Patents

Literature

810results about "Synchronising machines" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

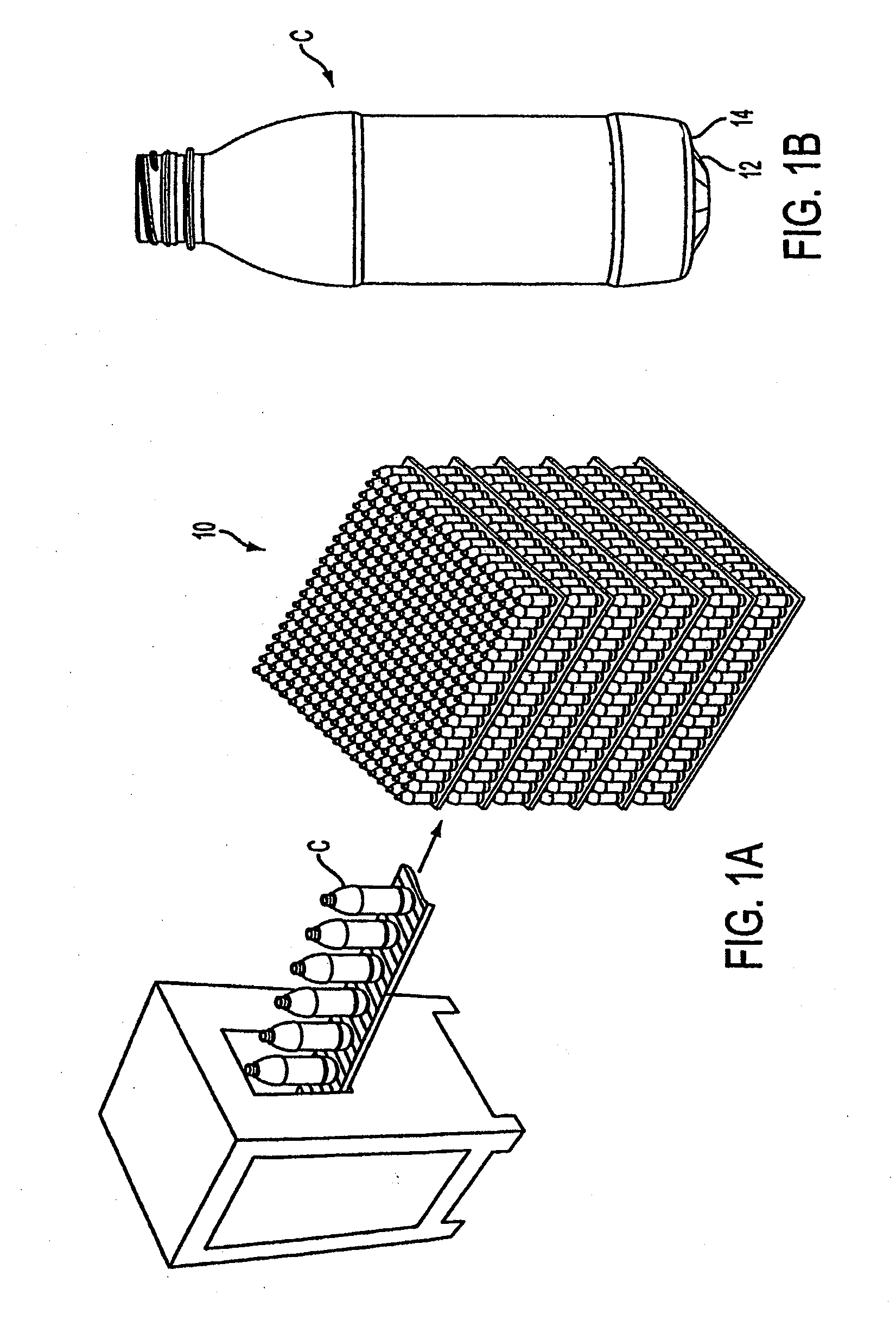

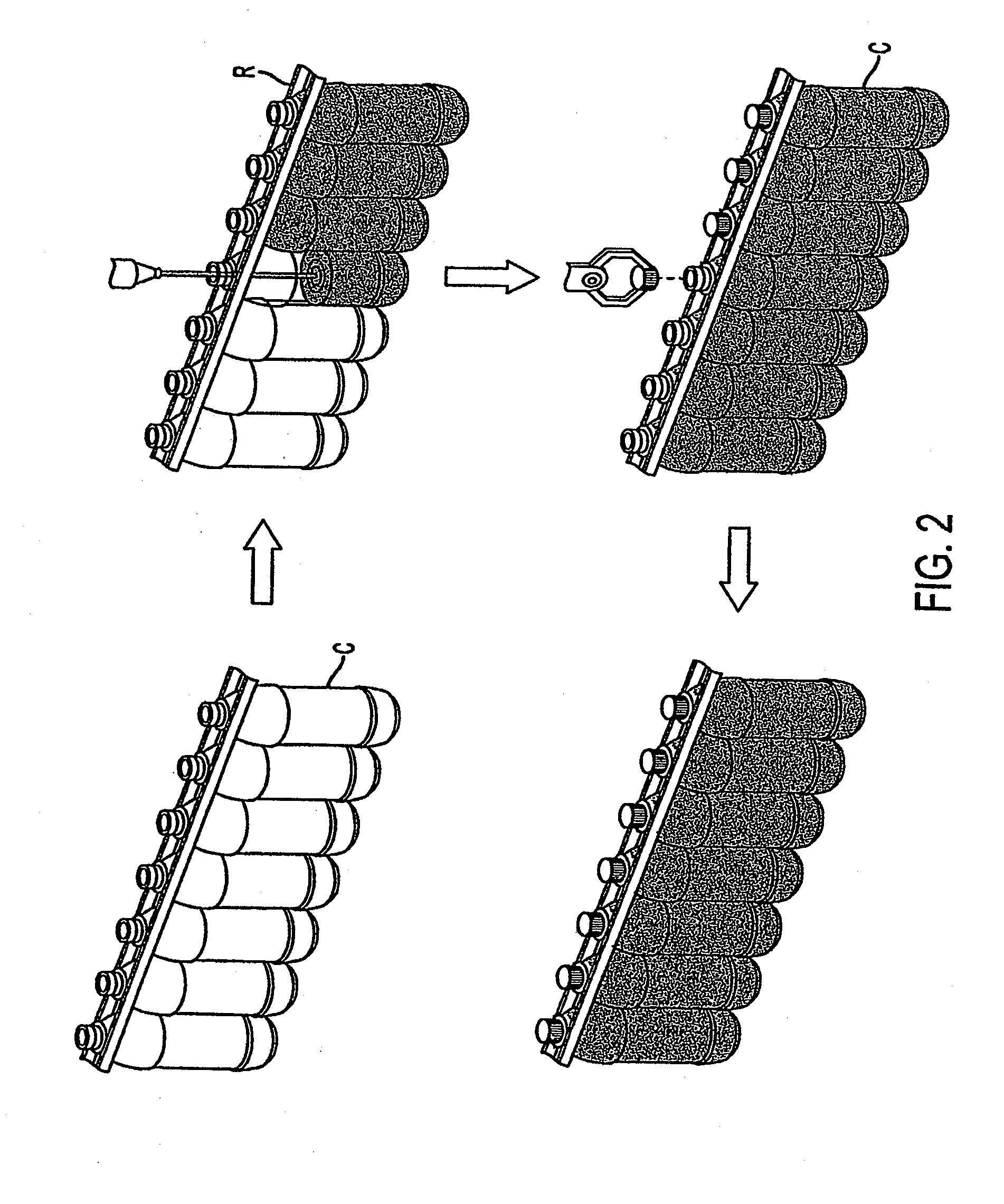

Container handling system

ActiveUS20070051073A1Smooth for label placementThorough removalCapsDecorative coversBlow moldingStructural geometry

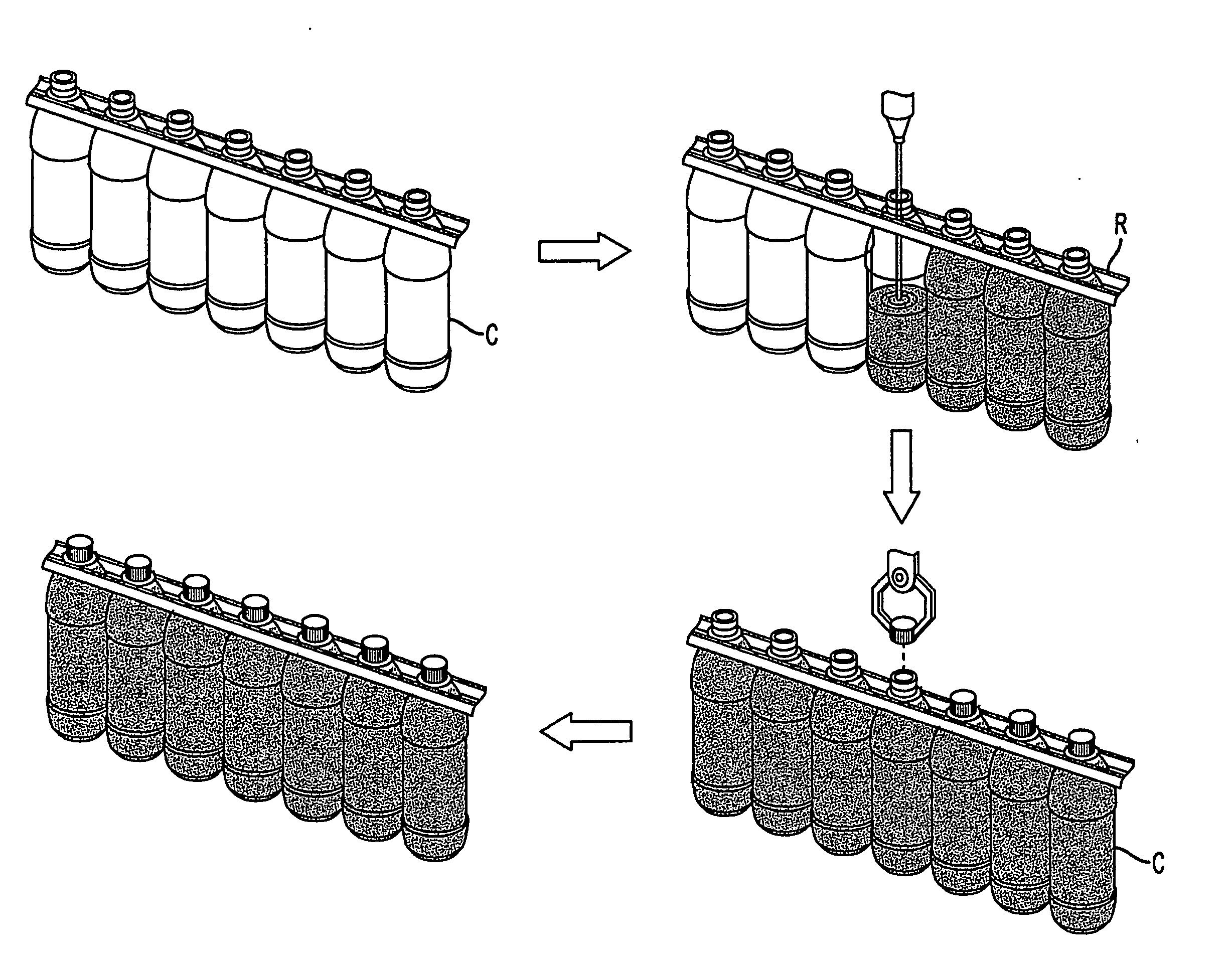

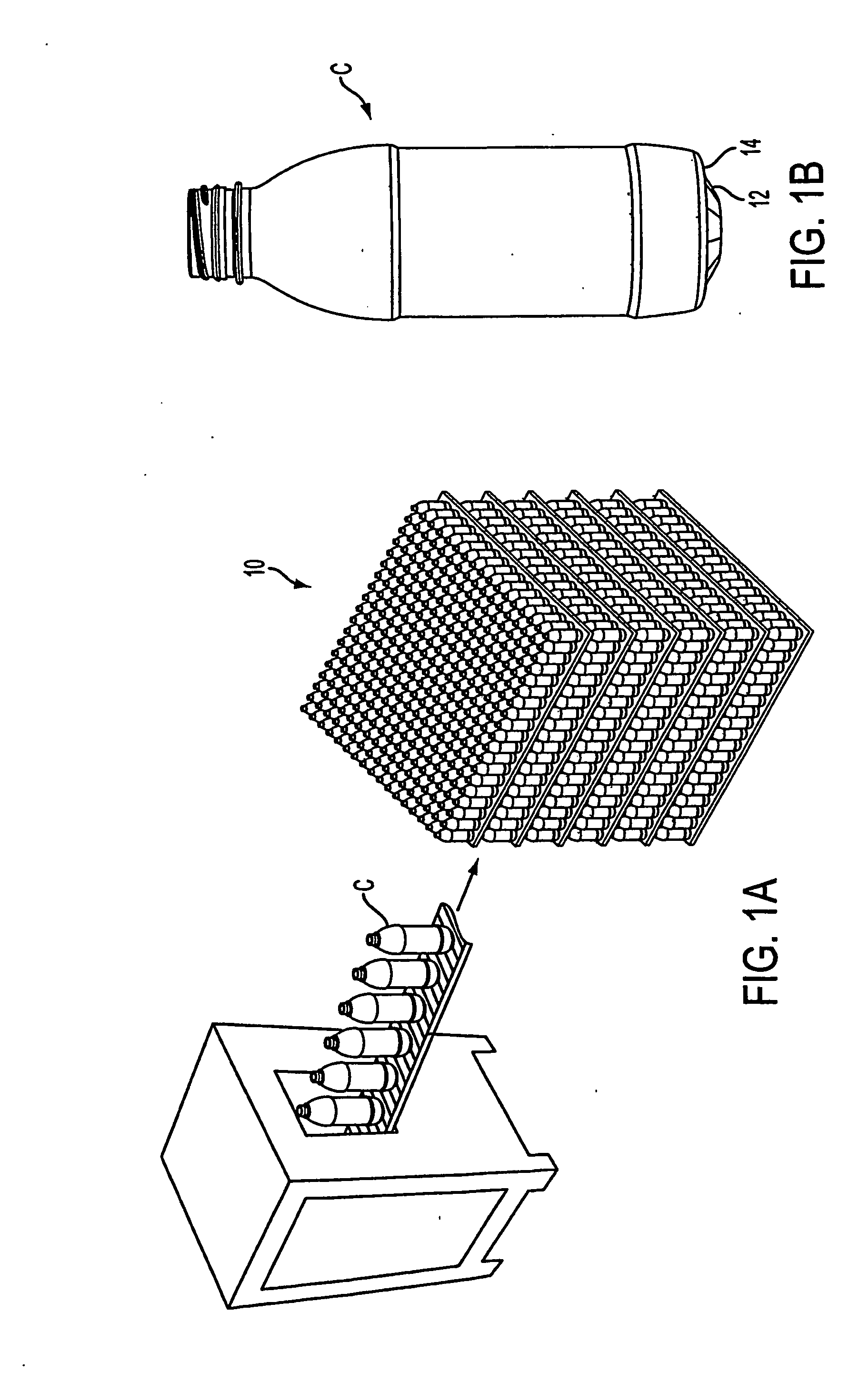

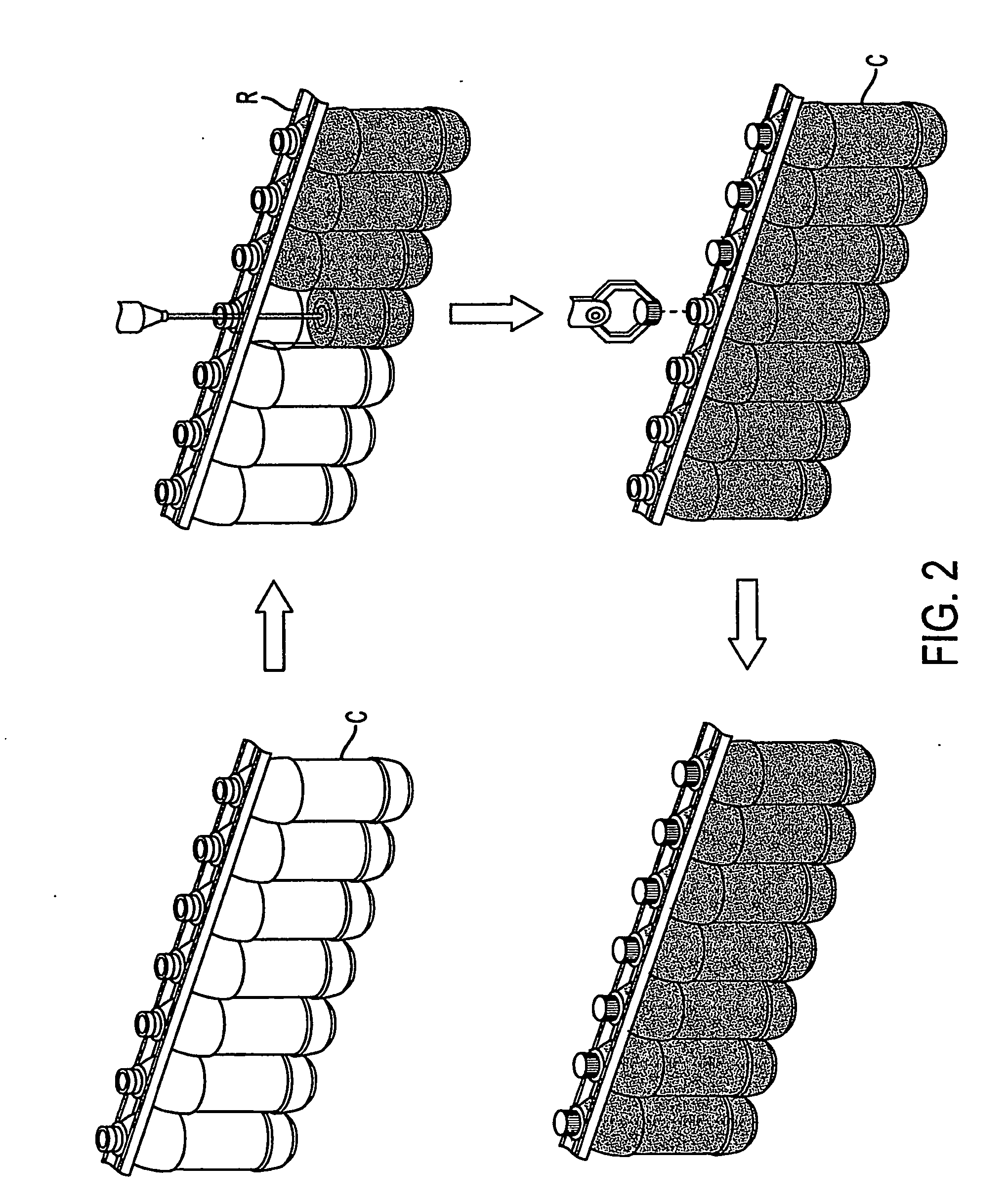

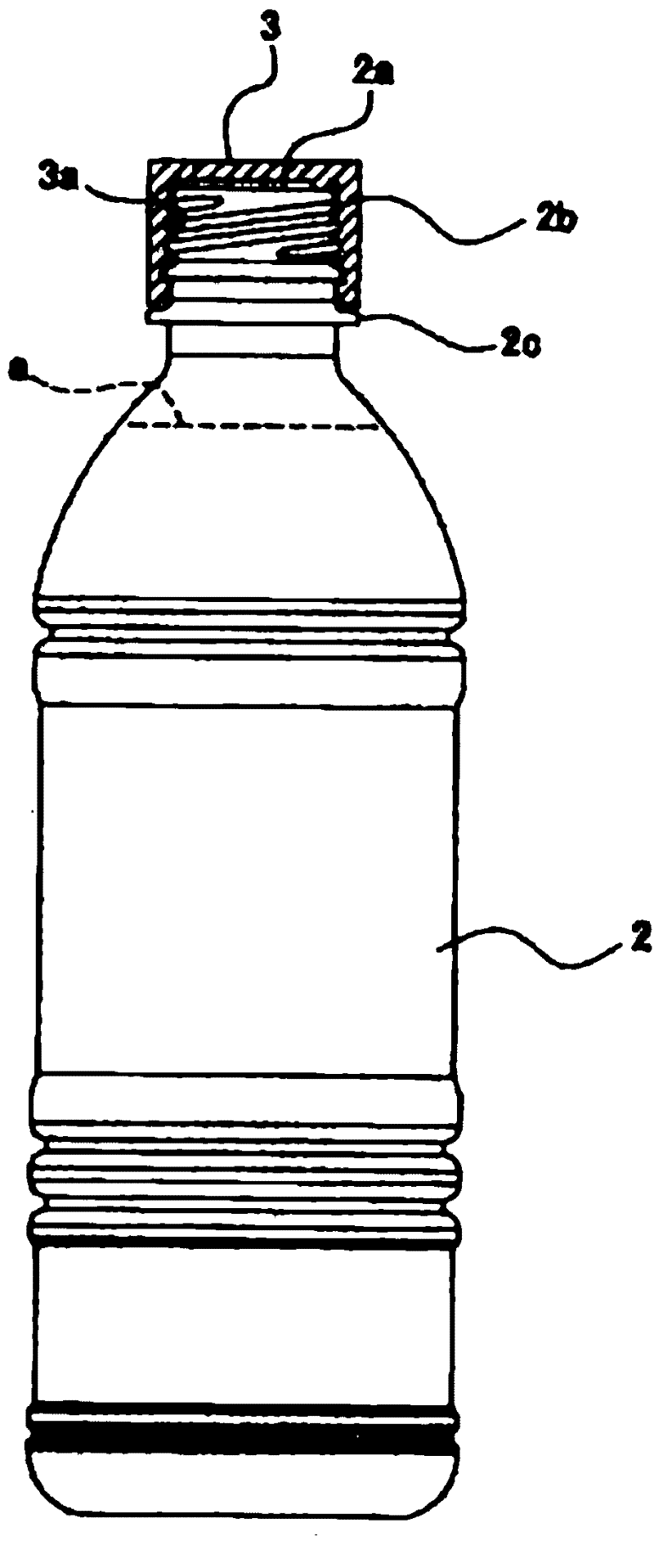

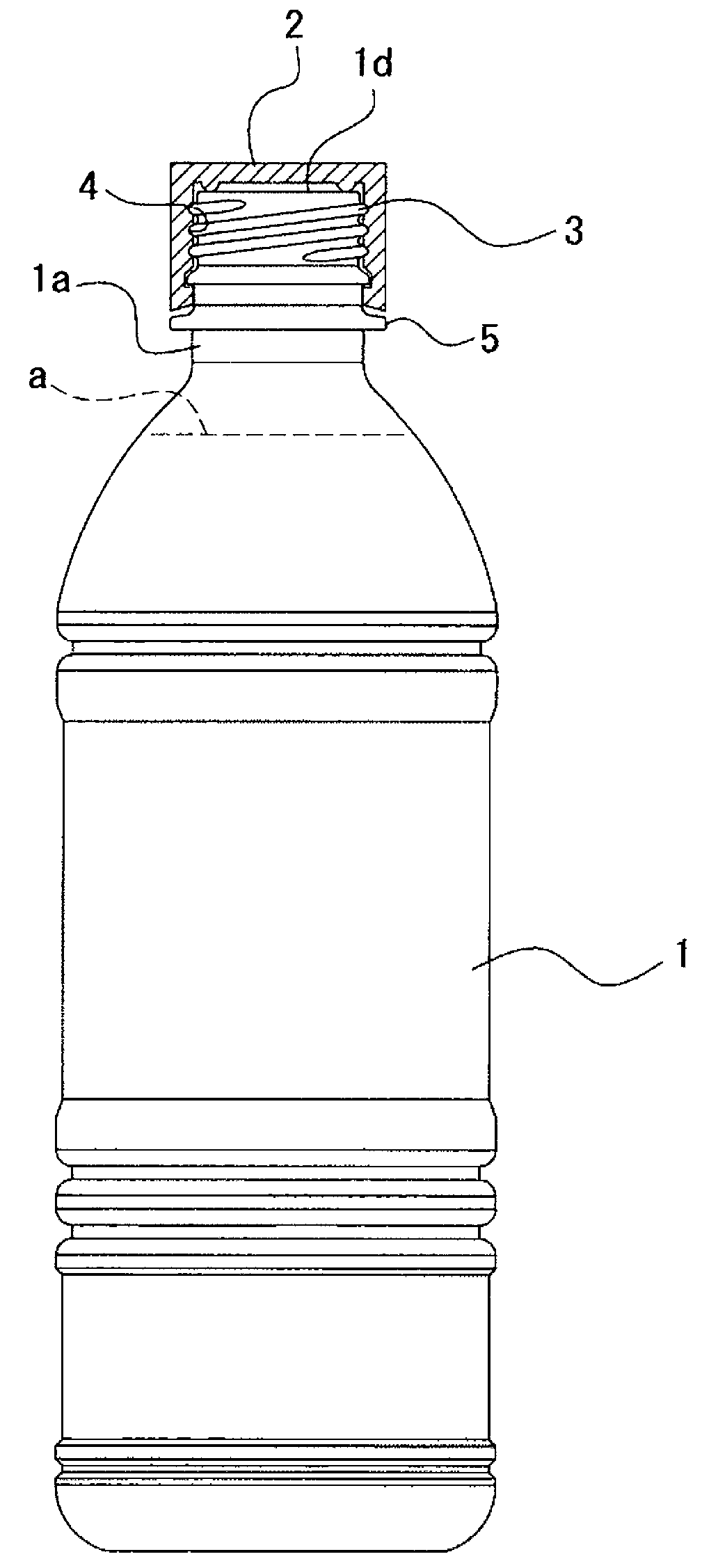

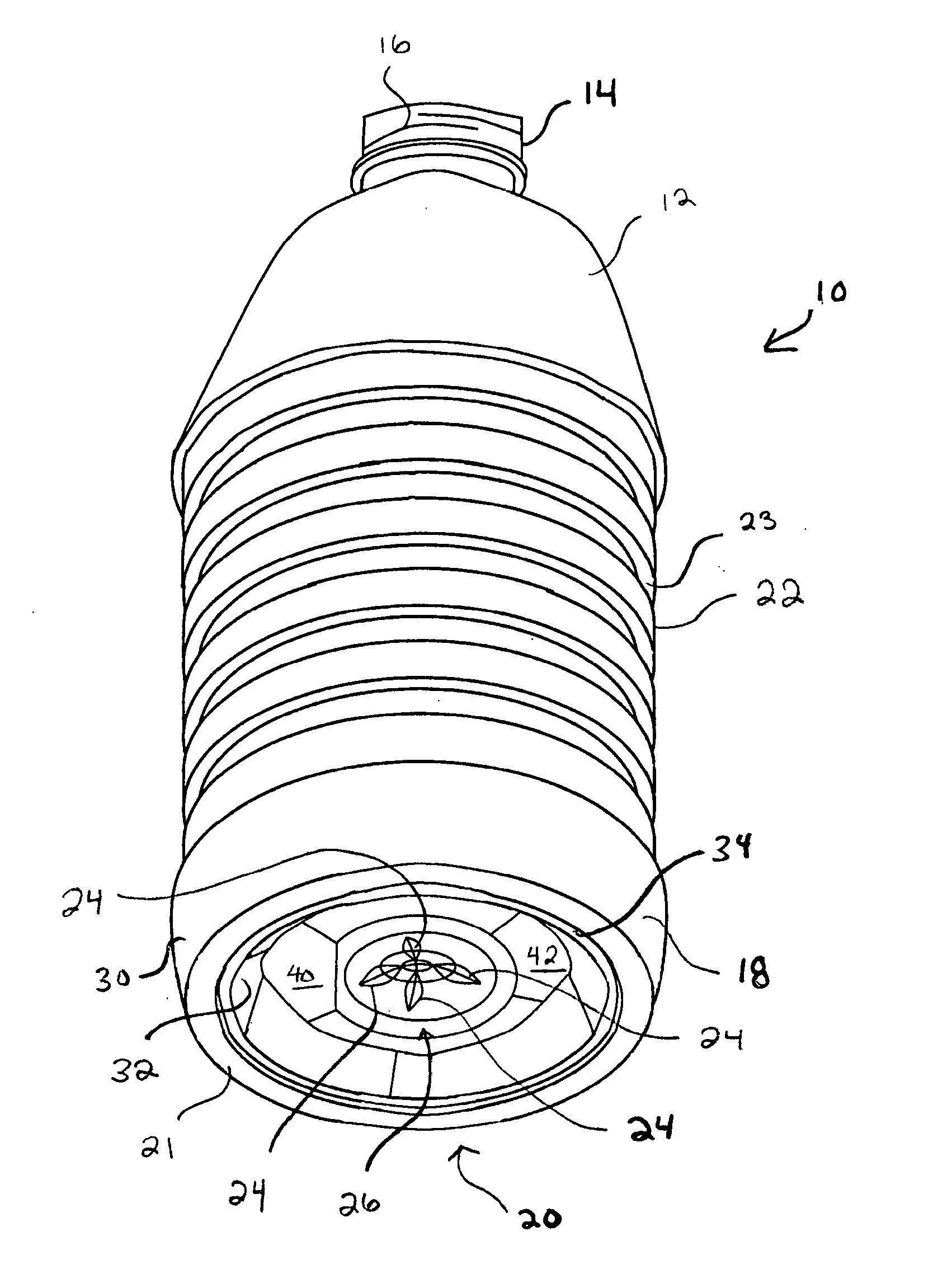

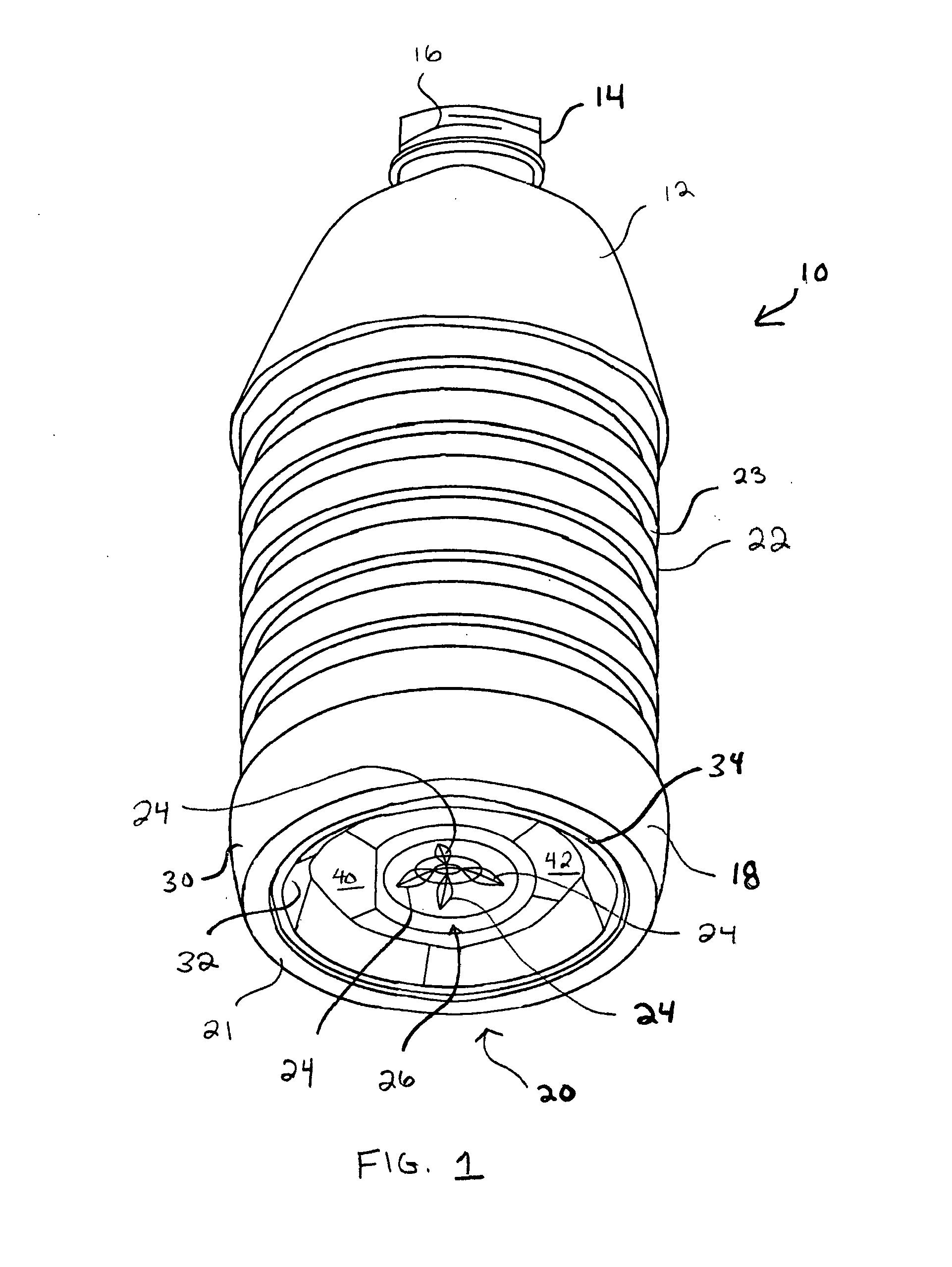

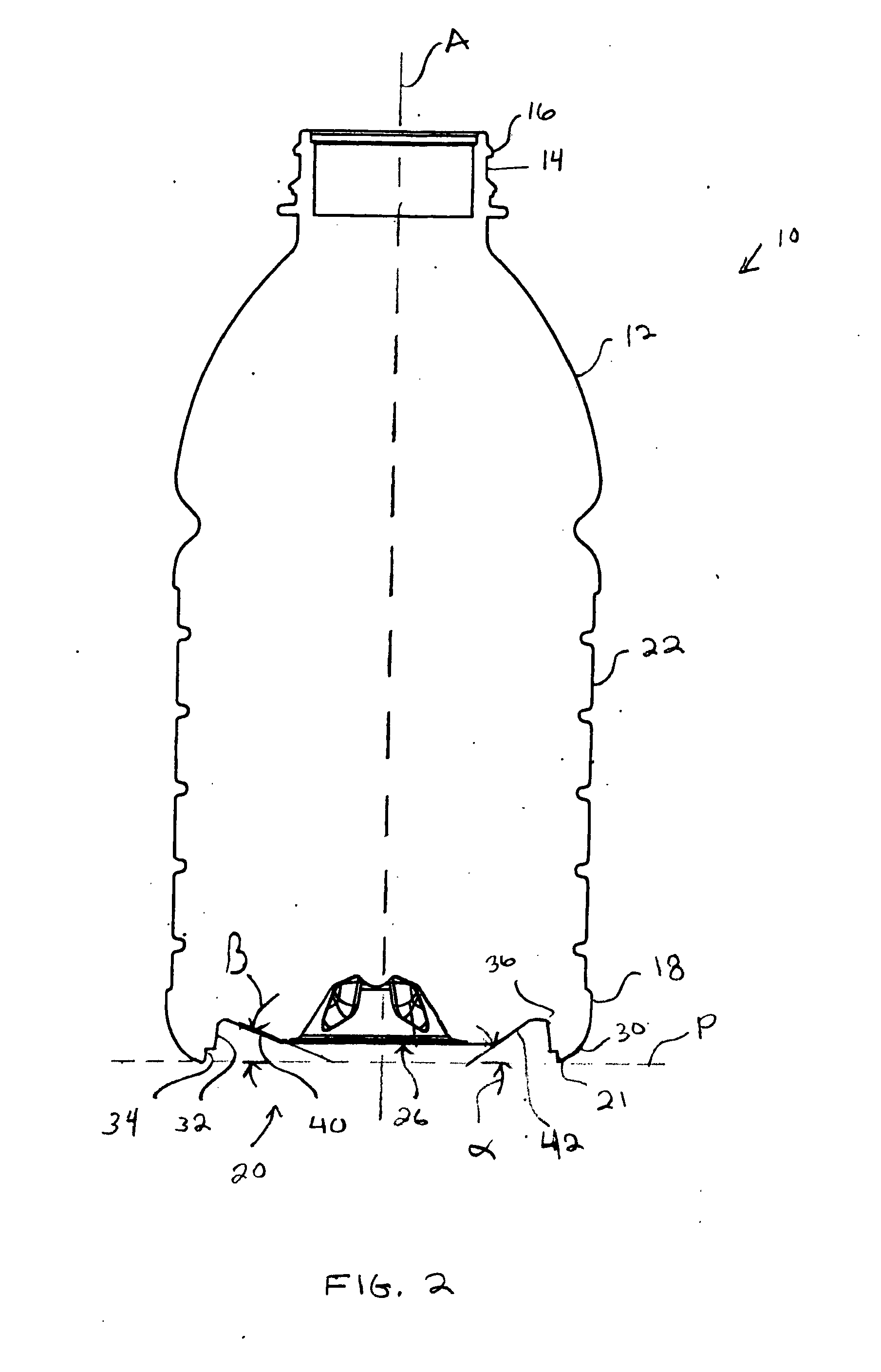

A system for processing a simplified plastic container (C) that is to be filled with a hot product includes the step of blow-molding parison to form a container body, where the container body has a neck, a base, a side surface relatively free of structural geometry that surrounds an interior of the container body and, prior to being filled with the hot product, a projection (12) extending from the container body. After the container body is filled with a hot product in a production line, the neck of the filled container body is capped with a cap and then, the container body is cooled. During the cooling operation, the hot product is contracted so that the projection extending from the container can be pushed (P) into the container body like a traditional push-up so that the resultant, filled and cooled container body is relatively free of structural geometry.

Owner:CO2 PAC

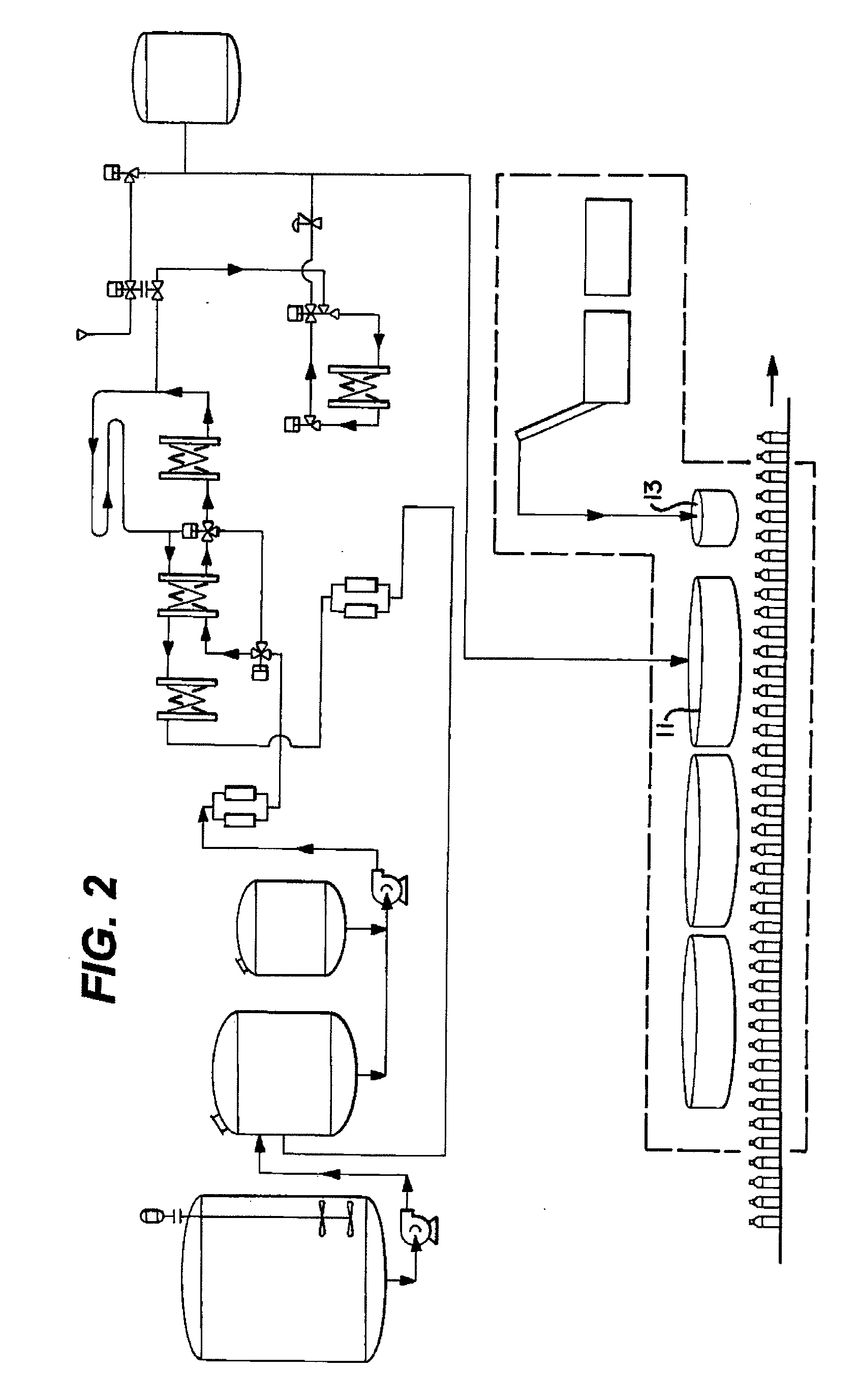

Method of treating at least one container in a container treatment plant

InactiveUS20120085071A1Simple and efficient mannerSynchronising machinesLiquid fillingEnvironmental engineeringPlant based

A method of treating at least one container in a container treatment plant, including marking at least one container with a marking, detecting the marking of the at least one container, selecting at least one container treatment machine of a container treatment plant and / or at least one operation setting of the at least one container treatment machine of the container treatment plant based on the detected marking, and treating the at least one container based on the selection of the at least one container treatment machine and / or the at least one operation setting.

Owner:KRONES AG

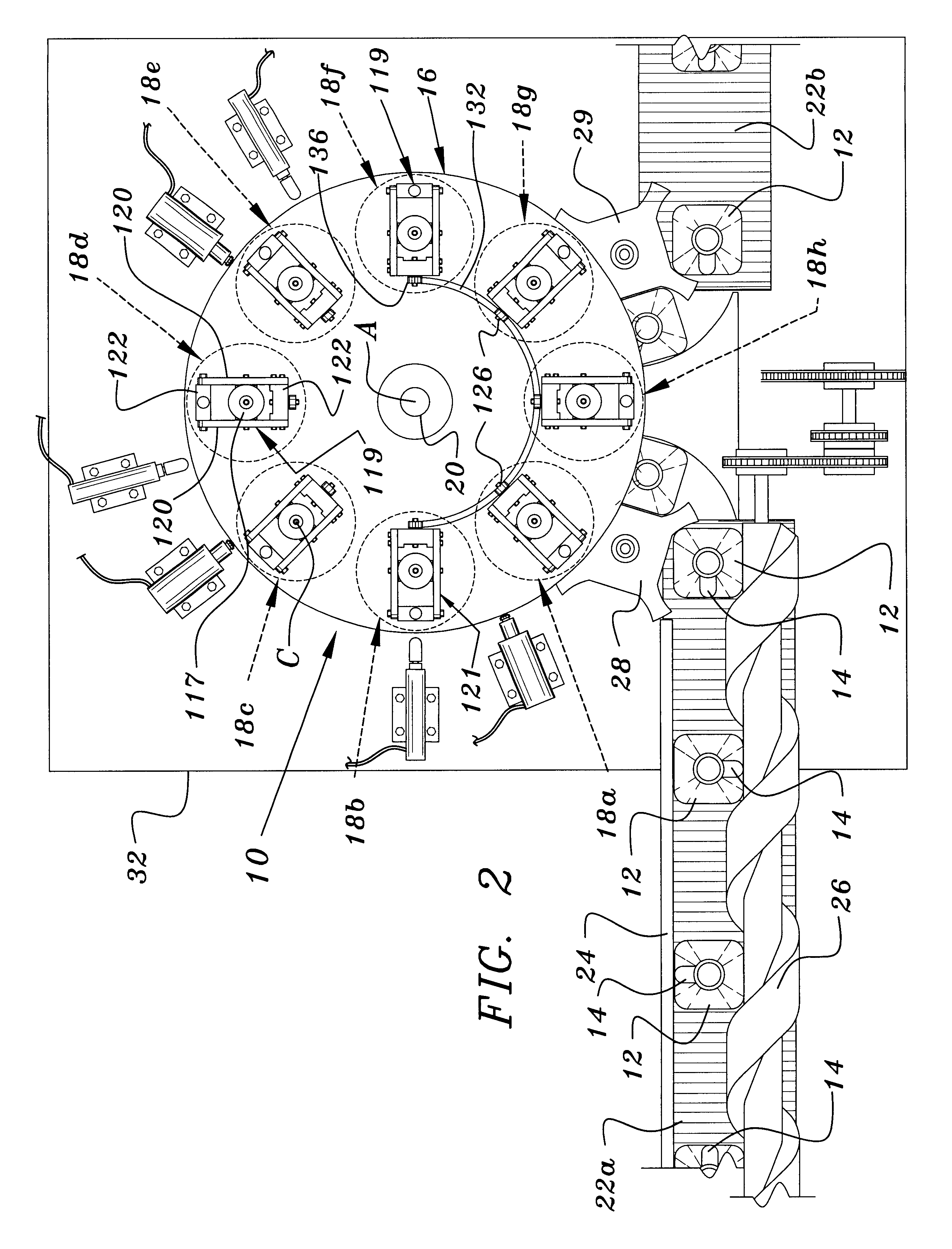

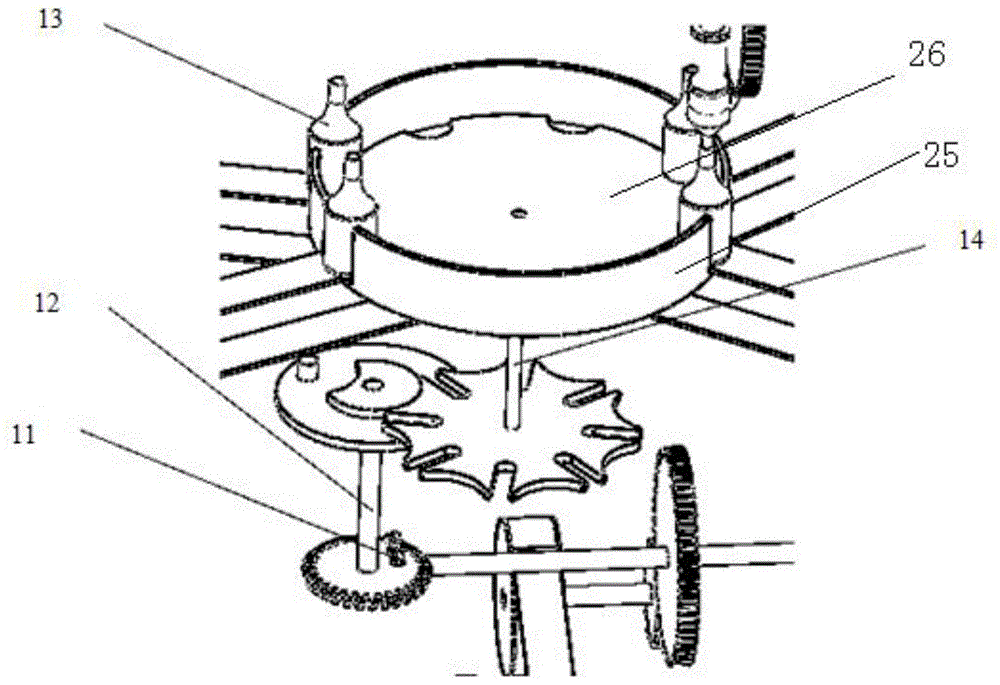

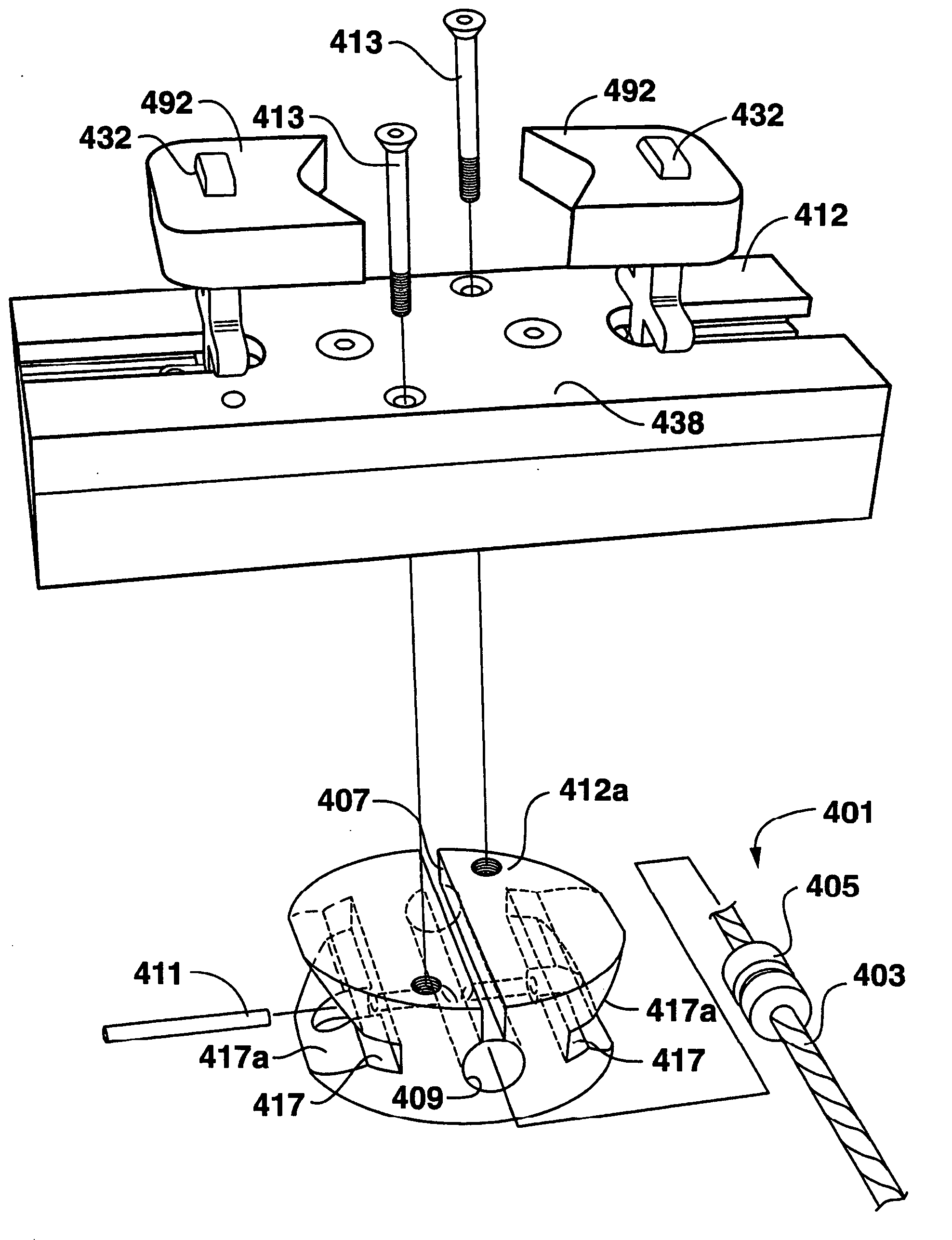

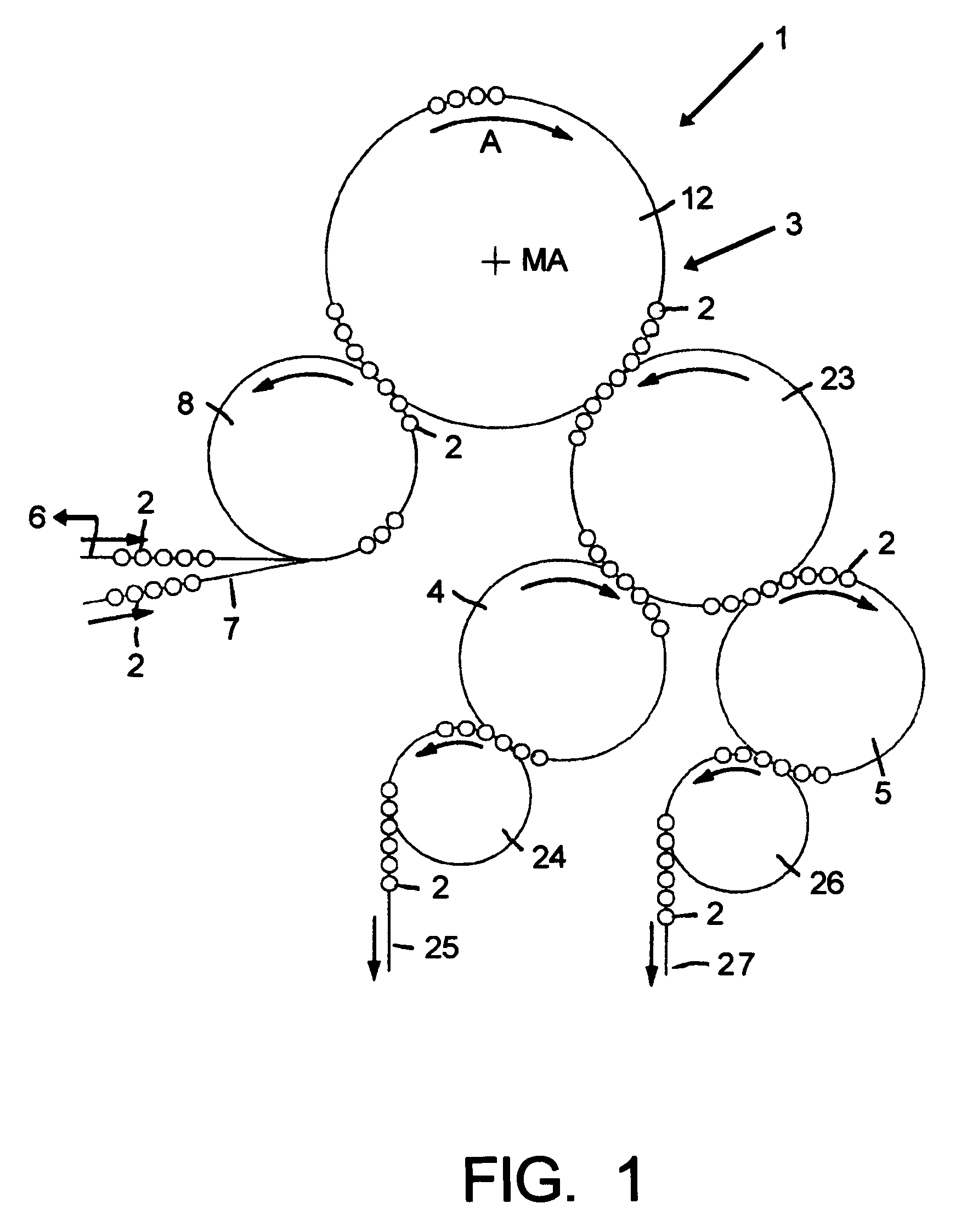

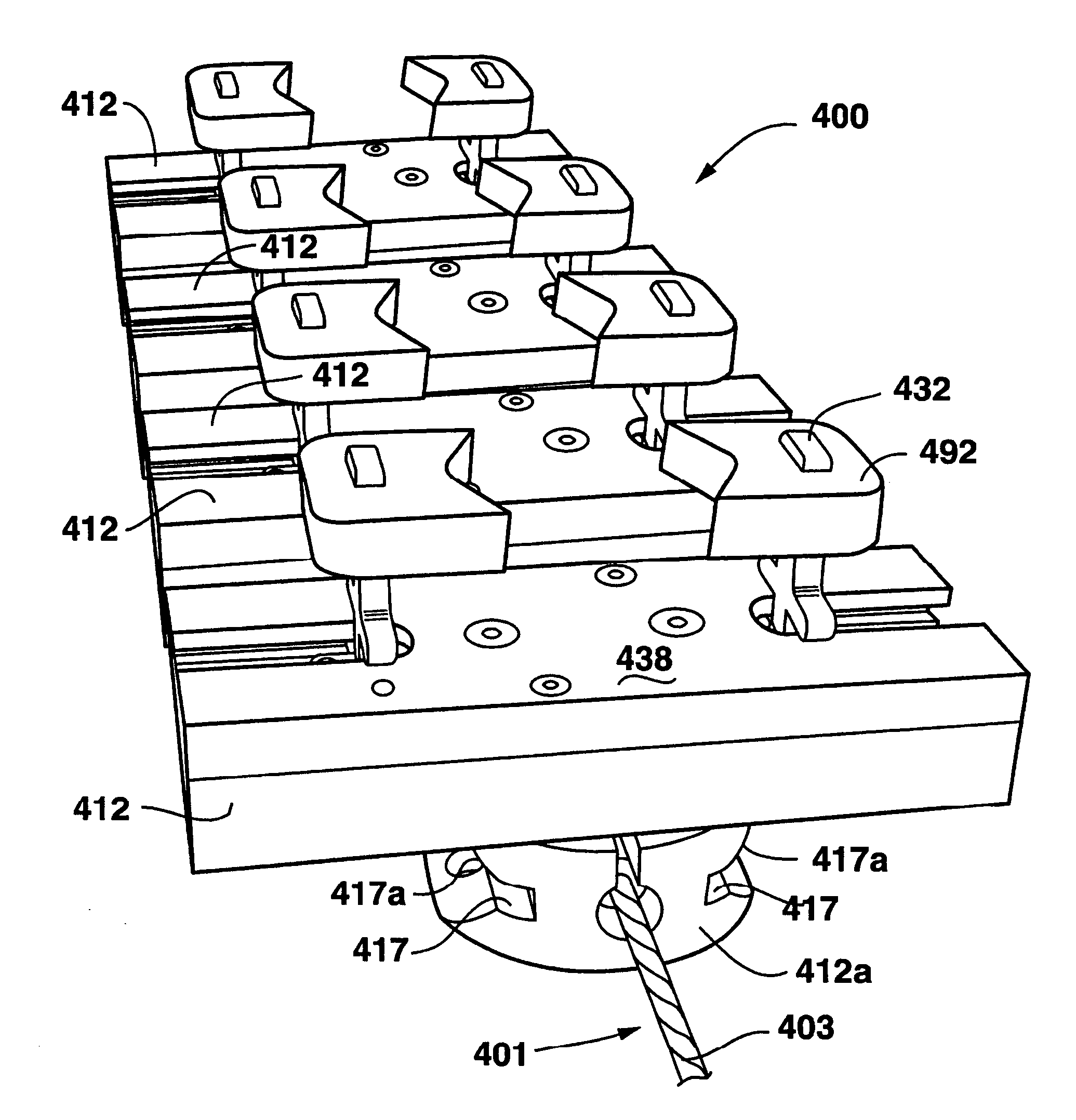

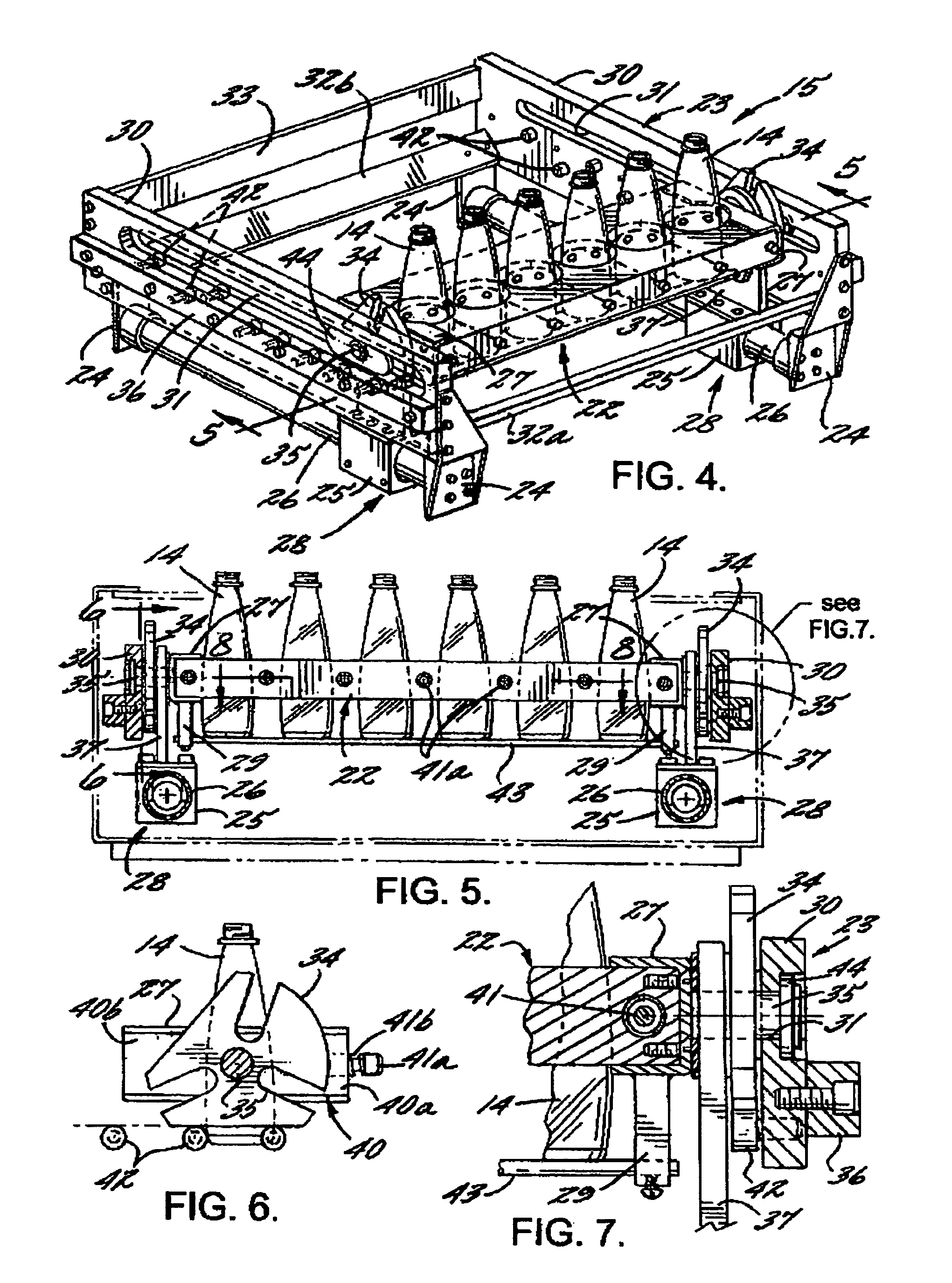

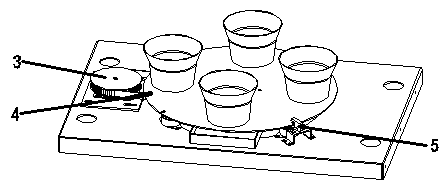

Rotary orienter indexing system

An indexing system for rotary orienters for positioning articles so that a feature of each article is facing in the same predetermined direction so that further operations may be accurately performed on the articles. The rotary orienter may be used in conjunction with filling, capping, labeling and inspection of containers, or other similar operations. The apparatus comprises a support frame to which is mounted a central column that is rotatable about its axis by a rotating means. The rotary orienter has at least one station that comprises a rotatable spindle to which a turntable is attached to one end and an indexing assembly is attached proximal the other end. The indexing assembly comprises a slip clutch and a means for rotating the spindle that is mounted proximal the second of the spindle. An indexing wheel, that has at least two detents formed therein, is mounted on the spindle intermediate the turntable and the slip clutch. The first end of an arm is pivotally mounted to the support frame and the arm is engageable with the detents of the indexing wheel so that when it is so engaged the indexing wheel and the spindle is prevented from rotating with the means for rotating the spindle. An actuator is connected to the support frame so that when it engages the arm, the arm disengages from one of the detents, thereby allowing the turntable to rotate until the arm is released by the actuator and the arm engages the other one of the detents.

Owner:NEW ENGLAND MACHINERY

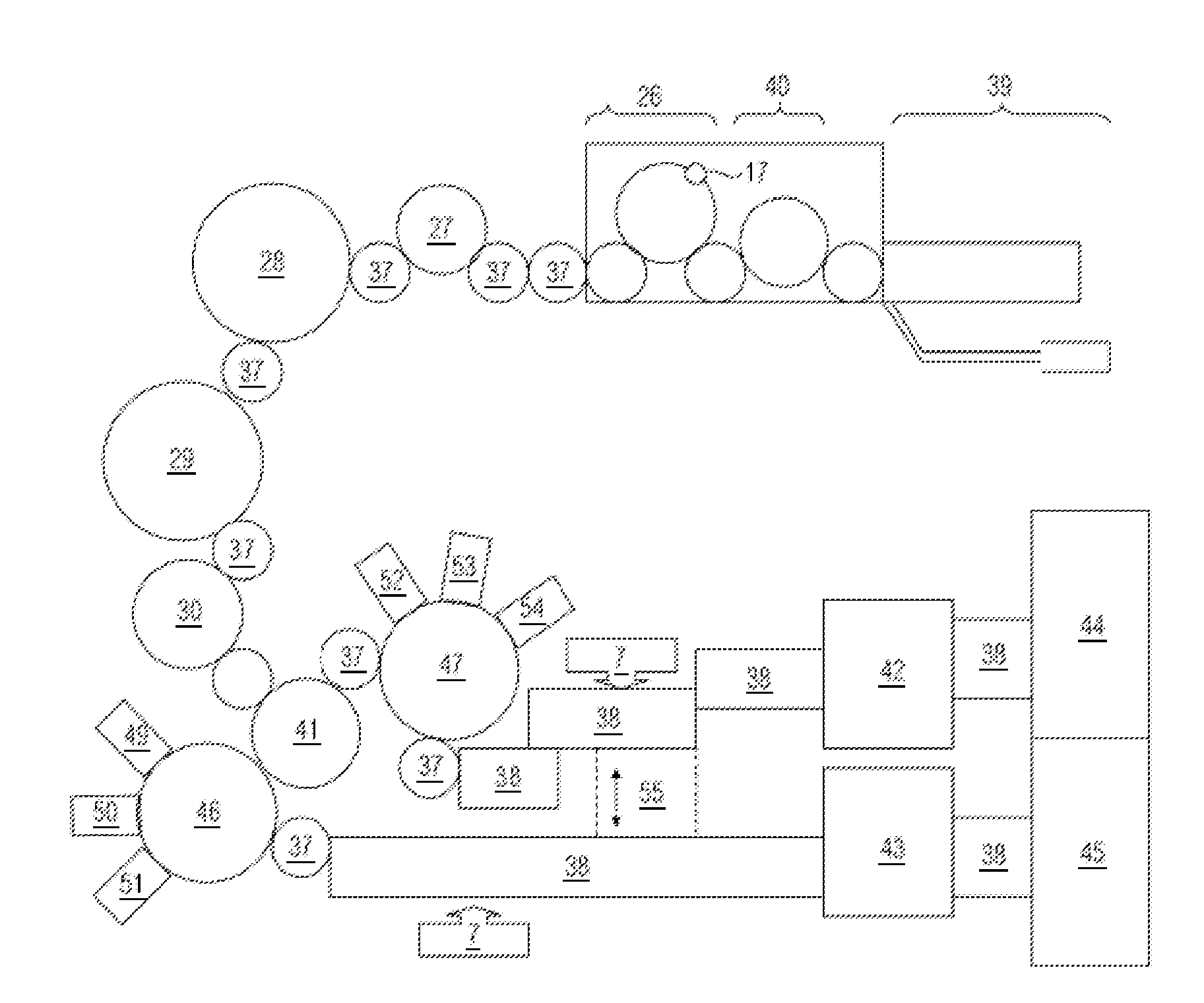

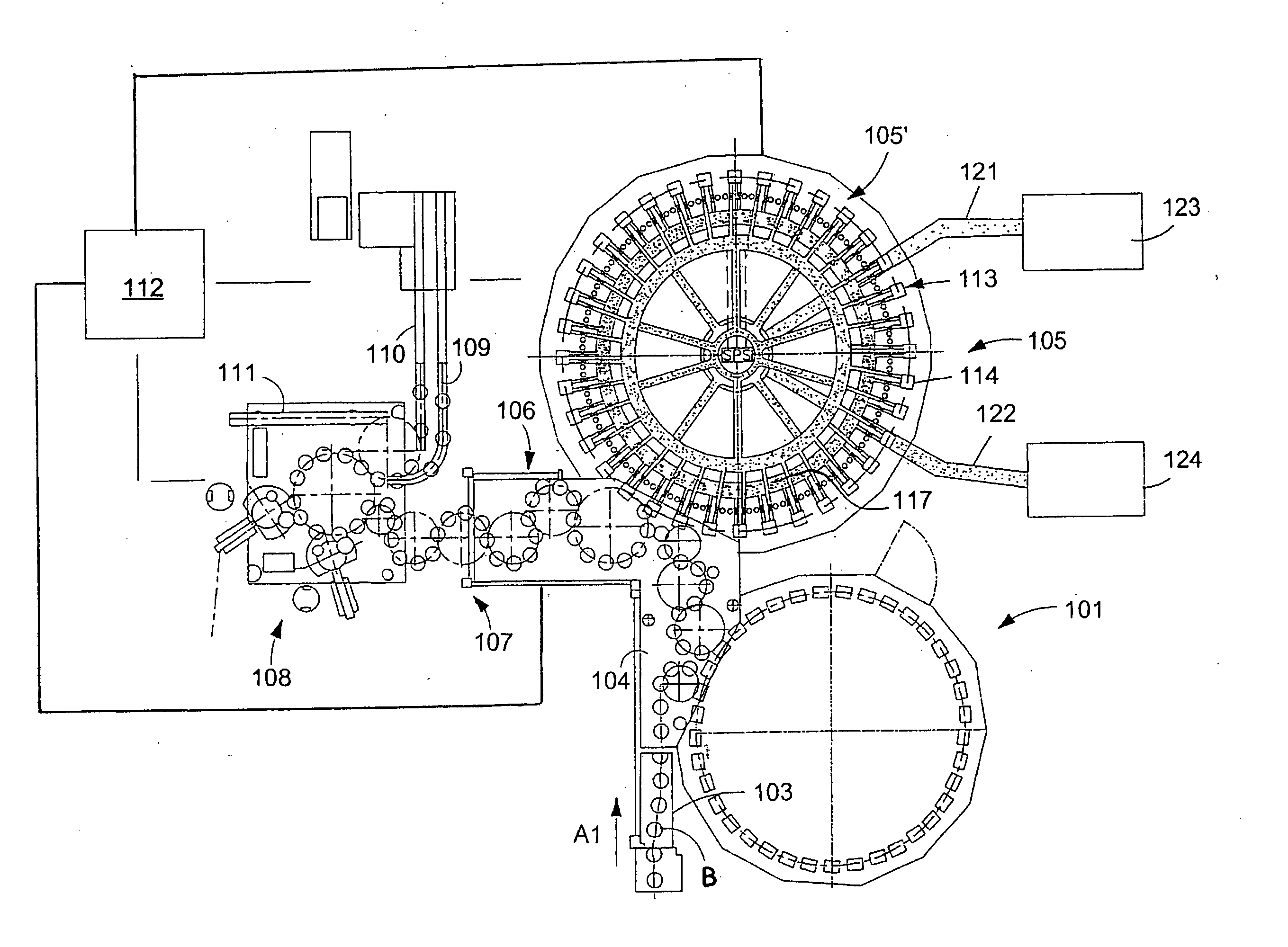

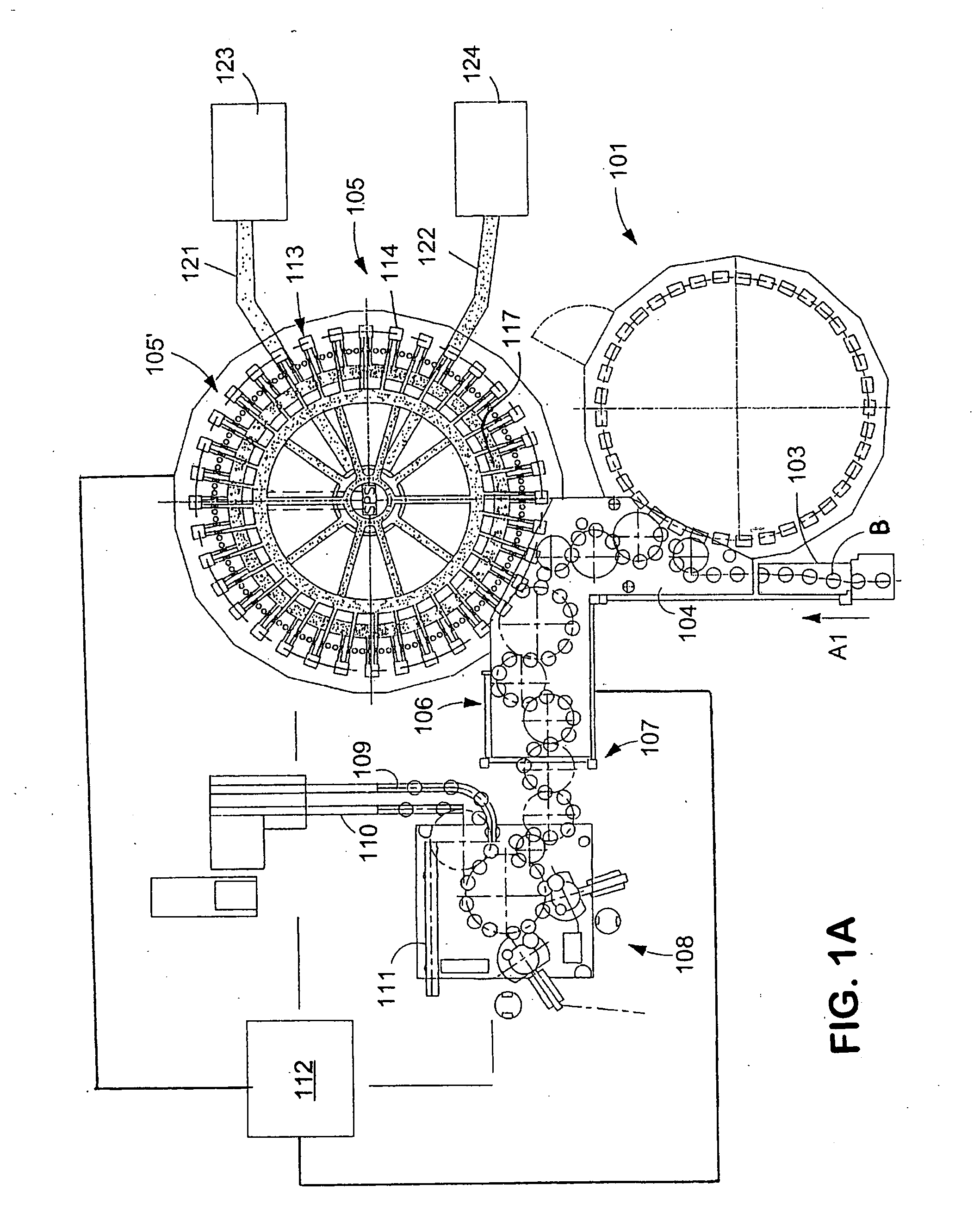

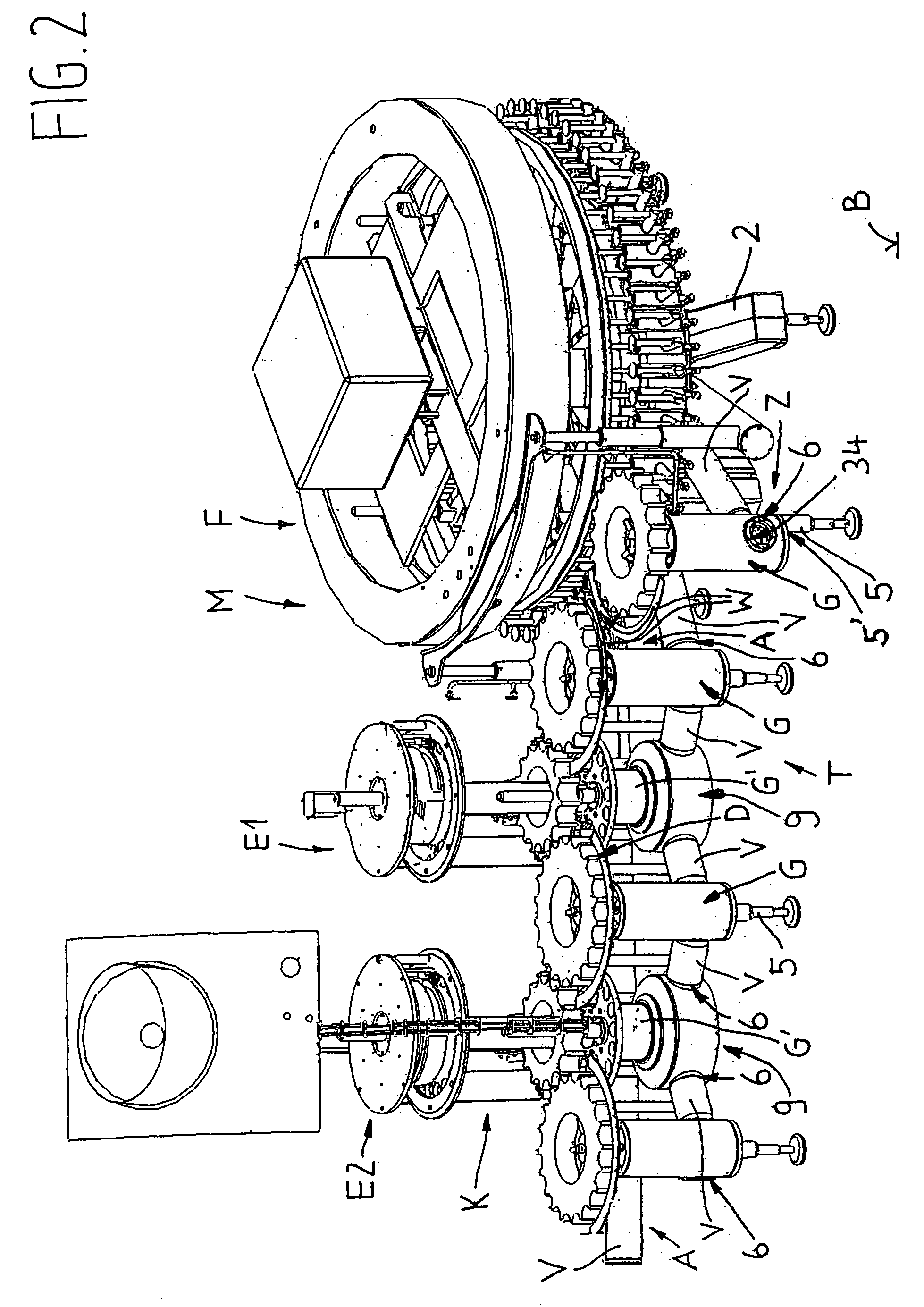

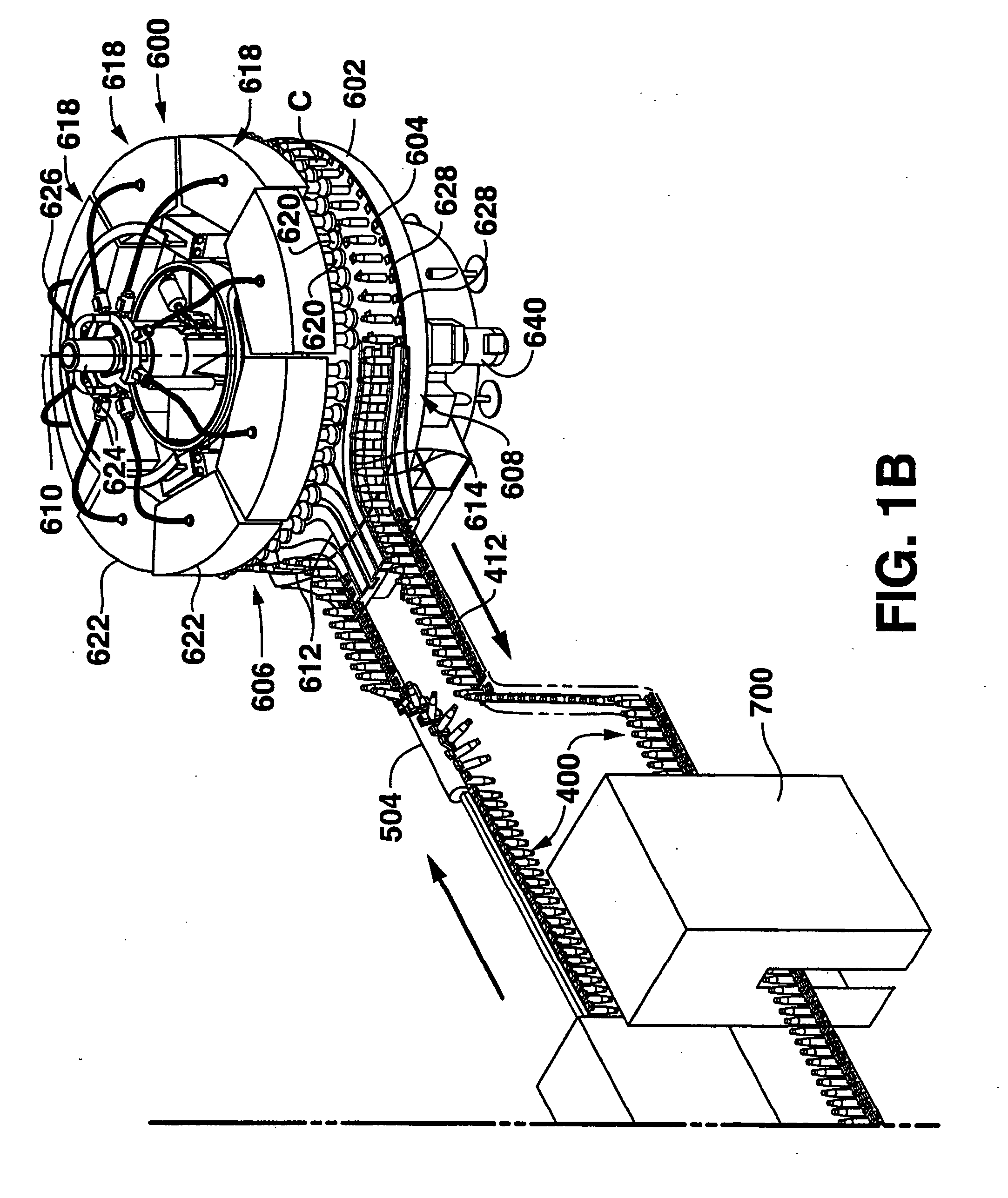

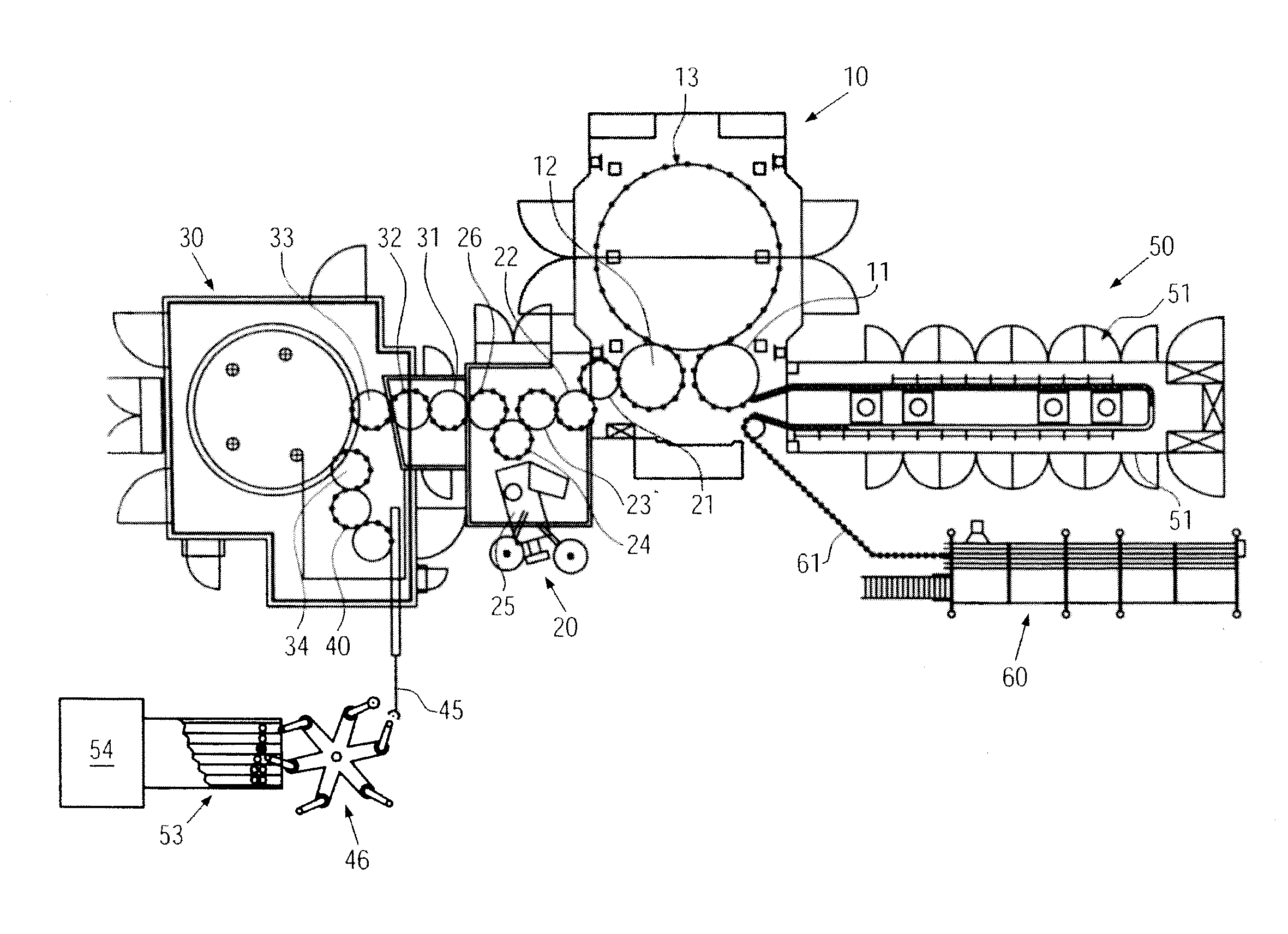

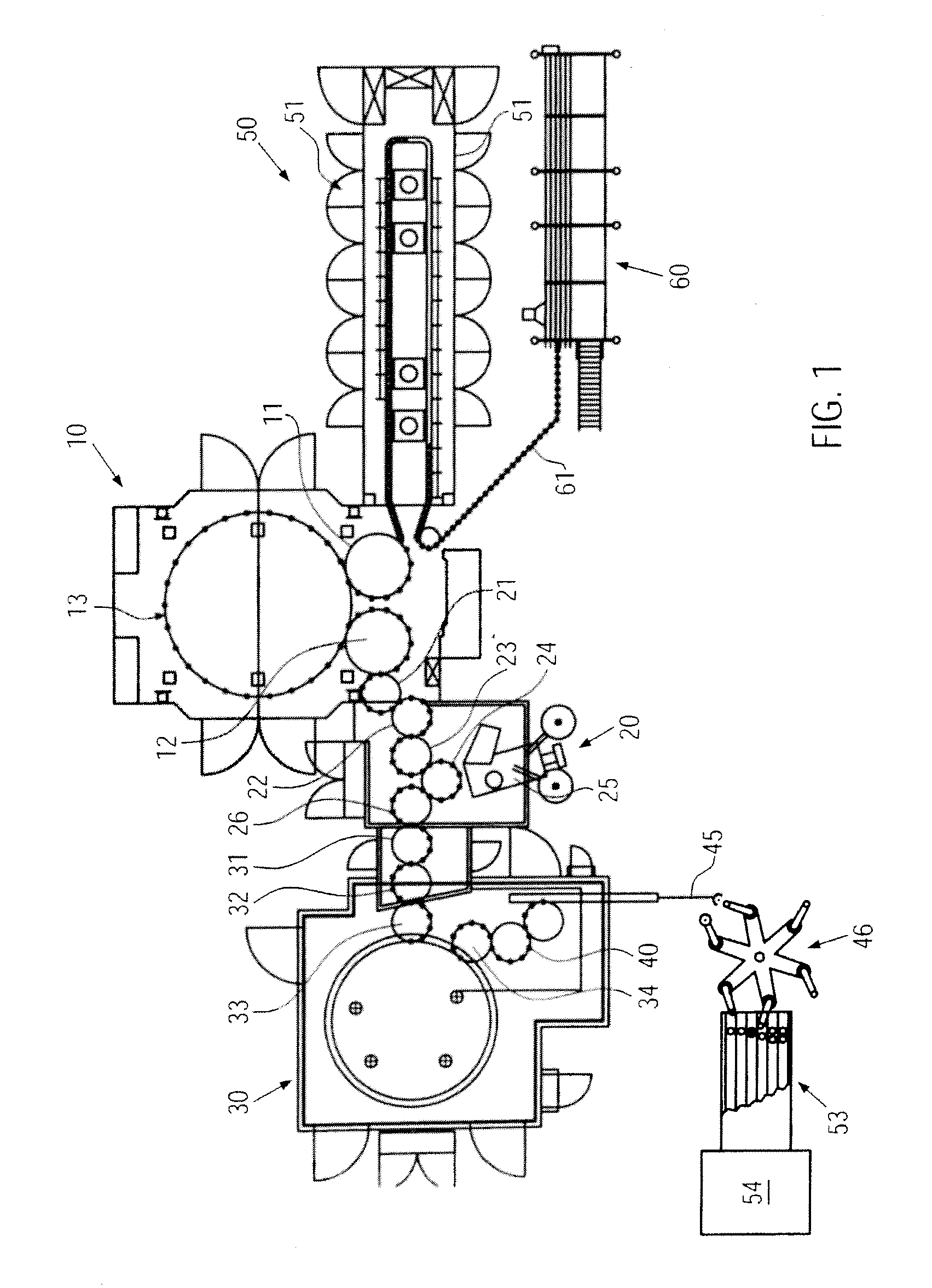

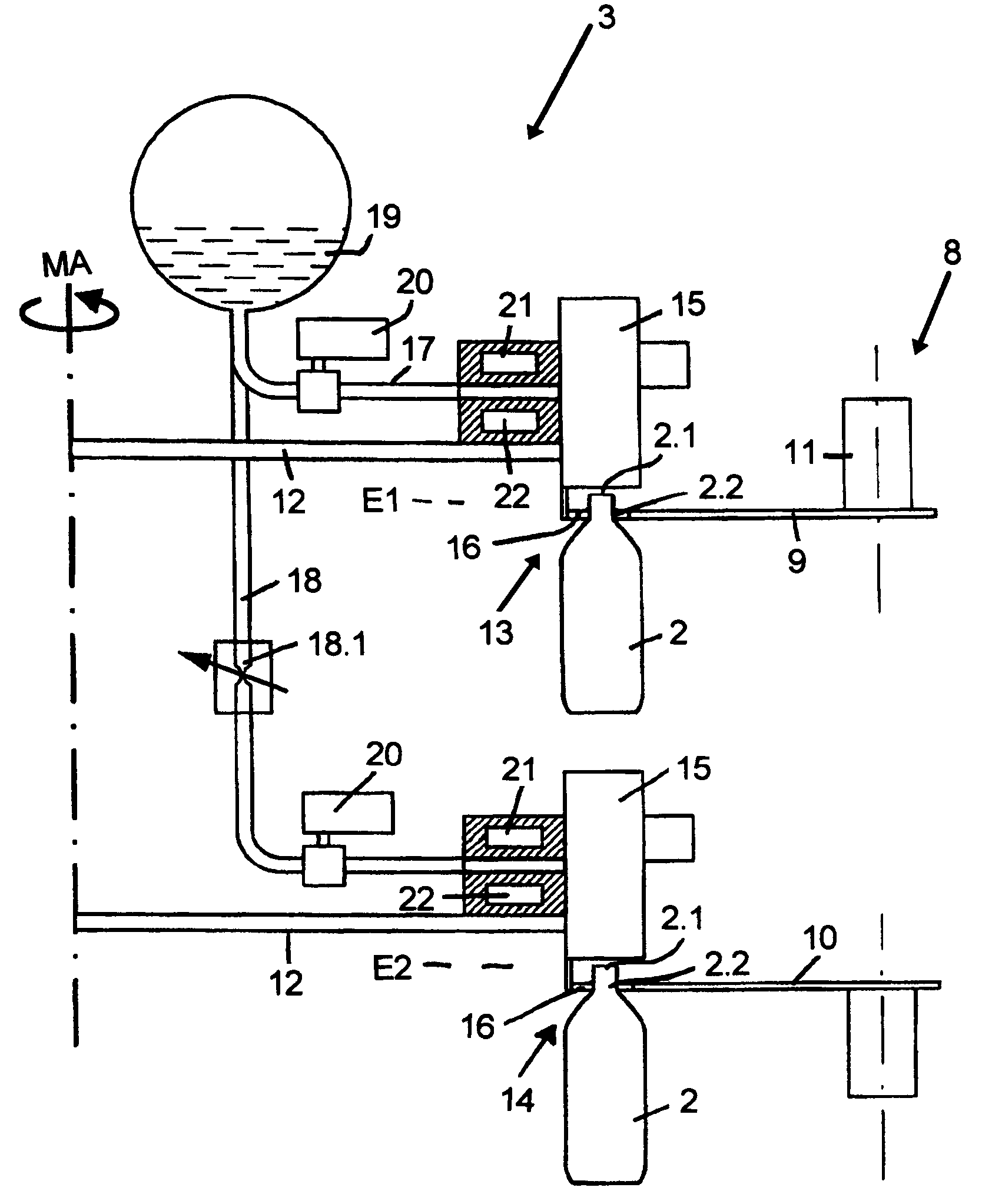

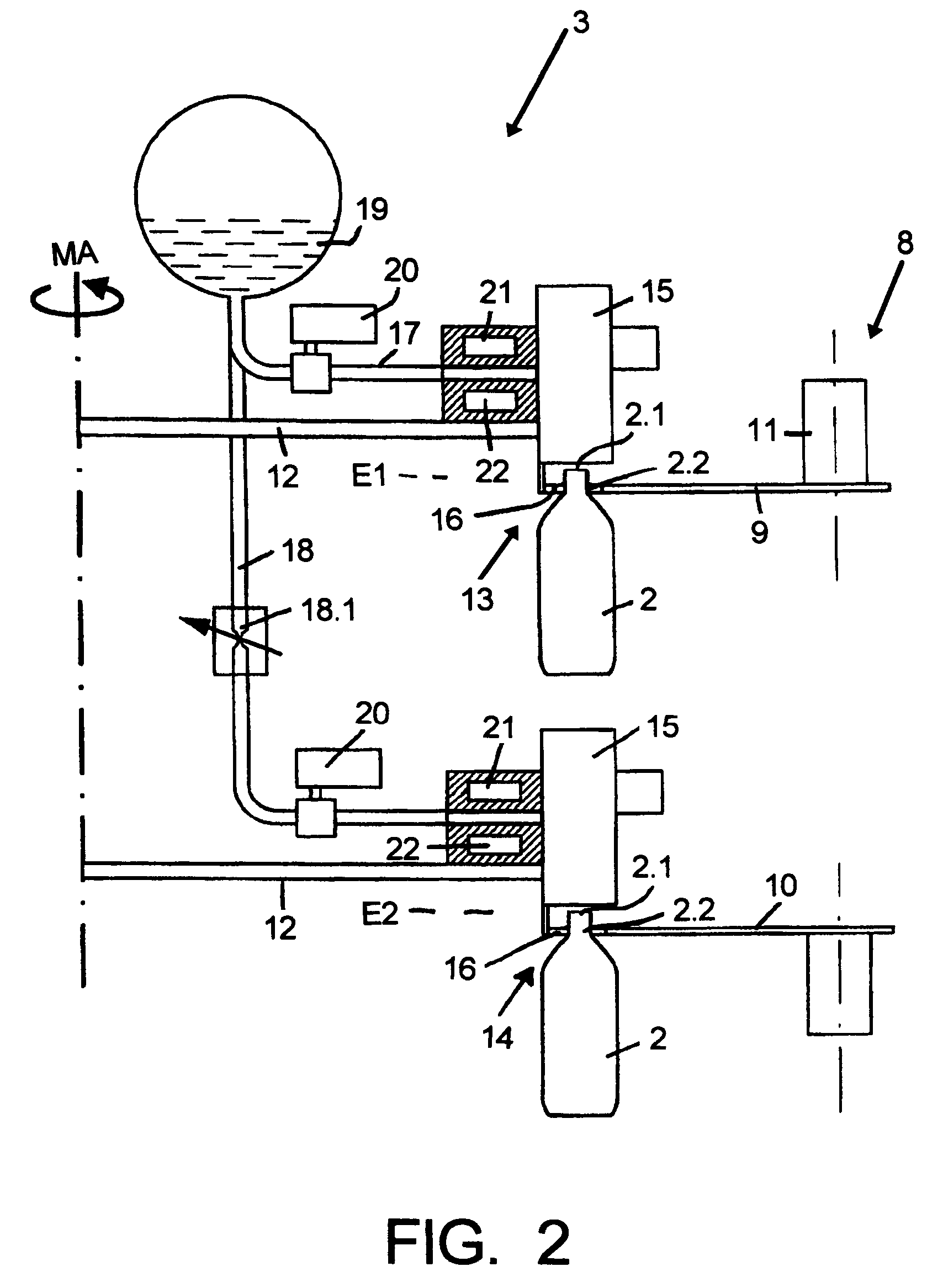

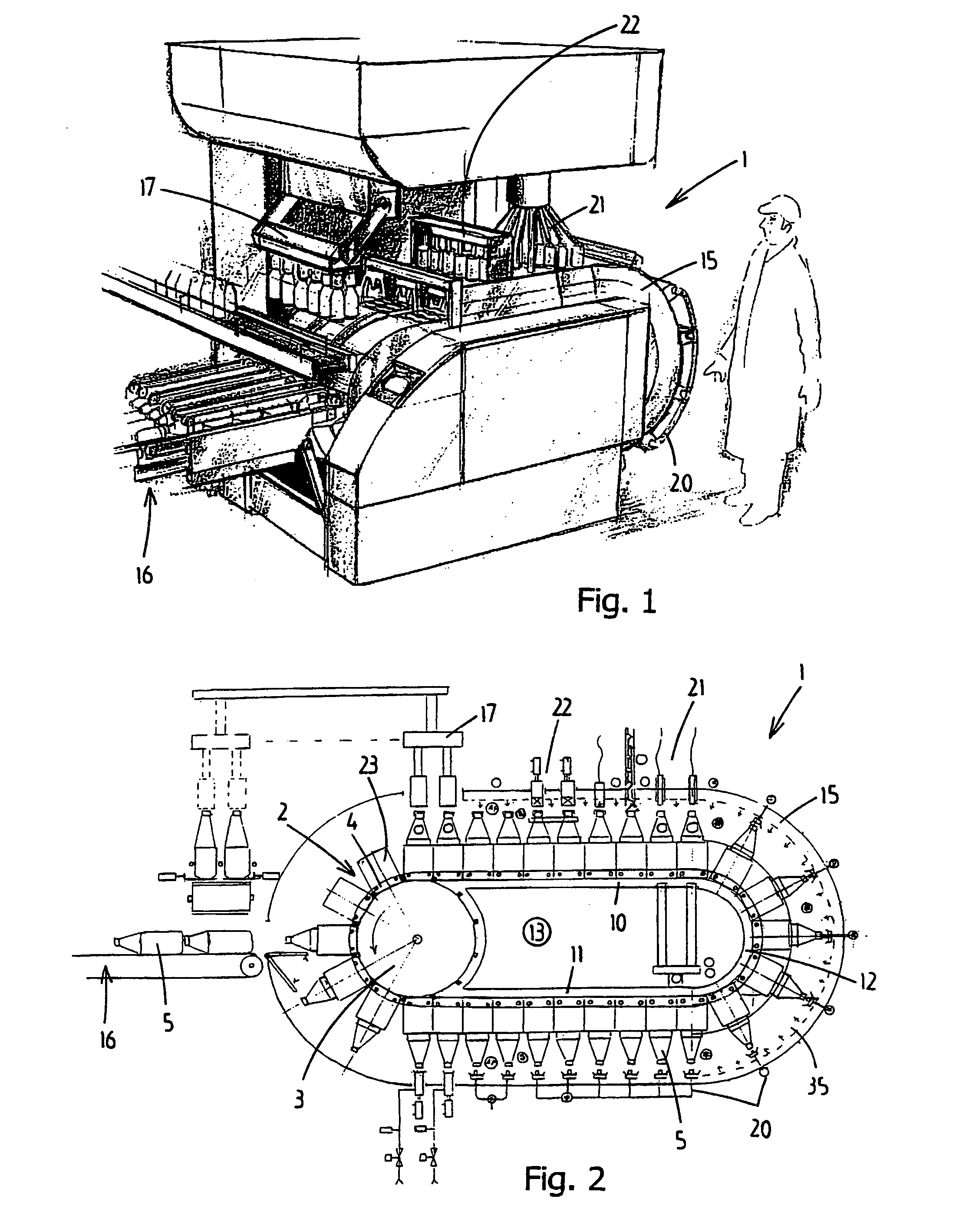

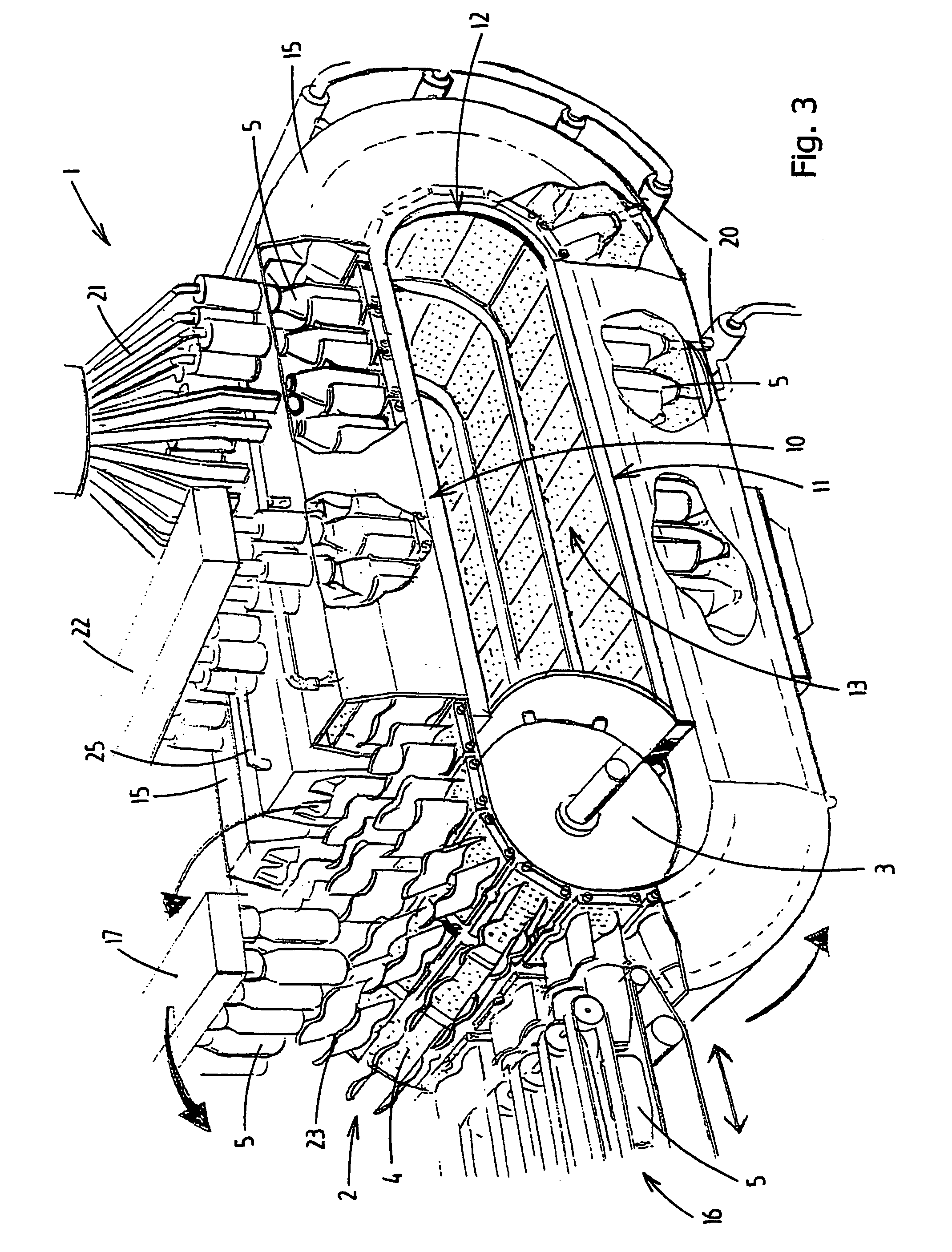

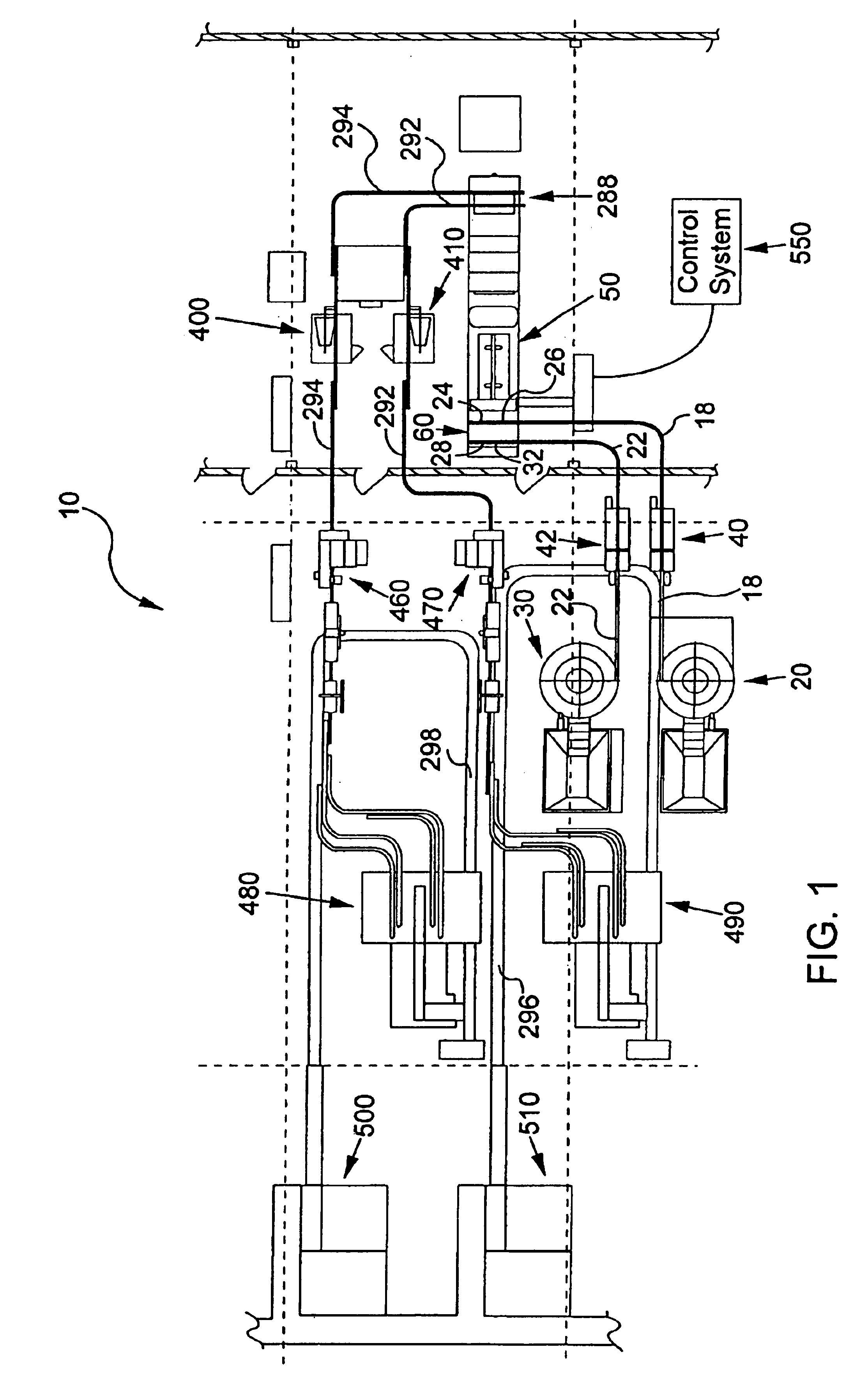

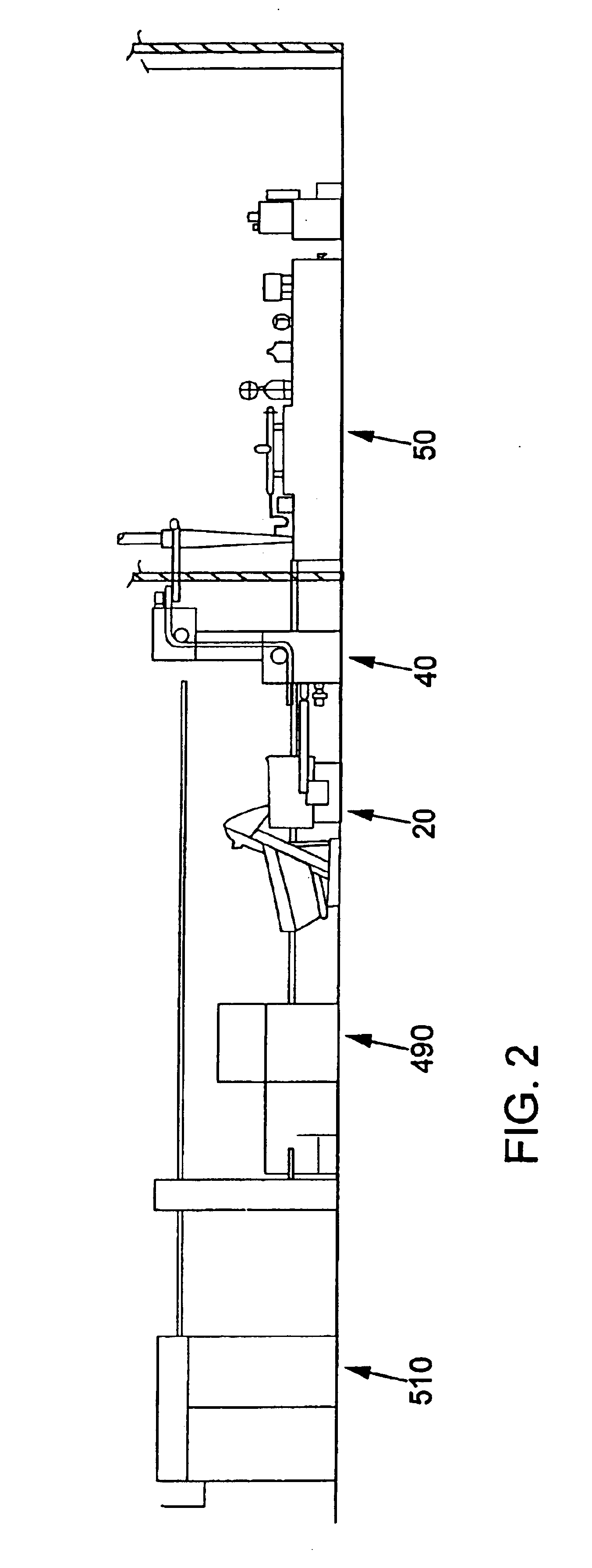

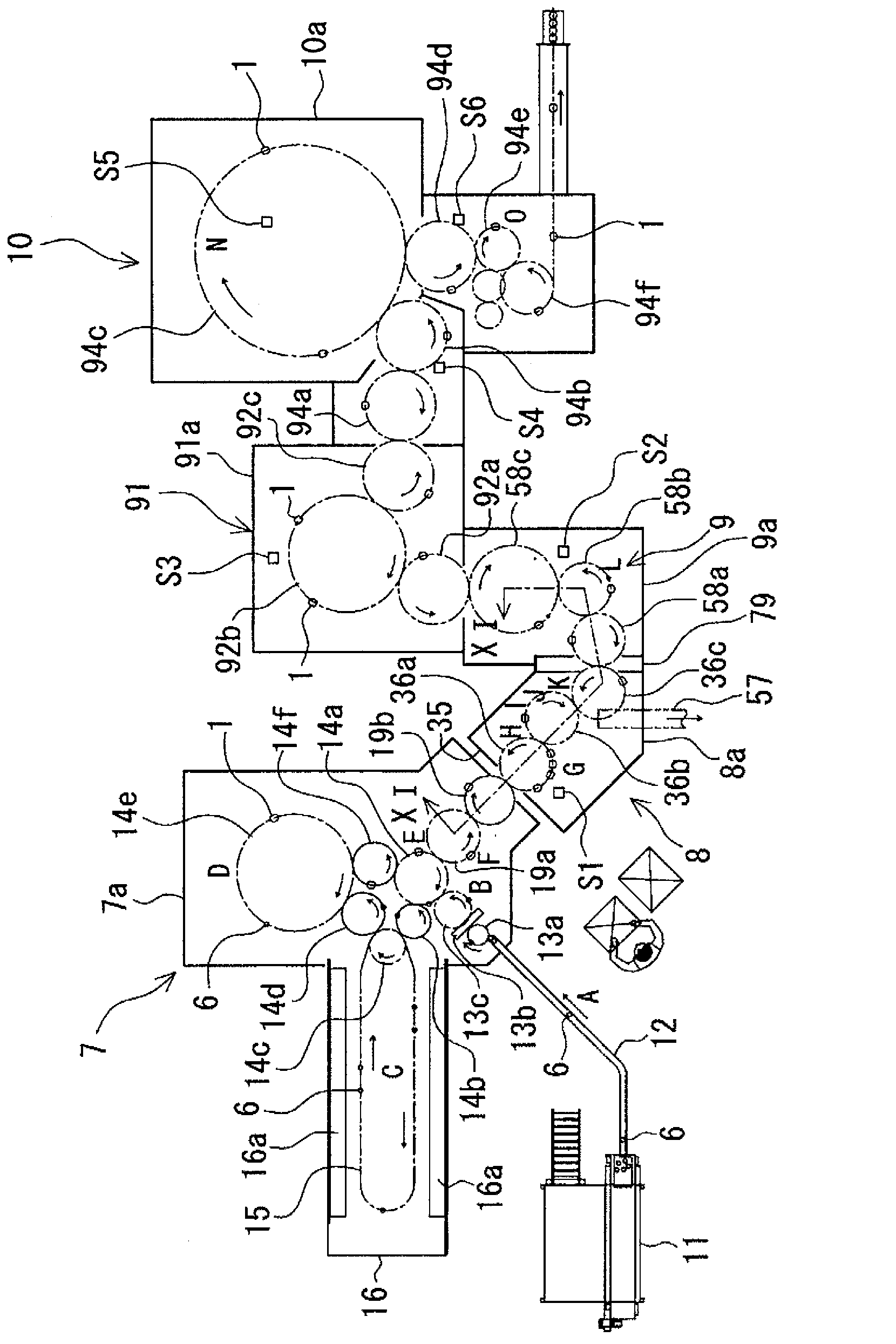

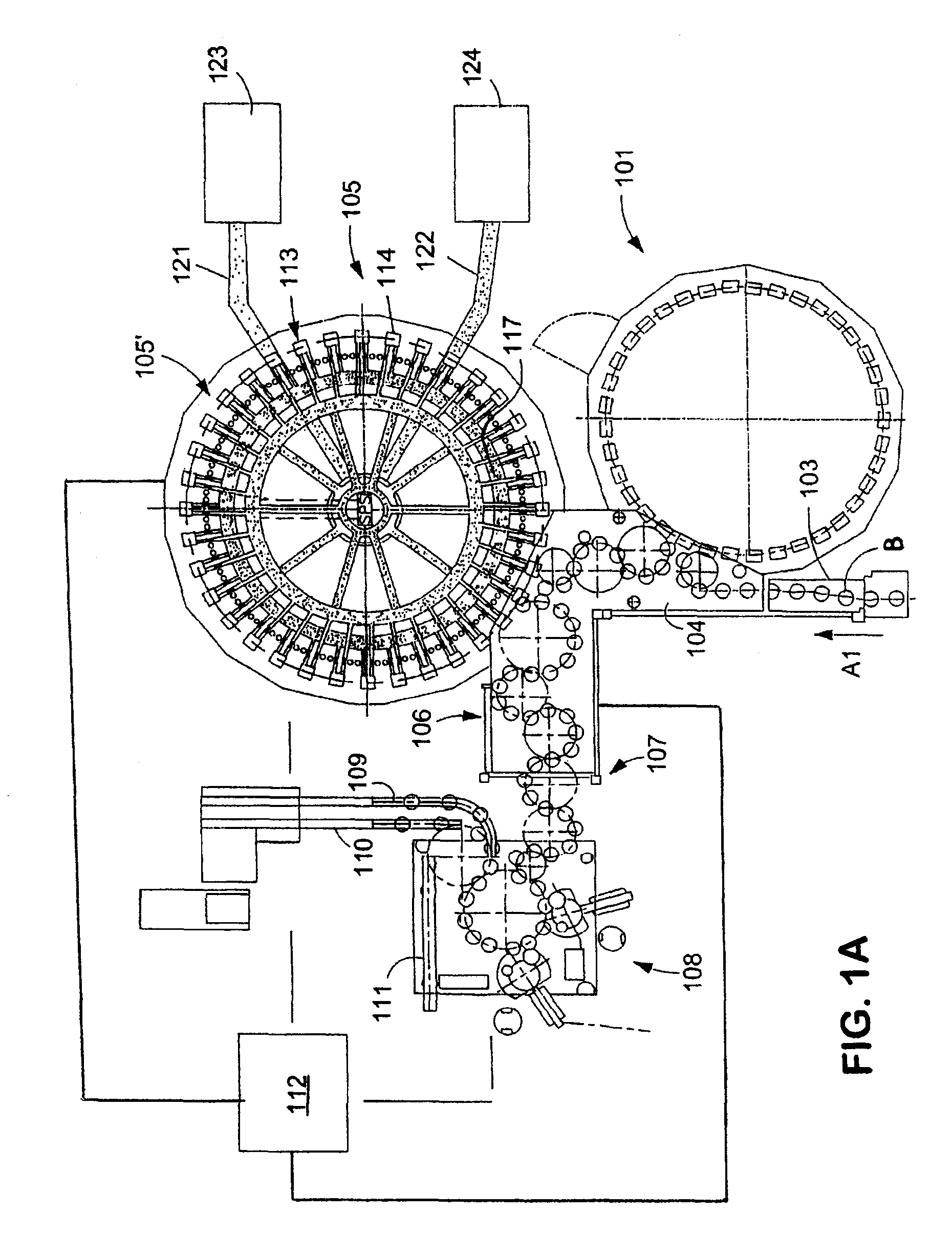

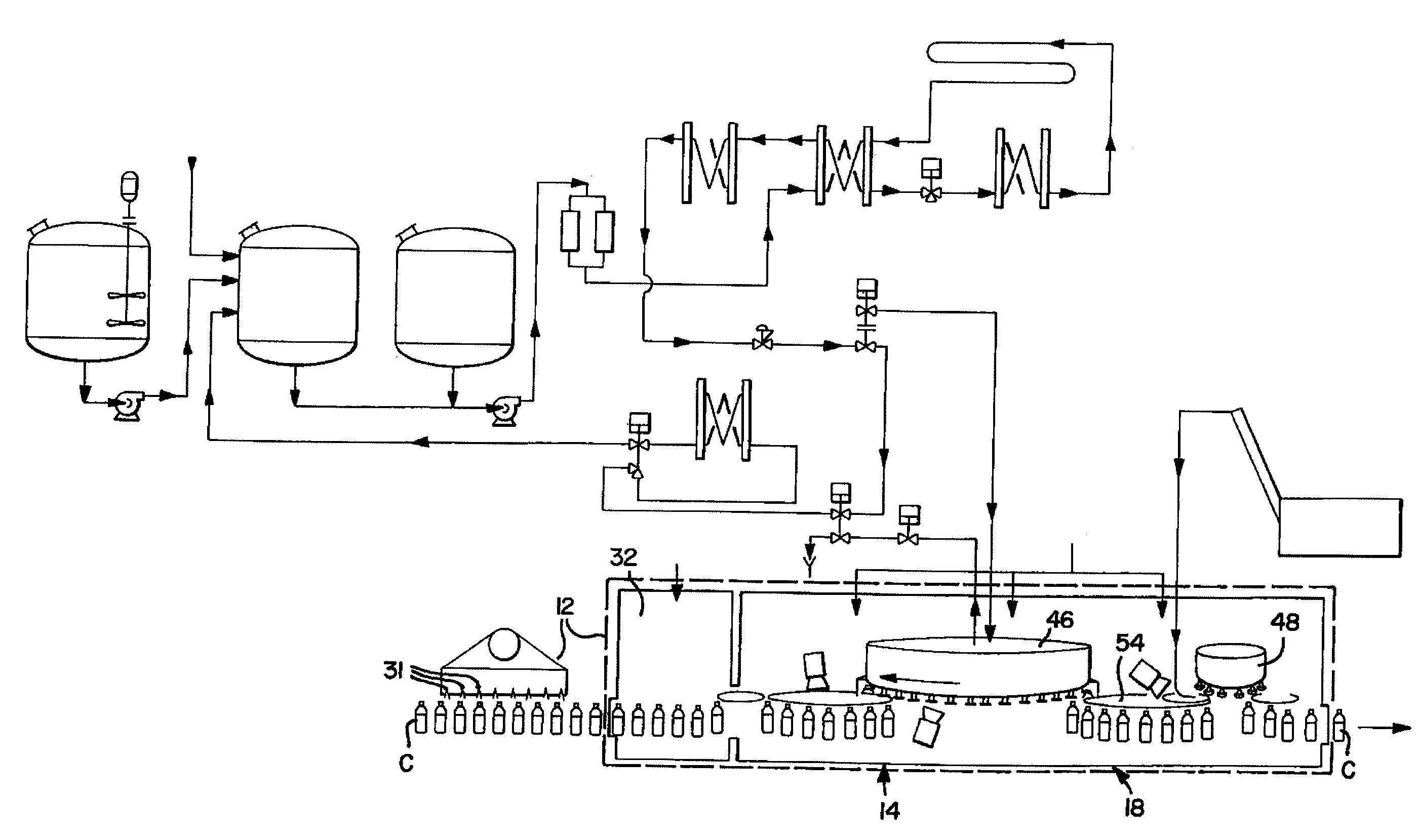

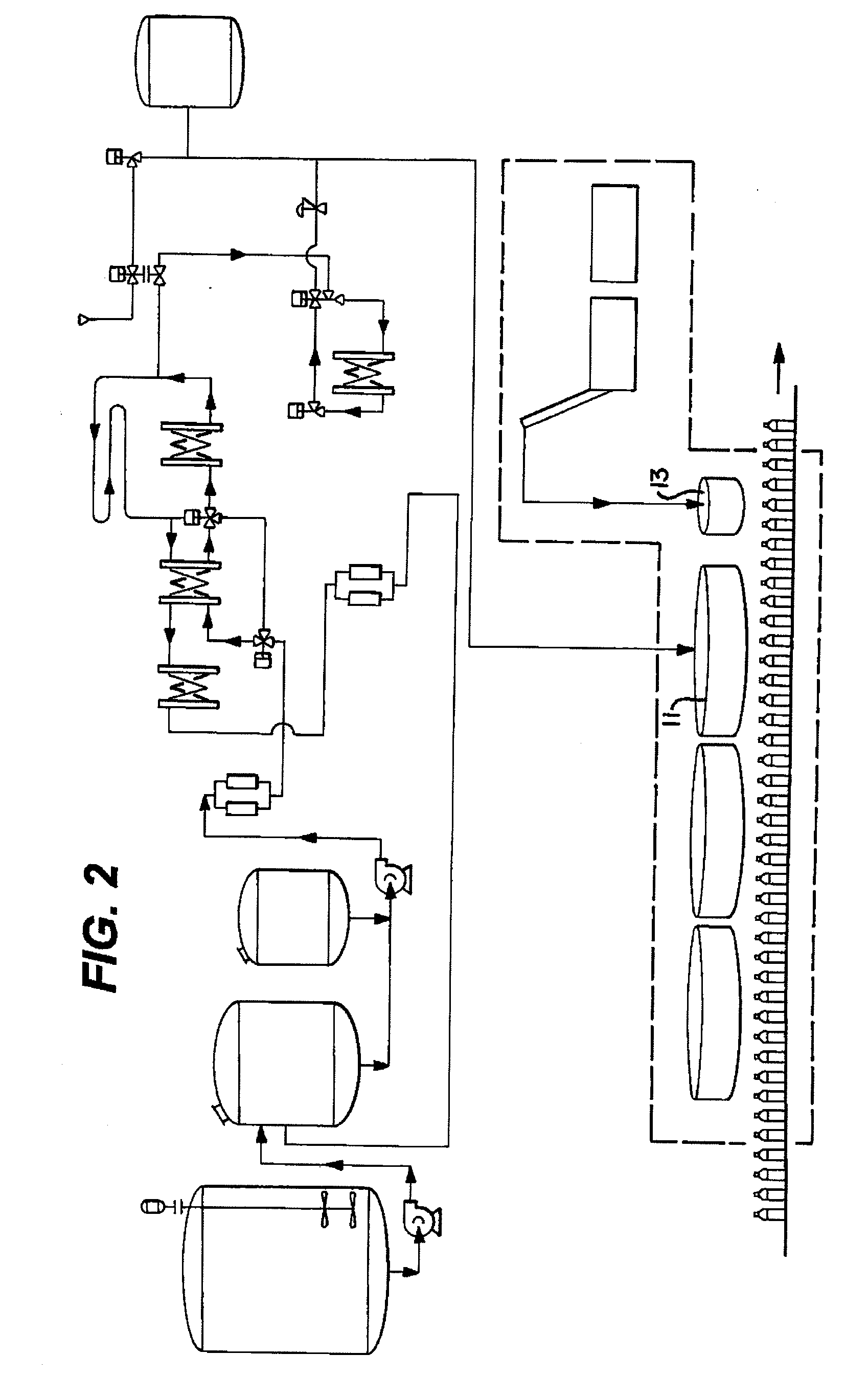

Container filling plant, such as a beverage bottling plant, for filling containers with a liquid beverage and for closing filled containers

Container filling plant, such as a beverage bottling plant, for filling containers with a liquid beverage and for closing filled containers. The abstract of the disclosure is submitted herewith as required by 37 C.F.R. §1.72(b). As stated in 37 C.F.R. §1.72(b): “A brief abstract of the technical disclosure in the specification must commence on a separate sheet, preferably following the claims, under the heading “Abstract of the Disclosure.” The purpose of the abstract is to enable the Patent and Trademark Office and the public generally to determine quickly from a cursory inspection the nature and gist of the technical disclosure. The abstract shall not be used for interpreting the scope of the claims.” Therefore, any statements made relating to the abstract are not intended to limit the claims in any manner and should not be interpreted as limiting the claims in any manner.

Owner:KHS GMBH

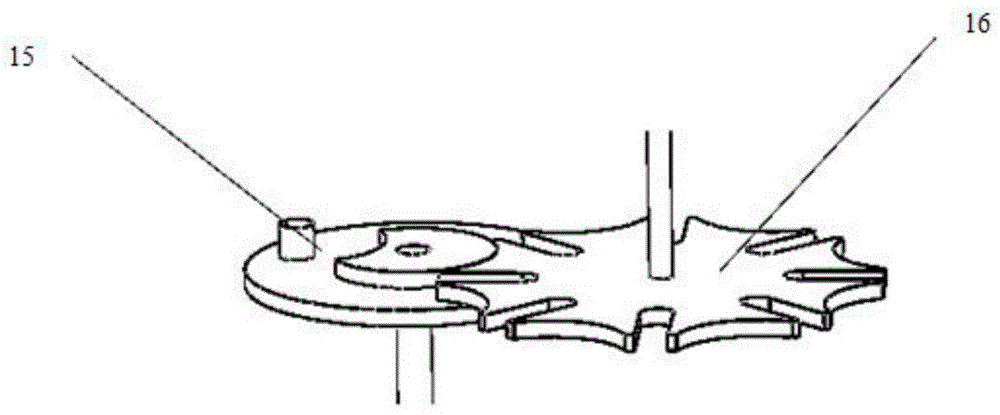

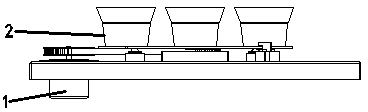

Rotary orienter dual indexing system

A dual indexing system for rotary orienters for positioning articles so that a feature of each article is facing in the same predetermined direction. The invention comprises a turret having at least one station that is connected to the turret column and rotates therewith as the column rotates about its axis. The station comprises a spindle with a driven turntable attached to support the bottom of an article and a shaft with a driven platen attached to hold the top of the article, the spindle and the shaft being rotatable about their longitudinal axes, which are coincident. A lower indexing assembly and an upper indexing assembly initiate simultaneous rotation of their respective turntable and platen. Each indexing assembly comprises a slip clutch, an indexing wheel that has at least two detents formed therein, an arm that is engageable with the detents and an actuator that is engageable with the arm. When the arms engage their respective indexing wheel, the spindle and the shaft are prevented from rotating. When a sensor indicates an article is improperly oriented, the actuators engage their respective arms so that the arms are disengaged from the detents allowing simultaneous rotation of the turntable and platen. Rotation continues until the arms are released by the actuators and engage another one of the detents.

Owner:NEW ENGLAND MACHINERY

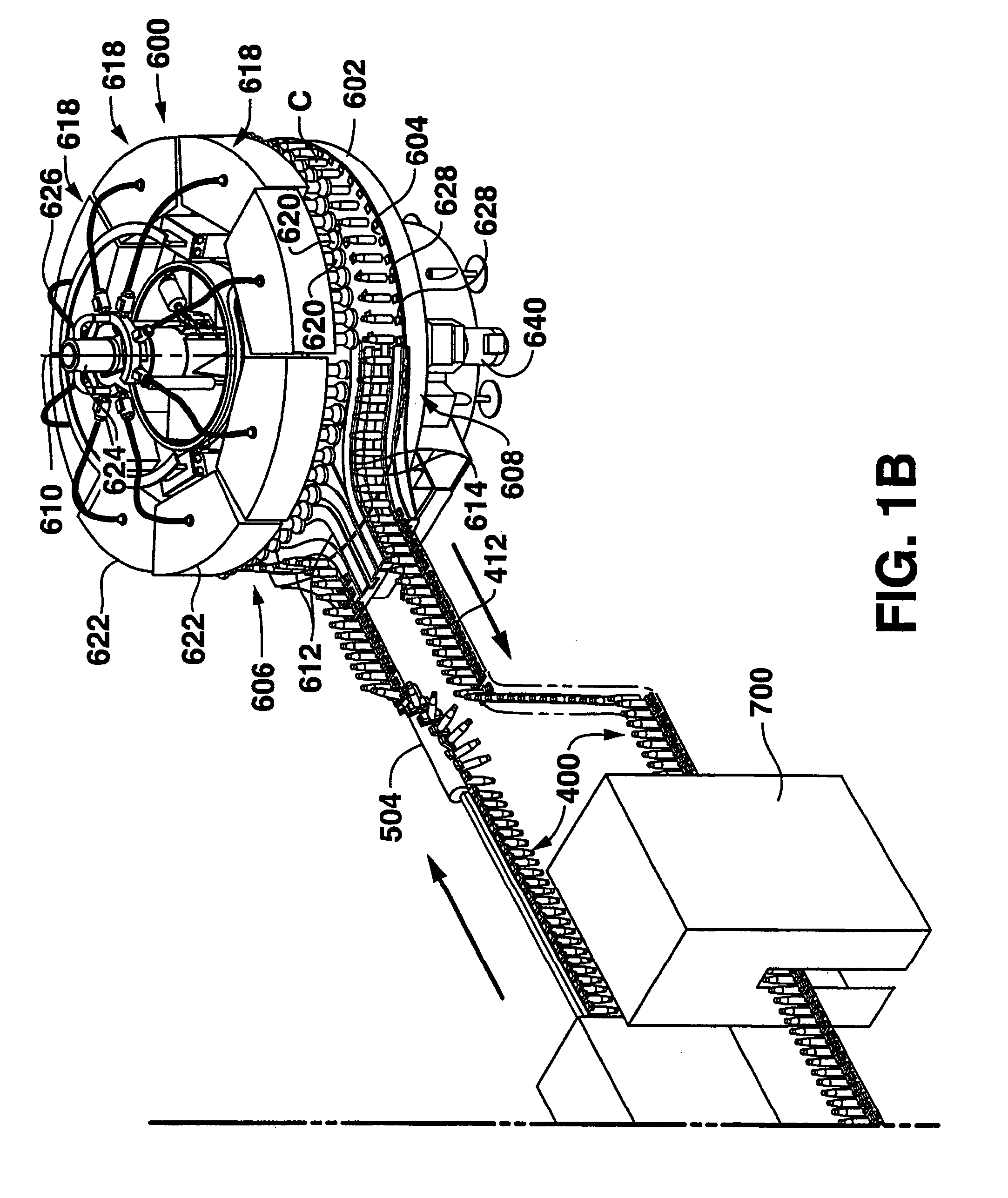

Rotary filling machine and related components, and related method

A rotary filling machine is disclosed for filling containers, the machine including a rotating platform rotatable relative to a vertical rotating axis through a filling zone, and a conveyor configured to convey empty containers to be filled to the rotating platform for filling and to convey filled containers from the rotating platform. Various aspects and designs of the above elements are disclosed, as well as a related method.

Owner:ILLINOIS TOOL WORKS INC

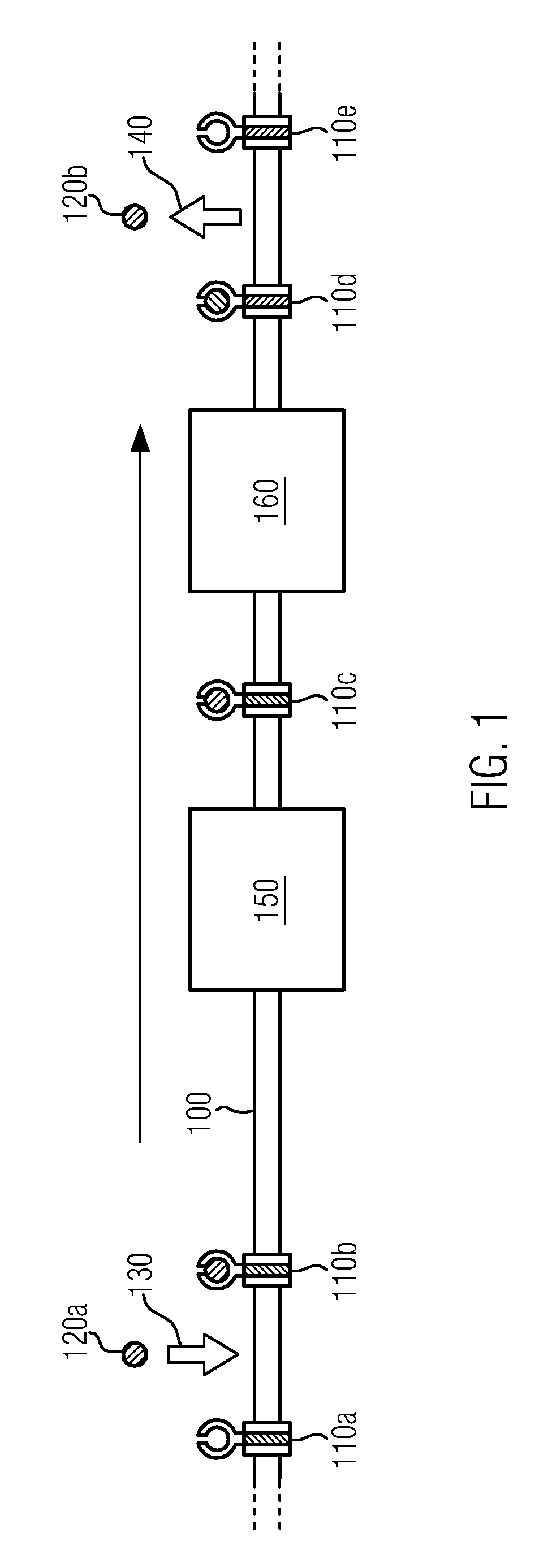

Transport system for container processing machines

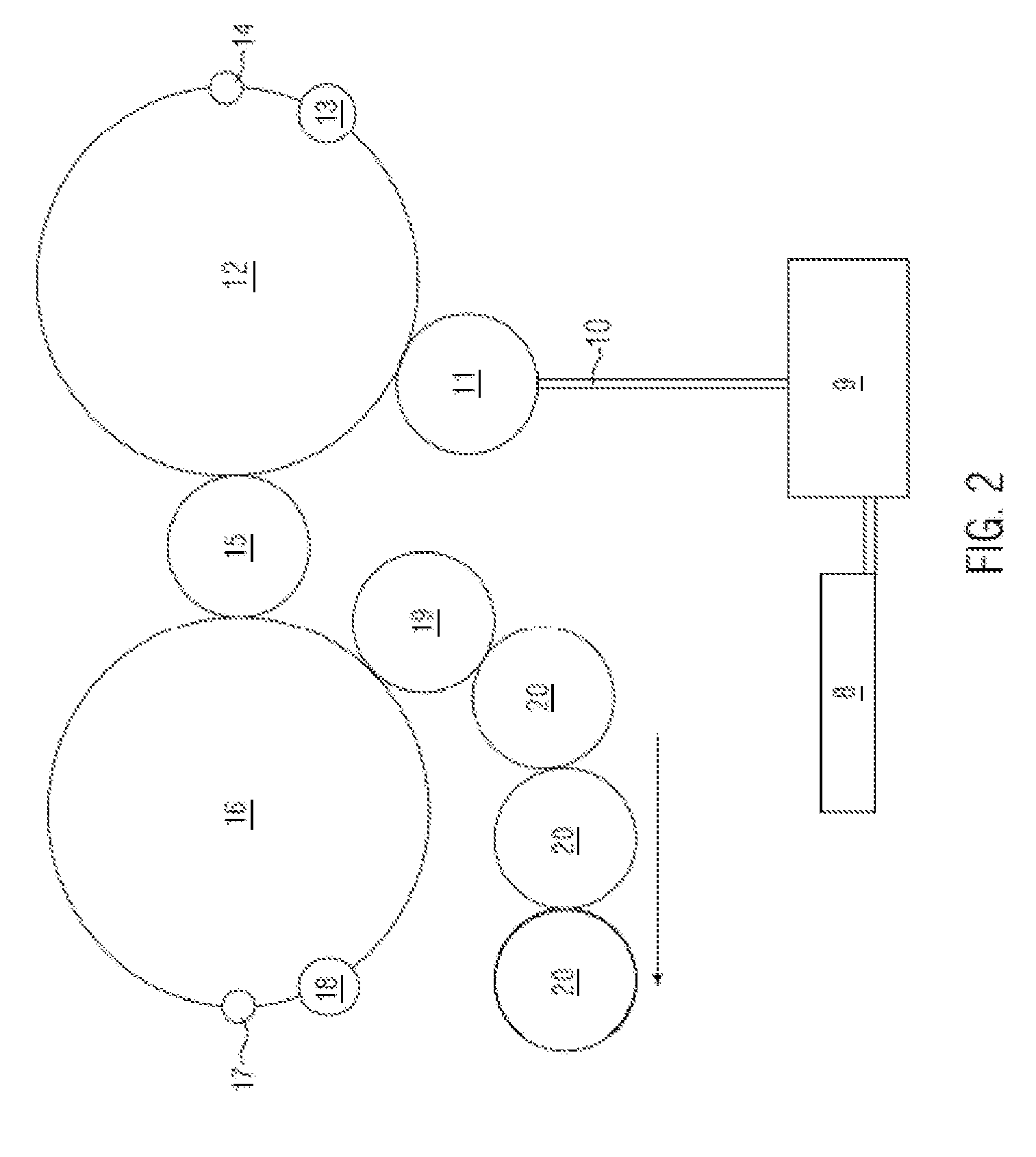

ActiveUS7743907B2Increase variabilityQuick cleanLiquid fillingSynchronising machinesTransport systemEngineering

A transport system for container processing machines, particularly for bottle fillers, with inlet and outlet stars, which can be driven and are arranged on columnar support housings, and define a star configuration, in which the inlet and outlet stars define container transport paths which are linked with the machine. Each support housing presents at least one, preferably lateral, connection interface, to which a joining end of a connection strut is attached, in a removable manner. The other joining end of the connection strut is connected, in a detachable manner, to a connection interface of an additional support housing or of a machine substructure. In each case, in such manner, the star configuration can be changed as desired in a modular manner.

Owner:KRONES AG

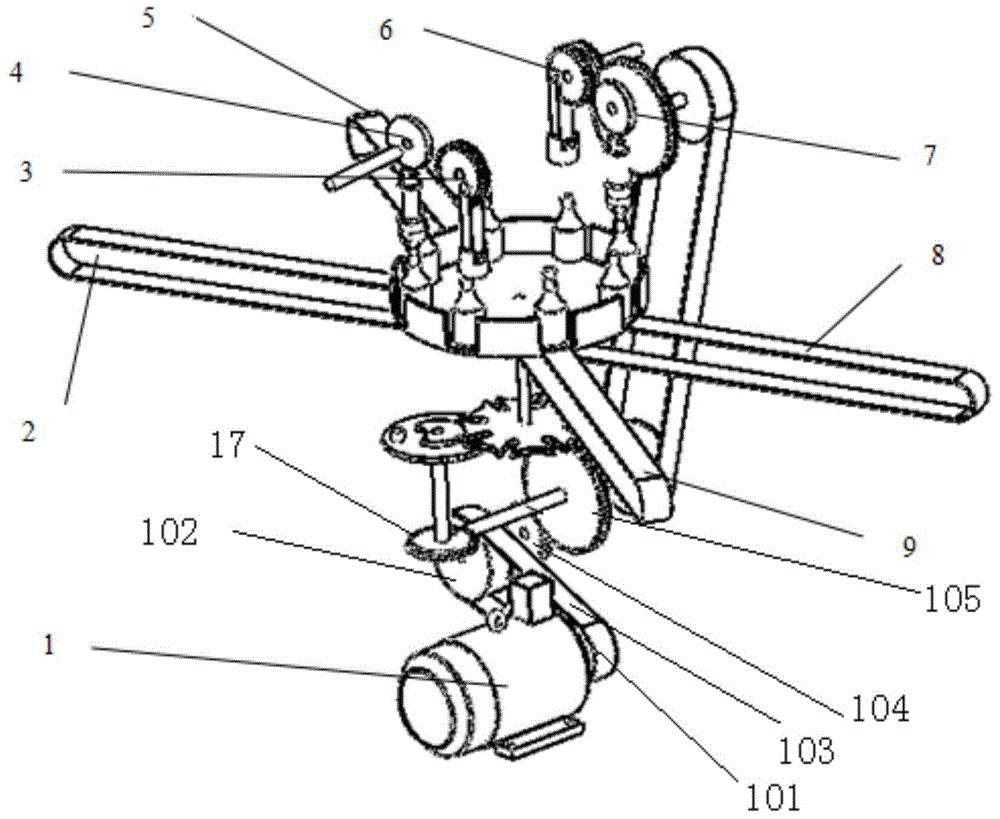

Rotary filling machine

ActiveCN104591064ASimple structureImprove structural performanceSynchronising machinesFlanged caps applicationIntermittent motionEngineering

The invention discloses a rotary filling machine, which comprises: a fixed workbench, which is provided with a plurality of constraint positions; a rotary workbench, which is equipped with a plurality of bottle clamping positions, during rotation of the rotary workbench, with the constraint positions and the corresponding clamping positions composing a plurality of stations, at least one of which is a gland station and at least one of which is a filling station; a workbench drive device, which is in transmission connection with the rotary workbench so as to drive the rotary workbench to do intermittent motion relative to the fixed workbench; a gland device, which comprises a gland component and a gland drive mechanism driving the action of the gland component, with the gland component being disposed over the gland station; and a filling device, which consists of a filling component and a filling drive mechanism driving the action of the filling component, with the filling component being disposed over the filling station. The rotary filling machine provided by the invention can perform filling on materials according to a fixed cycle to realize filling automation, thus improving the filling efficiency, reducing the cost and enhancing product quality.

Owner:无锡精派机械有限公司

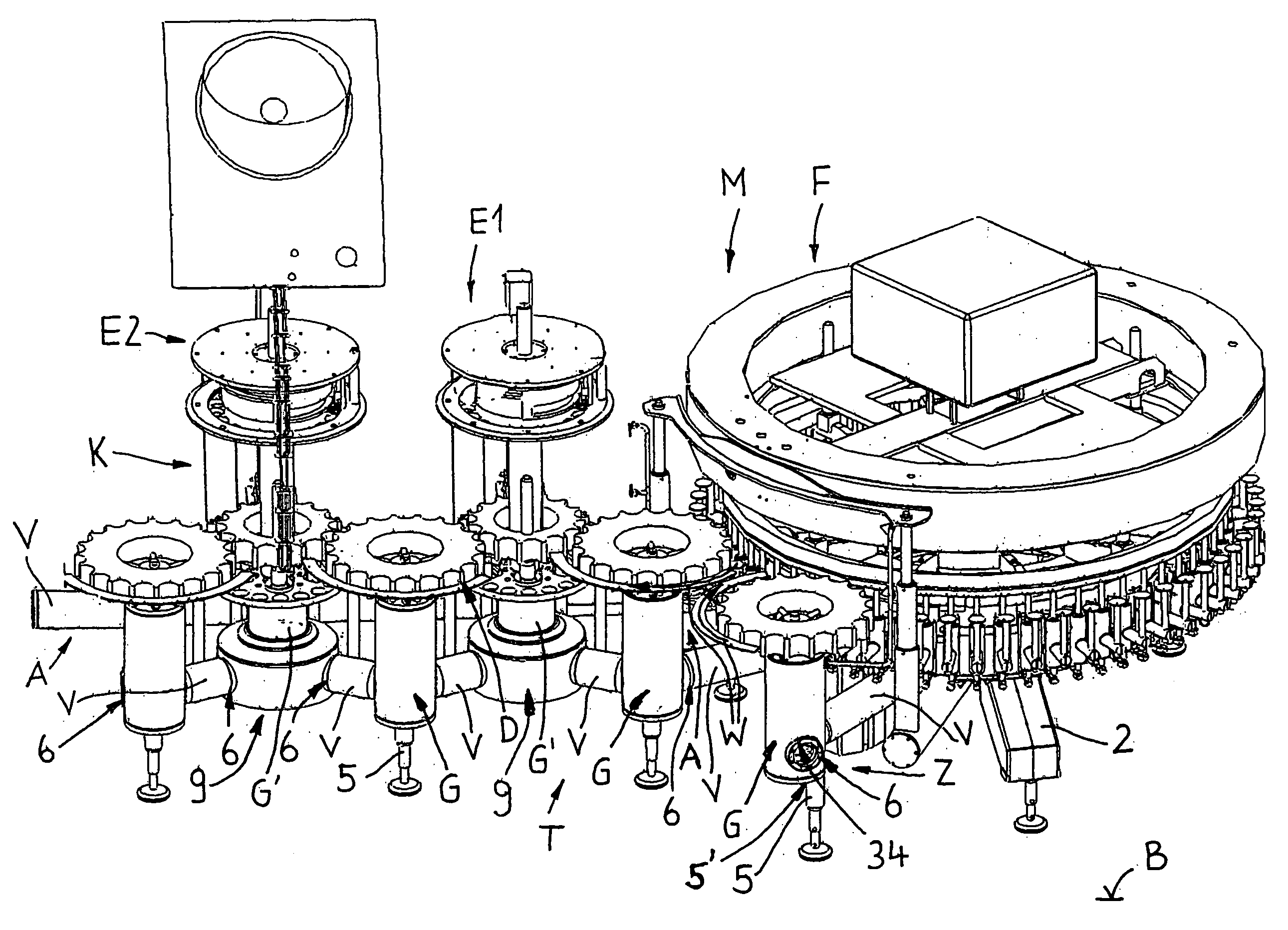

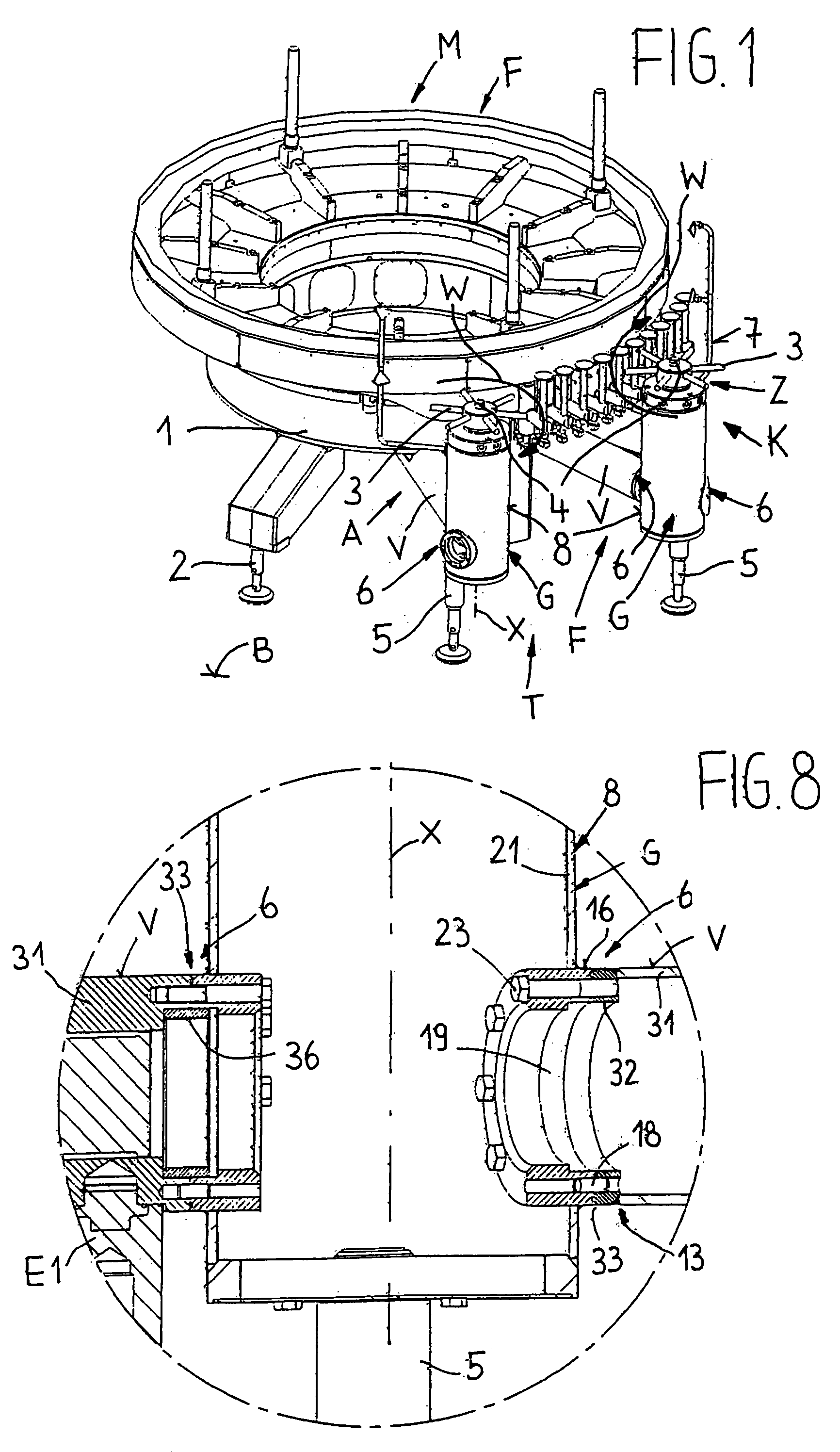

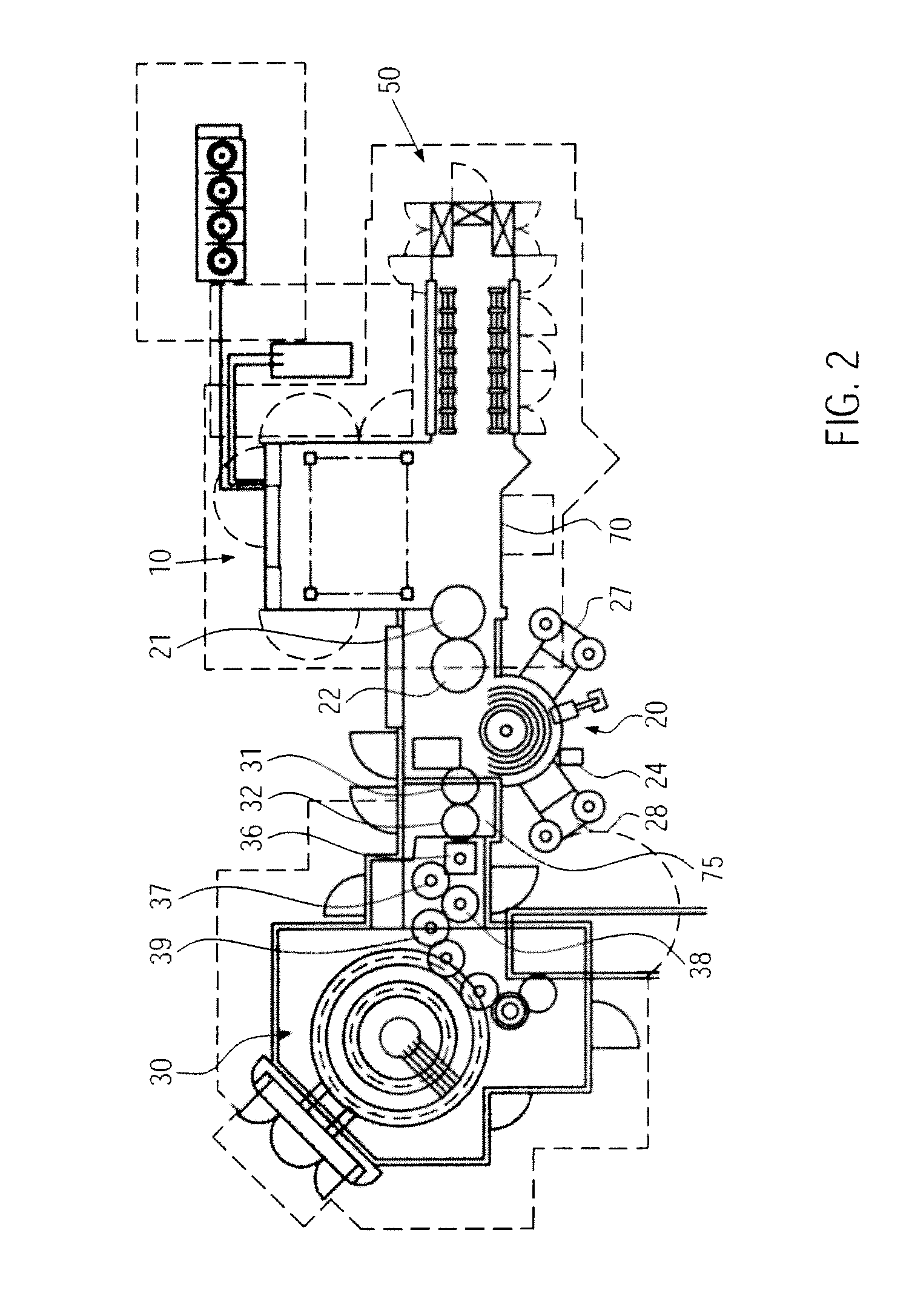

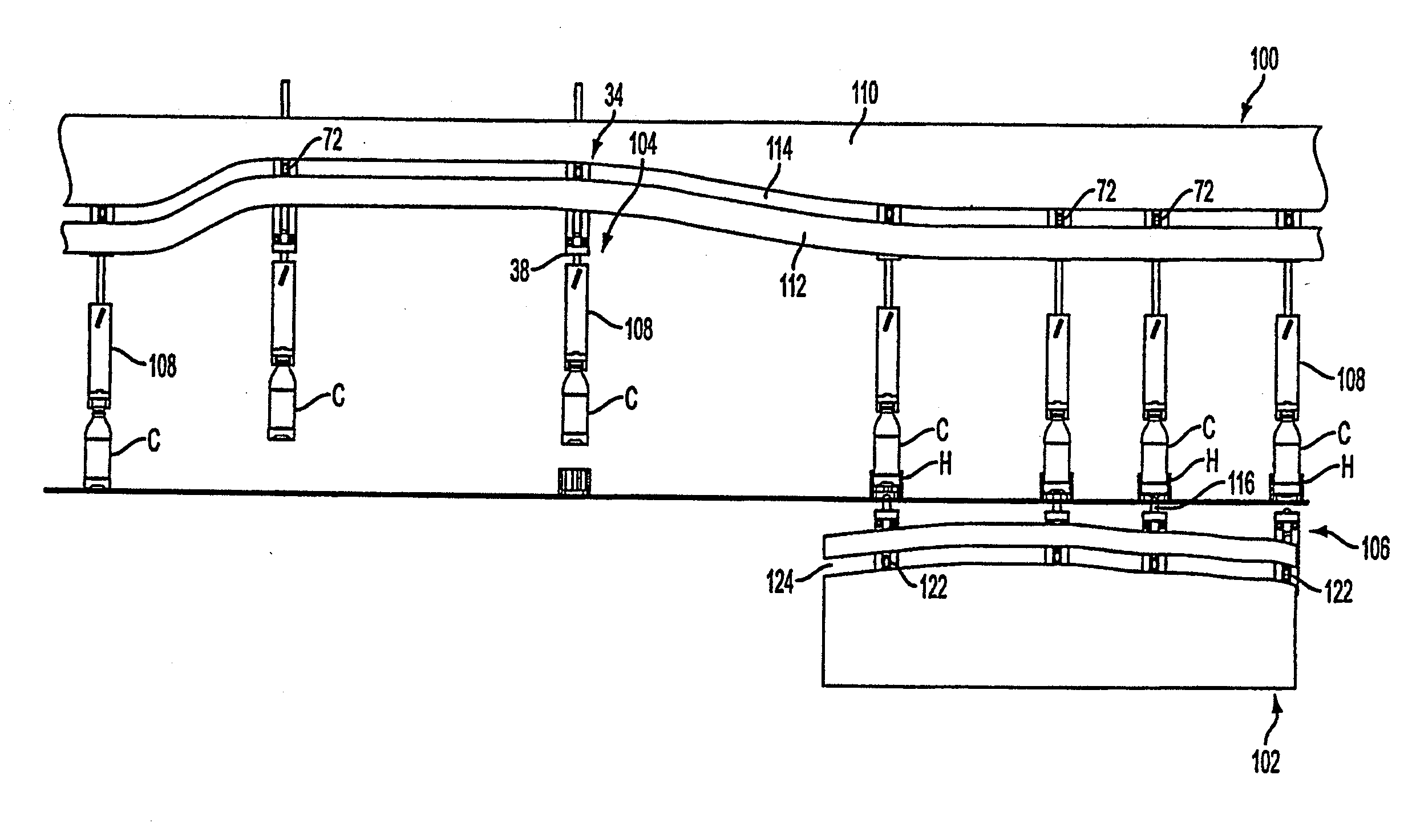

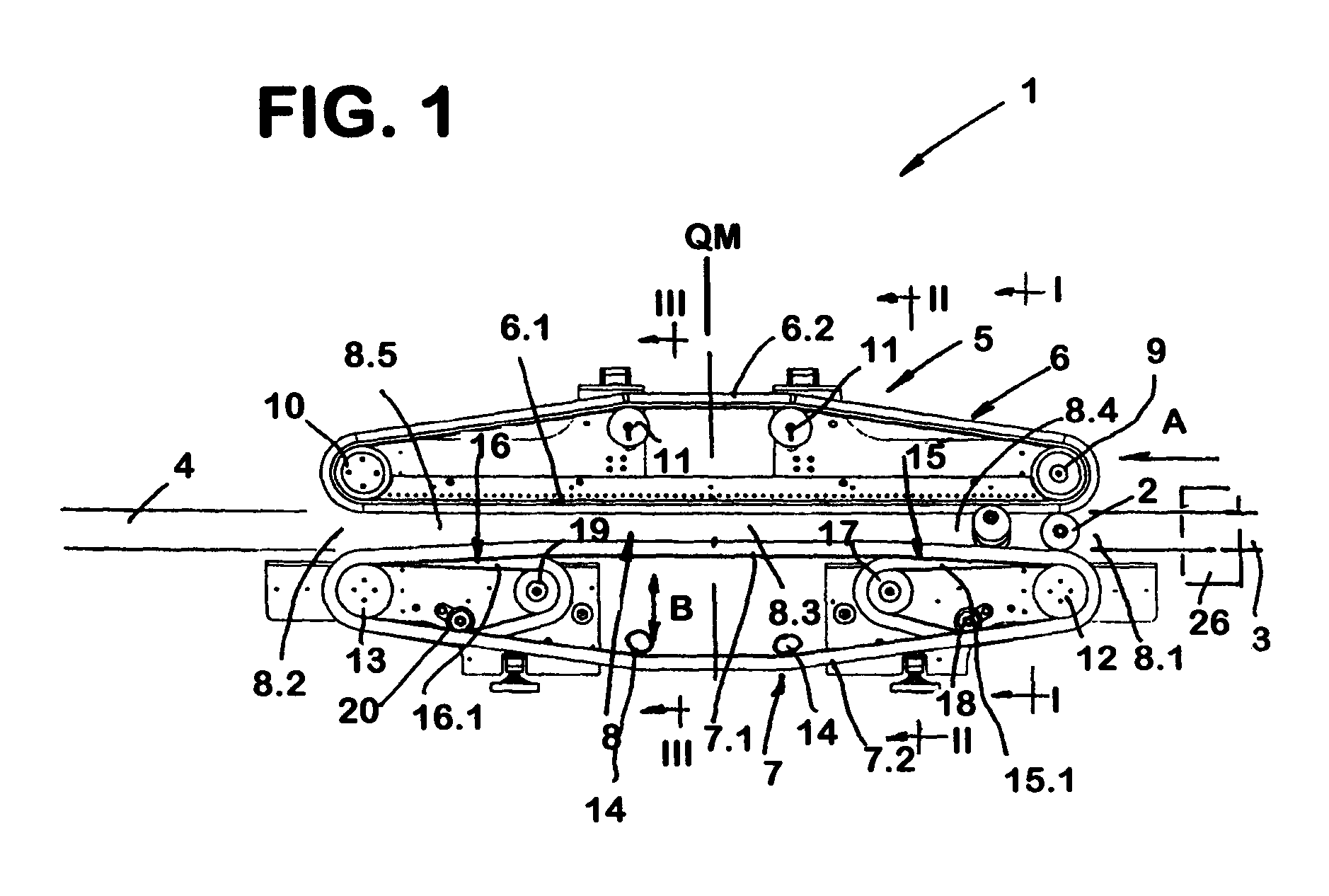

Container processing machine, and method for loading and unloading a container processing machine

InactiveUS20090045033A1Increase capacityReduce the overall diameterSynchronising machinesHollow article cleaningEngineeringMechanical engineering

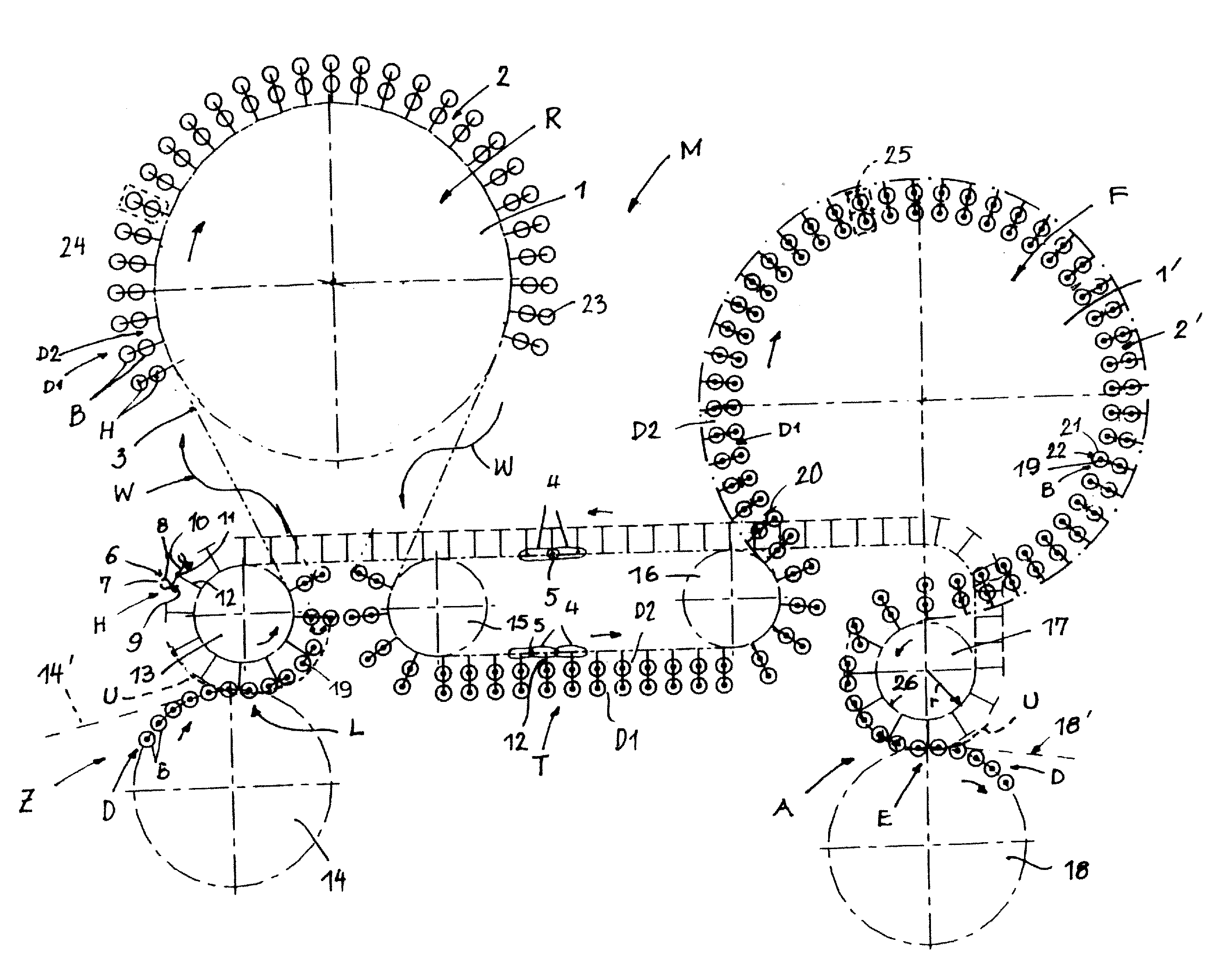

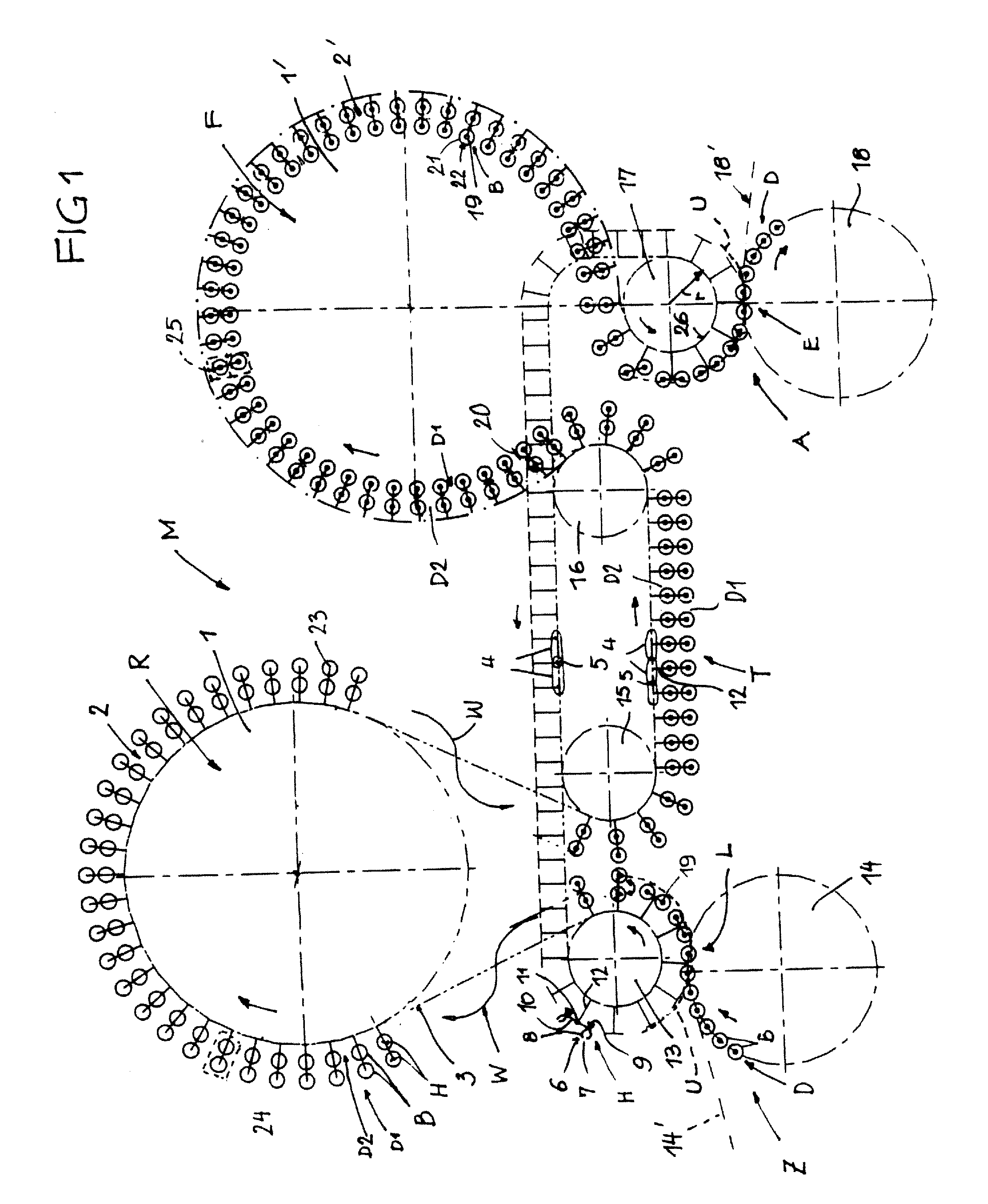

A container processing machine (M) with at least one carousel (1, 1′) which defines a multiple-row processing section (2, 2′), processing devices (24, 25) which move concurrently in multiple rows with the carousel, container holding element groups which are attached to sections of a concurrently moving conveyor device (3), holding elements (H), at least within the processing section (2, 2′), that are positioned next to each other transversely to the conveyance direction, and feed and removal systems (Z, A) for the loading and the unloading of the holding elements (H). The feed and removal systems (Z, A) are designed with a single row, while the holding elements (H) of the groups are resettable between a single-row position, in which they are oriented at least approximately parallel to the conveyance direction, and, in the area of the loading and unloading zones (L, E), a position resetting device (U) for the holding elements. In a procedure for loading and loading a container processing machine (M), the holding element groups are loaded from only one single row (D) and unloaded again into a single row (D), and the holding element groups, for the loading and unloading with respect to the conveyor device (3), are temporarily reset between single-row and multiple-row positions.

Owner:KRONES AG

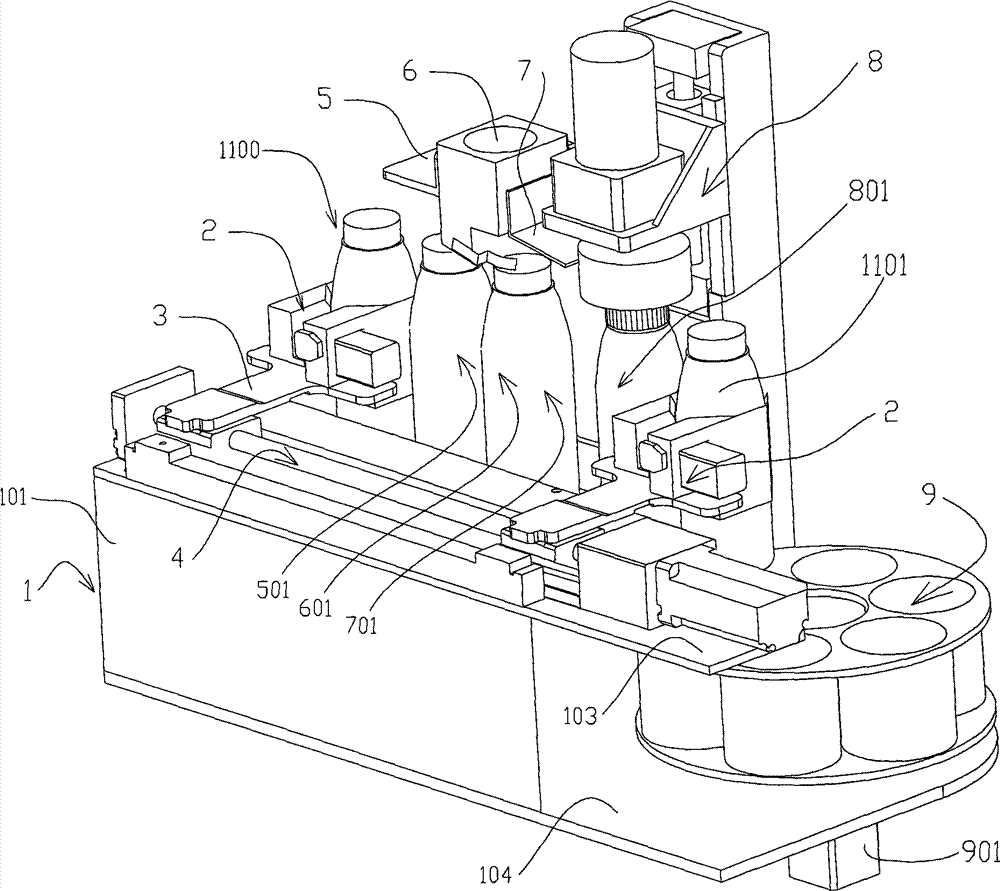

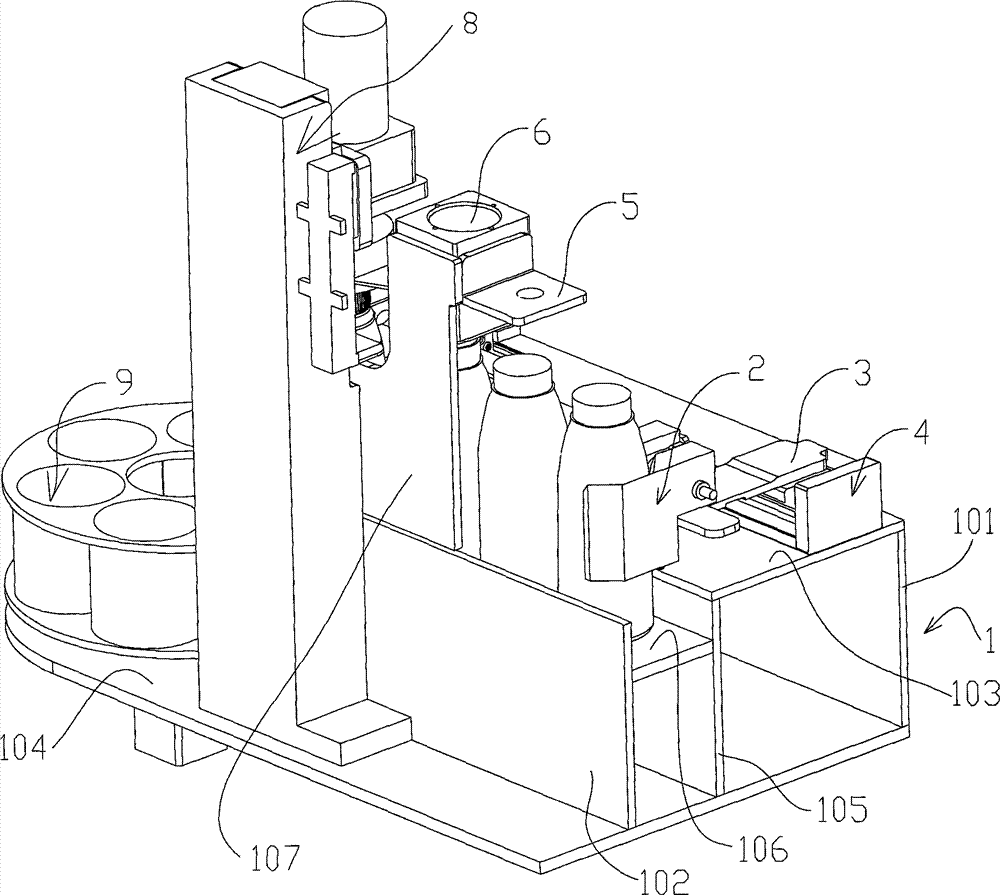

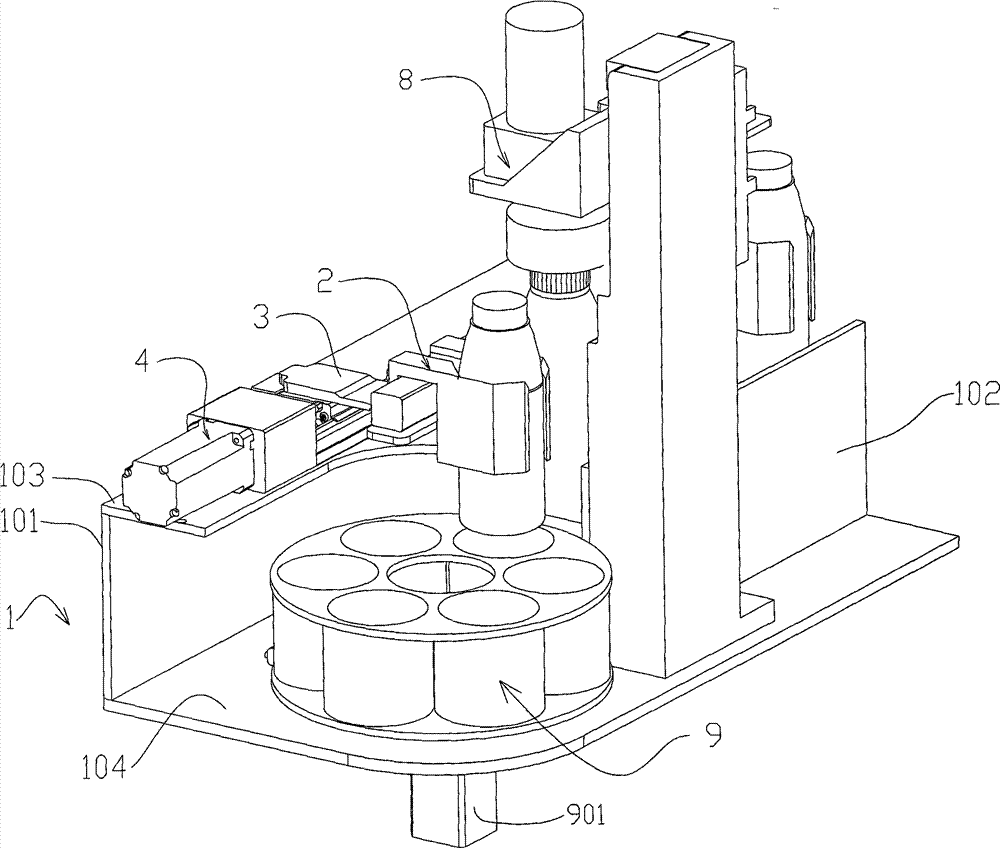

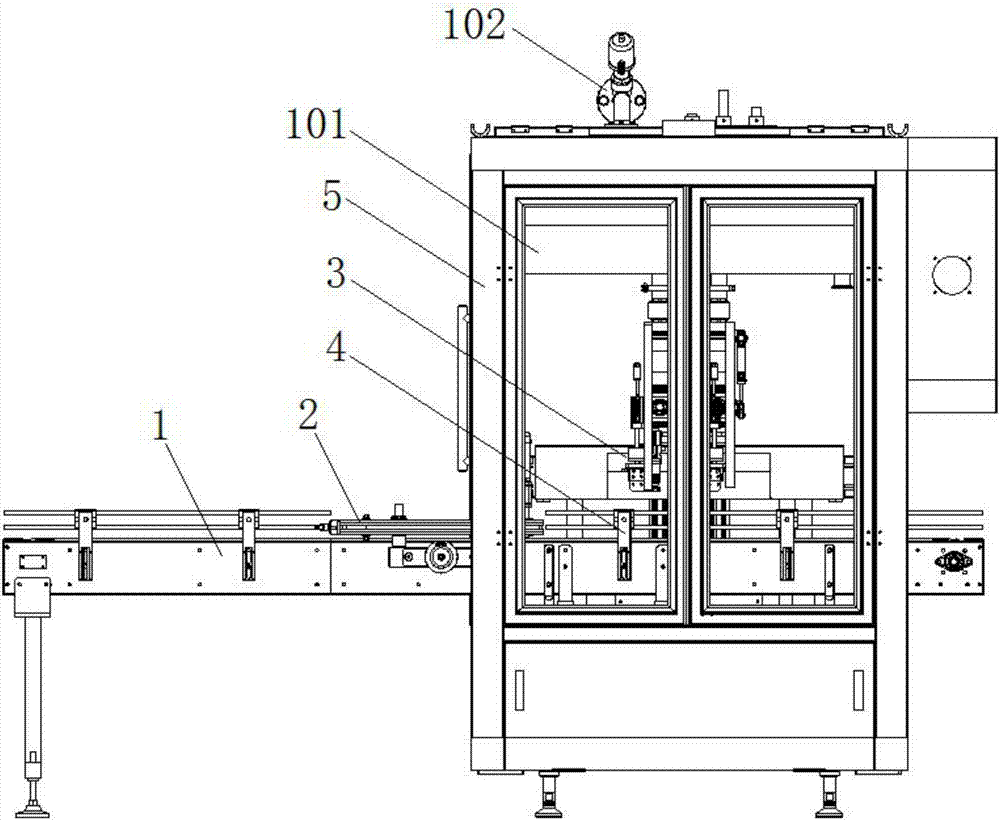

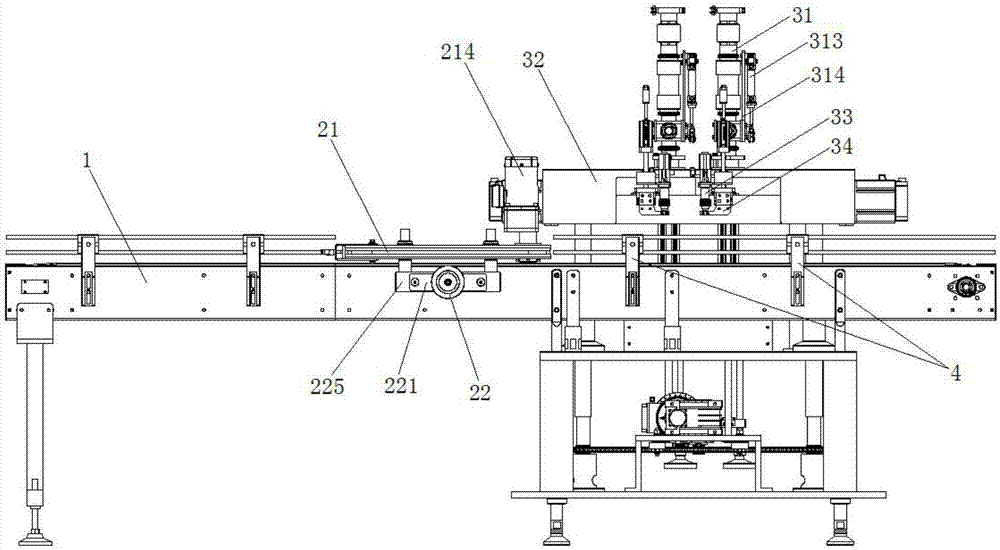

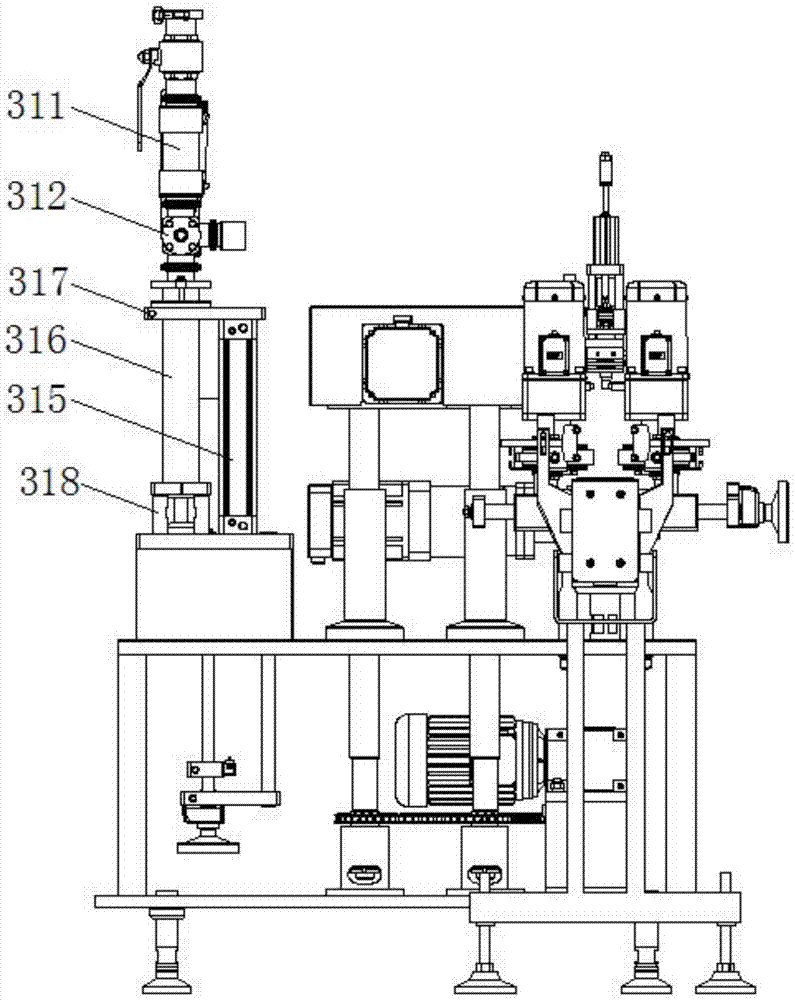

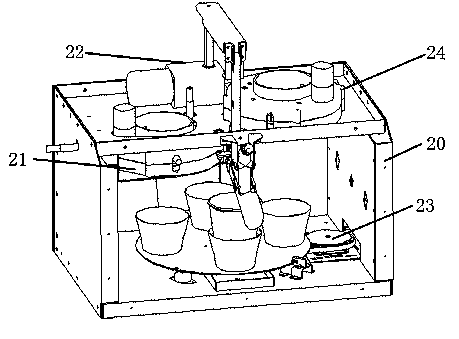

Freshly-squeezed orange juice bottling production line of vending machine

The invention discloses a freshly-squeezed orange juice bottling production line of a vending machine. The freshly-squeezed orange juice bottling production line comprises a production line structure frame, a bottle grabbing manipulator, a manipulator connecting plate, a transverse conveying mechanism, a filling device, a cover applying mechanism, a cover arranging mechanism, a cover fastening mechanism and a rotary delivery mechanism. The freshly-squeezed orange juice bottling production line has the advantages that one set of operation flows of cover applying, cover fastening and delivery of a bottle filled with freshly-squeezed orange juice in the vending machine is completed, so that the coordinated operation of automatic production, processing and controlling is realized, and the safety and quality of a product are ensured.

Owner:邓军

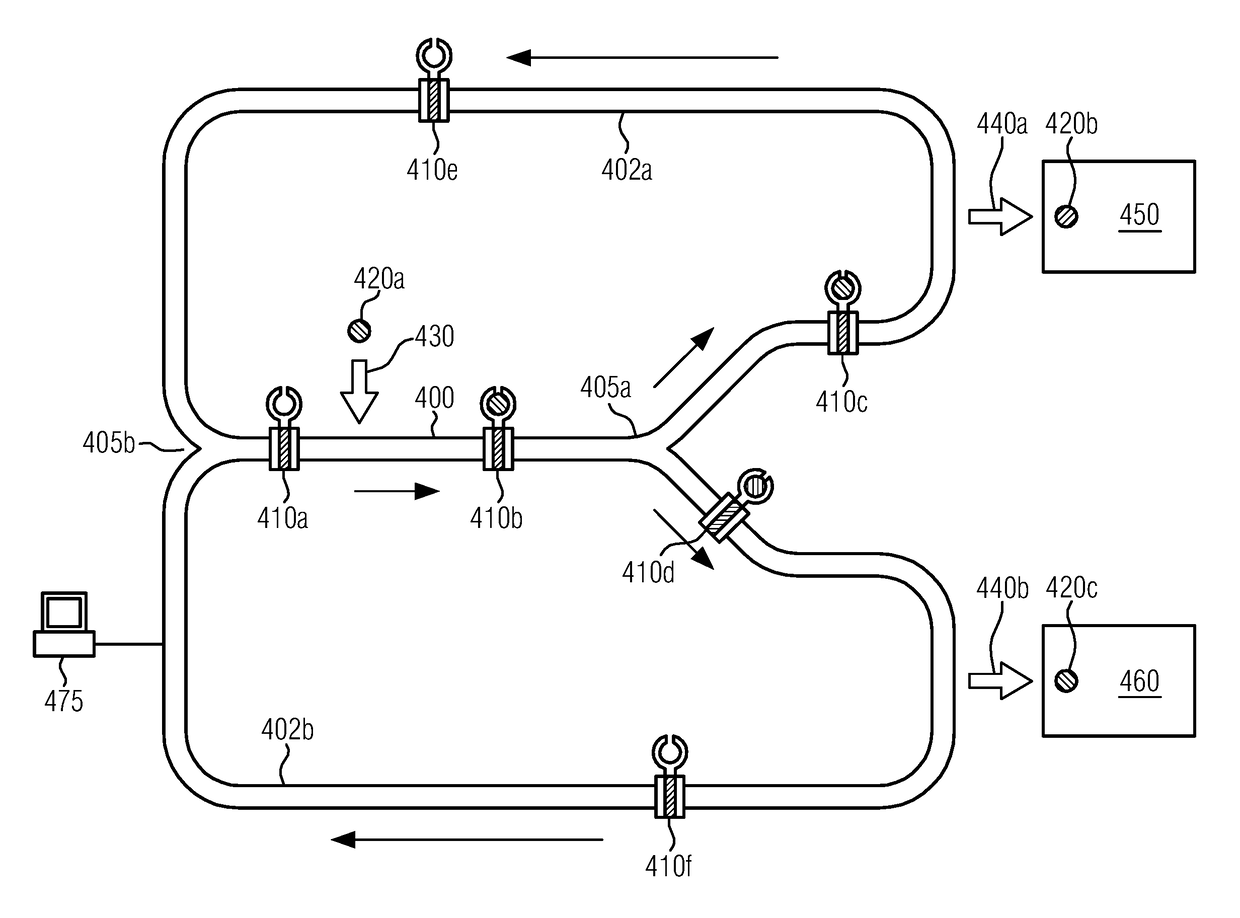

Device and method for transporting containers in a container treatment system

ActiveUS9809392B2Minimize production downtimeImprove utilizationSynchronising machinesControl devices for conveyorsTransport engineeringTreatment system

A transport device for transporting containers in a container treatment system which has a first container treatment unit for a process step and a second container treatment unit for the process step, the transport device having at least one receiving point for the containers, at least one delivery point for the containers, a transport track which connects the at least one receiving point, the at least one delivery point, the first container treatment unit, and the second container treatment unit, and at least one transport element for transporting a container, the transport element being movably arranged on the transport track. The transport track and the at least one transport element are designed such that the at least one transport element can be guided from a receiving point to a delivery point in an individually controllable manner.

Owner:KRONES AG

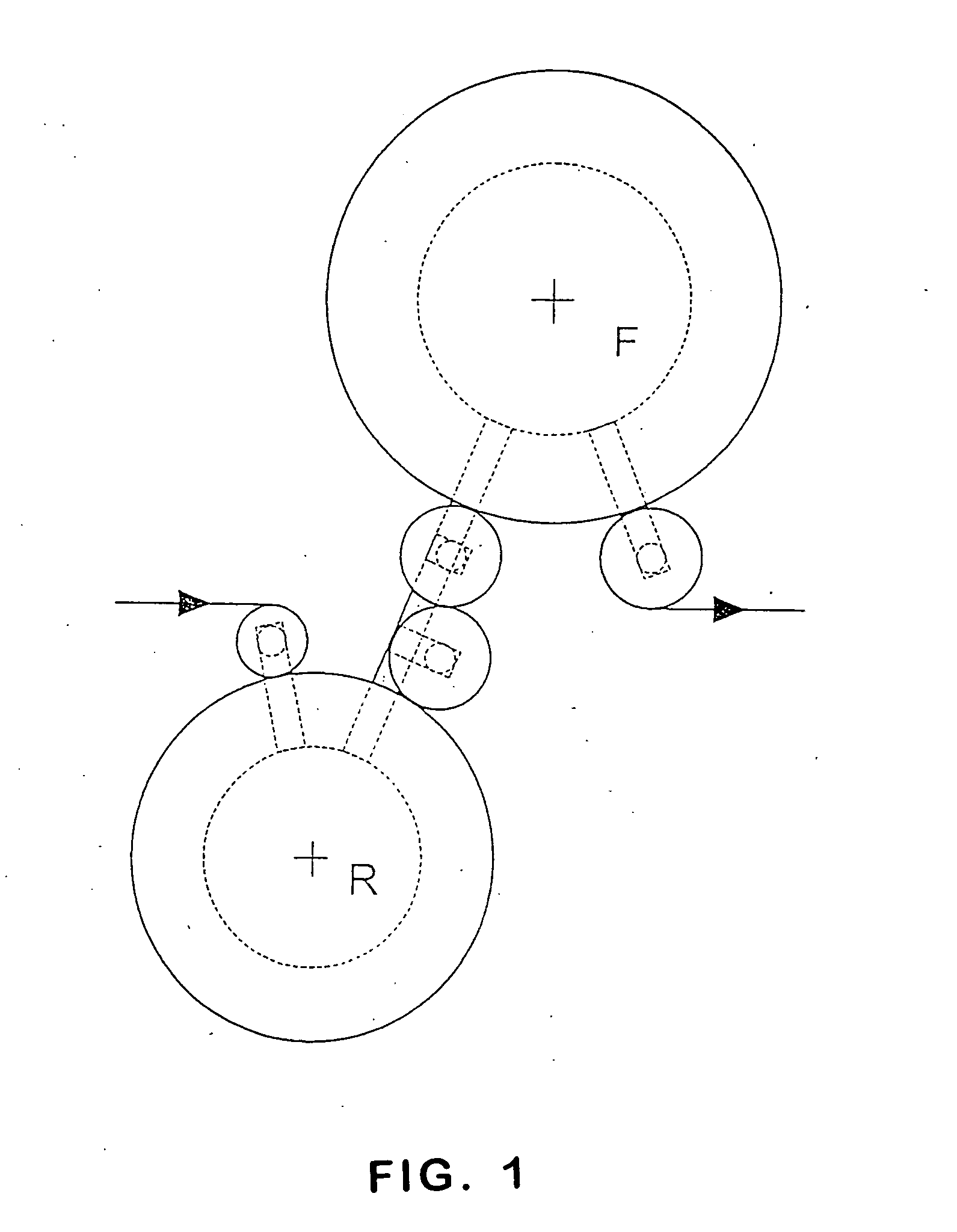

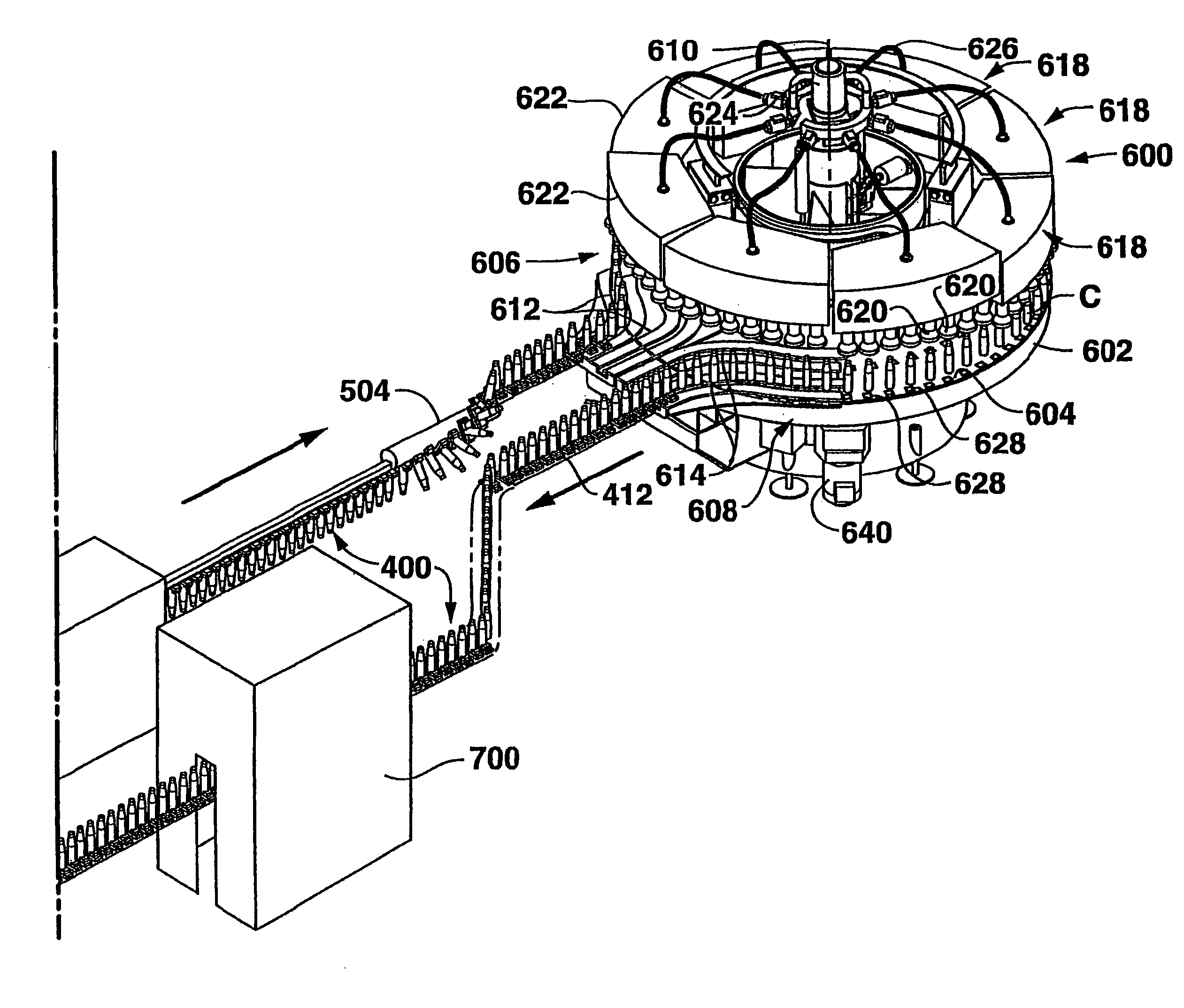

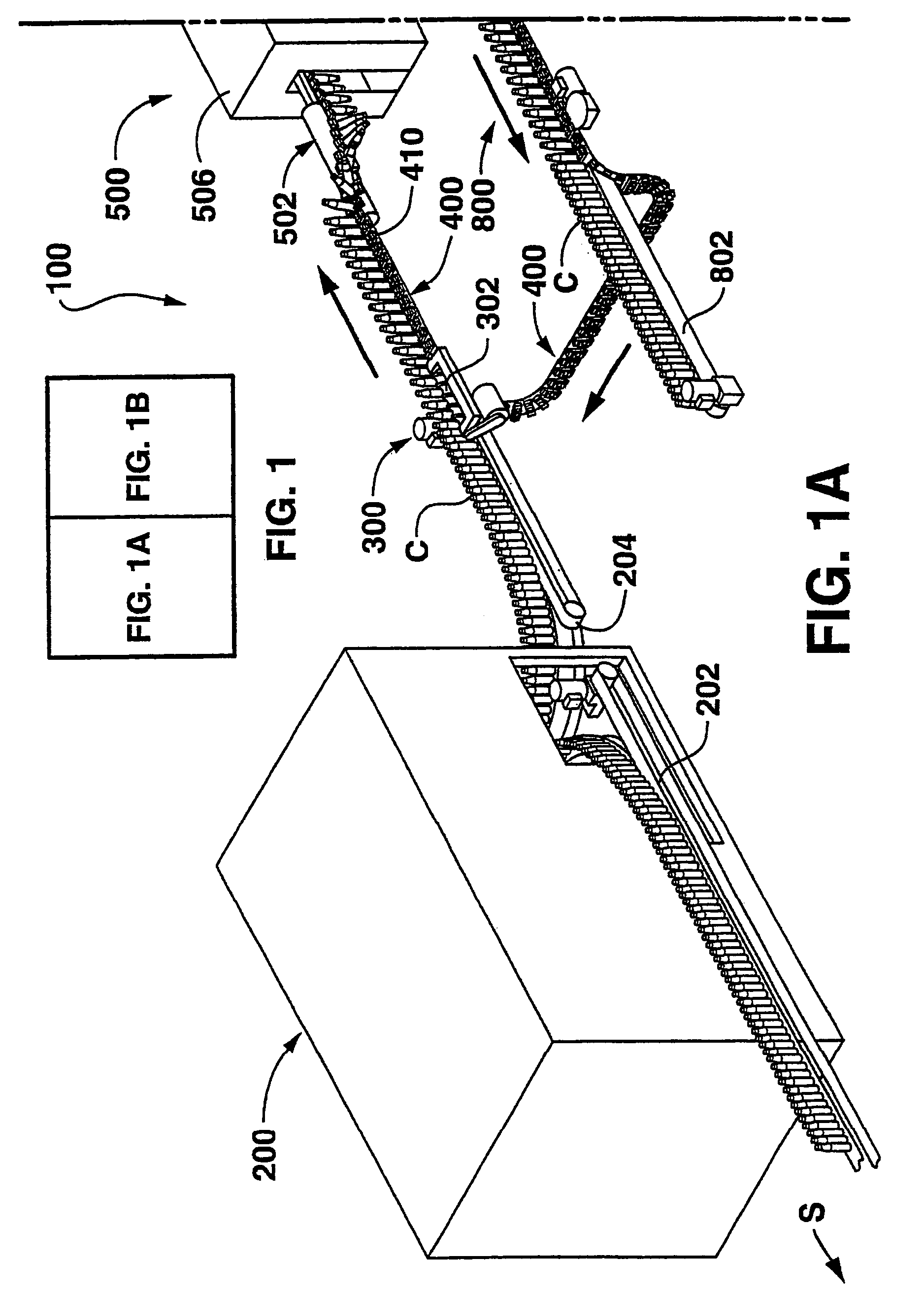

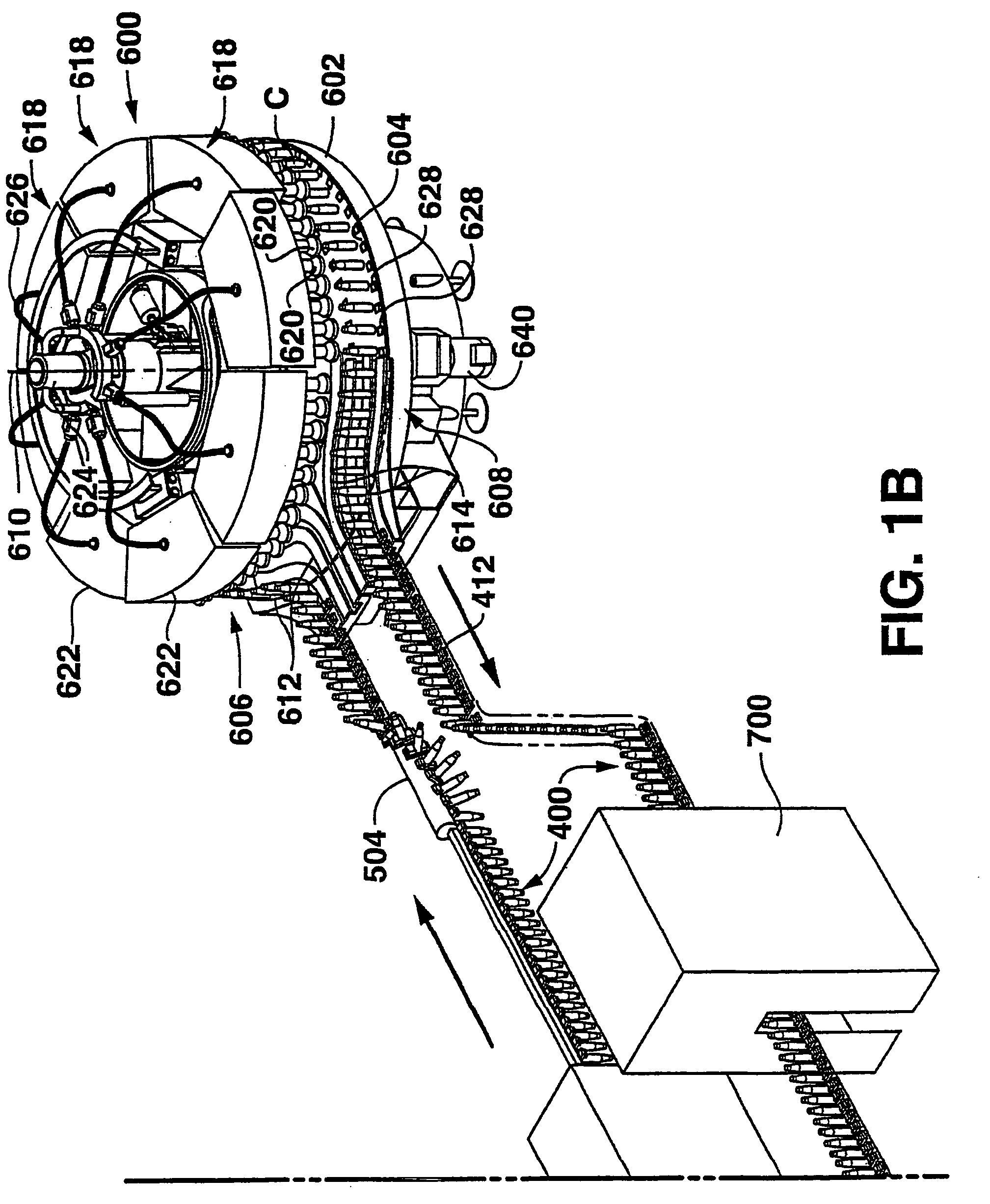

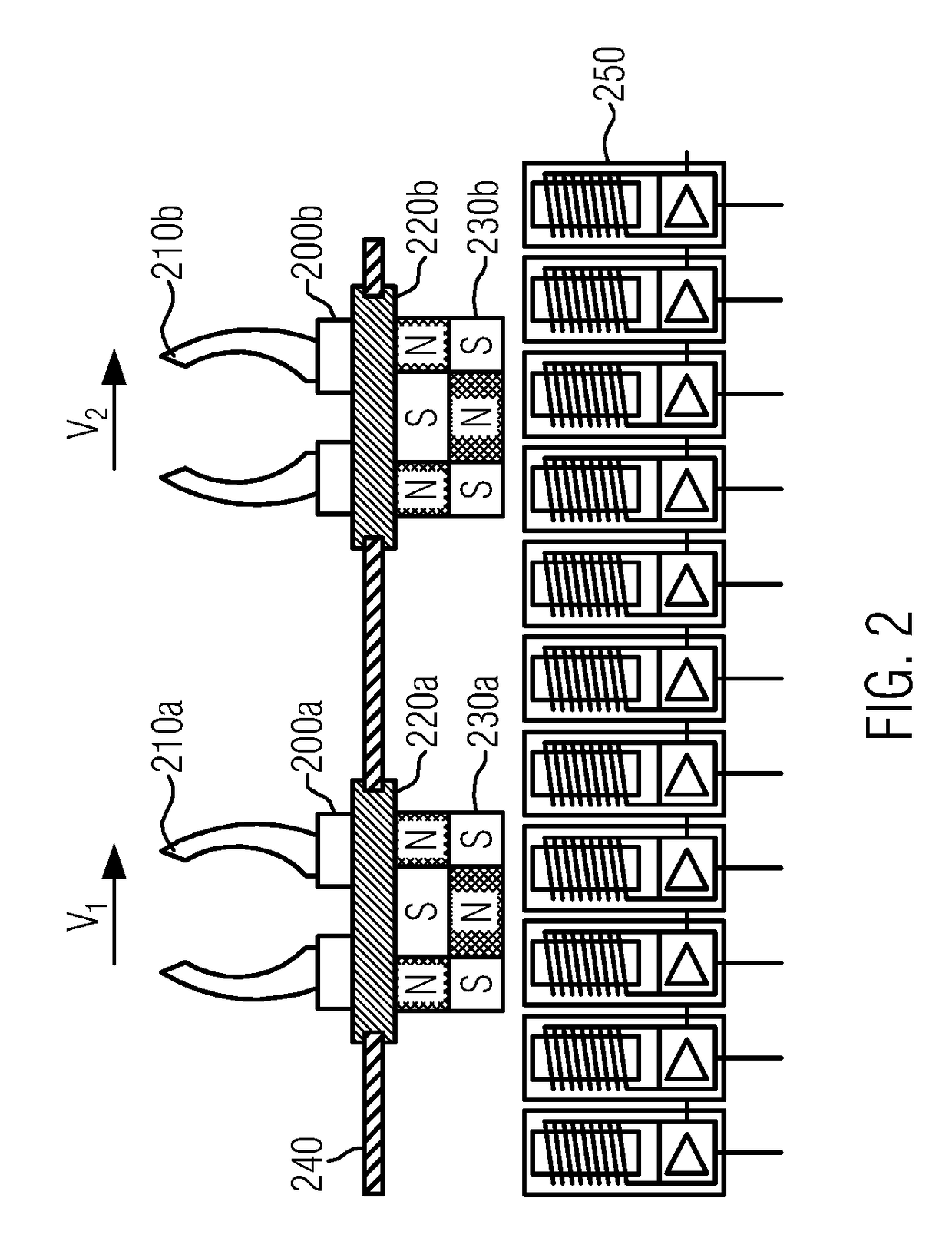

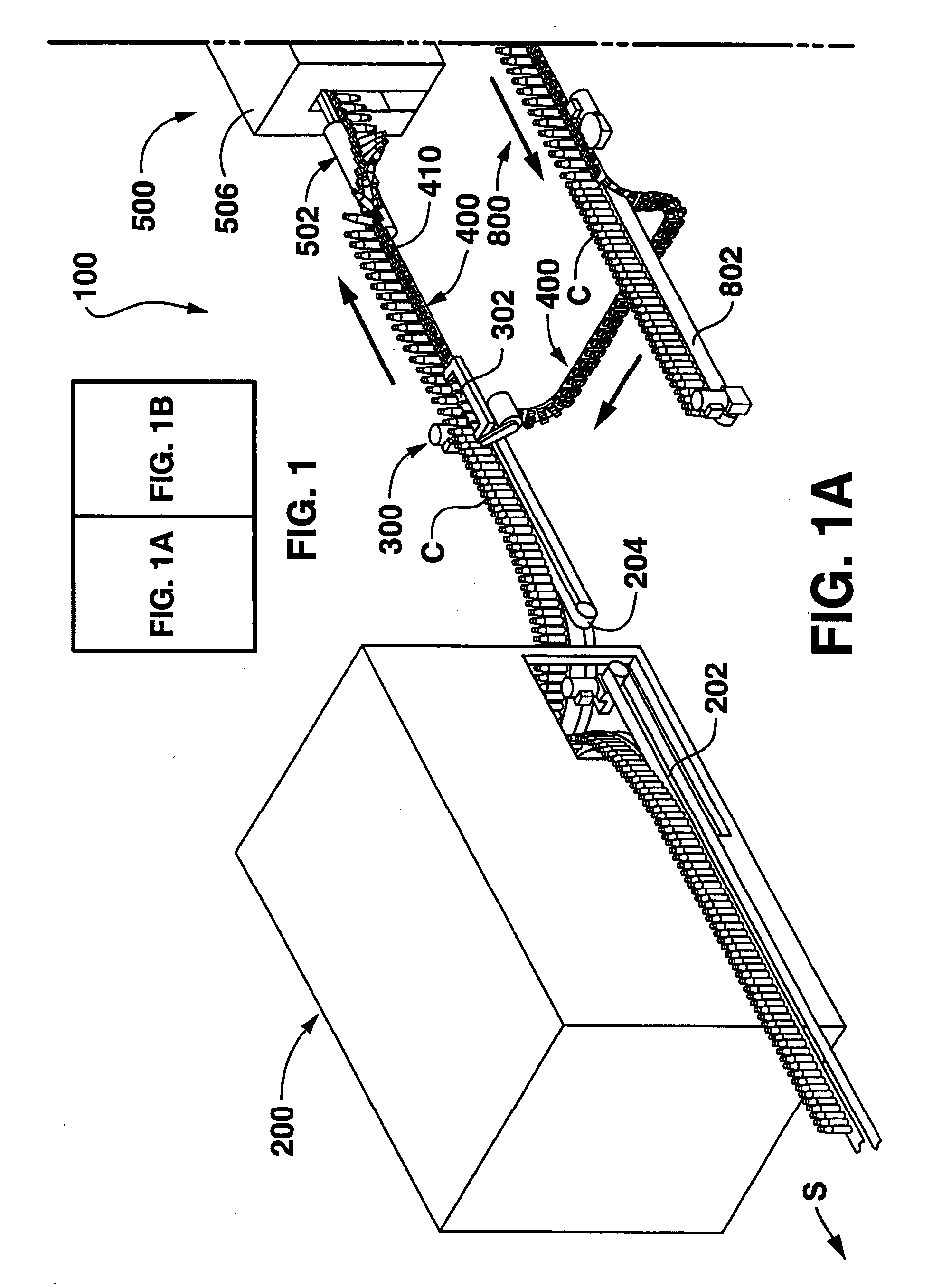

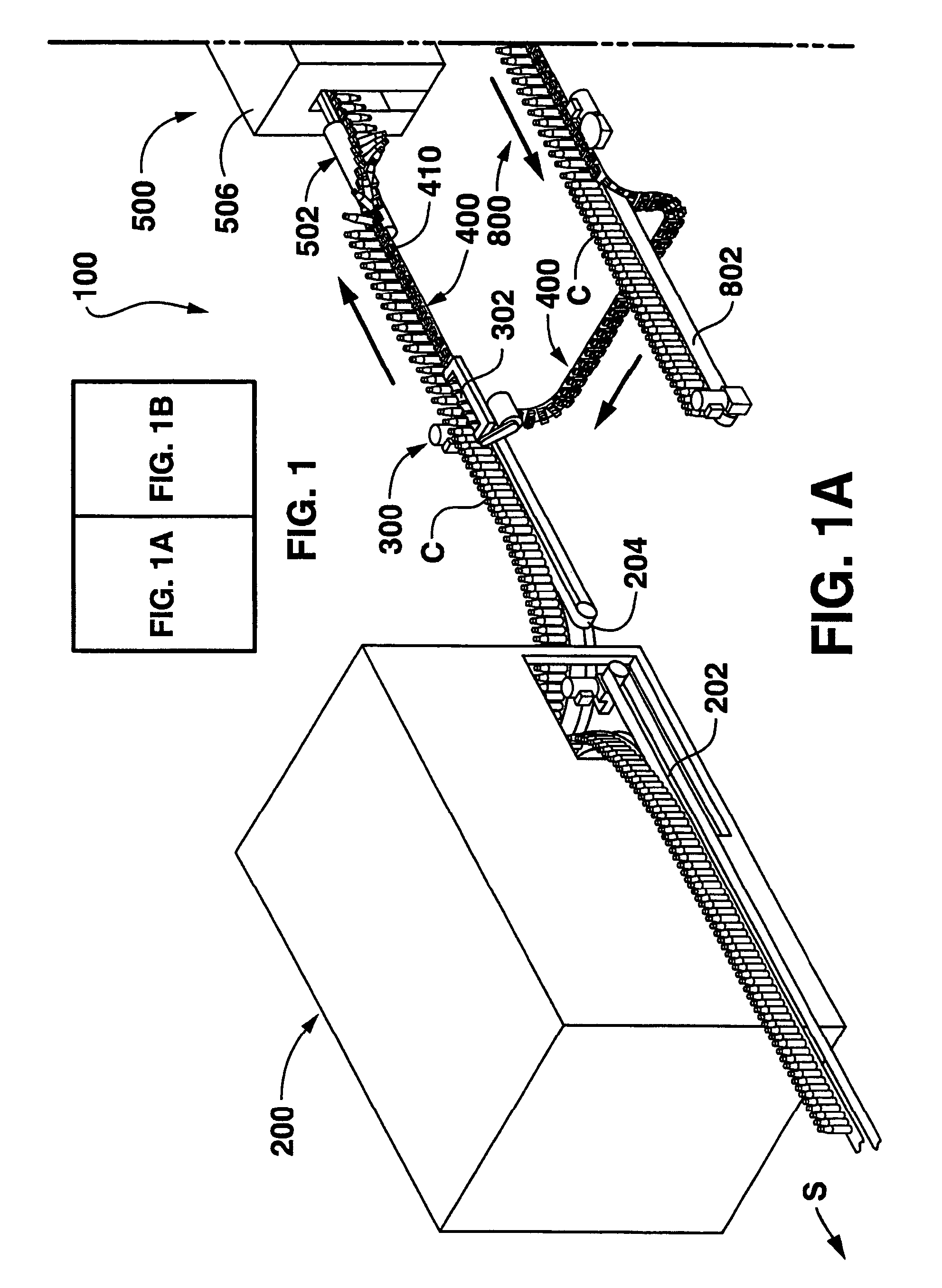

Neck gripping conveyor and link, and related rotary filler and system

InactiveUS20050284731A1Synchronising machinesFilling using counterpressureMechanical engineeringDelivery system

A conveyor is disclosed suitable for conveying objects such as containers to a processing station. The conveyor includes a plurality of connected links, and at least one gripping member extending from each of the links. Each gripping member is movable relative to its respective link for gripping a container by the neck of the container. A guide structure is disposed on the link for mating a component of the processing station to the neck of the container for processing the container. The processing station may be a filler such as a rotary filler, a capper, or a rinser. Related individual links, conveying systems, and filler components are also disclosed.

Owner:ILLINOIS TOOL WORKS INC

Anti-corrosion and anti-explosion full-automatic multihead filling packaging line

ActiveCN105502259ASatisfy anti-corrosionFulfil requirementsSynchronising machinesControl systemEngineering

The invention discloses an anti-corrosion and anti-explosion full-automatic multihead filling packaging line. The anti-corrosion and anti-explosion full-automatic multihead filling packaging line comprises a filling machine capable of conducting filling on bottles, a control system which is provided with a touch screen and adopts a PLC, a stopper sealing machine capable of installing a stopper in each bottle, a stopper installing detection photoelectric sensor, a stopper installing bottle blocking baffle, a stopper installing pneumatic mechanism, an outer cover installing machine capable of installing an outer cover on each bottle, an outer cover installing detection photoelectric sensor, an outer cover installing bottle blocking baffle, an outer cover installing pneumatic mechanism, a cover screwing machine capable of screwing the outer covers, a labeling machine, a labeling detection photoelectric sensor, an automatic inkjet printing machine and an inkjet printing detection photoelectric sensor. A transport mechanism runs through the whole anti-corrosion and anti-explosion full-automatic multihead filling packaging line and is responsible for transport of the bottles.

Owner:ZHUHAI YUZHOU ENVIRONMENTAL PROTECTION TECH CO LTD

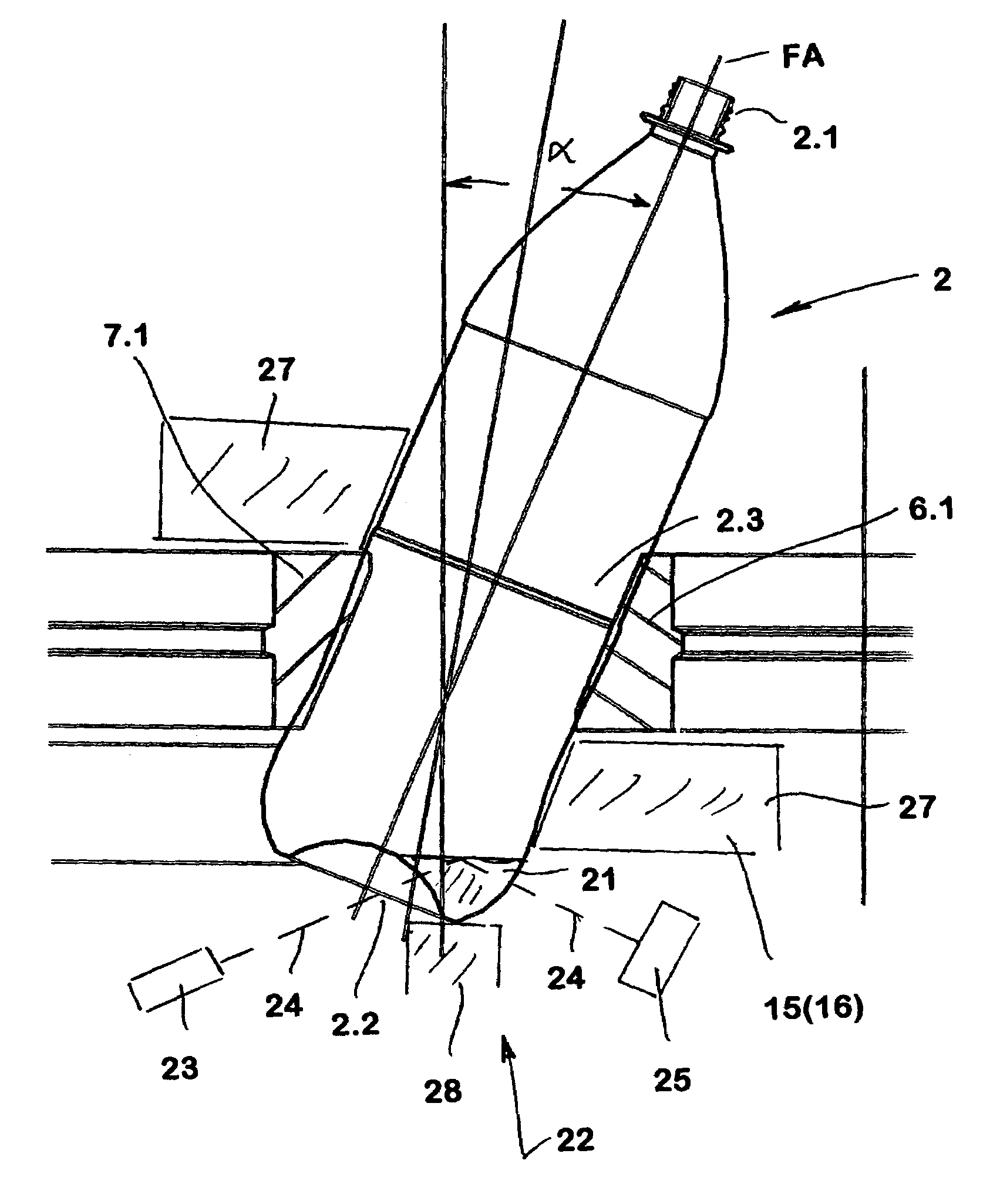

Apparatus and Method for Producing Plastic Bottles

ActiveUS20110056172A1Easy to adaptSpace-saving arrangementSynchronising machinesSolid materialMachine to machinePlastic bottle

A method and an apparatus for producing plastic bottles, including a blow molding machine, a labeler, at least one further treatment machine, and transfer starwheels provided and arranged for the machine-to-machine transportation of the bottles in such a way that the bottles are transported without buffers between the at least three machines.

Owner:KRONES AG

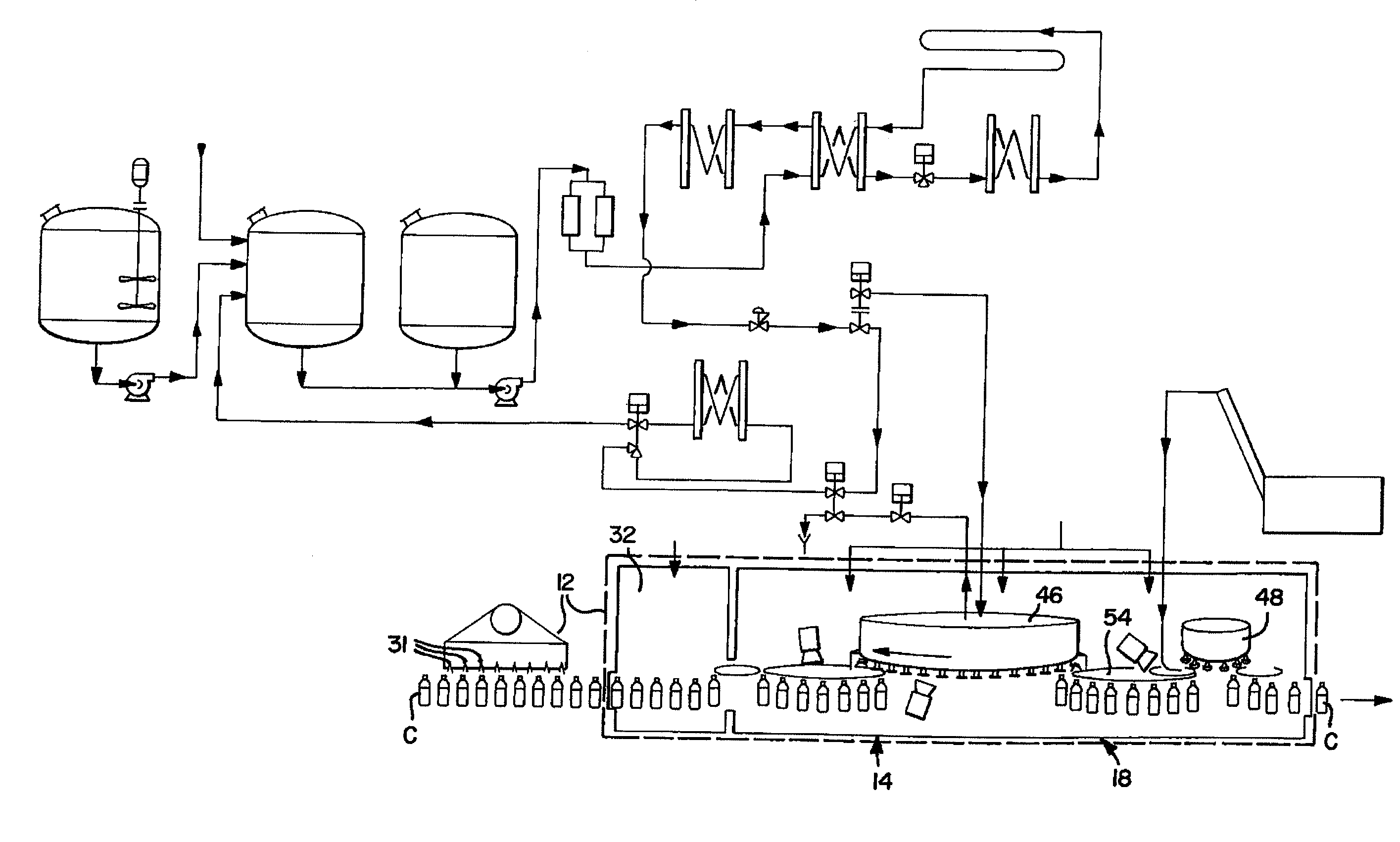

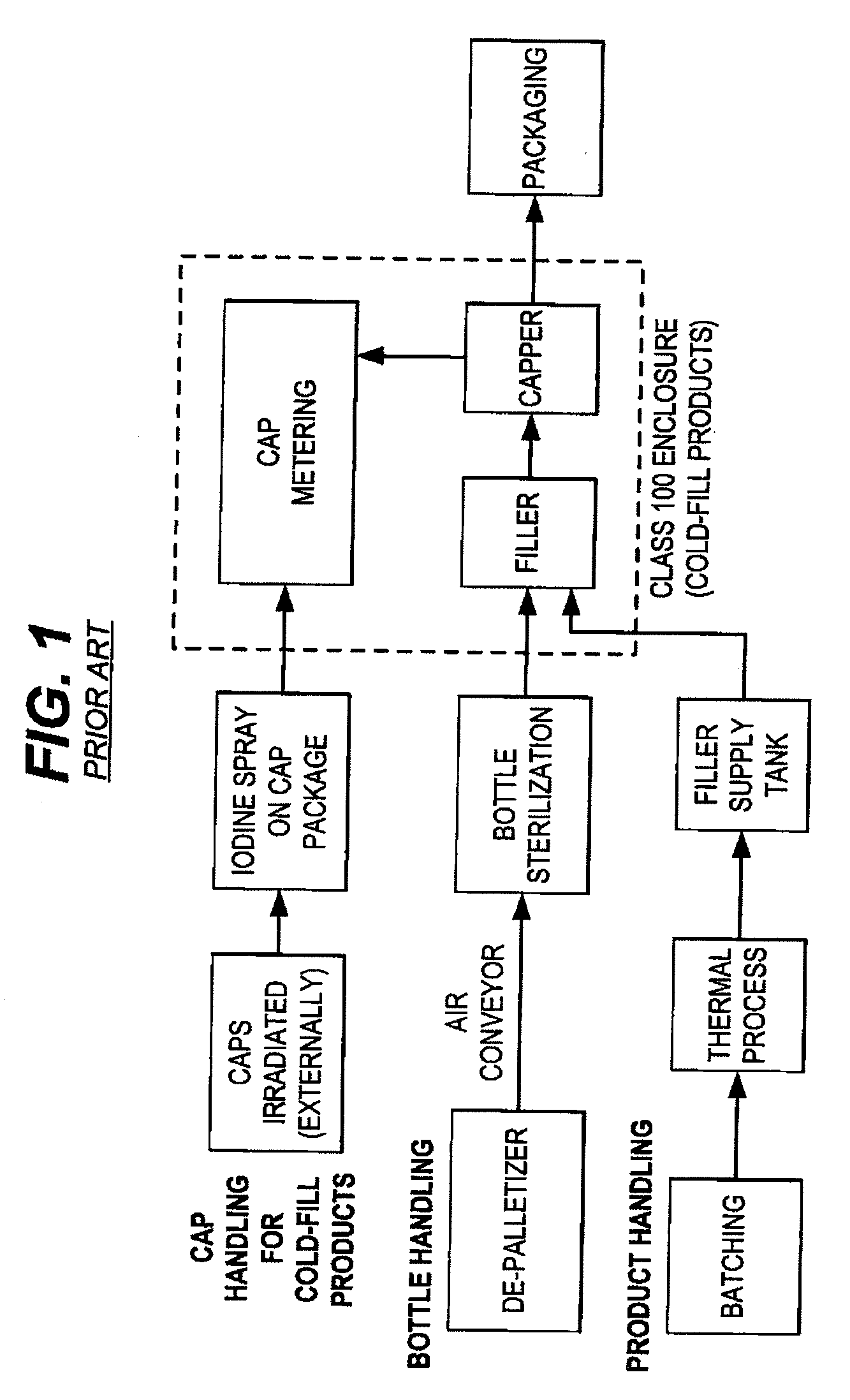

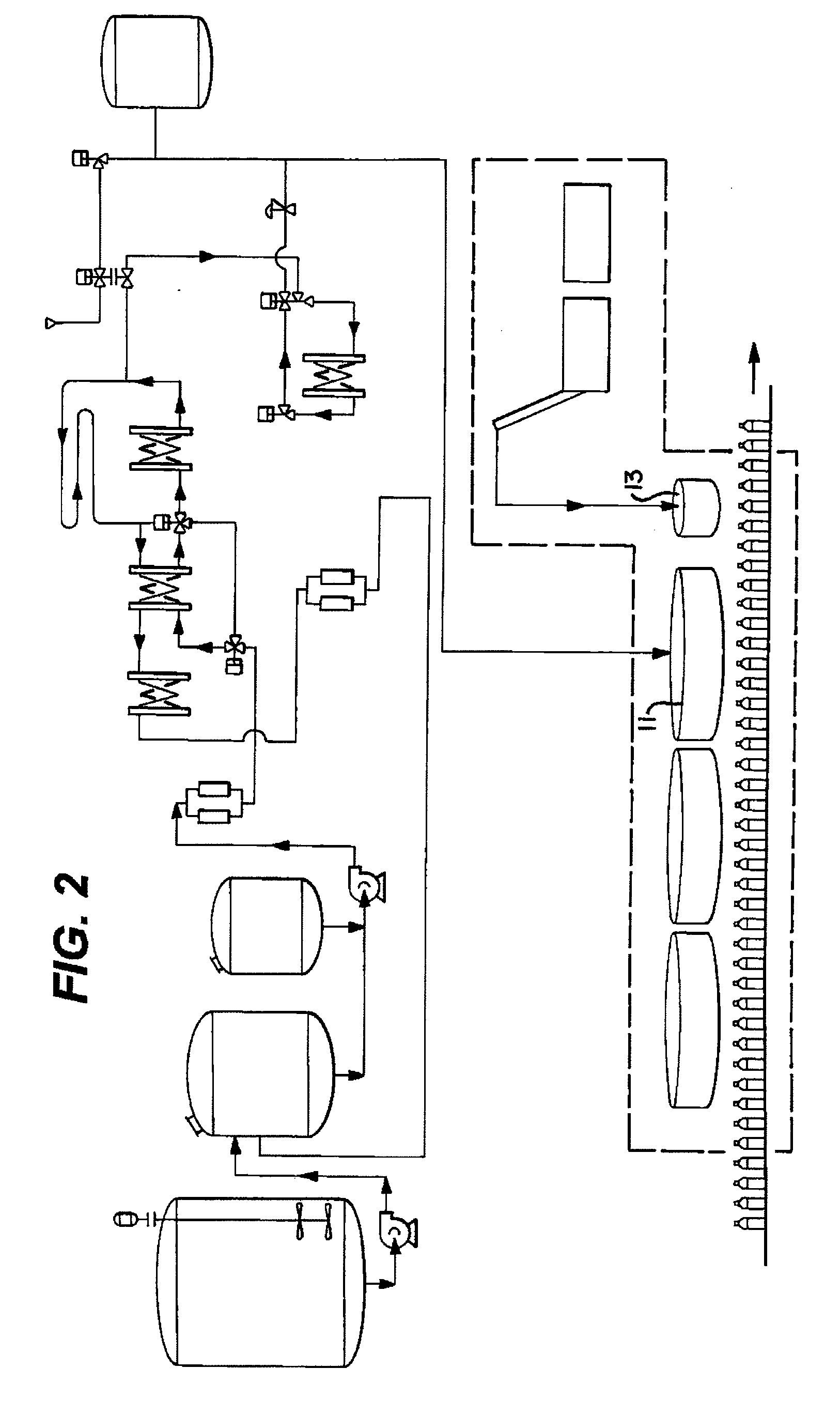

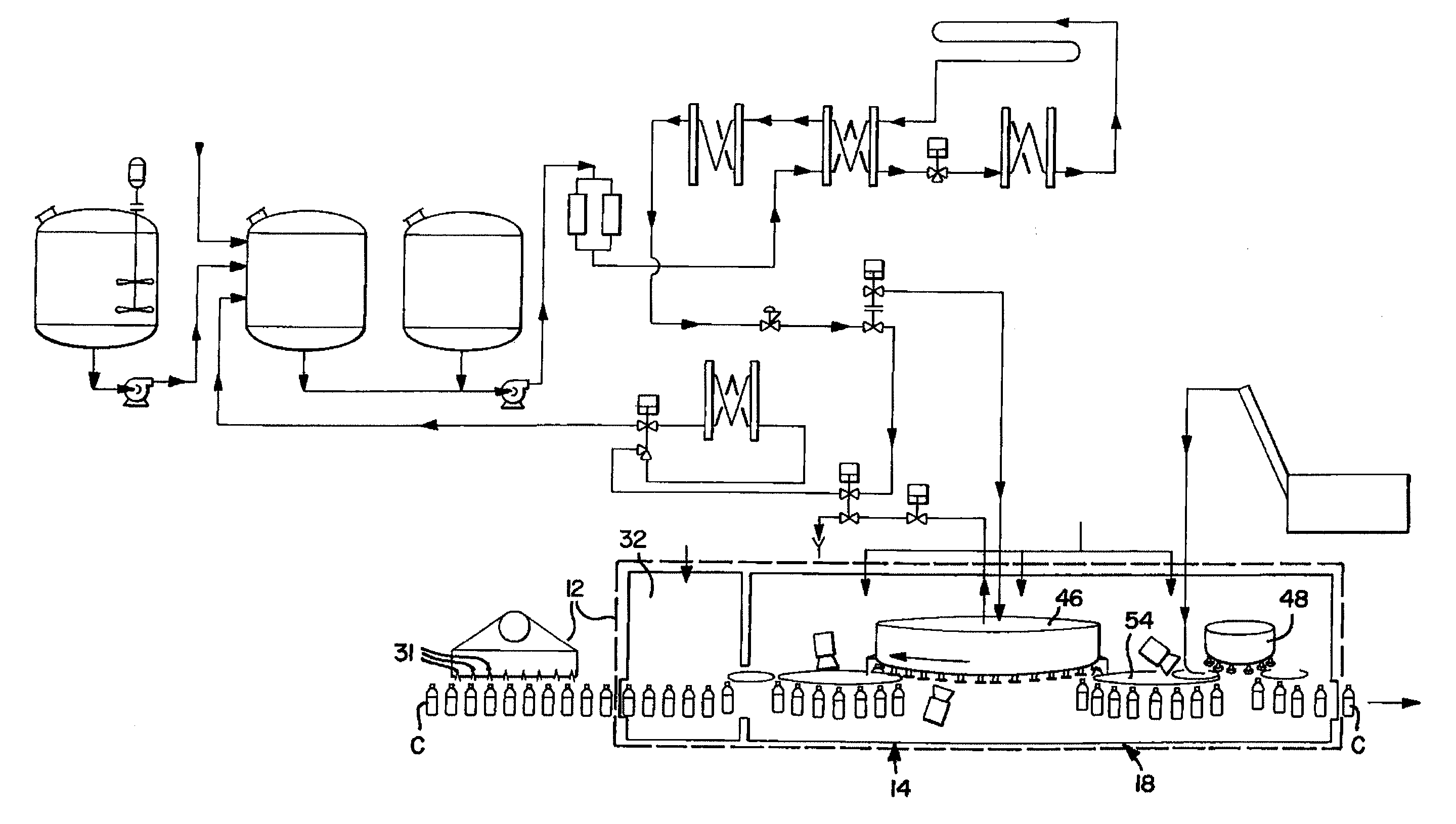

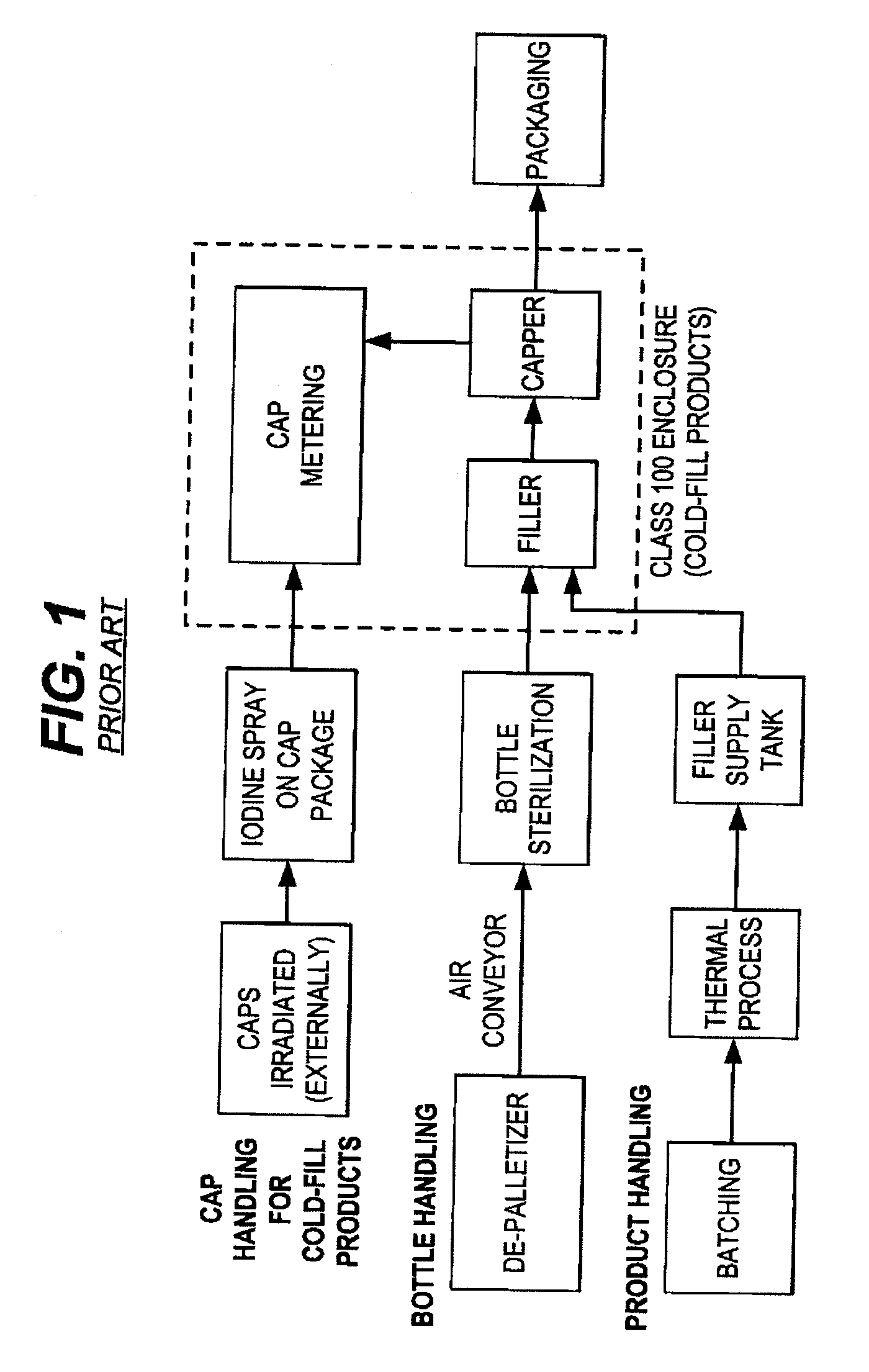

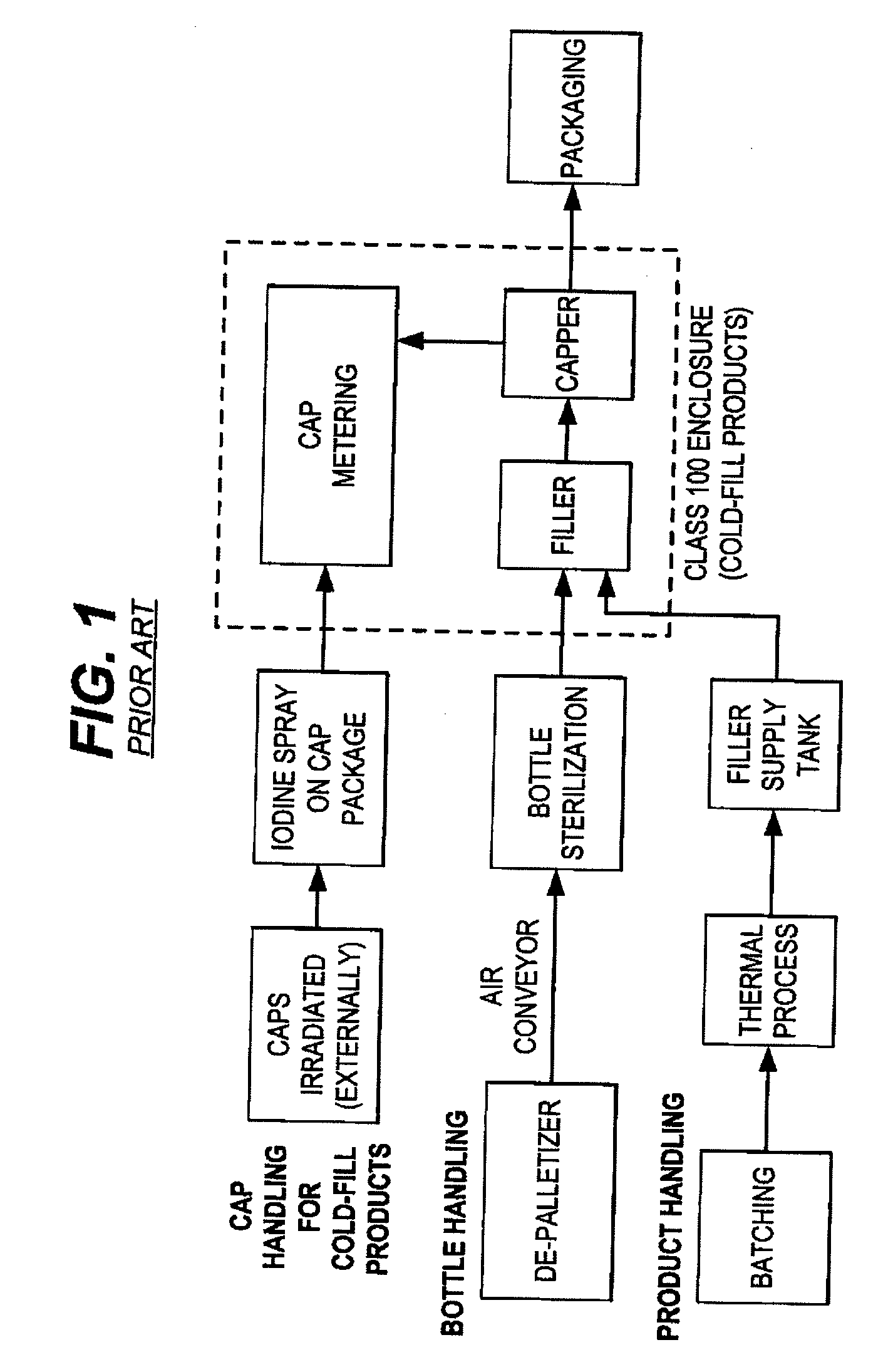

Active sterilization zone for container filling

InactiveUS20090013645A1Maintain a sterile environmentLiquid fillingSynchronising machinesEngineeringEMPTY CONTAINER

Owner:STOKLEY VAN CAMP INC

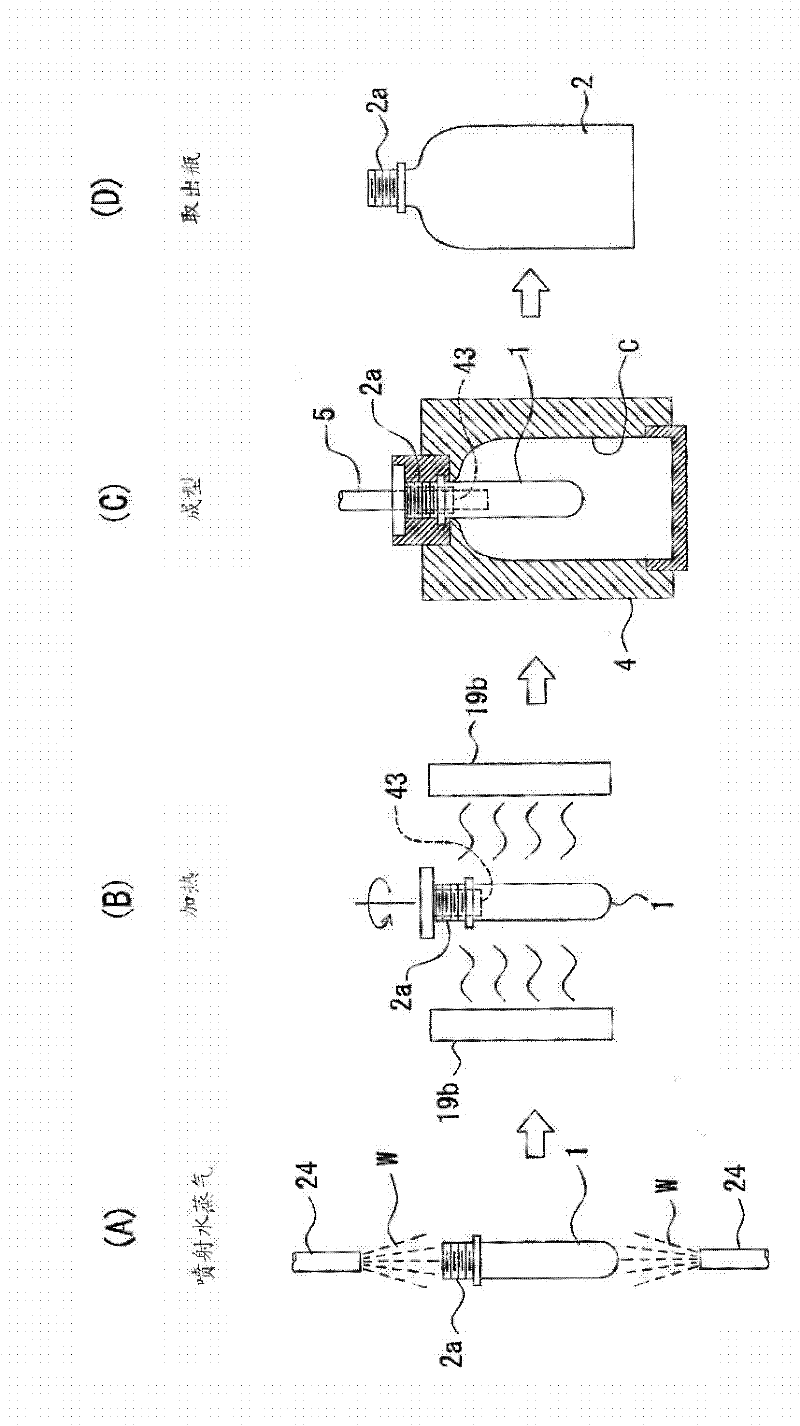

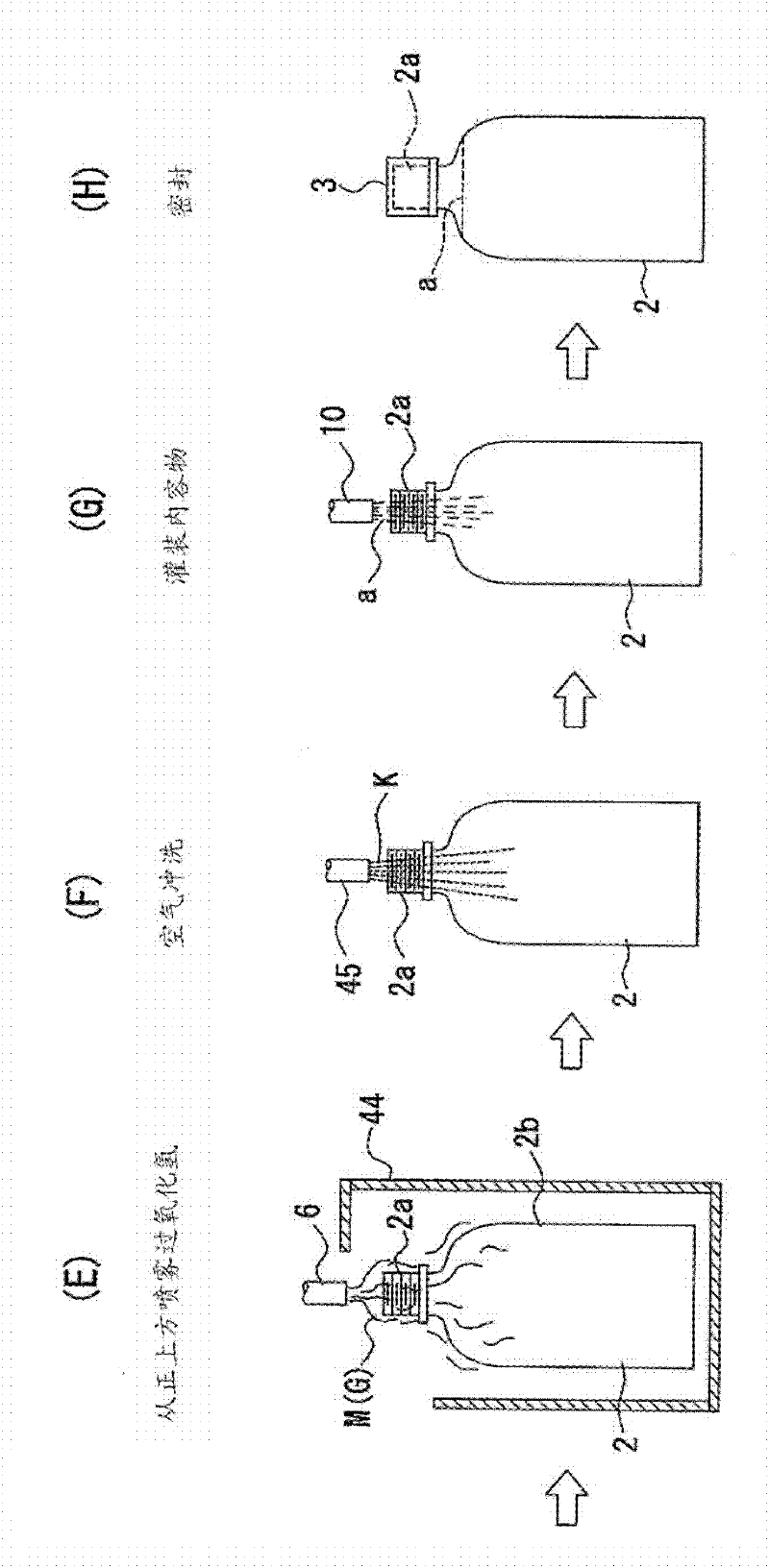

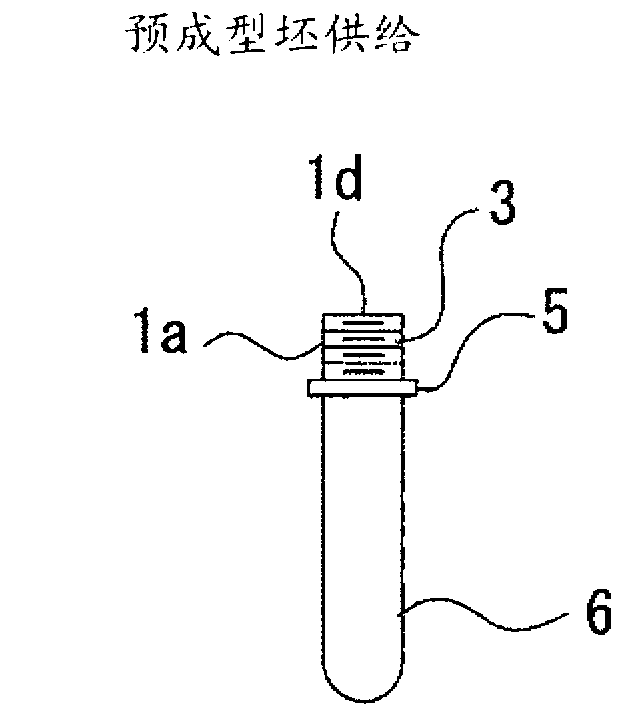

Beverage filling method and device

ActiveCN102282093AAvoid adsorptionReduce usageSynchronising machinesHollow article cleaningWater vaporEngineering

A preform (1) is sprayed with a water vapor (W) and heated while being made to travel continuously, thus performing preliminary sterilization; this preform which has been preliminarily sterilized is blow-molded within a forming die (4), which likewise continuously travels, and a bottle is formed; the bottle is extracted from this continuously traveling forming die, and while heat remains the bottle is sprayed with a condensed mist (M) or gas (G) of hydrogen peroxide and is air-rinsed; and this bottle is filled with a beverage and sealed with a cap while likewise being made to travel continuously. The bottle sterilization process in an inline system can be simplified.

Owner:DAI NIPPON PRINTING CO LTD

Multilevel container filling machine such as a multilevel beverage bottle filling machine

InactiveUS7866123B2Increase chanceReliable constructionSynchronising machinesSolid materialBottleEngineering

A filling machine for containers such as bottles, cans, or similar containers. The filling machine comprises at least one rotor, which is driven in rotation around a vertical machine axis, and filling stations on the rotor. Each filling station is designed to receive a container and for the filling of this container during the rotational movement of the rotor between a container inlet point and a container outlet point. The filling stations are provided in at least two filling planes, which are offset from one another in the direction of the machine axis.

Owner:KHS GMBH

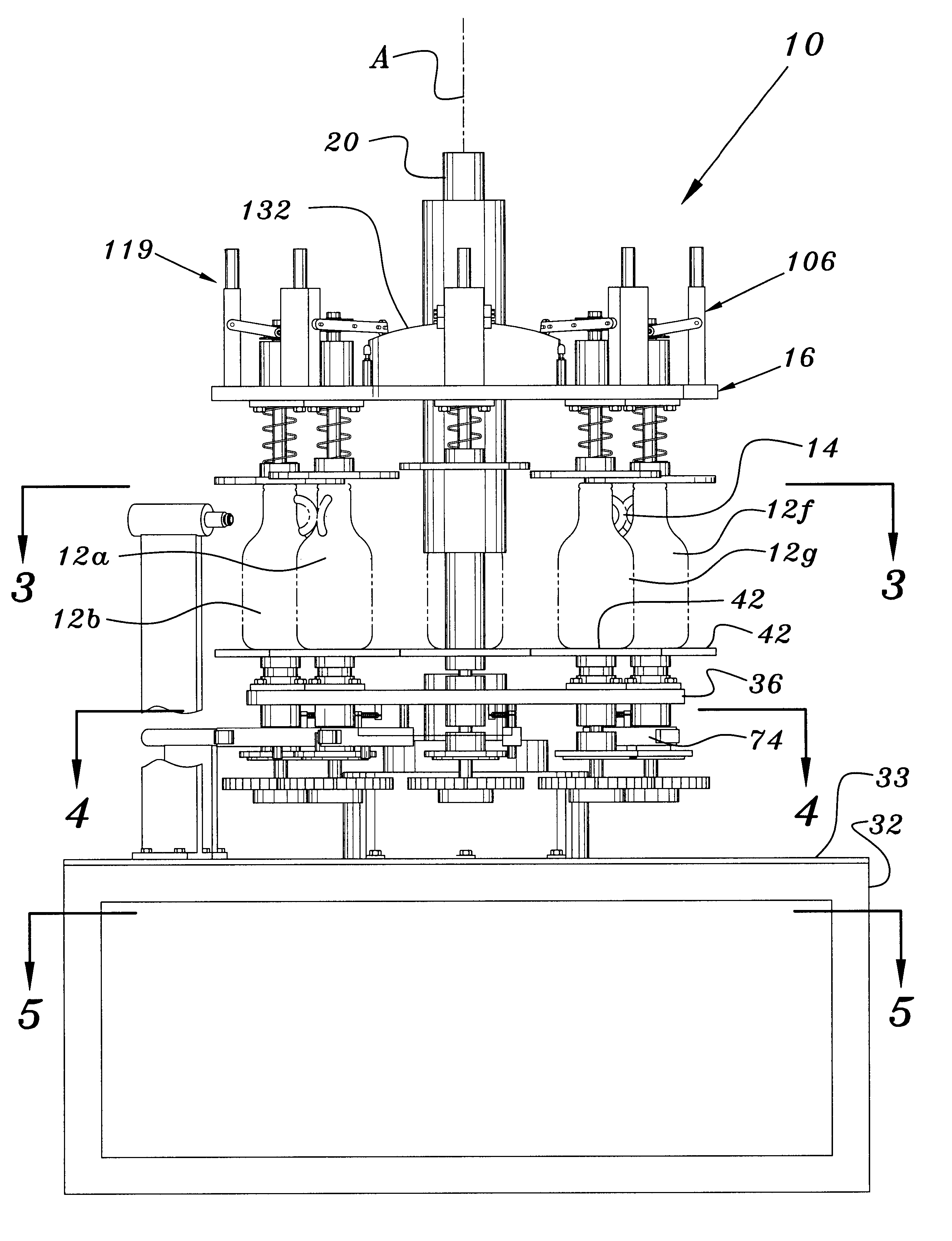

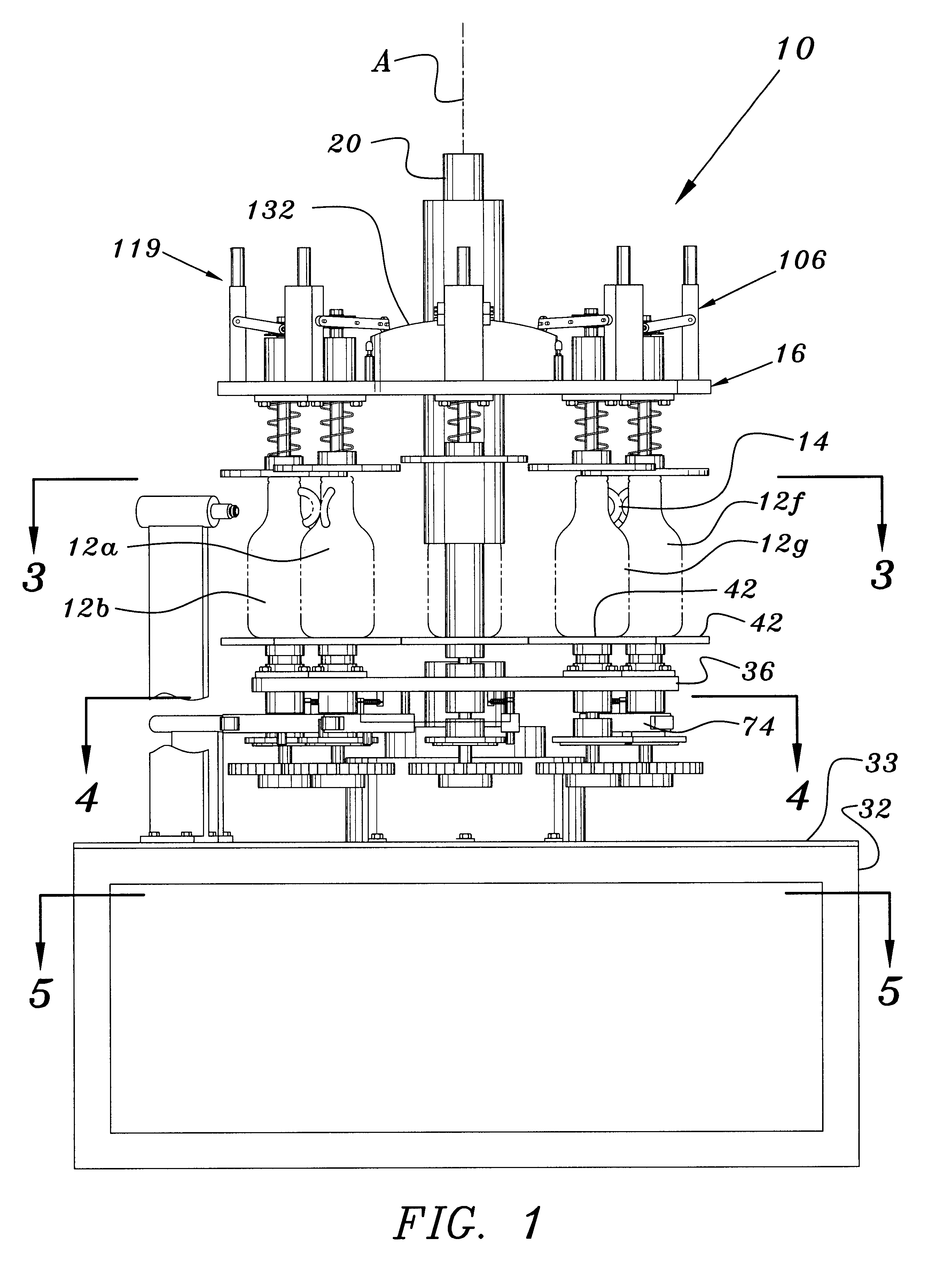

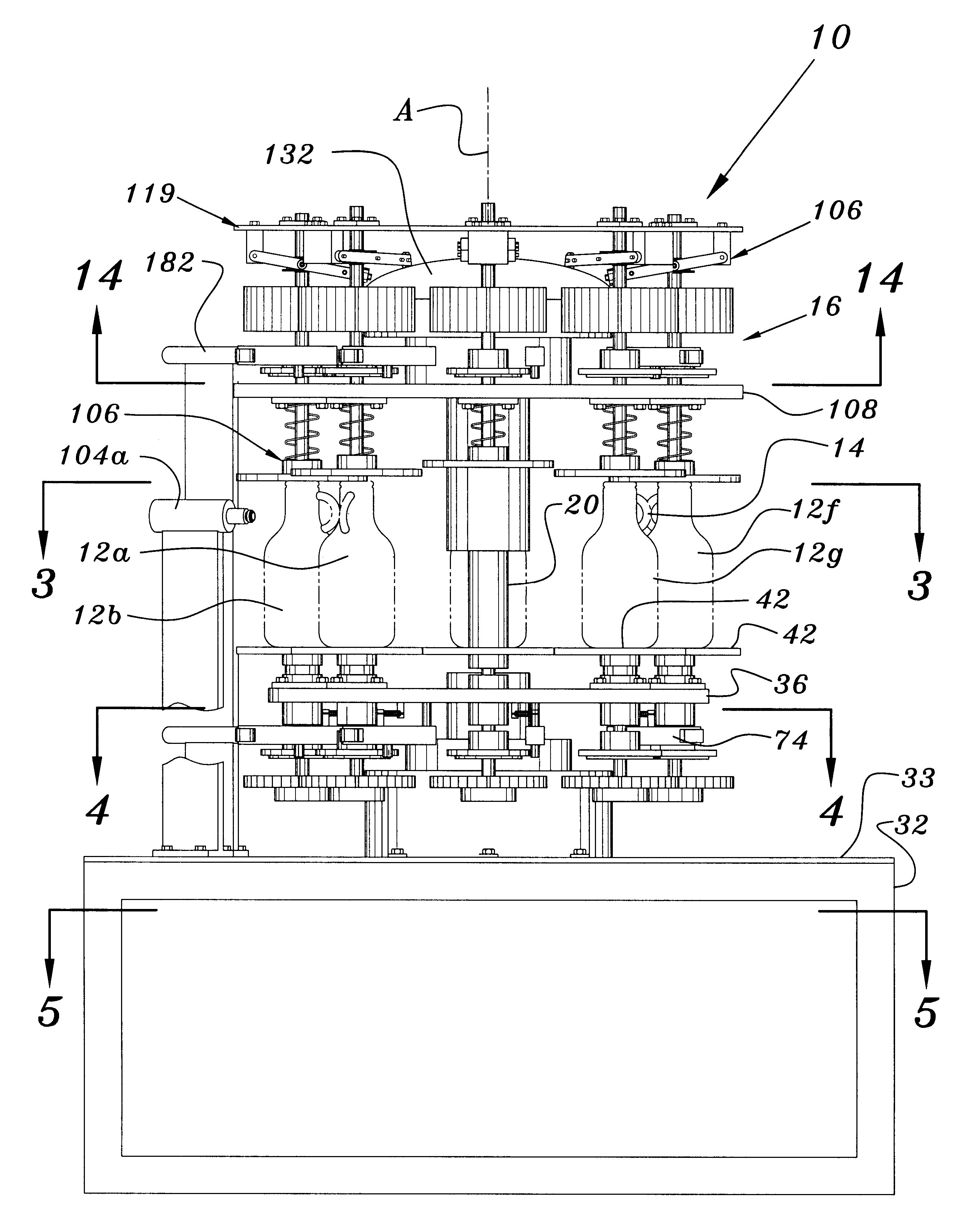

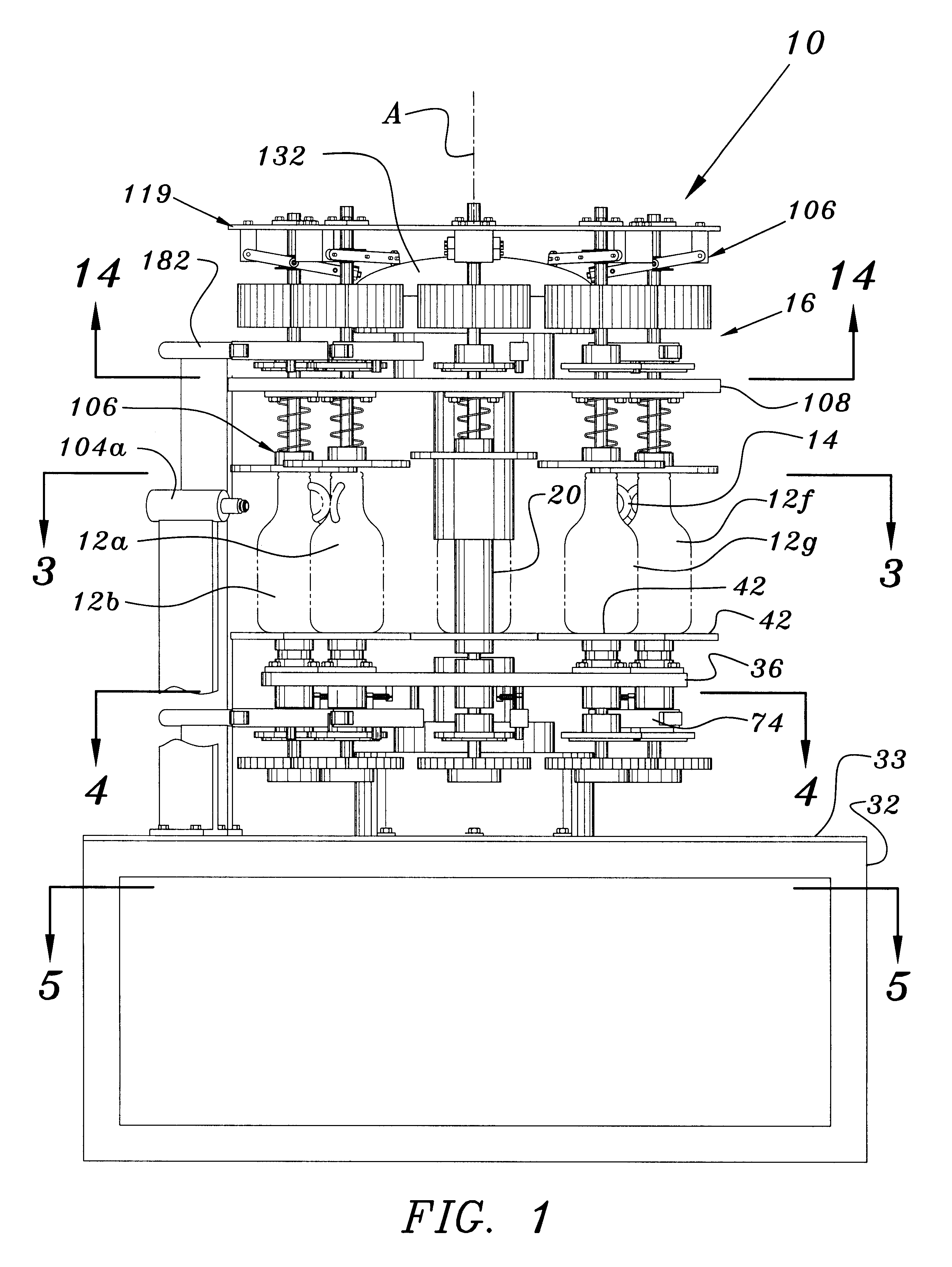

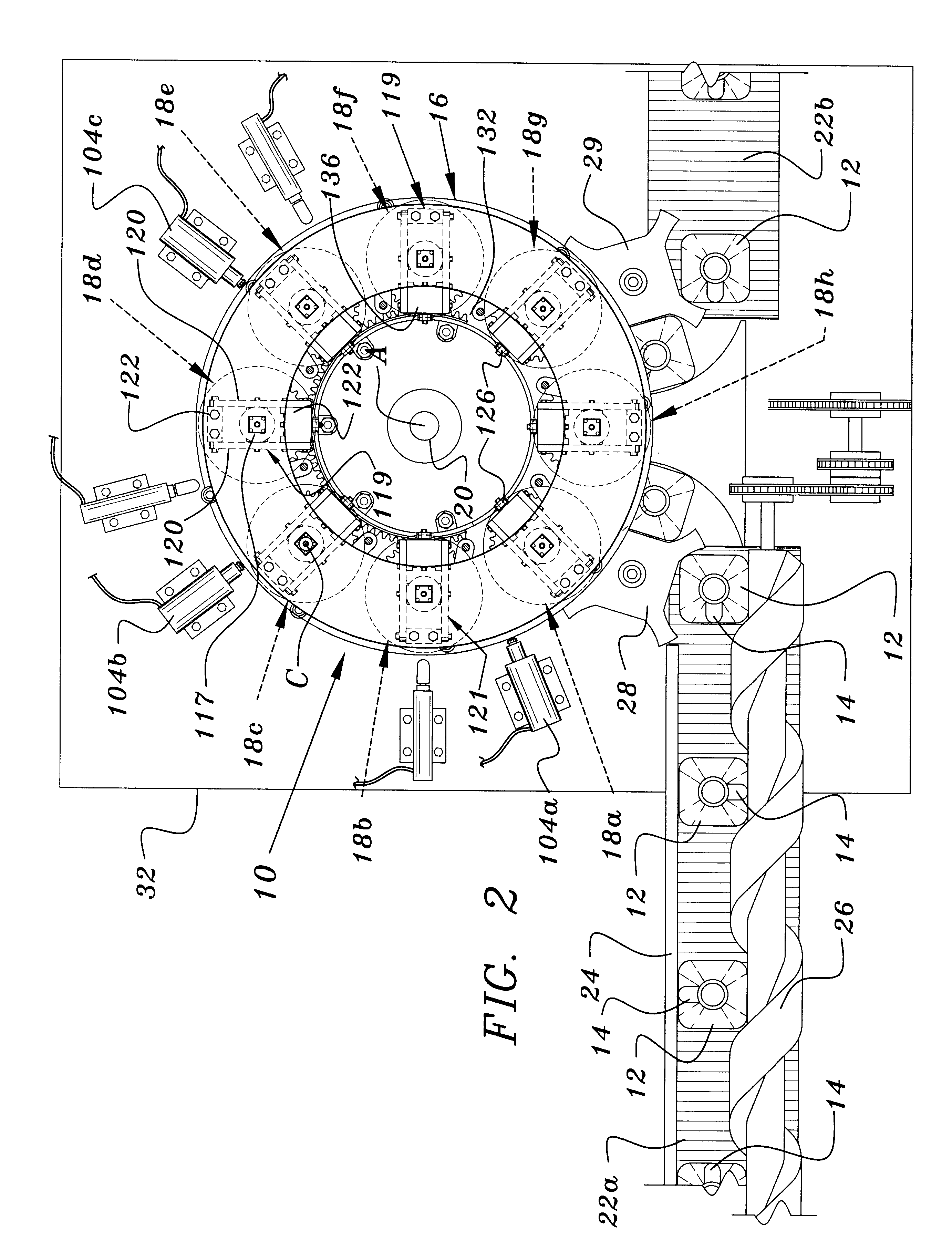

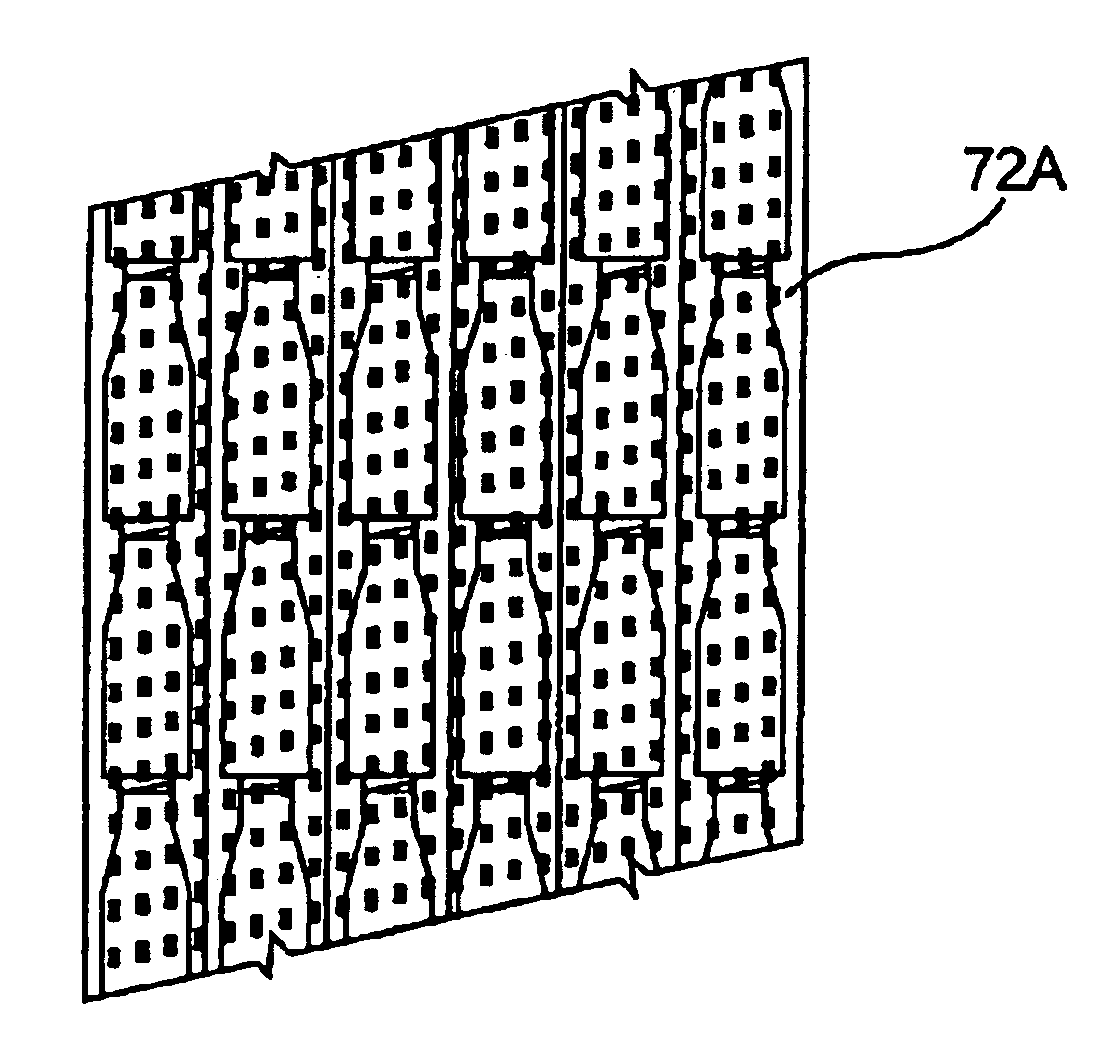

Container Handling System

ActiveUS20090120530A1Smooth for label placementThorough removalSynchronising machinesFilling using counterpressureBlow moldingStructural geometry

A system for processing a simplified plastic container (C) that is to be filled with a hot product includes the step of blow-molding parison to form a container body, where the container body has a neck, a base, a side surface relatively free of structural geometry that surrounds an interior of the container body and, prior to being filled with the hot product, a projection (12) extending from the container body. After the container body is filled with a hot product in a production line, the neck of the filled container body is capped with a cap and then, the container body is cooled. During the cooling operation, the hot product is contracted so that the projection extending from the container can be pushed (P) into the container body like a traditional push-up so that the resultant, filled and cooled container body is relatively free of structural geometry.

Owner:CO2 PAC

Neck gripping conveyor and link, and related rotary filler and system

InactiveUS7261199B2Synchronising machinesFilling using counterpressureEngineeringMechanical engineering

A conveyor is disclosed suitable for conveying objects such as containers to a processing station. The conveyor includes a plurality of connected links, and at least one gripping member extending from each of the links. Each gripping member is movable relative to its respective link for gripping a container by the neck of the container. A guide structure is disposed on the link for mating a component of the processing station to the neck of the container for processing the container. The processing station may be a filler such as a rotary filler, a capper, or a rinser. Related individual links, conveying systems, and filler components are also disclosed.

Owner:ILLINOIS TOOL WORKS INC

Full-automatic filling production line

PendingCN106865468AIncrease productivitySmall footprintCapsThreaded caps applicationProduction linePulp and paper industry

The invention discloses a full-automatic filling production line. The full-automatic filling production line comprises a bottle conveying belt mechanism, a following type filling machine and a following type cap screwing machine, wherein the following type filling machine and the following type cap screwing machine are sequentially arranged on the bottle conveying belt mechanism in the conveying direction; the following type filling machine comprises a bottle fixed-distance dispersing mechanism, a following filling mechanism and a first positioning sensor; and the following type cap screwing machine comprises a bottle cap conveying belt mechanism, a cap sorting mechanism, a capping mechanism, a positioning guiding decelerating mechanism and a following cap screwing mechanism. According to the full-automatic filling production line, two filling devices of the following type filling mechanism of the following type filling machine can move in the manner of following bottles in the filling process, a cap screwing device of the cap screwing mechanism of the following type cap screwing machine can move in the manner of following the bottles in the cap screwing process, the bottles do not need to stop in the filling and cap screwing processes, the production efficiency is high, the occupied space is small, and the equipment cost is greatly reduced.

Owner:江苏汤姆森智能装备有限公司

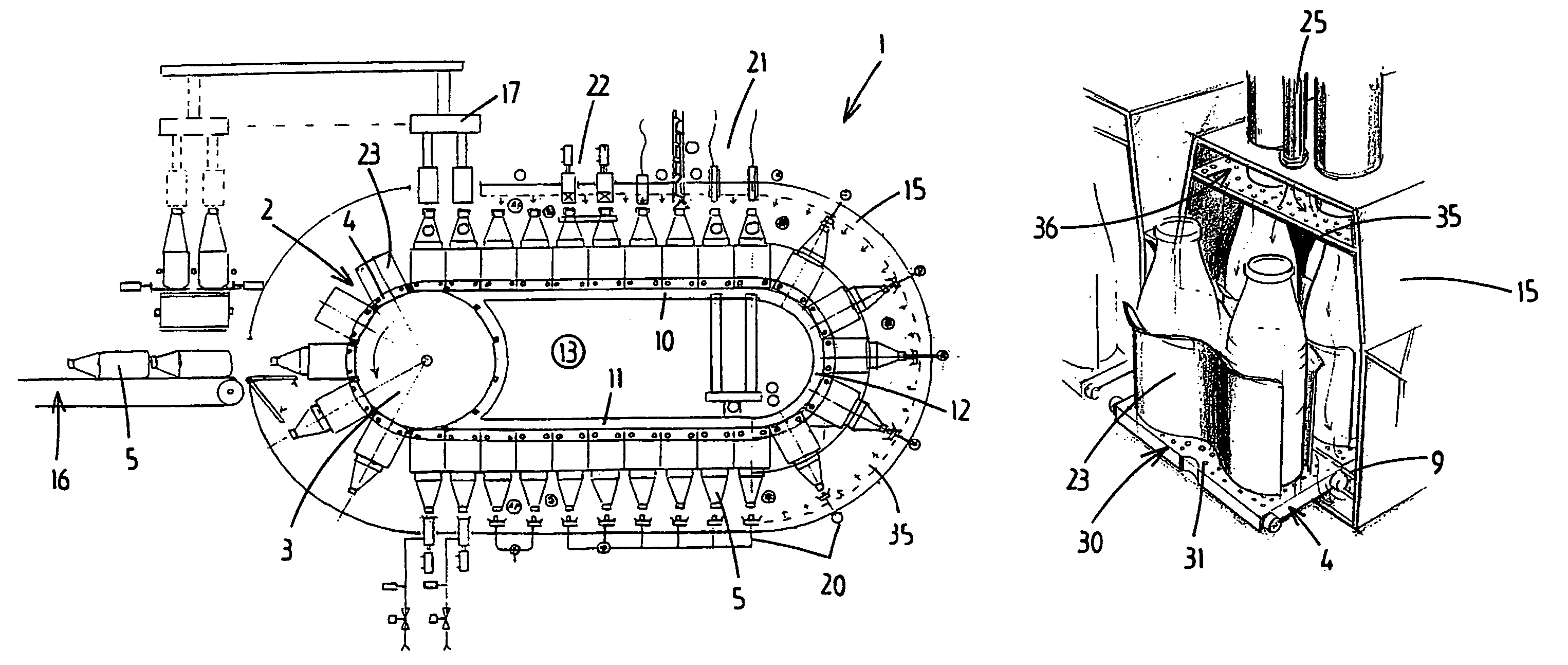

Filling device with housing having a directed gas supply

InactiveUS7162848B2Flexible useOptimized processing functionalitySynchronising machinesPackage sterilisationProduct gasPetrol station

A filling device for filling containers with foods and closing the containers includes an endless conveyor system for conveying container holders; a container infeed mechanism for supplying containers to the container holders; workstations for carrying out operations on containers conveyed therealong, including a filling station and a closing station; a container discharge mechanism for removing containers from the container holders; at least one processing line provided along the conveyor track for containers to be processed; a housing that at least partially encloses the processing line; and gas supply means for feeding conditioned gases into the housing. The housing extends at least along the filling station and the closing station. Inside the housing, the gas supply means supply gas flow substantially close to filling apertures along outsides of containers. The gas supply means includes a plurality of adjacent gas outflow apertures opening into the housing.

Owner:JBT FOOD & DAIRY SYST BV

Active Sterilization Zone for Container Filling

Owner:STOKLEY VAN CAMP INC +1

Method and apparatus for aseptic packaging

InactiveUS6945013B2Fast processingRule out the possibilitySynchronising machinesPackage sterilisationEngineeringProcess rate

A method and apparatus for providing aseptically processed low acid products in a container having a small opening, such as a glass or plastic bottle or jar, at a high output processing speed.

Owner:STEUBEN FOODS

Beverage filling method and machine

ActiveCN103261033AQuality improvementAppropriate and rapid sterilizationConveyorsSynchronising machinesBlow moldingEngineering

Owner:DAI NIPPON PRINTING CO LTD

Beverage bottling plant for filling beverage bottles having a bottle handling station and a method of operation thereof

A beverage bottling plant for filling beverage bottles having a bottle handling station and a method of operation thereof. The bottle handling station has an inspection station for inspecting bottles for observable contaminants that have been rinsed off of the interior of the bottles using an amount of liquid introduced into the bottles by a liquid dispenser, and then gathered in the amount of liquid in a bottom area of the bottles.

Owner:KHS GMBH

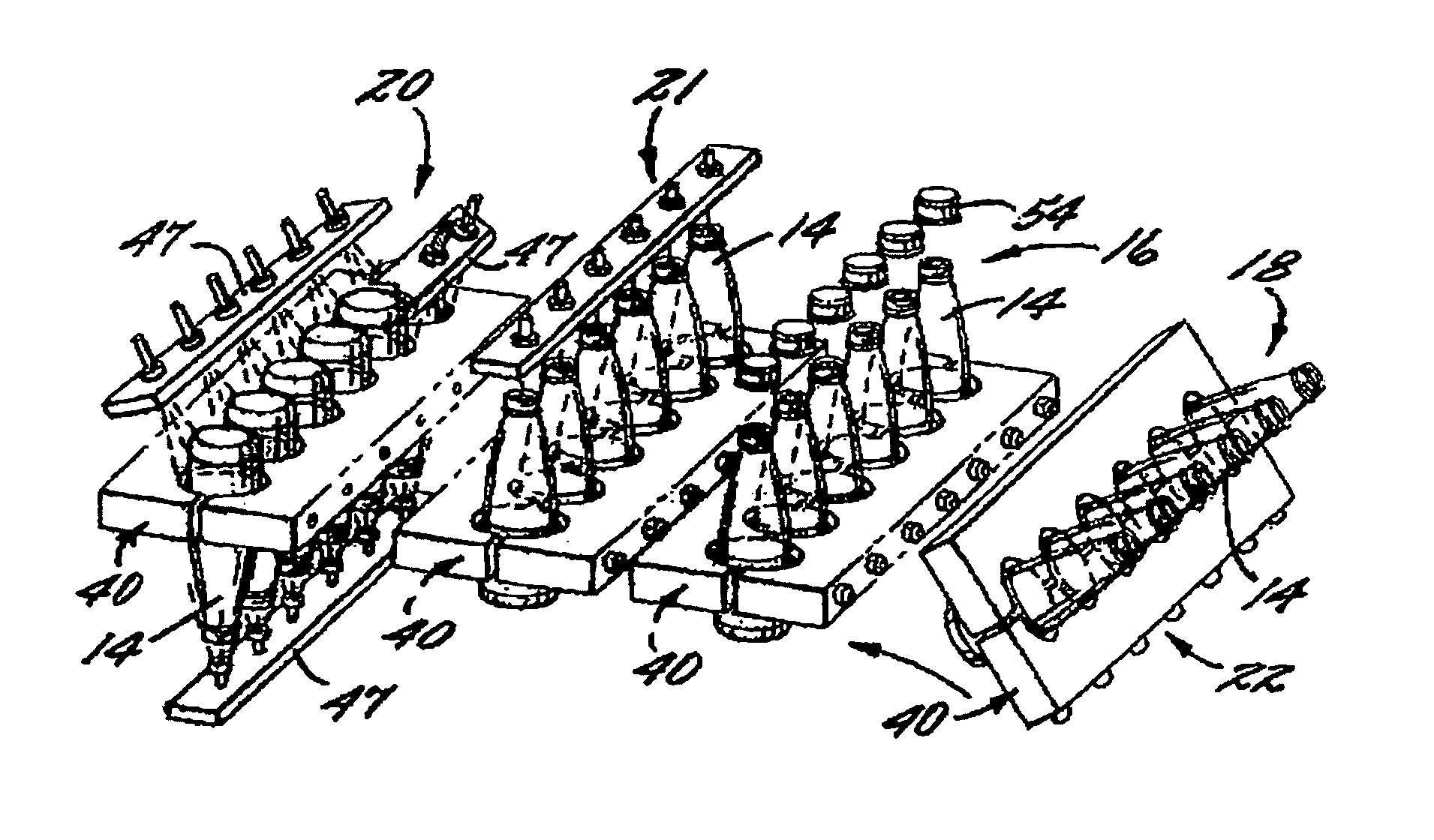

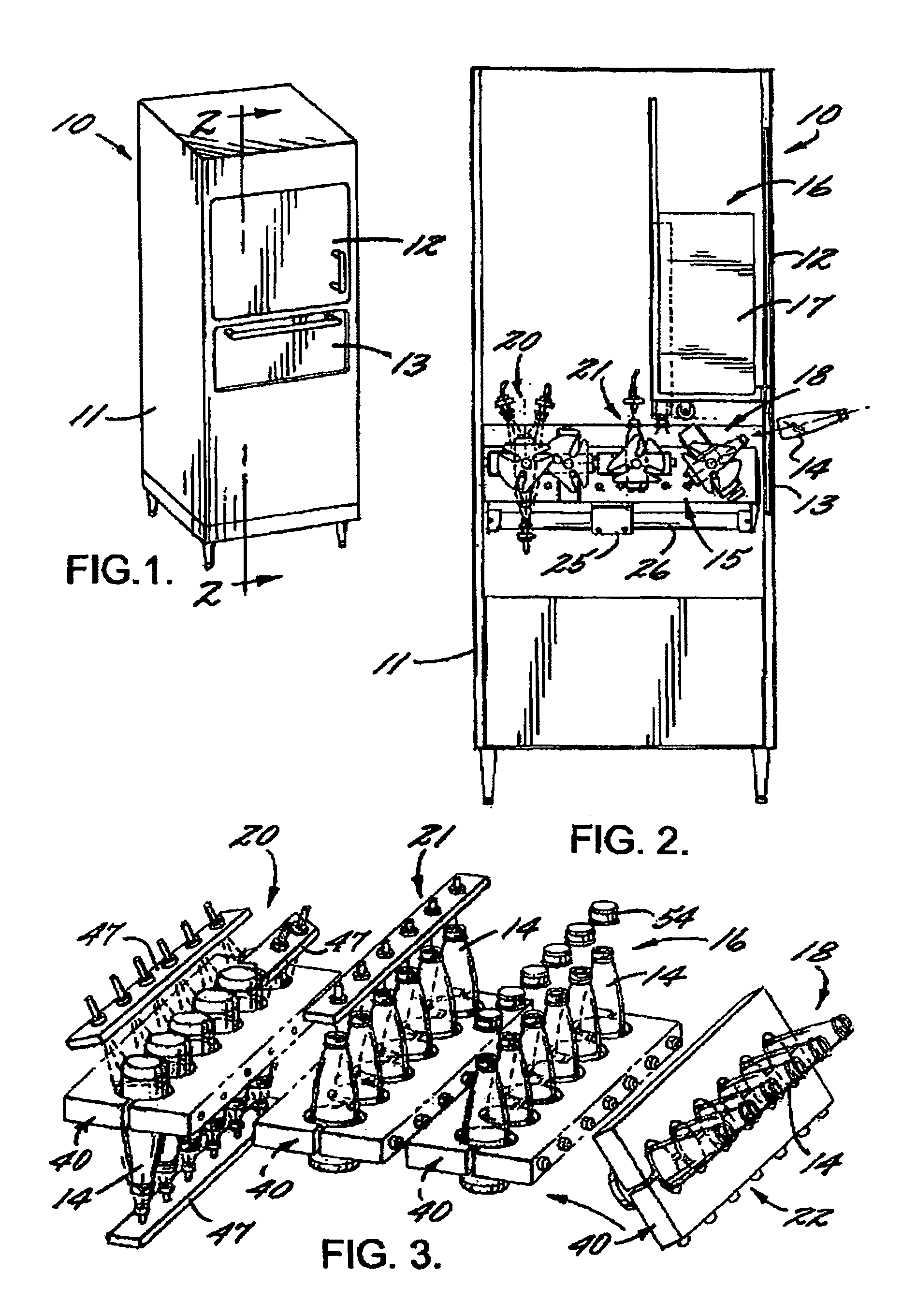

Apparatus for cleaning, filling, and capping a container

ActiveUS7980046B2Facilitates washing and filling and sealingCapsDecorative coversEngineeringMechanical engineering

An apparatus for filling a container includes an enclosure (11) having an opening for receiving a container (14). The apparatus may include a shuttle assembly (15), a wash station (20), a fill station (21), and a seal station (16) contained within the enclosure (11). The shuttle assembly (15) may include a frame structure (23) and a shuttle (22). The shuttle (22) may advance along a path of travel and facilitate the washing, filling, and sealing of the container (14). The apparatus may be employed in a method for consecutively washing, filling, and sealing at least one container in an enclosed housing. The method includes the steps of providing at least one container, washing the container, filling the container, and sealing the container. The method may be conducted along a path of travel.

Owner:H2LOCAL

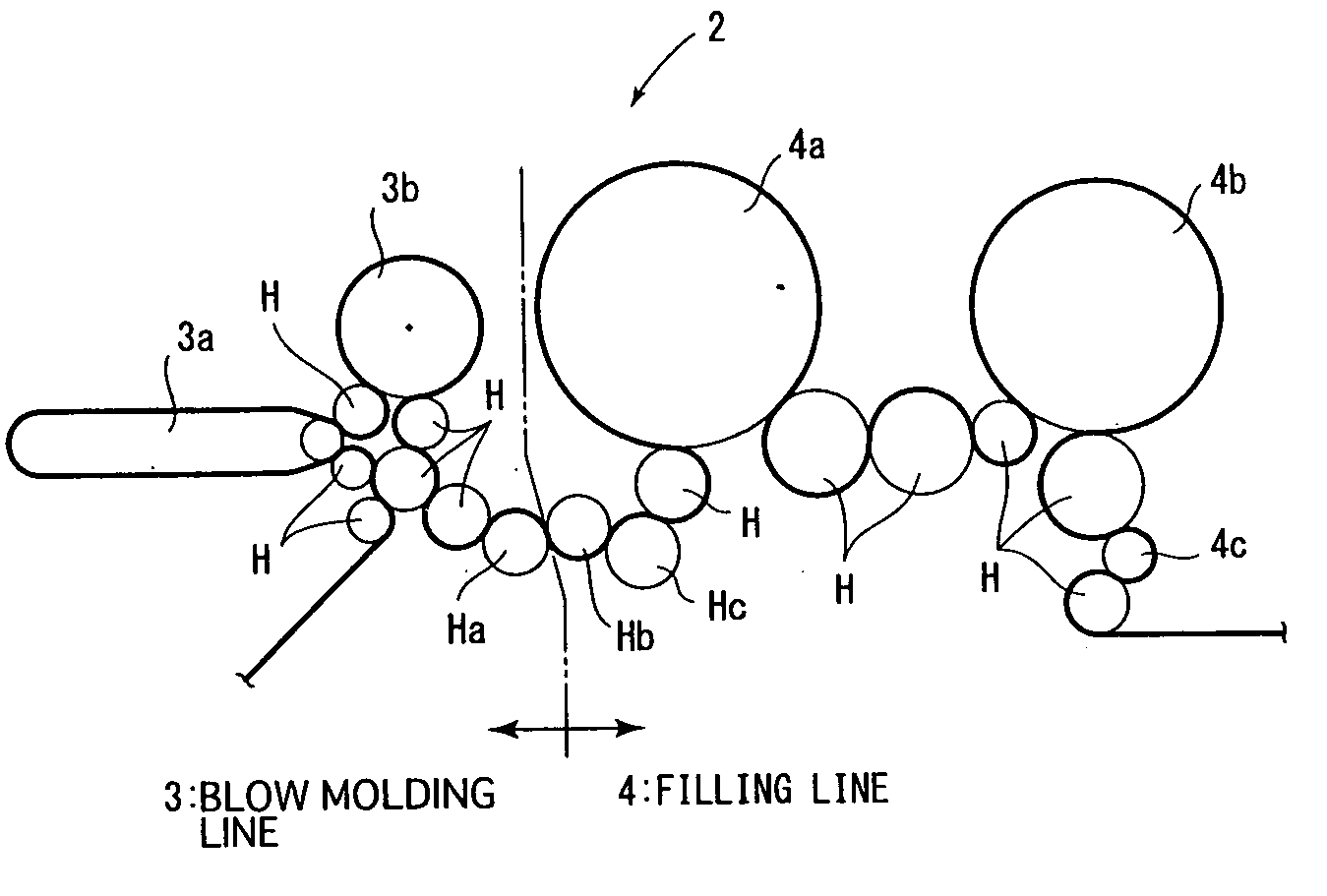

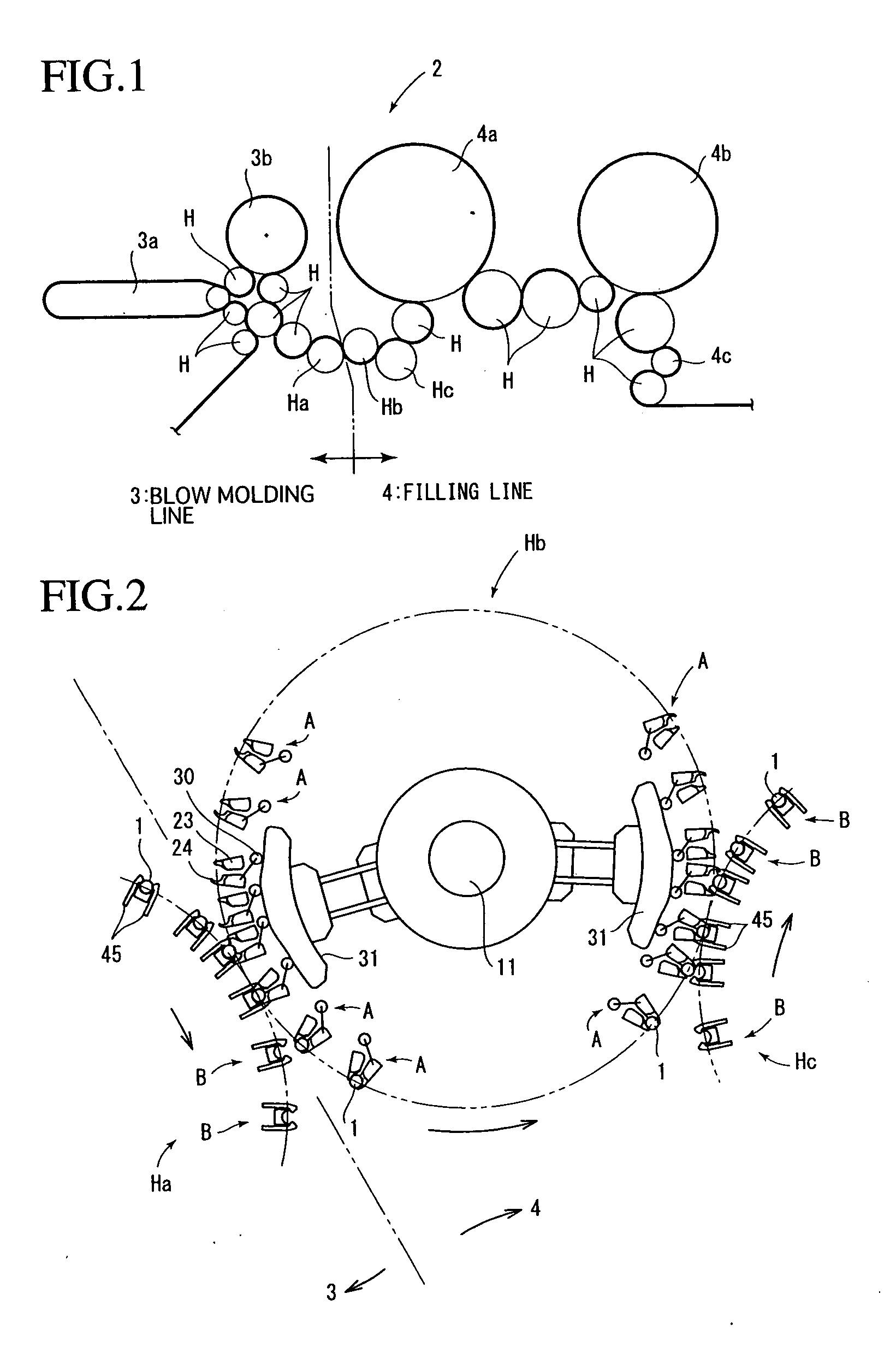

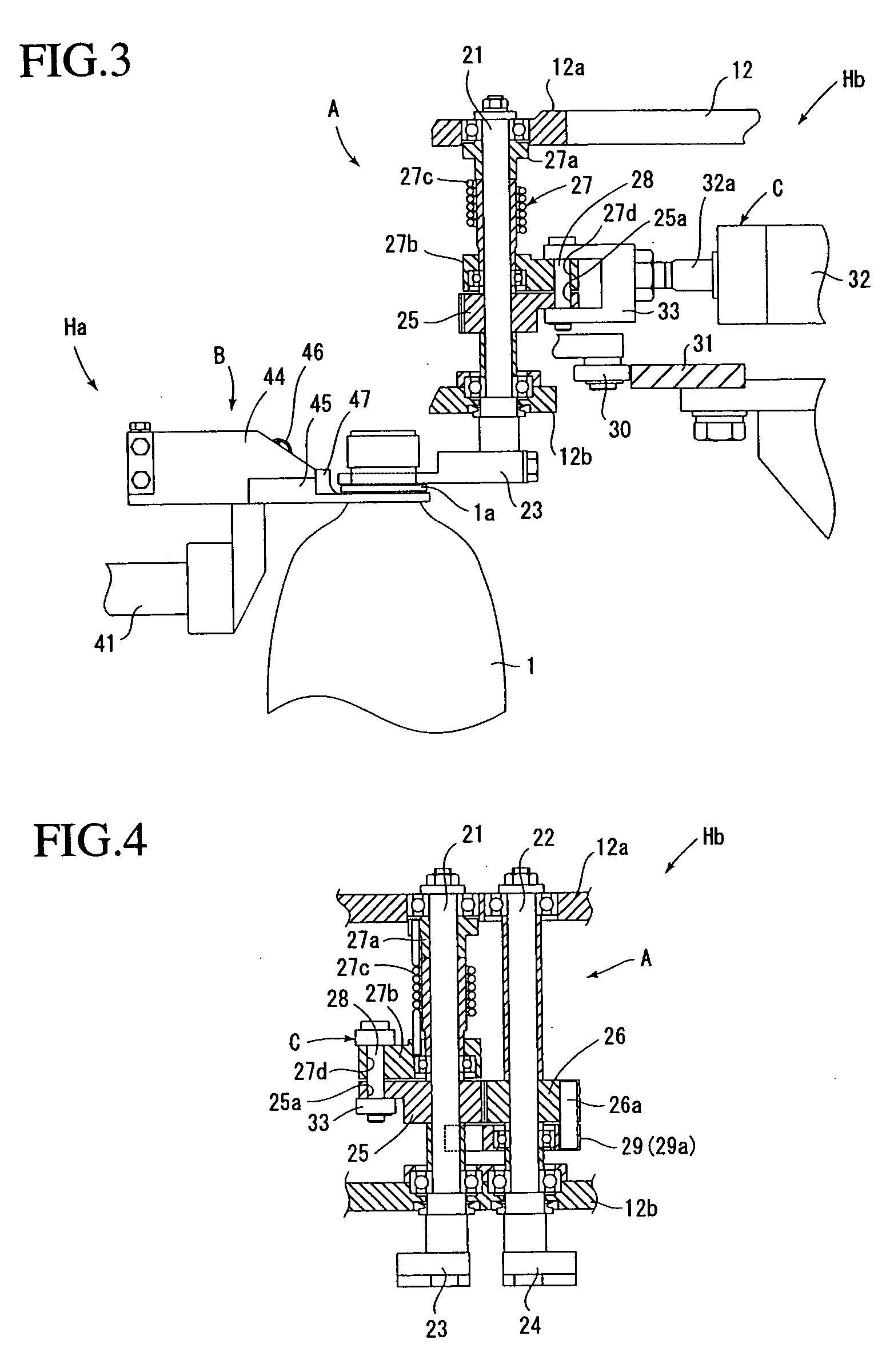

Article conveying device

ActiveUS20080223691A1Without increasing size of equipmentContinuous operationSynchronising machinesLiquid bottlingEngineeringMechanical engineering

An upstream side wheel Ha including grippers B which do not perform opening and closing operations for themselves, and a downstream side wheel Hb including grippers A each having an opening and closing mechanism are included, and in a delivery position in which both the wheels are adjacent to each other, a plastic bottle 1 is delivered from the gripper B to the gripper A. Here, if the upstream side wheel or the downstream side wheel abnormally stops, control means controls retreating means C provided at the downstream side wheel to switch the grippers A to a retreat state from a use state to make an opening degree of a first and second grip members 23 and 24 of each of the grippers A larger than an opening degree of both the grip members in the use state. Thereby, interference of the plastic bottles gripped by the upstream side grippers and the first and second grip members can be prevented. Even if one of the wheels abnormally stops, the other wheel can be continuously operated without increasing the equipment in size.

Owner:SHIBUYA IND CO LTD +1

Plastic container having a deep-set invertible base and related methods

ActiveUS20130312368A1Lower the volumeSynchronising machinesDomestic articlesEngineeringMechanical engineering

Owner:CO2 PAC

Automatic filling and capping mechanism of beverage dispenser and filling method

The invention discloses an automatic filling and capping mechanism of a beverage dispenser. The automatic filling and capping mechanism comprises a box, a cup dropping mechanism, a cap dropping mechanism, a material filling and cap pressing mechanism and a cup rotating mechanism, wherein the material filling and cap pressing mechanism is arranged above the box, the cup dropping mechanism and the cap dropping mechanism are respectively positioned at two ends of the material filling and cap pressing mechanism and symmetrically arranged at a middle place, the cup dropping mechanism is upwardly arranged, the cap dropping mechanism is downwardly arranged, and the cup rotating mechanism is located at the bottom of the part of the box below the material filling and cap pressing mechanism. Through rotation of a driving motor, cup dropping, material filling, cap dropping and cap pressing are respectively carried out at four positions; the automatic filling and capping mechanism has the advantages of full automatic operation, accurate positioning, no leakage and capacity of allowing consumers to conveniently and rapidly purchase loose-packed beverage on the automatic beverage dispenser; and the cup dropping and cap dropping structures are driven by gear rings, so stability is improved, a failure rate is low and the service life of the automatic filling and capping mechanism is long.

Owner:XINHUA XINCHENG TECH

Active Sterilization Zone for Container Filling

InactiveUS20090017747A1Synchronising machinesDispersed particle filtrationEngineeringEMPTY CONTAINER

Owner:STOKLEY VAN CAMP INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com