Beneficiation process for pulverized mine of specularite in alpine region

A technology for mirror iron ore in alpine regions, which is applied in the field of beneficiation technology of mirror iron ore powder in alpine regions, can solve the problems of uneven ore reduction, high roasting cost, and difficulty in industrial production, and achieves uniform and thorough particle roasting. The effect of eliminating the blockage of the mine silo and effectively and rationally using it

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The specific embodiments of the present invention will be further described below in conjunction with the drawings.

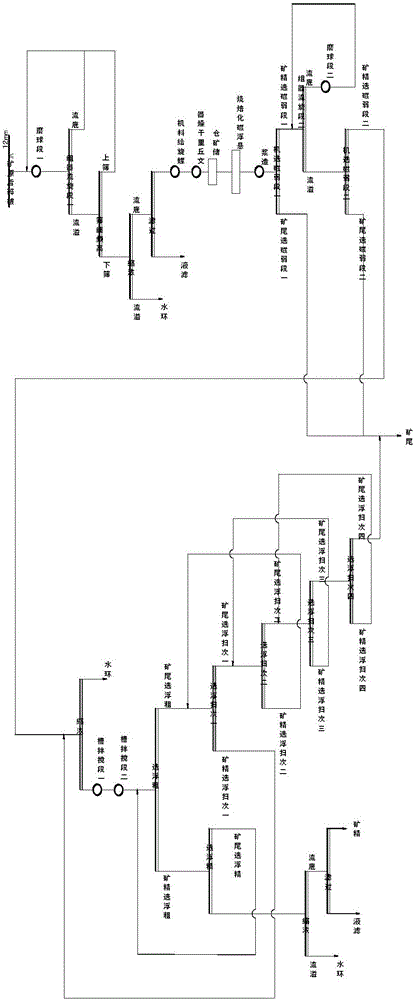

[0025] Such as figure 1 As shown, the beneficiation process of specularite fines in the high-cold area of this embodiment consists of beneficiation steps before roasting, magnetic levitation roasting, and beneficiation after roasting, which are specifically carried out according to the following steps:

[0026] (1) Beneficiation before roasting: the crushed specularite ore with a particle size of ≤12mm is sent to the pre-roasting beneficiation system for a ball milling-classification operation and a dewatering operation before roasting, and the discharge of a ball mill is fed to a cyclone group for classification. , The overflow of the first-stage cyclone group is fed into the high-frequency fine sieve for classification. The sieving particle size of the high-frequency fine sieve is 0.3mm. The top of the high-frequency fine sieve and the sedimentation of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com