Oily wastewater treatment method and whole set apparatus thereof

A technology for wastewater treatment and a complete set of equipment, which is applied in the directions of water/sewage multi-stage treatment, flotation water/sewage treatment, water/sludge/sewage treatment, etc. It can solve the problems of high equipment investment, large floor area, and high treatment cost. Problems, to achieve the effect of low investment, high transportation costs, and simple processing procedures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

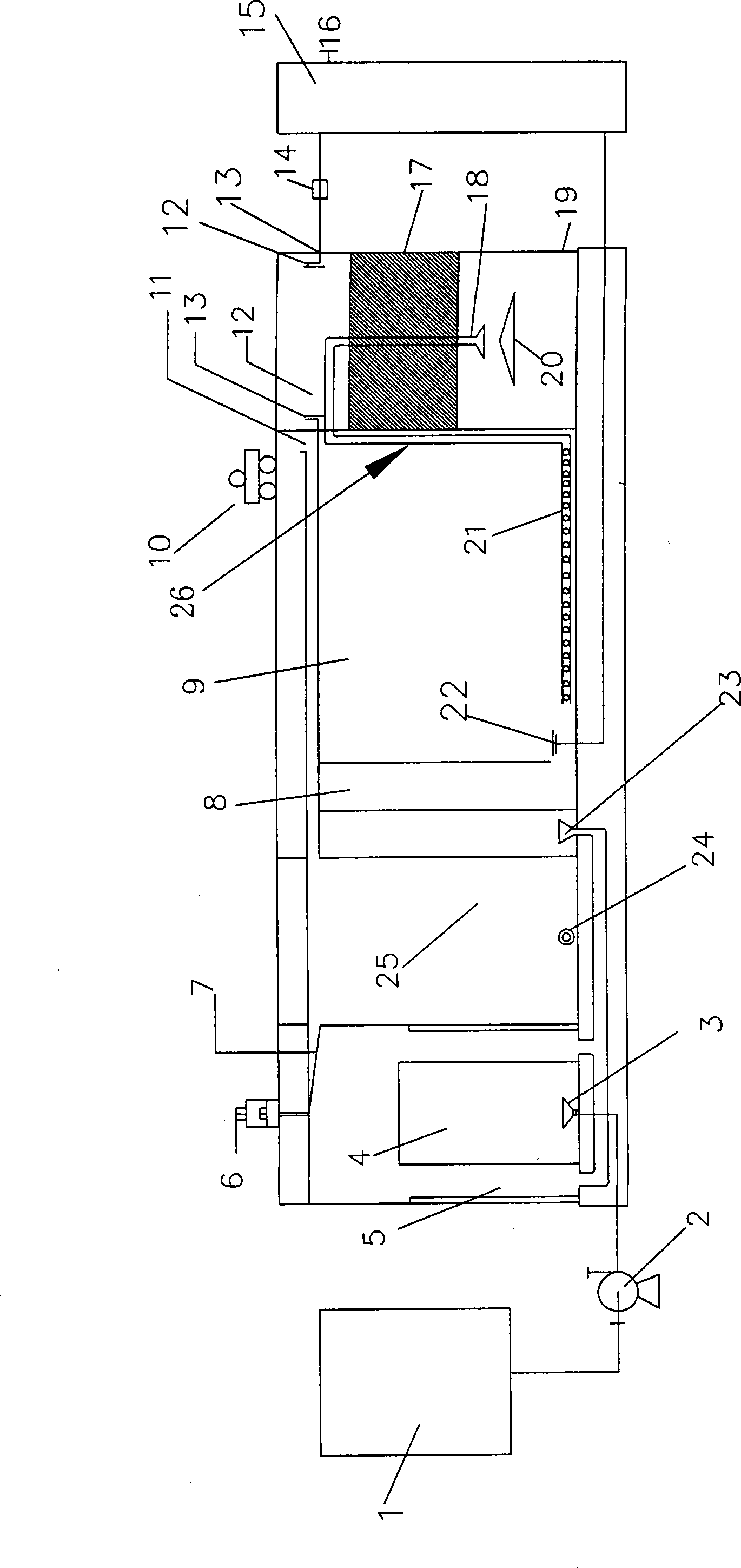

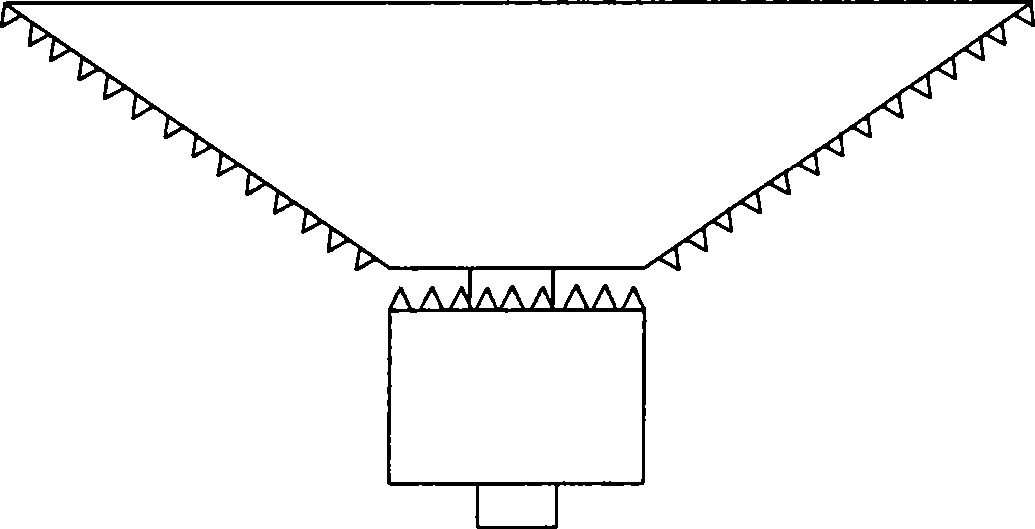

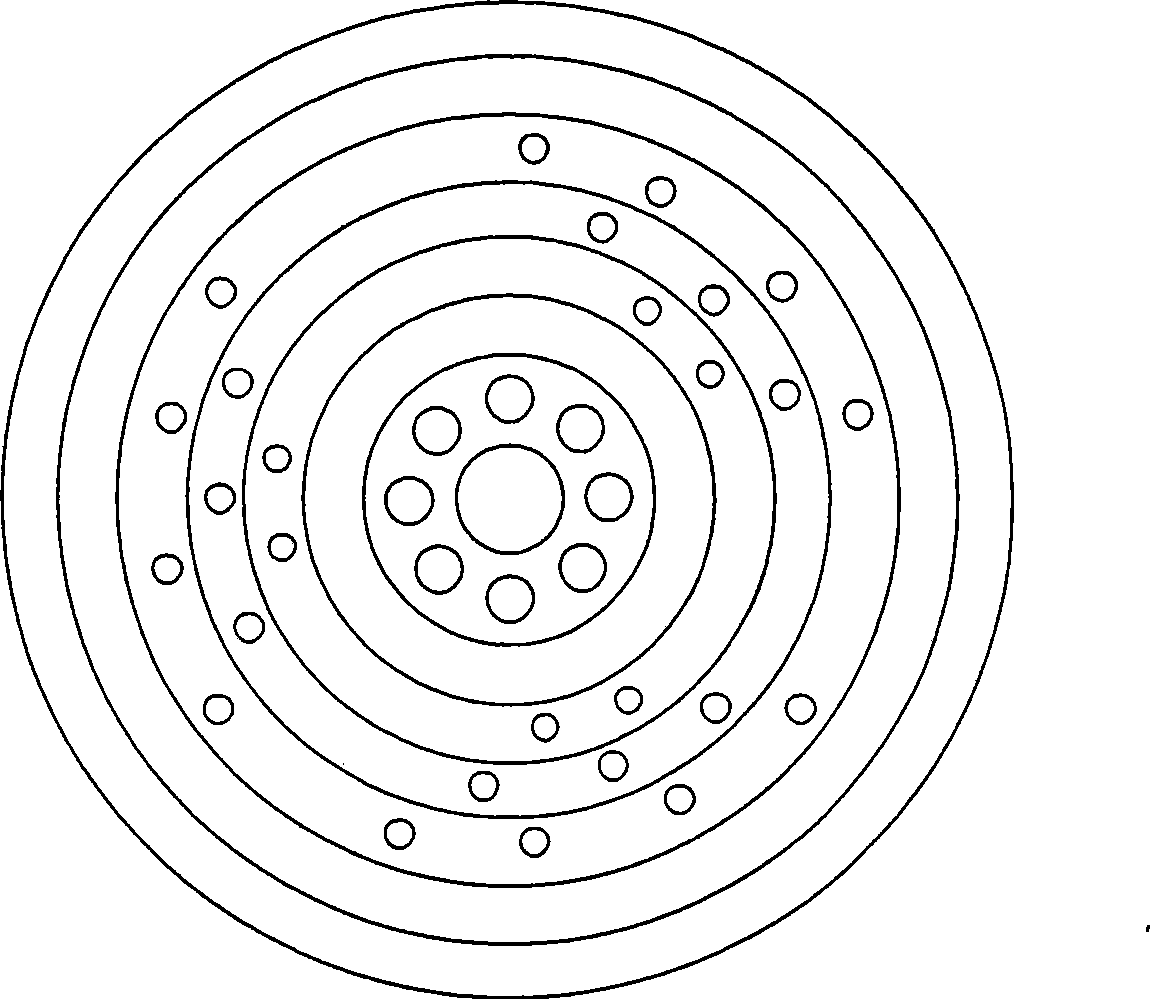

[0116] Such as Figure 1-4 shown.

[0117] A method for treating oily wastewater, comprising the steps of:

[0118] First, dissolve the flocculant (ordinary flocculant of several thousand yuan per ton, or polymer flocculant of tens of thousands of yuan per ton) in the dissolving box 1 at a ratio of 1:200 to 1000 to obtain flocculant solution;

[0119] Secondly, according to the ratio of injecting at least 5-120 kg of flocculant solution (including the flocculant solution containing demulsifier) per ton of wastewater, the flocculant solution and oily wastewater enter the high-speed injection pump 2 together (high-speed impeller pumps should be used) , the flow rate can be determined according to the amount of water to be treated), under the action of the high-speed injection pump 2, the oily wastewater is fully mixed with the flocculant solution to achieve the purpose of demulsification, and the oily wastewater after demulsification is obtained;

[0120] The third, the oil...

Embodiment 2

[0126] Such as Figure 1-4 .

[0127] The difference between this embodiment and Example 1 is that different amounts of demulsifiers are added according to the oily components (including oil content) in the waste water and the properties of the waste water to increase the treatment effect. For the added amount, please refer to the relevant instructions and manuals; The mixing ratio of the solution after the emulsion and the waste water is still the same as in Example 1, and its filling position is also the same, and it still enters the pump from the inlet port of the pump 2 together with the waste water and mixes at a high speed.

Embodiment 3

[0129] The difference between this embodiment and Embodiment 1 is that the solution in the dissolving tank 1 is added to the waste water pipe from the outlet end of the pump 2, and is directly mixed with the oily waste water pressurized by the pump 2 and then enters the swirl cutting cloth. Demulsification in tank 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com