Patents

Literature

38results about How to "Improve the use of limitations" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

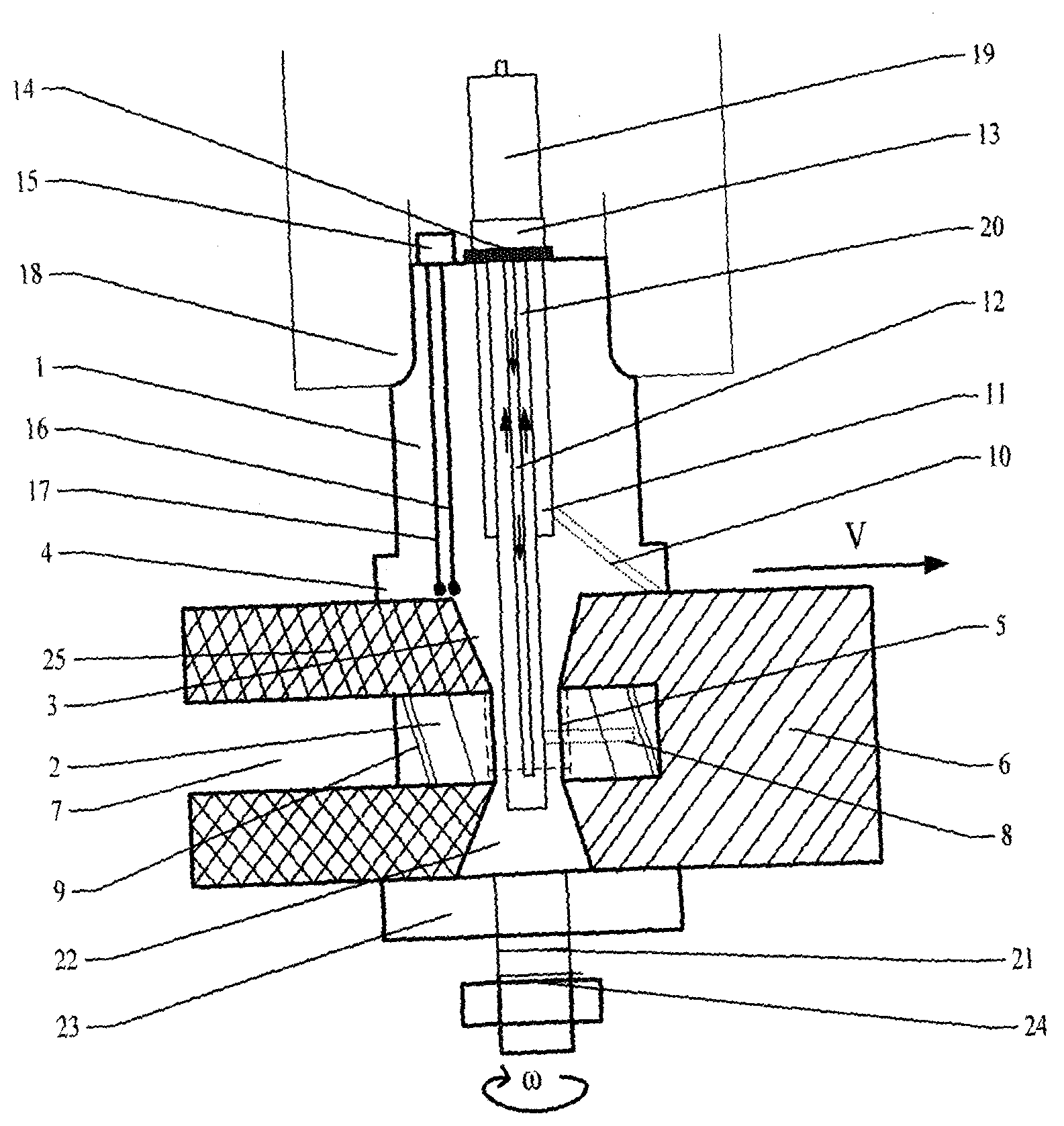

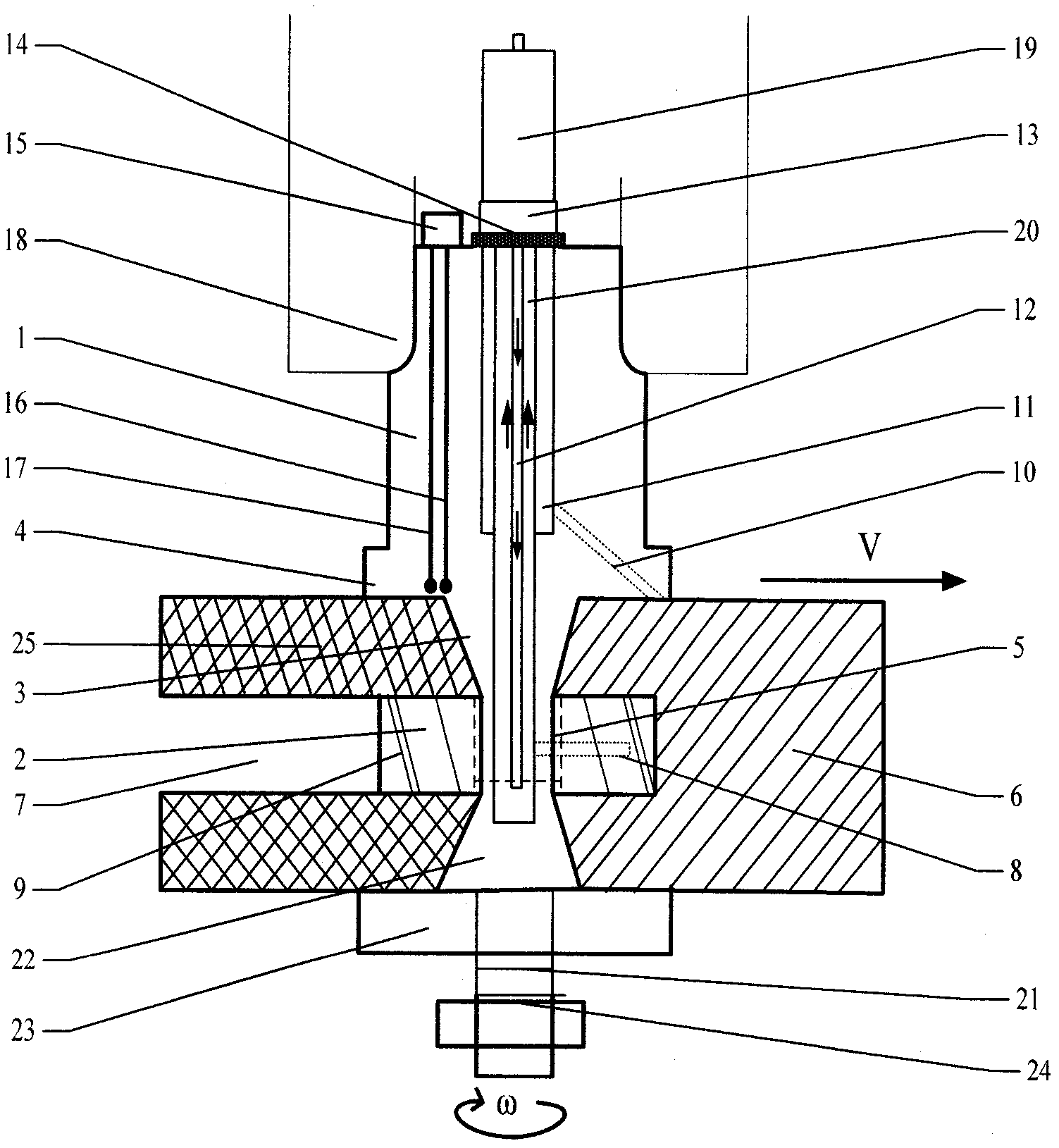

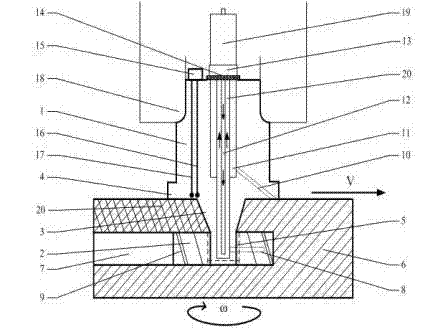

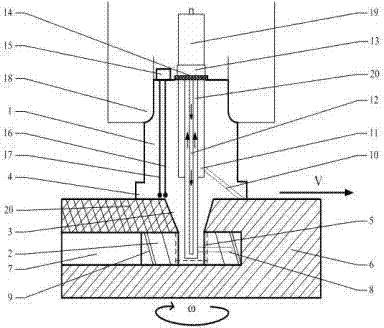

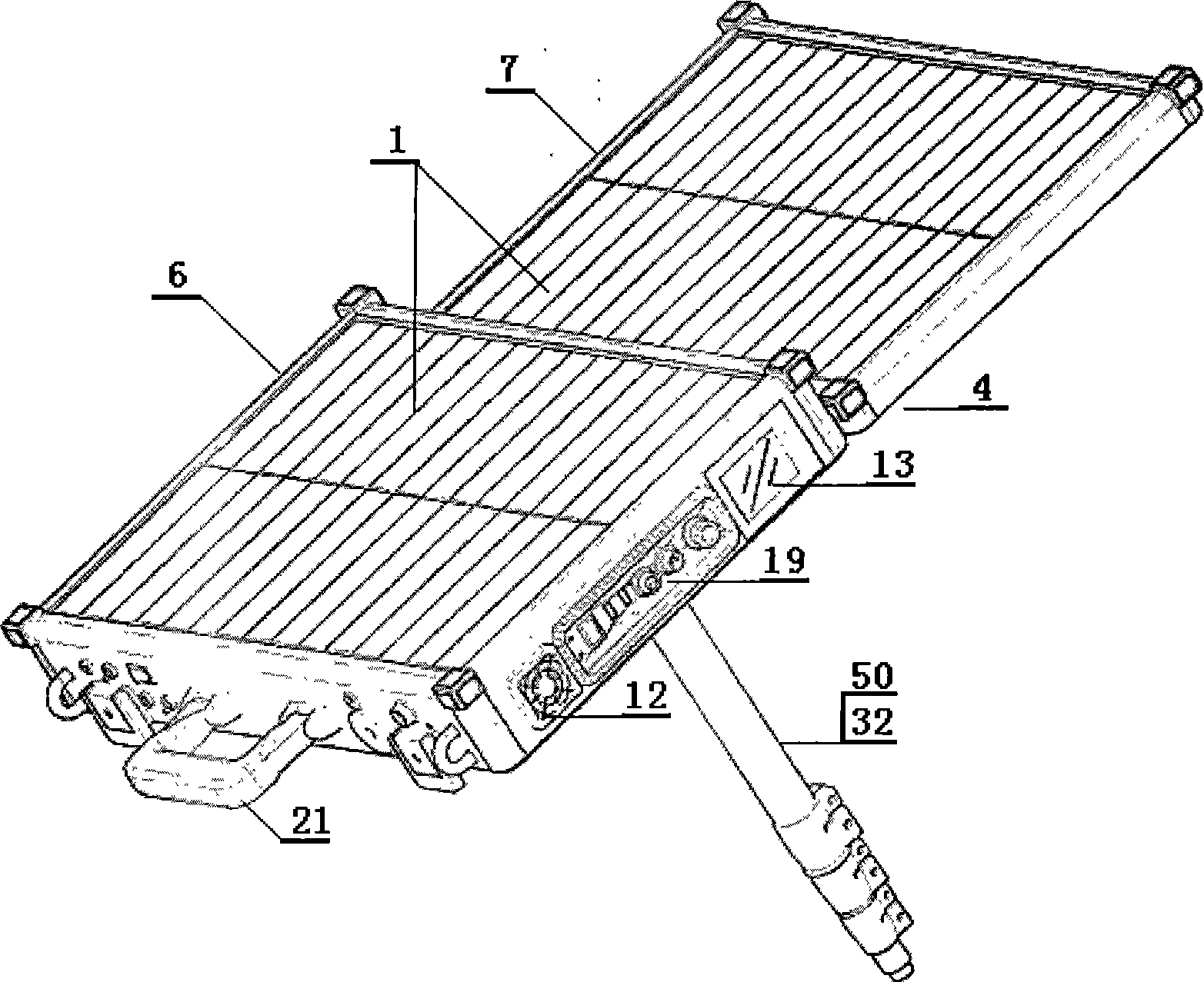

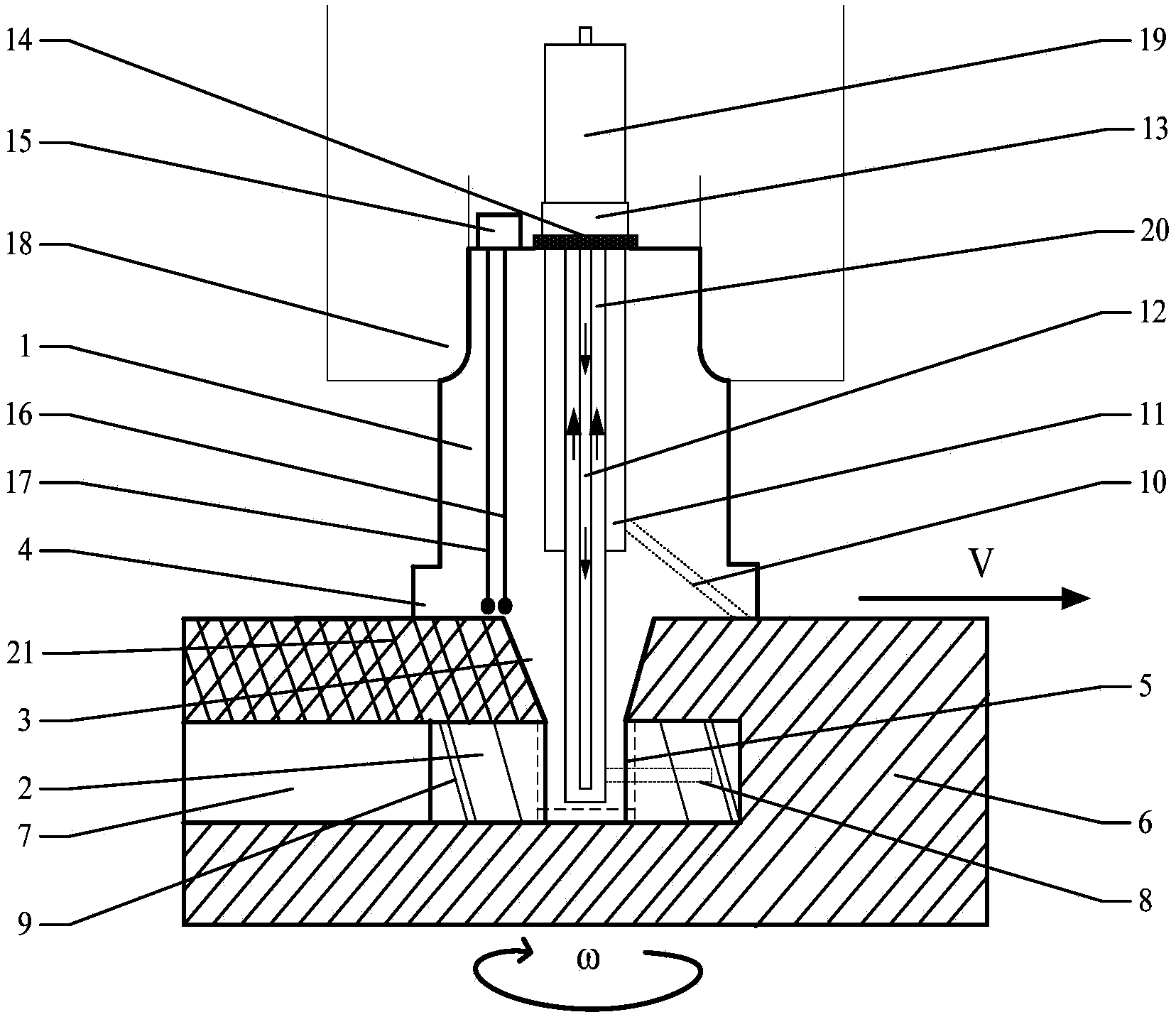

Cutting-stirring friction welding composite processing device for floating double-shaft-shoulder double-stirring needle and manufacture method thereof

InactiveCN102490018AEfficient coolingAvoid glitchesOther manufacturing equipments/toolsNon-electric welding apparatusInduction systemTemperature sensing

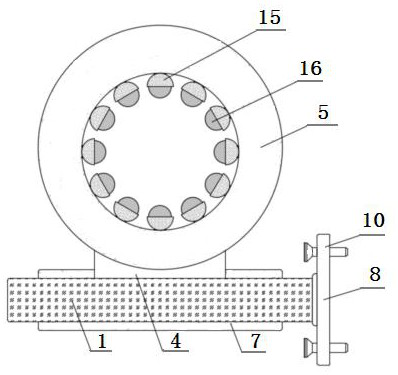

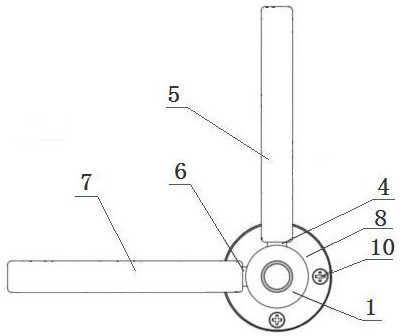

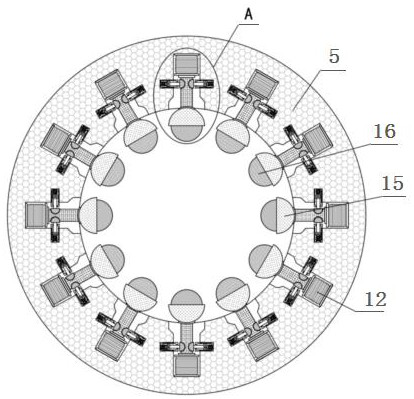

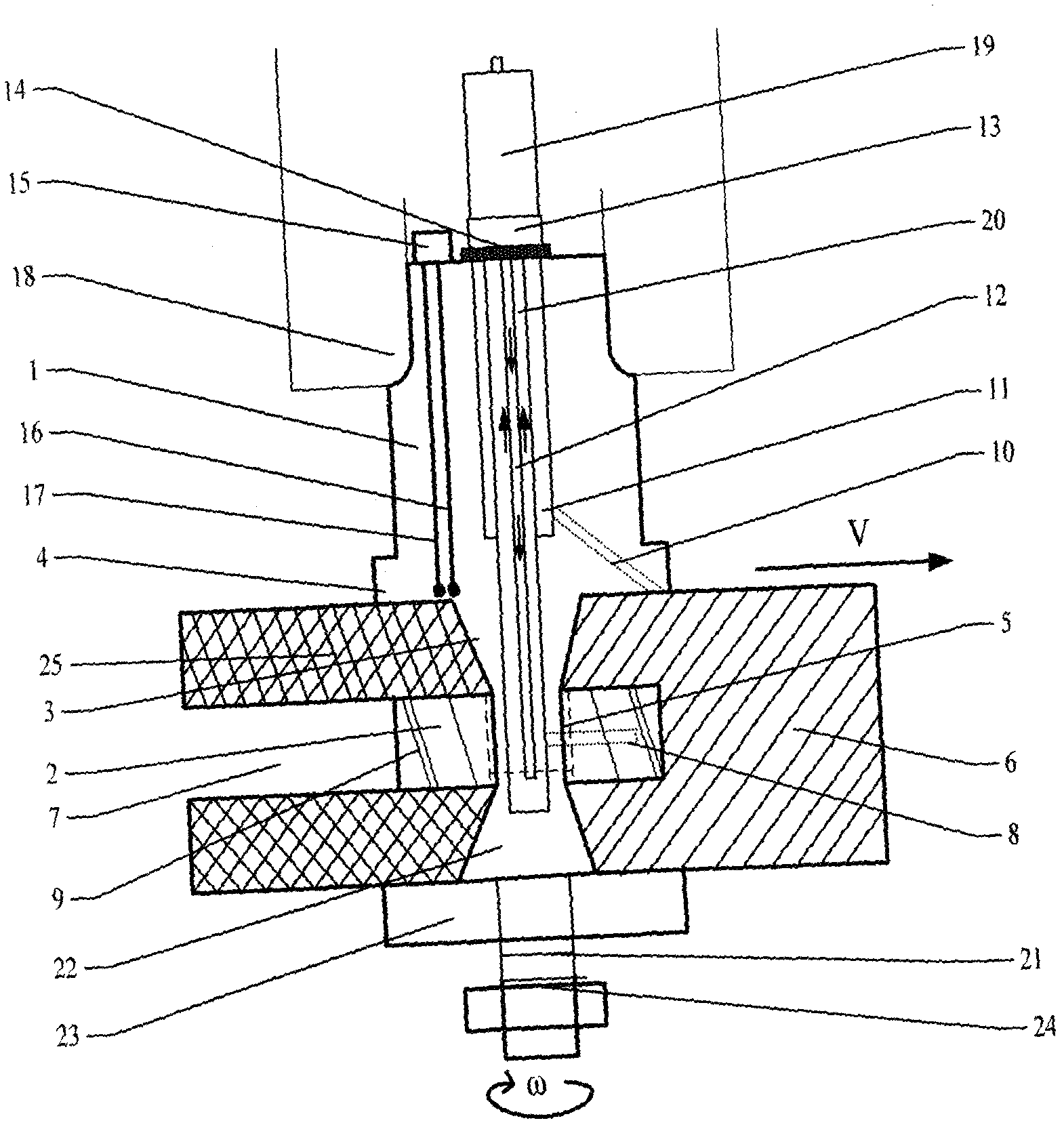

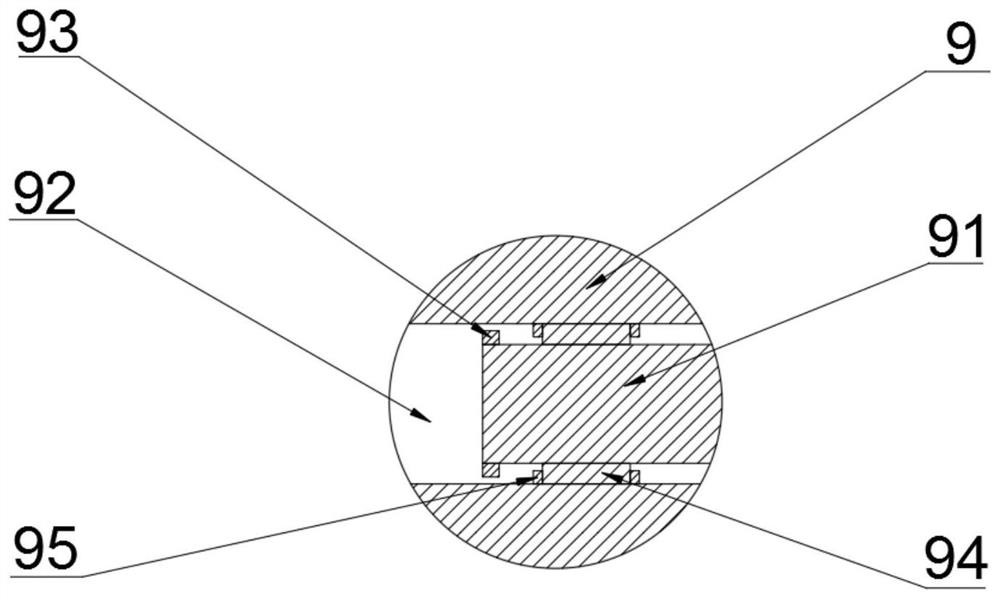

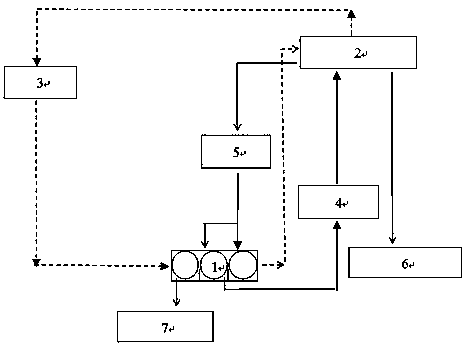

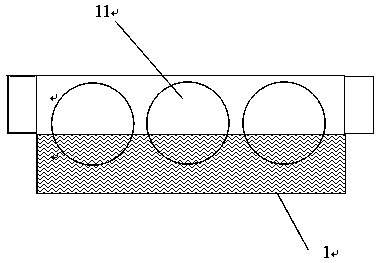

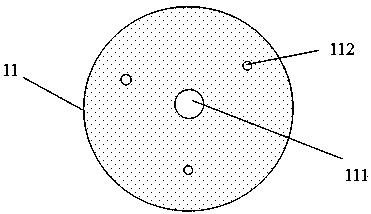

The invention discloses a cutting-stirring friction welding composite processing device for a floating double-shaft-shoulder double-stirring needle and a manufacture method thereof, and particularly relates to a combined or composite processing device capable of simultaneously carrying out milling or cutting processing and stirring friction welding processing and a method thereof. The cutting-stirring friction welding composite processing device for the floating double-shaft-shoulder double-stirring needle integrates a cutting system or a milling system, a stirring friction welding system, a forced cooling system, a gas protection system, a temperature sensing system, a pressure induction system, a milling liquid supply system and a sensing-free system. The cutting-stirring friction welding composite processing device has functions of temperature control, gas protection, pressure detection, cooling liquid protection, milling head replacing and floating double-shaft-shoulder self-supporting stirring friction welding. The method for carrying out cutting-stirring friction welding composite processing on workpieces can meet strength requirements of mechanical processing of ferrous light metal materials, carbon steel materials and alloy steel materials. The cutting-stirring friction welding composite processing device for a floating double-shaft-shoulder double-stirring needle and the manufacture method of the cutting-stirring friction welding composite processing device reduce manufacture procedures, save processing cost, have the advantages of being high in efficiency, excellent in quality, high in stability and saving in energy, break through limitation of conventional machining technology, form a new method and a new thought for machinery processing, and have wide application prospects in industries of heating, air conditioners, ice manufacture, freshness keeping, medicine preparation, construction, aquatic products and foods.

Owner:CHONGQING UNIV

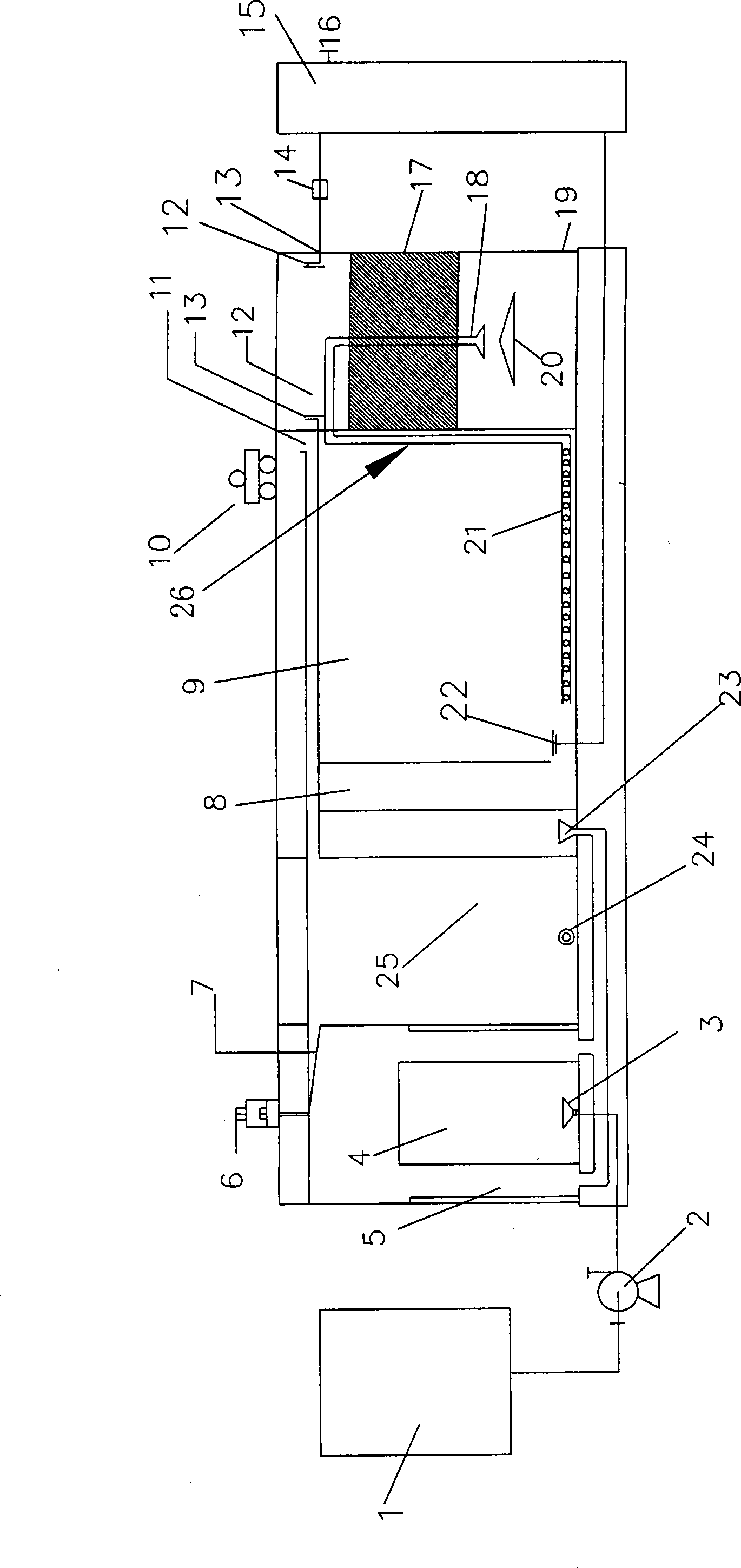

Oily wastewater treatment method and whole set apparatus thereof

InactiveCN101486515ACompact structureEasy to handleMultistage water/sewage treatmentWater/sewage treatment by flocculation/precipitationFlocculationOil water

The invention pertains to the waste water processing technical field and relates to an oily waste water processing method and complete set of equipment thereof, which is characterized in that: firstly, the waste water is processed by an express pump and then transmitted to a steady flow cylinder by a distributor so as to be treated with demulsification and perikinetic flocculation; afterward, the waste water is transmitted to a mixing tank so as to be treated with orthokinetic flocculation; after being further charged by a high-pressure dissolved air releaser, oil-water separation is carried out to the waste water; and finally, clean water meeting the requirement of environmental protection can be obtained after the waste water is separated in an inclined tube settling zone. The processing method is characterized by simple process and equipment, low investment and low running cost.

Owner:宜兴市芳惠子环保设备厂

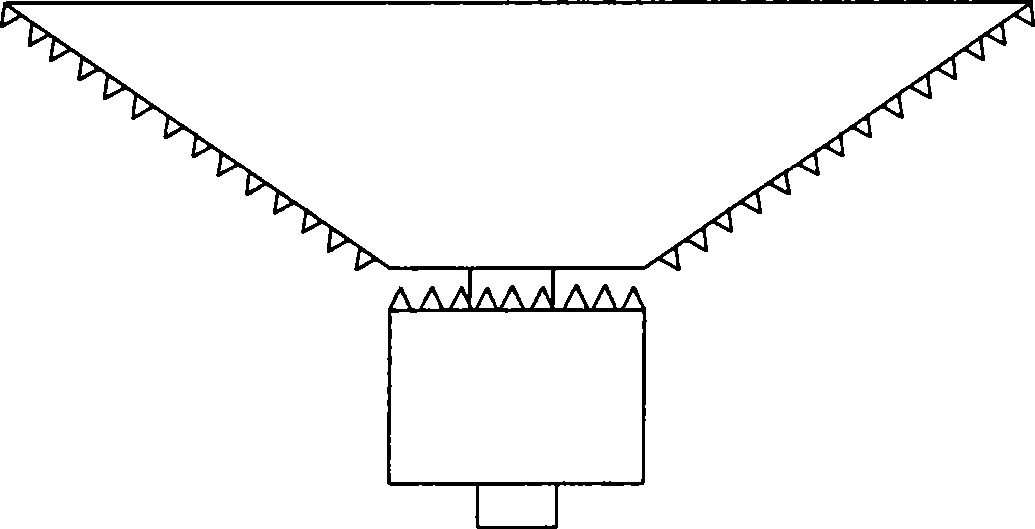

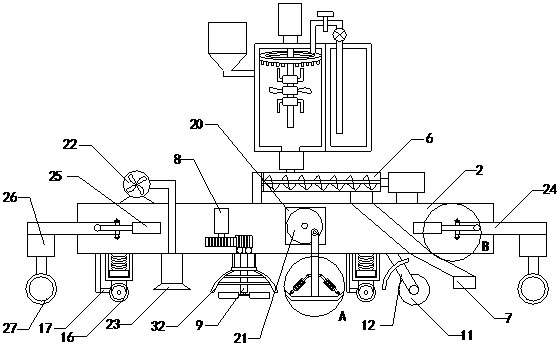

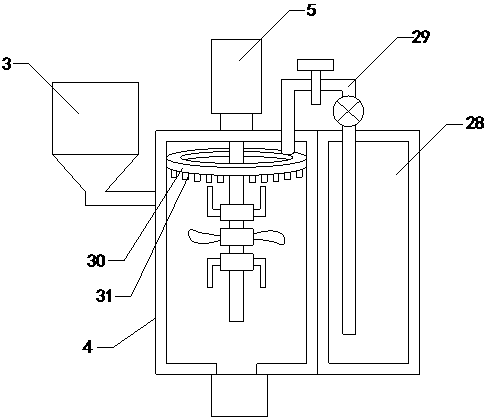

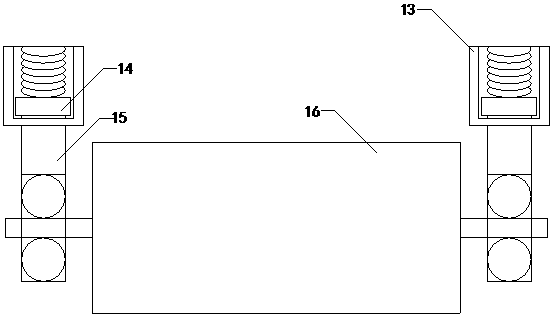

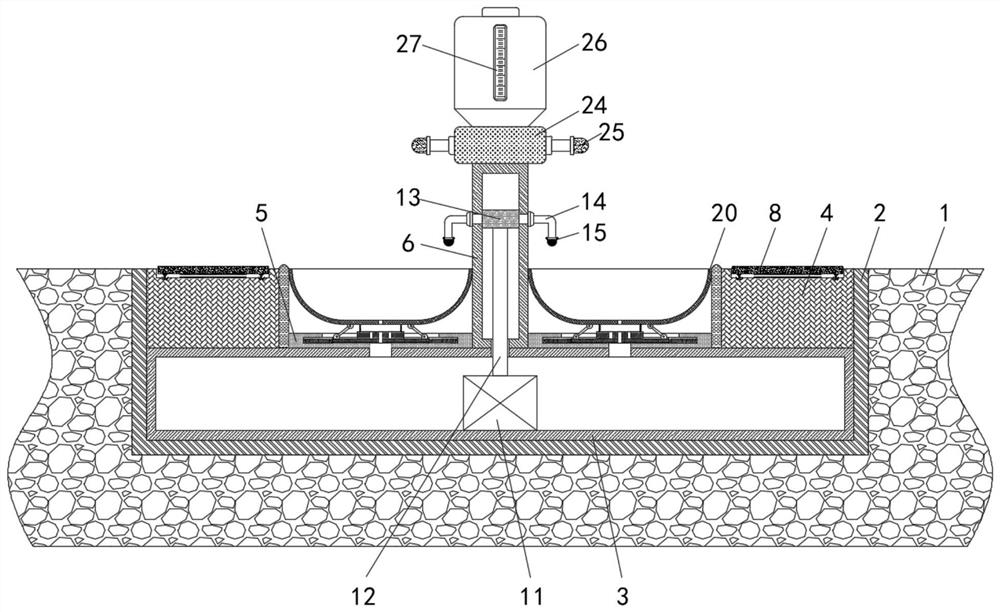

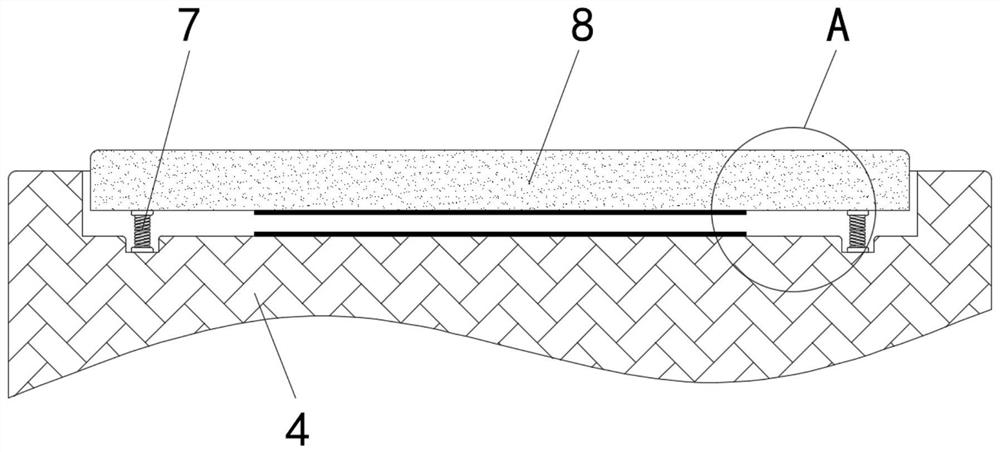

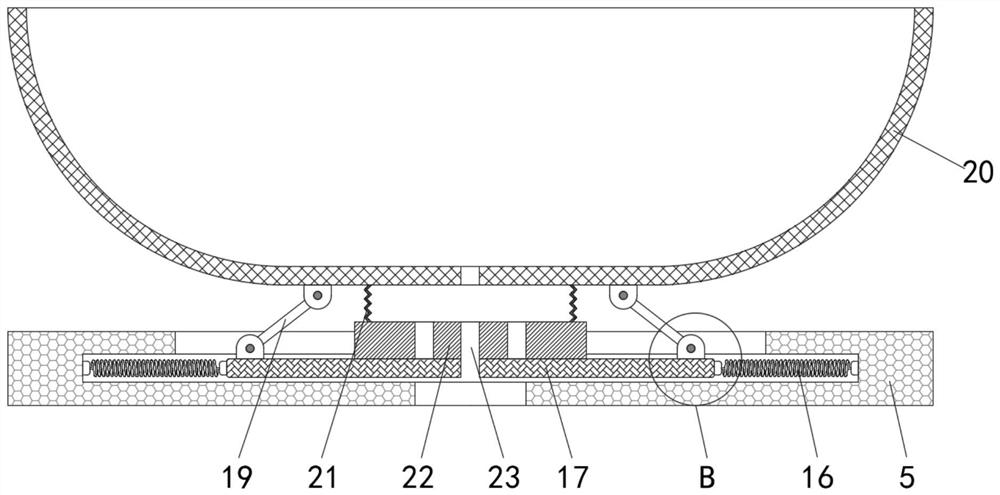

Pavement leveling device for road construction

InactiveCN108301292AImprove construction efficiencyImprove practicalityRoads maintainenceGear wheelDrive shaft

The invention relates to the technical field of auxiliary devices for road construction and building, in particular to a pavement leveling device for road construction. The pavement leveling device iscapable of independently mixing cement so as to improve the construction efficiency and practicability. The leveling area is large, so that the labor intensity, leveling time and use limitation are reduced. The pavement leveling device comprises leveling pieces, a bottom plate, a material charging hopper, a mixing tank, a mixing motor, a screw conveyor and a material discharging cover, wherein amixing shaft is arranged at the bottom output end of the mixing motor; the mixing shaft is provided with mixing blades; a material discharging opening is arranged at the bottom end of the mixing tank;and the output end of the screw conveyor communicates with a material feeding opening. The pavement leveling device also comprises a gear motor, a transmission shaft and a leveling piece support frame, wherein the gear motor is mounted on the front outer wall of the bottom plate; a driving gear is arranged at the bottom output end of the gear motor; a driven gear is arranged at the top end of thetransmission shaft; the driving gear is meshed with the driven gear; and the leveling pieces are mounted on the leveling piece support frame.

Owner:山西云度知识产权服务有限公司

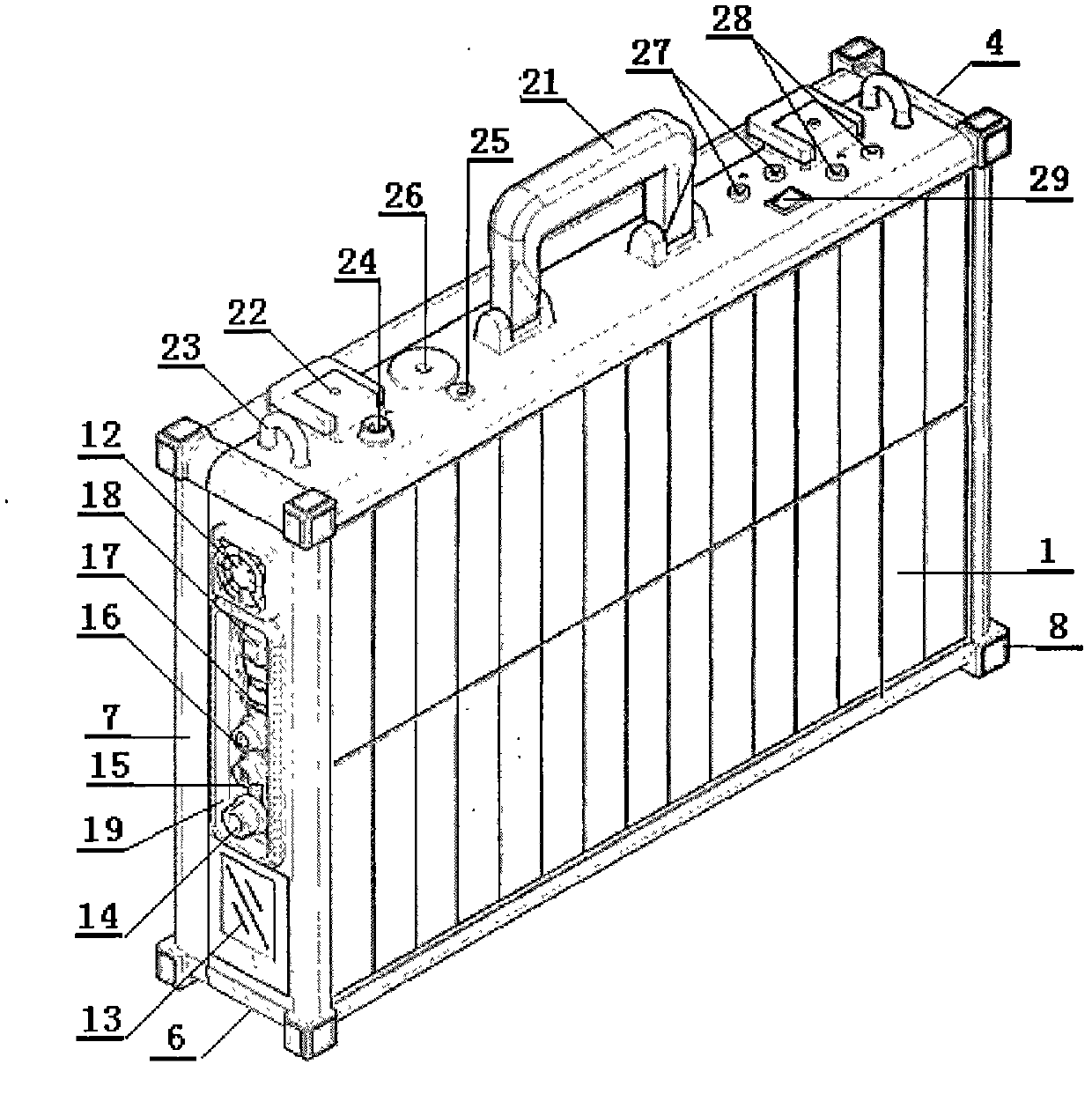

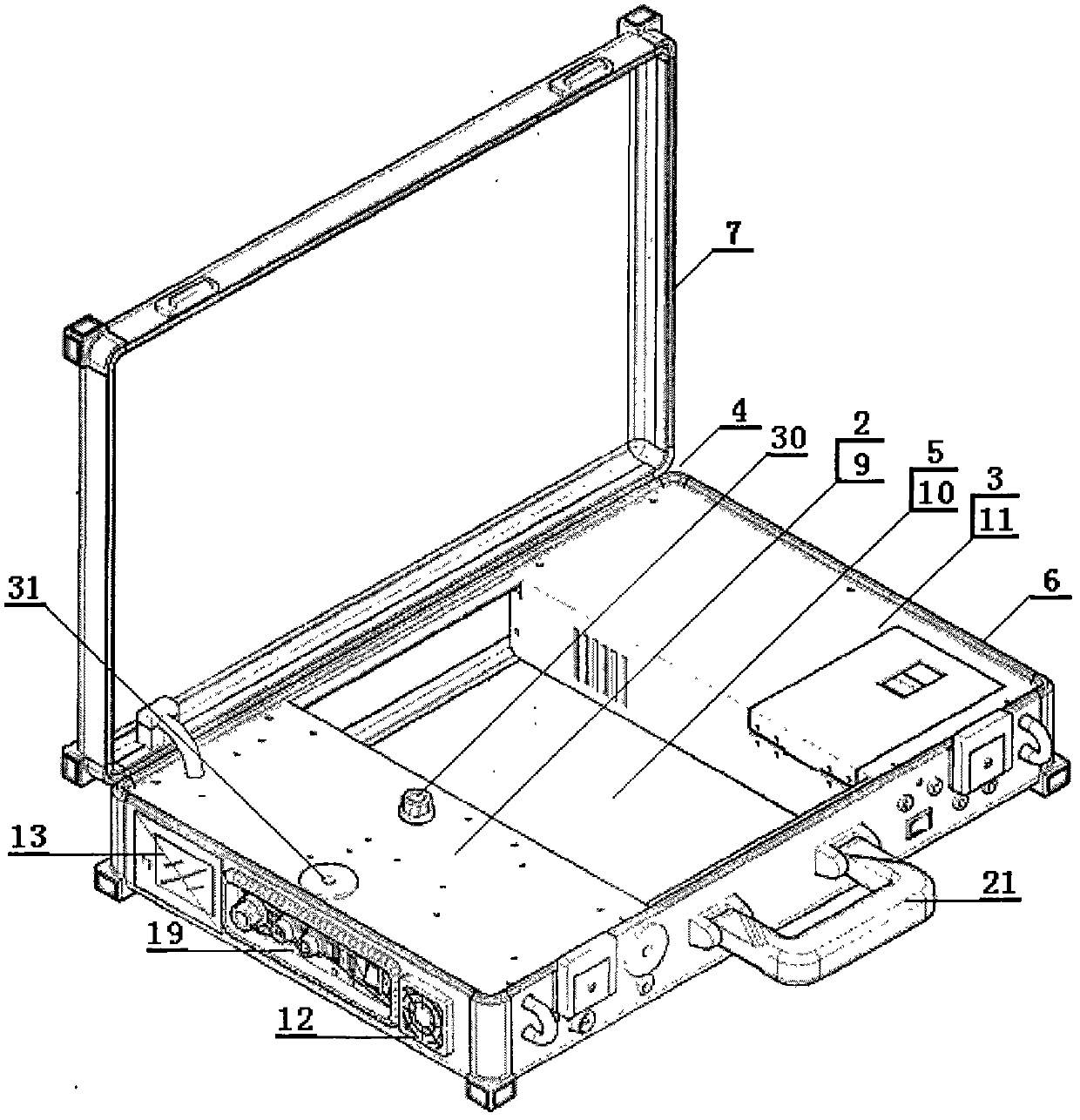

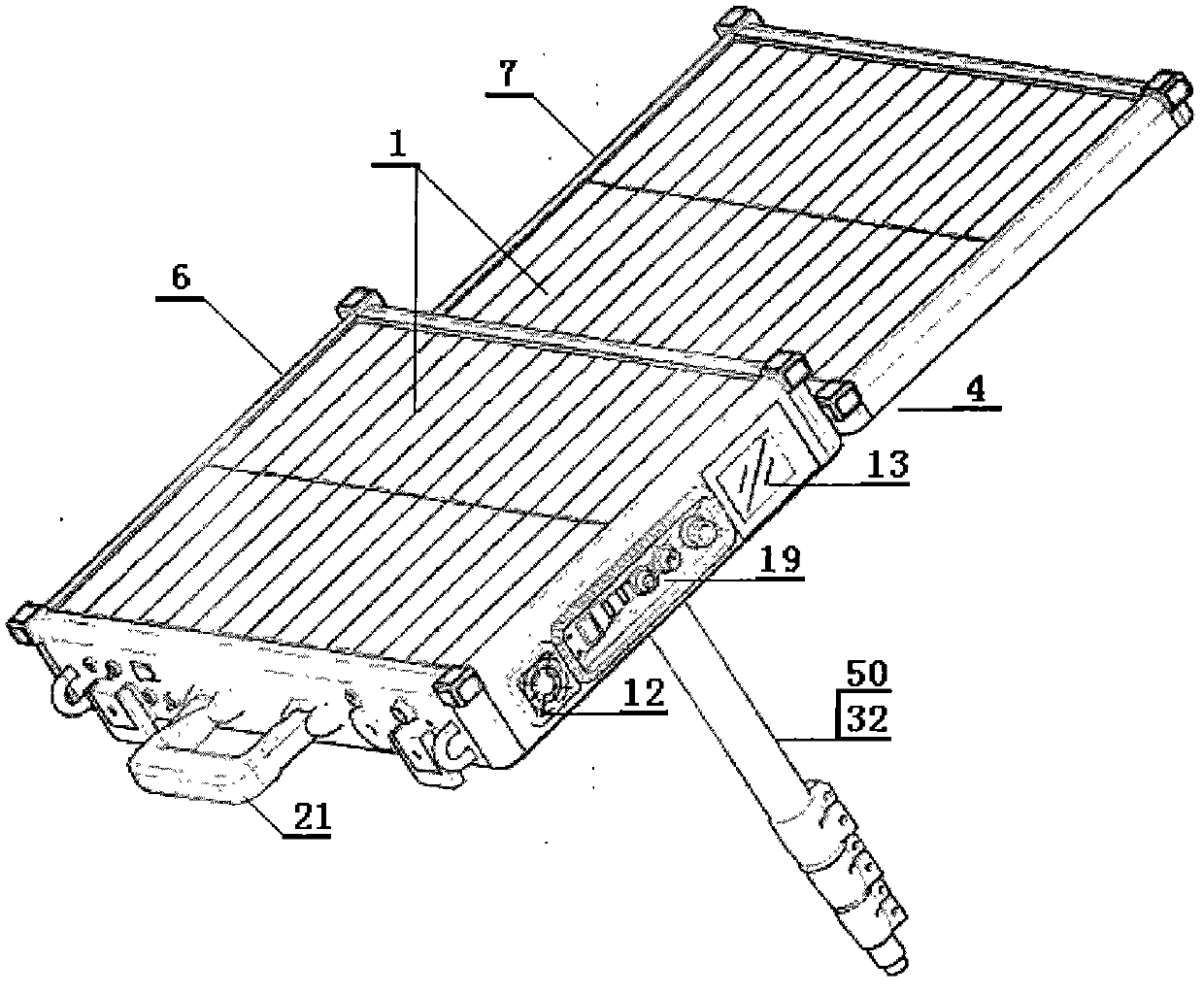

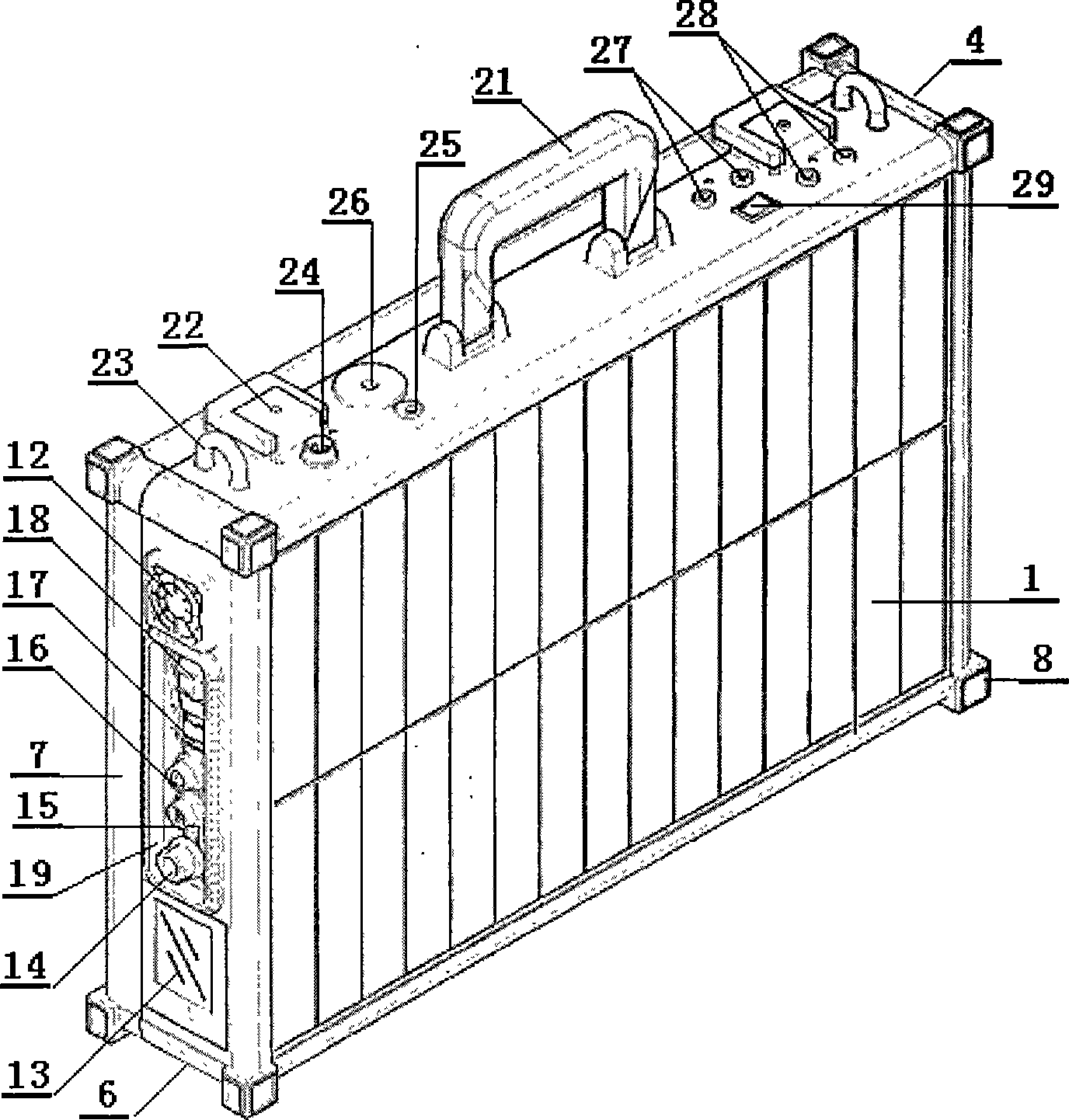

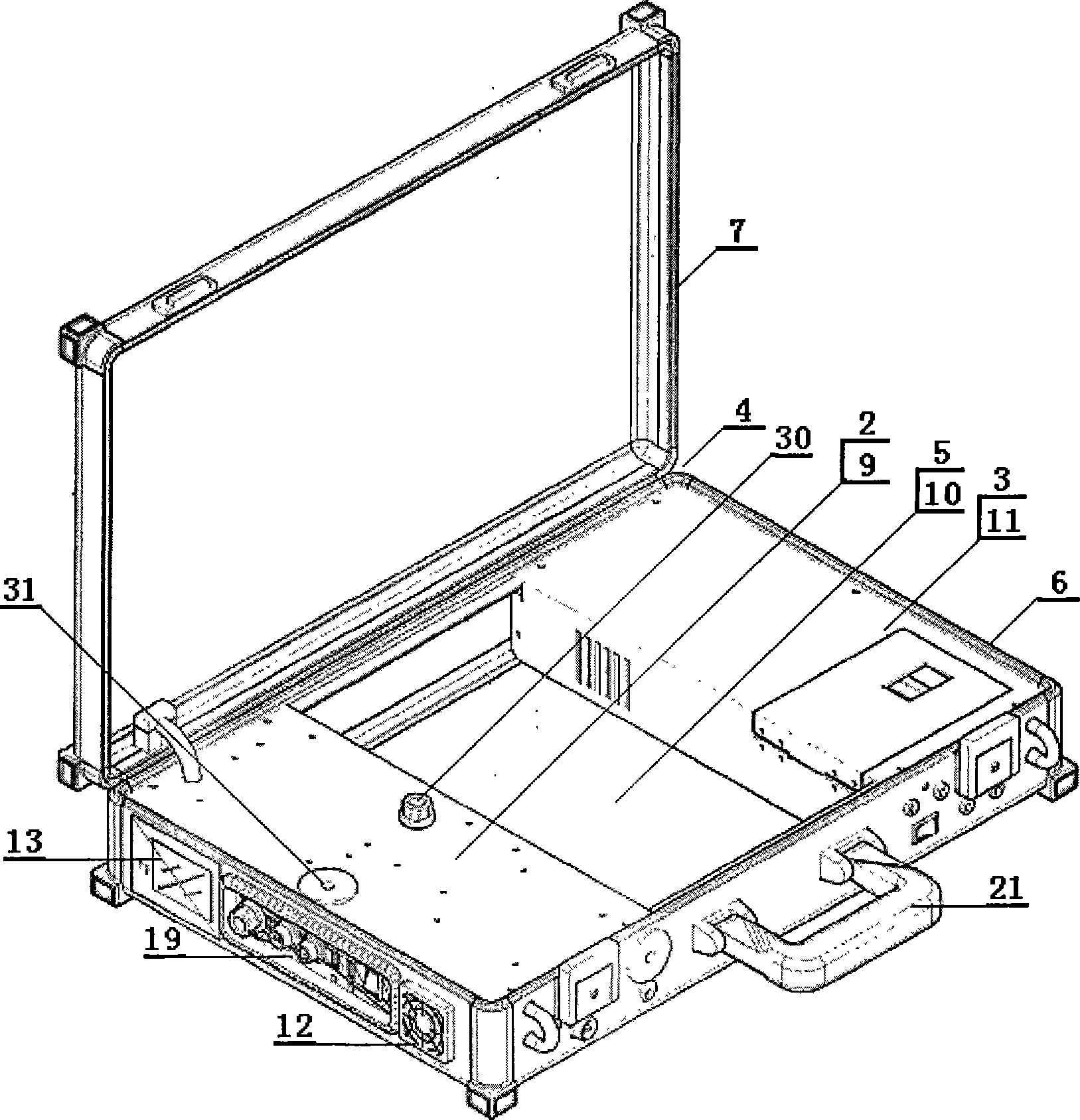

Utility-type solar energy power supply apparatus

InactiveCN102170250AImprove securityEnsure normal power supply requirementsBatteries circuit arrangementsPV power plantsCharge dischargeEngineering

The invention relates to a solar energy power supply apparatus formed by a portable case body, a solar energy photovoltaic cell panel arranged on the front and back surface of the case body, an automatic charge-discharge control circuit including a direct current- direct current (DC-DC) voltage transforming circuit and a direct current-alternating current (DC-AC) transforming circuit, a liquid crystal display (LCD) arranged on the surrounding frame of the case body, a voltage output interface for notebook computer, a USB output interface used for power supply or charging for digital electronic products, an AC 220V output socket, a DC emergency charging input interface, an automobile storage battery charging output interface, and a convenient setting combination hub specially used for lamp-post of high-efficient energy-saving light formed by a collapsible supporting rod which serves the purpose of a lamp-post and a LED lamp holder. The invention has advantages of high power supply capability, wide applicability, strong practicality, safety and reliability and can satisfy the normal power supply of basic electricity utilization in communication, business and daily life in no AC 220V power-supply environment, and the invention is especially suitable for high illumination needed for earthquake relief work in remote mountain area, travelling and dark environment.

Owner:驿网无际(上海)信息科技有限公司

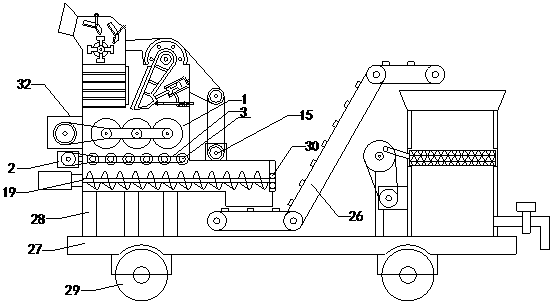

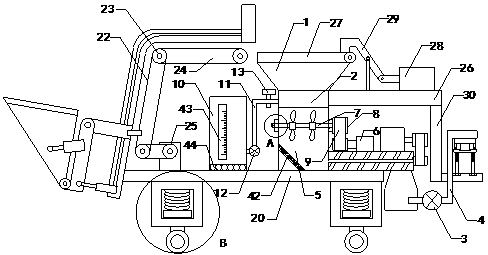

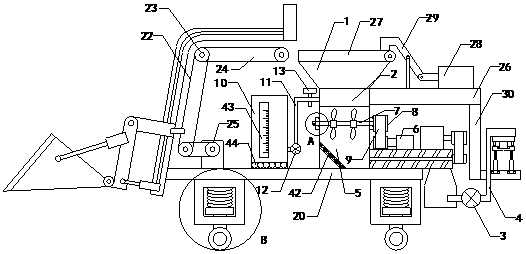

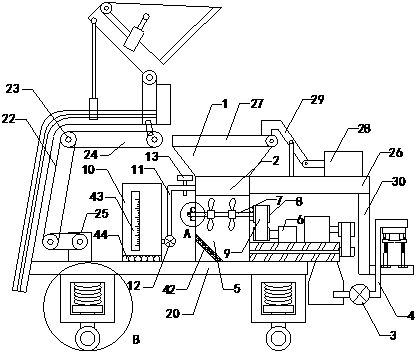

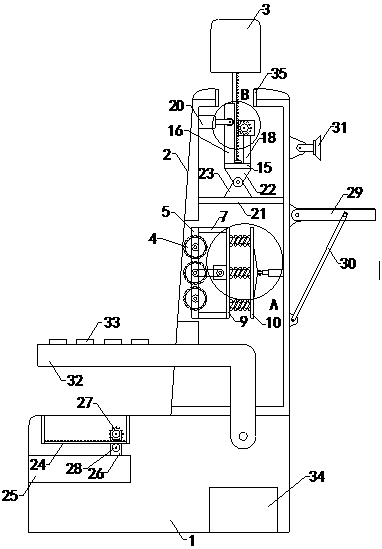

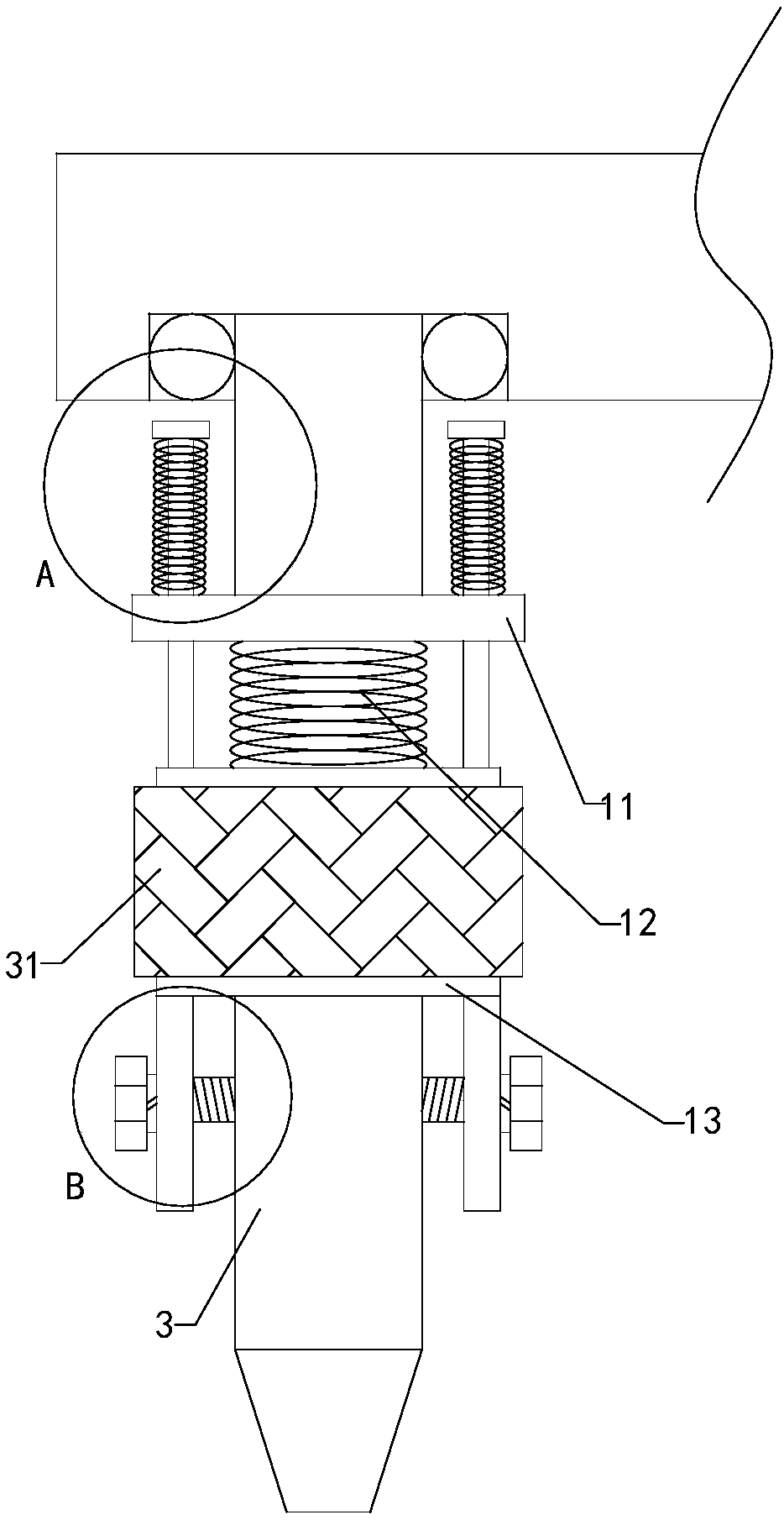

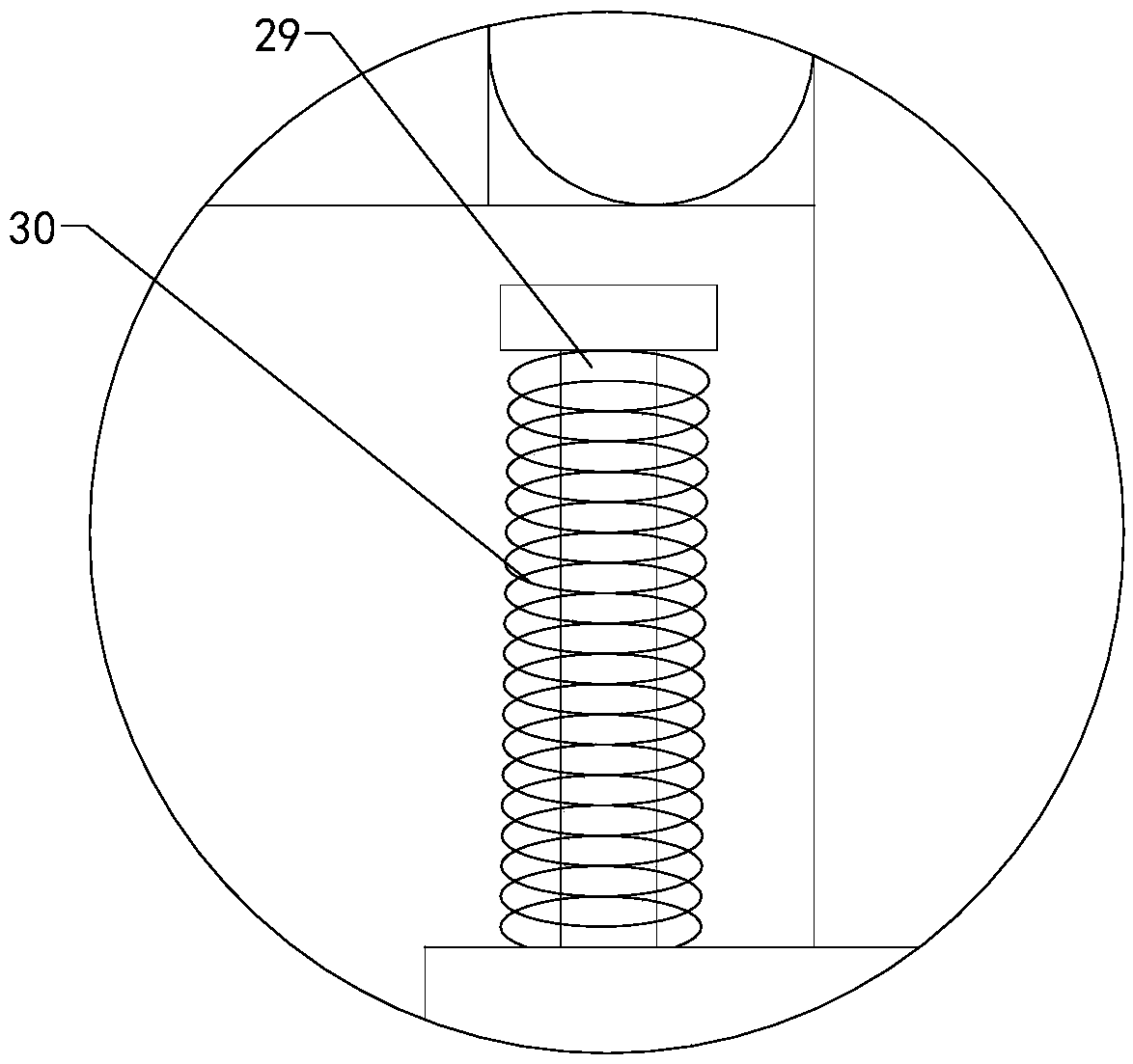

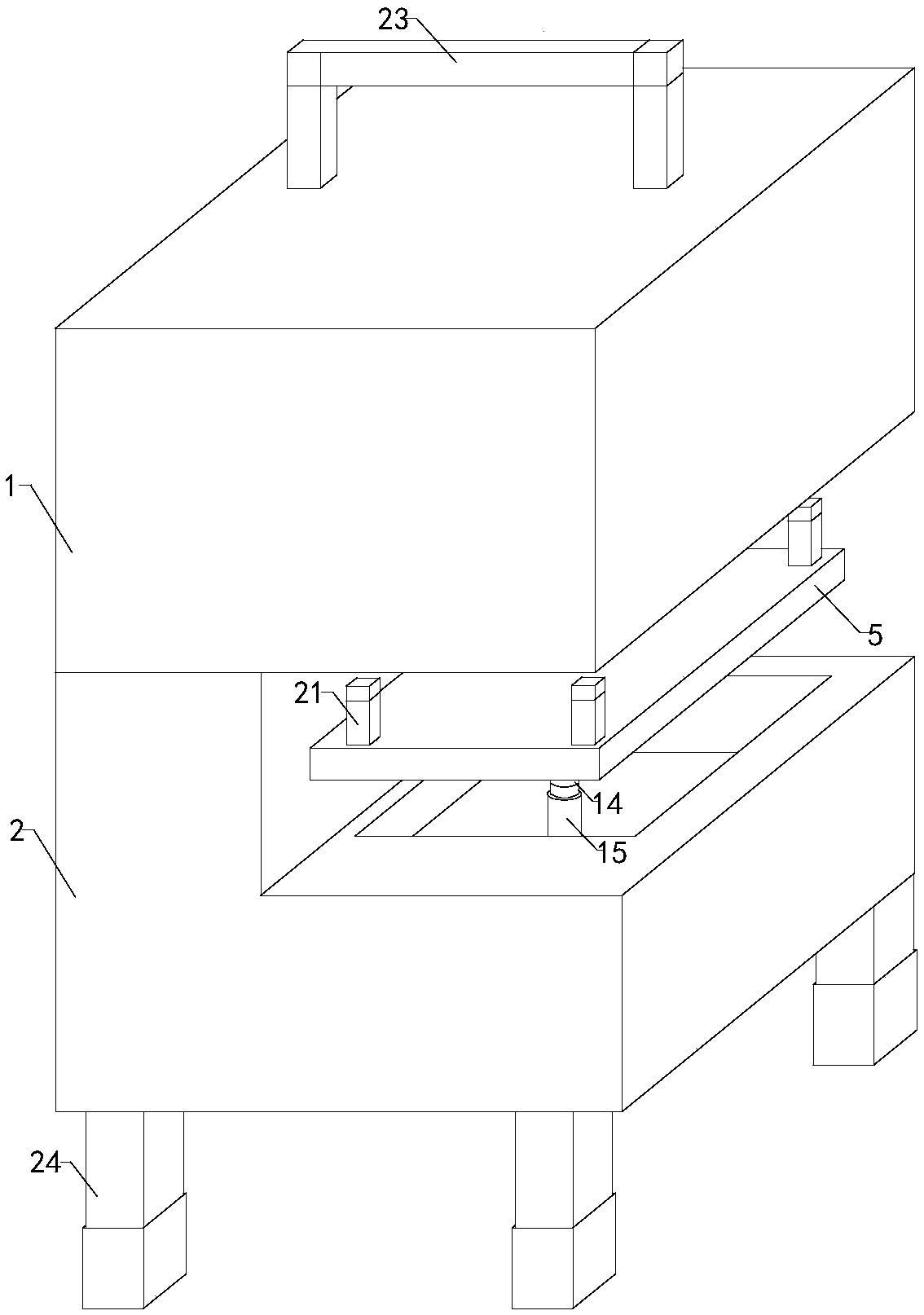

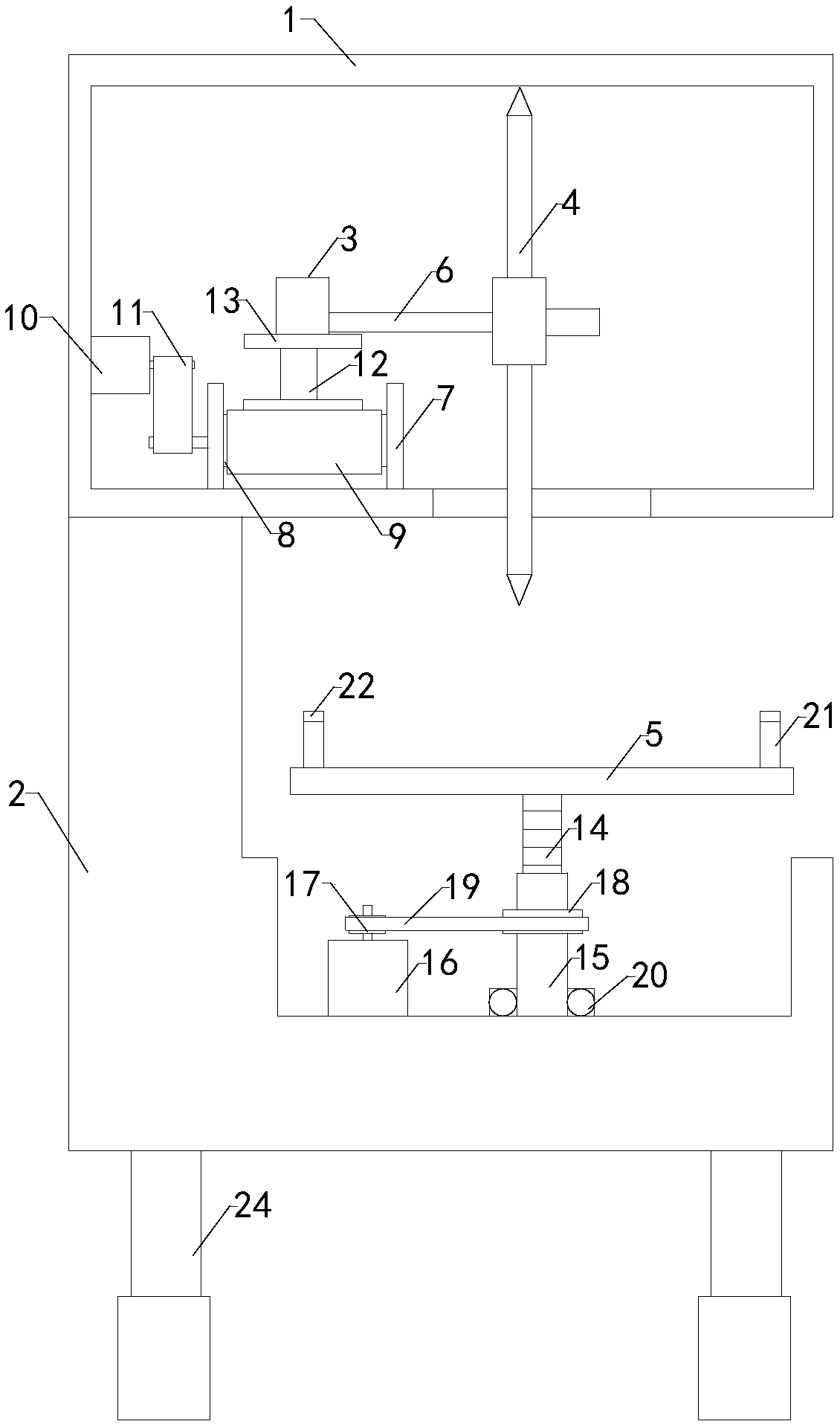

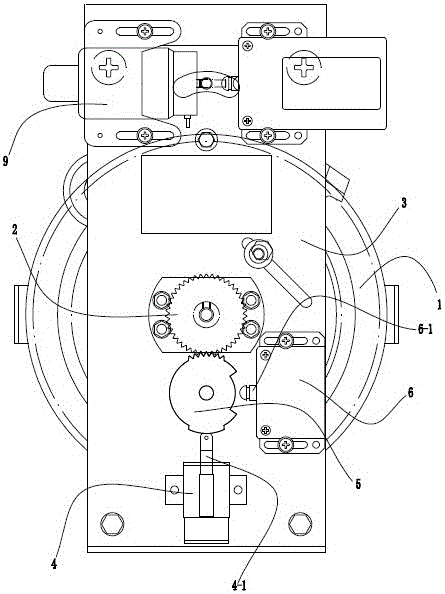

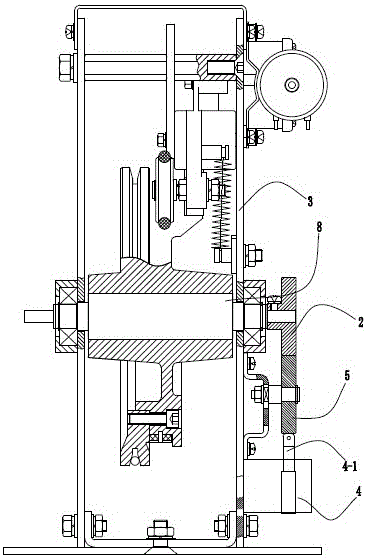

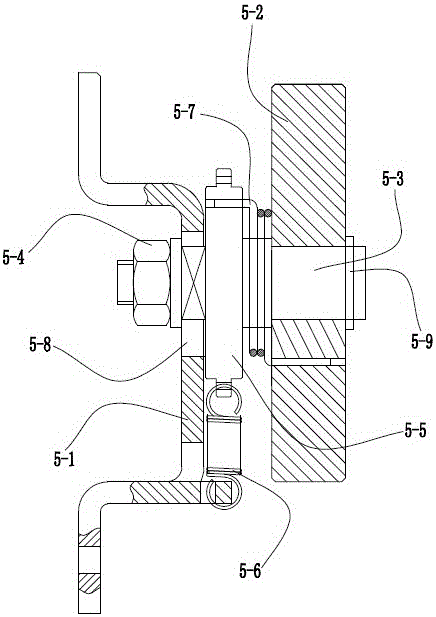

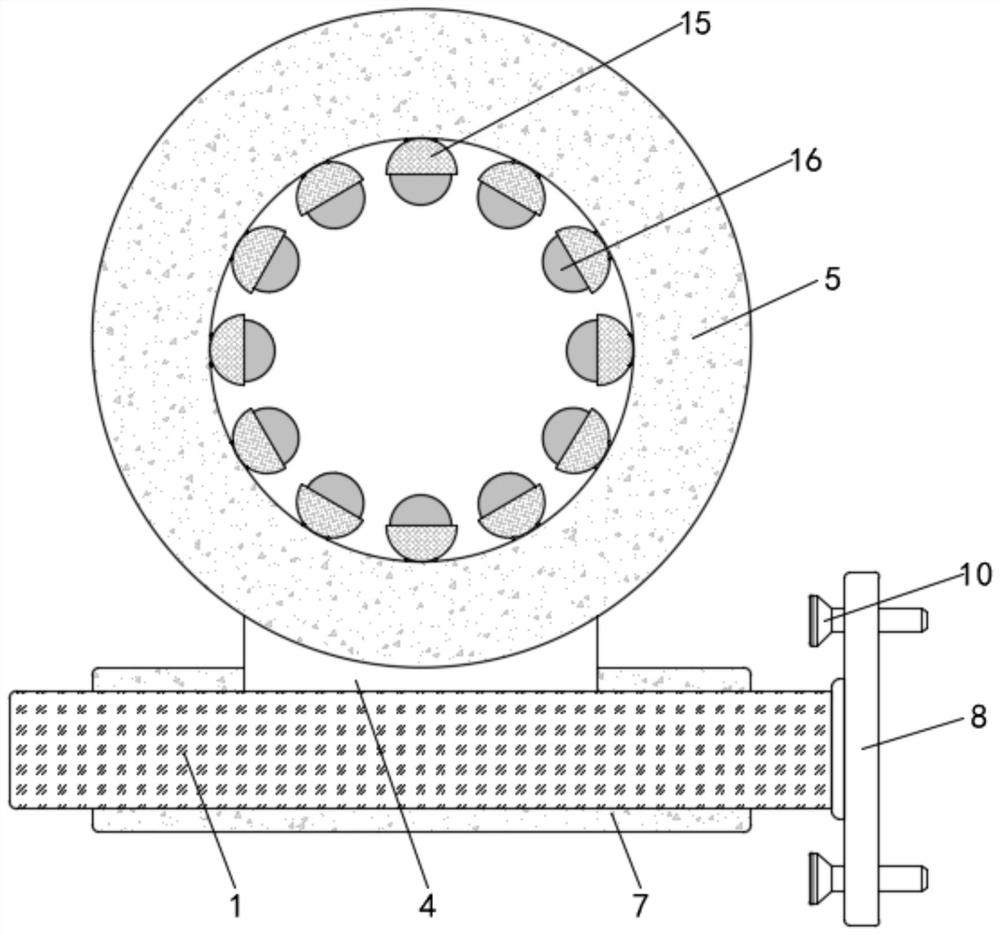

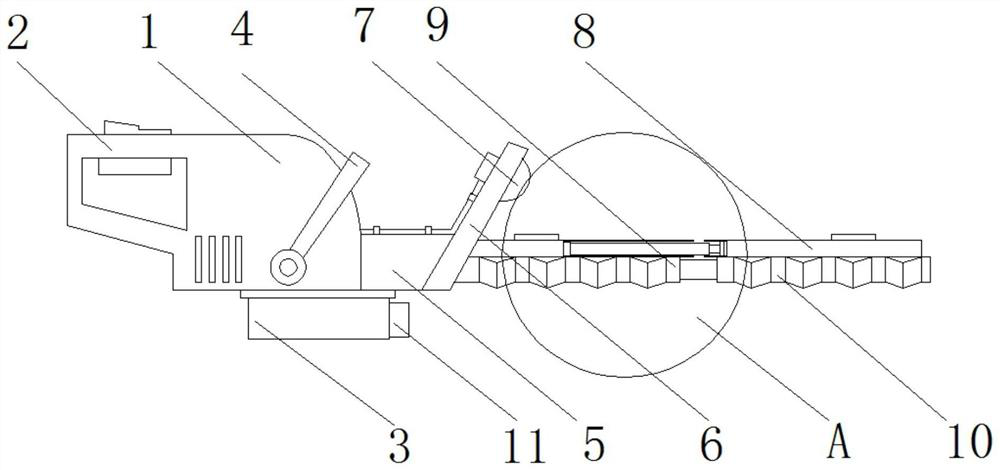

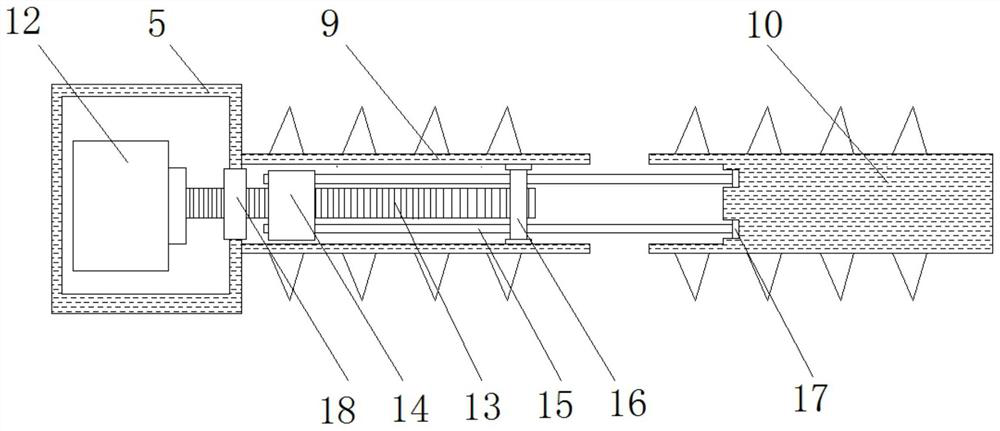

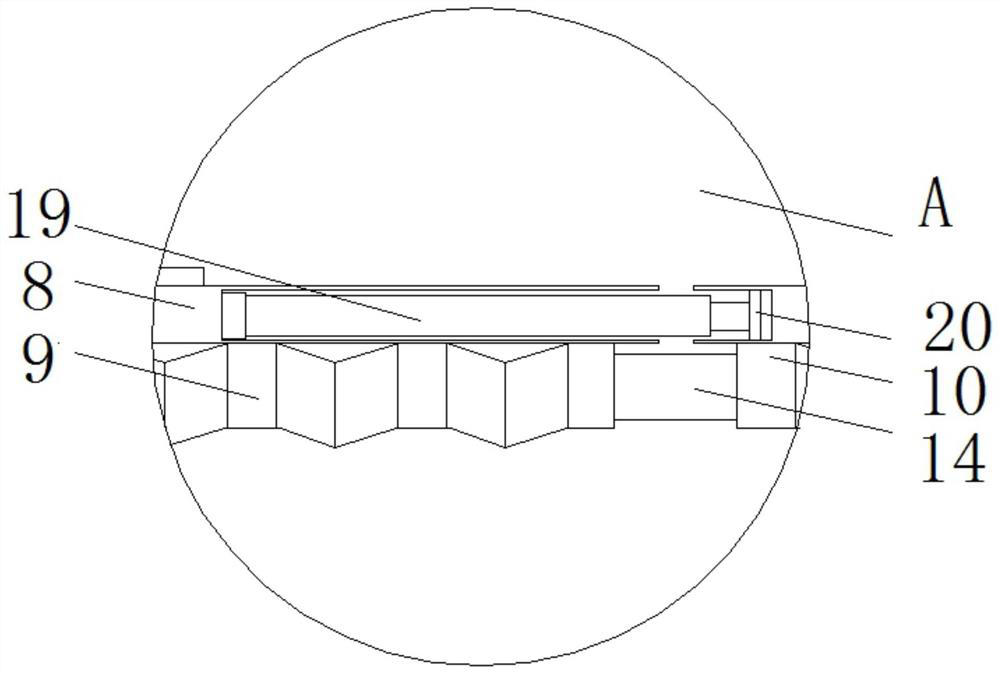

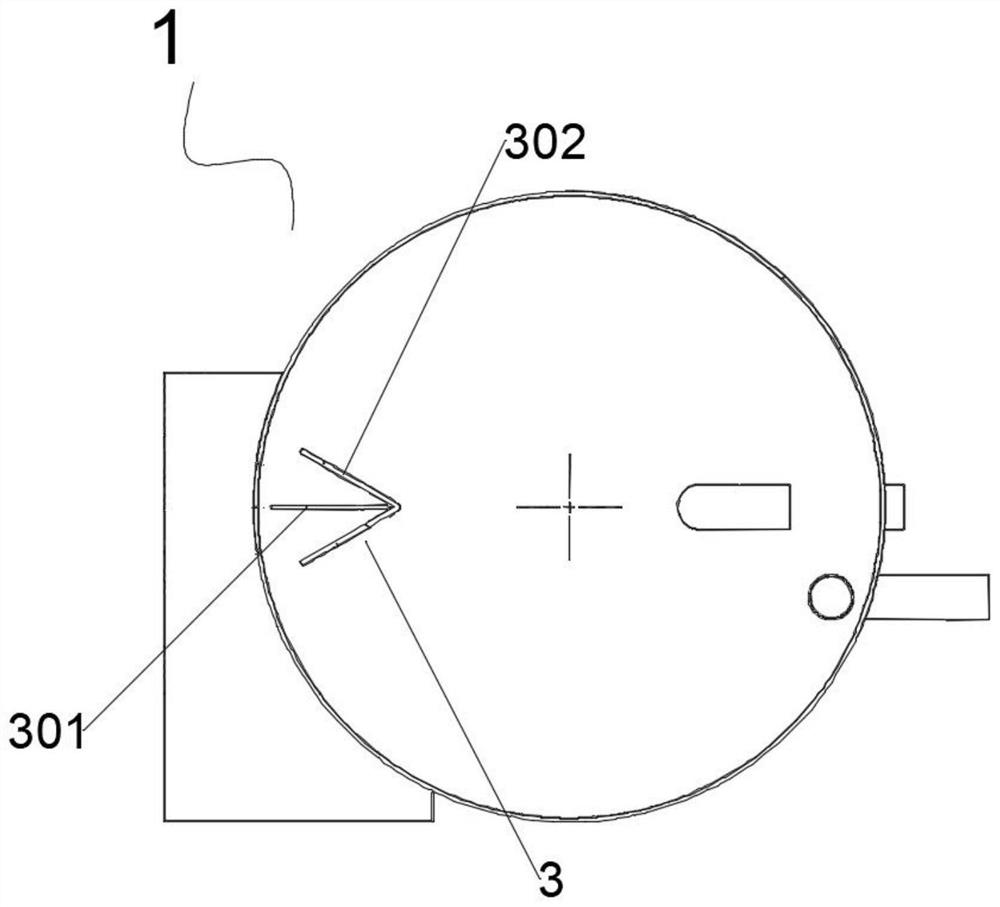

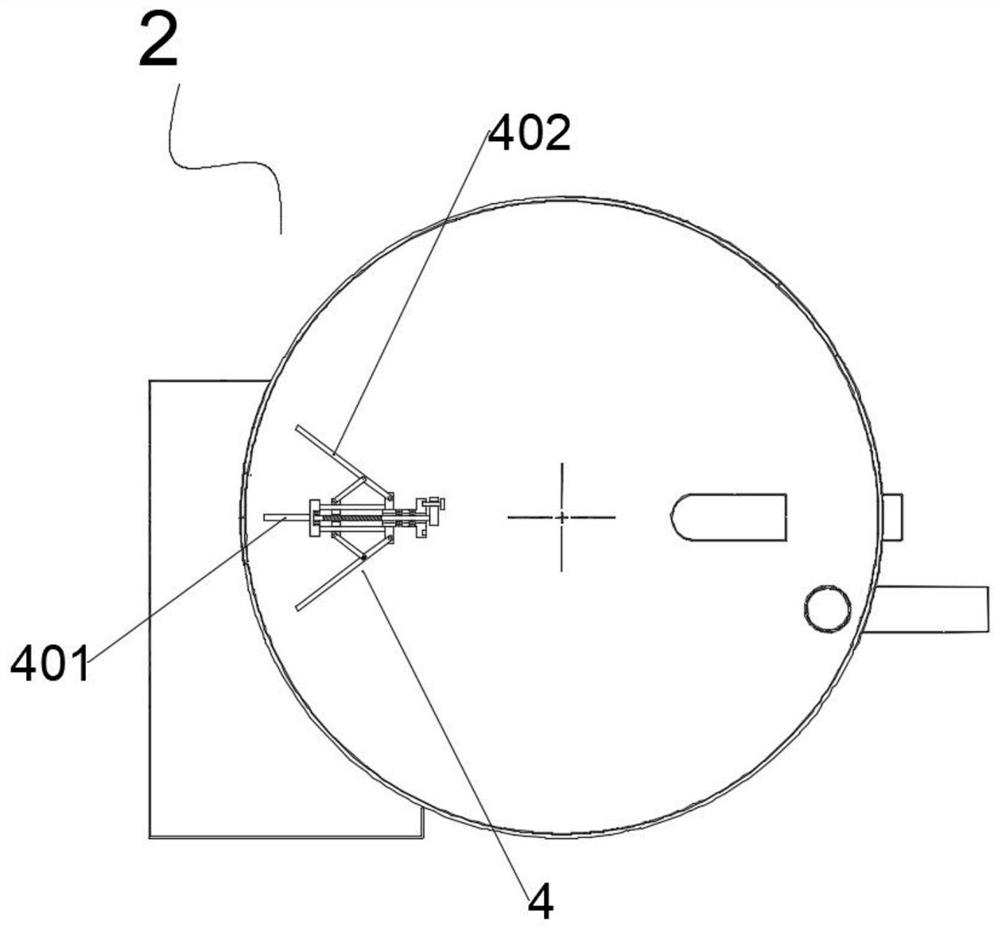

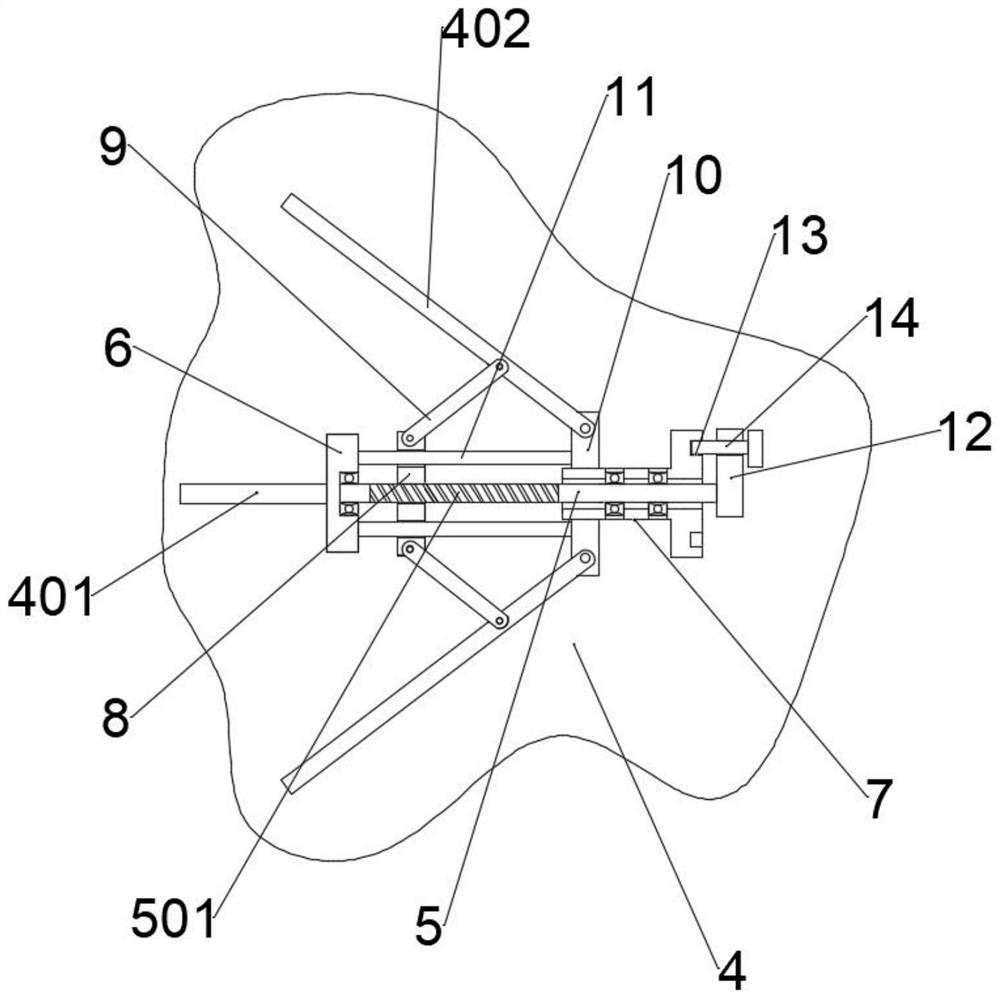

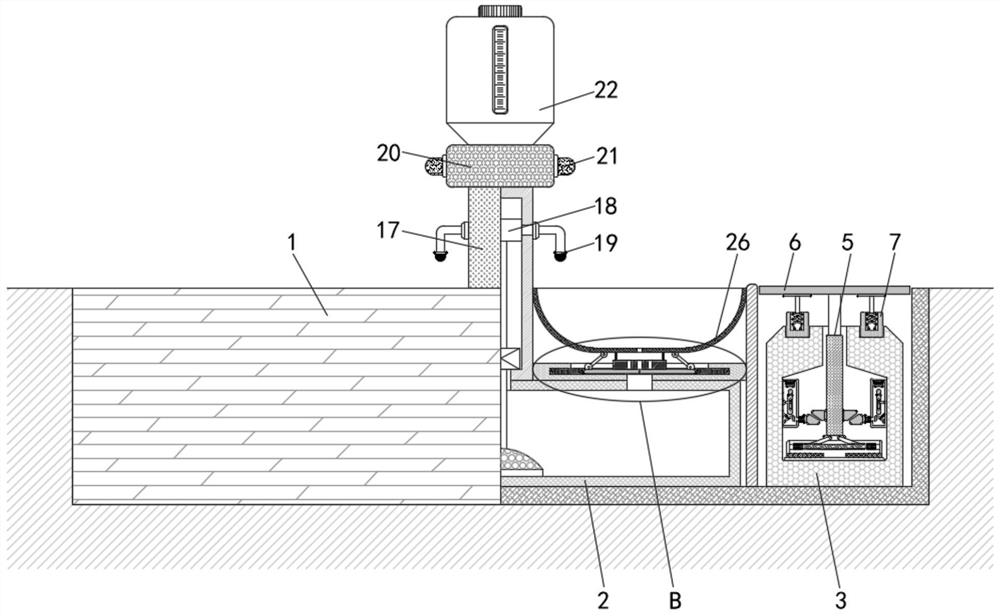

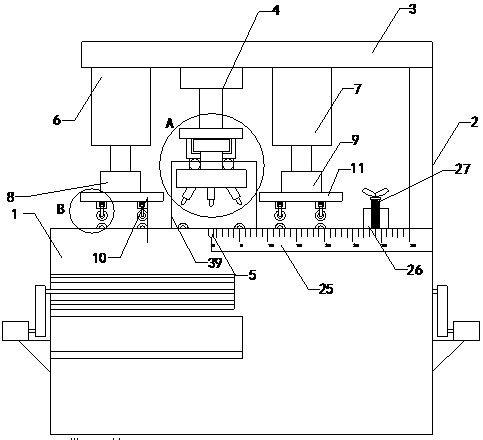

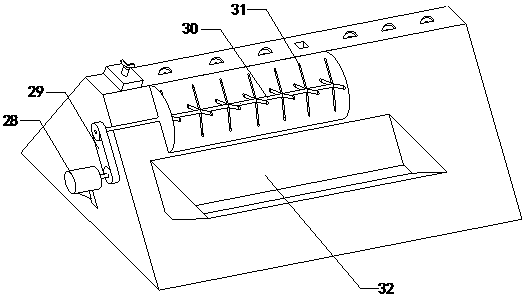

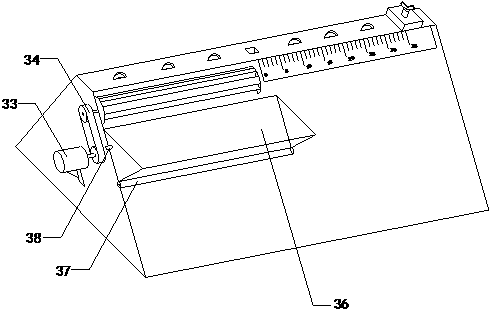

Cutting-stirring friction-welding combined machining equipment and manufacturing method thereof

ActiveCN102501074AEfficient coolingAvoid glitchesOther manufacturing equipments/toolsMaintainance and safety accessoriesTemperature sensingSensing system

The invention discloses cutting-stirring friction-welding combined machining equipment and a manufacturing method thereof. The cutting-stirring friction-welding combined machining equipment integrates a milling system or a cutting system, a stirring friction-welding system, a forced cooling system, a gas protection system, a temperature sensing system, a pressure sensing system, a milling liquid supply system and a non-sensing system. The invention provides a united or combined machining device which can carry out milling or cutting and stirring friction-welding in parallel simultaneously and a method thereof. The cutting-stirring friction-welding combined machining equipment has the functions of temperature control, gas protection, pressure detection, cooling liquid production, milling head replacement and dual-shaft shoulder self-supporting. According to the manufacturing method of the cutting-stirring friction-welding combined machining equipment, the manufacturing processes are reduced and the machining cost is saved. The limitation of the conventional mechanical machining technology is broken through, and a new method and a new idea about the mechanical manufacturing and machining are formed. The cutting-stirring friction-welding combined machining equipment and the manufacturing method in the invention have wide engineering applications to the heating industry, the air conditioning industry, the ice making industry, the freshness retaining industry, the pharmacy industry, the construction industry, the aquatic product industry and the food industry.

Owner:罗键

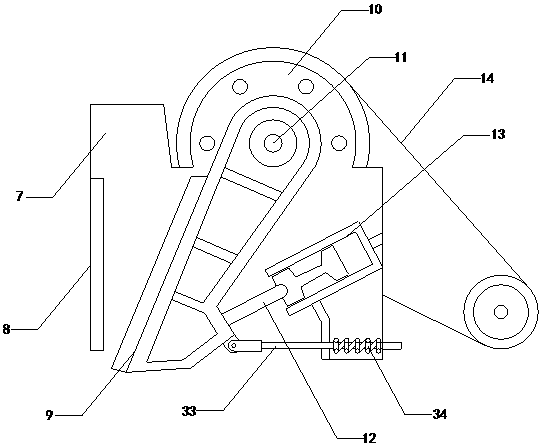

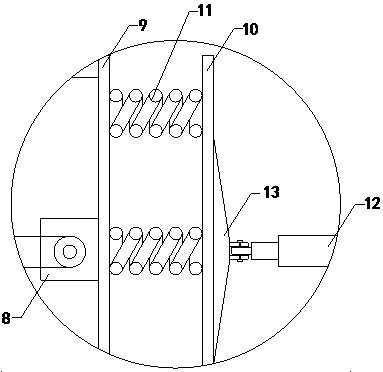

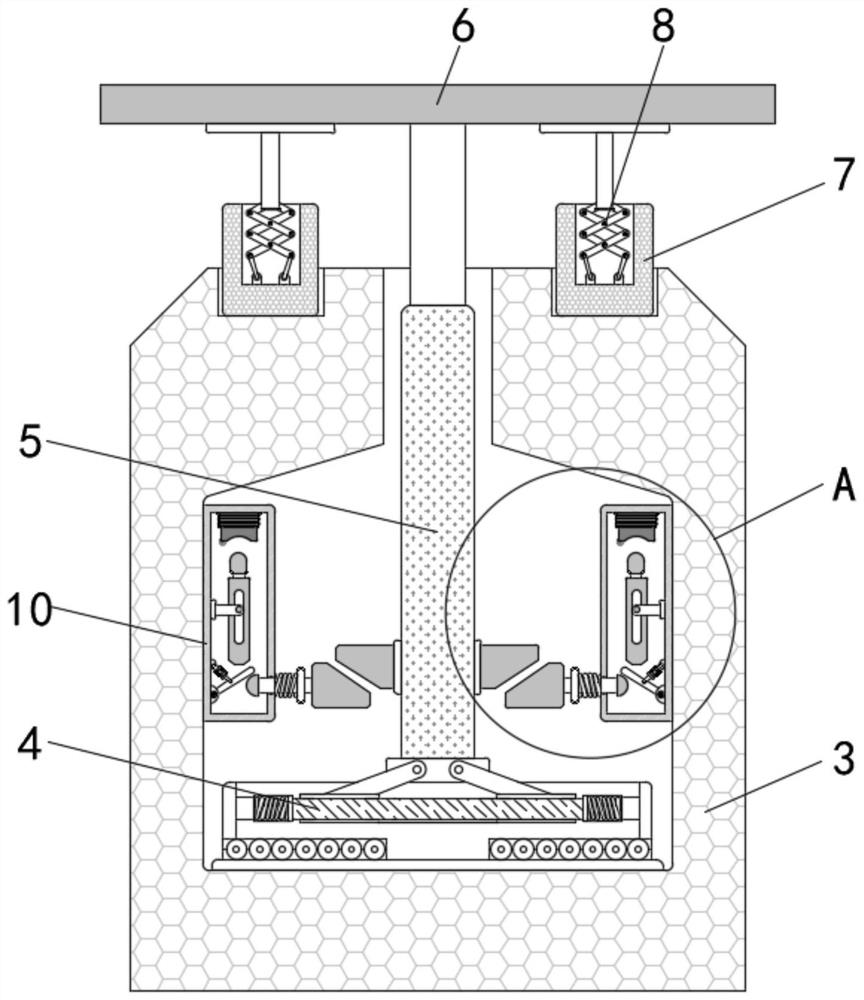

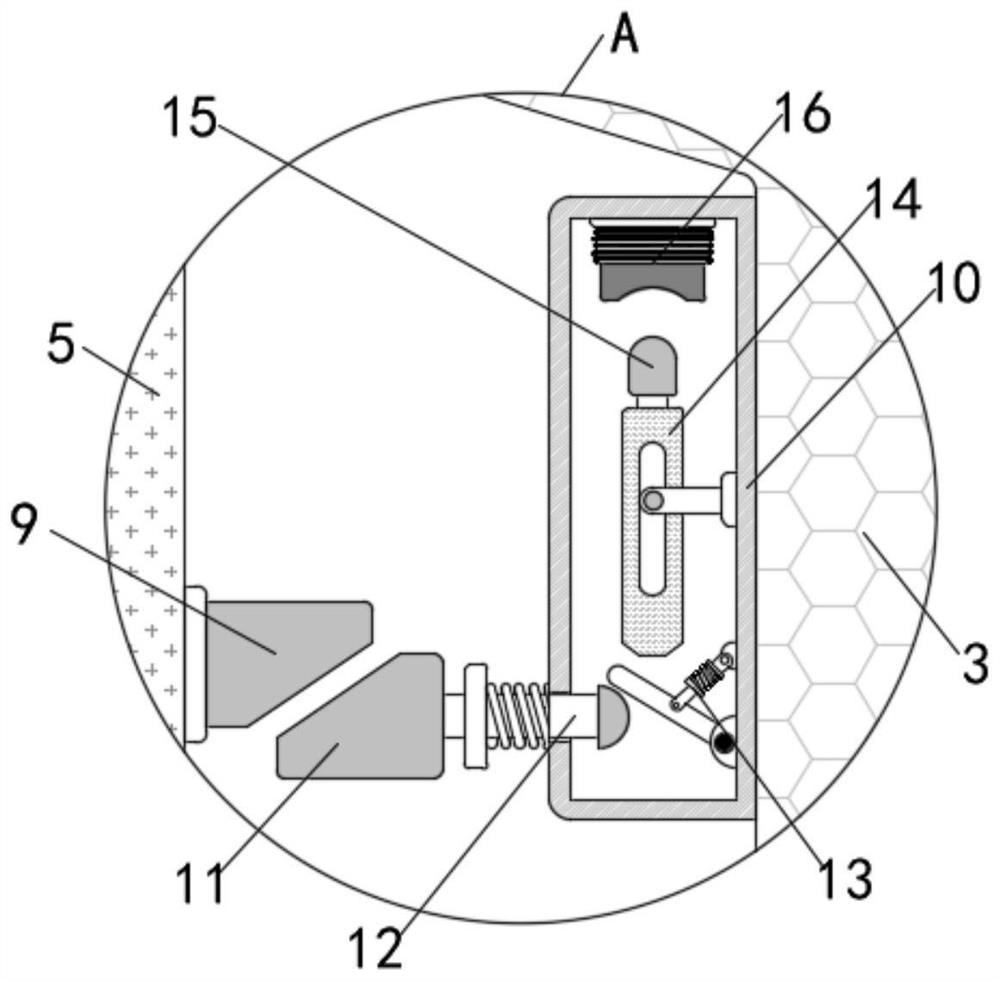

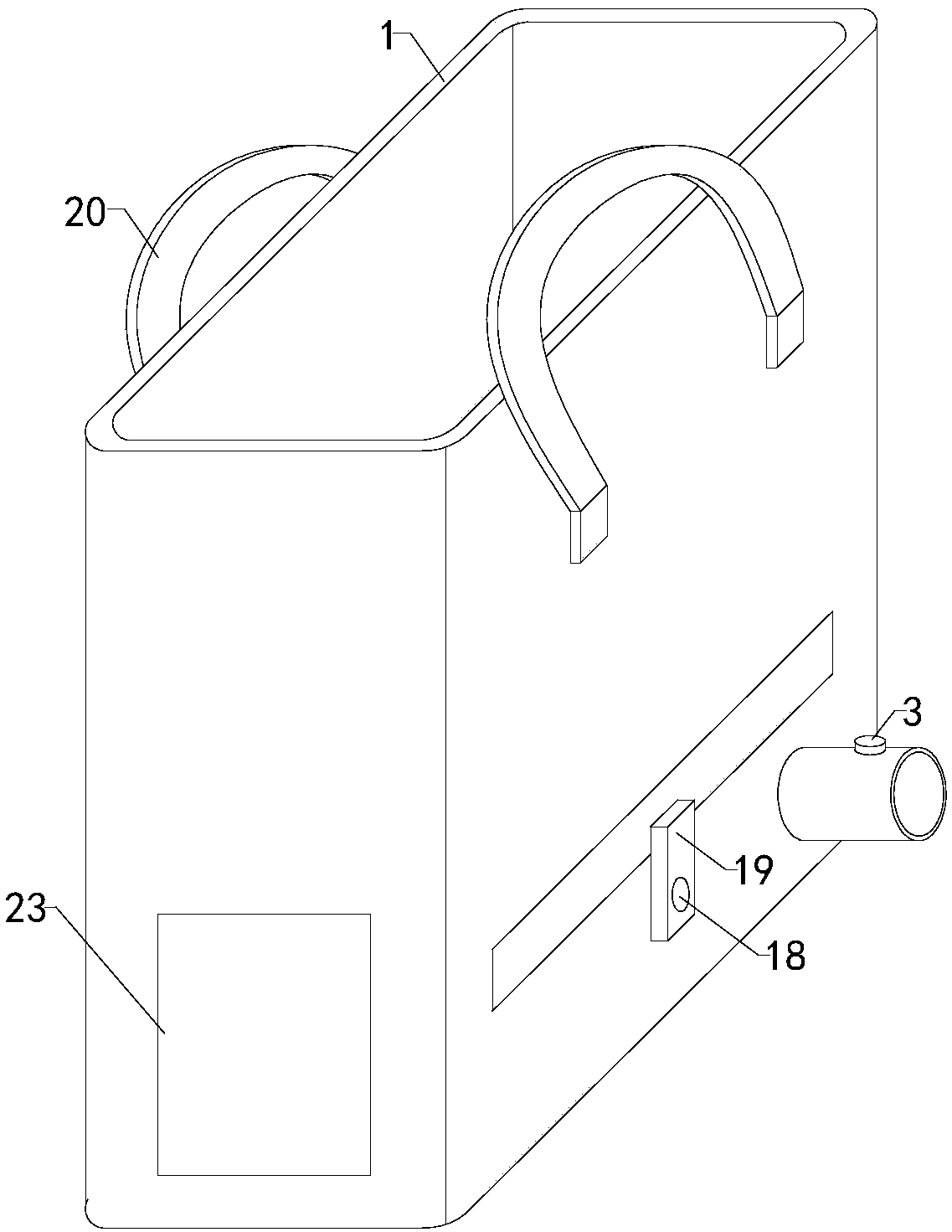

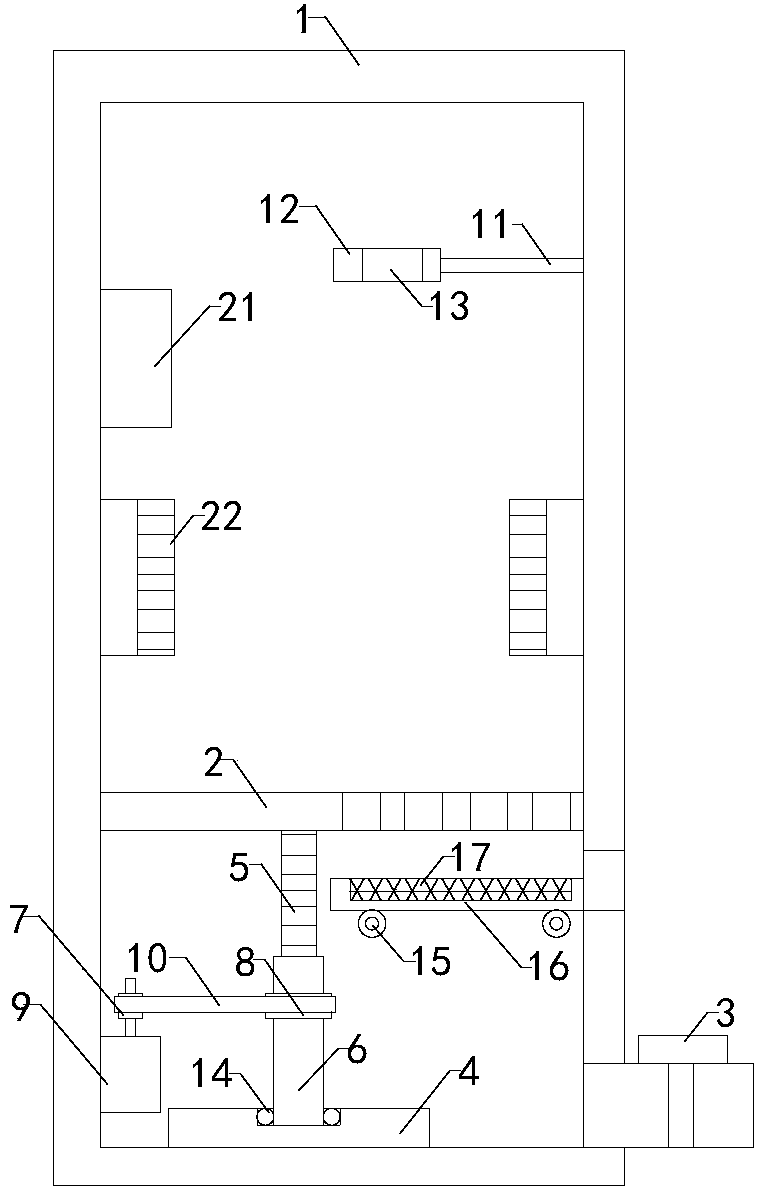

Concrete crusher for building

ActiveCN108311264AImprove the use of limitationsImprove practicalityPackagingGrain treatmentsEngineeringCrusher

The invention relates to the technical field of building accessory devices, in particular to a concrete crusher for building. According to the concrete crusher for building, the large volume of concrete can be smashed, and using limitation is improved; and the smashed concrete can be guided out timely, the subsequent workload is reduced, and practicality is improved. The concrete crusher comprisesa box body, a smashing compression roller motor and a first belt, and further comprises a first-stage crushing box, a pendulum bob, a counterattack plate, a second-stage crushing box, a static jaw plate, a movable jaw plate, a belt wheel, an eccentric shaft, a thrust plate, an adjusting block, a second belt and a crushing motor, wherein the first-stage crushing box, the second-stage crushing boxand box body communicate with one another; the concrete crusher further comprises a shredding motor, a shredding belt and a shredding roller, and the shredding motor is in rolling connection with theshredding roller through the shredding belt; and the concrete crusher further comprises a screw conveyor, the top end of the screw conveyor is provided with a conveying port which communicates with adischarging outlet of the box body, and the bottom end of the right side of the screw conveyor is further provided with a feeding inlet which communicates with the outside.

Owner:新疆智友建设工程有限公司

Building concrete conveyor

InactiveCN108274622AShorten delivery cycleImprove delivery efficiencyDischarging apparatusCement mixing apparatusHydraulic cylinderRocker arm

The invention relates to the technical field of house construction pouring accessory devices, in particular to a building concrete conveyor. According to the conveyor, automatic material mixing can beachieved, the conveying period can be shortened, conveying power is improved, automatic material putting is achieved, manpower is little, and use limitation is improved; the conveyor comprises a hopper, a material box, a conveying pump and a conveying pipe; a stirring box, a stirring motor, a stirring shaft, a driven belt shaft, a belt, a water tank and a water feeding pipe are included; the stirring box is located below the material box, the output end of the conveying pump is communicated with the input end of the conveying pipe, the water tank is located on the left side of the stirring box, the water feeding pipe is provided with a water feeding pump and a water feeding valve, a tipping bucket, a tipping bucket hydraulic cylinder, a receiving hydraulic cylinder, a first connecting rod, a rocker arm rod, a sliding support, a connecting plate and a chain transmission device are included, guide rails are arranged on outer walls of steel beams, on the front side and the rear side, ofthe sliding support, the right end of the first connecting rod and the right end of the receiving hydraulic cylinder are provided with sliding blocks, the sliding blocks are in sliding fit with the guide rails, and the chain transmission device is located below the sliding support.

Owner:山西云度知识产权服务有限公司

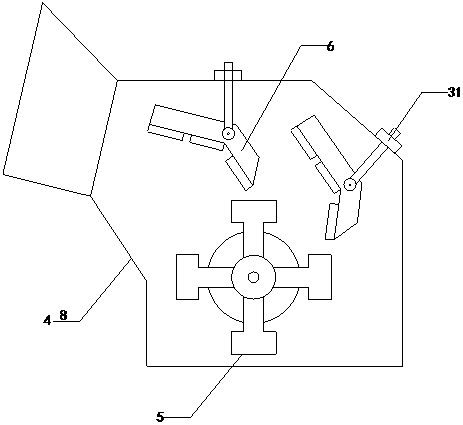

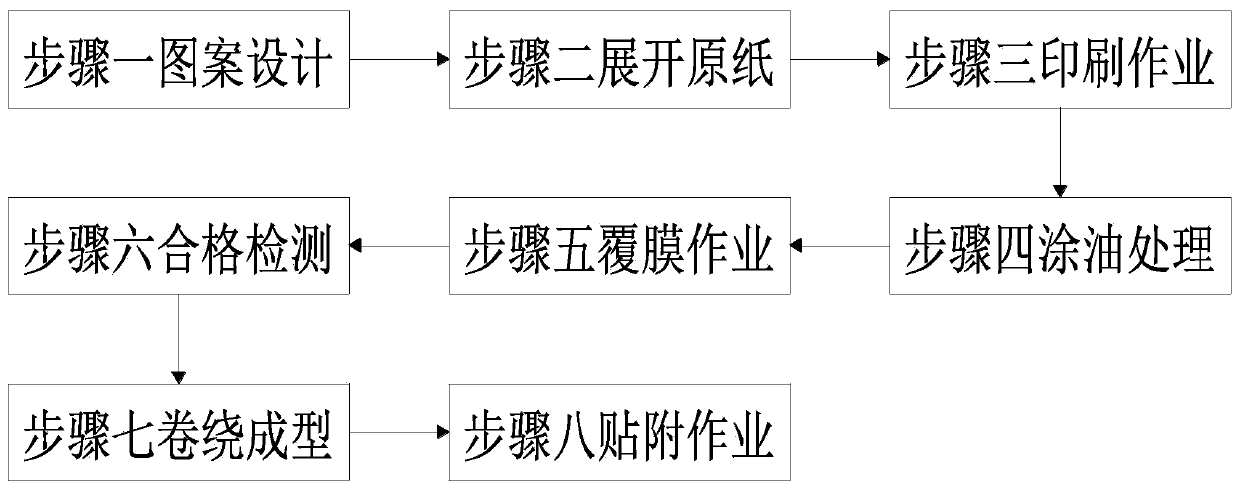

Method for manufacturing outer wall sticker of gift packaging paper can through adhesive sticker pasting

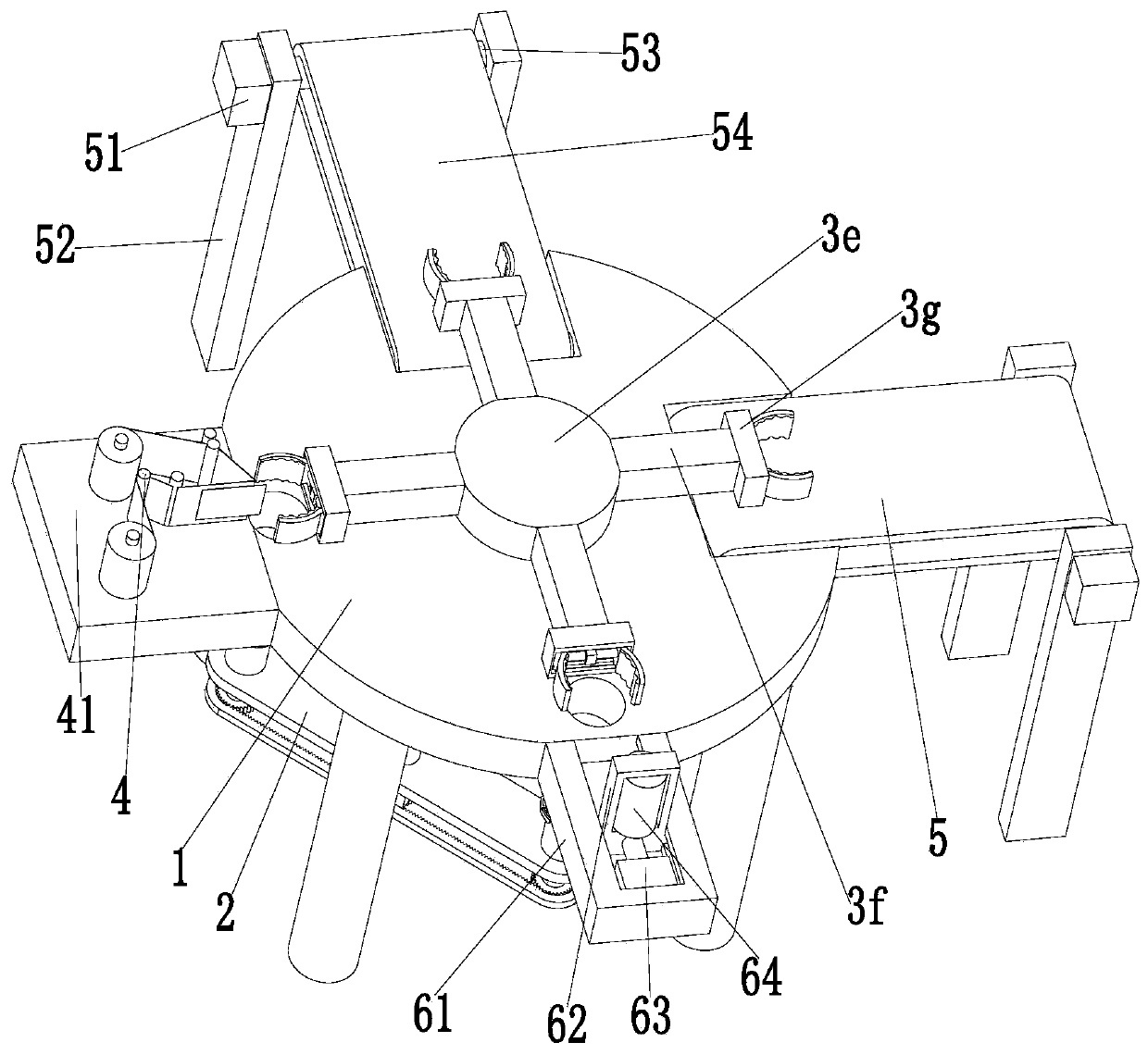

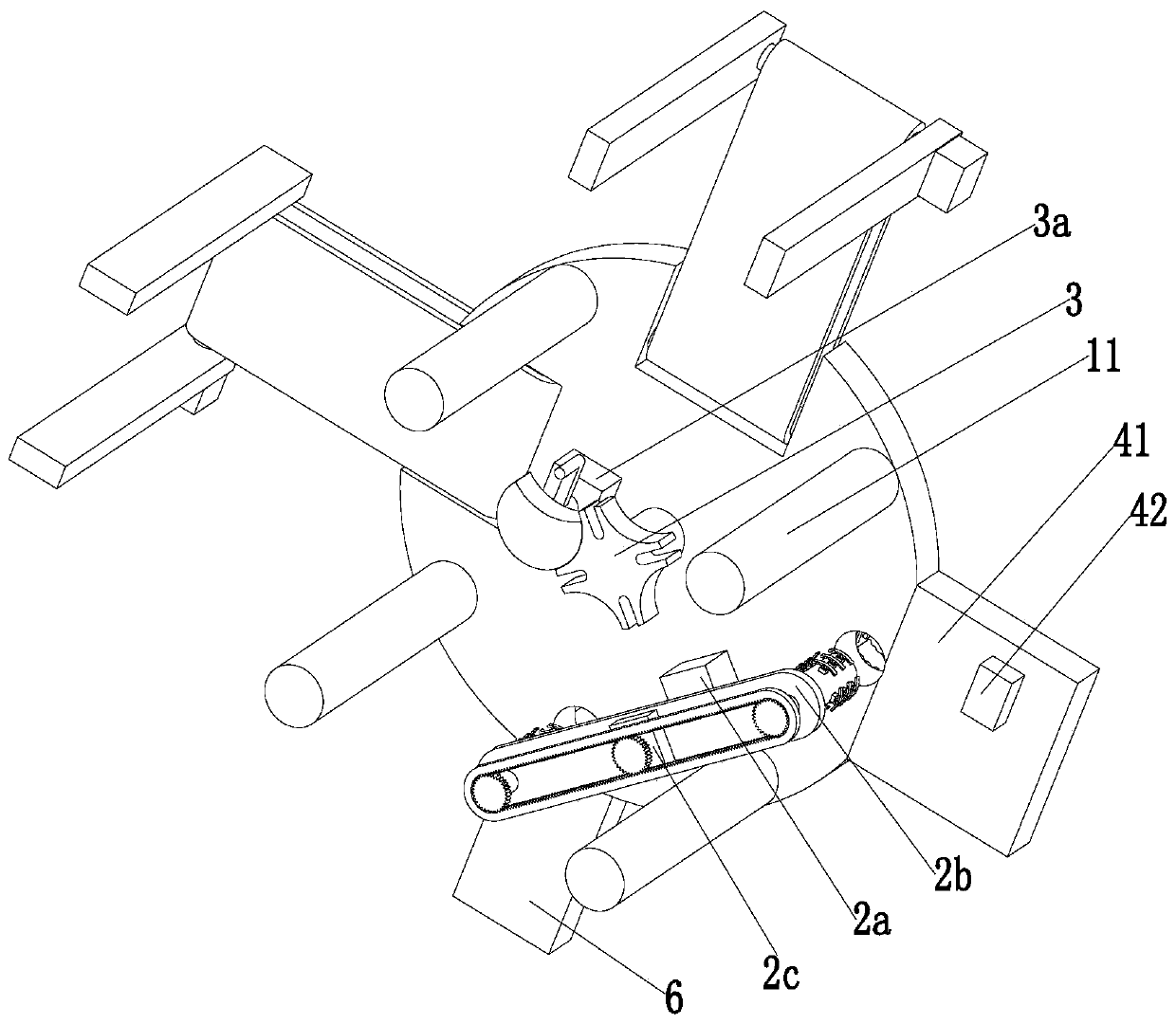

ActiveCN111086277AIncrease manpower duplication of workLow attachment efficiencyPaper/cardboard articlesLabelling short rigid containersMechanical engineeringMaterials science

The invention relates to a method for manufacturing an outer wall sticker of a gift packaging paper can through adhesive sticker pasting. The method mainly comprises the following steps of pattern design, raw paper unfolding, printing operation, oil coating treatment, film covering operation, qualification detection, winding forming, pasting operation and the like. Used pasting equipment comprisesa bottom circular plate, an internal clamping device, a rotating device, a pasting device, a feeding and discharging device and a flattening mechanism. The method can solve the following problems existing in the adhesive sticker pasting process in the prior art that a, in traditional production, pattern stickers are pasted to products manually, manual pasting is mainly judged through manual experience, in this way, part of the pattern stickers are pasted beyond the specified range, the pattern stickers need to be torn down and pasted again, and manual repeated work is greatly increased; and b, when a traditional sticker pasting machine pastes the adhesive sticker to the products, the situation that bubbles or uneven wrinkles are generated between the adhesive sticker and the pasting planeis likely to happen, and the like is likely to exist.

Owner:嘉兴市昭彰彩印有限公司

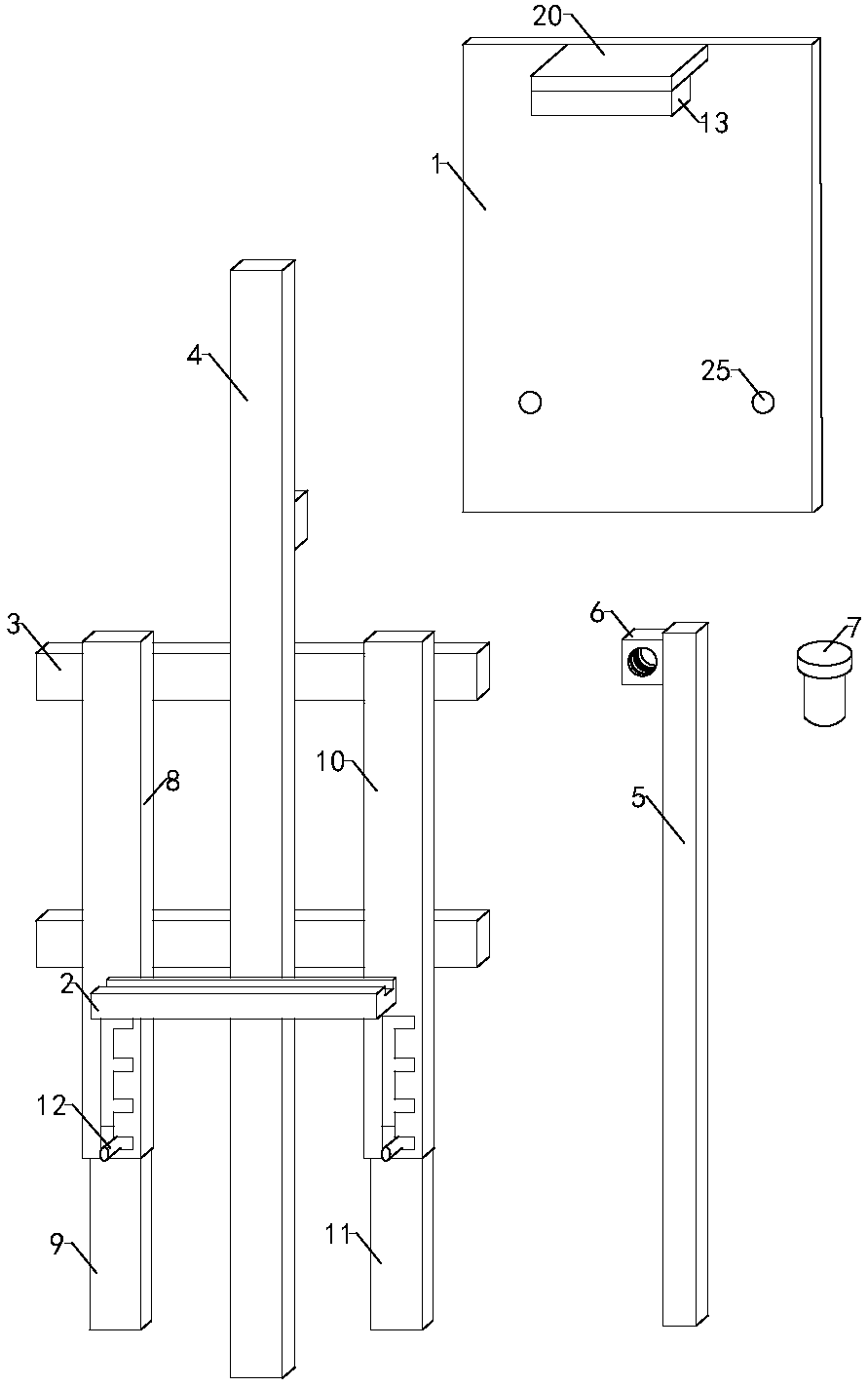

Magnetic one-piece easel

InactiveCN108407536AAdjust working heightEasy to fixFurniture partsOther artistic work equipmentsEngineeringScrew thread

The invention relates to the technical field of accessory devices of culture articles and particularly relates to a magnetic one-piece easel. The magnetic one-piece easel provides convenience for regulating the working height of a fixed plate, is relatively low in use limitation, provides convenience for a user and is relatively high in practicability; moreover, paper for drawing can be conveniently fixed, the drawing effect is effectively guaranteed, the using effect is relatively good, and thus the use reliability of the magnetic one-piece easel is improved; the magnetic one-piece easel comprises left fixing rods, right fixing rods, a fixed plate, a supporting plate, two groups of connecting rods, upright rods, supporting rods, two groups of connecting frames and bolts; the top end of the supporting plate is provided with grooves; the inner sidewalls of two groups of mounting holes and the outer sidewalls of the bolts are each of a threaded structure; the left fixing rods include a first left fixing rod and a second left fixing rod; the right fixing rods include a first right fixing rod and a second right fixing rod; the magnetic one-piece easel further comprises a shrinkable frame, a threaded rod, a threaded tube, a driving gear, a driven gear, a chain, a clamping plate and a servo motor; the chain is arranged on the driving gear and the driven gear in a sleeving manner; anda magnetic plate is arranged inside the fixed plate.

Owner:张雨欣

Production process of 6061 aluminum alloy stretch-bending profile

The invention discloses a production process of a 6061 aluminum alloy stretch-bending profile. The production process comprises the following steps of step A, the mass percentage of various componentsof the 6061 aluminum alloy material is as follows: 0.75 to 0.95% of Mg, 0.45 to 0.63% of Si, 0.2 to 0.35% of Fe, 0.1 to 0.2% of Mn, 0.2 to 0.25% of Cr, 0.1 to 0.24% of Cu, 0.1 to 0.24% of Zn, 0.2 to0.3% of Pb, 0.2 to 0.35% of Bi, 0.3 to 0.4% of Zr, 0.2 to 0.3% of Ti and the reset is AL; step B, cleaning a melting furnace and washing the furnace with pure aluminum ingots, putting the aluminum ingots into the melting furnace to heat and melt, and adding Si, Fe, Mn, Gr, Zn, Pb, Bi, Zr and Ti to the melting furnace and mixing and stirring uniformly; and step C, adding Cu after melting, completely melting furnace burdens in the melting furnace and reaching 730 to 750 DEG C, and adding Mg ingots. The production process of the 6061 aluminum alloy stretch-bending profile provided by the invention has the advantages of being good in corrosion resistance, wide in use range, long in service life, easy in cutting and processing, and solves the problems that an existing aluminum alloy tensile profile is low in strength, easy to break in the bending process, low in corrosion resistance, easy to cause corrosion of environmental factors during use, large in use limitation, the own service life is reduced, cutting is not easy in the processing process and the cutting difficulty is large.

Owner:广东吉源铝业有限公司

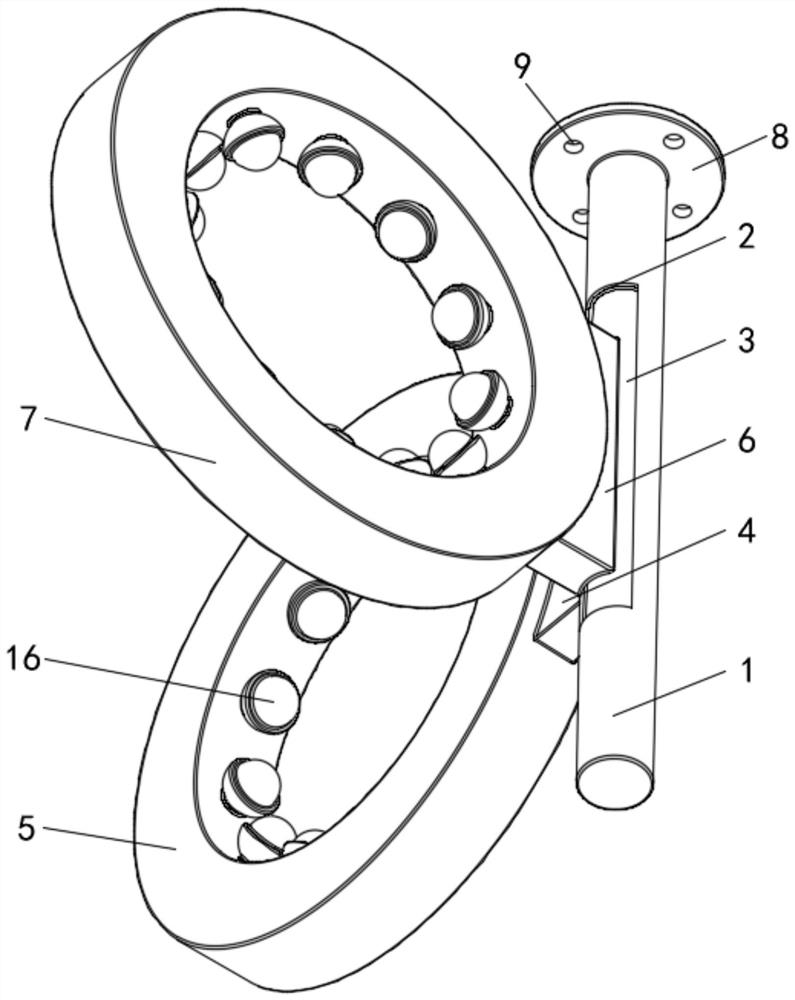

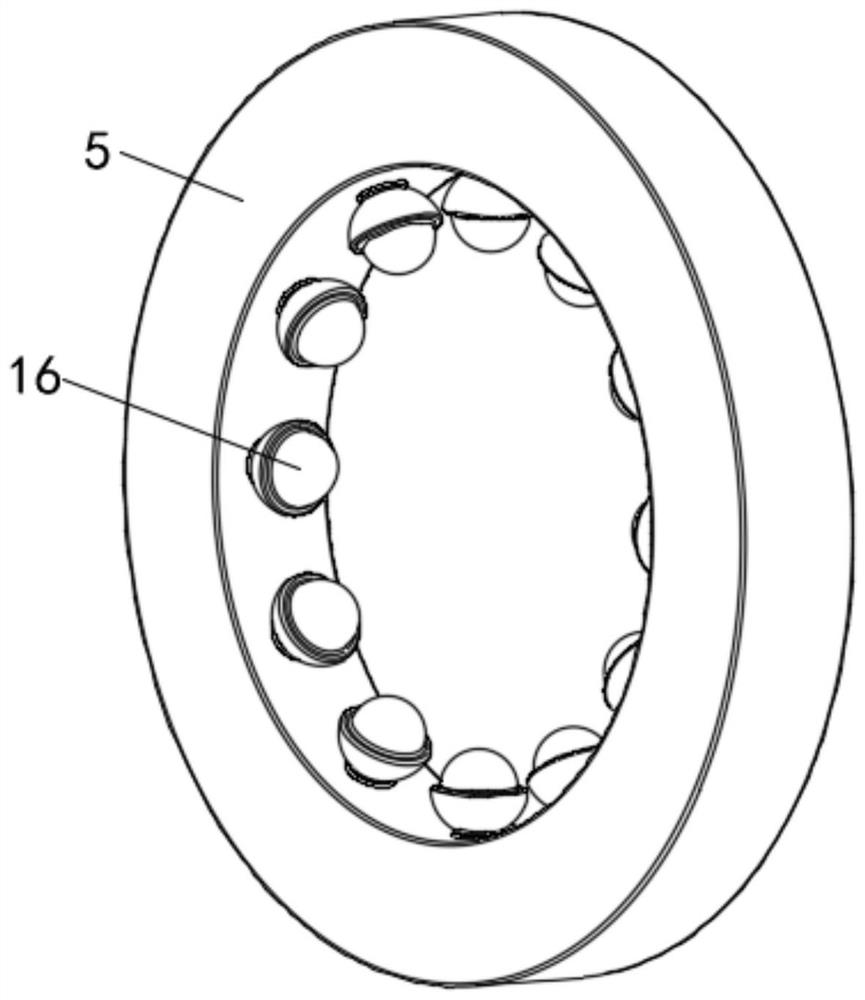

Fixing structure based on smart power grid cable and mounting method

PendingCN114336444AExtended service lifePlay a protective effectSuspension arrangements for electric cablesApparatus for overhead lines/cablesSmart gridPower grid

The invention relates to an installation method of a fixing structure based on a smart power grid cable. At present, the angle of a fixed cable cannot be rotated generally in the prior art, so that the cable is damaged due to the torsion requirement in actual use, the use limitation is high, and the use requirement cannot be met. A groove (2) is formed in one side of the body, a movable rotating shaft (3) is installed in the groove, a fixing piece A (4) is installed on the outer side of the body, a hoop A (5) is fixed to the fixing piece A, a fixing piece B (6) is fixed to the outer side of the movable rotating shaft, a hoop B (7) is installed on one side of the fixing piece B, an installation disc (8) is fixed to the right end of the body, and four evenly-distributed installation hole positions (9) are formed in the installation disc. Fixing bolts corresponding to the mounting hole positions are arranged on the mounting hole positions, and mounting grooves (11) are formed in the clamp A and the clamp B respectively. The invention is used for the fixing structure based on the intelligent power grid cable.

Owner:国网黑龙江省电力有限公司管理培训中心 +2

New energy automobile seat

InactiveCN108275046AExpand the range of massageImprove adaptabilityVehicle seatsHydraulic cylinderNew energy

The invention relates to the technical field of automotive accessory devices, and particularly relates to a new energy automobile seat. A backrest can alleviate the pain of the back of a driver and relieve fatigue to reduce safety hazards, improve adaptability and improve use limitation. The automobile seat includes a base, the backrest and a headrest, and further includes three sets of massage rollers, a front supporting rod, a rear supporting rod, an upper connecting rod, a lower connecting rod, an upper top plate, a lower bottom plate and a rotating motor; a working chamber is formed in thebackrest, a right side plate is arranged on the rear ends of the upper top plate and the lower bottom plate, a baffle is arranged at the right side of the right side plate, spring groups are arrangedbetween the baffle and the right side plate, a first double acting hydraulic cylinder and a second double acting hydraulic cylinder are further arranged on the right end of the baffle, a first hingering and a second hinge ring are respectively arranged on the front end and the rear end of the right side wall of the baffle, and right ends of the first double acting hydraulic cylinder and the second double acting hydraulic cylinder are connected with the front and rear sides of the right side inner wall of the working chamber of the backrest.

Owner:山西云度知识产权服务有限公司

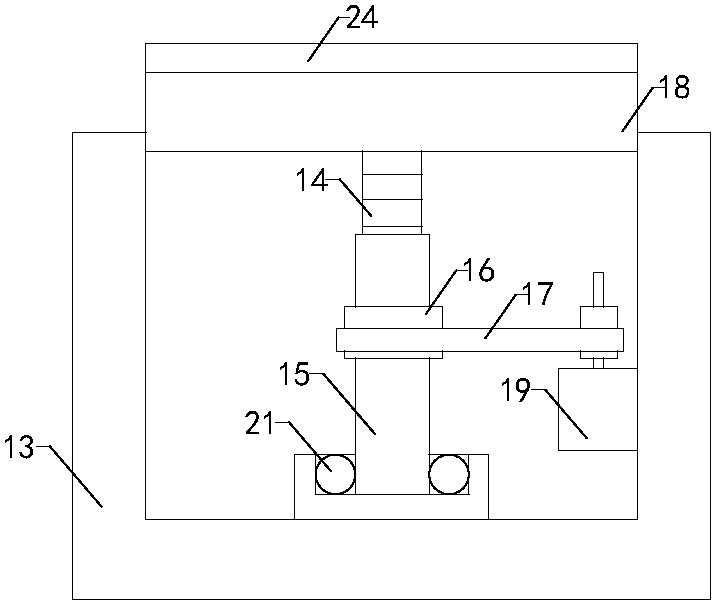

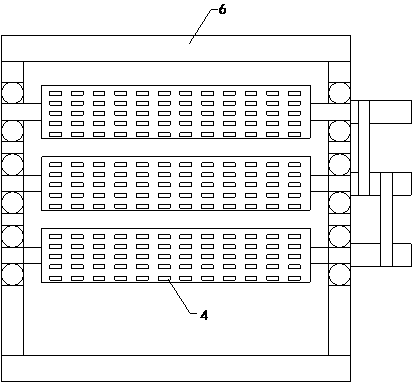

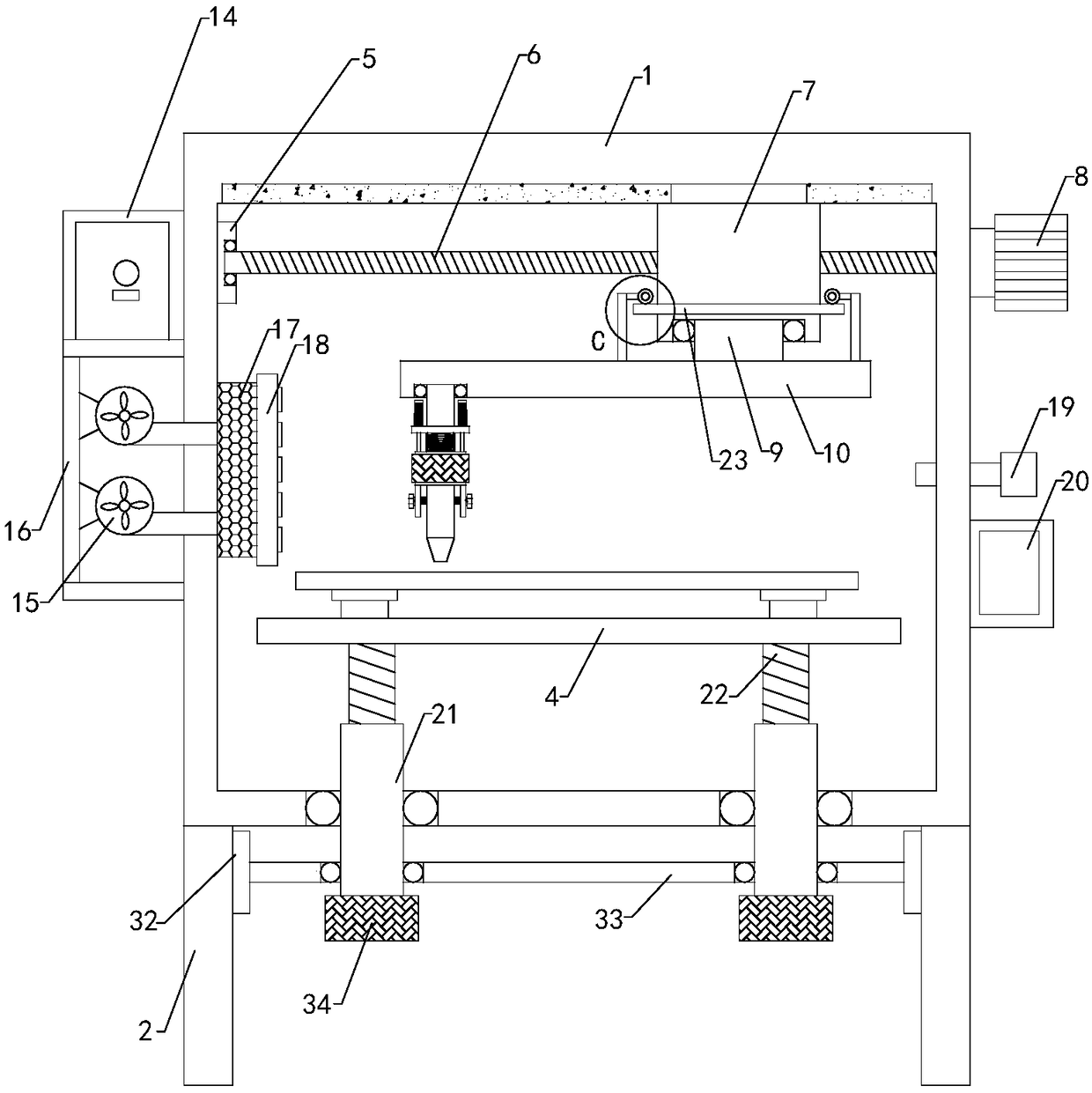

Module quality detecting device

InactiveCN109059713AReduce the temperatureEasy to operateMechanical measuring arrangementsDisplay deviceThermostat

The invention relates to the technical field of module quality accessory devices, in particular to a module quality detecting device, wherein a detecting pin can be adjusted at multiple angles, can perform multi-point detection on the module, has simple operation and improves adaptability; at the same time, the module can be detected at different temperatures, the detected data is comprehensive, the representativeness is improved, and the reliability of use is improved; and the height of a detecting table can be adjusted according to the modules of different thicknesses, thereby preventing theprobe of the detection pin from not touching the module and reducing the use imitation. The module quality detecting device includes a detection box, two sets of left legs, two sets of right legs, adetection pin and a detection table, wherein a detection chamber is provided in the detection box. The module quality detecting device includes a fixed plate, an adjusting screw, an adjusting block, an adjusting motor, a first rotating shaft, a second rotating shaft, a rotating arm, a mounting plate, a connecting spring and a mounting head, further includes a thermostat, two sets of fans, an upperbaffle, a lower baffle, a left baffle, a heating box, an exhaust hood, a temperature sensor and a display, and also includes four sets of threaded tubes and four sets of threaded rods.

Owner:YANCHENG HUAXU OPTOELECTRONICS TECH CO LTD

Linear cutting device

InactiveCN108687407AEasy to adjust the working heightImprove use reliabilityLarge fixed membersBall bearingThreaded pipe

The invention relates to the technical field of industrial production accessory devices, in particular to a linear cutting device. Relevant personnel do not need to manually move relevant industrial materials, so that convenience is brought to a user, the using effect is high, and practicability is high; and the working height of a supporting plate is conveniently adjusted, use limitation is high,and thus the using reliability of the linear cutting device is improved. The linear cutting device comprises a device body, a supporting frame, a connecting frame, a driving motor, a cutting knife set and the supporting plate. The device body is internally provided with a working cavity. The cutting knife set is mounted on a transmission shaft. The linear cutting device further comprises two setsof front fixing frames, two sets of rear fixing frames, two sets of rotating rollers, a conveying belt, a first servo motor, a transmission belt, a rotating shaft and a fixing plate. The conveying belt is arranged on the two sets of rotating shafts in a sleeving mode. The driving motor is mounted at the top end of the fixing plate. A groove is formed in the top end of the device body. The linearcutting device further comprises a threaded rod, a threaded pipe, a second servo motor, a driving gear, a driven gear and a chain. Ball bearings are arranged on the inner bottom wall of the groove, and the chain is arranged on the driving gear and the driven gear in a sleeving mode.

Owner:SUZHOU BLUE KING MACHINE TOOL TECH CO LTD

Method and device for leveling and anti-slipping of an elevator

The invention discloses a method for safe operation of a car elevator, in particular to a method for leveling and anti-slipping of a car elevator. Car emergency braking device, in which the sheave and / or sheave lead-out device operates synchronously with the elevator car, when the elevator car enters the leveling floor and stops, the elevator car is monitored in real time through the sheave and / or sheave lead-out device When the elevator car slips, the above-mentioned sheave and / or the pull-out device of the sheave will rotate synchronously, and the emergency braking device of the elevator car will be controlled to perform emergency braking by the amount of rotation displacement, thereby It solves the technical problem of preventing the elevator car from slipping when it is parked on the level floor, improves the operation stability of the car-elevator system, reduces the possibility of potential safety hazards during the operation of the car-elevator, and ensures the life and property of the passengers Safety.

Owner:NINGBO OULING ELEVATOR COMPONENTS

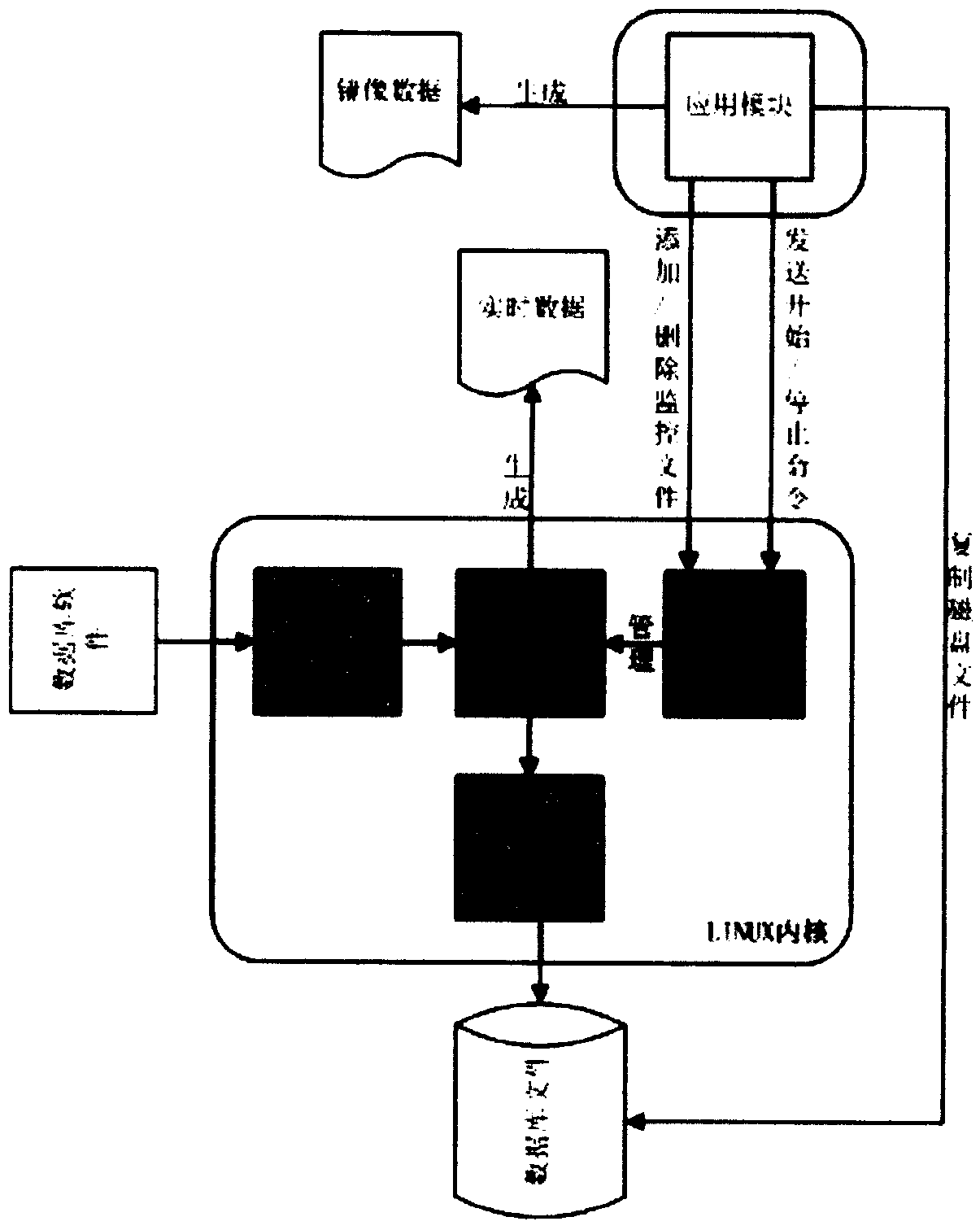

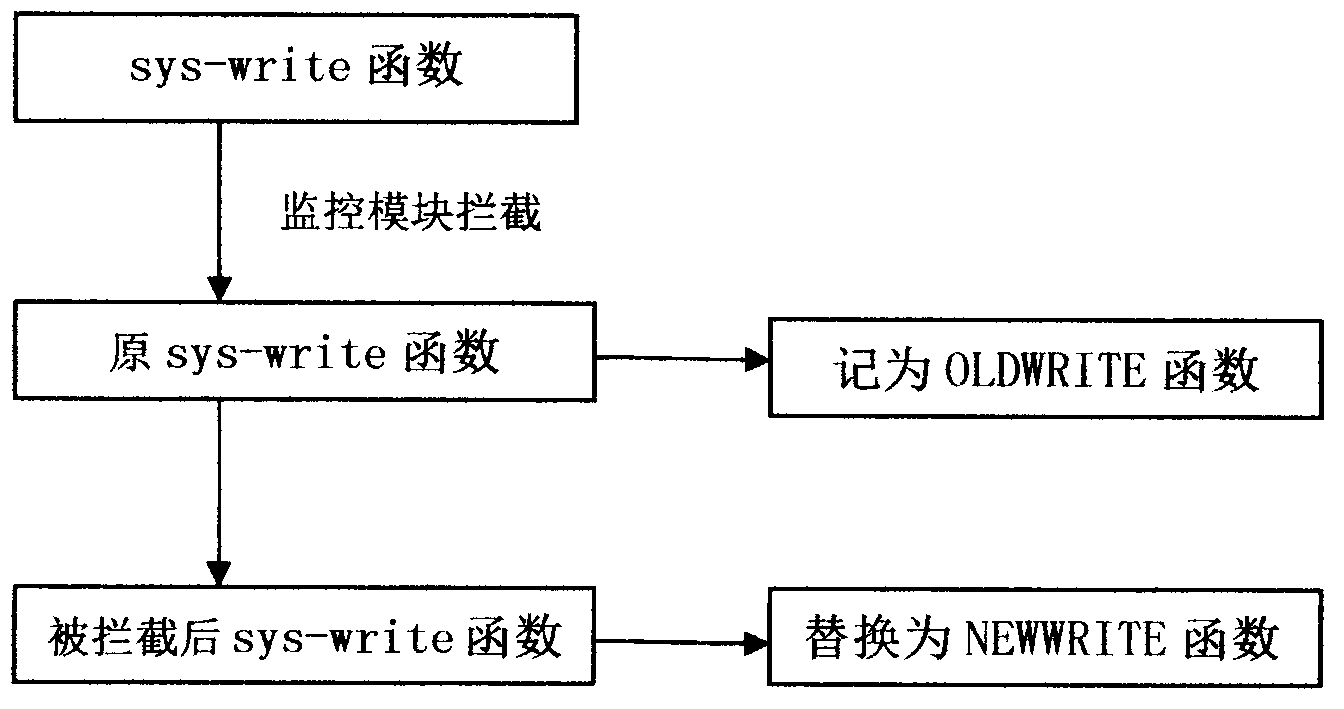

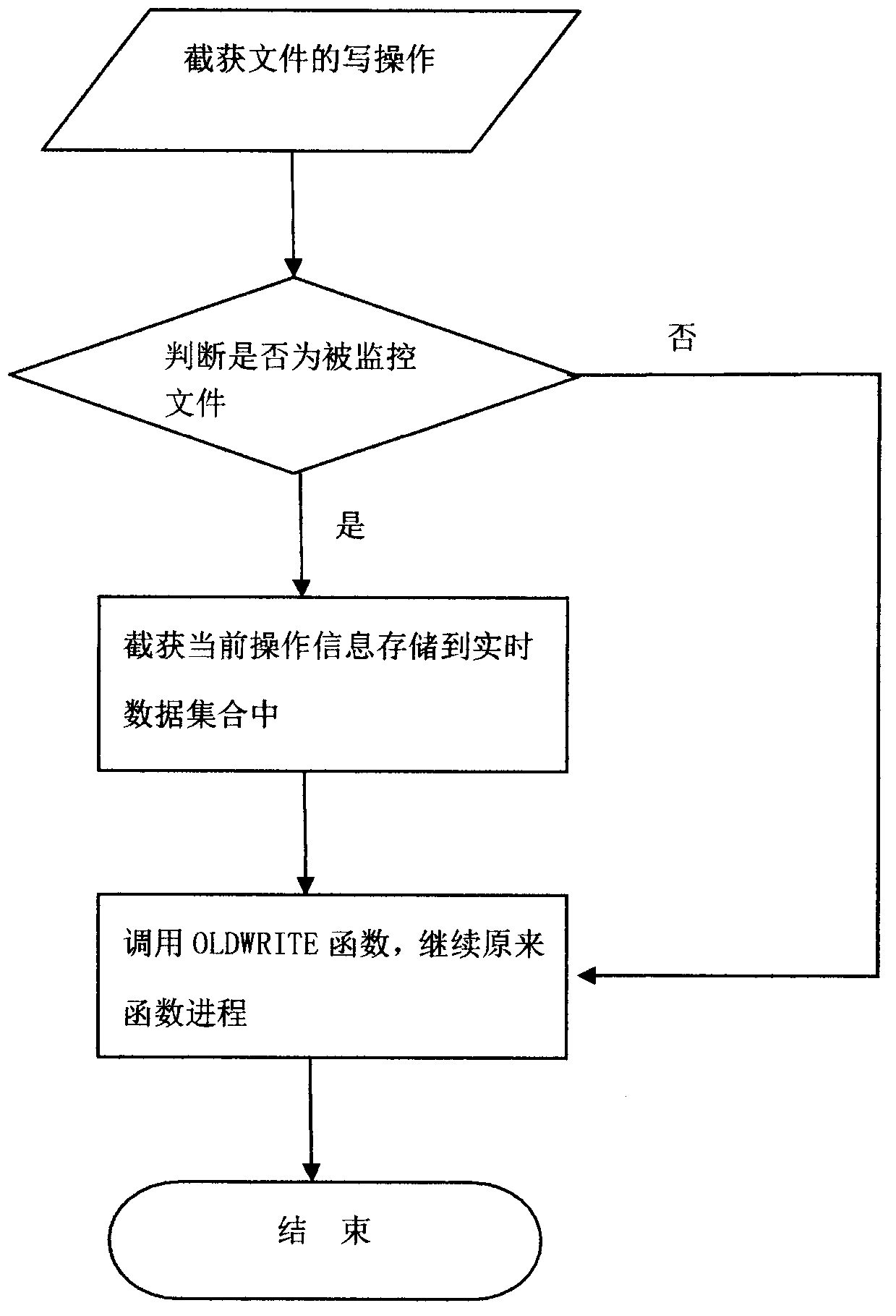

Method for obtaining consistent backup on Linux platform

InactiveCN103810056ALower requirementCommon methodRedundant operation error correctionReal-time dataOperational system

The invention discloses a method for obtaining a consistent backup on a Linux platform. The method comprises the steps that files to be backed up are monitored, write operations of the files are intercepted in the backup process of the files, real-time data files of the files in the process of the write operations are obtained, mirror image data of the monitored files and real-time data of the monitored files are combined to form a backup according to the time sequence, and the backup generated at the moment is the consistent backup. According to the method for obtaining the consistent backup on the Linux platform, the requirement for a Linux operating system is low; due to the fact that an application module and a kernel module are used, the consistent backup of files or databases can be obtained on any Linux operating system, and the method for obtaining the consistent backup on the Linux platform is universal, and does not depend on any selectable configuration or technologies.

Owner:NANJING UNARY INFORMATION TECH

Solar energy power supply apparatus

InactiveCN102170250BImprove securityEnsure normal power supply requirementsPV power plantsEnergy storageEngineeringCharge discharge

The invention relates to a solar energy power supply apparatus formed by a portable case body, a solar energy photovoltaic cell panel arranged on the front and back surface of the case body, an automatic charge-discharge control circuit including a direct current- direct current (DC-DC) voltage transforming circuit and a direct current-alternating current (DC-AC) transforming circuit, a liquid crystal display (LCD) arranged on the surrounding frame of the case body, a voltage output interface for notebook computer, a USB output interface used for power supply or charging for digital electronic products, an AC 220V output socket, a DC emergency charging input interface, an automobile storage battery charging output interface, and a convenient setting combination hub specially used for lamp-post of high-efficient energy-saving light formed by a collapsible supporting rod which serves the purpose of a lamp-post and a LED lamp holder. The invention has advantages of high power supply capability, wide applicability, strong practicality, safety and reliability and can satisfy the normal power supply of basic electricity utilization in communication, business and daily life in no AC 220V power-supply environment, and the invention is especially suitable for high illumination needed for earthquake relief work in remote mountain area, travelling and dark environment.

Owner:驿网无际(上海)信息科技有限公司

Cutting-stirring friction-welding combined machining equipment and manufacturing method thereof

ActiveCN102501074BExtended service lifeHigh strengthOther manufacturing equipments/toolsMaintainance and safety accessoriesFood sectorPressure sense

The invention discloses cutting-stirring friction-welding combined machining equipment and a manufacturing method thereof. The cutting-stirring friction-welding combined machining equipment integrates a milling system or a cutting system, a stirring friction-welding system, a forced cooling system, a gas protection system, a temperature sensing system, a pressure sensing system, a milling liquid supply system and a non-sensing system. The invention provides a united or combined machining device which can carry out milling or cutting and stirring friction-welding in parallel simultaneously and a method thereof. The cutting-stirring friction-welding combined machining equipment has the functions of temperature control, gas protection, pressure detection, cooling liquid production, milling head replacement and dual-shaft shoulder self-supporting. According to the manufacturing method of the cutting-stirring friction-welding combined machining equipment, the manufacturing processes are reduced and the machining cost is saved. The limitation of the conventional mechanical machining technology is broken through, and a new method and a new idea about the mechanical manufacturing and machining are formed. The cutting-stirring friction-welding combined machining equipment and the manufacturing method in the invention have wide engineering applications to the heating industry, the air conditioning industry, the ice making industry, the freshness retaining industry, the pharmacy industry, the construction industry, the aquatic product industry and the food industry.

Owner:罗键

Cable fixing device for smart power grid

InactiveCN113690820AExtended service lifeEffective clampingSuspension arrangements for electric cablesSmart gridPower grid

The invention provides a cable fixing device for a smart power grid. The cable fixing device comprises a main body. The main body is provided with a movable groove, and the movable groove is formed in one side of the main body. The movable groove is internally provided with a movable rotating shaft. A first fixing piece is fixedly mounted on the outer side of the main body. A first hoop is fixedly installed on the side, away from the main body, of the first fixing piece. A second fixing piece is fixedly installed on the outer side of the movable rotating shaft. According to the cable fixing device for a smart power grid, clamping balls are arranged on the inner walls of the first hoop and a second hoop, so that on one hand, a cable is prevented from being abraded due to friction with the inner walls of the first hoop and the second hoop when being pulled, and the service life of the cable is prolonged; and on the other hand, the cable can be effectively clamped and protected, the angle of the cable can be adjusted, the use limitation of the cable is improved, and meanwhile, the use effect of the equipment is further improved.

Owner:樊俊俊

Trimming machine for agricultural landscaping

ActiveCN109168708BImprove the use of limitationsReduce usage limitationsHedge trimming apparatusCuttersAgricultural engineeringLandscaping

The invention discloses a novel edge trimming machine for agricultural landscape greening, which comprises a machine body. The outer surface of one end of the machine body is fixedly connected with anoperating handle; the outer surface of the bottom part of the machine body is in bolt connection with a fan; the outer surface of one side, far away from the operating handle, of the machine body isfixedly connected with an auxiliary handle; the outer surface of one section, close to the auxiliary handle, of the machine body is in bolt connection with a transmission mechanism; the outer surfaceof one end, far away from the machine body, of the transmission mechanism is embedded and connected with a protective plate; the side wall of one side, far away from the transmission mechanism, of theprotective plate is fixedly provided with a lighting lamp; the side wall of one side, far away from the machine body, of the transmission mechanism is in bolt connection with a tool carrier; and theouter surface of the bottom of the tool carrier is in bolt connection with a first tool group and a second tool group sequentially along a horizontal direction. According to the novel edge trimming machine for agricultural landscape greening disclosed in the invention, the trimming range of the edge trimming machine is improved, the trimming efficiency is improved, operation by a user is facilitated at the same time, and a better use prospect is brought.

Owner:厦门大冶景观工程有限公司

Cutting-stirring friction welding composite processing device for floating double-shaft-shoulder double-stirring needle and manufacture method thereof

InactiveCN102490018BEasy to assembleIncrease flexibilityOther manufacturing equipments/toolsNon-electric welding apparatusEngineeringProcessing cost

The invention discloses a cutting-stirring friction welding composite processing device for a floating double-shaft-shoulder double-stirring needle and a manufacture method thereof, and particularly relates to a combined or composite processing device capable of simultaneously carrying out milling or cutting processing and stirring friction welding processing and a method thereof. The cutting-stirring friction welding composite processing device for the floating double-shaft-shoulder double-stirring needle integrates a cutting system or a milling system, a stirring friction welding system, a forced cooling system, a gas protection system, a temperature sensing system, a pressure induction system, a milling liquid supply system and a sensing-free system. The cutting-stirring friction welding composite processing device has functions of temperature control, gas protection, pressure detection, cooling liquid protection, milling head replacing and floating double-shaft-shoulder self-supporting stirring friction welding. The method for carrying out cutting-stirring friction welding composite processing on workpieces can meet strength requirements of mechanical processing of ferrous light metal materials, carbon steel materials and alloy steel materials. The cutting-stirring friction welding composite processing device for a floating double-shaft-shoulder double-stirring needle and the manufacture method of the cutting-stirring friction welding composite processing device reduce manufacture procedures, save processing cost, have the advantages of being high in efficiency, excellent in quality, high in stability and saving in energy, break through limitation of conventional machining technology, form a new method and a new thought for machinery processing, and have wide application prospects in industries of heating, air conditioners, ice manufacture, freshness keeping, medicine preparation, construction, aquatic products and foods.

Owner:CHONGQING UNIV

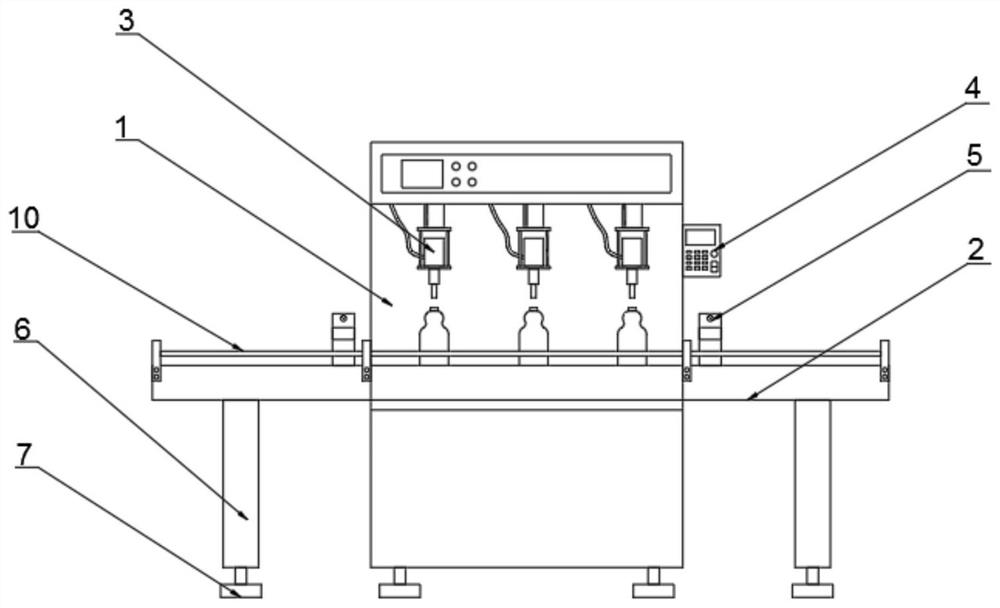

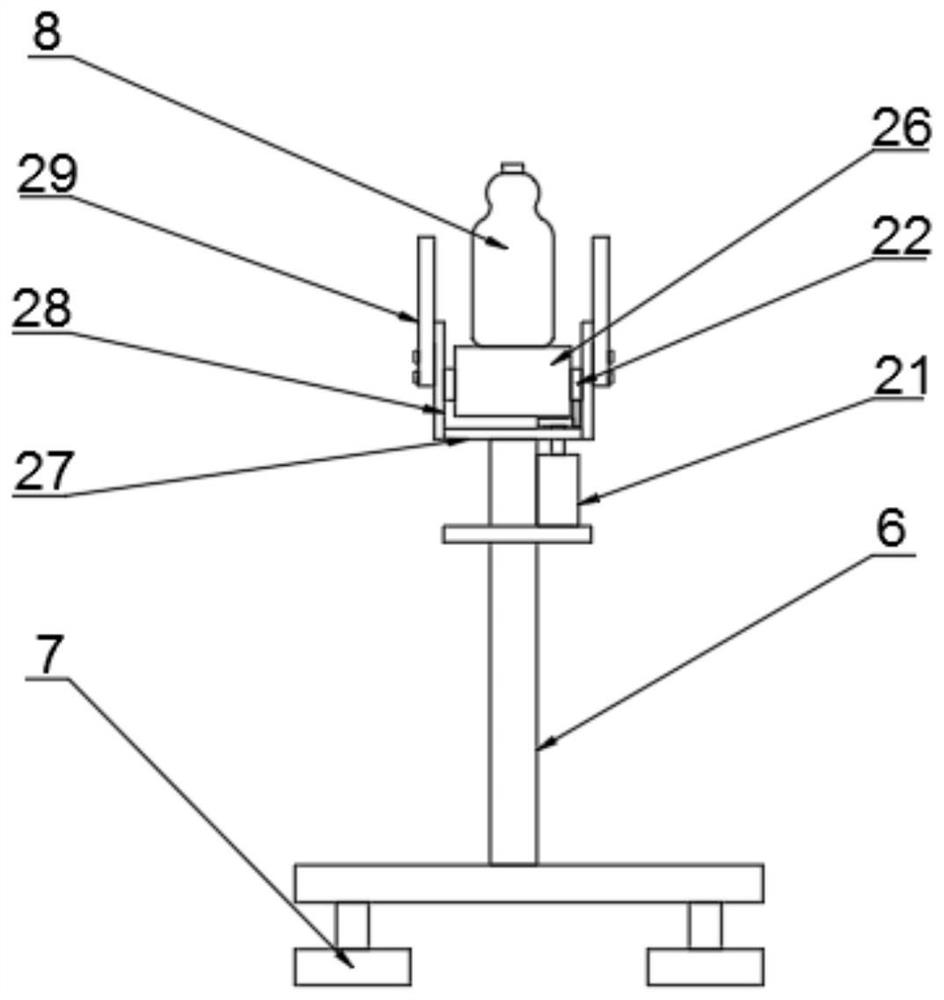

Conveying device for filling machine

InactiveCN112279203AImprove the use of limitationsAccurate fillingSynchronising machinesLiquid bottlingDrive shaftElectric machinery

The invention discloses a conveying device for a filling machine. The conveying device comprises the filling machine, a conveying device body and adjusting mechanisms, wherein filling valves are arranged in the filling machine; the conveying device body is arranged at the lower ends of the filling valves; support legs are arranged at the bottom end of the conveying device body; a reinforcing column is fixedly installed at the bottom end of each support leg; the conveying device body comprises a motor, a driving shaft, a driving roller, a driven shaft, a driven roller, a conveyor belt, a bottomplate, side plates and fixing plates; the side plates are arranged at two sides of the bottom plate; the driving shaft is arranged between the side plates, and one end of the driving shaft is rotationally connected with an output end of the motor; one side of each side plate is in threaded connection with one fixing plate; and a handrail is inserted into one side of each fixing plate. The adjusting mechanisms are arranged at two sides of the conveying device body, the side plates can be adjusted and moved towards two sides of the conveying device body through a first adjusting rod and a second adjusting rod, and filling bottles of different sizes can be adjusted through the adjusting mechanisms, so that the use limitation of the conveying device is improved.

Owner:ZHANGJIAGANG WANJIN MACHINERY CO LTD

PVA extraction device for PVA-containing wastewater

InactiveCN112777680AChange angleTargetedWater/sewage treatment by centrifugal separationSpecific water treatment objectivesWastewaterStructural engineering

The invention discloses a PVA extraction device for PVA-containing wastewater, the PVA extraction device comprises a rotary drum, a tray and a scraping mechanism, the scraping mechanism comprises a scraper and two water retaining wings, a power screw is rotatably arranged on a vertical-line-shaped supporting table and a T-shaped supporting table through a plurality of groups of bearings, the power screw, a guide sliding rod on the front side and a guide sliding rod on the rear side jointly penetrate through a strip-shaped shifting block, supporting swing arms are correspondingly and rotationally hinged to block bodies of the front end and the rear end of the strip-shaped shifting block respectively, and the other end of the supporting swing arm on the front side is correspondingly and rotationally hinged to a rear wing body of the water retaining wing on the front side, the other end of the supporting swing arm on the rear side is correspondingly hinged to a rear wing body of the water retaining wing on the rear side in a rotating mode. By means of the transmission effect of the supporting swing arms, the angles of the two wings can be freely adjusted according to actual conditions, pertinence is achieved, and therefore the application range is expanded.

Owner:湖北魔洗高新材料制品有限公司

Automatic feeding auxiliary device suitable for chicken feed

InactiveCN114586705AEasy to eatAvoid damageFood processingAvicultureAnimal scienceWater storage tank

The invention provides an automatic feeding auxiliary device suitable for chicken feed, which comprises a main body, a water storage tank and a supporting part are arranged in the main body, a supporting assembly is arranged in the supporting part, a supporting column is fixedly arranged at the upper end of the supporting assembly, a bearing plate is fixedly arranged at the top end of the supporting column, and a feeding device is fixedly arranged on the bearing plate. A mounting part is mounted on the upper side of the supporting part, and a supporting connecting rod is mounted in the mounting part. According to the automatic feeding auxiliary device suitable for the chicken feed, the chicken feed is stored in the feed storage tank, when the designated feeding time is reached, the driving device is used for spraying the chicken feed in the feed storage tank out of the spray heads, meanwhile, the sprayed chicken feed is evenly distributed on the periphery of the device, chicken flocks can eat the chicken feed conveniently, and the feeding efficiency is improved. And moreover, the damage caused by scrambling the feed among the chicken flocks can be effectively avoided, so that the chicken flocks achieve a better feeding effect.

Owner:李虹

Umbrella containing bag

InactiveCN108402624AImprove the use of limitationsImprove practicalityWalking sticksActive carbonThreaded pipe

The invention relates to the technical field of living-article accessory devices, in particular to an umbrella containing bag. A position of an umbrella in a containing cavity is conveniently fixed, the use limitation is high, and the practicability is high; multiple operating modes are achieved, stored rainwater can be effectively treated, and therefore the use reliability of the umbrella containing bag is improved. The umbrella containing bag comprises a body and a supporting plate, the containing cavity is formed in the body, a taking putting opening is formed in the top end of the body, and a valve is arranged on a water draining pipe; the umbrella containing bag also comprises a fixed plate, a threaded rod, a threaded pipe, a driving gear, a driven gear, a servo motor, a chain, a connecting rod, a limiting frame and a movable rod, the fixed plate is fixed on the bottom wall of a water storage cavity, the driving gear and the driven gear are installed on a transmission shaft and the threaded pipe respectively, the chain sleeves the driving gear and the driven gear, a through hole is formed in the limiting frame, and an opening is formed in the side wall of the limiting frame; the umbrella containing bag also comprises four pulleys, a sliding frame and an active carbon layer, the sliding frame is located on the four pulleys, and a baffle is connected to the right end of themovable frame.

Owner:曾意博

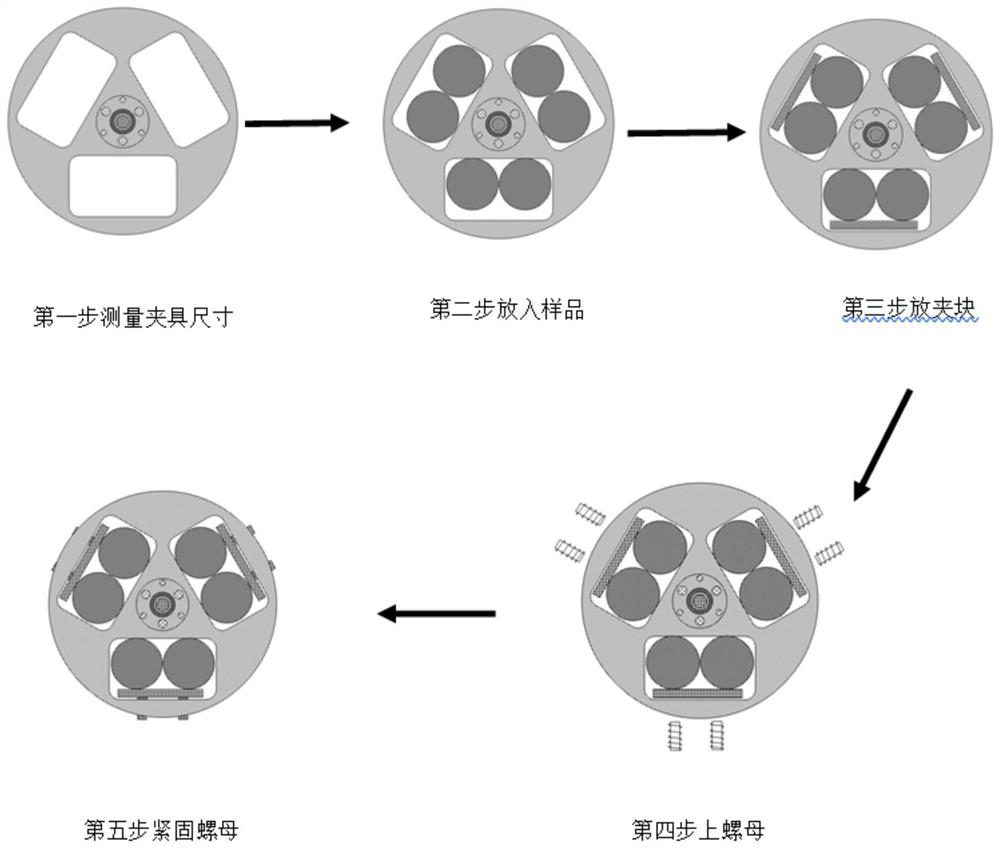

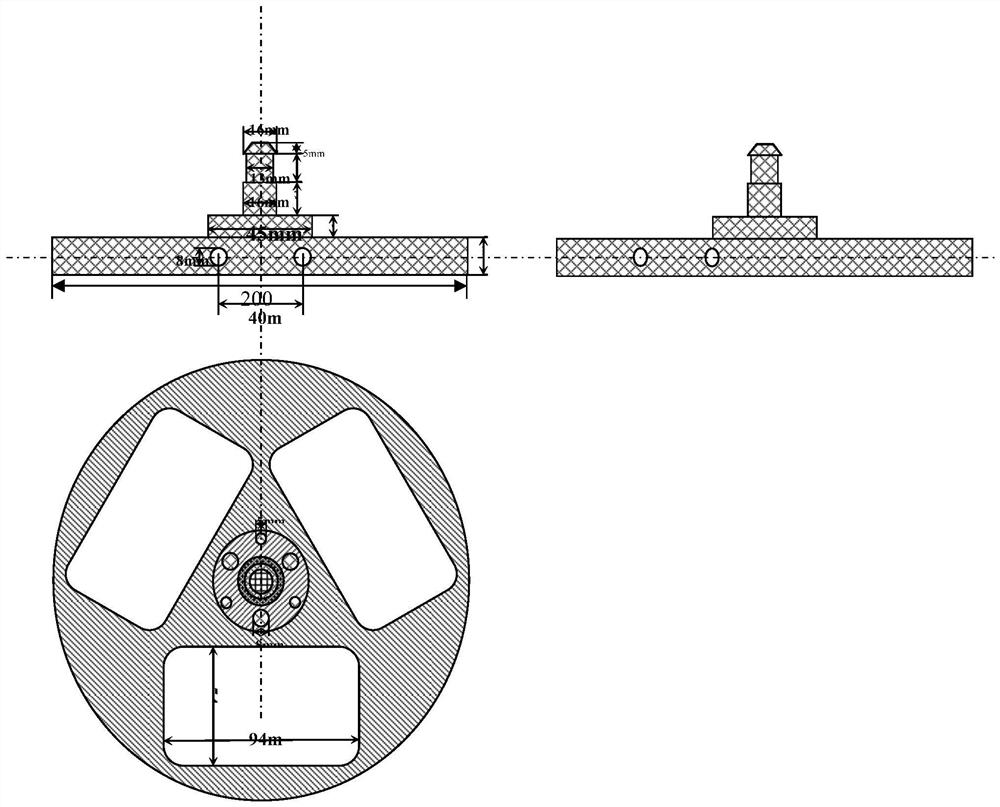

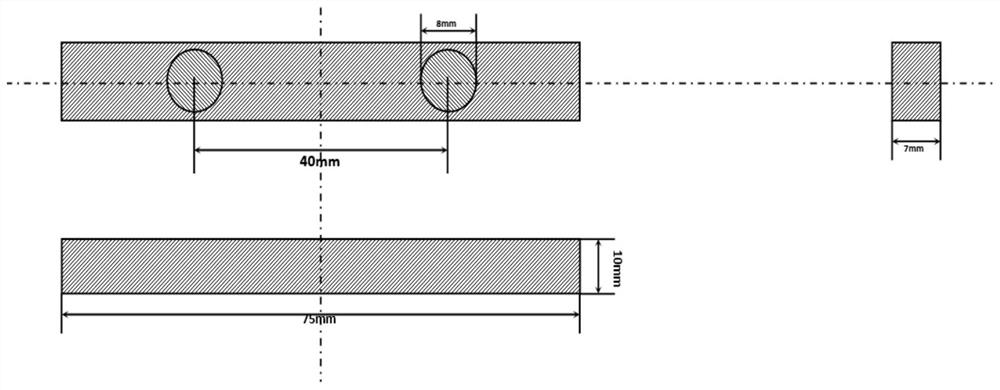

Method for expanding rectangular sample clamp of automatic sample grinding machine for laboratory

PendingCN111633487AIncrease usageSave moneyRevolution surface grinding machinesPreparing sample for investigationProcess engineeringMechanical engineering

The invention discloses a method for expanding a rectangular sample clamp of an automatic sample grinding machine for a laboratory. The method is characterized by comprising the following steps of measuring the relevant size of the rectangular sample clamp of the automatic sample grinding machine; measuring the gap size in the width direction of a hole groove after a circular sample is placed in;determining the size of a clamping block, and manufacturing the clamping block; punching a fixing hole in the clamping block; putting the manufactured clamping block and the circular sample into the hole groove together and performing fixation; and performing operation and sample preparation according to an automatic equipment flow. By the method provided by the invention, the use limitation of the rectangular clamp is expanded, the utilization rate of the clamp is improved, the requirement of preparation of samples in different shapes is met, and the money for purchasing corresponding clampsfor clamping the samples in different shapes is reduced.

Owner:NANJING IRON & STEEL CO LTD

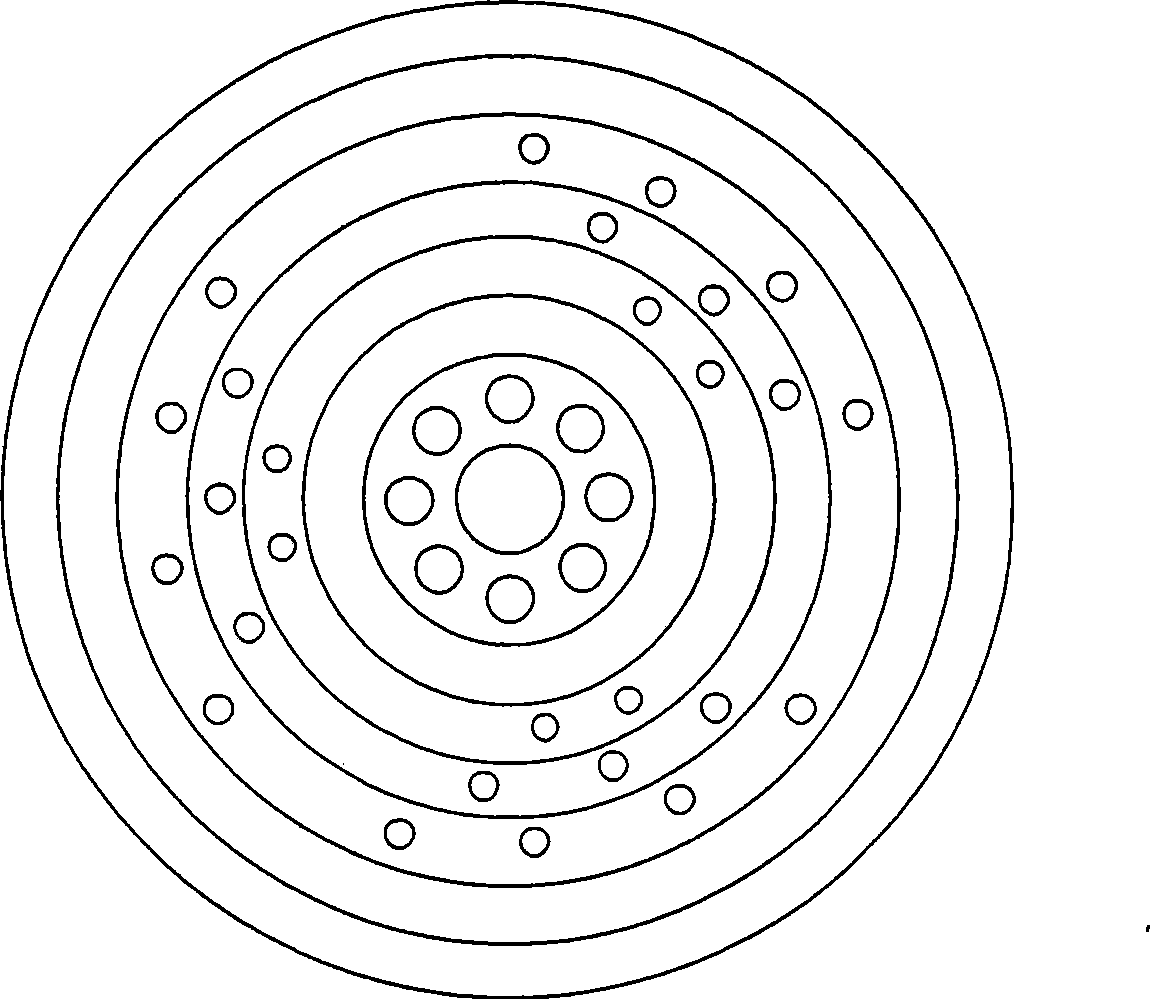

Steel bar cutter for bridge construction

InactiveCN108453199ARealize automatic pressingSave human effortMetal working apparatusHydraulic cylinderBall bearing

The invention relates to the technical field of steel bar machining accessory devices, in particular to a steel bar cutter for bridge construction. The steel bar cutter can carry out automatic pressing and improve safety coefficients, different cutter bits can be switched, and using limitation is reduced. The steel bar cutter comprises a workbench, a branch arm, a connection rod and a cutting hydraulic cylinder, the middle of the top end of the workbench is provided with a cutter slot, a left pressing hydraulic cylinder, a right pressing hydraulic cylinder, a left connection plate, a right connection plate, a left pressing plate, a right pressing plate, a limiting plate, a supporting rod, an upper pulley and a lower pulley, the bottom ends of the upper pressing plate and the lower pressingplate are sleeved with casing pipes, cavities are formed in the casing pipes, and springs are arranged in the cavities. A top plate, a sleeve, a limiting shaft, a rotating shaft, a cutter replacing disc, the first cutter bit, the second cutter bit and the third cutter bit are further involved, a rotary ball bearing is arranged between the cutter replacing disc and the sleeve, the first cutter bit, the second cutter bit an the third cutter bit are located below the cutter replacing disc, and the top ends of the first cutter bit, the second cutter bit and the third cutter bit are connected withthe bottom end of the cutter replacing disc.

Owner:山西云度知识产权服务有限公司

Energy-saving and environment-friendly animal feed feeding device

InactiveCN112167071AAvoid wastingEfficient use ofGeneral water supply conservationAnimal watering devicesWater storage tankWater source

The invention provides an energy-saving and environment-friendly animal feed feeding device which comprises a main body. A shell is installed on the main body, a water storage tank is fixedly installed at the bottom of the inner wall of the shell, fixing parts, installation parts and the shell are installed on the upper side of the water storage tank, and grooves are formed in the fixing parts; and supporting springs are arranged at the bottoms of the inner walls of the grooves, and bearing plates are fixedly connected to the upper sides of the supporting springs. According to the energy-saving and environment-friendly animal feed feeding device, due to the fact that livestock does not have the intelligent capacity, water resource waste caused by the livestock is avoided; when water sources in a water storage pool reaches a certain amount, the water storage pool drives a movable connecting rod to move downwards, a movable baffle is separated from a water through hole, water flow rapidly flows into the water storage tank, and water resource waste is avoided; and when it rains, rainwater can be effectively gathered through the design, effective utilization of the water resources is achieved, and therefore the use limitation of the device is increased.

Owner:温州铁坚建筑材料有限公司

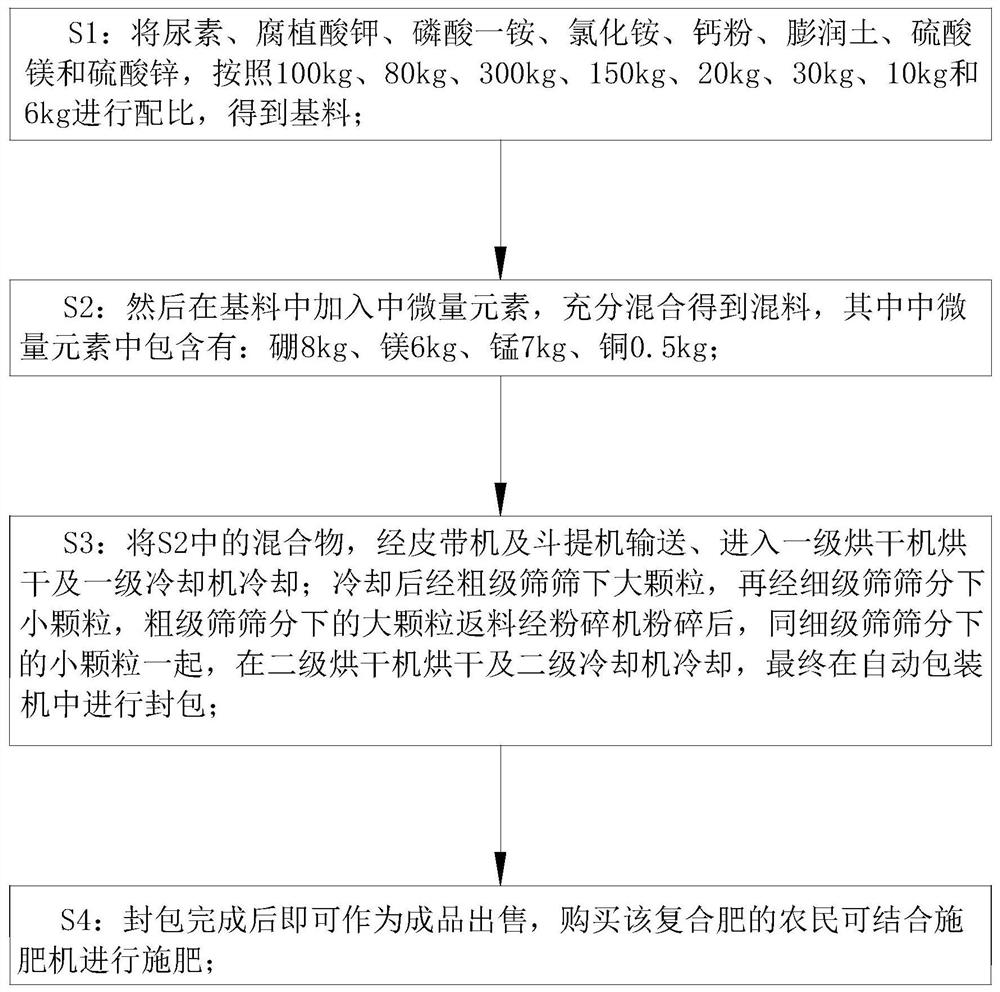

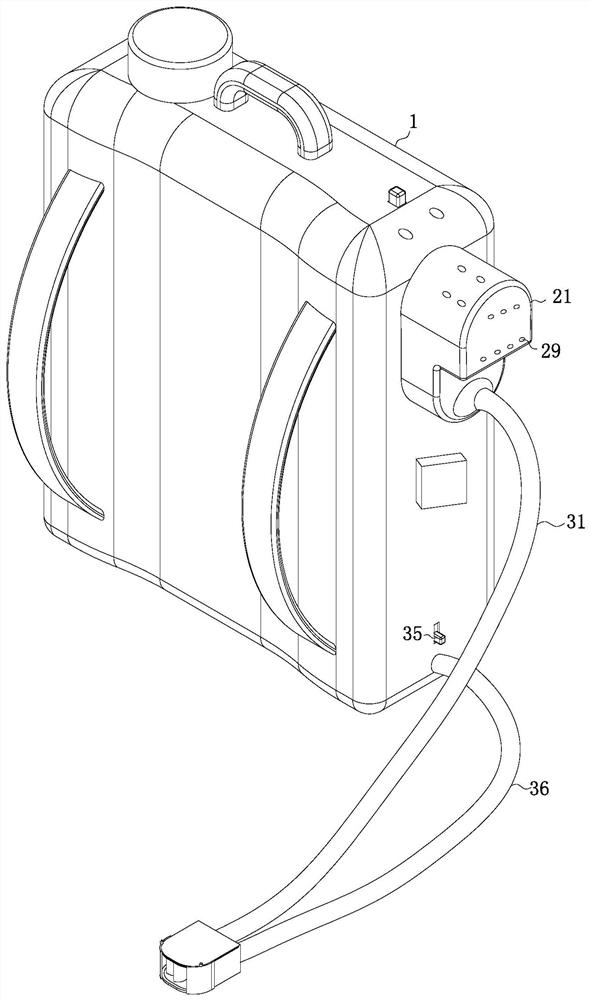

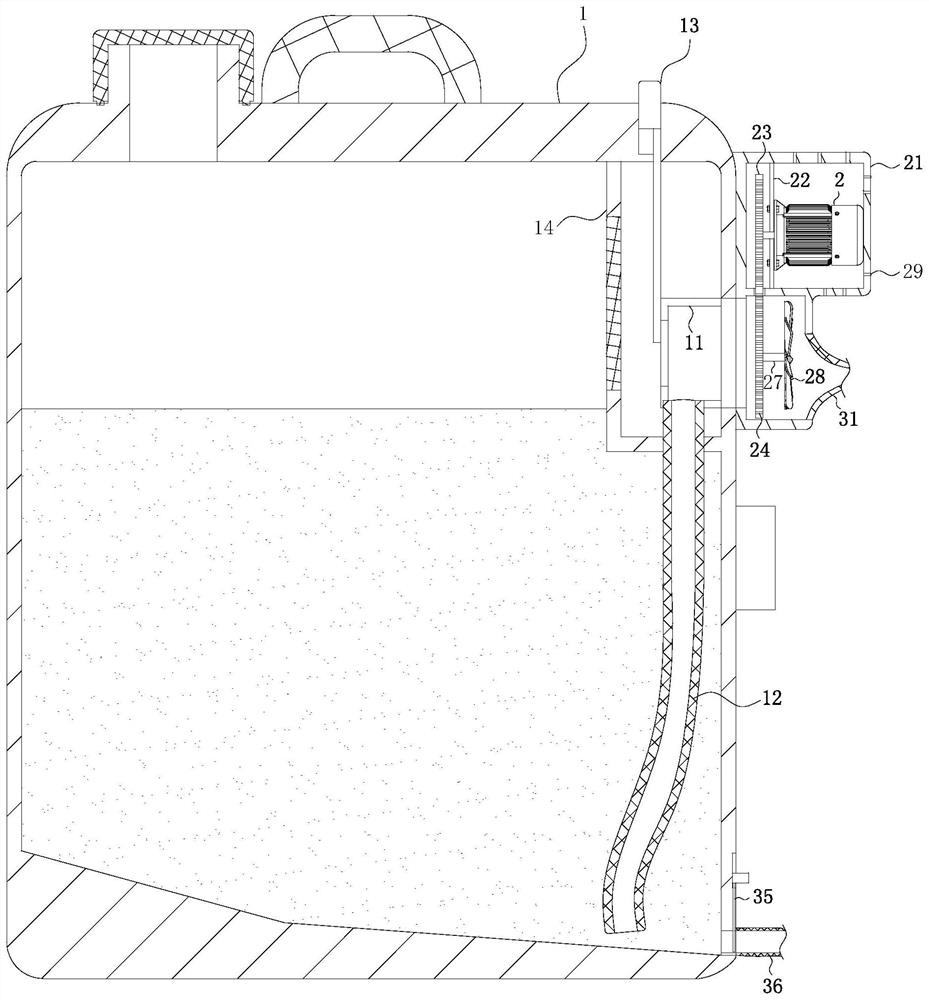

Preparation method of trace elements in compound fertilizer

InactiveCN112010713AImprove the use of limitationsImprove practicalityMagnesium fertilisersFertiliser distributersTrace elementElectric machinery

The invention belongs to the technical field of fertilizer, and particularly relates to a preparation method of trace elements in compound fertilizer. A fertilizer applicator used in the method comprises a shell, a motor and a spray head, a housing is fixedly connected to the side surface of the right side of the shell, a motor is arranged in the housing, a first soft catheter is connected to theside face of the right side of the housing, the end of the first soft catheter is connected with a spray head, a second soft guide pipe is fixedly connected to the bottom of the machine shell on the side face of the right side of the machine shell, and the other end of the second soft guide pipe communicates with the spray head. According to the fertilizer applicator, automatic spraying of compound fertilizer is achieved, the requirements of various working environment conditions are met, the practicability is high, and use is convenient and fast.

Owner:张先明

Low temperature evaporator

InactiveCN106362424BReduce energy consumptionLow investment costEvaporator accessoriesEnergy based wastewater treatmentEvaporationEngineering

The invention discloses a low-temperature evaporation device. An evaporation tank, a draught fan and a condenser form an air cycle through air pipes, the evaporation tank, a heat exchanger, the condenser and a circulation water pump form a liquid cycle through water pipes, a condensate water receiving tank is connected to the condenser, a concentrated liquid receiving tank is arranged at the bottom end of the evaporation tank, multiple slides are arranged in the evaporation tank, a central rotating shaft hole is formed in the center of each slide, multiple fixing connecting rod holes are formed in the portions, near the central rotating shaft hole, of each slide, and the slides are fixed in the evaporation tank through central rotating shafts and connected mutually through fixing connecting rods and are perpendicular to the air flowing direction; motors are connected to the two ends of each central rotating shaft and drive the central shaft to rotate to drive the slides to rotate. The production capacity is greatly improved, and the treatment cost is reduced.

Owner:南京德磊环保设备有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com