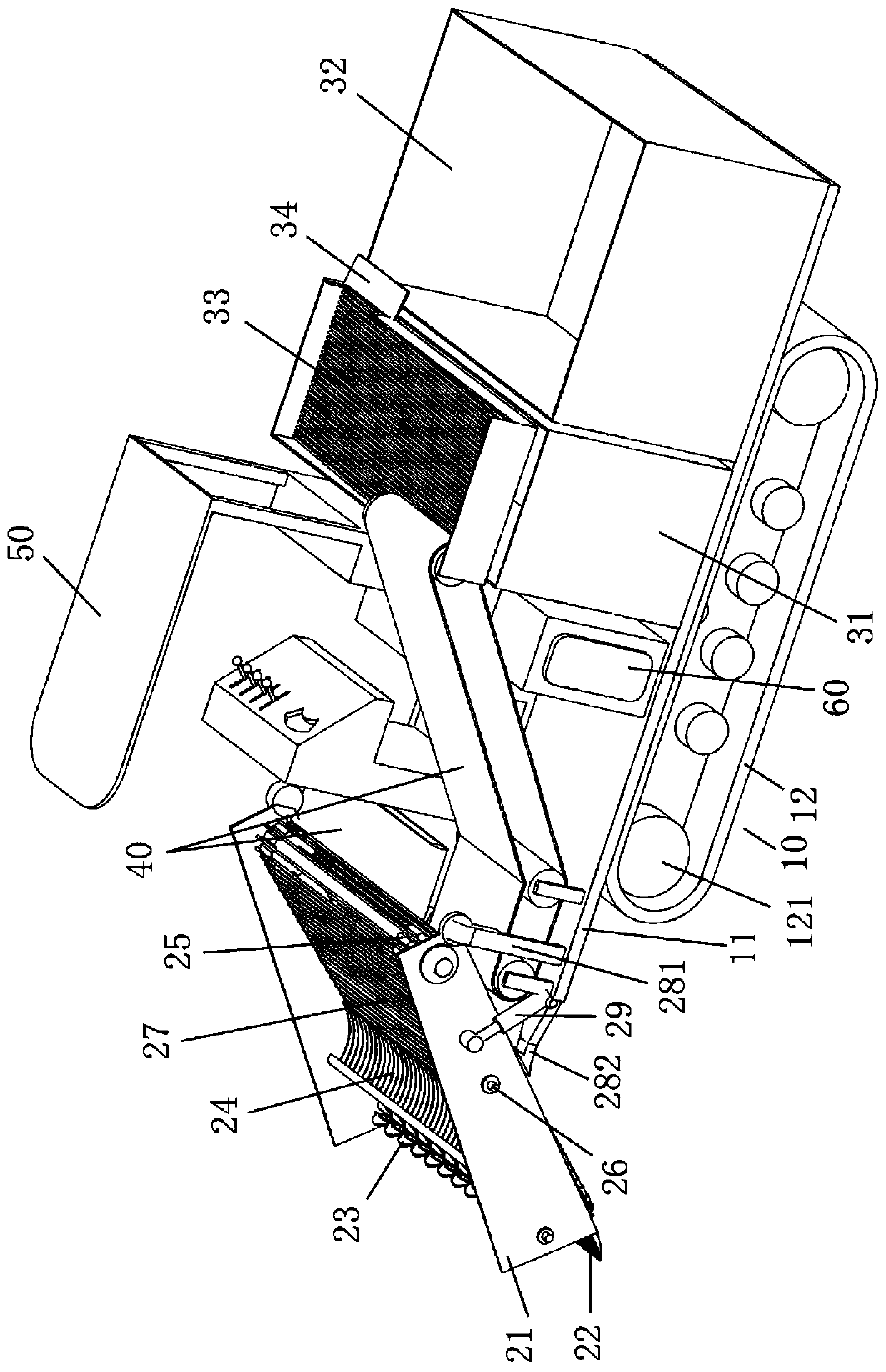

Ploughing type seashell harvesting machine

A harvester and seashell technology, which is applied in fish farming, application, animal husbandry, etc., can solve the problems of strong stickiness of sediment, increased workload, and difficult separation of seashells and sediment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

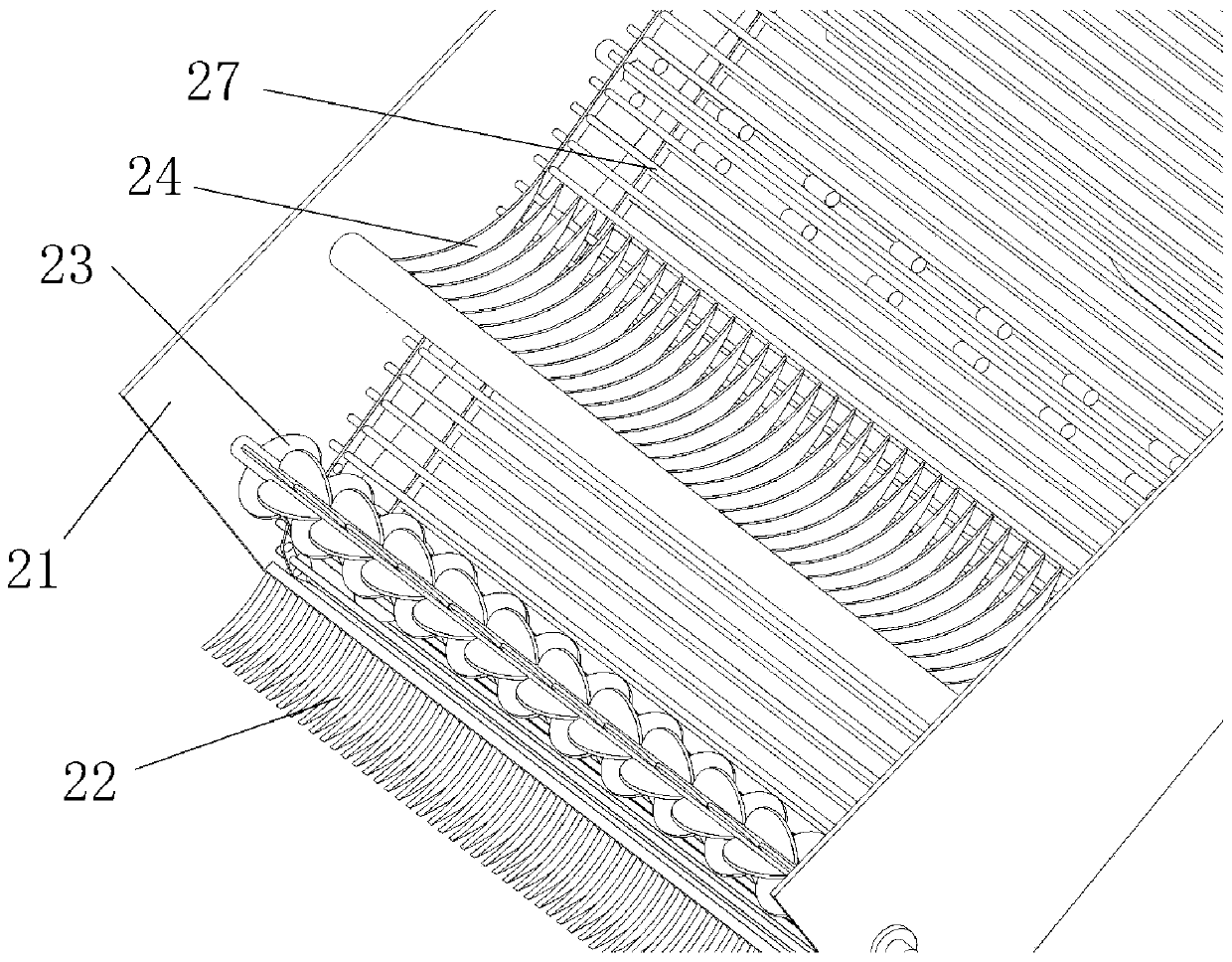

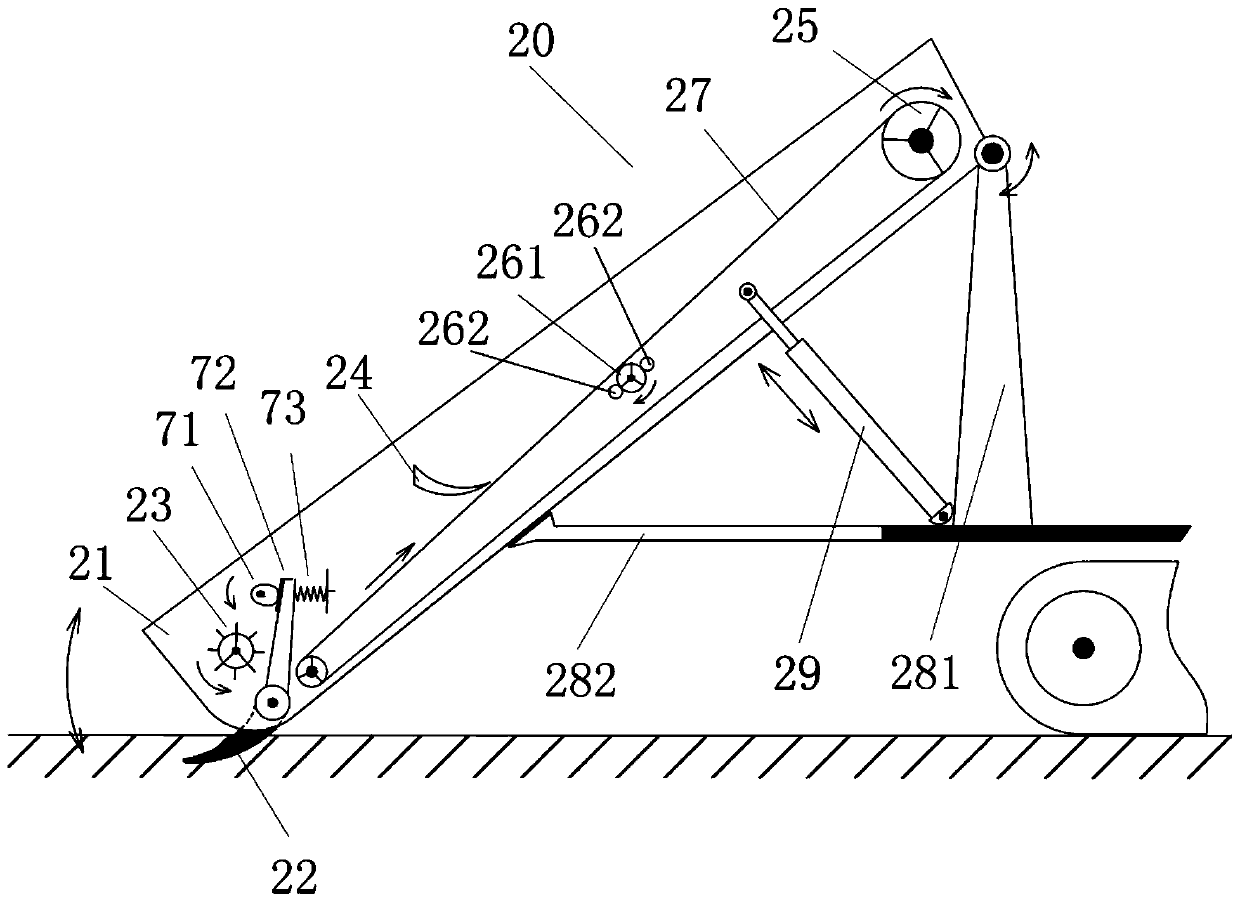

[0056] On the basis of embodiment 1, the vibrating wheel of the present embodiment is a vibrating cam, and the lowest point of the vibrating cam is tangent to the main conveyor belt or the lowest point of the vibrating cam is set close to the main conveyor belt, such as Figure 5 Shown, during the initial state, the lowest point of the vibrating cam is set close to the main conveyor belt. Similarly, during the rotation of the vibrating cam, when the highest point of the vibrating cam is close to the main conveyor belt, the main conveyor belt 27 ( Image 6 Provided the schematic diagram of vibration main conveyer belt 27 when the vibrating cam rotates 180 degrees); when the highest point of the vibrating cam is away from the main conveyer belt, the main conveyer belt can fall; Conveyor belt, and then shake the seashells and beach mud on the main conveyor belt, the beach mud attached to the seashells is basically shaken off, and the beach mud is shaken back to the beach.

Embodiment 3

[0058] On the basis of Embodiment 1, the layout of the cab in this embodiment is different from that of the cab in Embodiment 1, as Figure 9 As shown, the cab 50 on the tracked vehicle body is located on the rear side of the tracked vehicle body. The non-finished product bin and the finished product bin are arranged between the harvesting plow and the driving bin, the non-finished product bin is correspondingly arranged directly below the vibrating screen, the finished product bin is arranged on one side of the vibrating screen, and the finished product bin is connected to the vibrating screen. An inclined sliding plate of the vibrating screen is arranged between the vibrating screens, the upper end of the inclined sliding plate of the vibrating screen is flush with the screen mesh of the vibrating screen, and the lower end of the inclined sliding plate of the vibrating screen extends into the finished product bin. The seashells picked up by the harvesting plow are scraped an...

Embodiment 4

[0059] Embodiment 4: On the basis of any one of Embodiments 1-3, the plowing type seashell harvester also includes a plow tooth cam 71, and the plow tooth cam 71 is rotatably installed on the harvesting plow box, The plow teeth are hinged to the front end of the harvesting plow box, and the upper end of the plow teeth is extended upwards to connect with a rocker 72. The rocker is tangent to the plow tooth cam, and the plow tooth cam can be driven to rotate by the driving mechanism. During the rotation of the cam, when the highest point of the coterie cam is close to the rocker, if Figure 8 As shown, the rocker can be pushed to move backward, thereby driving the front end of the coulter to rotate forward and move forward; when the highest point of the coulter cam is far away from the rocker, the front end of the coulter will reverse under the action of gravity and move backward (such as Figure 7 As shown), preferably a spring 73 is fixedly connected on the rocking bar, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com