Fiber module for heating furnace and manufacturing method for fiber module

A fiber module and production method technology, applied in the field of fiber modules, can solve the problems of difficult repair, easy falling of fiber folded blocks, shortened service life of furnace lining, etc., and achieve the effects of lightening installation, reducing gaps, and strong adaptive performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

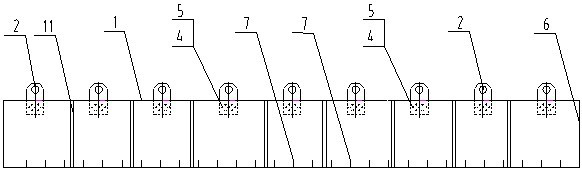

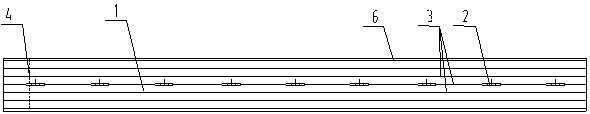

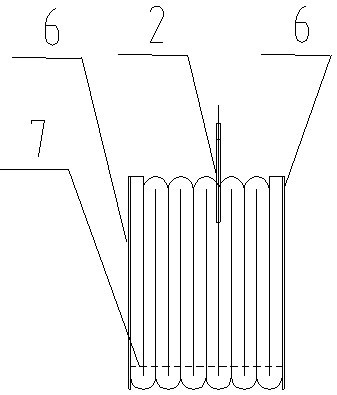

[0033] like figure 1 , 2 , 3, 4, and 5, the fiber module of the heating furnace of the present invention includes a body 1 made of fiber blankets, and the body 1 is one or more fiber blankets that are laid flat and folded several times along the length direction or width direction. It is obtained once, or two or more fiber blankets are folded several times along the direction of the seam after two or more fiber blankets are staggered with each other, and the width of each fold is the same, or basically the same (or kept within the error range required by the process) inside); in the body 1, there are several hangers 2 for installing or fixing the body 1, the hangers 2 are firmly connected with the body 1, and the fiber module of the present invention is arranged on the furnace of the heating furnace as the lining of the heating furnace When topping, hang the fiber module on the roof of the heating furnace through the hanging part 2, usually on the steel beam or steel mesh on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com