Fruit peeling and sectioning device

A technology for cutting into sections and fruits, applied in peeling utensils, metal processing, household utensils, etc., can solve the problems of unclean removal, manual operation, inconvenience, etc., to save manpower, avoid injury, and remove completely. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

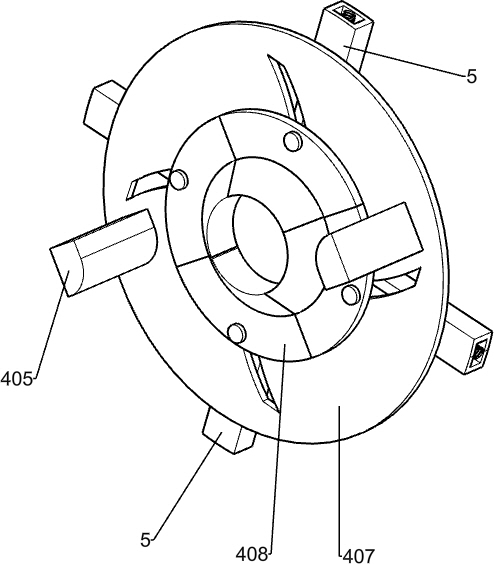

[0032] A kind of fruit peeling and sectioning device, refer to Figure 1-8 As shown, it includes a support 1, a first support frame 101 and a collection box 8. The first support frame 101 is fixedly installed on the upper side of the support 1, and the collection box 8 is fixedly installed on one side of the support 1. It is characterized in that it also includes There are: a transmission mechanism, a section cutting mechanism and a peeling mechanism, the two transmission mechanisms are fixedly installed on the upper left side and the middle position of the first support frame 101, and the section cutting mechanism is fixedly installed on the upper middle position of the first support frame 101 to the right Side, the section cutting mechanism is connected with the transmission mechanism, the peeling mechanism is fixedly installed in the upper middle position of the first support frame 101, and the peeling mechanism is located in the middle position of the transmission mechanism...

Embodiment 2

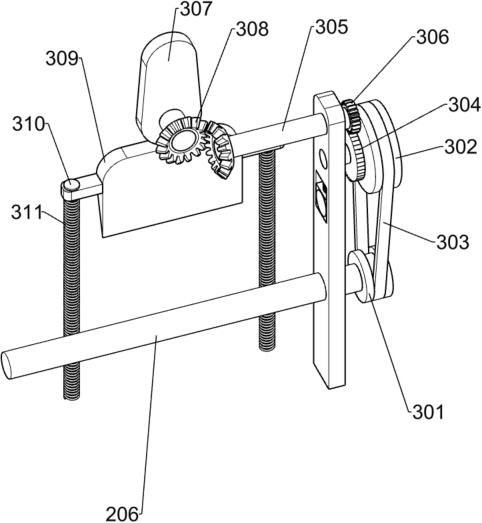

[0035] On the basis of embodiment 1, with reference to figure 2 As shown, the transmission mechanism includes a first support plate 2, a motor 201, a first shaft 202, a first pulley 203, a second pulley 204, a first belt 205, a second shaft 206, a toothed roller 207, The first slider 208, the first spring 209, the third pulley 210 and the second belt 211, two pairs of first support plates 2 are respectively fixedly installed on the upper left side and the middle position of the first support frame 101, and the motor 201 is fixedly installed On the inner left side of the first support frame 101, the first shaft 202 is fixedly mounted on the output shaft of the motor 201, the first pulley 203 is fixedly mounted on the first shaft 202, and the two second shafts 206 are rotatably mounted. In the middle part of a pair of first support plates 2, toothed rollers 207 are fixedly installed on each second axle bar 206, and the second pulley 204 is fixedly installed on a second axle bar 2...

Embodiment 3

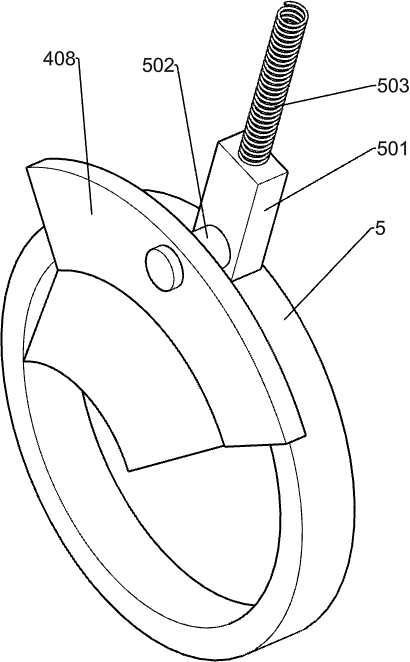

[0044] On the basis of embodiment 2, with reference to Figure 8 As shown, it also includes a peeling mechanism, and the peeling mechanism includes the sixth pulley 6, the fourth shaft rod 601, the fixed plate 602, the seventh pulley 603, the fifth belt 604, the second bevel gear 605, the third The bevel gear 606 and the second cutter 607, the sixth pulley 6 are fixedly installed on the front end of the first shaft 202, the fourth shaft 601 is rotatably installed on the inner side of the groove on the bracket 1, and the fixed plate 602 is fixedly installed on the side of the bracket 1. On the inner side of the groove, the seventh pulley 603 is fixedly installed on the front end of the fourth shaft 601, the fifth belt 604 is wound on the sixth pulley 6 and the seventh pulley 603, and the second bevel gear 605 is fixedly installed on the fourth At the rear end of the shaft 601, the third bevel gear 606 is rotatably mounted on the lower rear side of the fixed plate 602, the secon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com