspended solids, highly-free calcium oxide, high pH, high-concentration heavy metal ions, and over-standard COD (chemical oxygen demand) and BOD (biochemical oxygen demand). The new chemical has the multi-functions of rapidly removing calcium, removing suspended matters and precipitates, i.e., heavy metal ions and the like, as well as is large in the particle size of precipitate particles and complete in precipitation. Moreover, operation is simple and cost is low by using the chemical.

Owner:KUNMING UNIV OF SCI & TECH

Beneficiation process for pulverized mine of specularite in alpine region

The invention belongs to the technical field of iron ore beneficiation, and in particular relates to a beneficiation process for pulverized mine of specularite in an alpine region. The method provided by the invention comprises the steps of beneficiation before roasting, suspended magnetization roasting and beneficiation after roasting. According to the method, the recorded granularity of materials, in the step of beneficiation before roasting, which are fed into suspended Bayer is less than or equal to 0.3 mm, and adapts to the suspended magnetization roasting process, the beneficiation index of the pulverized mine of the specularite is further increased through the step of beneficiation after roasting, the pulverized mine antifreezing problem is solved, filtering operation in the alpine region is effectively realized, and the beneficiation process has the advantages of energy conservation and environmental friendliness.

Owner:MCC NORTH (DALIAN) ENG TECH CO LTD

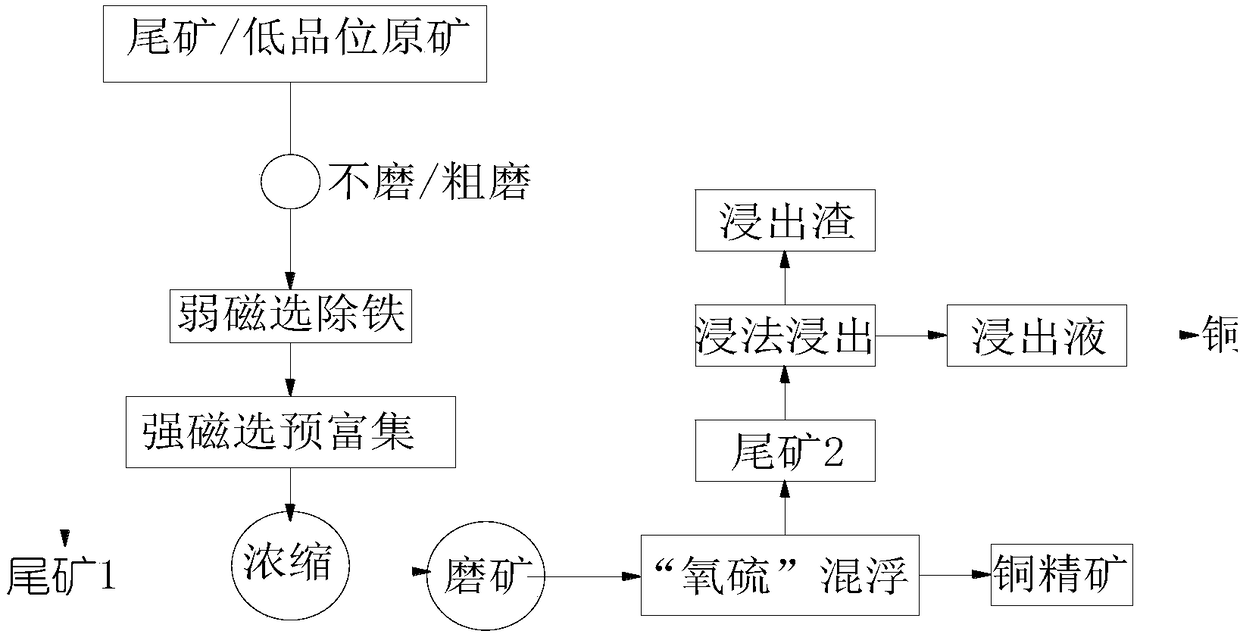

Ore dressing method of high-muddy high-alkalinity gangue low-grade refractory copper oxide ores

The invention relates to an ore dressing method of high-muddy high-alkalinity gangue low-grade refractory copper oxide ores, which belongs to the technical field of ore dressing. The ore dressing method comprises the following steps: making copper oxide crude ore into pulp, wherein the concentration of the ore pulp is 20 to 28 percent; uniformly stirring the ore pulp, performing low intensity magnetic separation to remove high-magnetic minerals, thus obtaining low intensity magnetic separation tailings, and performing high-gradient high intensity magnetic separation pre-concentration and tailings discarding on the low intensity magnetic separation tailings, thus obtaining high intensity magnetic separation rough concentrate and high intensity magnetic separation tailings; grinding the highintensity magnetic separation tailings, then performing oxygen-sulfur mixed floatation, thus obtaining oxygen-sulfur mixed concentrate and oxygen-sulfur mixed scavenging tailings; and performing wetleaching on the oxygen-sulfur mixed scavenging tailings. By adopting the method, ore dressing indexes of the high-muddy and high-alkalinity gangue and low-grade copper oxide ores can be favorably increased, the total recovery rate of the copper is greater than or equal to 89 percent, the adaptability is high, and the industrialized implementation is facilitated.

Owner:拜城县滴水铜矿开发有限责任公司 +1

Beneficiation method for spodumene ore

ActiveCN109127117AThe flotation process is stableGood beneficiation indexWet separationDecompositionEngineering

The invention discloses a beneficiation method for spodumene ore. The spodumene ore is crushed and ground, ore pulp obtained after ore grinding is sequentially subjected to low-intensity magnetic separation and high-intensity magnetic separation, and weak-magnetism concentrates and strong-magnetism concentrates are obtained; discharged strong-magnetism tailings are fed to the flotation operation after being subjected to concentration and desliming, and the flotation operation process includes primary roughing, secondary scavenging and secondary fine selecting; calcium fatty acid prepared through the double decomposition reaction of a sodium fatty acid soap solution and a calcium chloride water solution is adopted as a collecting agent, the Li2O grade in the finally-obtained lithium concentrate reaches up to 5.7%-6.2%, and the recycling rate is 78%-88%. According to the beneficiation method, the beneficiation technology process is simple, stability and reliability are achieved, applicability is high, and the laboratory index highly conforms to the industry application index; and the defect that in the existing spodumene ore beneficiation technology, the difference between the industry application index and the laboratory index is large is overcome; and the adopted collecting agent has excellent properties that selectivity is good, the collecting capability is high, and environment friendliness is achieved.

Owner:SINOSTEEL MAANSHAN INST OF MINING RES

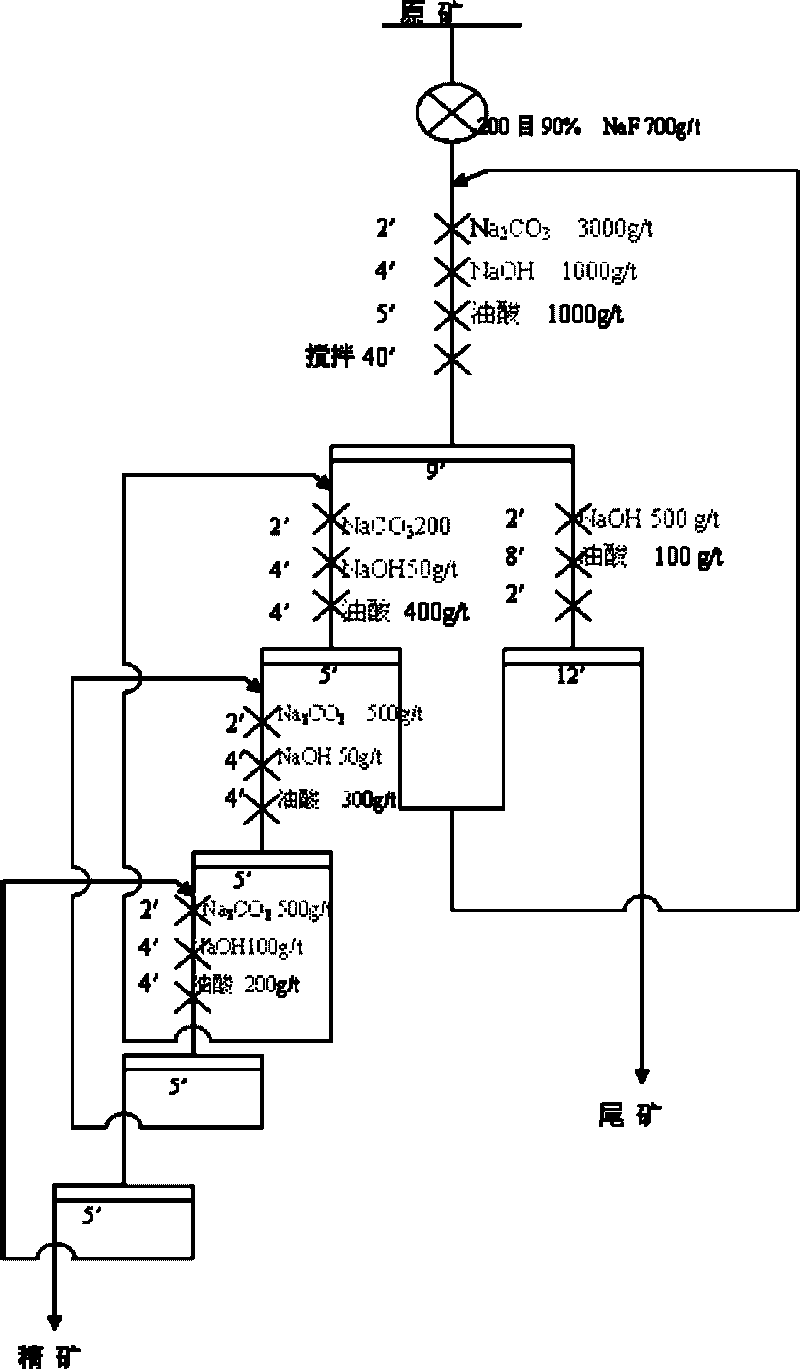

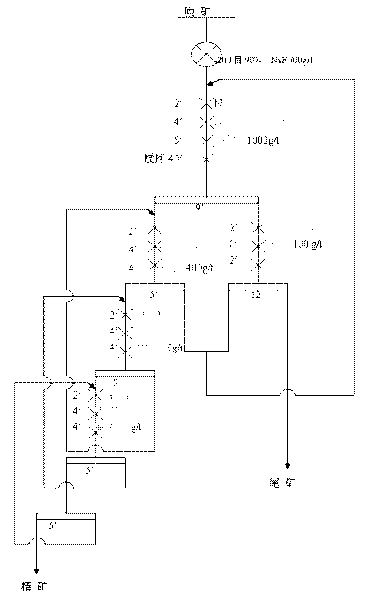

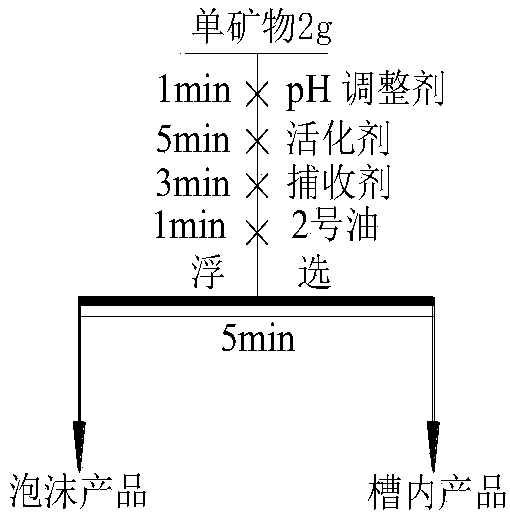

Efficient ore dressing method for bertrandite

InactiveCN101722109AEfficient separationTo achieve the purpose of enriching beryllium oreFlotationBeryllium oxideBeryllium Metal

The invention discloses an ore dressing method for bertrandite. The invention adopts the technical scheme that the method adopts a comminuting-flotation process, uses an inhibitor to inhibit gangue, uses an efficient activator to activate the beryllium ore and uses a collecting agent to float and reclaim beryllium. By treating the phenacite containing 0.17 percent of beryllium through the technology, the phenacite containing 3.21 percent of beryllium metal, namely 8.92 percent of beryllium oxide, can be obtained; the reclaiming rate reaches 85.18 percent; and the method can meet the requirement of good-quality raw materials smelted by beryllium ores, provides a new efficient path for comprehensive utilization of beryllium ore resources in China, and has the advantages of simple process flow, good effect, no pollution and the like compared with the current process for extracting the beryllium by a sulfuric acid method.

Owner:CENT SOUTH UNIV

Beneficiation method for ilmenite

InactiveCN106755998AReduce consumptionReduce crushing energy consumptionFlotationMagnetic separationHigh pressureMaterials science

A beneficiation method for ilmenite is characterized by comprising the following steps that firstly, a high-pressure roller mill conducts pulverized grinding to -3 mm, and iron selecting is conducted; secondly, iron selecting tailings are ground to P80 0.140 mm; thirdly, strong magnetism concentrates are obtained through strong magnetic separation enrichment, and the magnetic field intensity ranges from 0.6 T to 0.7 T; fourthly, the strong magnetism concentrates are ground to P80 0.070 mm; fifthly, after being subjected to desulfuration, the strong magnetism concentrates are subjected to primary roughing, four-time fine selecting and primary scavenging, flotation titanium concentrates are obtained, and SYR3 is adopted as a collecting agent of the ilmenite; and sixthly, titanium concentrates obtained through flotation are subjected to acid leaching, final titanium concentrates are obtained, the immersion liquid is 10% sulfuric acid, the titanium concentrates obtained through flotation are subjected to acid leaching for 3 h at the temperature approximately ranging from 80 DEG C to 85 DEG C, the liquid-solid ratio is 7:1, the titanium concentrates are obtained through three times of filtering and washing, and the qualified titanium concentrates in which the content of TiO2 is larger than 45% are obtained.

Owner:SHENYANG RES INST OF NONFERROUS METALS

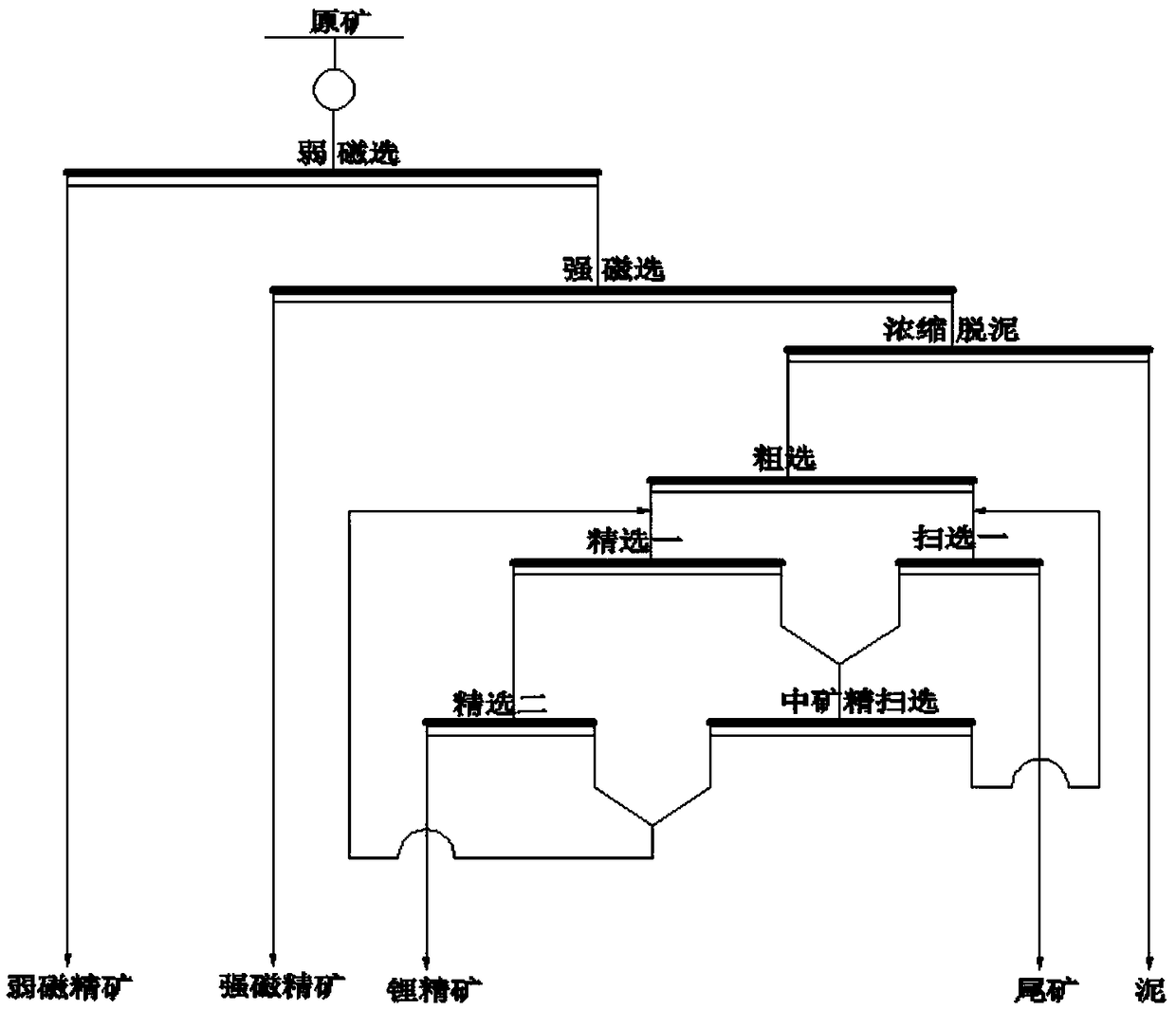

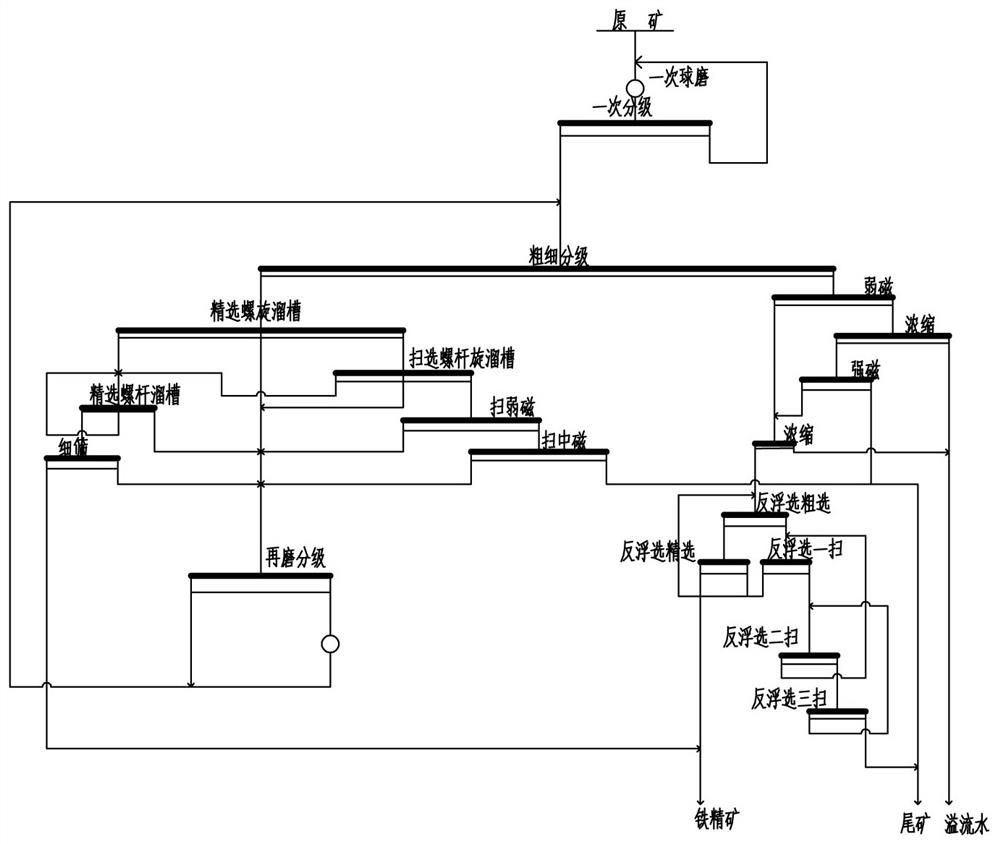

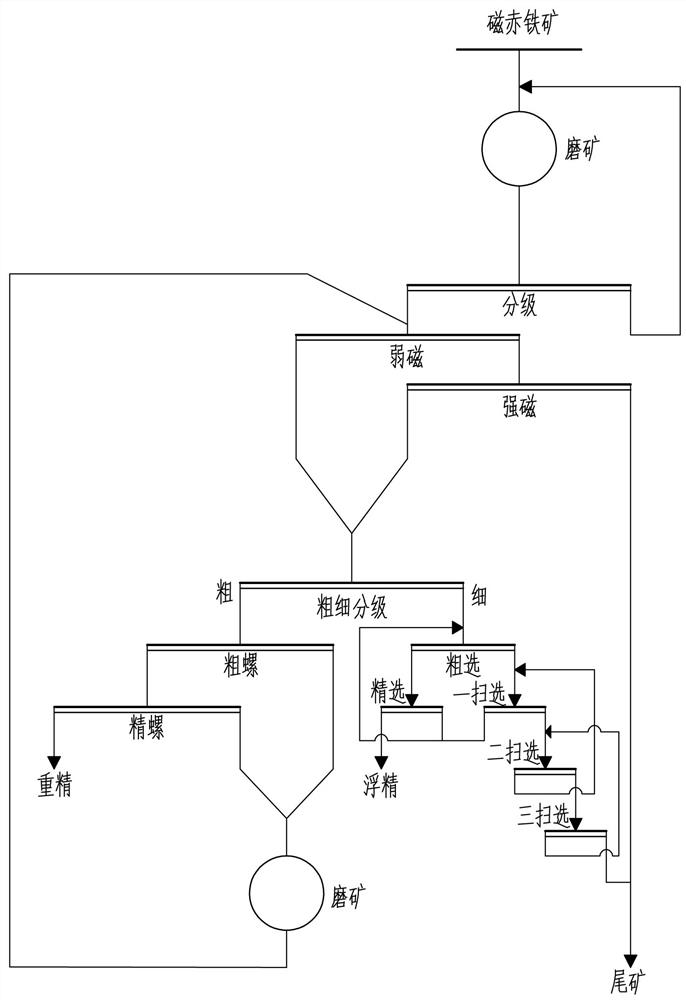

Ore grinding weak-magnetic strong-magnetic gravity separation reverse flotation process for magnetic hematite ore

InactiveCN112588431AShorten the beneficiation processGood beneficiation indexFlotationMagnetic separationIronstoneMaghemite

The invention relates to an ore grinding weak-magnetic strong-magnetic gravity separation reverse flotation process for a magnetic hematite ore. The ore grinding weak-magnetic strong-magnetic gravityseparation reverse flotation process for the magnetic hematite ore is characterized by comprising the following steps that the magnetic hematite ore with the grade of 25%-45% and the magnetite distribution rate of more than or equal to 60% is subjected to grinding and weak and strong magnet separation tailing discarding, coarse-fine classification is carried out on weak and strong magnetic concentrate, coarse-fine spiral chute gravity separation is carried out on a coarse fraction to obtain gravity concentrate, and tailings in gravity separation are re-ground and then returned to the weak andstrong magnetic separation; reverse flotation of rough flotation-fine flotation-three scavenging is carried out on the fine fraction to obtain floating concentrate, and floating tailings are discarded; and the gravity concentrate and the floating concentrate are combined to form the final concentrate with the iron grade larger than or equal to 65% and the total recovery rate larger than or equal to 80%. The ore grinding weak-magnetic strong-magnetic gravity separation reverse flotation process for the magnetic hematite ore has the advantages that (1), the method is suitable for all iron ores with high magnetic iron content, and fine-grained embedded iron ores are included; (2), the existing process is remarkably shortened, the concentrate grade is high, and the recovery rate is high; and (3), the ore treatment amount of the magnetic gravity separation process is a main body part, equipment operation is stable, operation and control are simple, meanwhile, the flotation pressure is reduced, investment is low, energy is saved, and environment friendliness is achieved.

Owner:ANSTEEL GRP MINING CO LTD

Low grade precious metal ore negative pressure multistage enrichment technology and device

ActiveCN103100484AThe process is compactSmall footprintGrain treatmentsWet separationGrindingNonmetal

The invention provides a low grade precious metal ore negative pressure multistage enrichment technology and a device. After coarse crushing and fine grinding, ore raw material mostly becomes powder material, in the fine grinding and screening process, non-metallic particles, suspended in the air, of the powder material can be recycled under the effect of confined space negative pressure, residual powder particles containing large density metal and nonmetal are mixed with water after sedimentation, and components large in density of precious metal and nonmetal mixture are further separated under the effect of a hydrocyclone. According to multistage negative pressure dry and wet mixing method separation technology, the low grade precious metal enrichment purpose is achieved, low grade precious metal sources are enabled to be fully recycled and reused, and water and power sources are saved, and precious metal source waste is reduced.

Owner:山东黄金矿业股份有限公司新城金矿

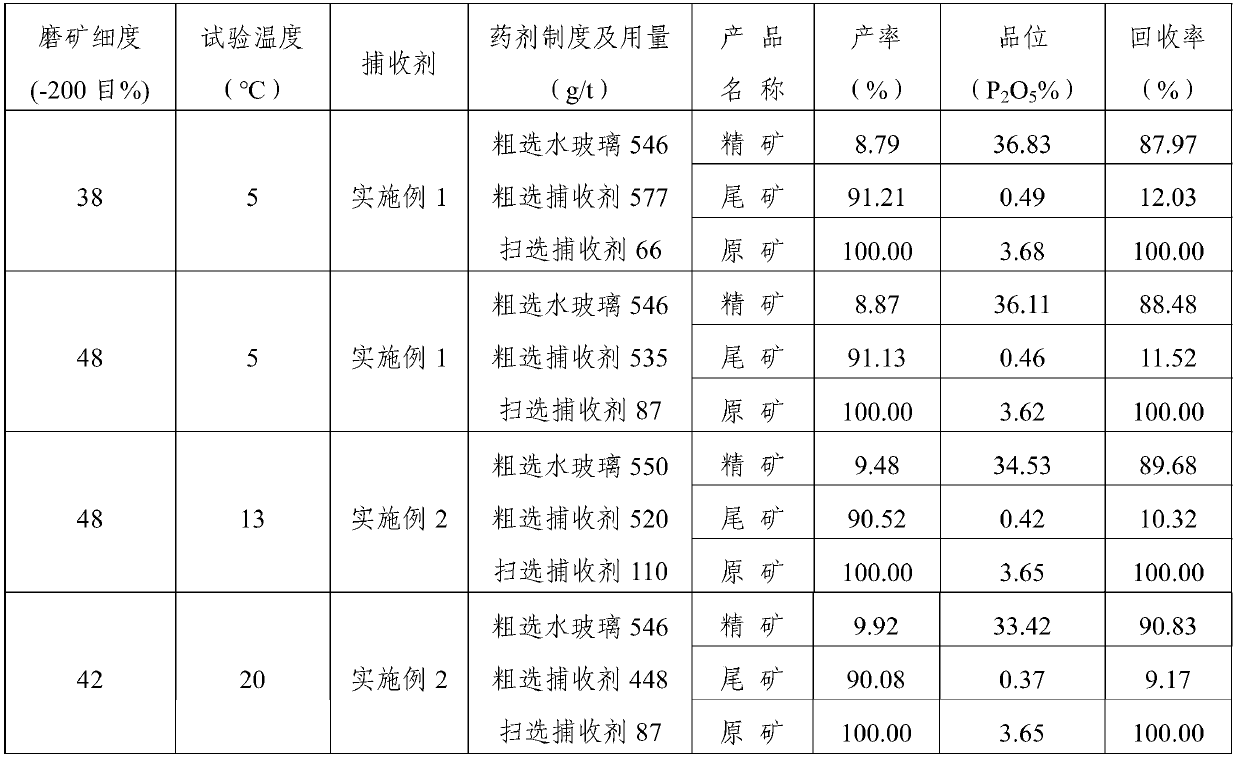

Apatite low-temperature flotation collector and preparation method thereof

The invention relates to an apatite low-temperature flotation collector and a preparation method thereof. The apatite low-temperature flotation collector comprises the following components in parts byweight: 35-55 parts of oxidized paraffin soap, 20-40 parts of soybean oil fatty acid soap and 20-30 parts of sodium fatty acid methyl ester sulfonate. The apatite low-temperature flotation collectordisclosed by the invention can realize effective flotation under the low-temperature condition of 5 DEG C. The apatite low-temperature flotation collector has good biodegradability, and can keep the COD content (less than or equal to 50 mg / L) in flotation tailing water at a low level.

Owner:中化地质矿山总局地质研究院

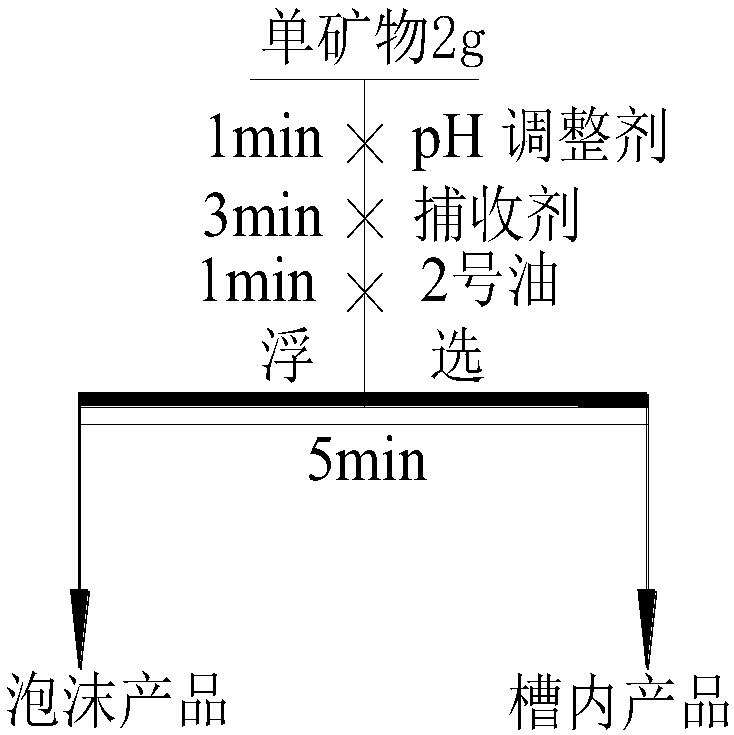

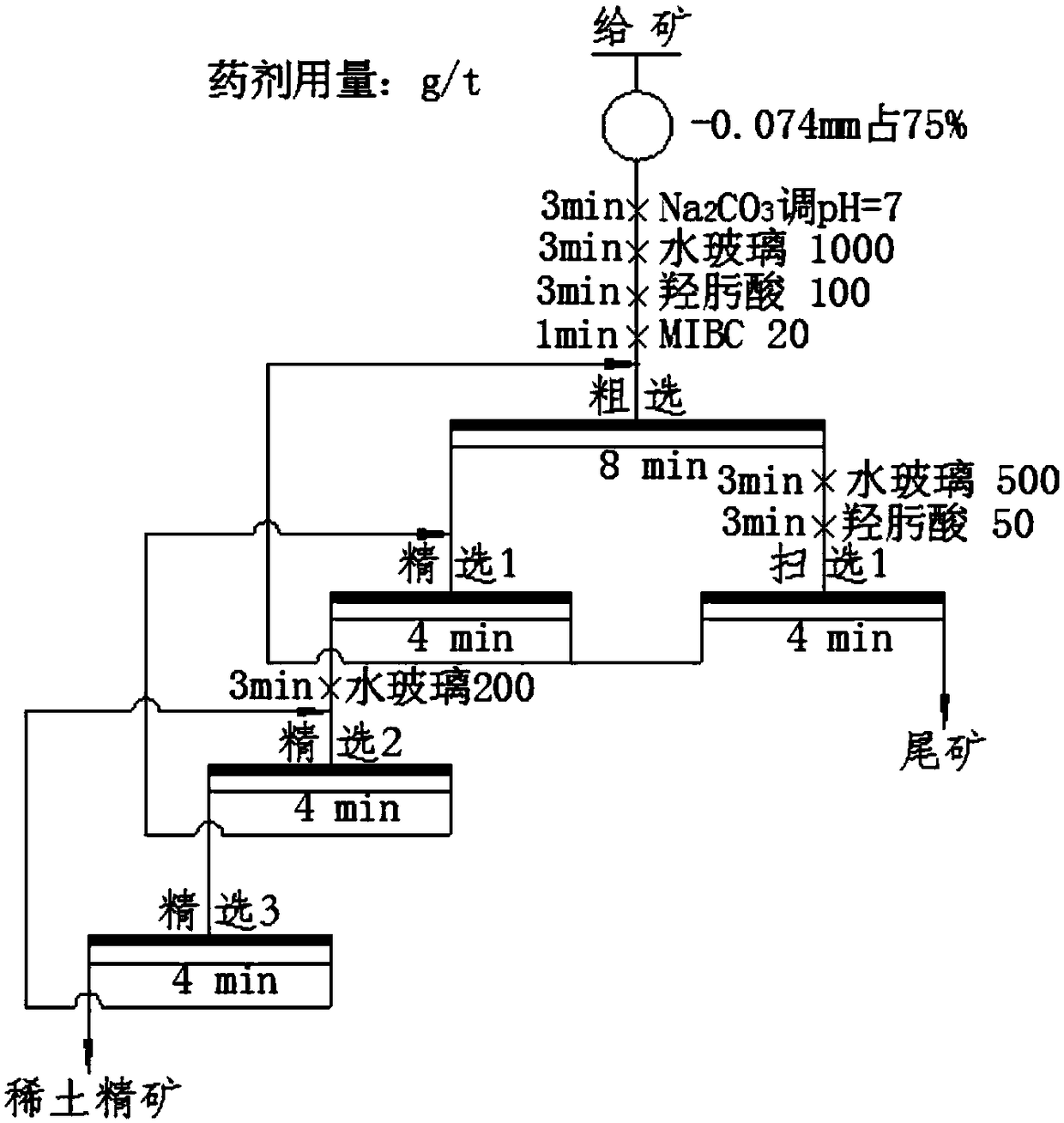

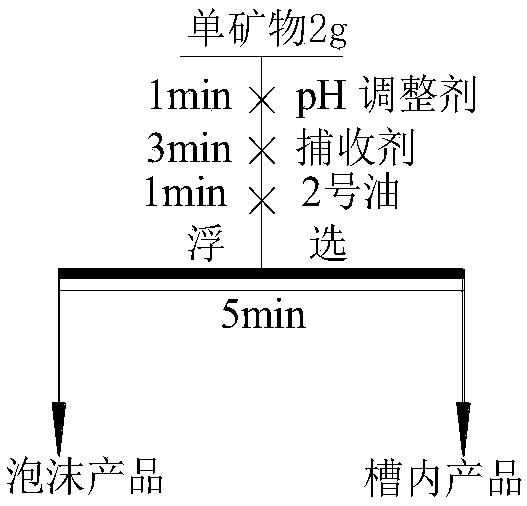

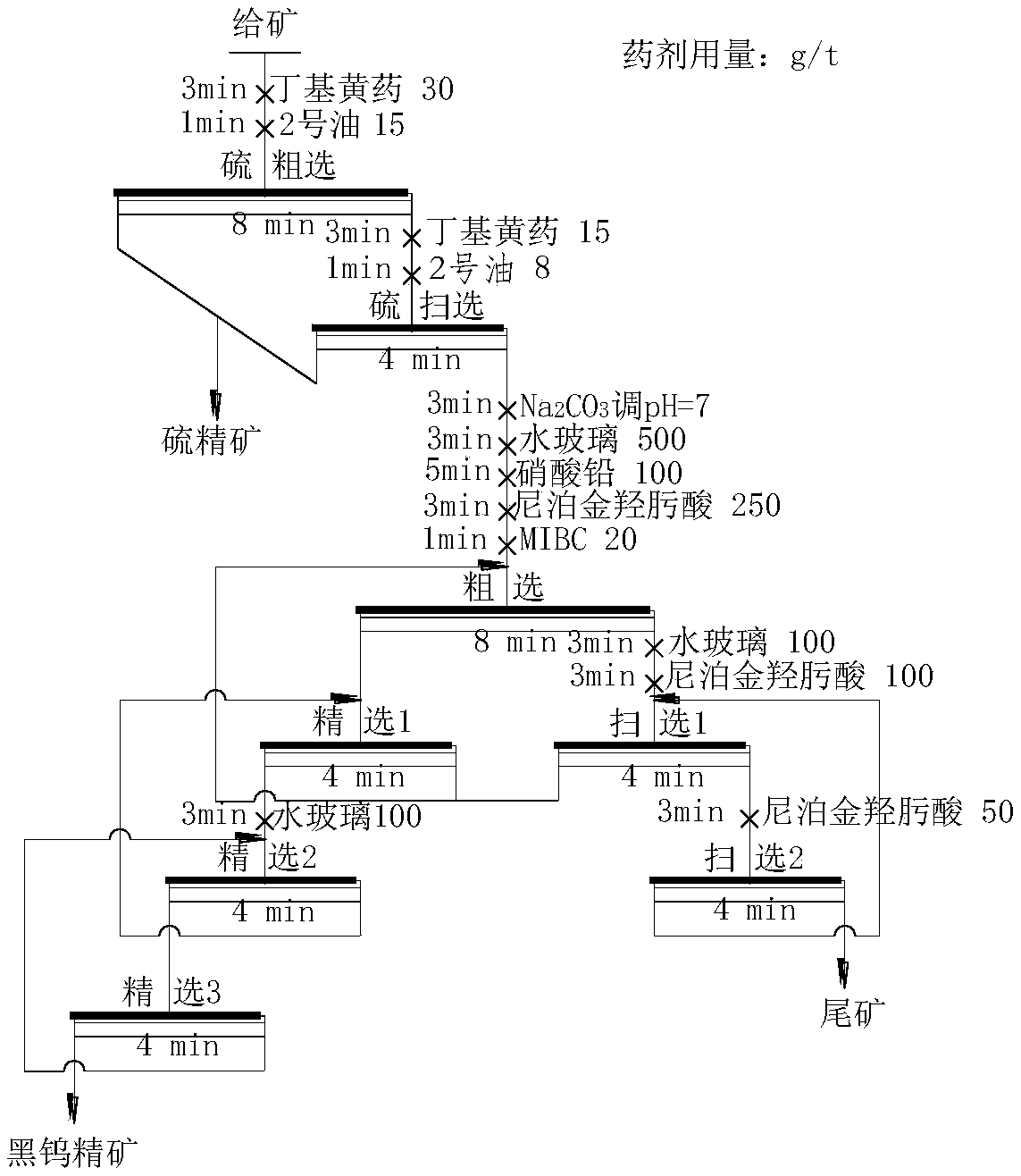

Flotation process of ilmenite or bastnaesite

ActiveCN108452949AImprove adsorption capacityStrong harvesting abilityFlotationFoaming agentGranularity

The invention relates to the technology of flotation, and particularly relates to a flotation process of ilmenite or bastnaesite. According to the process disclosed by the invention, a using amount ofa nipagin hydroximic acid collecting agent is more than or equal to 15g / t, and the granularity of ores is minus 0.074mm, occupying 60 percent to 100 percent; lime, sodium hydroxide or sodium carbonate is added to regulate pH of ore pulp to reach 4 to 12; water glass is an inhibitor, and a using amount of the inhibitor is 200g / t to 2000g / t; and MIBC (Methyl Isobutyl Carbinol) is a foaming agent, ausing amount of the MIBC is 10mg / L to 20mg / L, and the acting time is about 1 minute. The process disclosed by the invention is applied to flotation and refractory of fine-particle oxidized ores, andcan improve the flotation effect and mineral processing indexes. According to the process disclosed by the invention, medicament is reduced, and the mineral processing cost is reduced.

Owner:JIANGXI UNIV OF SCI & TECH

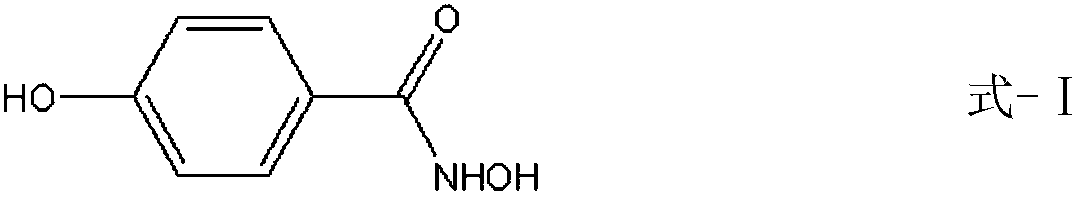

Nipalgin hydroximic acid as well as preparation method thereof and application thereof in tungsten ore flotation

InactiveCN108503562AStrong harvesting abilityEnhanced harvesting capacityOrganic chemistryFlotationHydroxylamine HydrochlorideSodium hydroxide

The invention relates to the field of flotation, in particular to nipalgin hydroximic acid as well as a preparation method thereof and application thereof in tungsten ore flotation. The preparation method of the nipalgin hydroximic acid comprises the following four steps: preparing raw materials; preparing hydroxylamine hydrochloride and a sodium hydroxide solution; preparing a nipalgin hydroximicacid crude product; purifying the nipalgin hydroximic acid. The nipalgin hydroximic acid provided by the invention has a higher collecting ability, is suitable for flotation of refractory fine-particle oxidized ore, can improve the flotation effect and indexes of mineral dressing, saves reagents and lowers the mineral dressing cost.

Owner:JIANGXI UNIV OF SCI & TECH

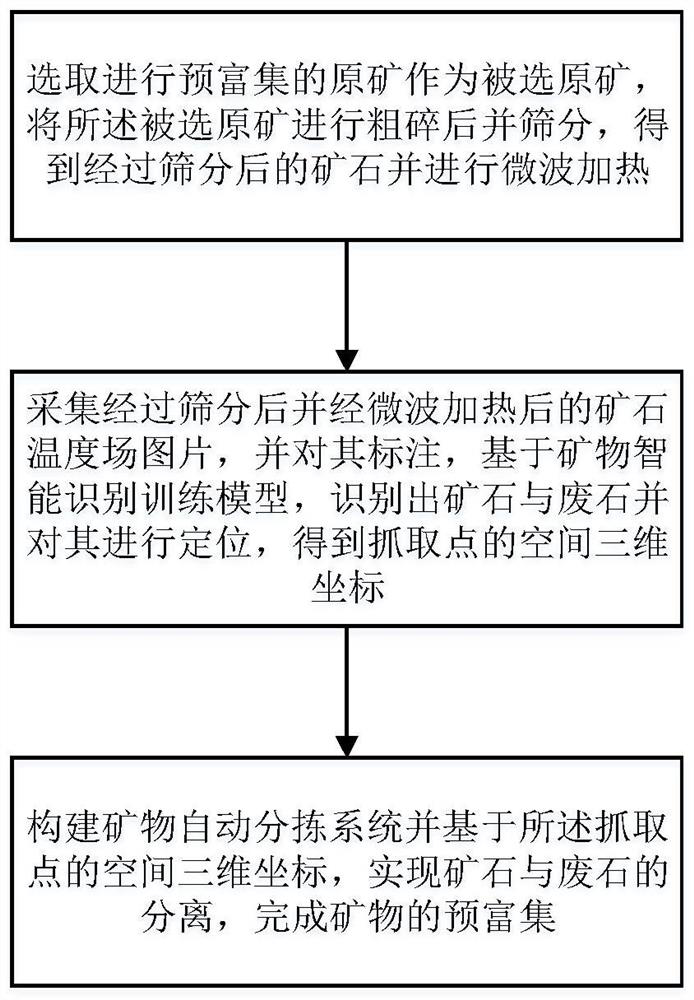

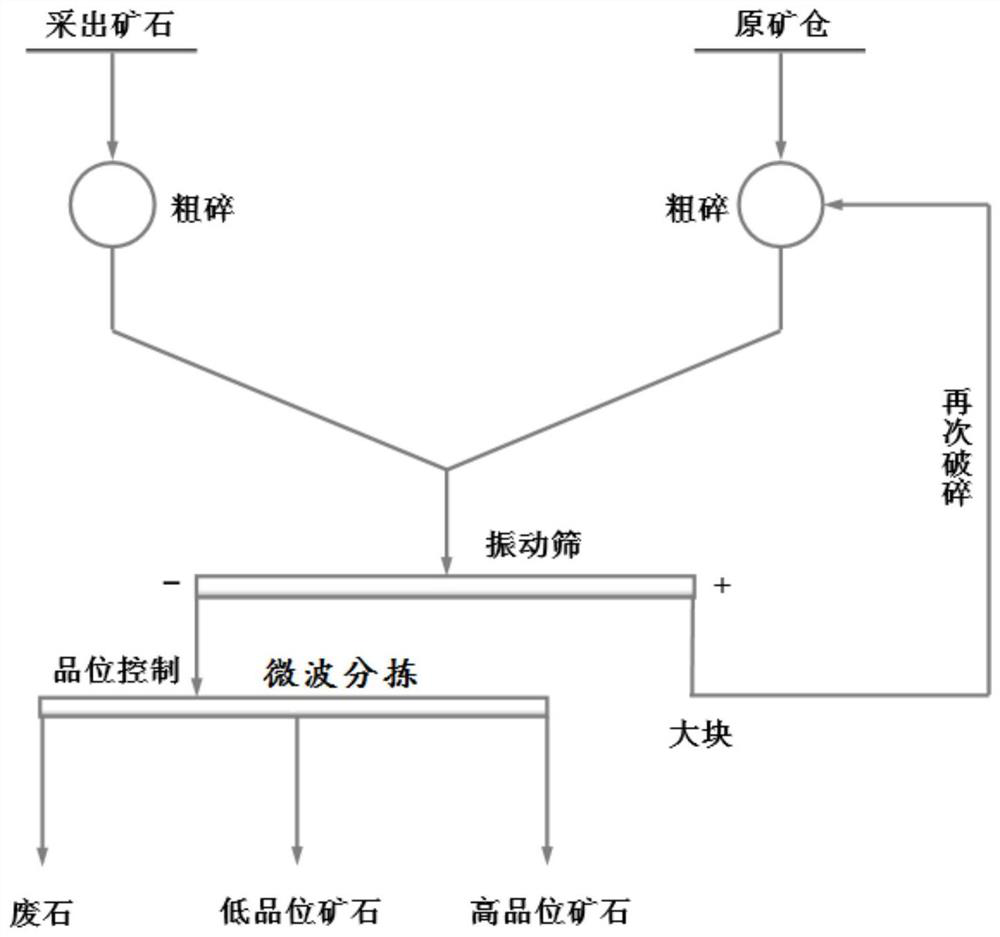

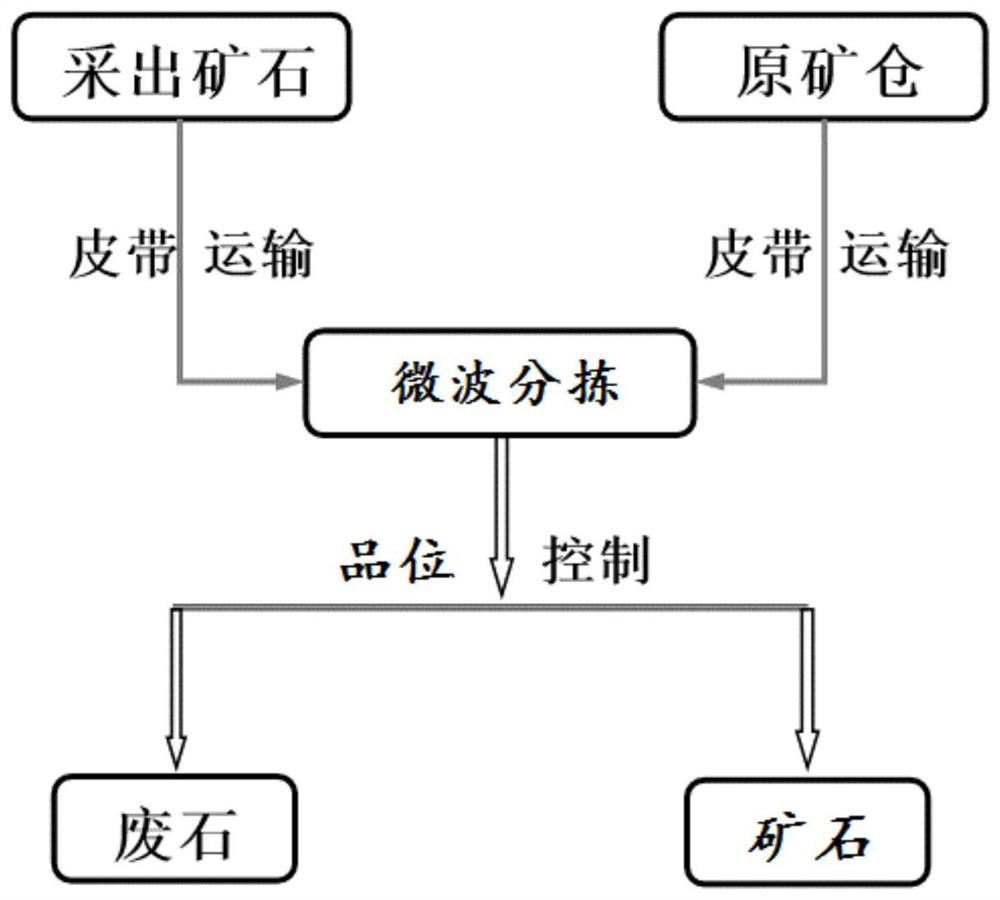

Mineral pre-enrichment method based on solid microwaves

ActiveCN113953067AHigh resolutionShort detection timeProcess efficiency improvementGrain treatmentsImage resolutionMaceral

The invention relates to a mineral pre-enrichment method based on solid microwaves, which comprises the following steps: selecting pre-enriched raw ores as selected raw ores, carrying out coarse crushing on the selected raw ores, screening to obtain screened ores, and carrying out microwave heating on the screened ores; acquiring temperature field pictures obtained after screening and microwave heating, making minerals and barren rocks in the pictures, on the basis of a large number of experiments, constructing an intelligent mineral recognition training model based on deep learning, recognizing and positioning the minerals and the barren rocks, and obtaining spatial three-dimensional coordinates of grabbing points; and constructing an automatic mineral sorting system, achieving separation of the ores and the barren rocks based on the spatial three-dimensional coordinates of the grabbing points, and completing pre-enrichment of the minerals. The method can be used for directly detecting whether the target mineral exists in a certain volume of mineral or not, can be used for quantitatively detecting the content of the mineral in the ore, and has a relatively high resolution ratio.

Owner:CENT SOUTH UNIV +1

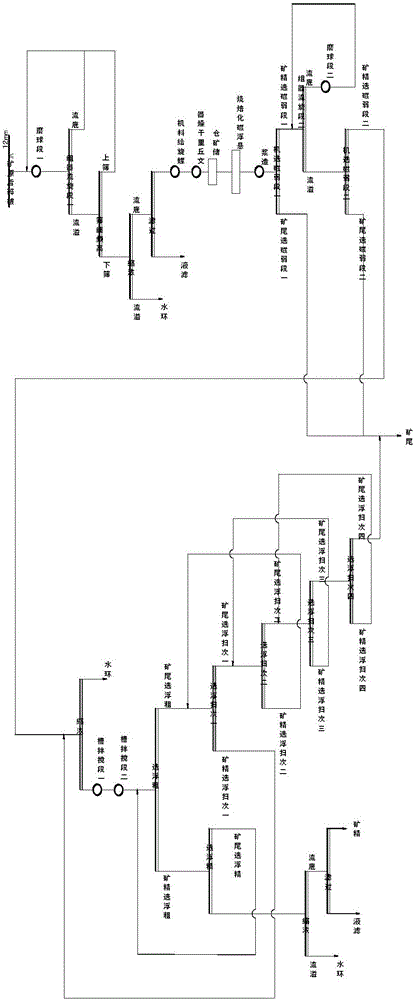

Flotation separation process of copper sulfide lead ore

The invention discloses a flotation separation process of copper sulfide lead ore. The copper sulfide lead ore is ground till the mass percent of the partial ore with the particle fineness less than 0.074 mm is 70%-95%; water is added into the ground copper sulfide lead ore to adjust the mass percent concentration of ore pulp to 25-35%; and 200g / t-1500g / t of a combined inhibitor, namely, a mixtureof ferric sulfate and magnesium chloride is added into the ore pulp, and 40g / t-120g / t of a combined collecting agent composed of ethionine ester, O-isooctyl-N-ethyoxyl carbonyl thionocarbamates and 4-terpene alcohol is added to carry out floatation separation. According to the flotation separation process, flotation separation of the copper sulfide lead ore is realized; and the process is simple,low in reagent cost, high in concentrate quality and free of environmental pollution.

Owner:KUNMING UNIV OF SCI & TECH

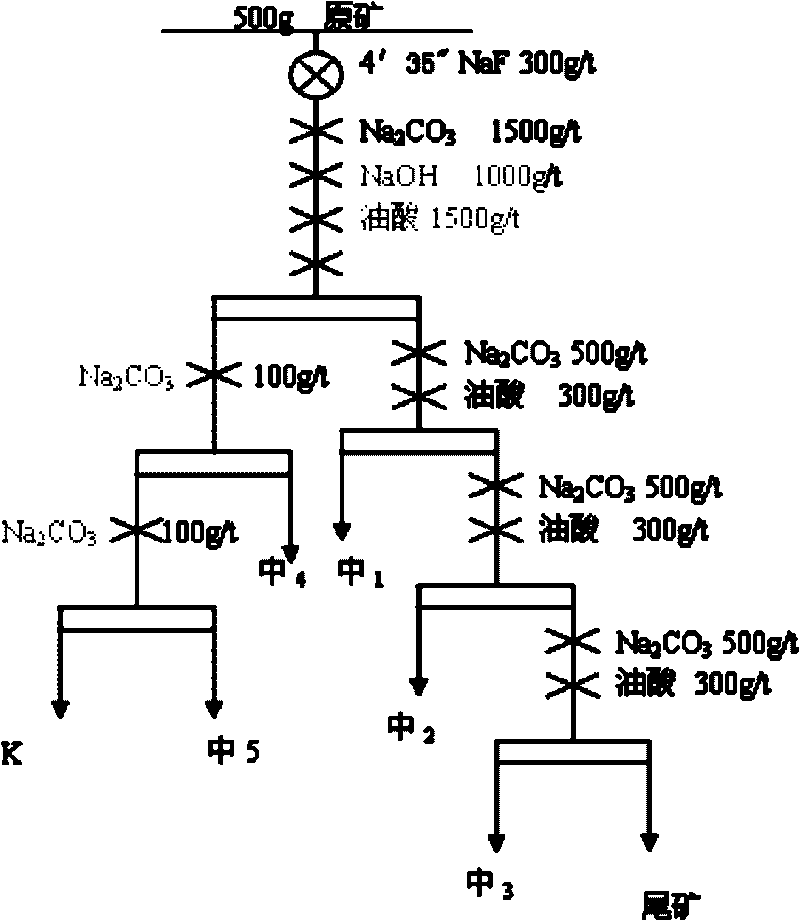

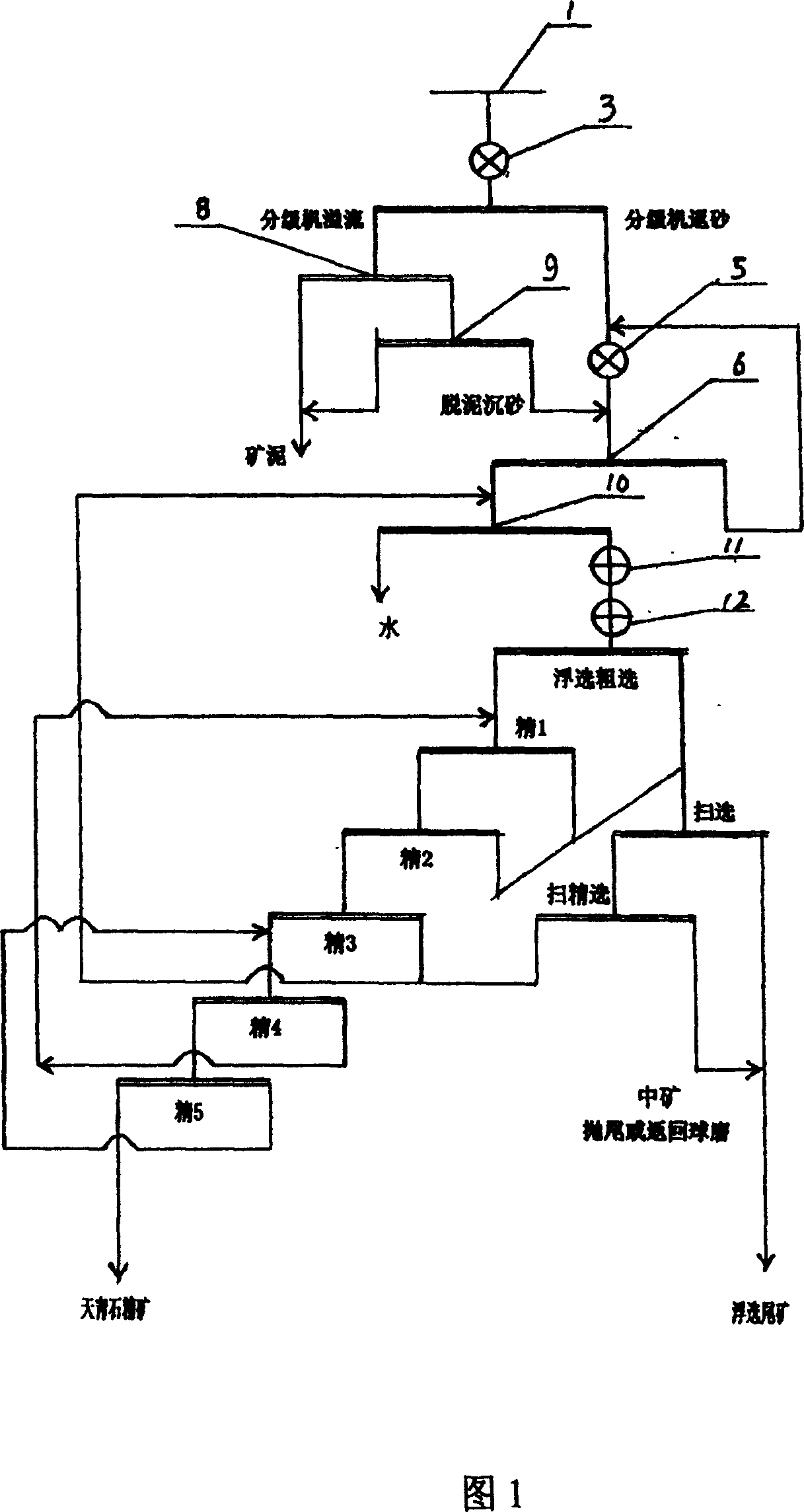

Deslim-floatation celestite inished ore process

InactiveCN1321746CRaise the gradeLarge amount of processingFlotationGrain treatmentsStrontium carbonateScavenger

The invention relates to a process for separating mineral of Celestine, especially relating to a finished ore process of desliming-multiple selection. The inventive method comprises: the ore is processed with rod milling, secondary desmliming, spiral classifying, floatation-roughing separation, secondary scavenger, and fifth classifying. The invention comprises following advantages: the inventive process has better mineral separation index when it is used to classify the Celestine with large content of low-grade mud, while the finished ore productivity is 37.82-42.09%, the content of SrSO4 is 75.75-80.10% and the recovery ratio is 75.17-79.59%; the fifth floatation device has large handling capacity, lower water consumption, lower cost of finishing ore, and lower medicament consumption with simple device. The invention has stable process, simple operation and wide application in the finishing-separation production of Celestine, while it can supply high grade Celestine finished ore for producing strontium carbonate.

Owner:QINGHAI JINRUI MINERAL DEV

Method for cyclic utilizing mineral dressing waste water from sulphur ore of lead-zinc

InactiveCN1234620CEliminate the effects ofAvoid pollutionWater/sewage treatment by neutralisationWater/sewage treatment by flocculation/precipitationAluminium sulfateWastewater

The waste water circular utilization provided by this invention is to use mineral operation waste water for milling of ores prodn. zenc tail water can be direct reused to zenc selecting operation, flume water can be direct reused to sulphur selecting operation, mineral operation waste water can be reused for ore grinding, lead selecting and mineral operation after being processed suitably. Said processes include: to add sulphuric in mineral operation waste water to adjust pH value to 8-11, add flocculator and aluminum suffate to do coagulating sedimentation, then to do adsorption to the waste water being processed by coagulating sedimention by adding active carbon again, to add defoaming agent into the mineral operation waste water.

Owner:南京银茂铅锌矿业有限公司 +1

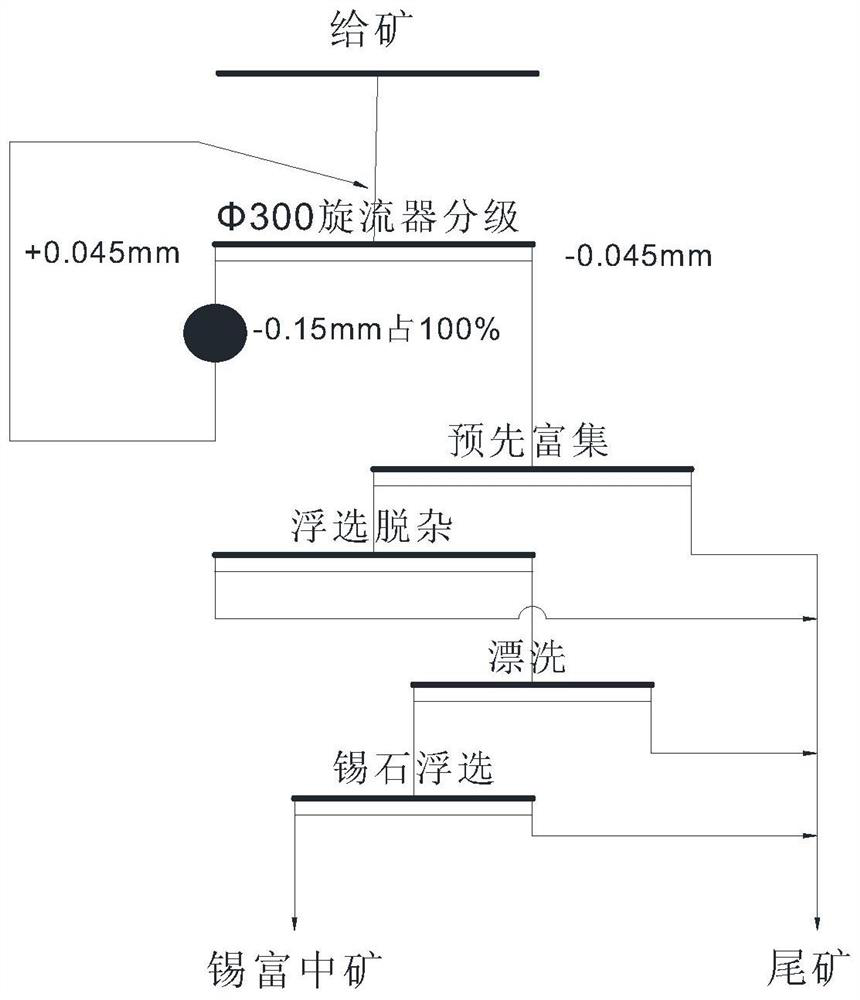

Method for recovering tin metal from low-grade tin old tailings

The invention relates to a method for recovering tin metal from low-grade tin old tailings. The method comprises the following steps: grading the tin old tailings pulped by using a cyclone; after grading, grinding + 0.045 mm size fraction minerals till 0.015 mm size fraction minerals account for 100%; combining the graded 0.045 mm product with the ground 0.015 mm product and carrying out pre-enrichment; carrying out flotation on the enriched concentrate for impurity removal; adding water to rinse after removing calcium-containing impurities, removing reagents, and concentrating; and finally, carrying out tinstone flotation to obtain a product rich in middlings, the tin grade of which is greater than 5%. The method is simple in technological process, good in beneficiation index, low in operation cost and easy to implement industrially, and has good application and popularization prospects.

Owner:云南锡业研究院有限公司

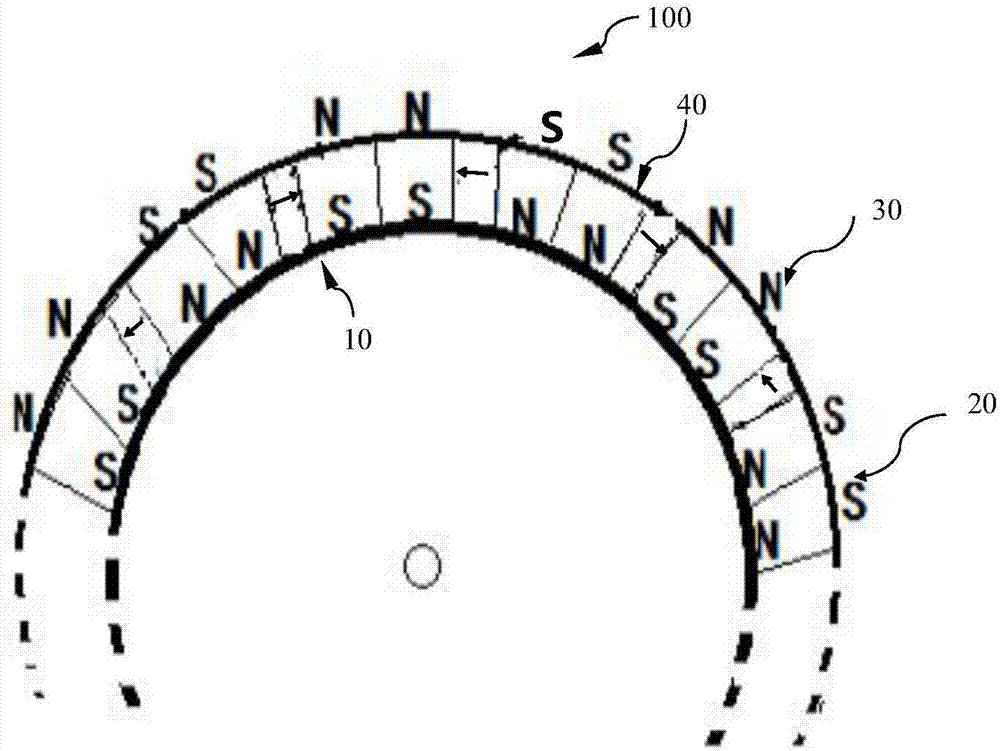

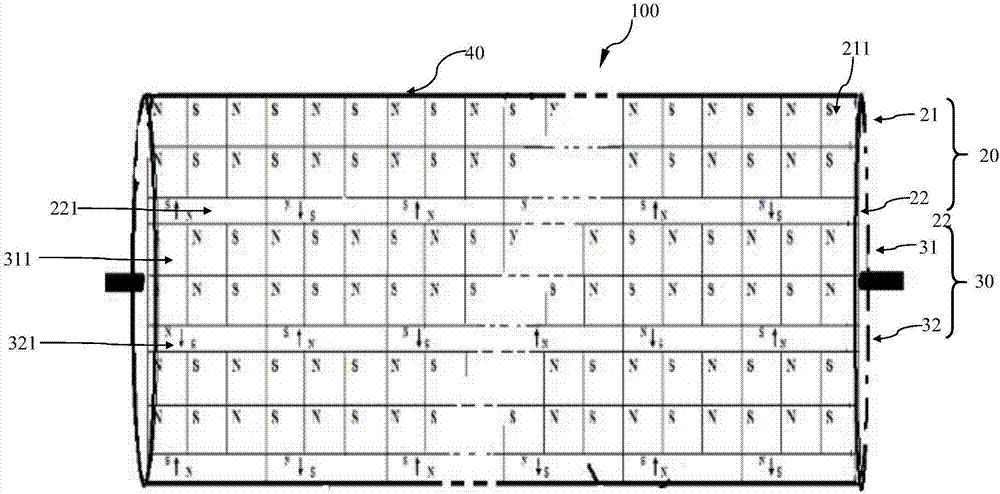

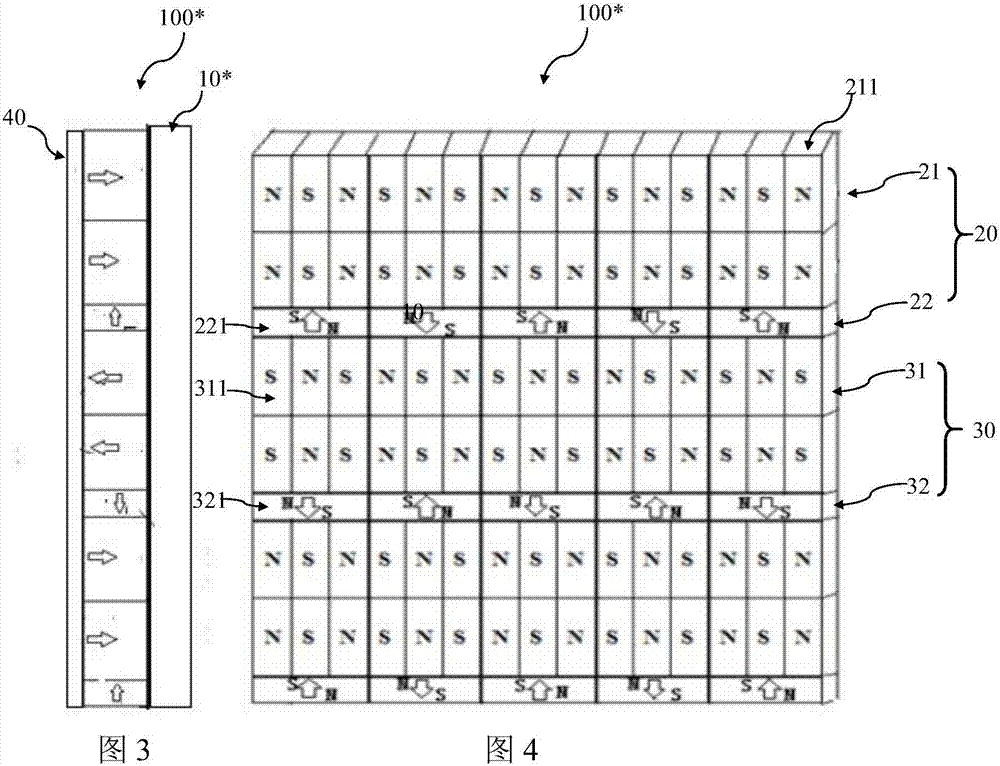

Magnet device, magnetic separator and application

ActiveCN107185709ARaise the gradeAccelerated disengagementMagnetic separationElectrical polarityMagnetic separator

A magnet device comprises a magnetic conductive layer and a magnet layer, wherein the magnet layer is attached to the surface of the magnetic conductive layer and composed of a plurality of first magnet parts and a plurality of second magnet parts; each first magnet part comprises first main magnet units and a first auxiliary magnet unit; each first main magnet unit is formed by arranging first main magnet blocks in the second direction perpendicular to the first direction, and the polarities of every two adjacent magnetic poles of the first main magnet blocks are opposite; each first auxiliary magnet unit is formed by arranging first auxiliary magnet blocks in the second direction in the mode that the polarities of every two adjacent magnetic poles of the first auxiliary magnet blocks are opposite; each second magnet part comprises second main magnet units and a second auxiliary magnet unit; the magnetization direction of the first main magnet blocks and the magnetization direction of second main magnet blocks are parallel, and the magnetization direction of the first auxiliary magnet blocks and the magnetization direction of second auxiliary magnet blocks are perpendicular to the magnetization direction of the first main magnet blocks and the magnetization direction of the second main magnet blocks; and according to the arranging sequence in the second direction, the polarities of the magnetic poles of the first main magnet blocks and the second main magnet blocks in the same serial number are opposite, and the polarities of the magnetic poles of the first auxiliary magnet blocks and the second auxiliary magnet blocks in the same serial number are opposite.

Owner:张弦

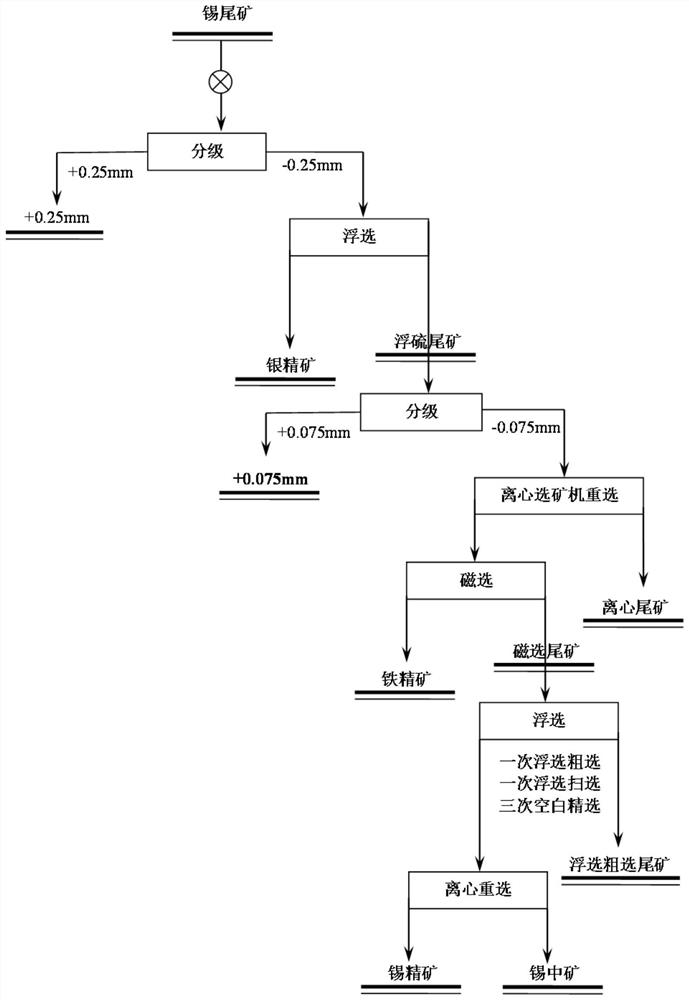

A method for comprehensive recovery of silver, tin and iron from quartz vein type tin tailings

ActiveCN110479499BReduce follow-up workloadIncrease production capacityFlotationMagnetic separationCassiteriteEngineering

The invention relates to a method for comprehensively recovering silver, tin and iron from quartz vein type tin tailings. The beneficiation method includes the following steps: S1: classify the tin tailings and carry out flotation at the fine-grained grade; S2: adjust the slurry, perform a rough separation, a sweep separation and a blank separation to obtain silver concentrate and sulfur separation tailings ;S3: Sulfur separation tailings classification, fine-grained class for cassiterite separation operations; S4: Gravity separation, to obtain centrifugal rough concentrate and centrifugal tailings; S5: Magnetic separation and centrifugal coarse concentrate to obtain iron concentrate and magnetic separation Tailings; S6: Perform a flotation roughing on the magnetic separation tailings to obtain a flotation roughing concentrate and a flotation roughing tailings; S7: Perform a flotation sweep on the flotation roughing tailings to obtain a flotation roughing Concentrate and sweeping tailings; S8: perform three blank separations on the flotation rough concentrate to obtain tin rough concentrate; S9: re-select tin rough concentrate to obtain tin concentrate and tin medium ore. The beneficiation method has low energy consumption, small equipment footprint and high separation efficiency.

Owner:INST OF RESOURCES UTILIZATION & RARE EARTH DEV GUANGDONG ACAD OF SCI

Magnetic-flotation combined beneficiation process of spodumene

ActiveCN109107754BThe flotation process is stableGood beneficiation indexWet separationOleic Acid TriglycerideMagnetic separation

The invention discloses a magnet-flotation combined beneficiation technology of spodumene. Spodumene ore is subjected to smashing and grinding. Ore pulp after grinding is sequentially subjected to lowintensity magnetic separation and high intensity magnetic separation to respectively obtain low intensity magnetic concentrated ore and high intensity magnetic concentrated ore. The discharged high intensity magnetic tailing ore is subjected to concentration and desliming, and is provided for flotation operation. Procedures of the flotation operation comprises one time of roughing, two times of scavenging and two times of concentrating. A collecting agent adopts compound of Fatty calcium, hydroxylamine compound and oleic acid, wherein the ratio is (6-7):(2.0-2.5):(1.0-1.5). The Li2O grade inthe final lithium concentrate is as high as 5.8-6.4%, and the recycling rate is 79.0-88%. The beneficiation technology is simple, stable and reliable, applicability is high, the laboratory index and the industrial application index are in agreement with each other, and the disadvantage of a big gap between the industrial application index and the laboratory index in the spodumene beneficiation technology is overcome. The collecting agent is excellent in selectivity, high in collecting performance, and is environmentally friendly.

Owner:SINOSTEEL MAANSHAN INST OF MINING RES CO LTD +1

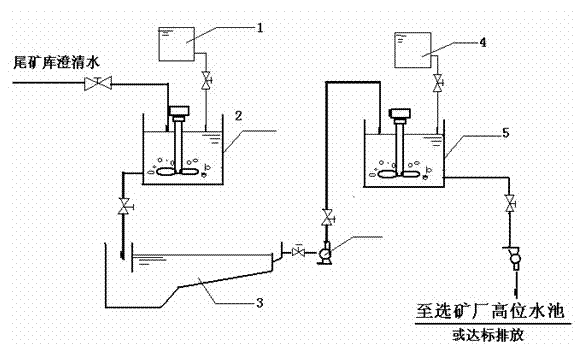

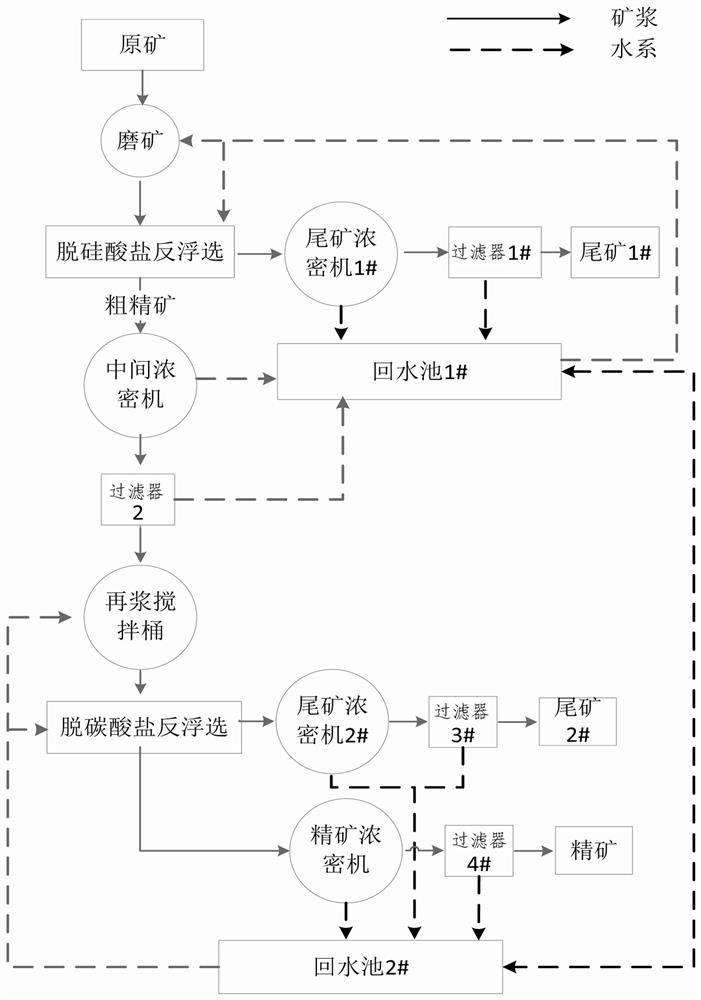

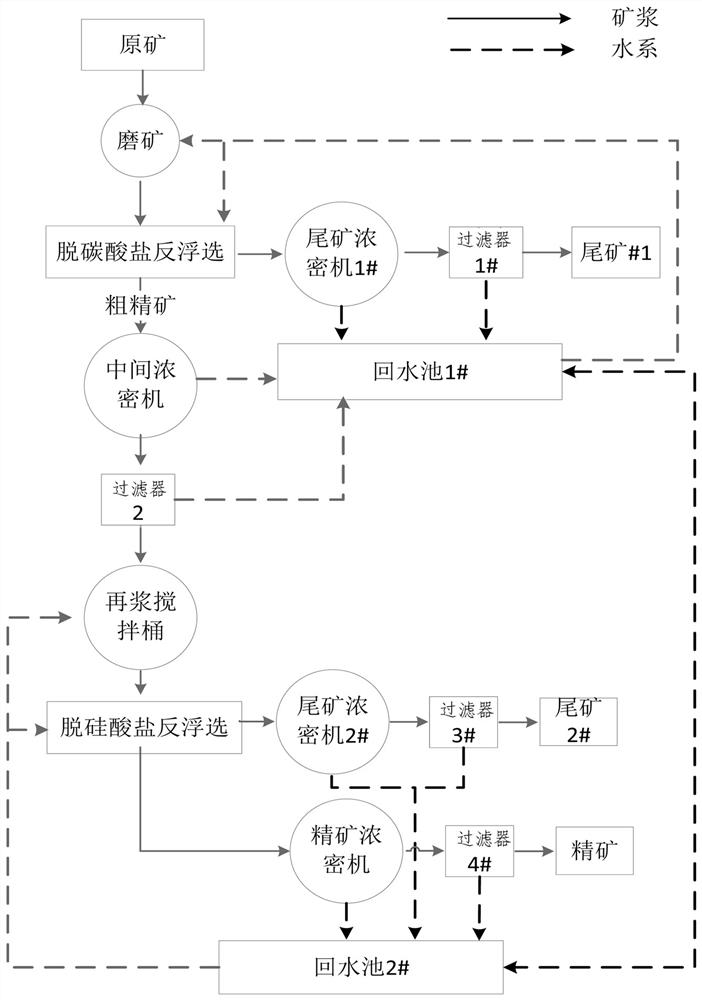

Method for recycling waste water in collophanite double-reverse flotation process according to different qualities

ActiveCN112237993AStable productionGood beneficiation indexGeneral water supply conservationFlotationPhosphoriteProcess engineering

The invention provides a collophanite double-reverse flotation process wastewater quality-based recycling method, and the method comprises the following steps: grinding collophanite, performing reverse flotation of silicate mineral removal on graded overflow to obtain tailings and rough concentrate, feeding the tailings into a tailing thickener for thickening, and filtering to obtain tailings; enabling the rough concentrate to enter an intermediate thickener to be thickened, performing filtering, performing size mixing on a filter cake obtained after filtering, performing reverse flotation forremoving carbonate minerals again, and obtaining tailings and concentrate pulp; thickening the tailings by a tailing thickener, and performing filtering to obtain tailings; thickening the concentratepulp by a concentrate thickener and then performing filtering to obtain concentrate. Reverse flotation for removing silicate minerals is carried out under the alkaline condition that the pH value is8.5-9.5, and an amine cation collecting agent is added; reverse flotation for removing carbonate minerals is carried out under the acidic condition that the pH value is 4.0-5.0, and a fatty acid anioncollecting agent is added. The method creates a scientific and economic industrial implementation scheme for dual reverse flotation of collophanite.

Owner:YIDU XINGFA CHEM COMPANY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com