Disk type separator for concentrating corn starch gluten

A corn starch, disc type technology, used in centrifuges with rotating drums, centrifuges, etc., can solve the problems of inability to meet the concentration requirements, large outlet flow, low protein concentration, etc., to reduce the follow-up workload. , the effect of reducing the flow and increasing the concentration of gluten

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

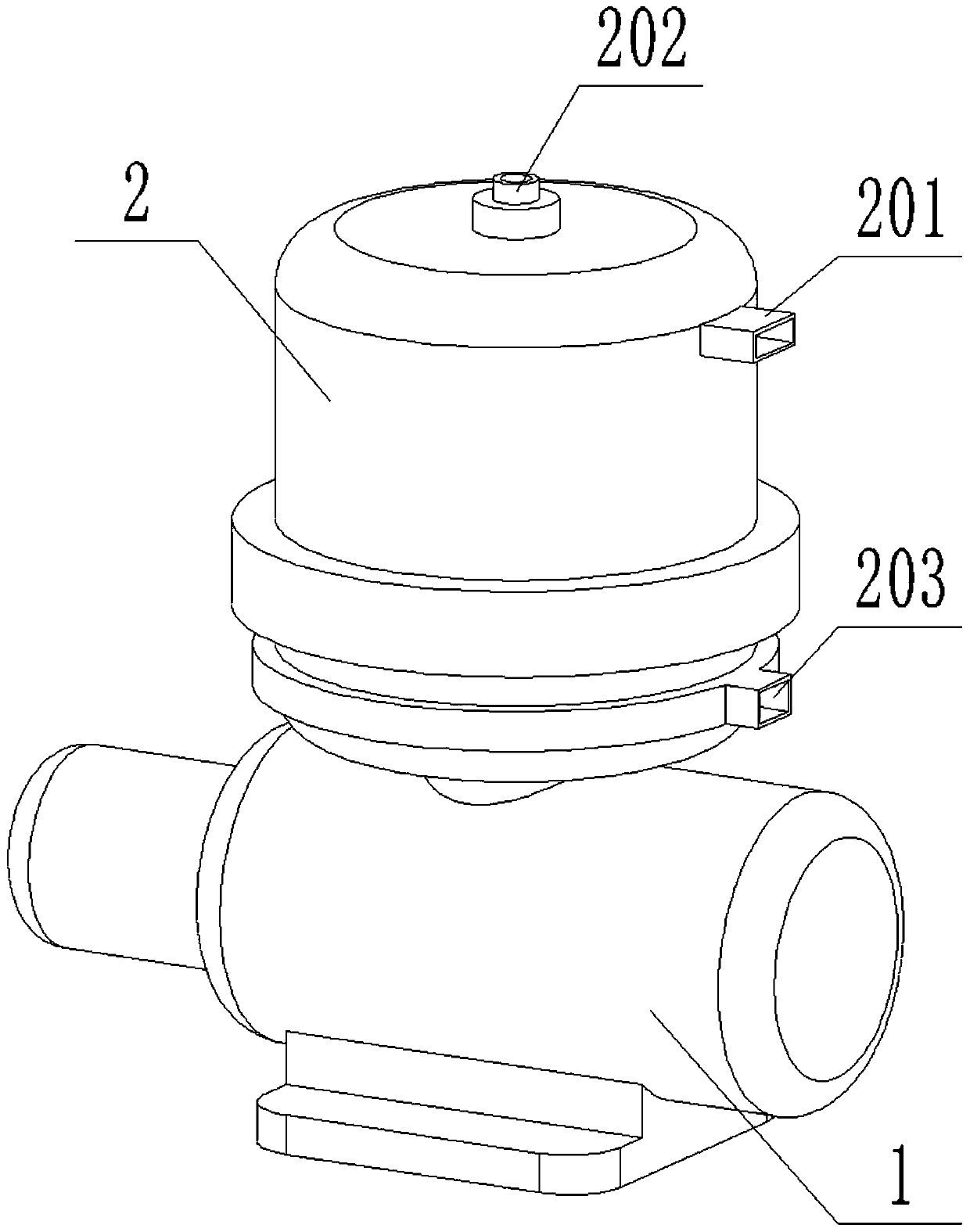

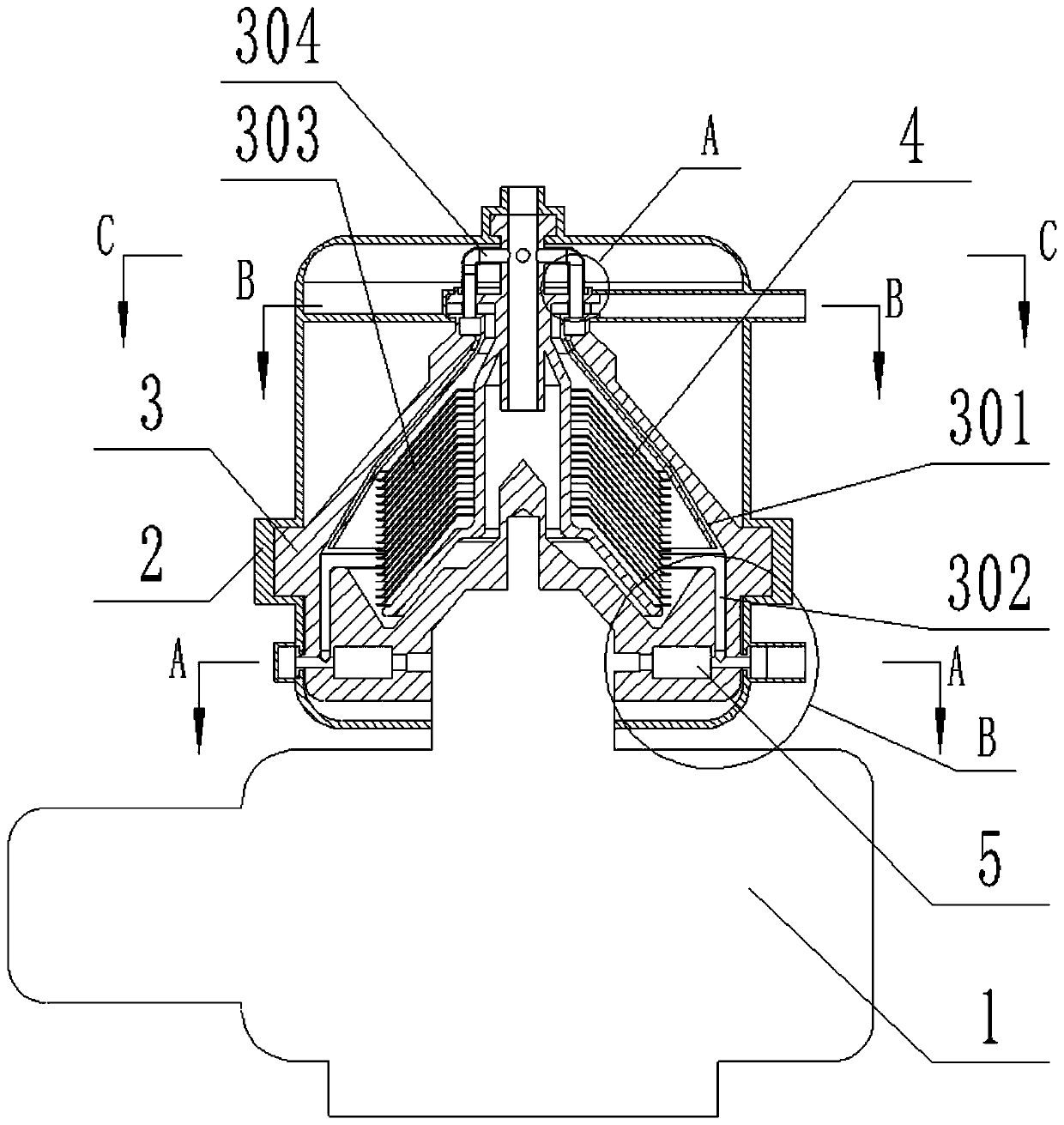

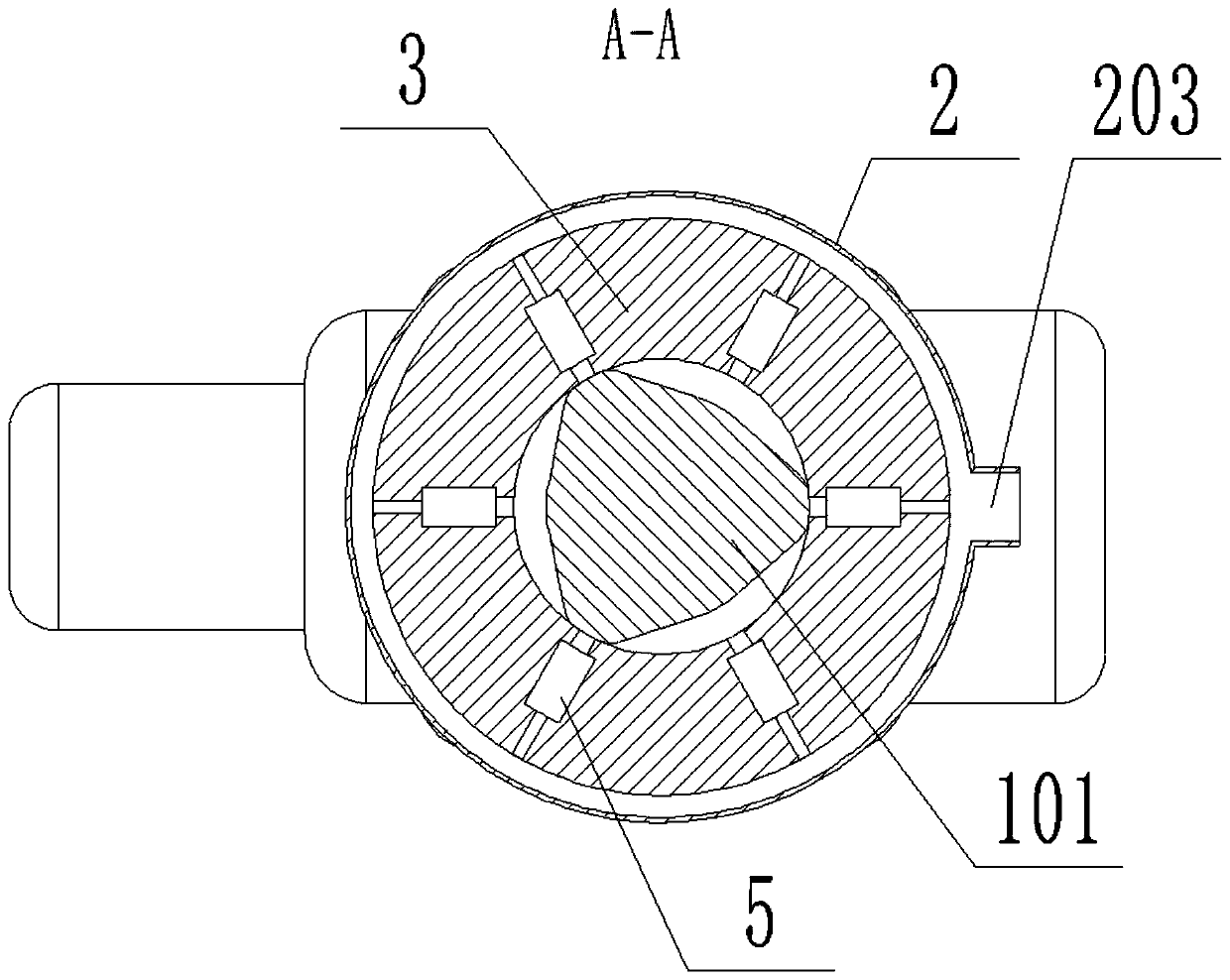

[0030] as attached figure 1 to attach Figure 8 Shown:

[0031] The present invention provides a disc separator for cornstarch gluten concentration, comprising: power body 1, cam 101, outer shell 2, light liquid outlet 201, raw liquid inlet 202, gluten outlet 203, drum 3 , heavy medium return chamber 301, gluten sinking chamber 302, disc gap 303, return pipe 304, disc 4, plunger pump 5, check valve 6, spring 601 and spool 602; the top of power body 1 A group of outer casings 2 are fixedly connected; a group of rotating drums 3 are fixedly connected to the rotating shaft of the power body 1; the rotating drum 3 and the outer casing 2 are axially connected; the inner sides of the bottom of the rotating drums 3 are arranged radially and fixedly There are six sets of plunger pumps 5; the inside of the drum 3 is uniformly arranged and fixedly connected to multiple sets of discs 4; the top of the drum 3 is provided with four sets of return pipes 304; each set of return pipes 304 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com