Full-automatic filling production line

A production line, fully automatic technology, applied in packaging, bottling machines, liquid bottling, etc., can solve the problems of high equipment cost, affecting production efficiency, and multiple production spaces, so as to achieve high production efficiency, reduce equipment costs, and realize full production The effect of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

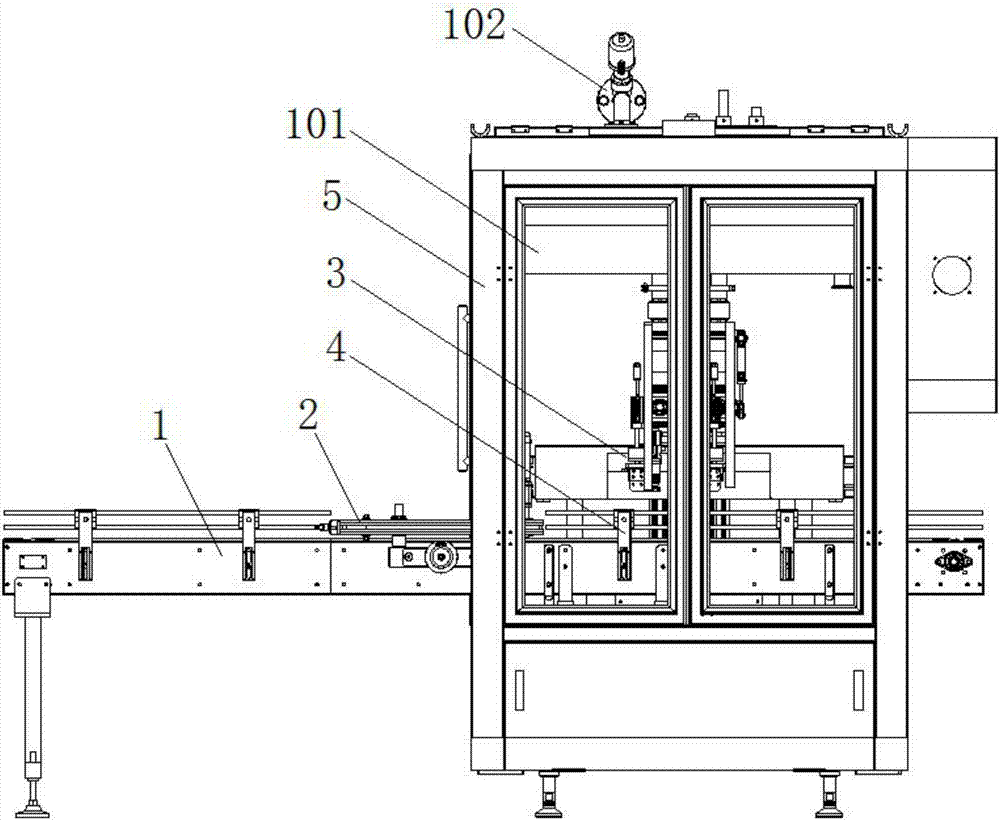

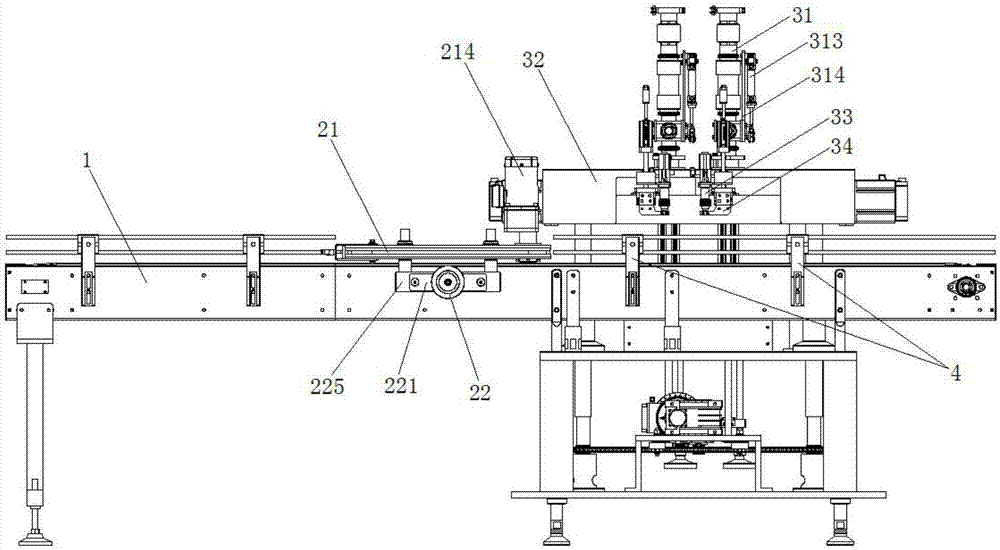

[0055] See Figure 1 to Figure 19 , the fully automatic filling production line of this embodiment includes a bottle conveyor belt mechanism 1, and a follow-up filling machine and a follow-up capping machine arranged sequentially on the bottle conveyor belt mechanism 1 along the conveying direction.

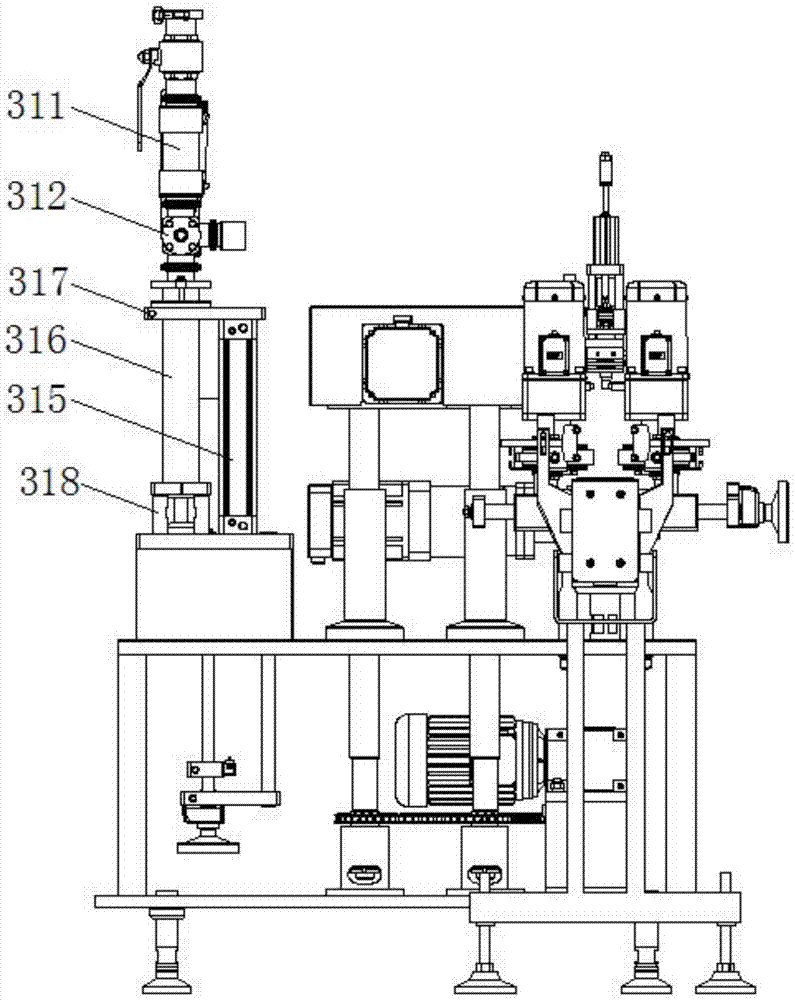

[0056] The follow-up filling machine includes a bottle body distance dispersing mechanism 2 , a follow-up filling mechanism 3 and a first positioning sensor 4 . The bottle body fixed-distance dispersing mechanism 2 and the follow-up filling mechanism 3 are arranged in sequence along the bottle conveying direction. Two filling devices 33 are provided following the filling mechanism 3, and the two filling devices 33 successively follow the movement of two adjacent bottles on the bottle conveyor mechanism 1, and fill the materials into the bottle conveyor mechanism respectively 1 in two adjacent bottles. The first positioning sensor 4 is provided with two groups, and the two group...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com