Automatic filling and capping mechanism of beverage dispenser and filling method

An automatic filling and beverage machine technology, applied in the field of beverage machines, can solve the problems of many choices, short service life and high failure rate, and achieve the effects of improving stability, long service life and low failure rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further explained below in conjunction with the accompanying drawings and specific embodiments. It should be understood that the following specific embodiments are only used to illustrate the present invention and are not intended to limit the scope of the present invention. It should be noted that the words "front", "rear", "left", "right", "upper" and "lower" used in the following description refer to the directions in the drawings, and the words "inner" and "outer ” refer to directions towards or away from the geometric center of a particular part, respectively.

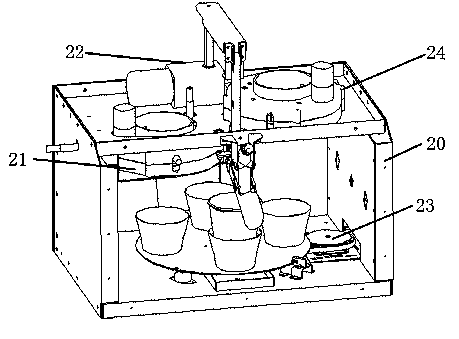

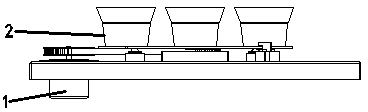

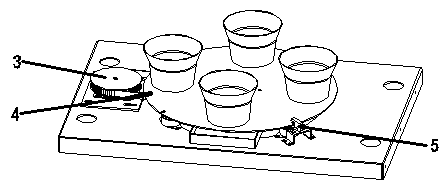

[0031] As shown in the figure, an automatic filling and capping mechanism for a beverage machine according to the present invention includes a box body 20, a cup dropping mechanism 21, a cap dropping mechanism 24, a filling and capping mechanism 22, and a cup rotating mechanism 23. The capping mechanism 22 is arranged directly above the box body 20. The cup dropping mechanism 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com