Patents

Literature

76results about How to "Reduce follow-up workload" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

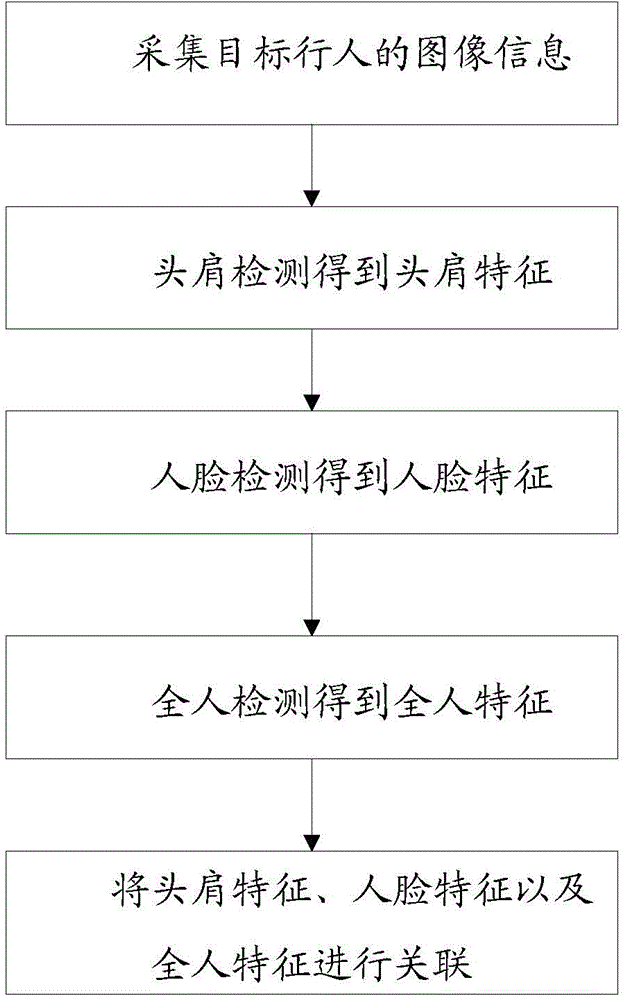

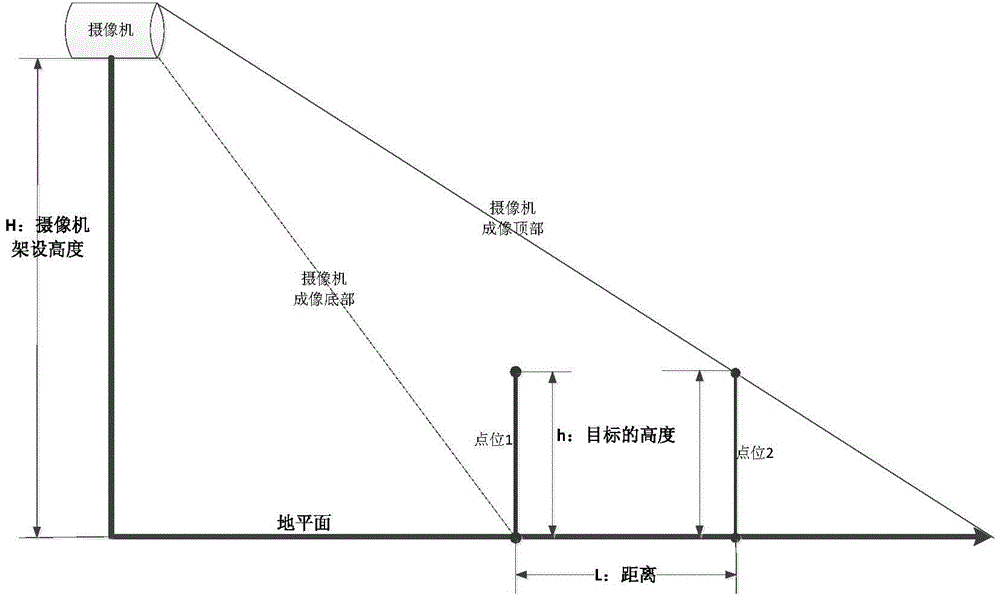

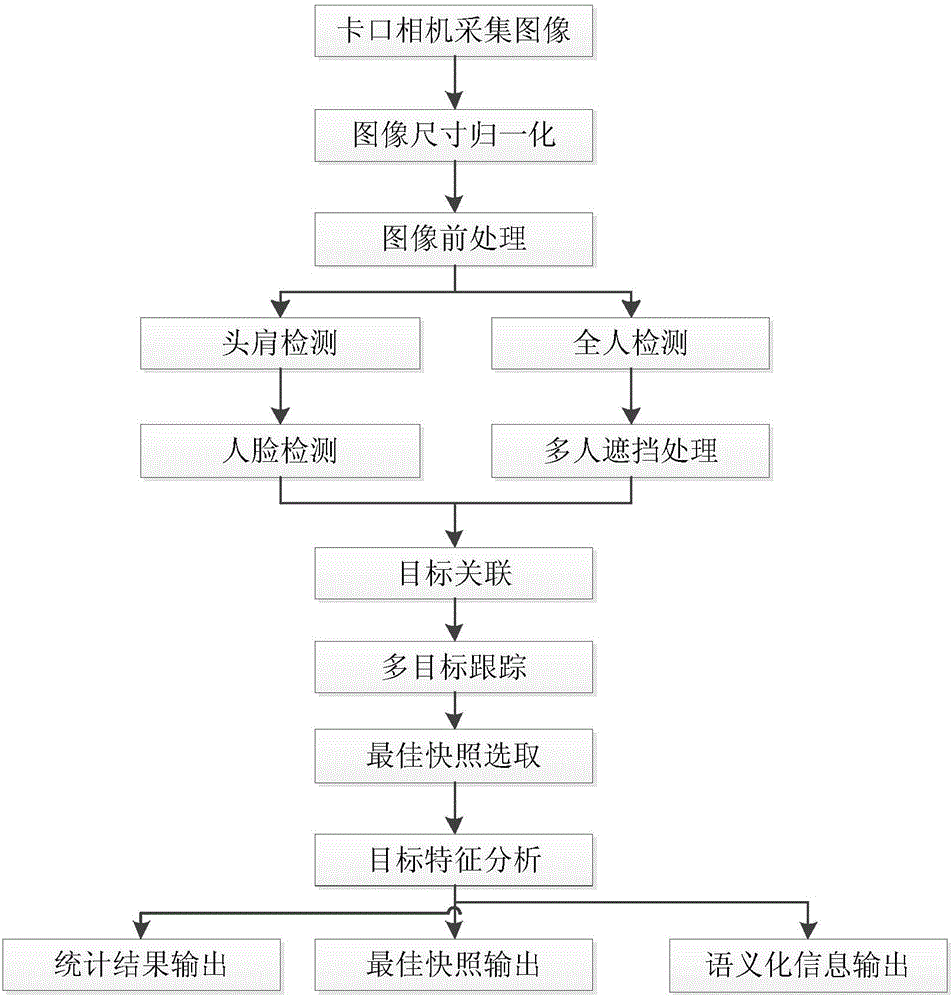

Pedestrian detection method and system

ActiveCN104361327AReduce follow-up workloadReduce the amount requiredCharacter and pattern recognitionFace detectionPhysical medicine and rehabilitation

The invention provides a pedestrian detection method and system. According to the pedestrian detection method, head and shoulder detection, face detection and whole body detection are carried out on a collected image to obtain one or more kinds of features of the head and shoulders in front, the head and the shoulders at back or the head and the shoulders on the side, feature information of the whole body in front, feature information of the whole body at back, feature information of the whole body on the left and feature information of the whole body on the right. Accordingly, the features of the head and the shoulders in front, at back and on the side and features of the whole body at multiple angles of a target pedestrian with the covered face or a camouflage target pedestrian can be obtained, real-time handling of illegal activities and postmortem analysis are facilitated, and later workload of related staff can be greatly reduced. Defects of a staff gate system based on face detection in the prior art are overcome. The method and system are suitable for face detection in front, can be used for pedestrian detection at back and on the side, all information of a person is basically included in a face snapshot and a whole body snapshot of the person, and later deep analysis is facilitated.

Owner:SUZHOU KEDA TECH +2

Dressing method for high-phosphor-content oolitic hematite

InactiveCN102716801AScientific and reasonable processEasy to operate on siteFlotationWet separationFinenessDressing method

The invention relates to a dressing method for high-phosphor-content oolitic hematite. The dressing method has the technical scheme that the method comprises the following steps that 1, high-phosphor-content oolitic hematite ore with the crushing granularity smaller than 20mm to 30mm is fed into an ore grinding machine, and the high-phosphor-content oolitic hematite is subjected to continuous two-section ore milling until the ore with the ore fineness smaller than 0.074 accounts for about more than 90 weight percent; 2, the milled ore pulp passes through a pulp removing hopper for removing sludge smaller than 0.020m, and the removed sludge is directly subjected to tail-escaping; 3, the ore pulp subjected to the sludge removal is subjected to twice continuous wet type strong magnetic sorting, tailings in the first strong magnetic sorting and tailings in the second strong magnetic sorting are directly discharged into a tailing storage pool; 4, the hematite ore pulp subjected to the strong magnetic sorting is subjected to re-sorting by a table concentrator to obtain coarse particle hematite concentrate; 5, the re-sorted table concentrator middlings and tailings after the coarse particle hematite concentrate sorting are mixed, then, a one-coarse one-sweep and three-concentration floatation process is adopted, fine particle hematite concentrate is obtained, the two parts of hematite concentrate including the coarse hematite concentrate and the fine hematite concentrate are mixed, dephosphorizing agents are added for stirring treatment, and the final oolitic hematite concentrate is obtained. The method has the characteristics that the process flow is simple, the in-site operation is simple, the cost is low, the grade of the oolitic hematite concentrate is high, and the recovery rate is high. The TFe grade of the obtained oolitic hematite concentrate is higher than 58 weight percent, P is less than 0.12 weight percent, and the recovery rate is higher than 70 weight percent.

Owner:宜昌市正济文化传播有限公司

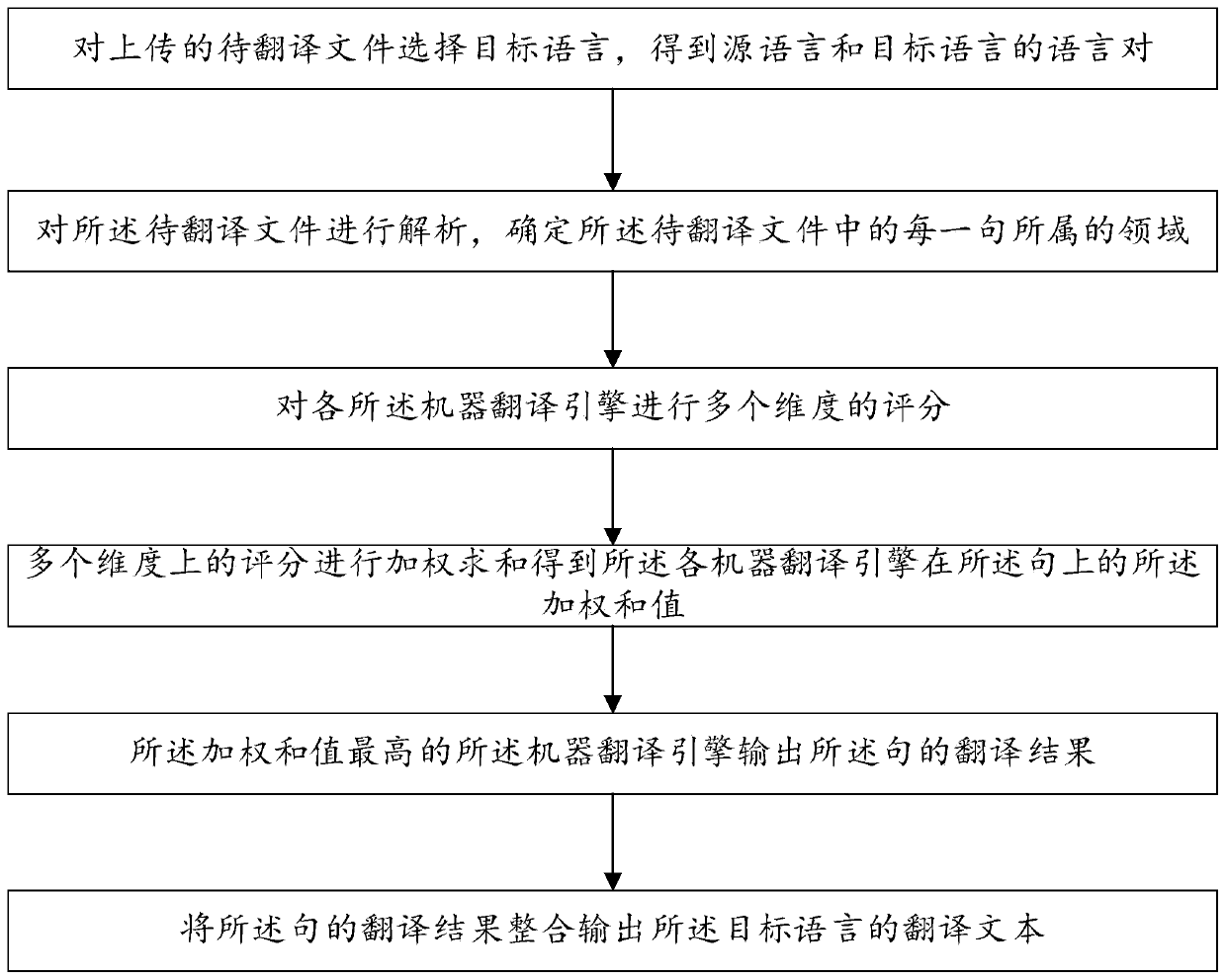

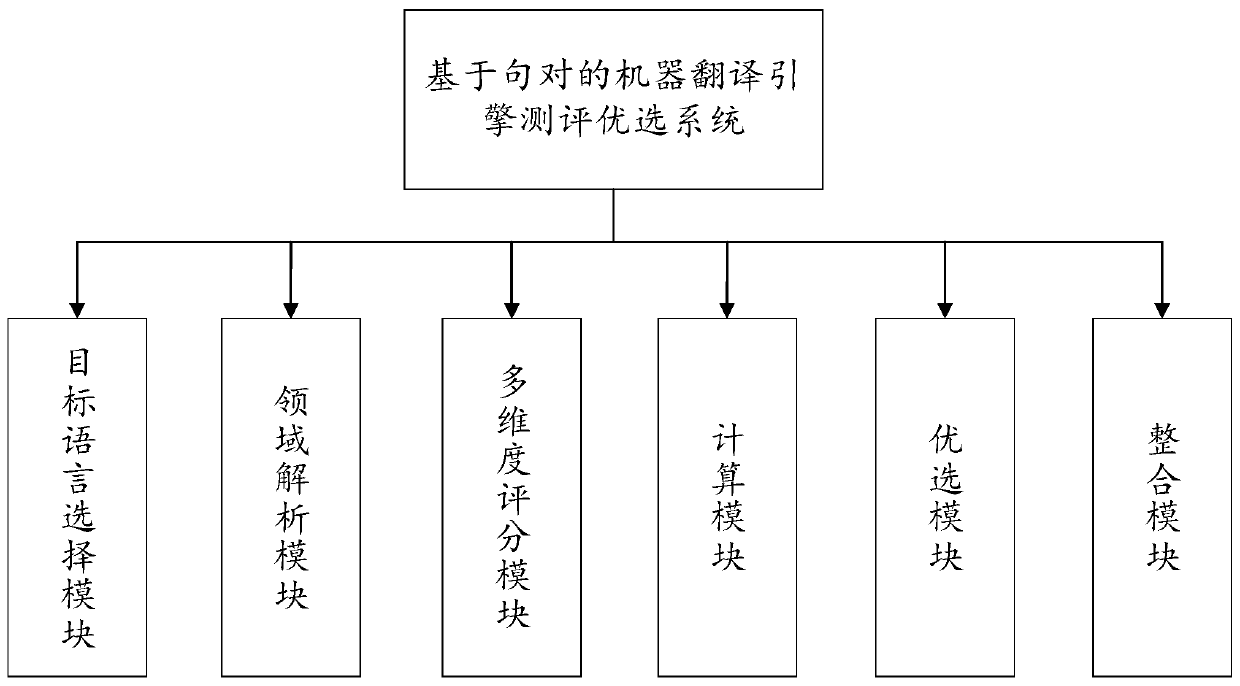

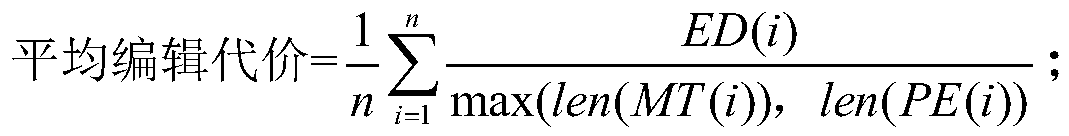

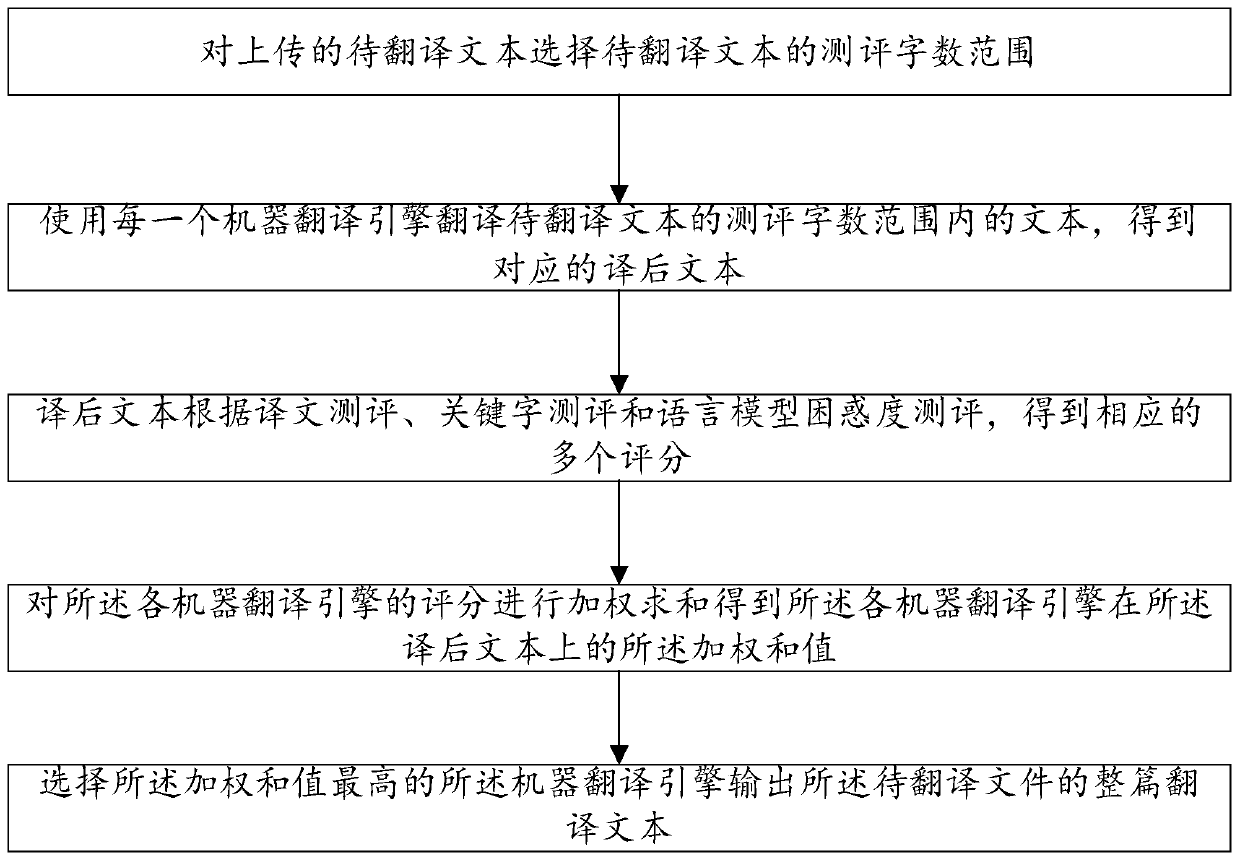

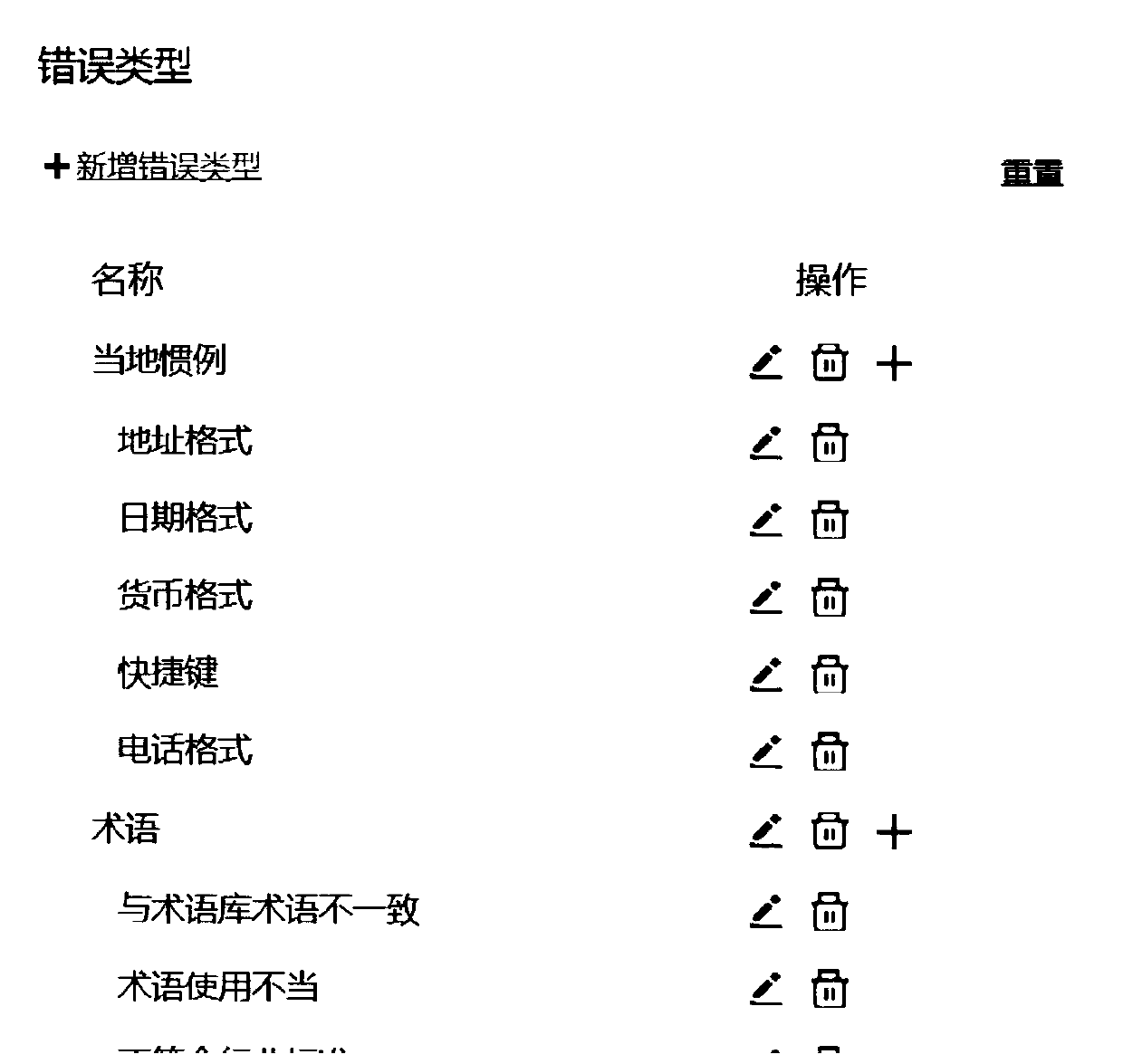

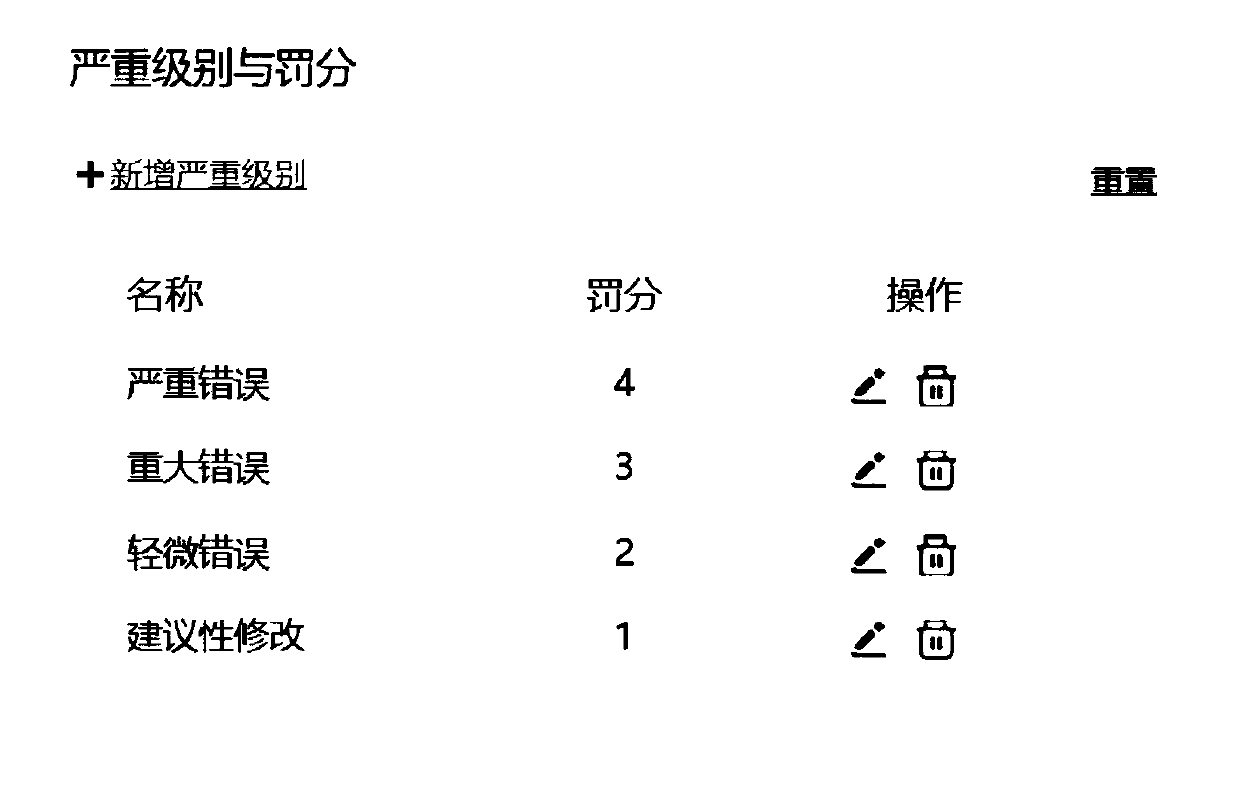

Sentence pair-based machine translation engine evaluation optimization method and system

PendingCN110472257AReduce follow-up workloadGood serviceSpecial data processing applicationsSentence pairWorkload

The invention discloses a sentence pair-based machine translation engine evaluation optimization method and system. According to the method, multi-dimensional scoring is carried out on all machine translation engines according to selected language pairs and sentence fields, then weighted summation is carried out on scores to obtain weighted sum values of all the machine translation engines on sentences, the machine translation engine with the highest weighted sum value is selected to output translation results of sentences, and therefore a whole translation text is obtained through integration. Through the method, machine translation engine automatic optimization service can be provided for users in various complex machine translation engines with uneven translation quality and different skilled fields and language pairs; each sentence can obtain the most excellent machine translation engine service at present when a user translates a file and other long texts, the translation efficiency is improved, the subsequent workload of the user is reduced, and high-quality machine translation service is provided.

Owner:南京题麦壳斯信息科技有限公司

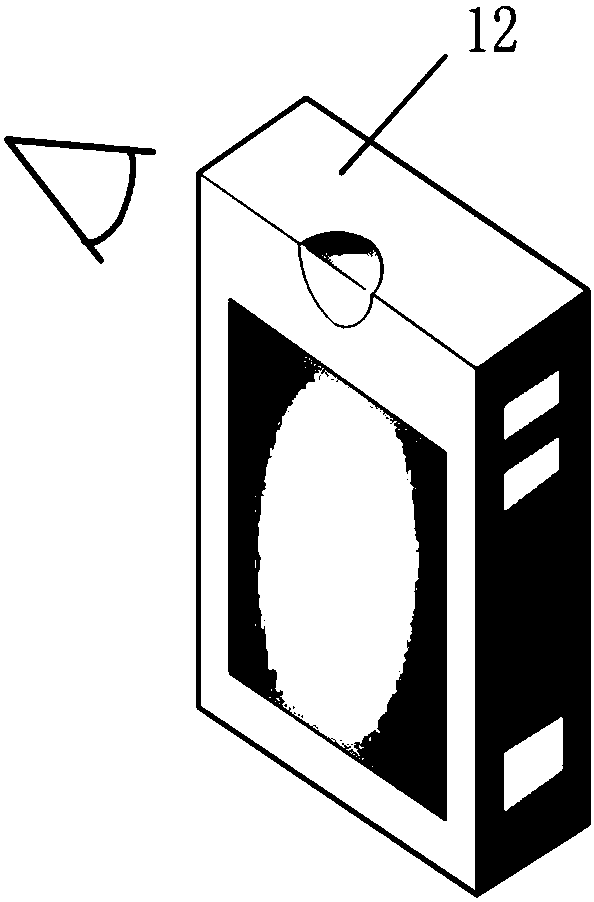

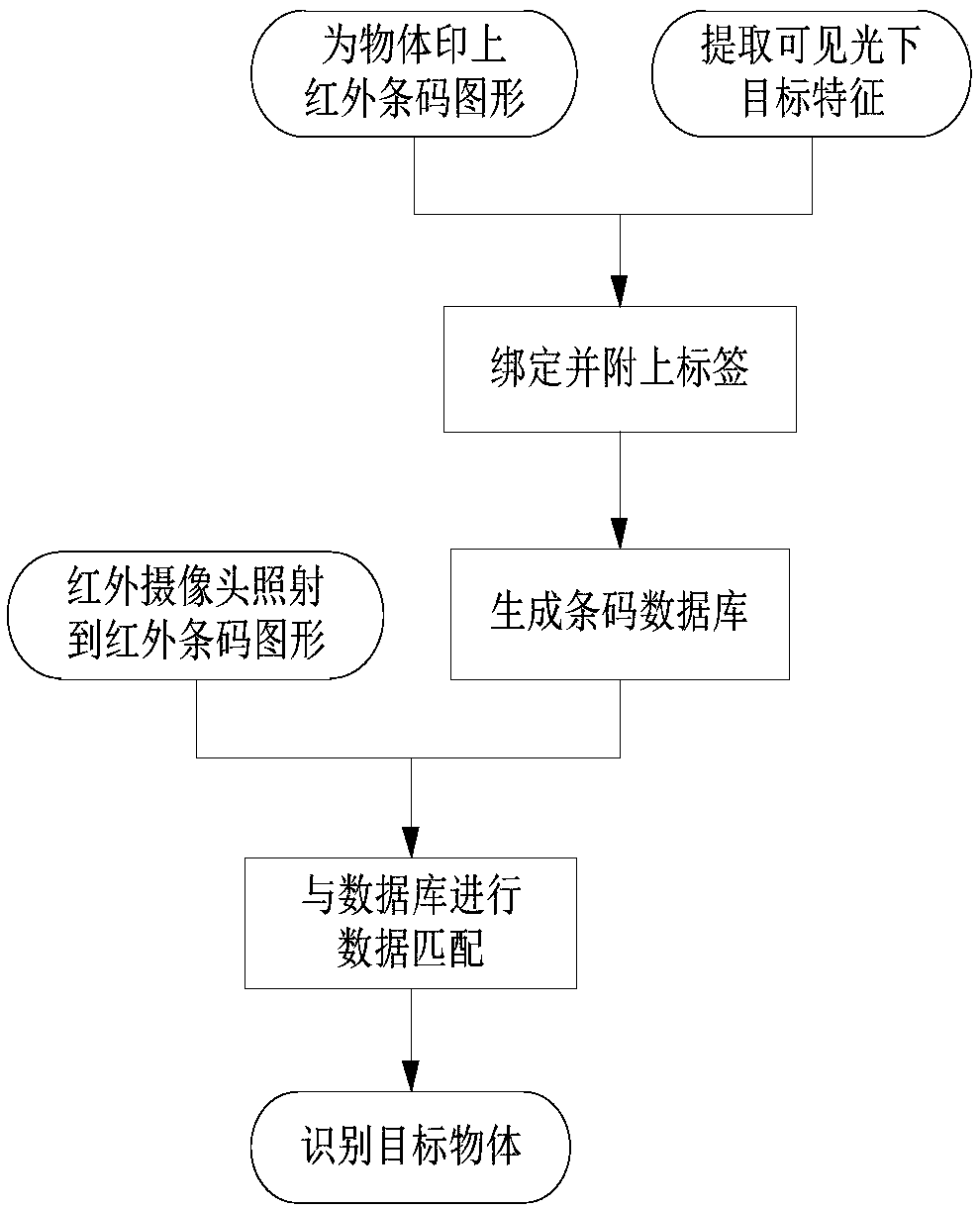

Target tracking method based on visible light and invisible light information fusion

ActiveCN108229238AReduce follow-up workloadRecord carriers used with machinesSensing by electromagnetic radiationGraphicsBarcode

The invention relates to a target tracking method based on visible light and invisible light information fusion. The method comprises steps as follows: 1) invisible light recognizable barcode graphs are added to a target object; 2) an image of the target object is collected by a visible light camera and an invisible light camera simultaneously; 3) target object features recognized by the visible light camera and target object barcode graphs recognized by the visible light camera are bound, and double-target tracking is performed. Compared with the prior art, the method has the advantages thatno matter whether the target is a life body or a nonlife body, the target can be recognized and tracked, accordingly, convenient information can be provided under many conditions, and following workload is reduced.

Owner:苗鹏

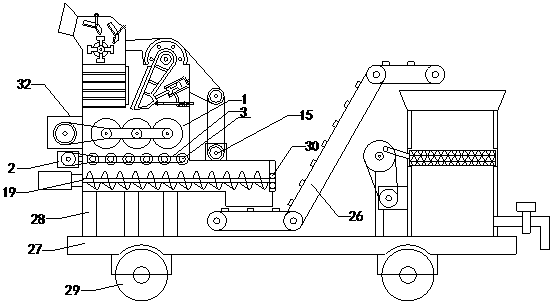

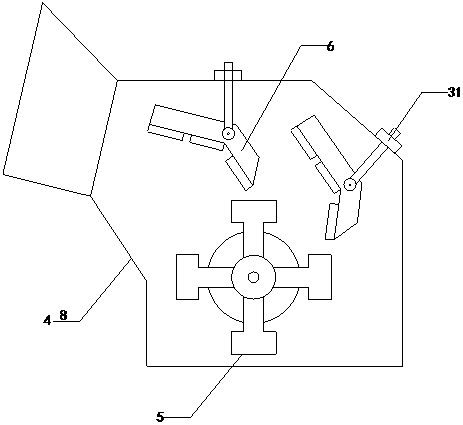

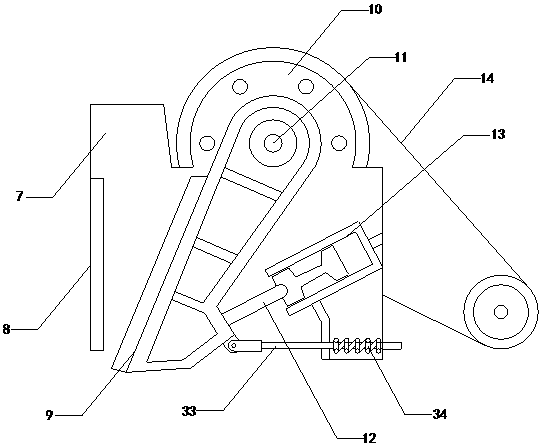

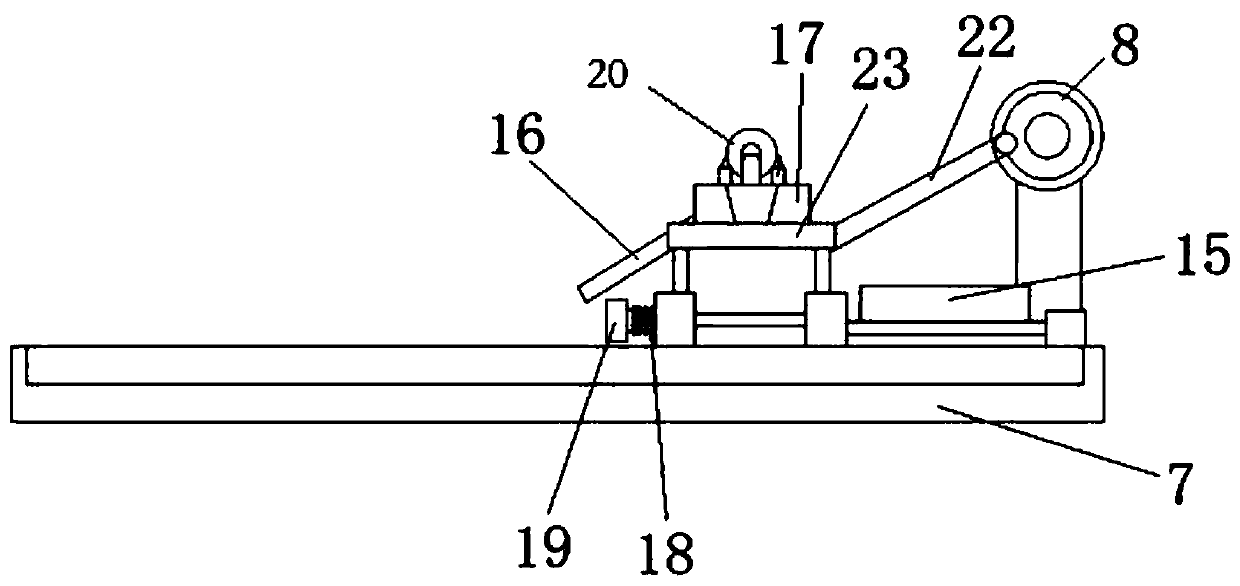

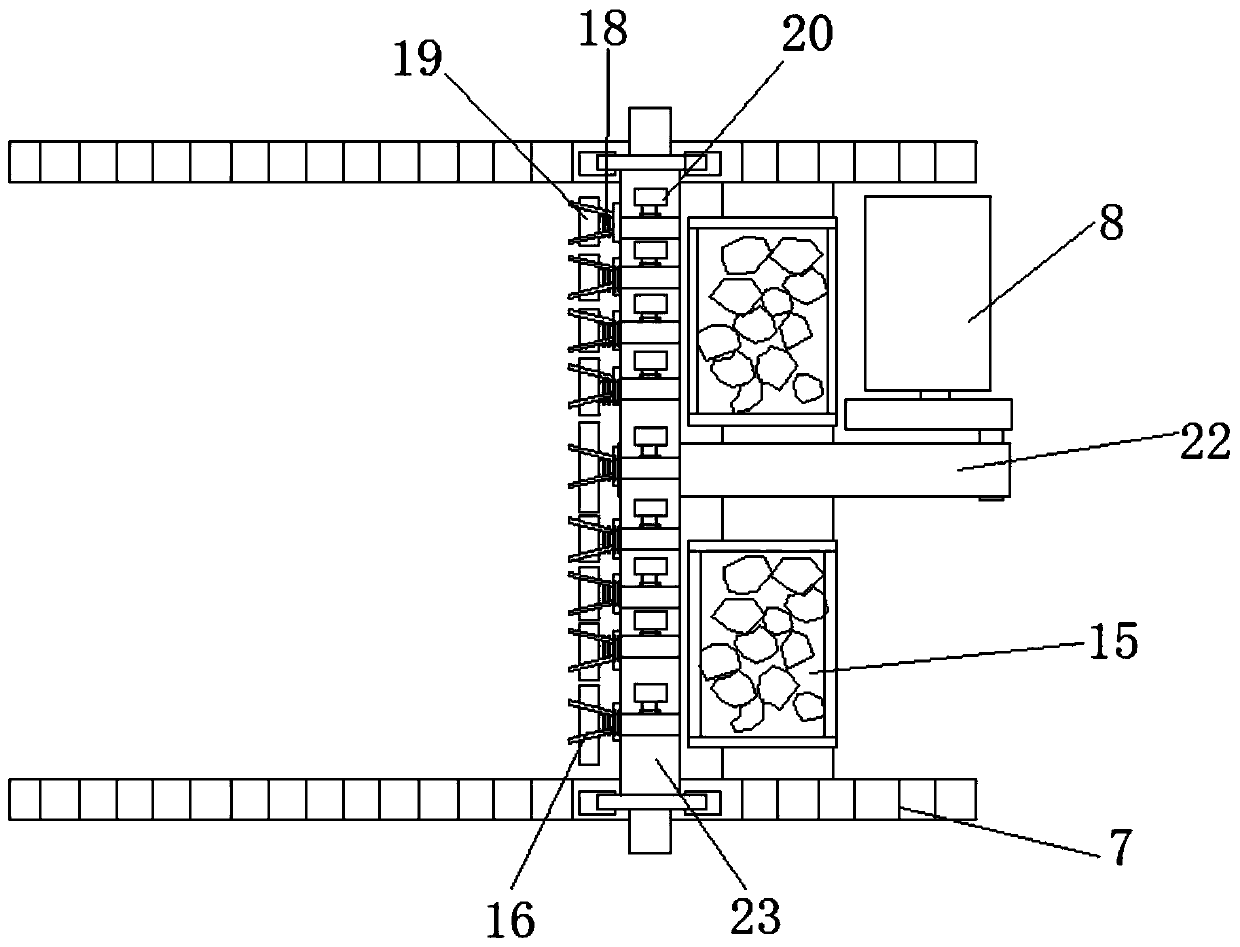

Concrete crusher for building

ActiveCN108311264AImprove the use of limitationsImprove practicalityPackagingGrain treatmentsEngineeringCrusher

The invention relates to the technical field of building accessory devices, in particular to a concrete crusher for building. According to the concrete crusher for building, the large volume of concrete can be smashed, and using limitation is improved; and the smashed concrete can be guided out timely, the subsequent workload is reduced, and practicality is improved. The concrete crusher comprisesa box body, a smashing compression roller motor and a first belt, and further comprises a first-stage crushing box, a pendulum bob, a counterattack plate, a second-stage crushing box, a static jaw plate, a movable jaw plate, a belt wheel, an eccentric shaft, a thrust plate, an adjusting block, a second belt and a crushing motor, wherein the first-stage crushing box, the second-stage crushing boxand box body communicate with one another; the concrete crusher further comprises a shredding motor, a shredding belt and a shredding roller, and the shredding motor is in rolling connection with theshredding roller through the shredding belt; and the concrete crusher further comprises a screw conveyor, the top end of the screw conveyor is provided with a conveying port which communicates with adischarging outlet of the box body, and the bottom end of the right side of the screw conveyor is further provided with a feeding inlet which communicates with the outside.

Owner:新疆智友建设工程有限公司

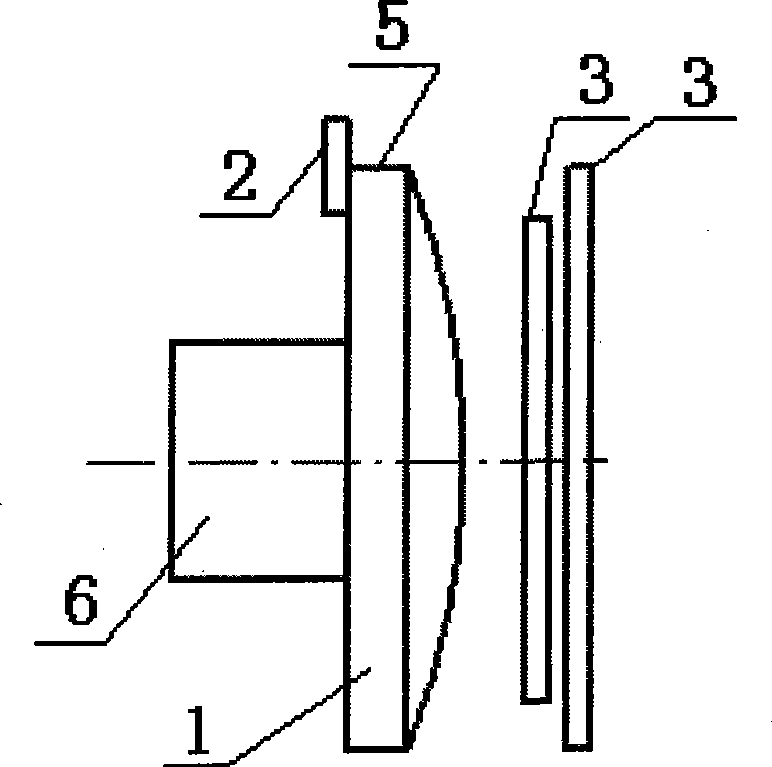

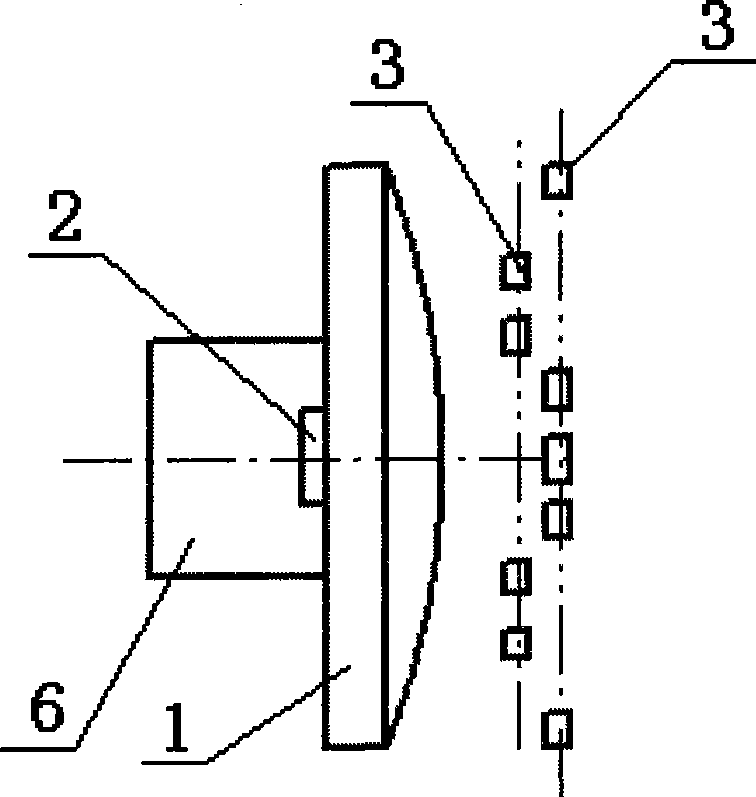

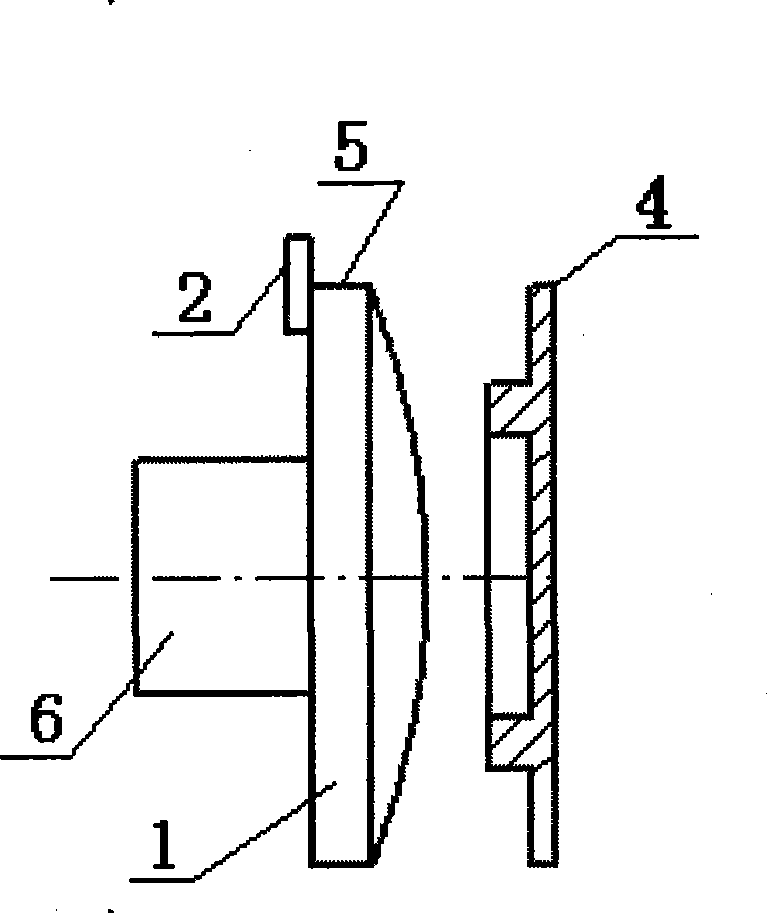

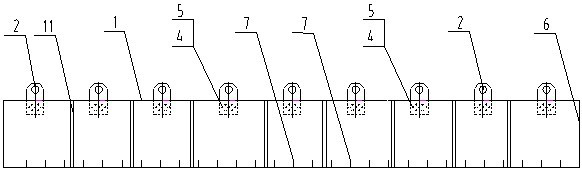

Chrome plating method for spherical crown surface of major diameter spherical crown workpiece

The invention provides a method for plating chromium on a spherical cap surface of a large-diameter spherical cap workpiece. In a step of immersing and positioning, the arrangement mode or structure of an anode strap or an anode plate is changed; in a step of plating chromium, opacified chromium is plated under the conditions that the temperature of the plating solution is 70 to 75 DEG C and the current density is 20 to 25A / decimeter<2>; and then, hard chromium is plated under the conditions that the temperature of the plating solution is 50 to 55 DEG C and the current density is 25 to 30A / decimeter<2>. The polishing processing is carried out on the spherical cap surface of the workpiece, which has the advantages of good evenness of chromium plated coating, defect prevention, high electroplating efficiency, fast speed of cladding deposit, high surface finish of the spherical cap surface after chromium is plated, and subsequent mechanical processing workload reduction.

Owner:LUOYANG SUNRUI SPECIAL EQUIP

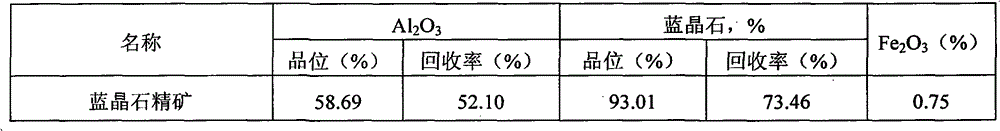

Beneficiation method for preparing kyanite ores

The invention specifically relates to a beneficiation method for preparing kyanite ores. The technical scheme includes that step one, the kyanite ores with certain particle sizes are subjected to ore grinding; step two, ore slime which is less than 0.020 mm in ground ore pulp is removed through a desliming bucket; step three, the desliming ore pulp is subjected to continuous wet type strong magnetic sorting; step four, the kyanite ore pulp which is subjected to the strong magnetic sorting is subjected to reselection through a table concentrator to obtain coarse particle kyanite ore concentrates; and step five, a flotation selection process is used for tailings of the table concentrator to obtain fine particle kyanite ore concentrates, and the coarse particle kyanite ore concentrates and the fine particle kyanite ore concentrates are combined and subjected to treatment of acid leaching and iron impurity removing to finally obtain the kyanite ore concentrates. The beneficiation method for preparing the kyanite ores has the advantages of being simple in technological process, easy to operate in scene and low in cost; the grade of aluminum oxide of the obtained kyanite ore concentrates is over 58 wt. %, the recovery rate of kyanite is over 70%, requirement of the country-levelkyanite ore concentrate standard can be satisfied, and the kyanite ore concentrates can be used as high-level refractory materials or raw materials of other industrial products.

Owner:XINGTAI XINGGUO KYANITE MFG

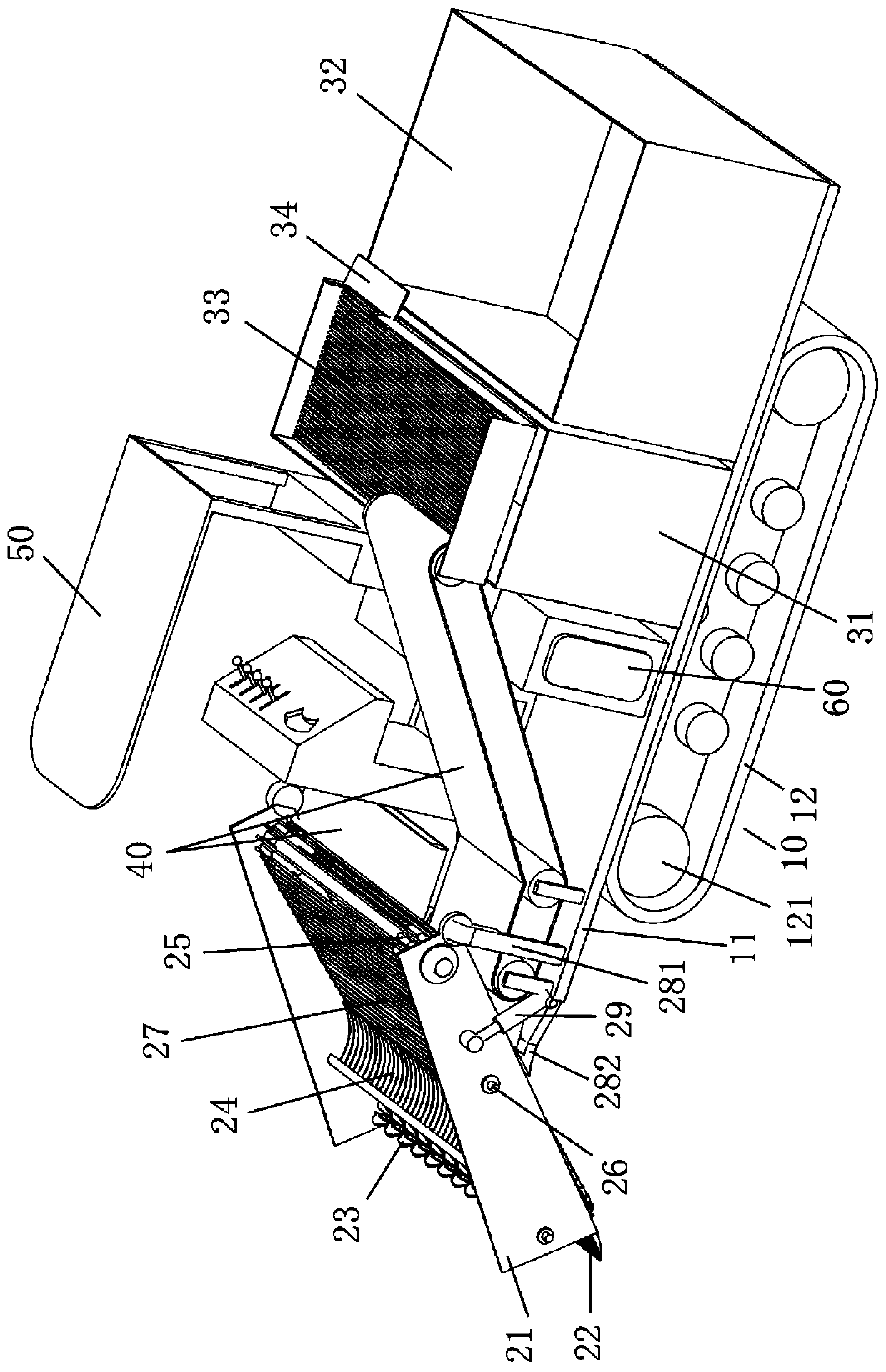

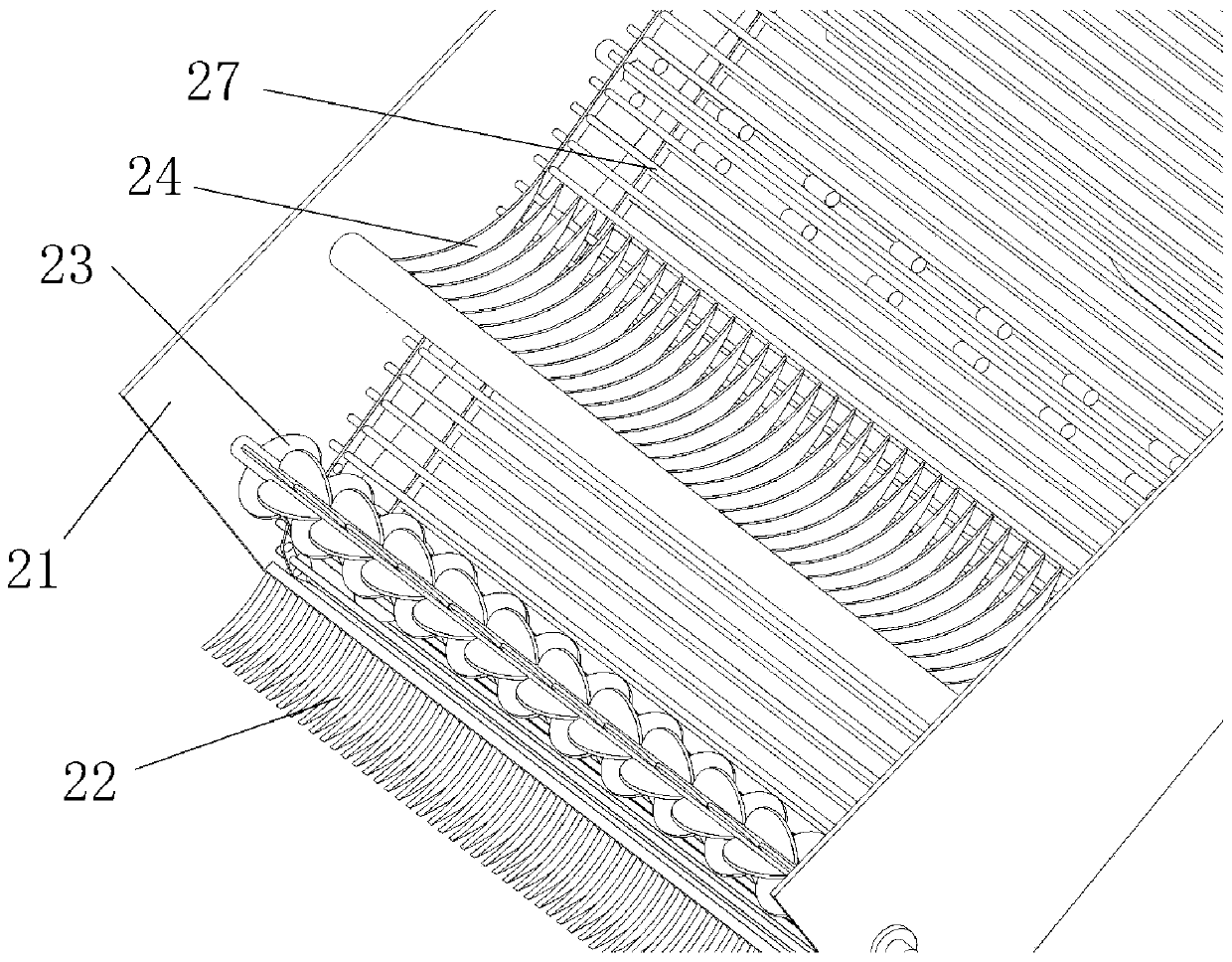

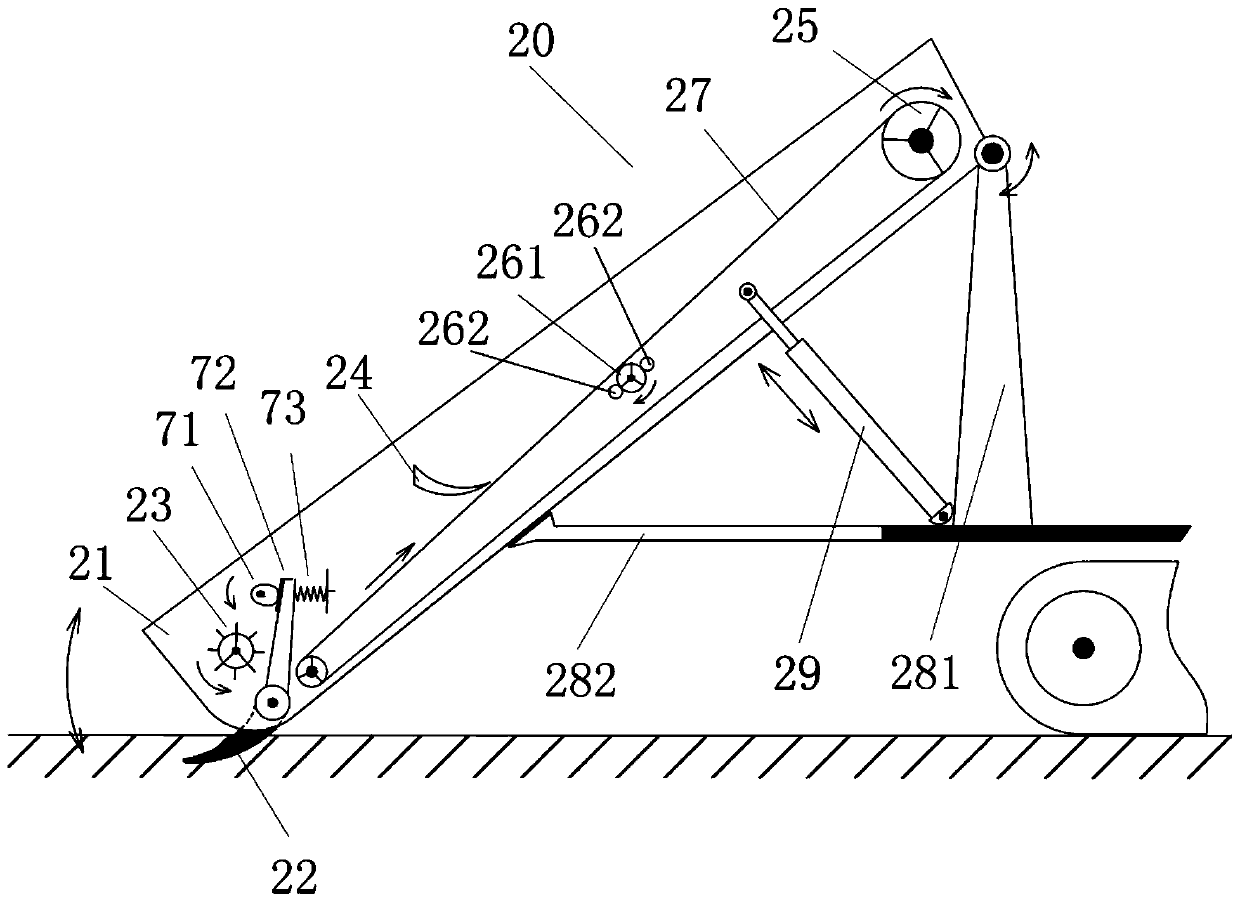

Ploughing type seashell harvesting machine

PendingCN110074076AEasy to separateImprove work efficiencyPisciculture and aquariaAgricultural engineeringShovel

The invention belongs to the technical field of shell harvesting equipment, and discloses a ploughing type seashell harvesting machine. The ploughing type seashell harvesting machine comprises a crawler belt vehicle body, a driving mechanism and a harvesting plough, wherein the driving mechanism is mounted on the crawler belt vehicle body; the harvesting plough is mounted at the front side of thecrawler belt vehicle body; the harvesting plough comprises a harvesting plough box body, plough teeth, a main conveying belt, mud cutting teeth and a vibration wheel; the harvesting plough box body isobliquely arranged at the front side of the crawler belt vehicle body; the plough teeth can be used for shoveling and collecting tidal mud, and are mounted at the front end of the harvesting plough box body; the main conveying belt is upwards transported in an inclined direction of the harvesting plough box body; the mud cutting teeth are used for cutting the tidal mud, and are mounted on the harvesting plough box body; the vibration wheel can vibrate the main conveying belt, and is rotationally arranged at the inner side of the main conveying belt. The ploughing type seashell harvesting machine has the advantages that the separation effect of a plough shovel and shell mud is relatively good; the continuous mechanical operation of the seashell shoveling and digging, sieving and picking and collection is realized.

Owner:古勇

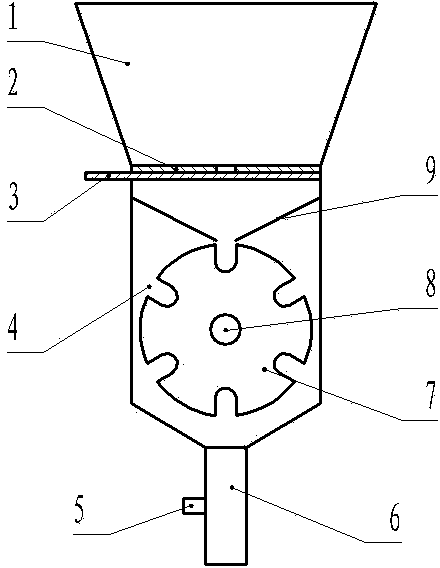

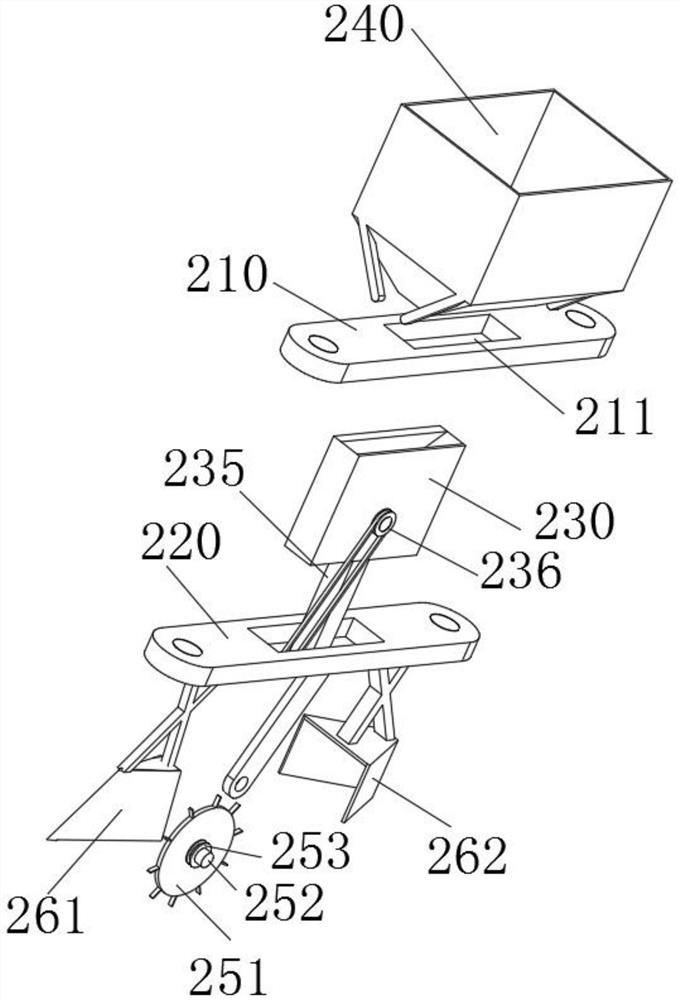

Seeding device

InactiveCN104303656AUniform dischargeAccurate outputSeed depositing seeder partsAgricultural engineering

The invention discloses a seeding device and relates to the technical field of agricultural machines. The seeding device comprises a storage box and a discharging box located below the storage box, a partition plate is arranged between the storage box and the discharging box, the partition plate is provided with a discharging port, two baffles arranged oppositely are installed in the discharging box, the two baffles incline downwards and form a discharging channel, a discharging rotating wheel is installed in the discharging box through a rotating shaft, a plurality of arc-shaped discharging grooves are evenly distributed in the periphery of the discharging rotating wheel, and a discharging pipe is arranged at the bottom of the discharging box. Compared with the prior art, the seeding device has the advantages that the rotating shaft drives the discharging rotating wheel to rotate, seeds are put into the discharging grooves, the seeds slide out of the discharging grooves and fall into formed furrows when the discharging grooves containing the seeds rotate to be above the discharging pipe, the seeds are uniformly discharged, the discharging quantity is accurate, and follow-up workloads are reduced.

Owner:LIUZHOU MEINA MACHINERY

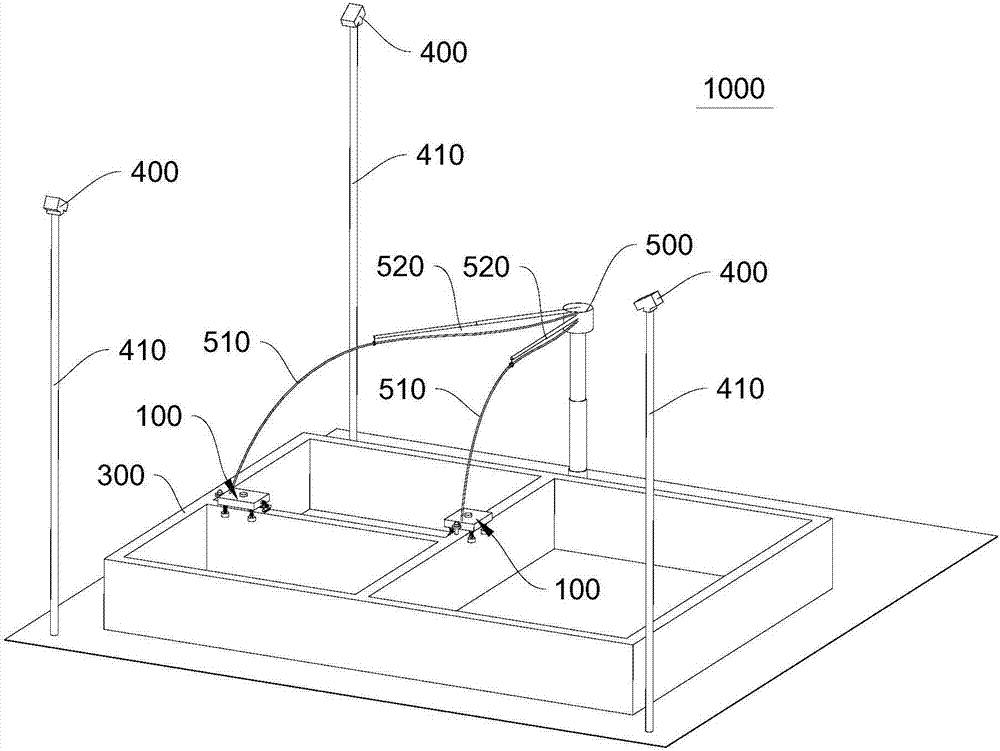

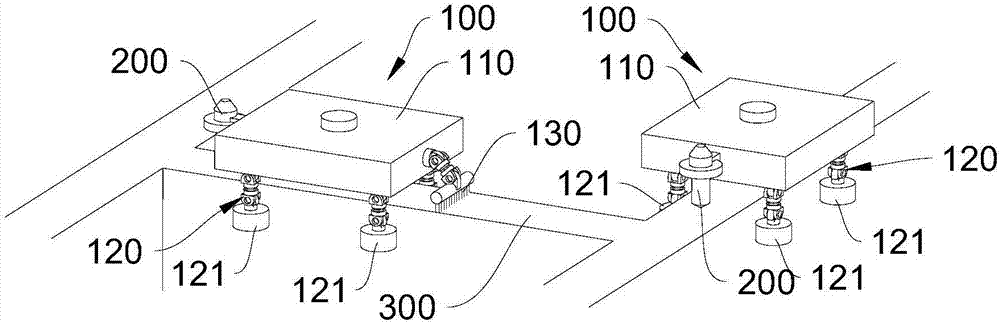

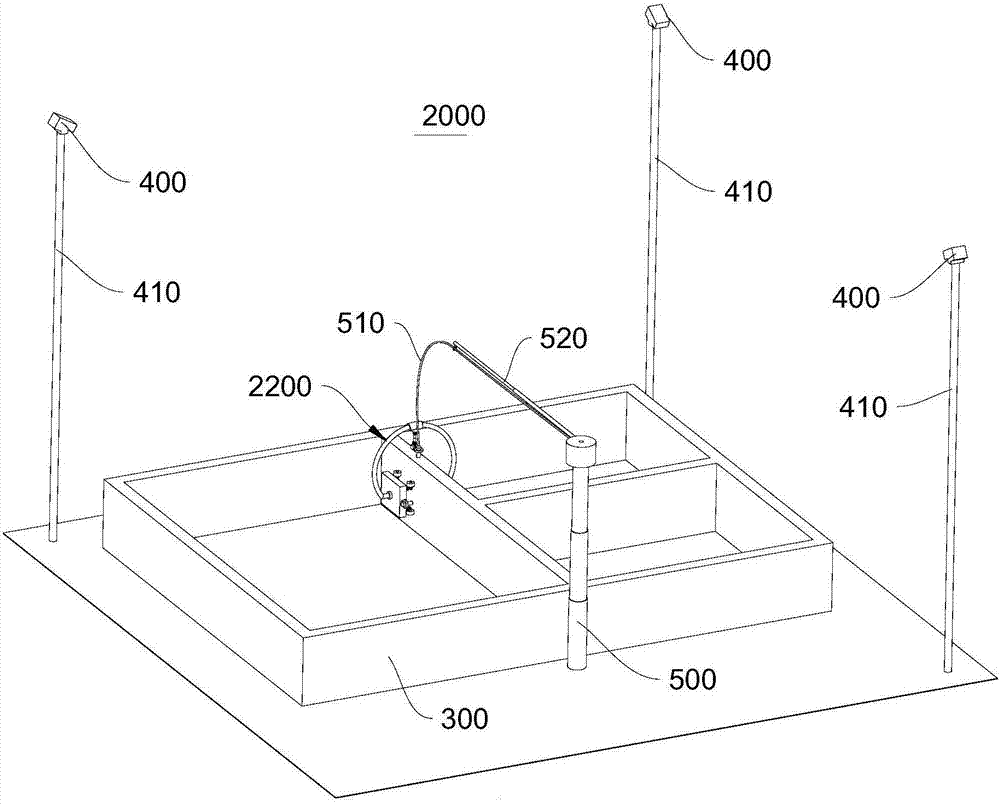

Building method and apparatus of architectural structure

ActiveCN107246151ASimple structureReduce volumeAdditive manufacturing apparatusBuilding material handlingArchitectural engineeringRobot communication

The invention relates to the technical field of building of architectural structures, in particular to a building method and apparatus of an architectural structure. The method comprises: manipulating a building robot to move along a preset trajectory to perform building construction. The building robot includes at least one of an aircraft and an execution robot walking close to a wall. The apparatus used herein is simple in structure and convenient to move and mount. The apparatus comprises a control device, a building robot and a construction device; the building robot includes at least one of an aircraft and an execution robot walking close to a wall; the construction device is in communication connection with the building robot; the control device is used for operating the building robot to move along a preset trajectory. The apparatus is simple in structure and convenient to move and mount, and a built architectural structure has high quality.

Owner:HUNAN SANY KUAIERJU RESIDENTIAL IND CO LTD

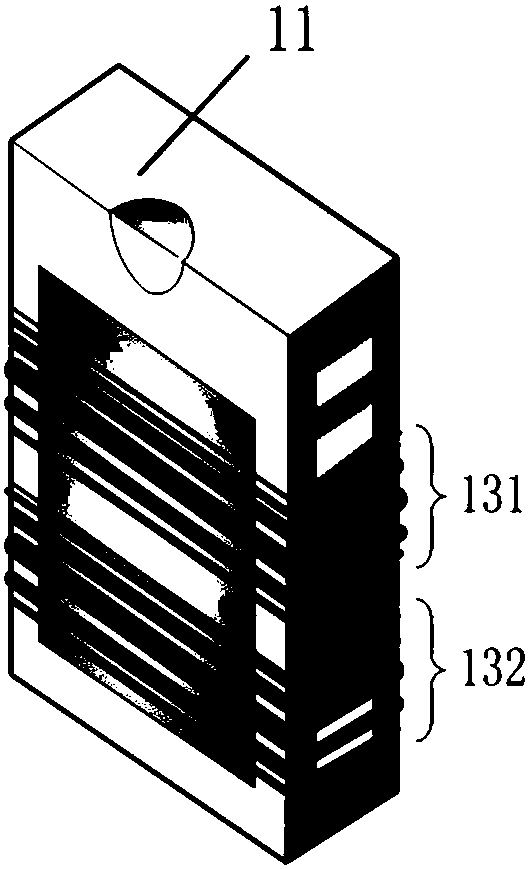

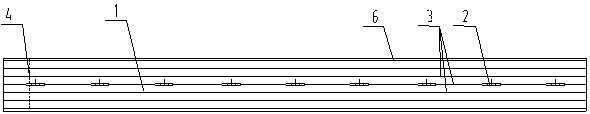

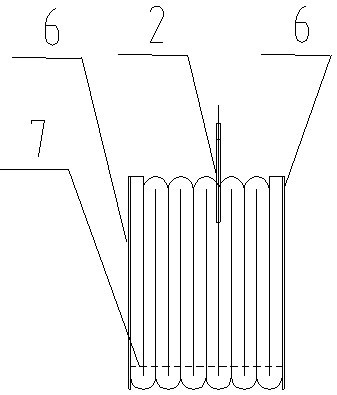

Fiber module for heating furnace and manufacturing method for fiber module

The invention discloses a fiber module for a heating furnace and a manufacturing method for the fiber module. The fiber module comprises a body consisting of a fiber blanket and is characterized in that: the body is formed by flatly paving the fiber blanket and folding the fiber blanket for many times along a length direction or a width direction or flatly paving a plurality of fiber blankets in a staggered manner and folding the fiber blankets for many times along directions of staggered gaps; in the body, a plurality of hangers are arranged; the hangers are fixedly connected with the body; and fixed clamping plates are arranged on two side faces of the body. By the fiber module of the heating furnace, the shortcomings that a furnace lining has shorter service life, the fiber module on the top of the furnace or a fiber folding block is easy to fall off and difficult to repair and the like of the conventional heating furnace can be overcome; the gaps of the fiber module in a compression-free direction (the length direction) can be reduced to the maximum extent; at high temperature, the fiber module has higher adaptability and has an outward extending function, so that the same distance between two ends of the fiber module can be substantially kept in the length direction; and the two ends of the fiber module cannot be inwardly contracted substantially.

Owner:CHONGQING AOKEQI TECH

Method for treating phenol-containing wastewater in gas generator

InactiveCN104163524AReduce consumptionImprove mass transfer efficiencyOrganic chemistryOrganic compound preparationLiquid wasteThree level

The invention discloses a method for treating phenol-containing wastewater in a gas generator and relates to the technical field of wastewater treatment. The treatment method comprises the following steps: slowly dropwise adding 98 percent concentrated sulfuric acid into wastewater, and regulating the pH value of the wastewater; filtering the acidified wastewater, pumping the wastewater into a liquid collector, and removing suspended solids and tar; metering the wastewater liquor and a QH-1 complexing extraction agent, and pumping the liquor and extraction agent into extraction equipment for performing multistage countercurrent extraction phenol removal; performing five-level countercurrent extraction on the wastewater liquor, allowing the wastewater subjected to phenol removal to enter a production process for recycling or to enter the next-level biochemical treatment process; and performing three-level countercurrent reverse extraction on a load extraction agent subjected to the five-level countercurrent extraction, recycling a solvent subjected to reverse extraction in a solvent tank, and collecting and storing the sodium phenolate liquid removed by reverse extraction. A phenomenon that the product yield is influenced due to abnormal production of a cracking furnace caused by instable air supply as well as brought safety and environmental protection risks can be eliminated. Meanwhile, industrial effluent is greatly reduced, and the economic benefits are good.

Owner:JIANGSU TIANCHENG BIOCHEM PROD

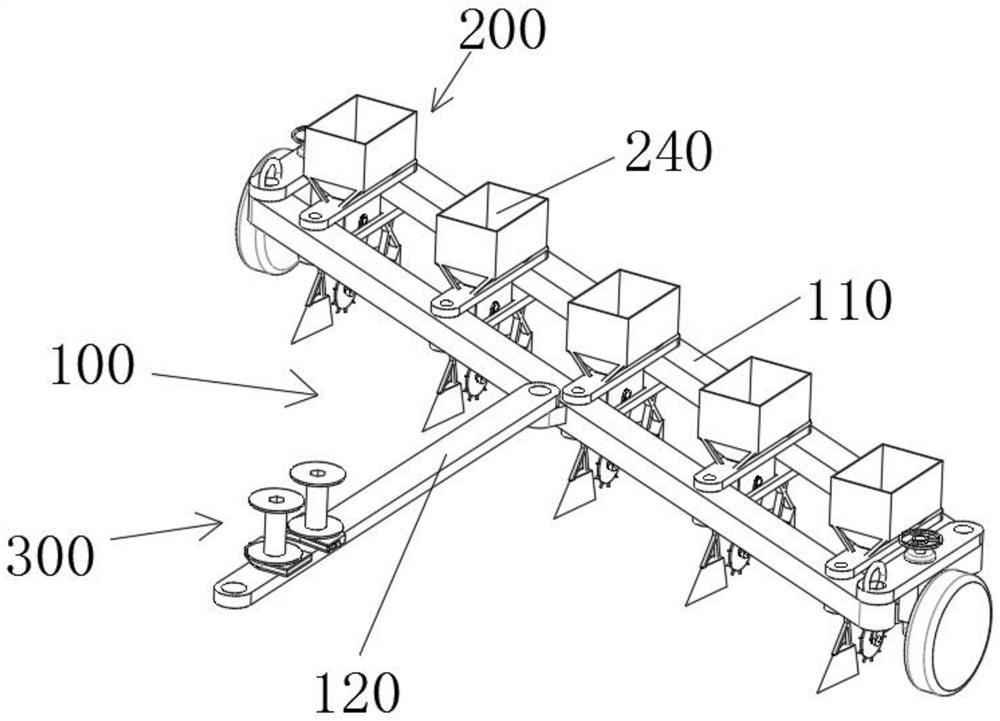

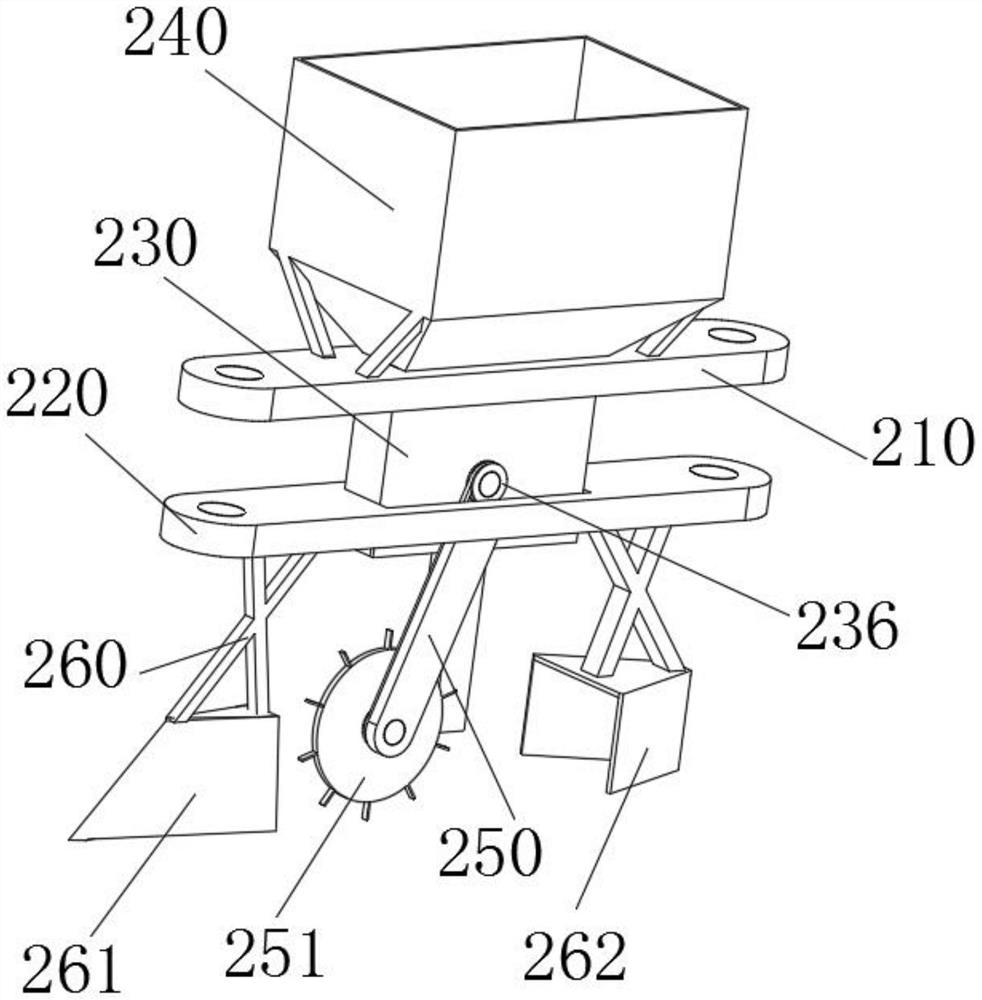

Seeding machine capable of adjusting seed seeding spacing

ActiveCN112753325AChange tilt angleChange horizontal spacingPlantingSeed depositing seeder partsSeederAgricultural engineering

The invention relates to the technical field of multi-row seeding machines, in particular to a seeding machine capable of adjusting seed seeding spacing. The seeding machine comprises an advancing mechanism, wherein the advancing mechanism comprises two cross beams arranged in parallel, the middle position of the outer side wall of one cross beam is fixedly connected with an adapter, and connecting rods are rotatably connected between two ends of the two cross beams. According to the seeding machine capable of adjusting the seed seeding spacing, through the arrangement of the cross beams, the connecting rods and seeding mechanisms, the two cross beams and the two connecting rods form a parallelogram frame structure, after inclination angles of the two cross beams are changed, the connecting rods and the multiple seeding mechanisms are still parallel to each other, orientation is not changed, and only transverse spacing between the multiple seeding mechanisms is changed, so that multi-row sowing at the same time and adjustable row spacing are achieved; by arranging a threaded rod, a sliding sleeve and a fixing rod, the heights of the cross beams are adjusted by rotating the threaded rod, the depth of a soil breaking shovel inserted into soil is conveniently adjusted, sowing burying depth of seeds is adjusted, and the sowing requirements of different crop seeds are met.

Owner:YONGZHOU GOLDEN ANT NEW ENERGY MASCH CO LTD

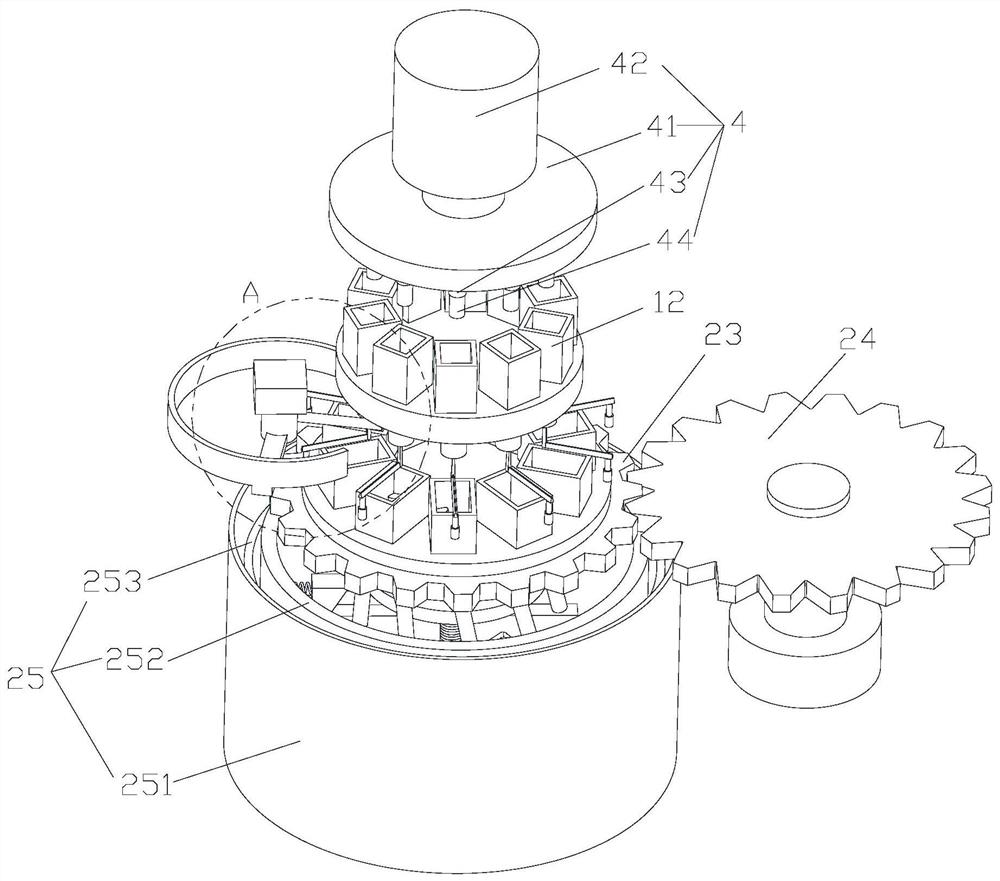

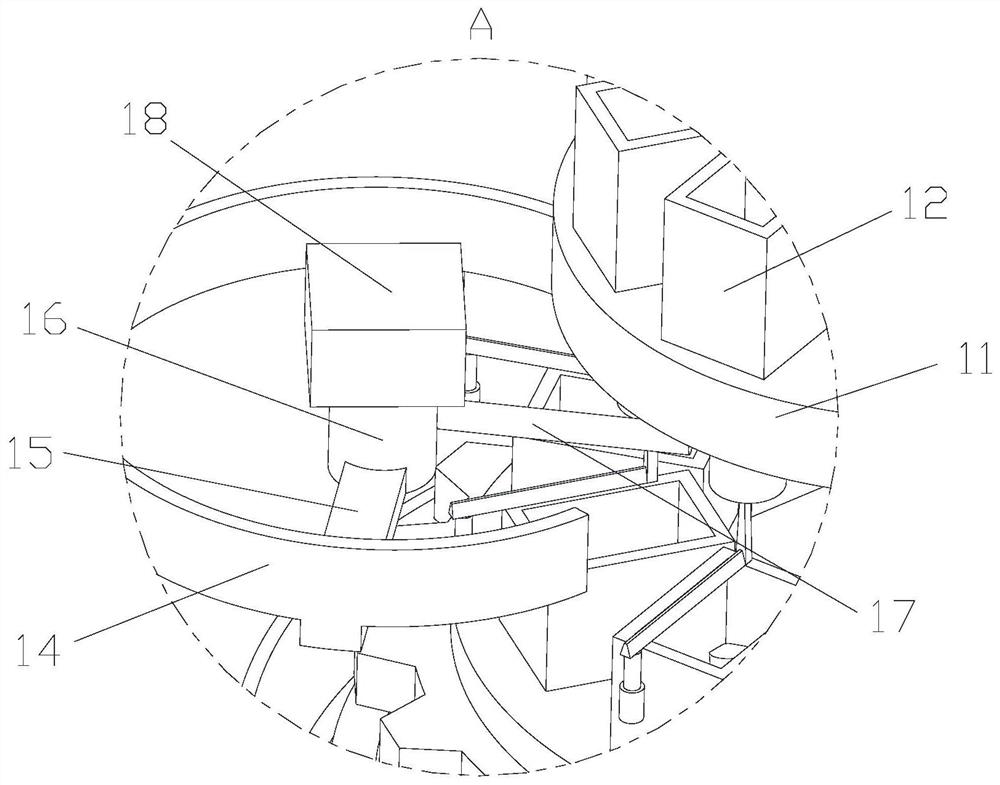

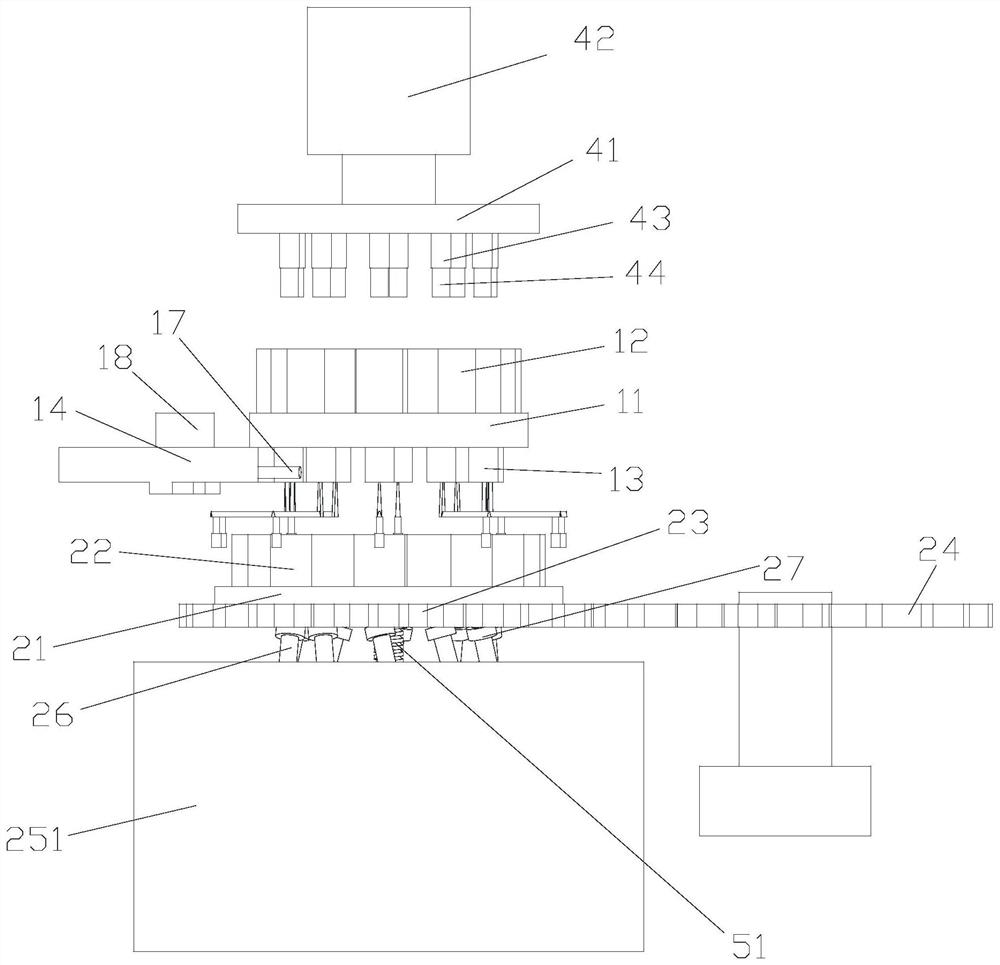

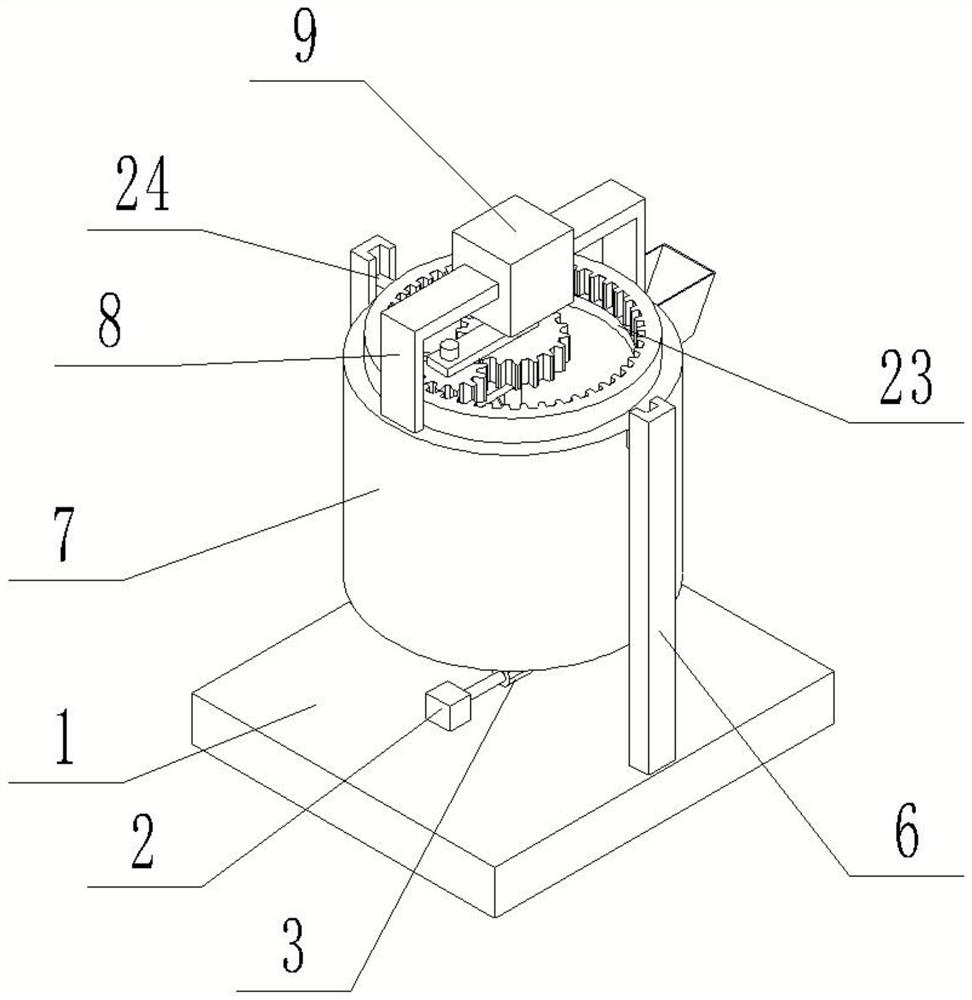

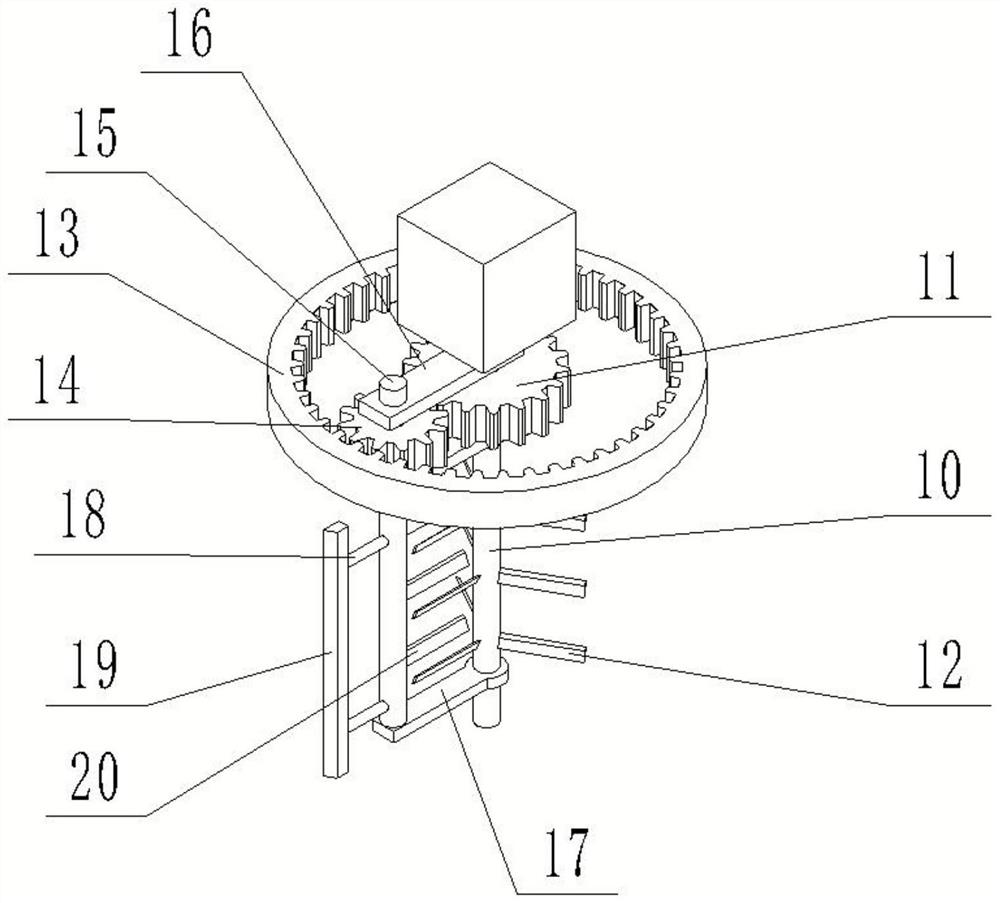

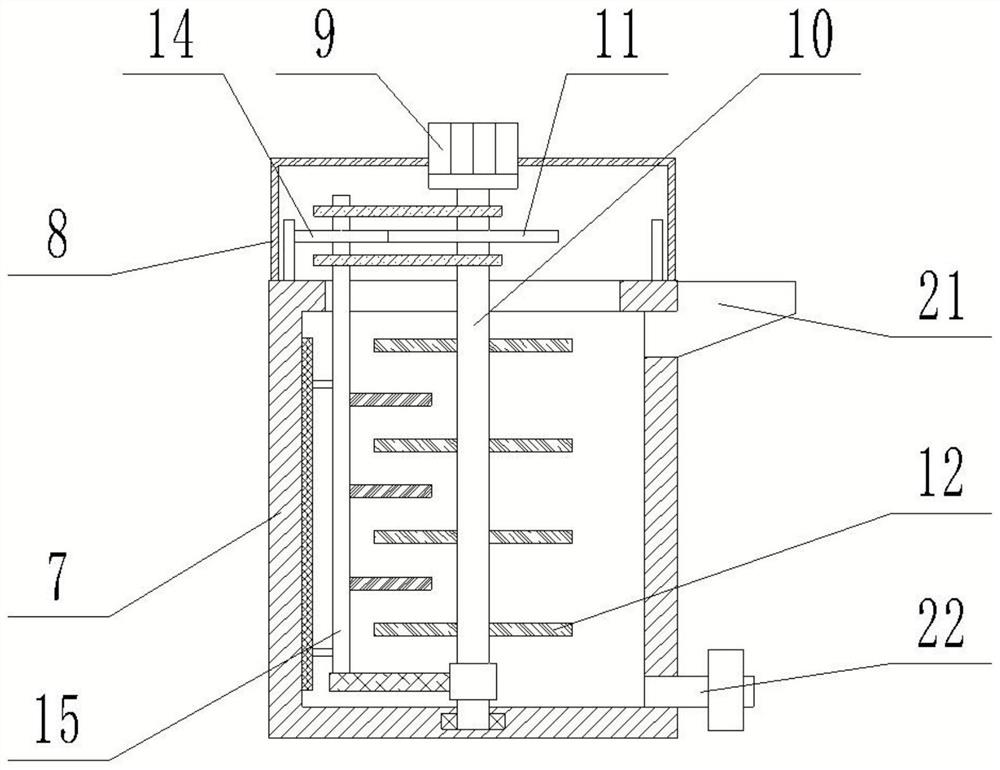

Raw material proportioning device and method for molten aluminum production

ActiveCN112535991AImprove the mixing effectReduce follow-up workloadTransportation and packagingMixer accessoriesElectric machineryManufacturing engineering

The invention discloses a raw material proportioning device and method for molten aluminum production. The method comprises the following steps: different raw materials are put into a plurality of feeding boxes; a first motor operates to drive a rotating shaft to rotate so as to drive an annular piece with a notch and an abutting rod to rotate, and the abutting rod makes contact with a first conveying pipe to drive a rotating disc to rotate; a first air cylinder drives a moving rod to move upwards to abut against a covering plate, the raw materials in the feeding boxes fall into correspondingmaterial receiving barrels through the first material conveying pipe till the rotary disc rotates by a circle, and each material receiving barrel contains the raw materials in the multiple feeding boxes; a second gear rotates to drive a first gear meshed with the second gear to rotate so as to drive a material receiving plate to rotate and achieve uniform mixing; and an electromagnetic valve is opened, and the uniformly mixed raw materials in the receiving barrels are conveyed into a mixing barrel through a second conveying pipe, so that a plurality of equal-proportion raw material componentsare mixed and then are uniformly mixed, the mixing effect is good, the subsequent workload is reduced, and the efficiency is improved.

Owner:CHONGQING AOBO ALUMINUM COMPANY

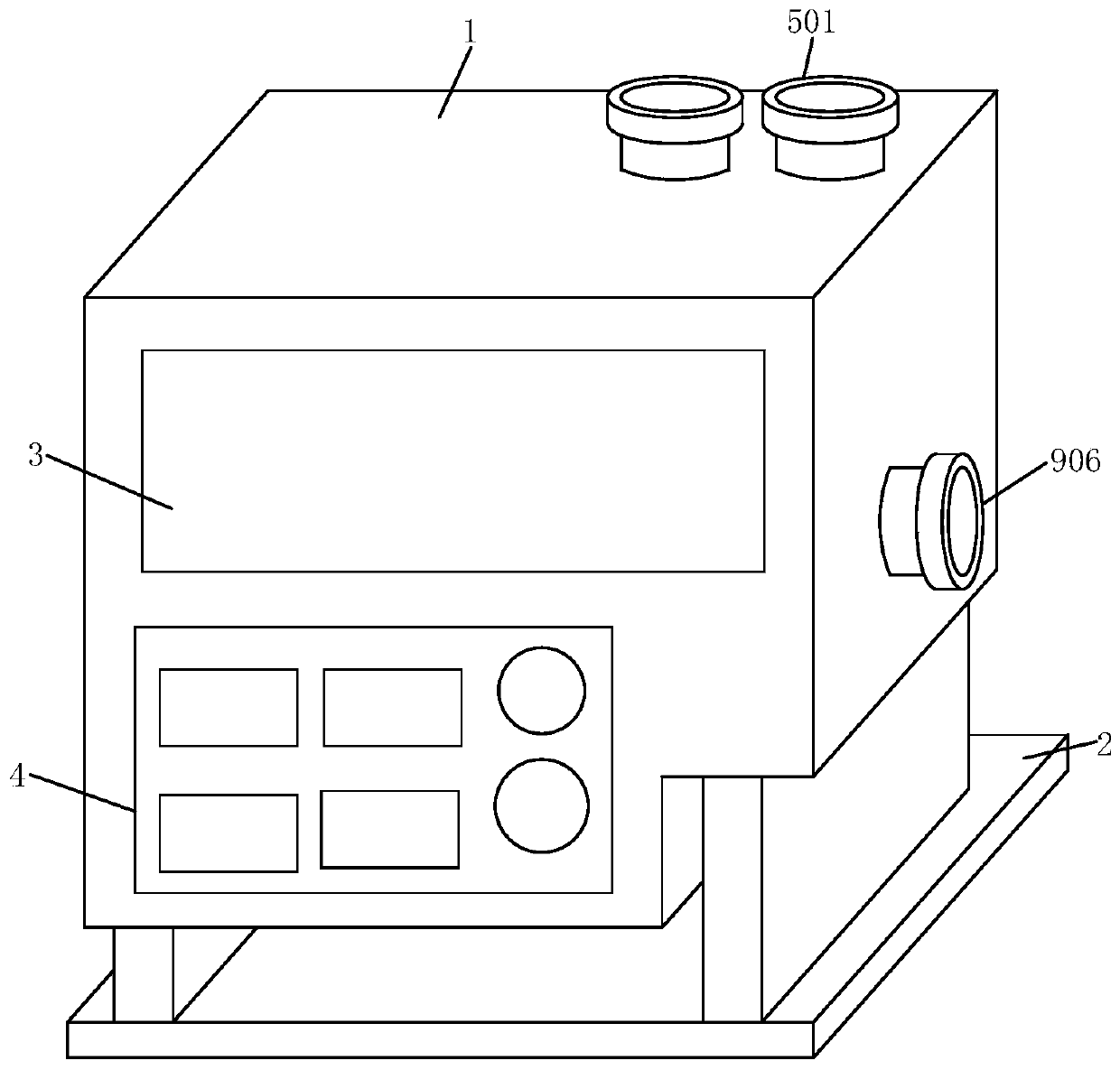

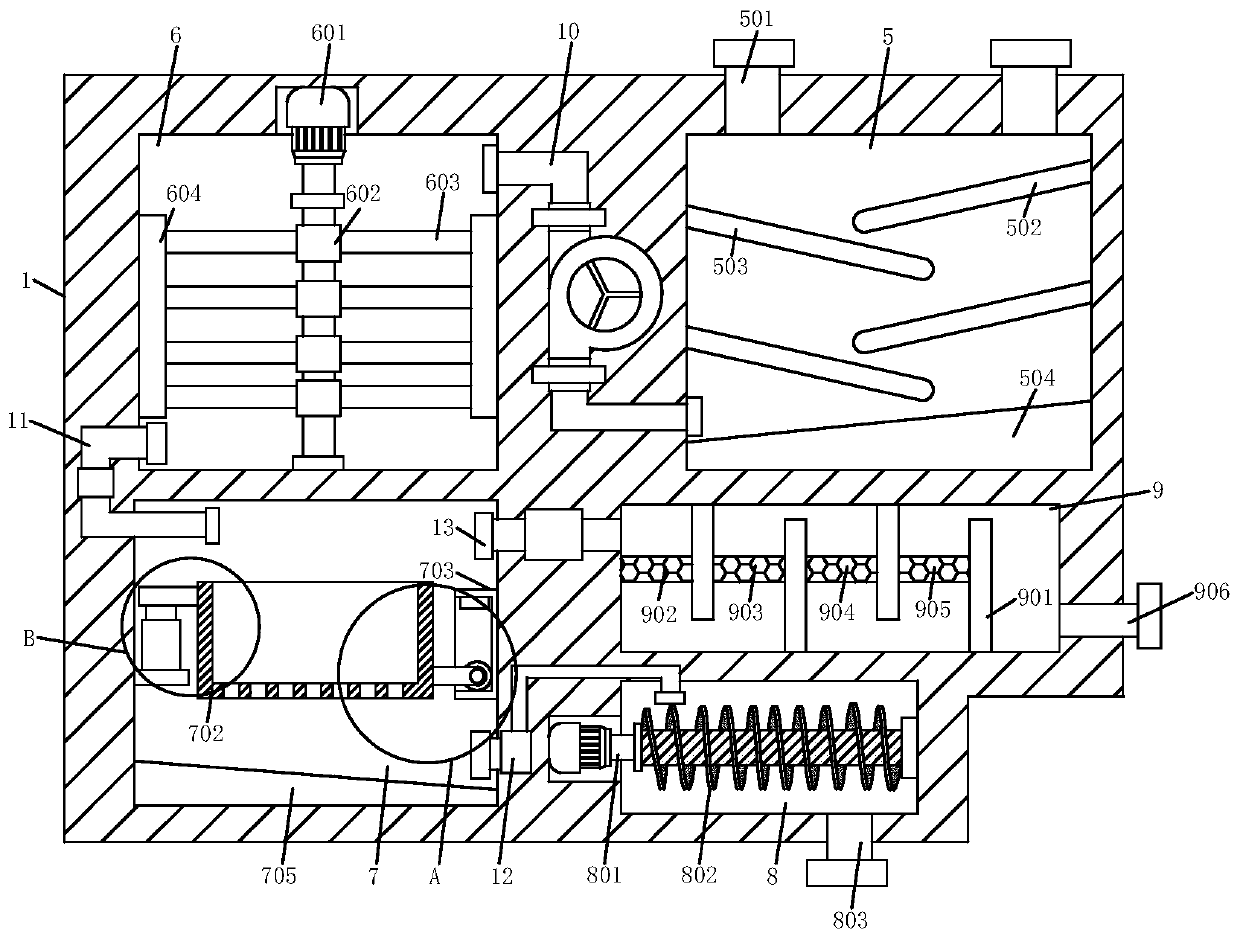

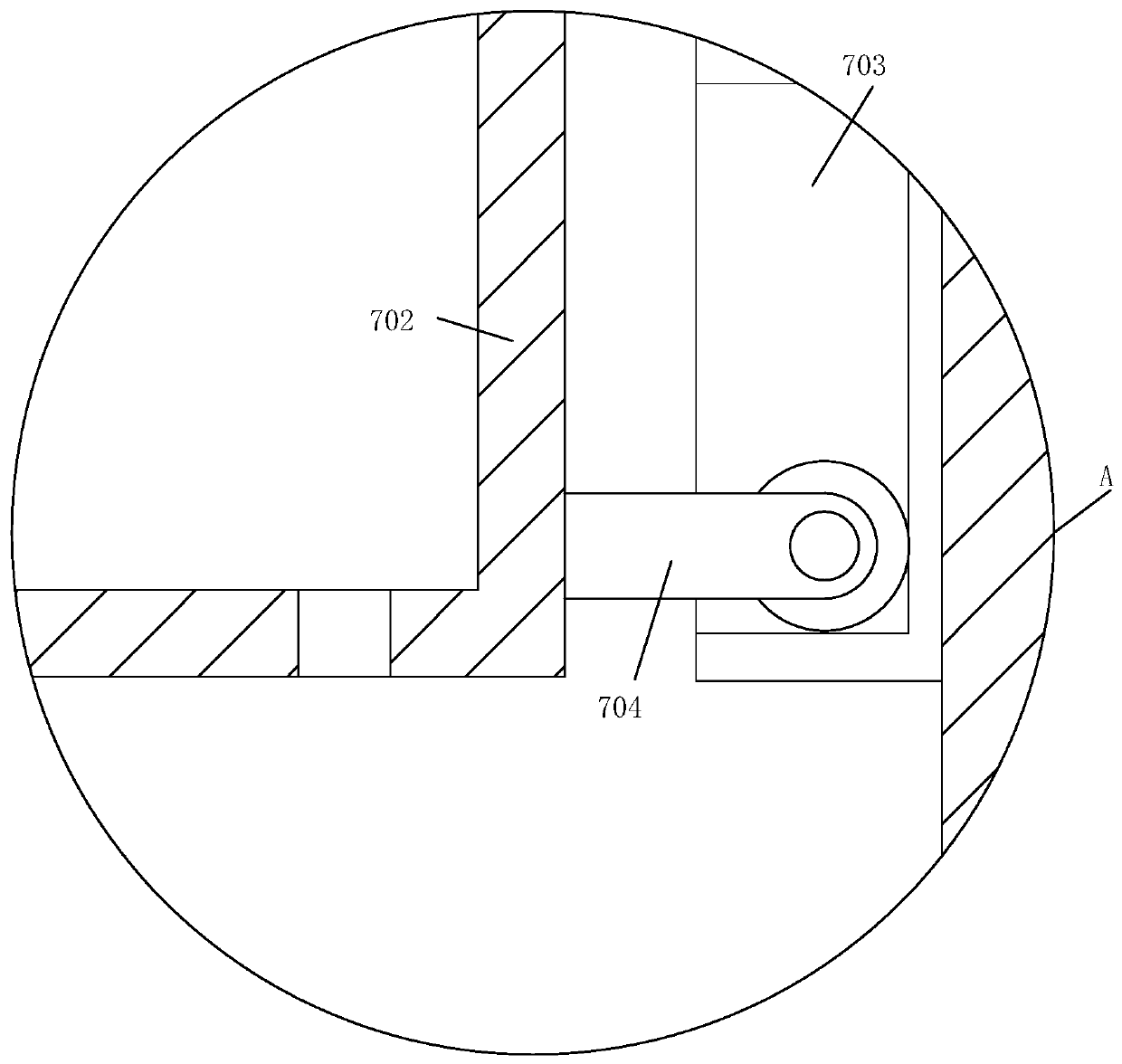

Electrolytic aluminum liquid preparation device

PendingCN110559940AUse thoroughlyAvoid stickingTransportation and packagingMixer accessoriesElectrolysisEngineering

The invention relates to the field of electrolytic aluminum, and more specifically relates to an electrolytic aluminum liquid preparation device. The electrolytic aluminum liquid preparation device comprises a box body; a placement base is fixedly installed at the bottom of the box body, an observation window and a control panel are fixedly installed on the front face of the box body, and the boxbody comprises a mixing cavity, a stirring cavity, a separation cavity, a discharging cavity, an air inlet cavity, a first water pump pipe, a control valve pipe, a second water pump pipe and an air pump pipe. According to the electrolytic aluminum liquid preparation device, the materials can be pre-mixed while being matched by utilizing the mixing cavity, so that subsequent workload is reduced effectively, and the working efficiency and the mixing effect are improved; the stirring cavity is adopted for matching to realize enhanced mixing of materials, so that the materials are mixed more uniformly; meanwhile, the inner wall of the stirring cavity is scraped through a scraping plate, adhesion of molten aluminum onto the inner wall of the stirring cavity is avoided, the molten aluminum in the stirring cavity is utilized more thoroughly, and the quality of the molten aluminum is guaranteed while the cost is saved.

Owner:臧龙

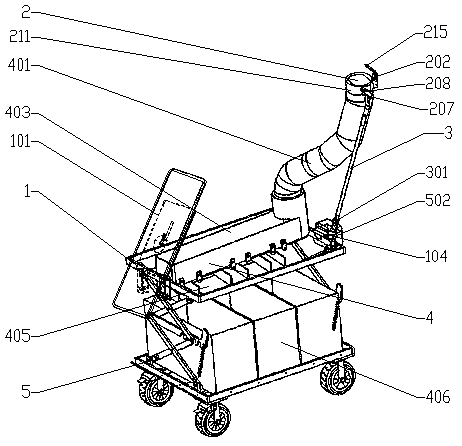

Apple picking and collecting method

ActiveCN109601128ANo damageReduce follow-up workloadGradingPicking devicesEngineeringCollection methods

The invention discloses an apple picking and collecting method. A picking device comprises a power supply system, a cutting mechanism, a picking rod, a collecting and sorting mechanism, a bracket mechanism and the like. The power supply system is connected with the cutting mechanism by wires. The wires pass through the middle of the picking rod. The picking rod is fixed to a bracket by a rod end bearing and a bolt, and the rod end bearing can drive the picking rod to rotate. The picking rod and the rod end bearing are connected by a nut. The collecting and sorting mechanism is located below the cutting mechanism. According to the portable apple picking and collecting device provided by the invention, the device is controlled by adopting an infrared sensor switch, so that the picking efficiency can be improved; by adopting a blade for cutting and picking and a buffering landing method, apples are not damaged; the apples can be sorted and collected by diameter, so that the follow-up workload of fruit farmers is reduced; the device can be charged while working by utilizing a solar panel, so that the electric energy is saved; the bracket is adjustable in height and foldable, and the picking rod is retractable, therefore, the device is convenient to carry and store.

Owner:IANGSU COLLEGE OF ENG & TECH

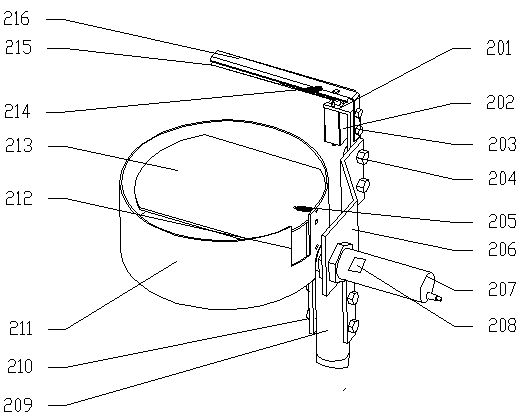

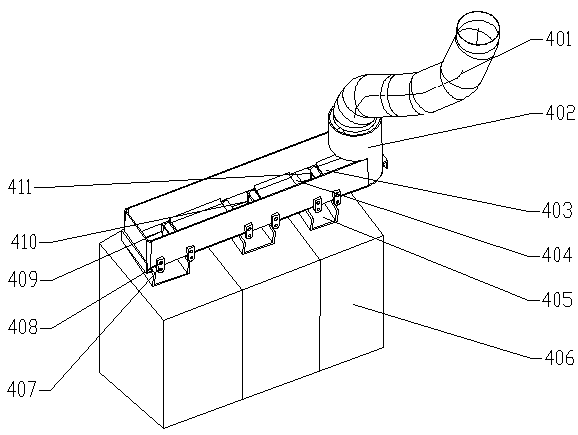

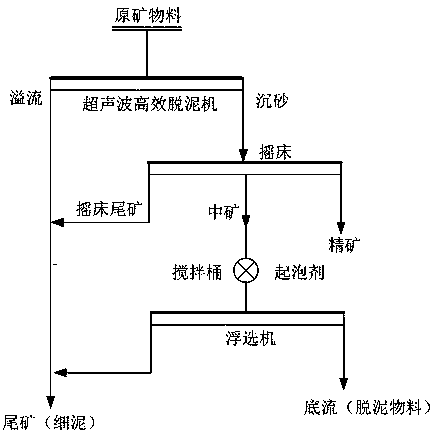

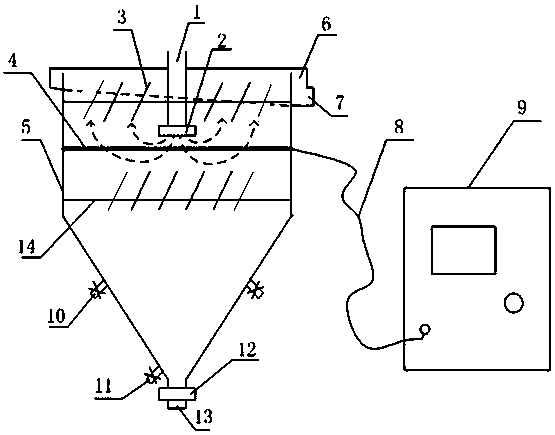

Ultrasonic-table-floatation combined desliming process

The invention discloses an ultrasonic-table-floatation combined desliming process which comprises the following steps: at first, part of ore slime is removed from a raw ore material through an ultrasonic desliming machine; the overflow from the ultrasonic desliming machine is directly subject to tailings discarding; settled sand from the ultrasonic desliming machine is subject to separation desliming by adoption of a table; table concentrate is taken as a qualified deslimed material; table tailings are directly discarded; a foaming agent is added into table middlings, and then the mixture is uniformly stirred by adoption of a stirring tank; after the uniform stirring, floatation desliming is performed; floatation foam is taken as fine slime and directly subject to tailings discarding; andthe floatation underflow is taken as a deslimed material. The ultrasonic desliming machine utilized in the ultrasonic-table-floatation combined desliming process comprises an ore feeding pipe, an orefeeding nozzle, flow regulating plates, an ultrasonic probe, a machine shell body, an overflow dam, an overflow port, a lead wire, an ultrasonic control cabinet, water supplementing pipes, a high-pressure water pipe, a sand settling port switch, a sand settling port, a flow regulating plate bracket and an ore feeding pipe bracket. The ultrasonic-table-floatation combined desliming process disclosed by the invention has the advantages that the desliming effect is thorough and the desliming efficiency is high; the agent consumption by the ore slime during the follow-up operation can be reduced;and the application prospect is relatively broad.

Owner:KUNMING UNIV OF SCI & TECH

Fruit peeling and sectioning device

ActiveCN112386085AAchieve fixationRealize automatic feedingMetal working apparatusPeelersMedicineEngineering

Owner:山东公社联盟食品有限公司

Biological enzyme for catalyzing synthesis of glutathione and preparation and extraction methods of biological enzyme

The invention provides a biological enzyme that catalyzes the synthesis of glutathione and its preparation and extraction method. The biological enzyme is the amino acid sequence shown in SEQ ID NO: 2; the biological enzyme is derived from a genetically engineered strain constructed by in vitro recombination The nucleotide sequence is shown in SEQ ID NO: 1; the preparation method of the biological enzyme that catalyzes glutathione synthesis comprises the steps of: constructing a genetically engineered strain of glutathione biosynthetic enzyme, The nucleotide sequence is recombined into the expression vector by enzyme cutting, and then transferred into the host cell. The enzyme obtained by the invention has high catalytic efficiency, low production cost, environmental protection, high economic value and market competitiveness.

Owner:JIANGSU CHENGXIN PHARMA

Device for demounting bearing

ActiveCN108035979AImprove clamping stabilityReduce cleaning workloadCleaning using liquidsBearing load reliefEngineeringMachining

The invention relates to the technical field of car accessory machining device, and particularly discloses a device for demounting a bearing. The device comprises a working table, the working table isprovided with a first supporting shaft, a clamping mechanism, a second supporting shaft and an air cylinder. The first supporting shaft is fixedly connected with a cylinder body, a first piston is arranged in the cylinder body, an elastic material layer and an air outlet pipe are arranged in the cylinder body, the air outlet pipe is in sealed connection with a U-shaped pipe, and an oil contamination washing agent is contained in the U-shaped pipe; a first piston rod is connected to the first piston, and a stopping block is fixedly connected to the first piston rod; the clamping mechanism comprises a strut, a clamping body, a first clamping piece and a second clamping piece; a second piston is arranged in the air cylinder, and the air cylinder is communicated with the cylinder body throughan air pipe; and a second piston rod is connected to the second piston. By means of the device, the bearing can be stably clamped, bearing stress is even in the bearing demounting process, and bearing damage is avoided.

Owner:宁波江北清锐汽车零部件有限公司

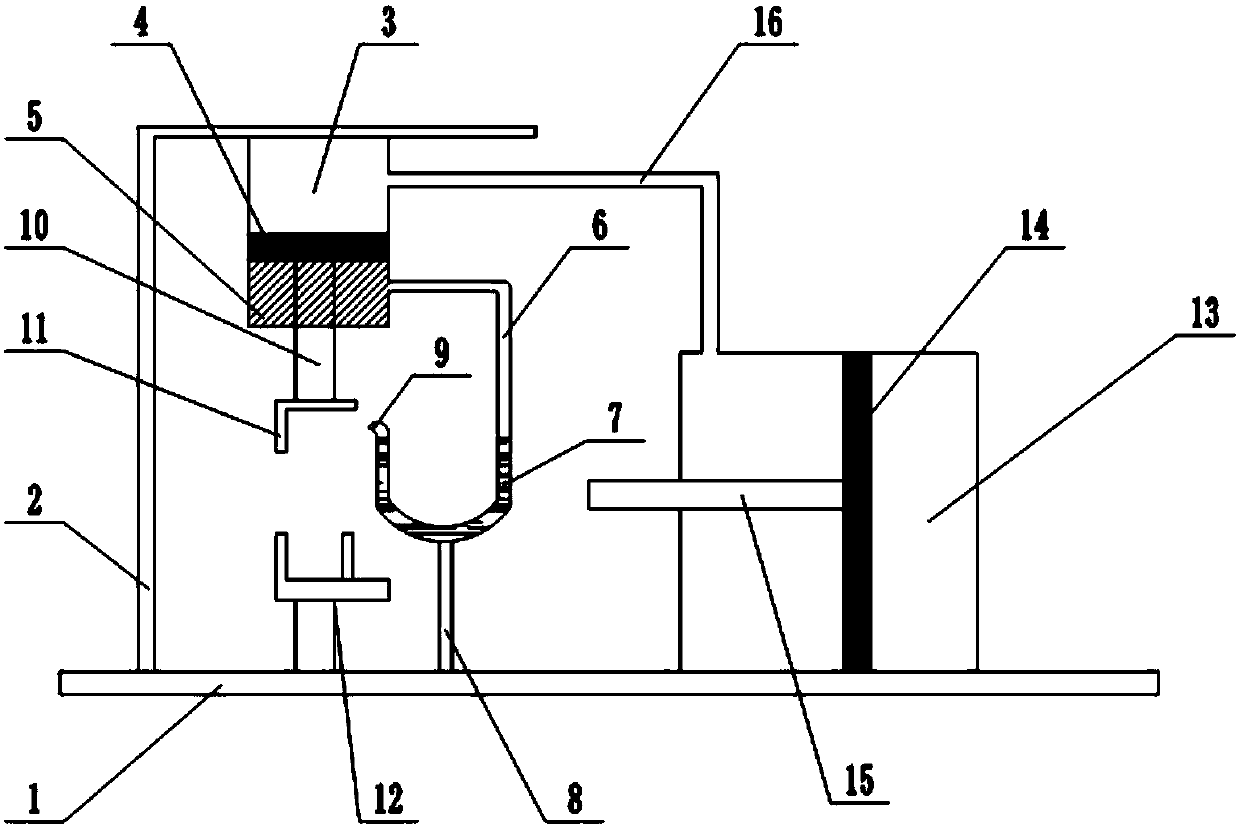

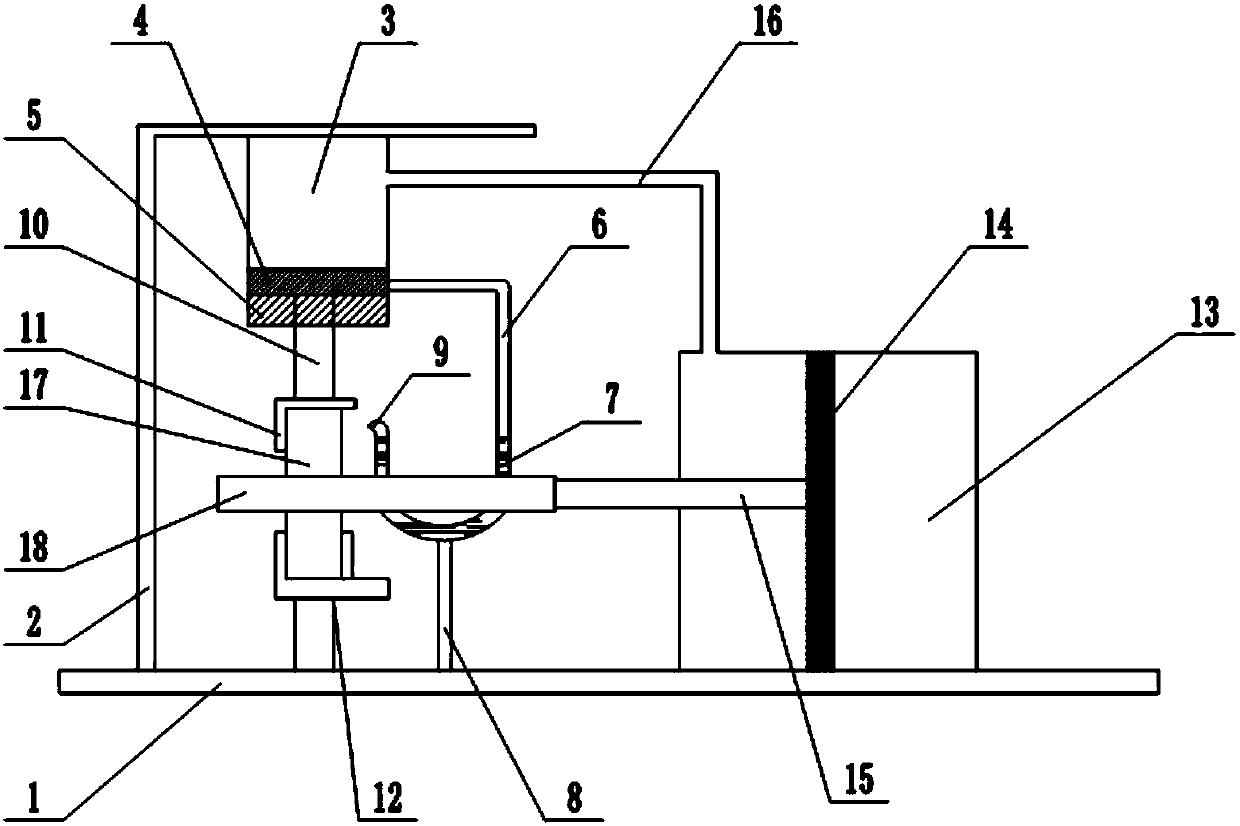

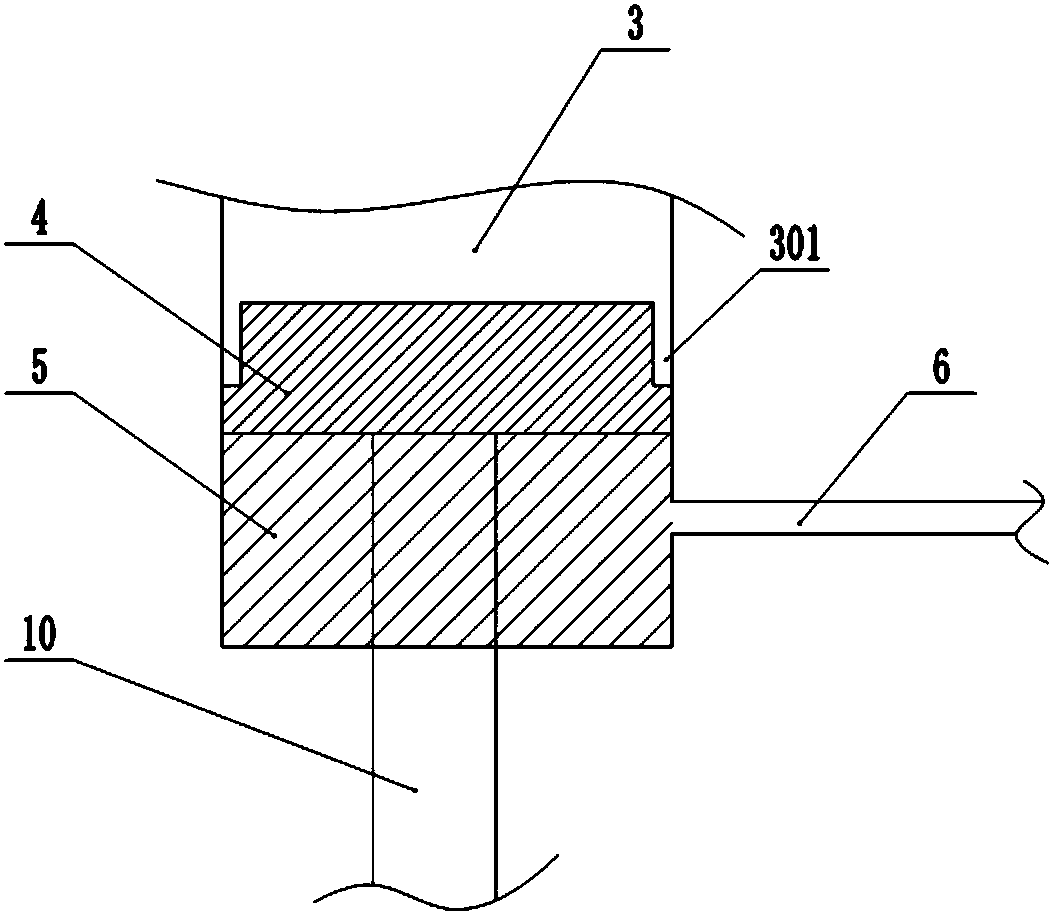

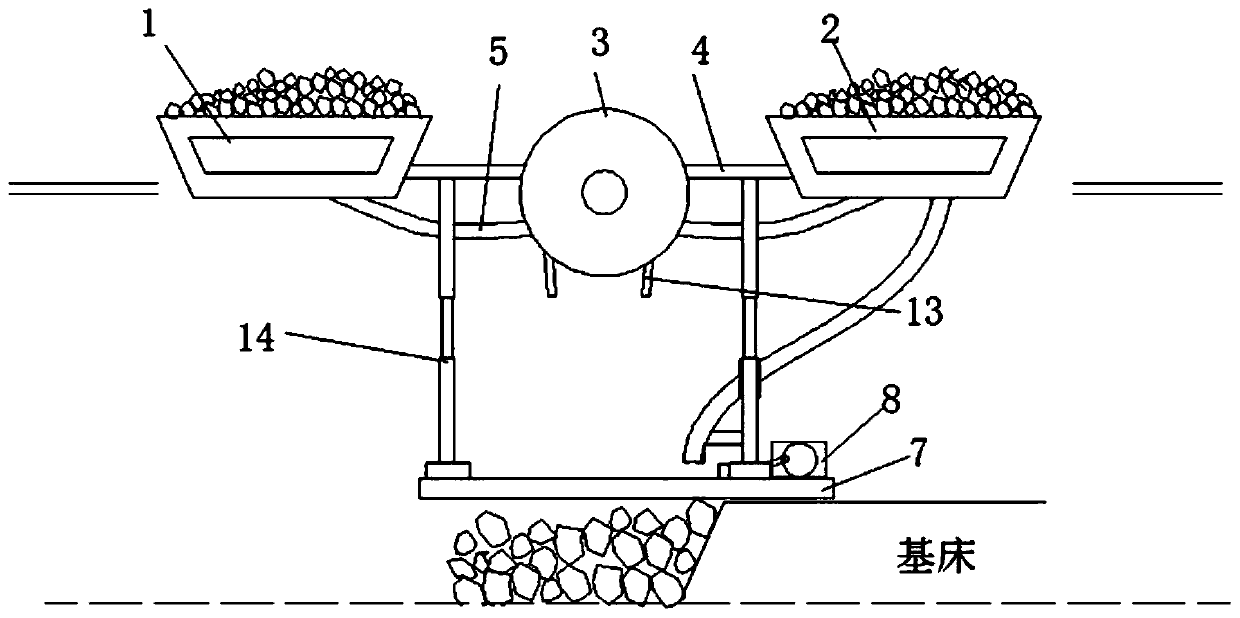

Underwater riprap foundation bed construction device

ActiveCN111456017AEvenly distributedAvoid uneven riprapFoundation engineeringUnderwaterArchitectural engineering

The invention discloses an underwater riprap foundation bed construction device which comprises a left-side garbage scow, a right-side garbage scow, a stone block storage device, a horizontal track, astone block grab bucket, a movable support frame and a slider-crank mechanism. According to the underwater riprap foundation bed construction device provided by the invention, through arranging the stone block storage device and a rock rip-rap container in the stone block storage device for riprapping, through arranging a baffle plate and a spring on one side of the movable support frame and arranging a stone storage tank on the other side of the movable support frame, and by utilizing the stone block grab bucket for carrying out underwater exact leveling on the riprap foundation bet, stone blocks can be distributed uniformly, so that the occurrence of the phenomenon of nonuniformity in riprapping is effectively avoided, and the follow-up work load is greatly reduced.

Owner:HOHAI UNIV

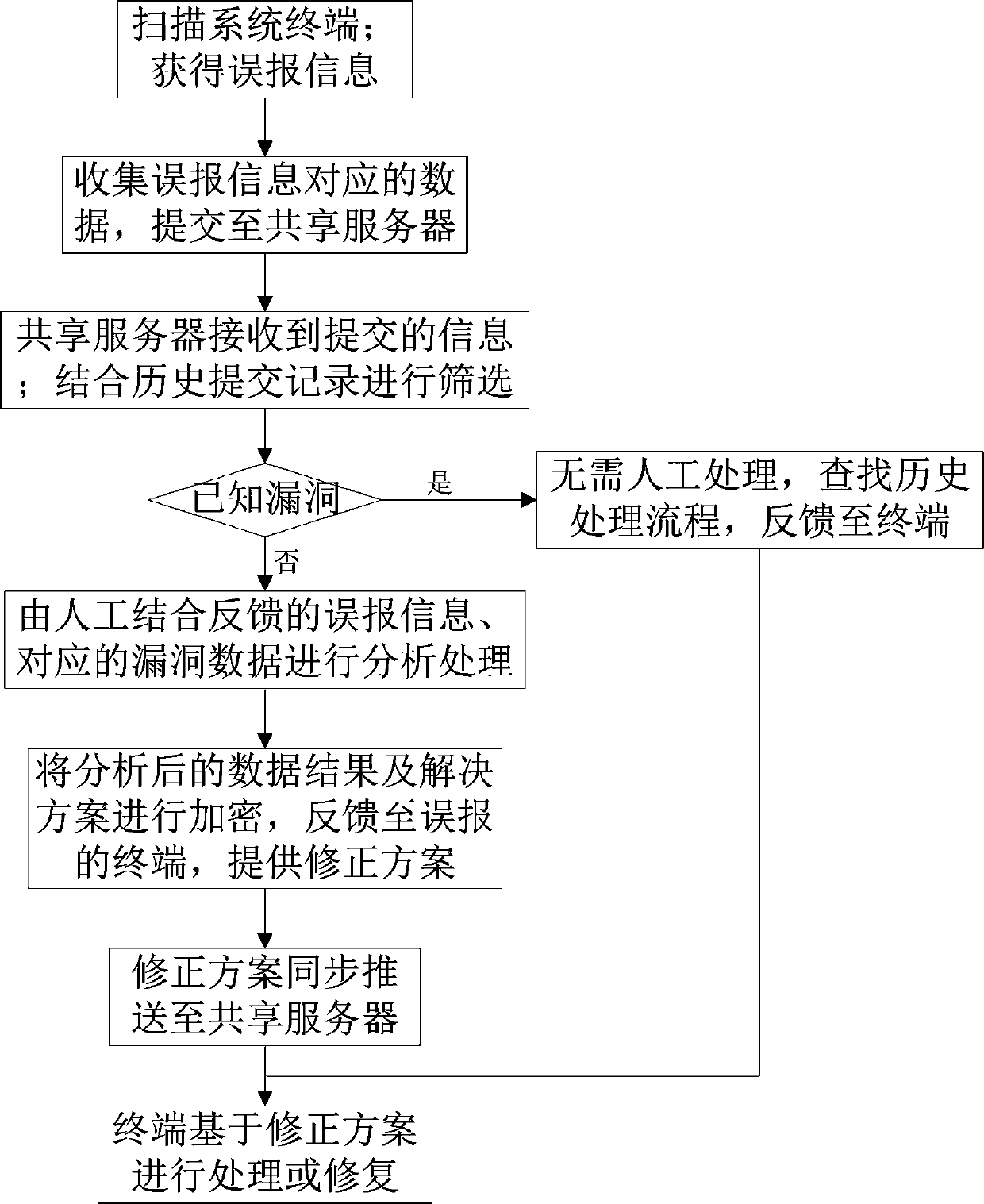

Method for reducing false alarm of vulnerability scanning

ActiveCN110753047AReduce false alarm rateReduce follow-up workloadPlatform integrity maintainanceTransmissionData setData mining

The invention relates to a method for reducing the false alarm of vulnerability scanning. The method comprises the following steps of: obtaining false alarm information and corresponding data by scanning a system terminal, submitting the false alarm information and the corresponding data to a shared server for manual auditing and affirmation, adjusting technical parameters, providing and synchronizing a correction scheme, and finally processing or repairing by the terminal based on the correction scheme. According to the invention, vulnerability types with high false alarm rate can be marked in a unified manner; determining a false alarm point, refining the collected false alarm items, then performing content analysis processing and refining in a unified manner, performing professional analysis on the collected false alarm content by a technician, performing misjudgment and corresponding correction, and performing correction processing on a database and a vulnerability library; data centralized processing and updating optimization processing are adopted to solve false alarm, the detection efficiency is improved, effective false alarm related data can be collected, the subsequent workload is reduced, qualitative improvement is brought to vulnerability scanning accuracy, the false alarm rate is reduced, and repeated work is greatly reduced.

Owner:HANGZHOU ANHENG INFORMATION TECH CO LTD

Machine translation engine evaluation optimization method and system

ActiveCN110705318AReduce follow-up workloadImprove translation efficiencyNatural language translationEnergy efficient computingLinguistic modelWord count

The invention discloses a machine translation engine evaluation optimization method and system. The method comprises the following steps: selecting an evaluation word number range of a to-be-translated text; each machine translation engine performs translation evaluation, keyword evaluation and language model confusion evaluation on the to-be-translated text in the range to obtain a plurality of scores; and performing weighted summation on the scores to obtain a weighted sum value of each machine translation engine, and selecting the machine translation engine with the highest weighted sum value to output a translation result of the sentence, thereby integrating to obtain a whole translation text. Through the method, the machine translation engine evaluation optimization service can be provided for the user in various complex machine translation engines with uneven translation quality, the translation efficiency is improved, the subsequent workload of the user is reduced, and the high-quality machine translation service is provided.

Owner:南京题麦壳斯信息科技有限公司

A high-density moisture-proof ammonium nitrate fuel oil explosive and a preparation method thereof

PendingCN108774097AHigh densityImprove working abilityExplosive ingredient compoundingHigh densityFuel oil

A high-density moisture-proof ammonium nitrate fuel oil explosive and a preparation method thereof are provided. The explosive includes porous ammonium nitrate particles, mineral oil and a latex matrix. The mass percentage of the latex matrix in the explosive is 35-36.4%, and the density of the latex matrix is 1.38-1.40 g / cm<3>. The method includes fully mixing the latex matrix, the porous ammonium nitrate particles and the mineral oil to obtain the explosive. The invention provides the high-density moisture-proof ammonium nitrate fuel oil explosive and the preparation method thereof.

Owner:CHINA SHENHUA ENERGY CO LTD +1

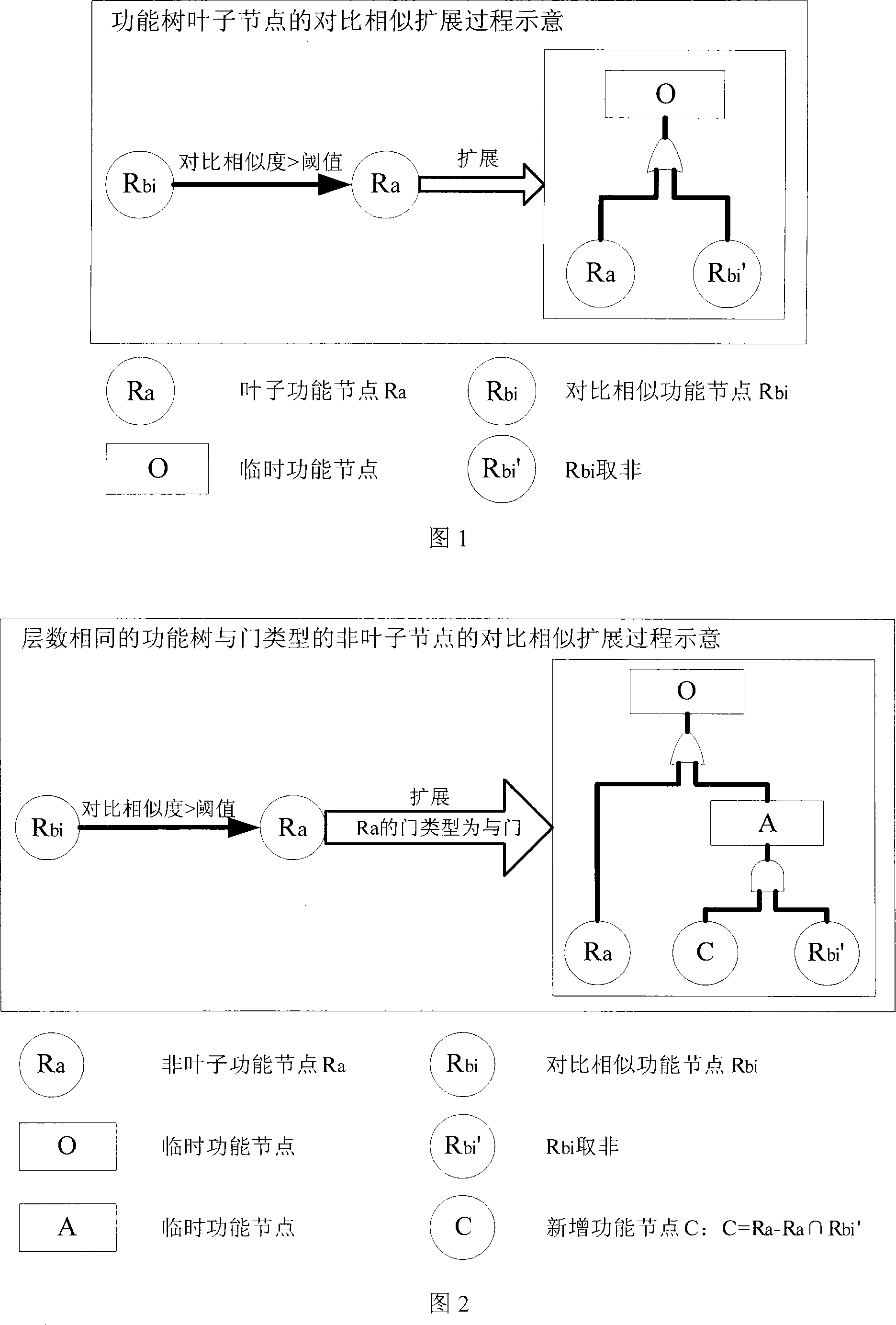

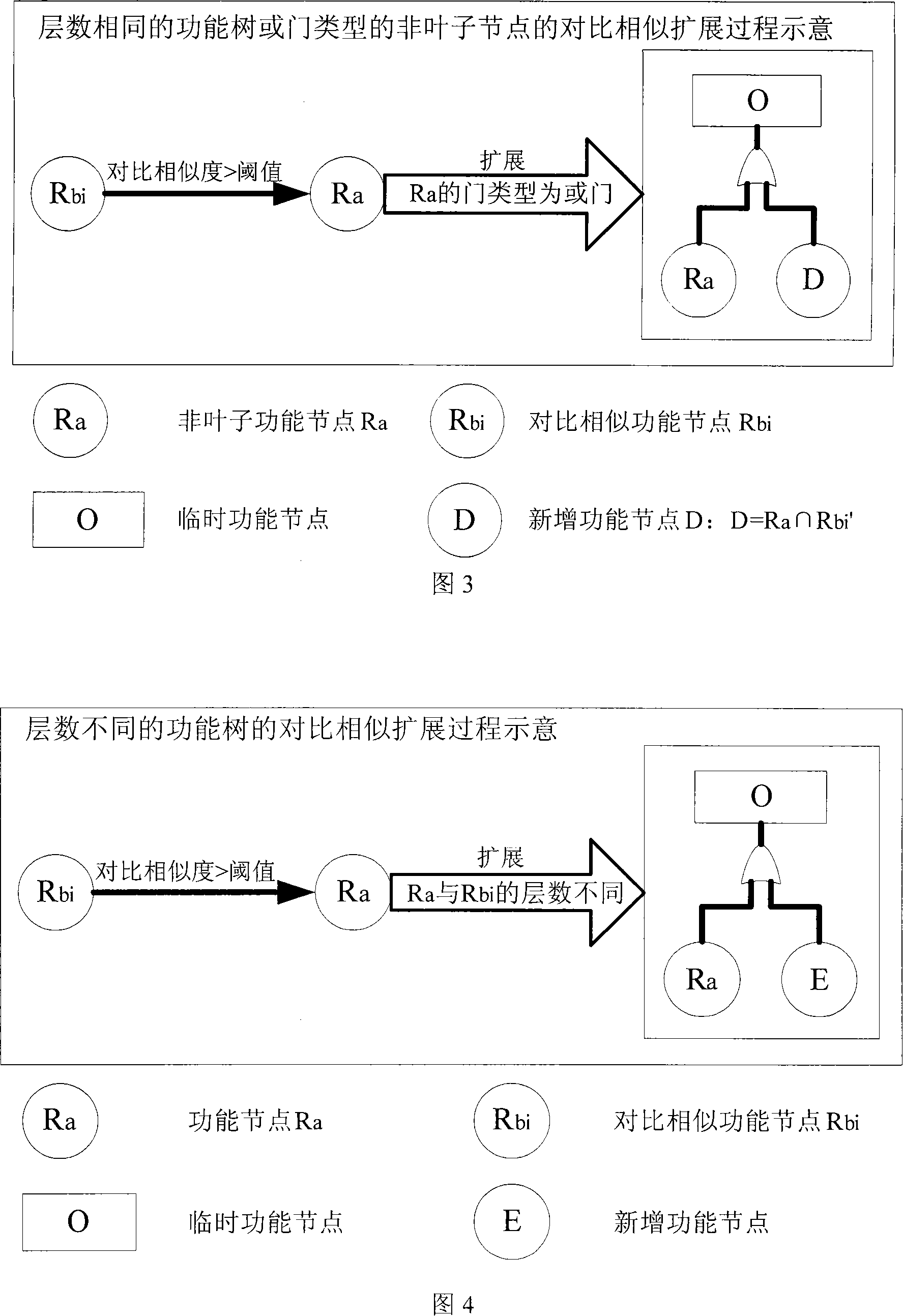

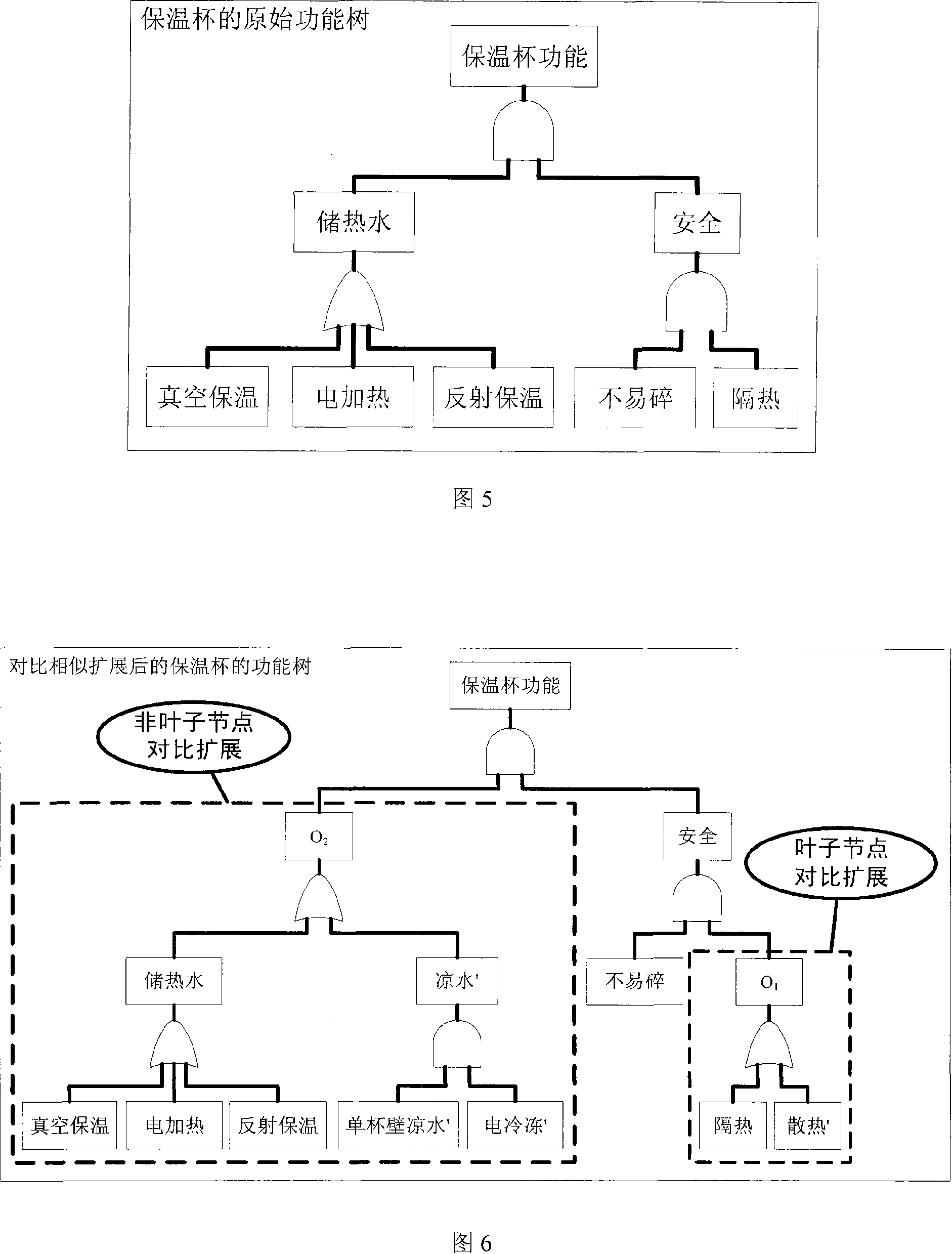

Contrast, analog extending method for product function

InactiveCN101154232AGive full play to the guiding roleRich design informationSpecial data processing applicationsExtension theoryFunction tree

A contrast similar expansion method of product function is characterized by provided with a known product knowledge base storing a function tree and bounded relation information of known product and building an original function tree and bounded relation information of novel product; on the base of combining a similar theory and an extension theory and according to the specific needs of product designers, any function node of the original function tree of novel product is compared with the product functions in the known knowledge base; according to a certain rule, the novel functions are appended to the product function tree to generate a novel product function tree. Compared with the original product function tree, the novel product function tree is richer; therefore, the possibility of obtaining an innovation function is greatly increased. The invention gives full play to the guiding function of designers in the process of product design and makes designers release from the complicated and mechanical work of data comparison, thereby providing a design method which has high freedom, strong deduction capacity and aims at innovation of product function.

Owner:HEFEI UNIV OF TECH

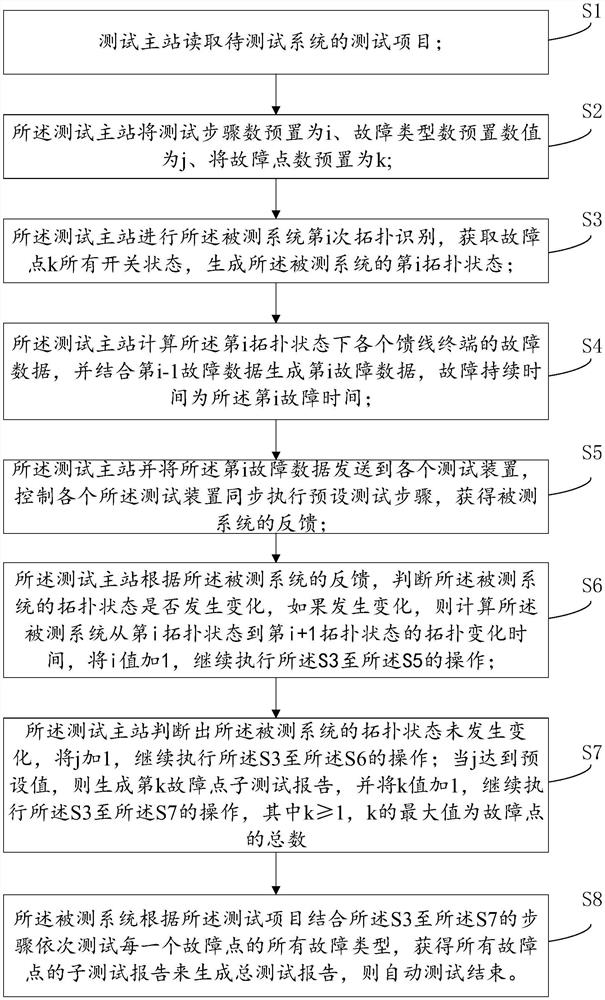

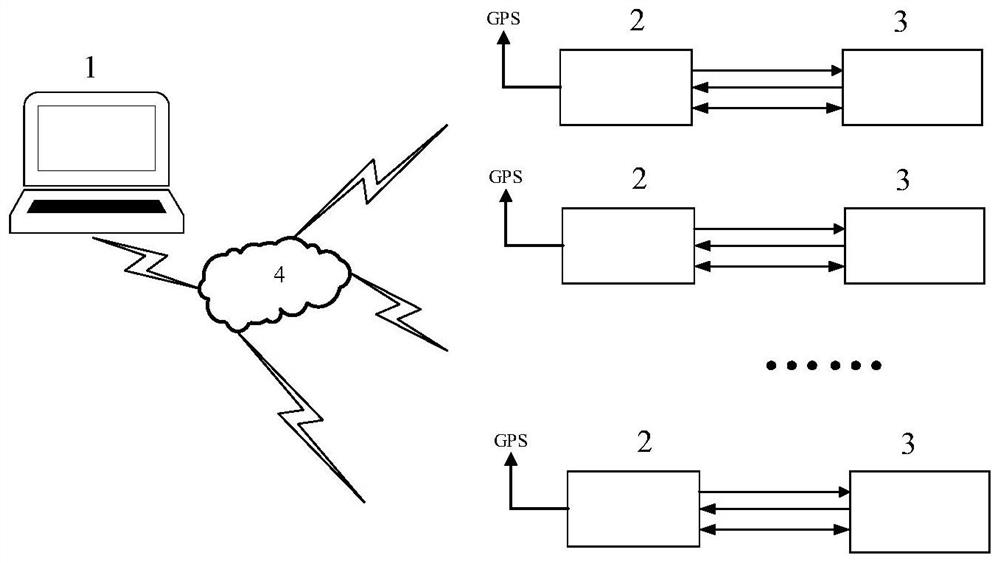

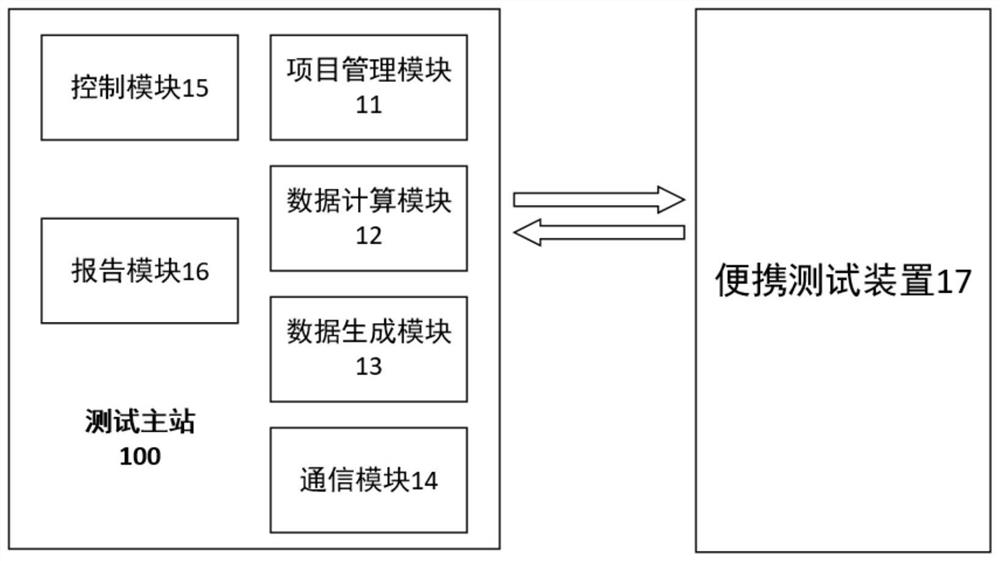

Feeder automation field automatic test method and system

ActiveCN113030642ALower requirementSimple on-site testing processFault location by conductor typesFeeder lineSystem under test

The invention discloses a feeder automation field automatic test method and system, which relate to the field of power distribution automation. The method comprises the following steps of in a test process, performing data synthesis according to three parts of data, namely test data of a previous step, topology change time obtained by feedback of action behaviors of a feeder terminal in a tested system after the test of the previous step is executed and data calculated in the current step, generating test data for the current step, and controlling the test to be automatically performed until the action behavior of the tested system does not change any more. According to the test method of the scheme, multiple test schemes do not need to be compiled in advance and sequence working states do not need to be manually set, the test scheme is automatically generated according to the action behavior feedback of the feeder terminals in the tested system, the feeder automation function can be checked, the coordination among the multiple feeder terminals in the system can be checked, the requirements on testers are reduced, the field test process is simple, the test result is reliable, and the test is comprehensive.

Owner:北京天能继保电力科技有限公司

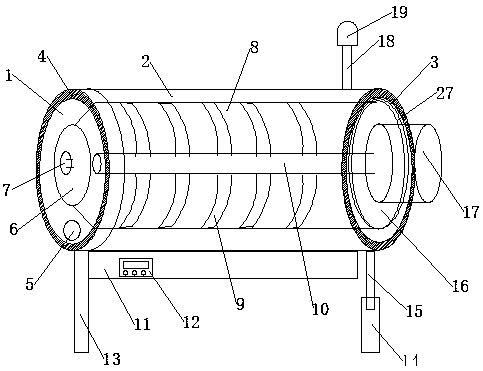

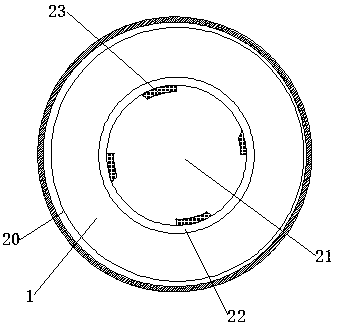

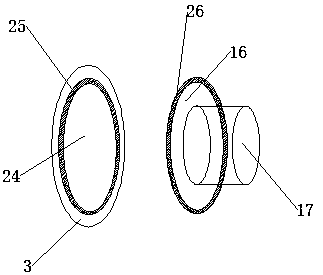

Medicine stir-frying machine for processing traditional Chinese medicinal materials

InactiveCN110464642AEvenly heatedSpeed up fryingPharmaceutical product form changeDomestic articlesHydraulic cylinderMedicine

The invention relates to a medicine stir-frying machine for processing traditional Chinese medicinal materials, wherein the medicine stir-frying machine comprises an upper cover body, an outer cylinder body and a lower cover body; the inner part of the outer cylinder body is provided with a heating piece; the upper cover body is provided with a first opening, and the first opening is provided witha medicine feeding cover body; the lower cover body is provided with a second opening, the second opening is provided with a lower fixed plate, the outer part of the lower fixed plate is provided with a motor, and the inner part of the outer cylinder body is provided with an inner cylinder body; the outer side of the first opening is provided with a second clamp slot; the inner side of the lowerfixed plate is provided with a third clamp slot, and two ends of the inner cylinder body are respectively arranged in the second clamp slot and the third clamp slot; the output shaft end of the motoris connected with a rotating shaft; the outer part of the rotating shaft is provided with a stir-frying plate; a smoke exhaust pipe is arranged above the outer cylinder body, a bracket is arranged below the outer cylinder body, and the bracket is provided with an operation plate; front support legs are hinged at the front end and the rear end of the left side of the bracket, and hydraulic cylinders and piston rods are arranged at the front end and the rear end of the right side of the bracket. The medicine stir-frying machine has the advantages of good stir-frying effect, simple operation andreduction of working procedures.

Owner:禹州市润之堂药业有限公司

Stirring device for processing vermicelli raw materials

InactiveCN112844153AAchieving stirringAvoid stirringShaking/oscillating/vibrating mixersTransportation and packagingElectric machineryEngineering

The invention relates to the technical field of vermicelli production devices, and discloses a stirring device for processing vermicelli raw materials. The stirring device comprises a bottom plate and a shell, a first motor with an output shaft extending rightwards is fixedly mounted on the left side of the upper surface of the bottom plate, and a cam is fixedly mounted at the right end of the output shaft of the first motor; two sets of symmetrically distributed guide rails with opposite U-shaped openings are fixedly mounted on the front side and the rear side of the middle of the upper surface of the bottom plate, the shell located over the cam is jointly slidably mounted on guide rails, a through hole is formed in the middle of the upper surface of the shell, and two sets of symmetrically distributed L-shaped second supports are fixedly mounted on the upper surface of the shell; and a second motor located over the shell is jointly and fixedly installed on the horizontal sections of the second supports. The stirring device has the beneficial effects that starch stirring is effectively realized, starch is prevented from being attached to the inner wall of the shell, the subsequent workload is reduced, friction is reduced, lasting use of the device is facilitated, the stirring effect is more ideal, and use is facilitated.

Owner:重庆巫峡粉丝有限公司

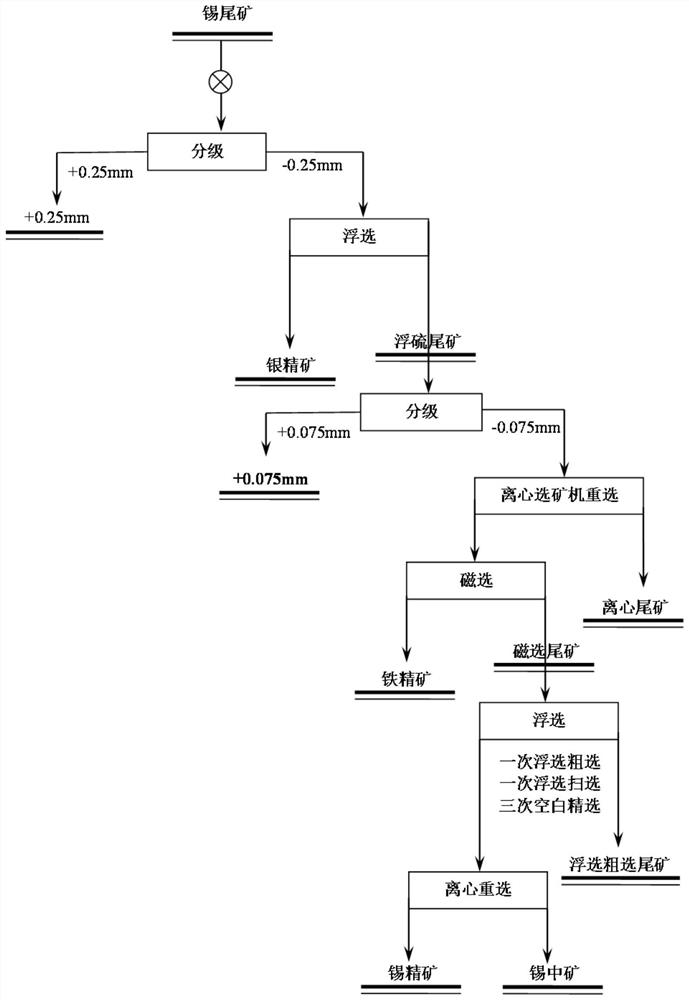

A method for comprehensive recovery of silver, tin and iron from quartz vein type tin tailings

ActiveCN110479499BReduce follow-up workloadIncrease production capacityFlotationMagnetic separationCassiteriteEngineering

The invention relates to a method for comprehensively recovering silver, tin and iron from quartz vein type tin tailings. The beneficiation method includes the following steps: S1: classify the tin tailings and carry out flotation at the fine-grained grade; S2: adjust the slurry, perform a rough separation, a sweep separation and a blank separation to obtain silver concentrate and sulfur separation tailings ;S3: Sulfur separation tailings classification, fine-grained class for cassiterite separation operations; S4: Gravity separation, to obtain centrifugal rough concentrate and centrifugal tailings; S5: Magnetic separation and centrifugal coarse concentrate to obtain iron concentrate and magnetic separation Tailings; S6: Perform a flotation roughing on the magnetic separation tailings to obtain a flotation roughing concentrate and a flotation roughing tailings; S7: Perform a flotation sweep on the flotation roughing tailings to obtain a flotation roughing Concentrate and sweeping tailings; S8: perform three blank separations on the flotation rough concentrate to obtain tin rough concentrate; S9: re-select tin rough concentrate to obtain tin concentrate and tin medium ore. The beneficiation method has low energy consumption, small equipment footprint and high separation efficiency.

Owner:INST OF RESOURCES UTILIZATION & RARE EARTH DEV GUANGDONG ACAD OF SCI

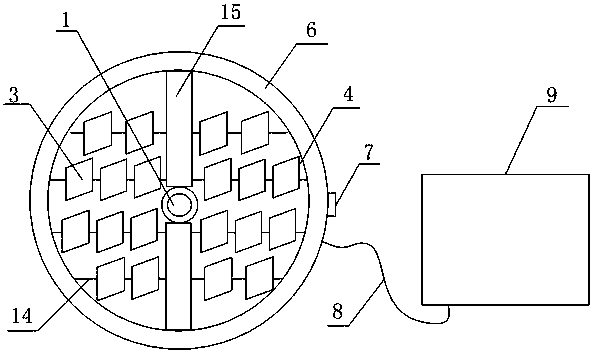

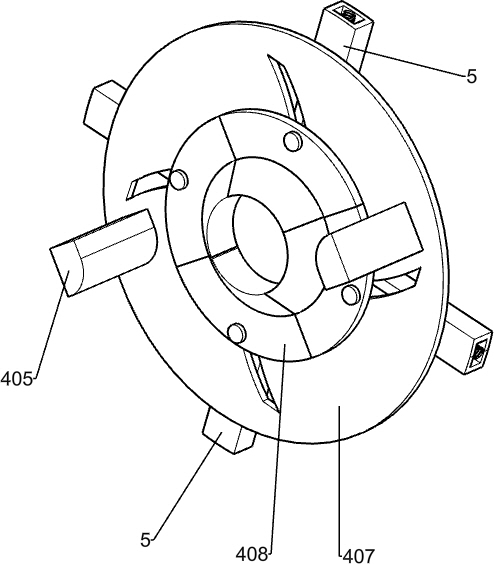

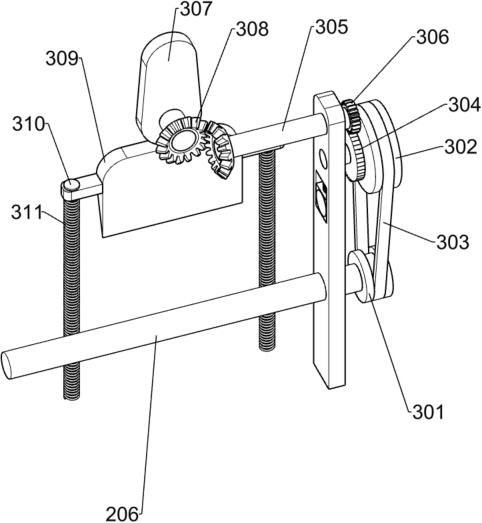

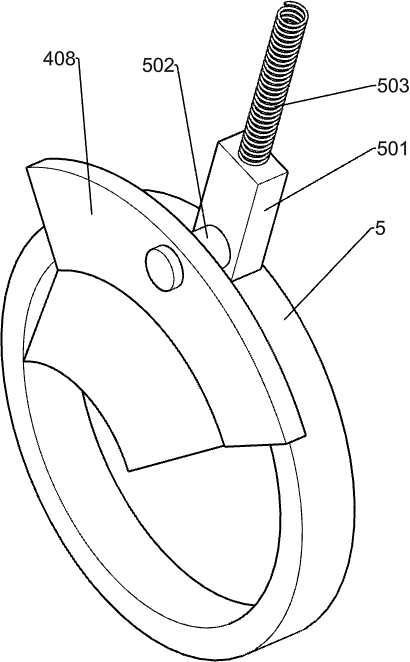

Disk type separator for concentrating corn starch gluten

The invention provides a disk type separator for concentrating corn starch gluten. The disk type separator for concentrating corn starch gluten comprises a power engine body, a cam and a valve element. A set of outer shells is fixedly connected to the top of the power engine body. A set of rotary drums is fixedly connected to a rotary shaft of the power engine body. Multiple sets of disks are uniformly distributed and fixedly connected inside the rotary drums. Four sets of backflow pipes are arranged on tops of the rotary drums. A set of one-way valves is fixedly connected inside each set of backflow pipes correspondingly. A set of primary liquid inlets is fixedly formed in the top of the outer shell. A set of light weight liquid outlets is formed in the upper portion of the right end faceof the outer shell. A set of gluten outlets is formed in the lower portion of the right end face of the outer shell. According to the disk type separator for concentrating corn starch gluten, cyclictype separation is adopted; the separating effect is better; intermittent type gluten discharging is adopted; the outflow volume is reduced; the gluten concentration of the gluten outlets is improved;follow-up workload is reduced; and working efficiency is improved.

Owner:安徽省蒙城县恒瑞面粉有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com