Stirring device for processing vermicelli raw materials

A technology of stirring device and raw materials, which is applied in the directions of mixer accessories, transportation and packaging, dissolution, etc., can solve the problems of increased cleaning workload, low paste-forming efficiency, unfavorable use, etc., achieve better stirring effect, and reduce follow-up workload. , beneficial effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

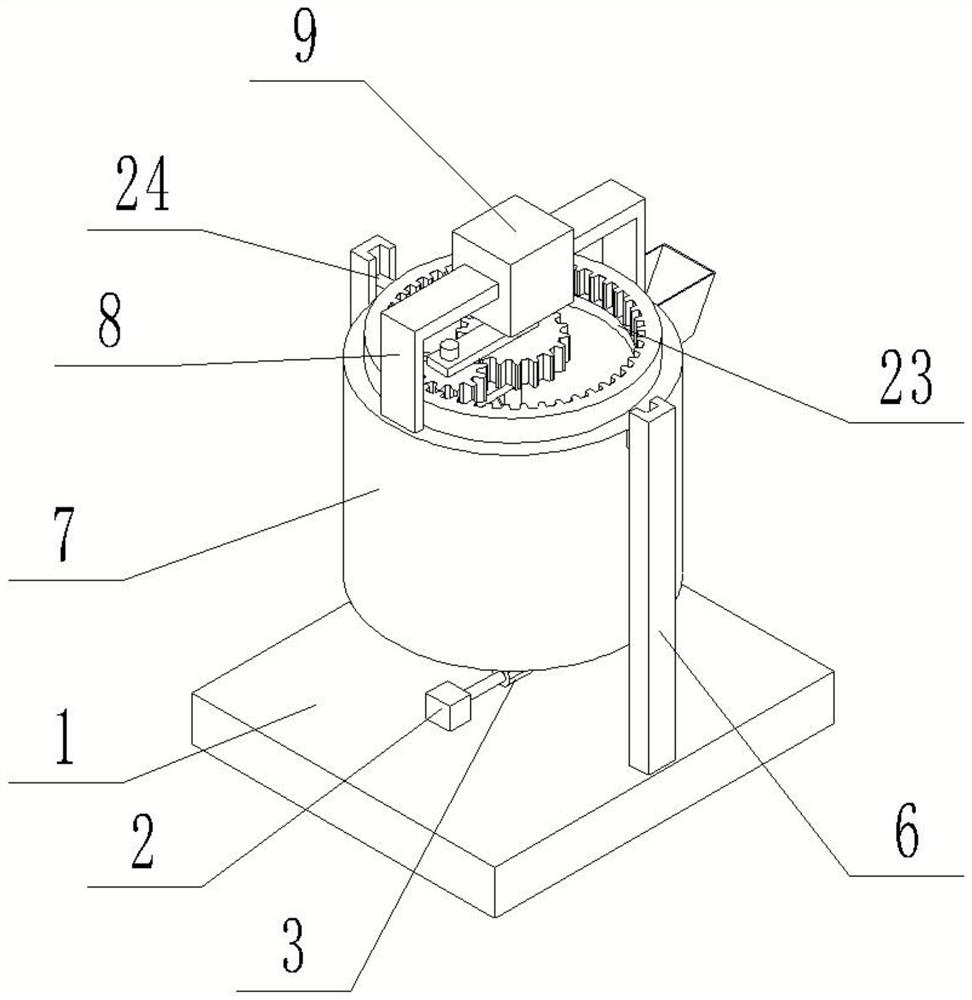

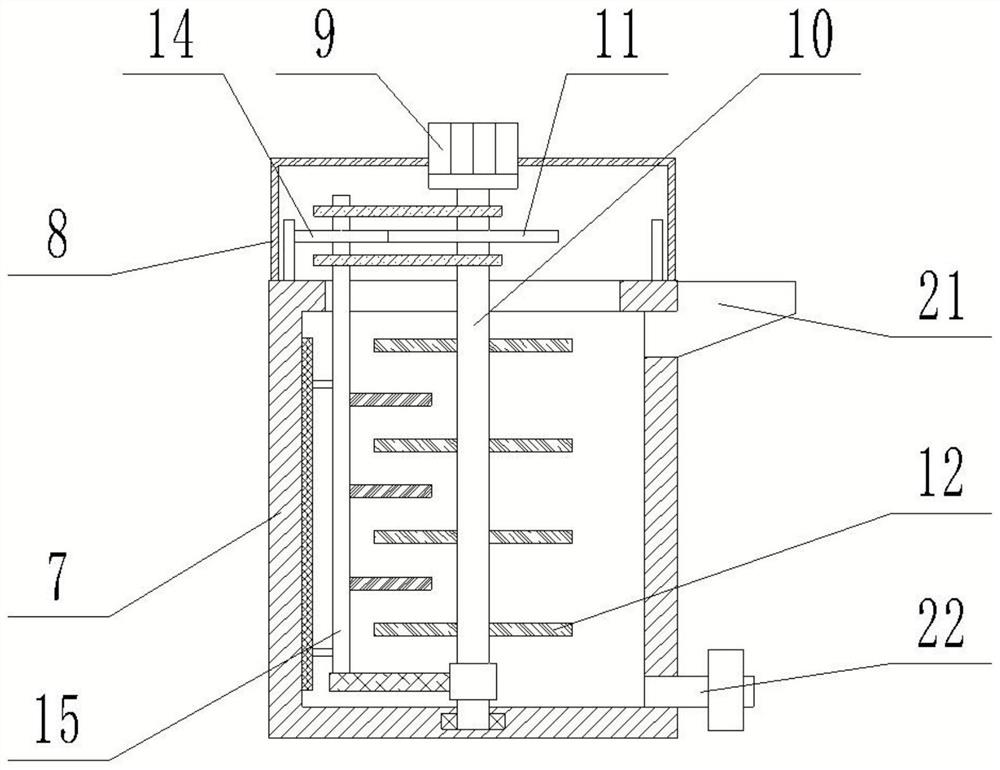

[0024] see Figure 1-4 , a mixing device for raw vermicelli processing, comprising a base plate 1 and a housing 7, the left side of the upper surface of the base plate 1 is fixedly installed with a first motor 2 with an output shaft protruding from the right side, and the right end of the output shaft of the first motor 2 is fixedly installed with Cam 3, two groups of guide rails 6 with U-shaped openings opposite and symmetrically distributed are fixedly installed on the front and rear sides of the upper surface of the bottom plate 1, and the housing 7 located directly above the cam 3 is slidably installed on the guide rails 6, and the upper surface of the front and rear sides of the housing 7 A sliding block 24 is fixedly installed, and the end of the sliding block 24 away from the housing 7 is slidably installed on the guide rail 6. The middle part of the lower surface of the housing 7 is fixedly installed with a first bracket 4 with a U-shaped opening facing downward, and th...

Embodiment 2

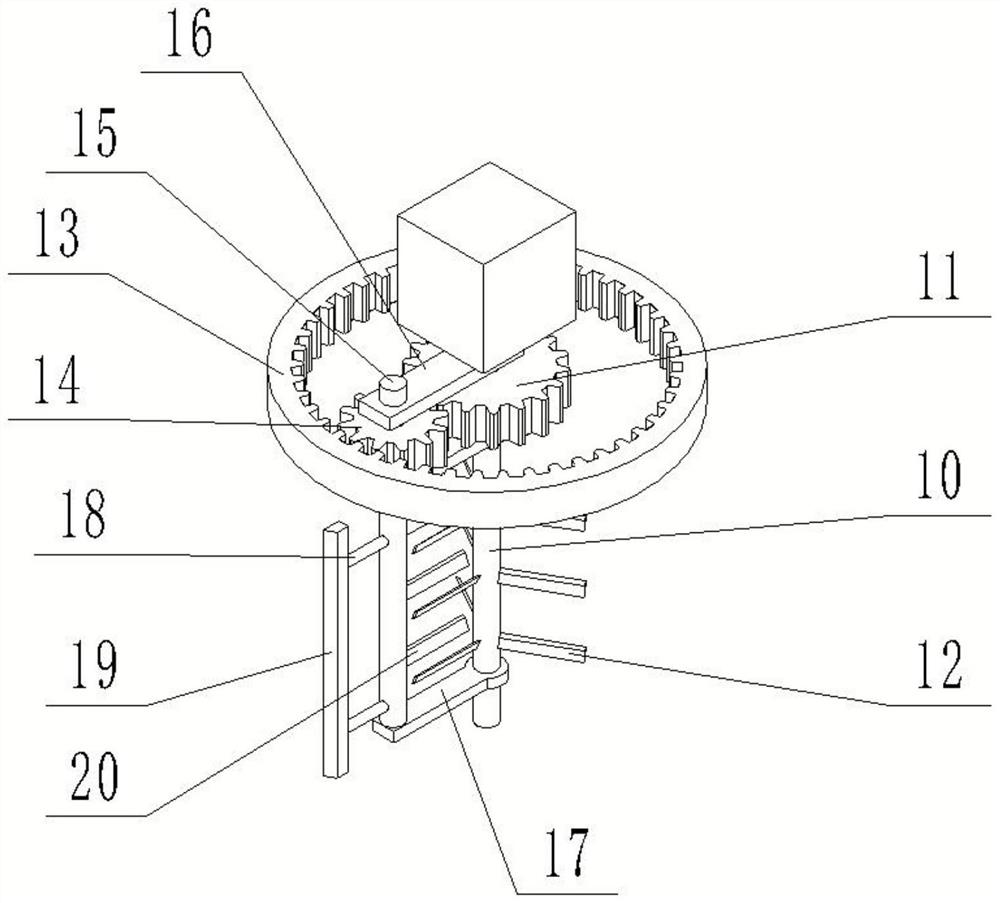

[0026] On the basis of Embodiment 1, the second gear 13 distributed around the through hole 23 is fixedly installed on the upper surface of the housing 7, the second gear 13 is set as an internal gear, and the second gear 13 meshes with the planetary gear 14; the first stirring blade 12 and the second stirring blade 20 are distributed at intervals and are arranged at a certain angle with the horizontal plane of the first stirring blade 12 and the second stirring blade 20; The lower part communicates with a discharge pipe 22 with a valve.

[0027] The working principle of the present invention is: sweet potato starch and water are poured into the housing 7 through the feed hopper 21, the first motor 2 and the second motor 9 are turned on, and the first motor 2 drives the cam 3 to rotate so that the housing 7 is positioned on the guide rail. 6 moves up and down, the second motor 9 rotates to drive the first rotating shaft 10 to rotate, and at the same time, the first gear 11, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com