Method for expanding rectangular sample clamp of automatic sample grinding machine for laboratory

A sample fixture and rectangular technology, which is applied in the field of laboratory material analysis and testing, can solve the problems of limited use range of rectangular hole slot fixtures, and achieve the effect of saving money and improving utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] A new method for expanding the sample holder of the laboratory automatic sample grinding machine involved in the present invention will be further described below in conjunction with specific embodiments and accompanying drawings.

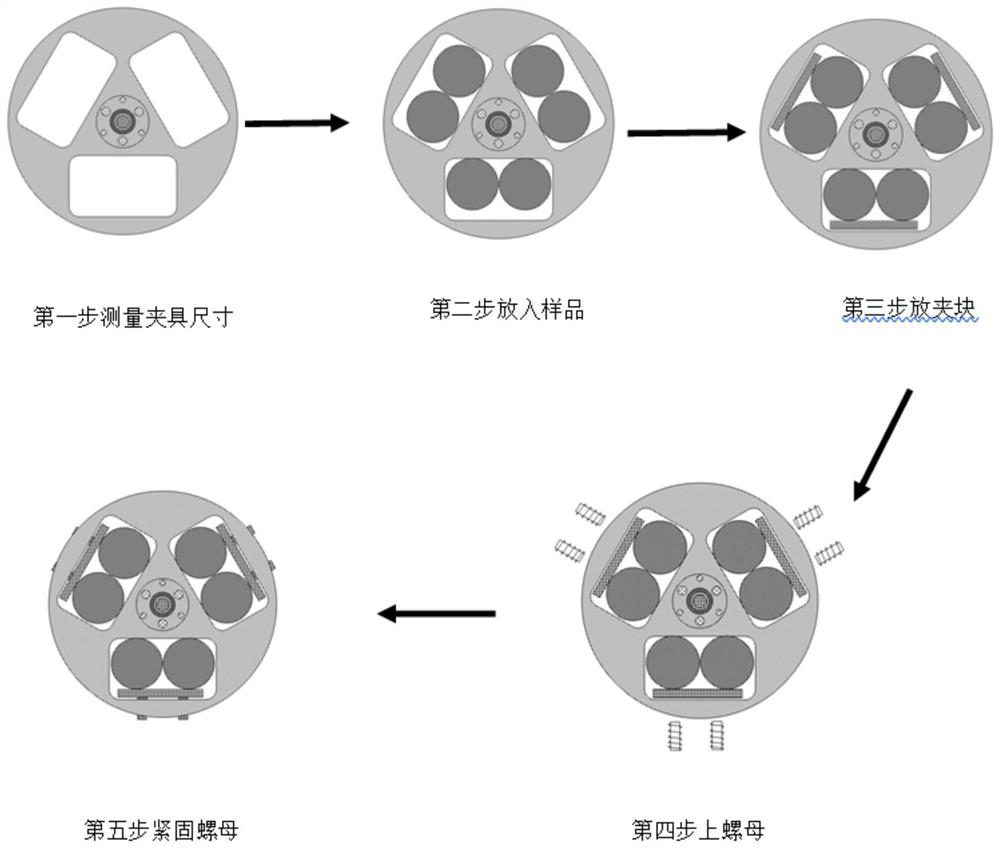

[0022] Such as figure 1 As shown, the method for expanding the rectangular hole slot fixture of the automatic sample grinding machine includes the following steps:

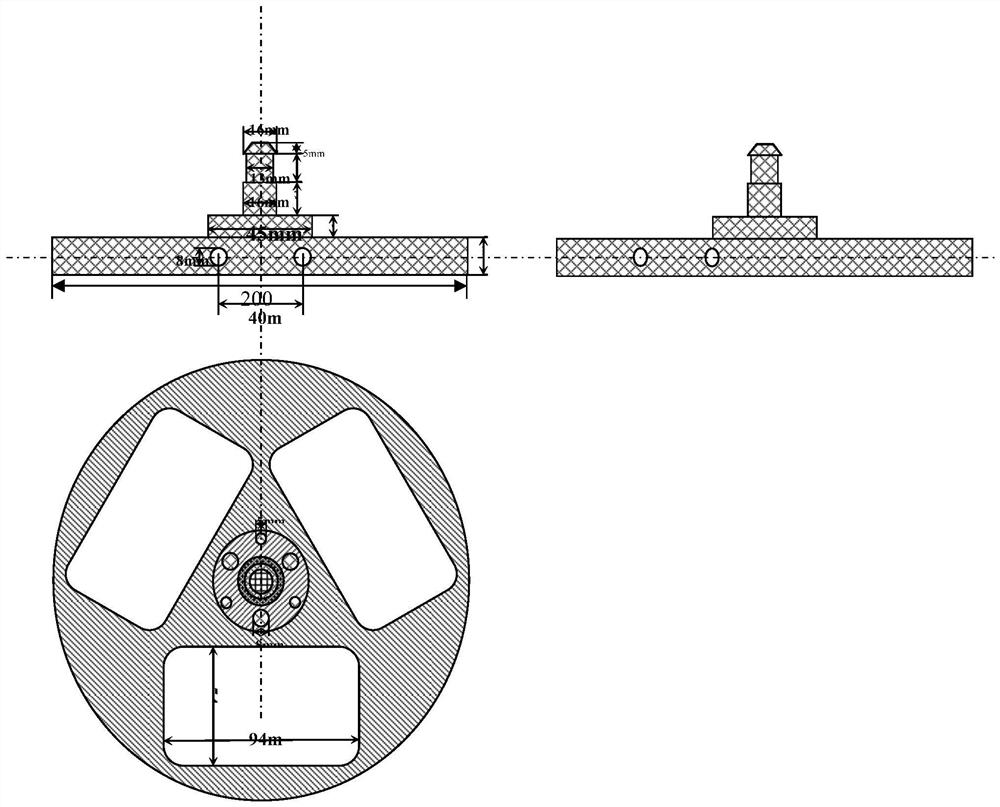

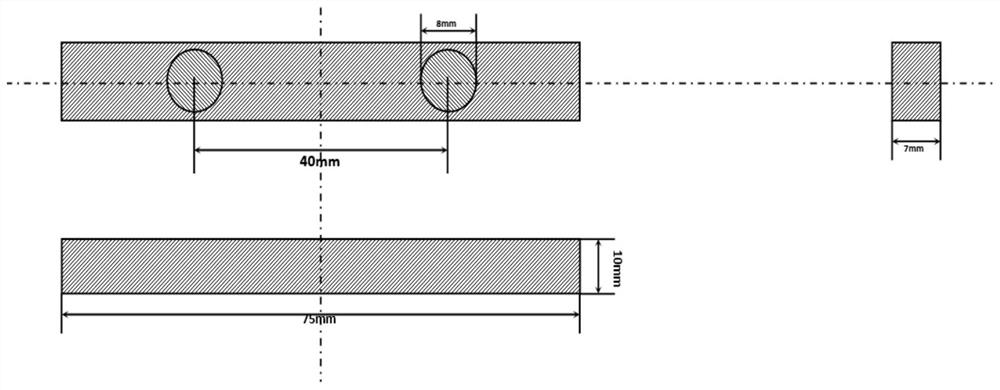

[0023] 1. Measure the length, width and height of the hole groove, the spacing of the fastening nuts, and the diameter of the fastening nuts for the rectangular sample fixture of the Struers automatic grinding machine. The values are: 94mm, 54mm, 17mm, 40mm, 7mm.

[0024] 2. If it is a non-circular sample, select the φ45mm mounting machine aperture according to the shape of the rectangular sample fixture hole (the sample hole size of the Struers rectangular sample fixture is 94mm*54mm, which is suitable for placing a φ45mm mounting sample. The mounting machine aperture It is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com