Patents

Literature

126results about How to "Reduce welding residual stress" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

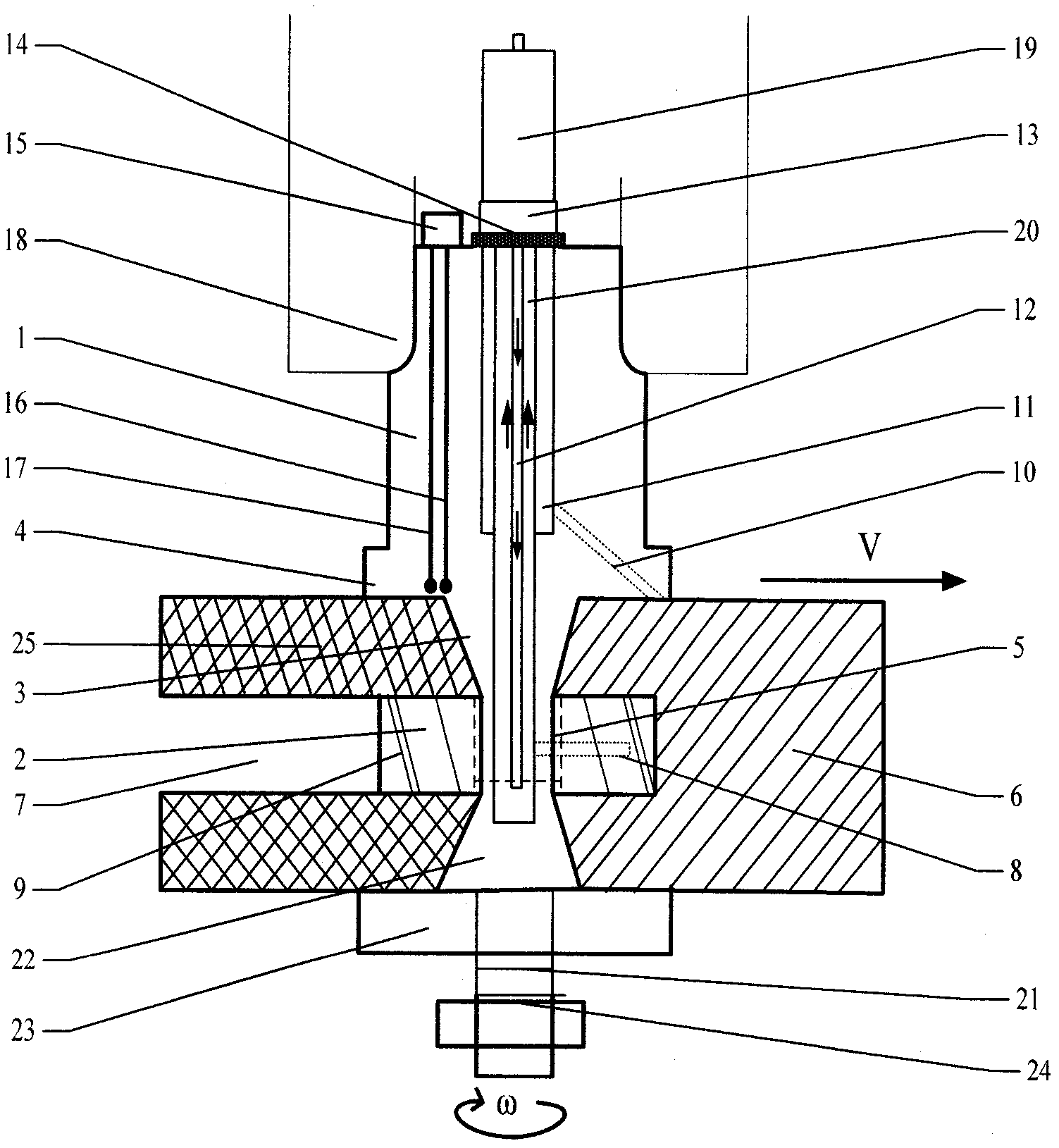

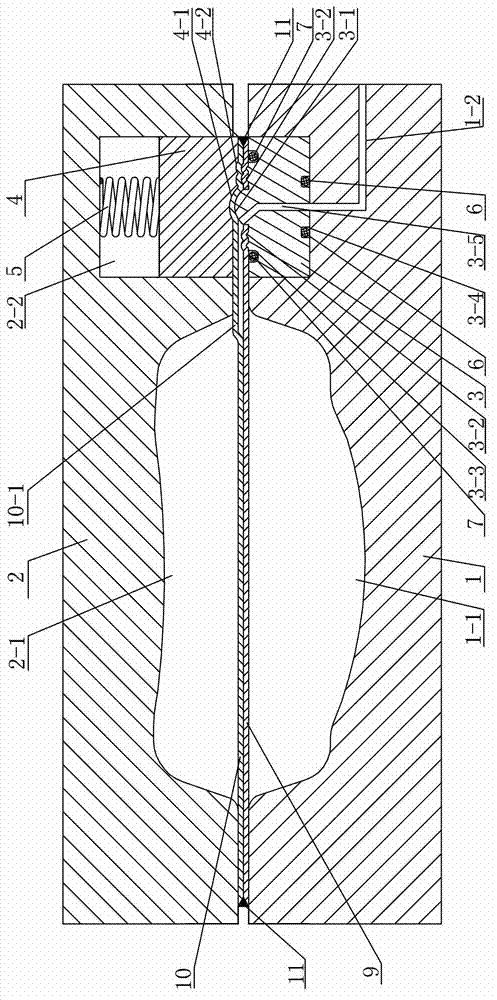

Cutting-stirring friction welding composite processing device for floating double-shaft-shoulder double-stirring needle and manufacture method thereof

InactiveCN102490018AEfficient coolingAvoid glitchesOther manufacturing equipments/toolsNon-electric welding apparatusInduction systemTemperature sensing

The invention discloses a cutting-stirring friction welding composite processing device for a floating double-shaft-shoulder double-stirring needle and a manufacture method thereof, and particularly relates to a combined or composite processing device capable of simultaneously carrying out milling or cutting processing and stirring friction welding processing and a method thereof. The cutting-stirring friction welding composite processing device for the floating double-shaft-shoulder double-stirring needle integrates a cutting system or a milling system, a stirring friction welding system, a forced cooling system, a gas protection system, a temperature sensing system, a pressure induction system, a milling liquid supply system and a sensing-free system. The cutting-stirring friction welding composite processing device has functions of temperature control, gas protection, pressure detection, cooling liquid protection, milling head replacing and floating double-shaft-shoulder self-supporting stirring friction welding. The method for carrying out cutting-stirring friction welding composite processing on workpieces can meet strength requirements of mechanical processing of ferrous light metal materials, carbon steel materials and alloy steel materials. The cutting-stirring friction welding composite processing device for a floating double-shaft-shoulder double-stirring needle and the manufacture method of the cutting-stirring friction welding composite processing device reduce manufacture procedures, save processing cost, have the advantages of being high in efficiency, excellent in quality, high in stability and saving in energy, break through limitation of conventional machining technology, form a new method and a new thought for machinery processing, and have wide application prospects in industries of heating, air conditioners, ice manufacture, freshness keeping, medicine preparation, construction, aquatic products and foods.

Owner:CHONGQING UNIV

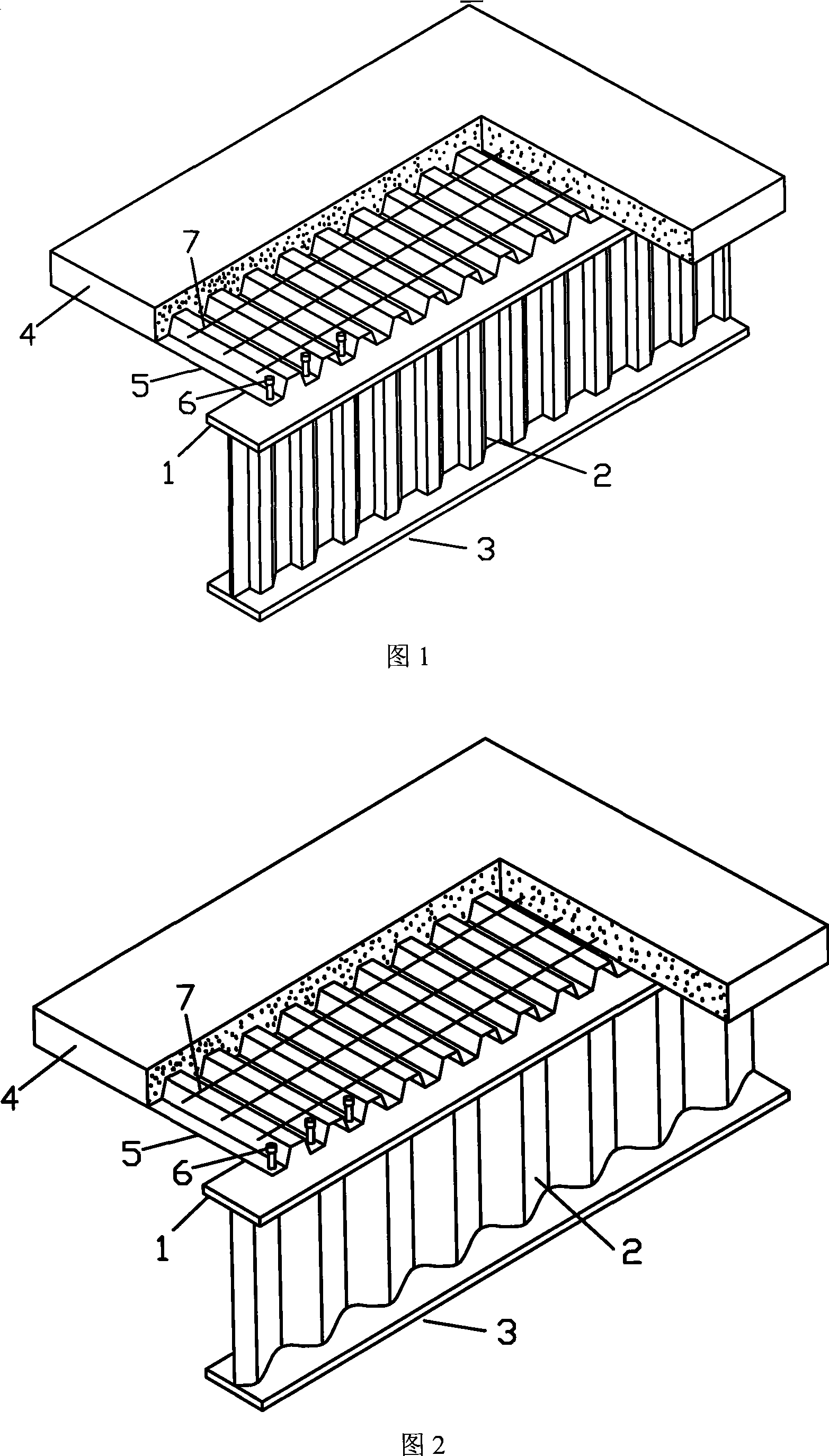

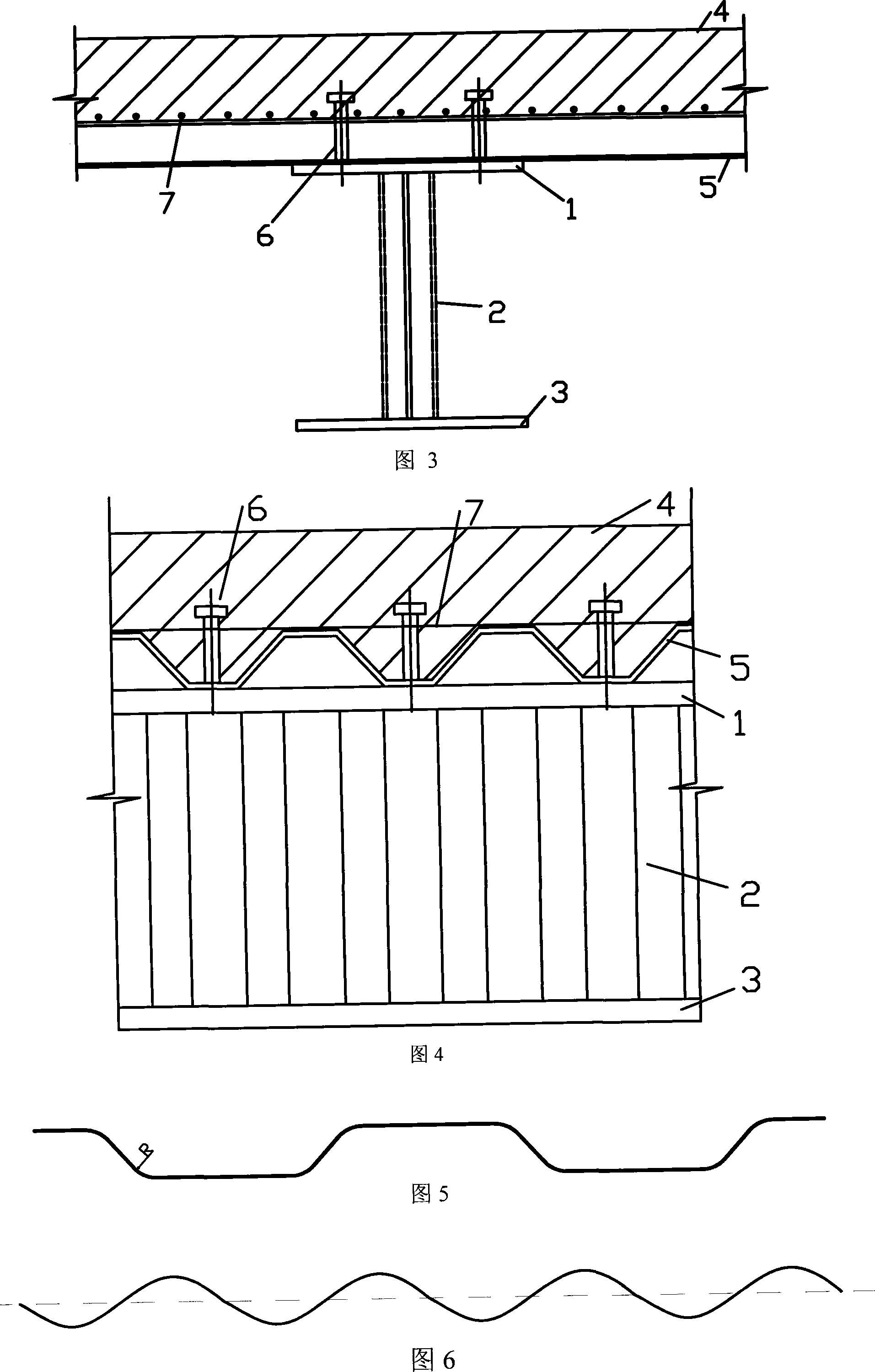

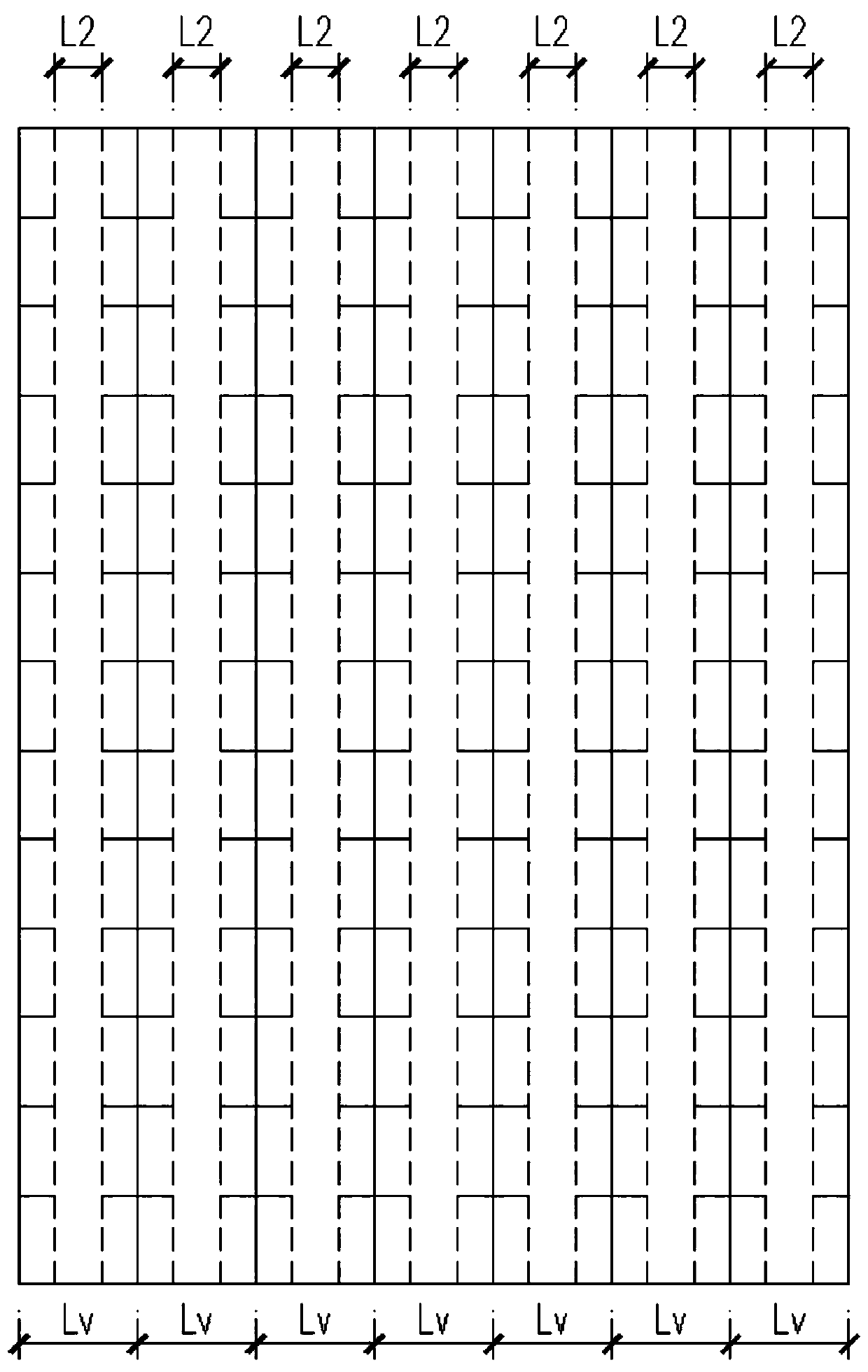

Corrugated sternum H-shaped steel composite beam

InactiveCN101225688APrecise positioningImprove carrying capacityLoad-supporting elementsFillet weldJoist

The invention relates to a corrugated web plate H-shaped profile steel composite bean, belonging to the technical field of building profile materials . The cross section port type comprises a corrugated web plate and an upper and lower flange joints. The upper flange is in parallel with the lower flange; the web plate is vertical to the upper flange and the lower flange; the web plate is connected with the flanges by single-sided fillet weld; the web plate is a trapezoid ripple or a sine curve ripple, wherein the lengthwise direction of the trapezoid ripple is repeated periodically. The upper part of a composite beam is a reinforced concrete swing plate and a profiled steel sheet. The upper flange, the reinforced concrete plate and the profiled steel sheet are connected by a plurality of studs; the reinforced concrete swing plate can be connected with the profiled steel sheet by additional lateral steel bar. The traditional hot-rolling joist steel and H-shaped profile steel composite beam can be replaced by the corrugated web plate H-shaped profile steel composite bean which has the wider application than joist steel and H-shaped profile steel composite beam; the maximization can be realized for special field and special location comprising the construction of large span industrial and civil building and large span bridge.

Owner:TONGJI UNIV

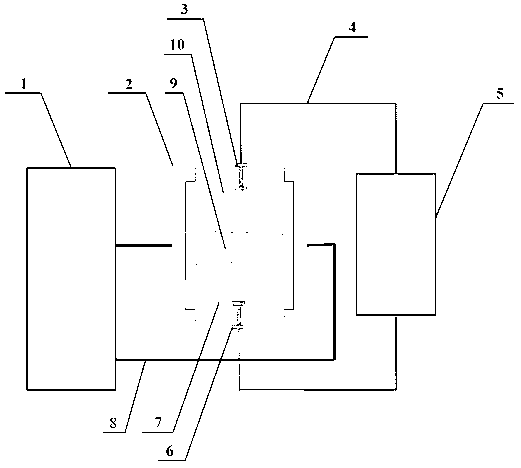

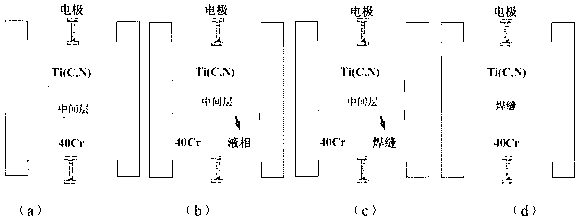

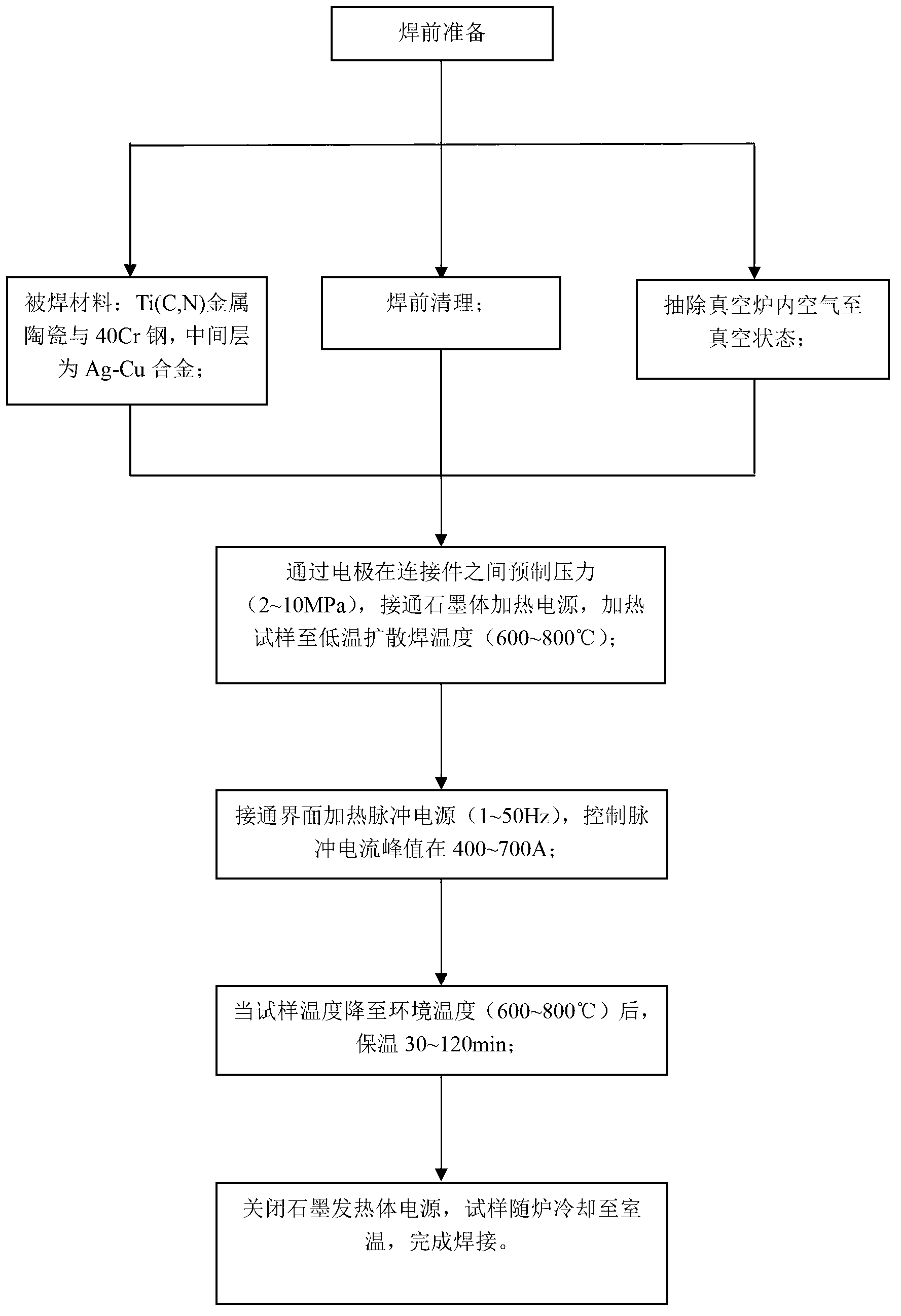

Low-temperature rapid diffusion welding device and method based on pulse current auxiliary heating

ActiveCN102699520APromote fragmentationLow machining accuracy requirementsNon-electric welding apparatusRadiant heatPulse power supply

The invention discloses a low-temperature rapid diffusion welding device and method based on pulse current auxiliary heating. The device comprises a graphite body heating power supply, a graphite body, electrodes, an interface heating pulse power supply and a sample. According to the method, graphite body radiant heat is mainly used, welding interface contact resistance heat and discharge heat are used as accessory, an original liquid phase is formed by the resistance heat and discharge heat which are formed at an interface to be connected by the pulse current, and diffusion welding is realized by virtue of less externally-applied extrusion force. The device and the method can be used for reducing the residual stress, obviously shortening the welding time, requiring smaller applied pressure and preventing workpieces from being subjected to serious deformation in a pressurization direction, are conductive to crushing oxidation films on the surfaces of materials and simultaneously can be used for reducing the material surface processing precision requirement; and the device disclosed by the invention is simple in process, smart in design and convenient in use, and can be widely applied to the diffusion welding of various nonmetals and metals.

Owner:JIANGSU UNIV OF SCI & TECH

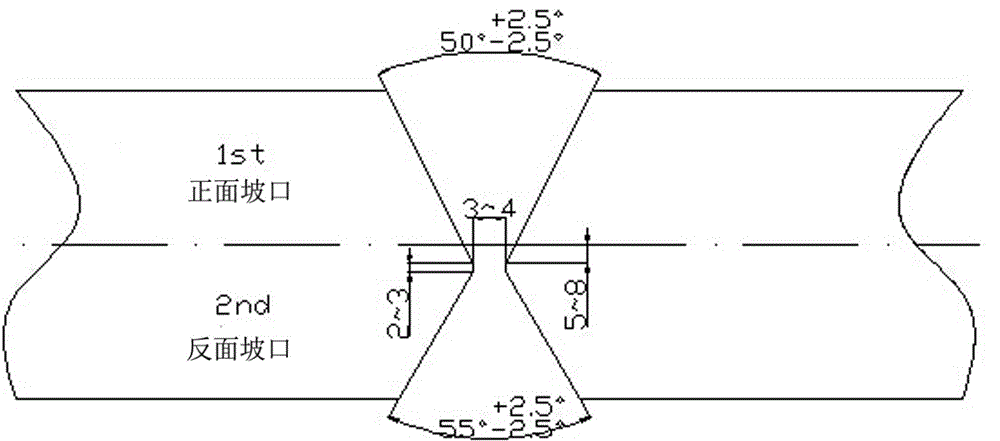

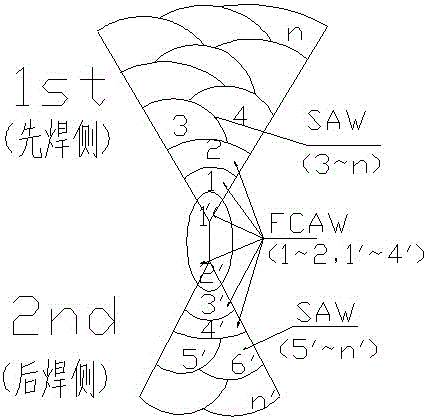

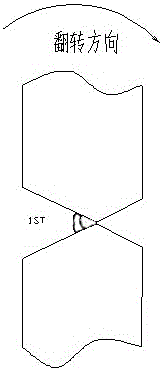

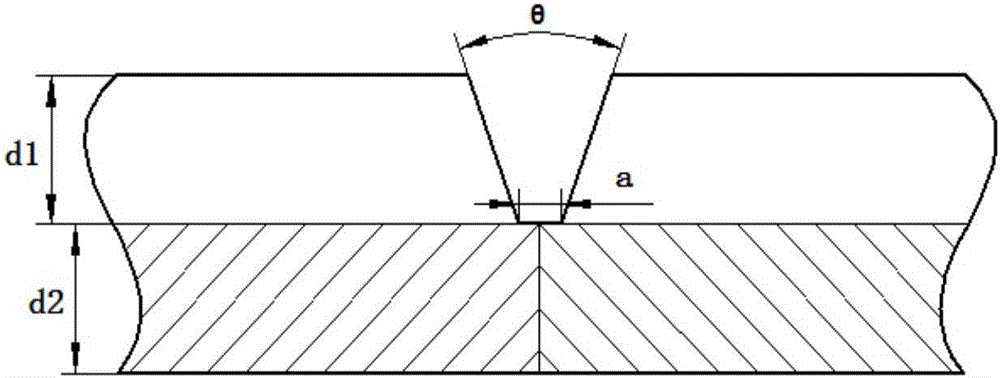

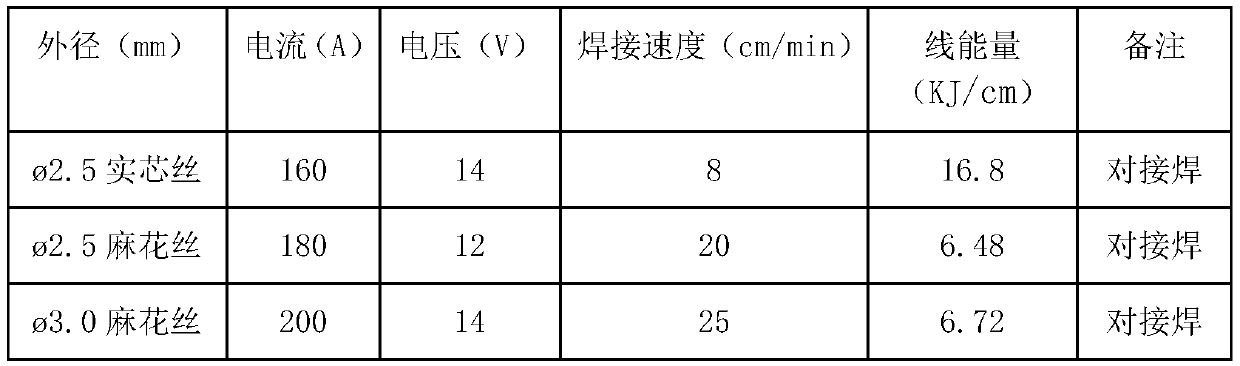

Extra-thick sheet submerged-arc welding technique

ActiveCN105057856ASmall amount of welding deformationReduce turning timesArc welding apparatusWelding/soldering/cutting articlesThick plateWelding residual stress

The present invention discloses an extra-thick sheet submerged-arc welding technique. The technique comprises the following technological parameters and steps: 1) connector preparation: X-type beveled edges are adopted by extra-thick sheets; 2) preheating: first heating a back side of an extra-thick sheet and then a front side of the extra-thick sheet, a preheating temperature being 150 DEG C to 160 DEG C, and a heating rate being not higher than 105 DEG / h; 3) backing welding: after preheating, using flux-cored wire gas shield welding for backing welding for two paths to form two layers, and using submerged-arc welding to fill at least two paths to form one layer, maintaining interlayer temperature to be not higher than 230 DEG C; 4) turning over after an inter-welding deformation is not larger than 6-8 mm; 5) backside welding: after carbon gouging and back chipping, backing welding according to the step 3) after the extra-thick sheet reaches a preheating requirement according to the preheating method described in the step 2); 6) stress relief treatment; and 7) carrying out post heating treatment at 200 DEG C / 2h after the welding, then slowly cooling the extra-thick sheet to be at the room temperature. With adoption of the technique provided by the present invention, rooting welding deformation is reduced, welding residual stress for subsequently filling a cover face is also reduced, and thus turn-over times in welding of the extra-thick sheet are reduced.

Owner:CHINA MERCHANTS HEAVY IND JIANGSU +1

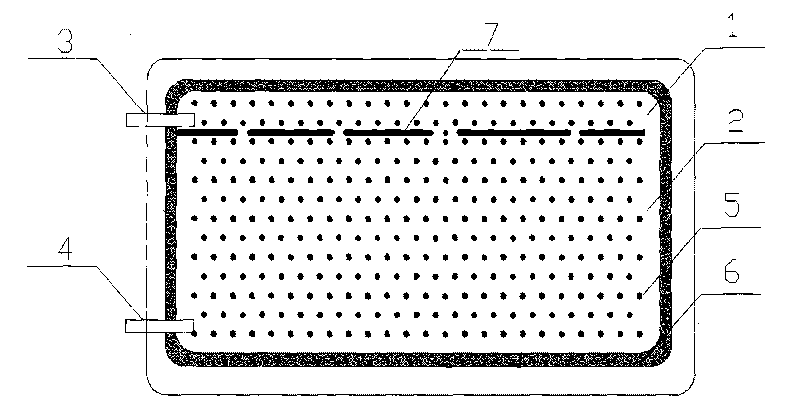

Aluminum honeycomb type evaporation plate and processing molding method thereof

InactiveCN101691978ANot easy to form dead angleLow flow resistanceShaping toolsArc welding apparatusAluminum honeycombEvaporation

The invention discloses an aluminum honeycomb type evaporation plate and a processing molding method thereof. The evaporation plate adopts a high strength aluminum alloy plate and consists of an upper plate, a lower plate, an inlet pipe and an outlet pipe, wherein the two high strength aluminum alloy plates are overlapped and welded together by a solid-phase stir friction connecting method; the inlet pipe and the outlet pipe are inserted in the upper end and the lower end between the two high strength aluminum alloy plates and are connected with the high strength aluminum alloy evaporation plate body by using an electric arc welding method; and then the evaporation plate is finally molded through a mould and high-pressure bulging technology.

Owner:CHONGQING UNIV

Integral forming process method of thin-wall hooped tube workpieces

The invention discloses an integral forming process method of thin-wall hooped tube workpieces. The technical scheme comprises the flowing steps of: 1, preparing a mould: firstly forming overflow holes in corresponding parts on the mould, welding reinforcing ribs in a thin-wall tubing without welded lines in advance and placing into a mould cavity, performing spotting on the mould, sealing ends of a tube blank, filling a strain rate sensitive medium between the mould and the tube blank, then filling liquid forming medium in the tube blank and applying certain pressure; 2, forming: increasing the pressure of the inside liquid, meanwhile adjusting the flow state of the strain rate sensitive medium to cause a tube body and a reinforcing plate to be deformed in a coordinated way to form qualified parts; and 3, picking up the parts: reducing the pressure to 0MPa, opening the mould and then taking out the parts from the mould. The integral forming process method of the thin-wall hooped tube workpieces has the advantages of few forming processes, low manufacturing cost, high mechanical property of formed members, high dimension precision and the like, and is particularly suitable for forming thin-wall hooped tube workpieces with a sealed complex section shape.

Owner:HARBIN INST OF TECH AT WEIHAI +1

Metal type flux-cored wire and method of manufacturing austenitic stainless steel structural part

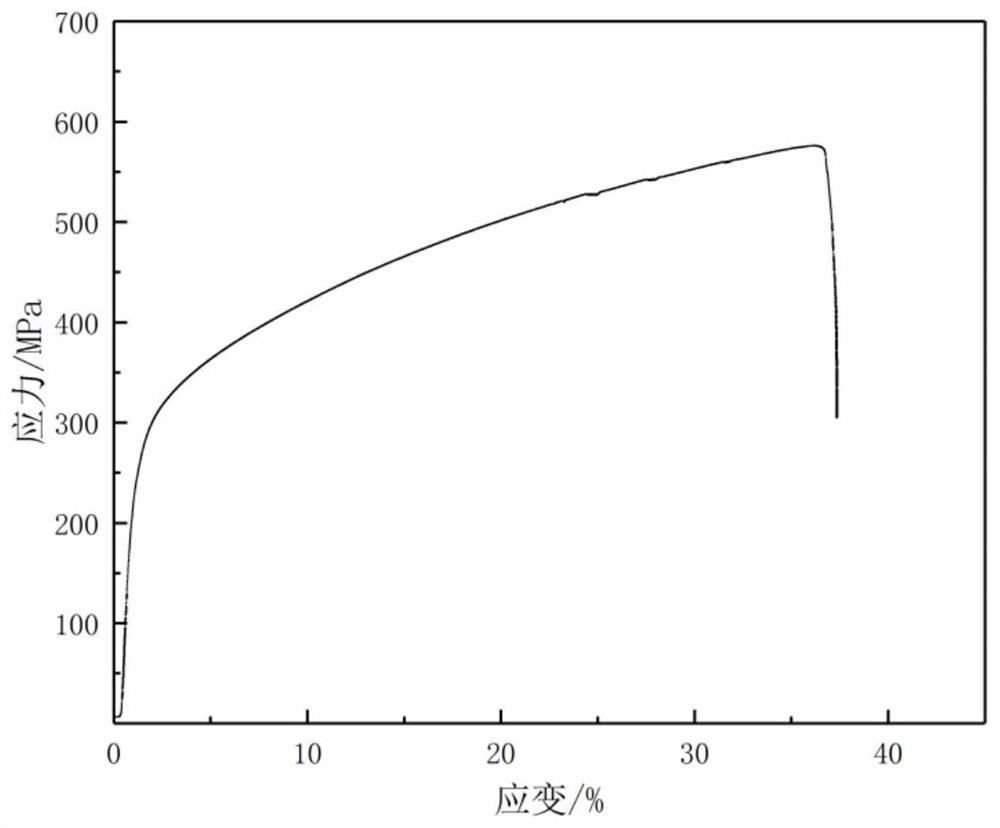

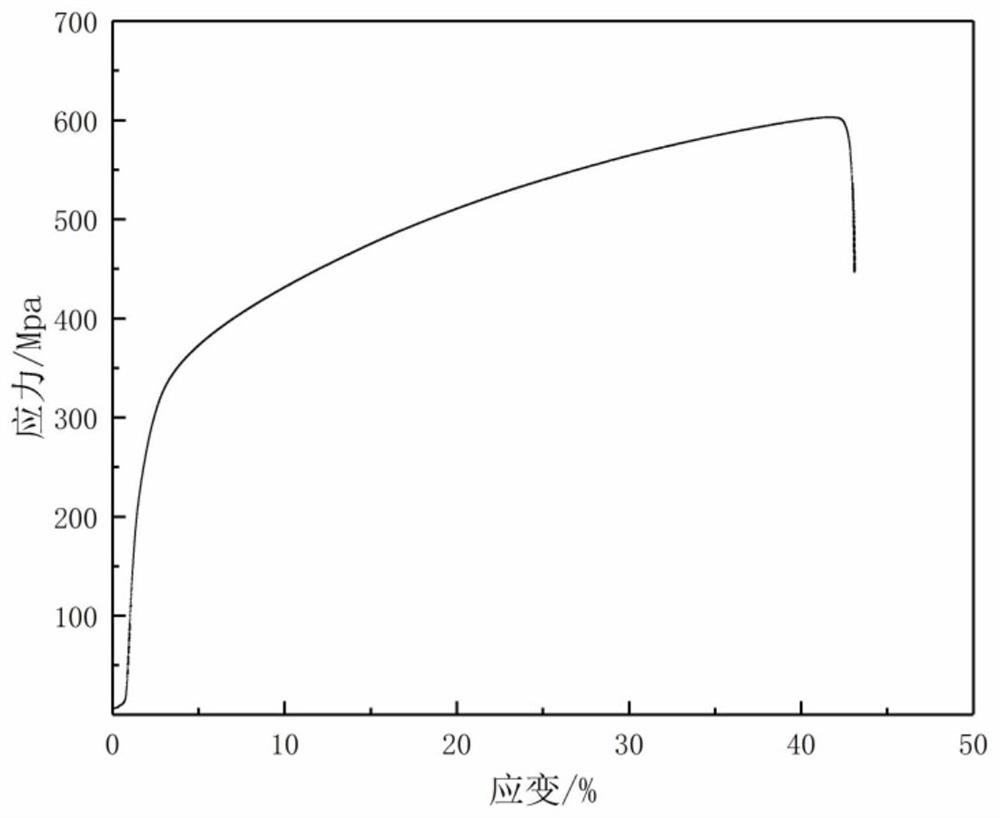

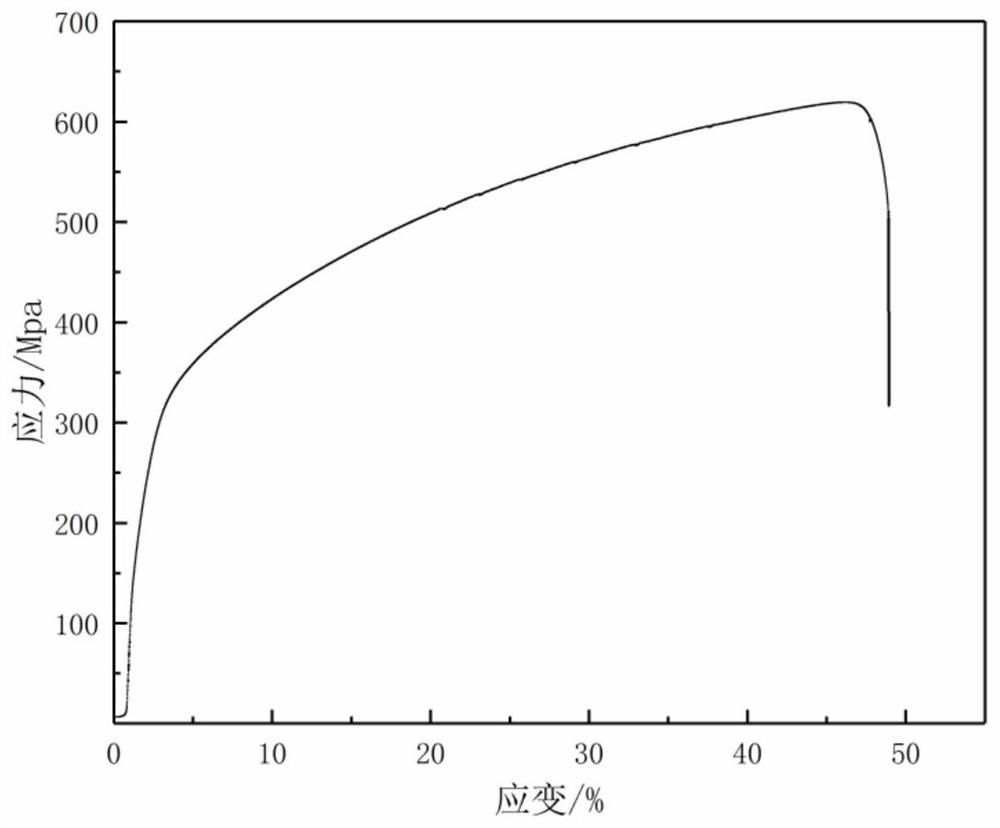

ActiveCN111992923AShort preparation cycleIncrease productivityWelding/cutting media/materialsSoldering mediaManufacturing technologyFerrosilicon

The invention discloses a metal type flux-cored wire. The metal type flux-cored wire is adopted as a raw material, an austenitic stainless steel structural part is manufactured on the basis of an electric arc additive manufacturing technology, and the formed thin-wall structural part has excellent mechanical properties. Flux-cored alloy of the metal type flux-cored wire comprises, by mass percentage, 8% of silicon iron, 18%-22% of manganese powder, 27% of nickel powder, 26% of chromium powder, 4%-8% of molybdenum powder, 1%-3% of copper powder, 0.5% of titanium powder, 0.2% of aluminum powder,0.5% of lanthanum oxide, 1% of niobium carbide and the balance iron powder. The sum of the mass percentages of the components is 100%. The austenitic stainless steel thin-wall structural part obtained through additive manufacturing is attractive in appearance and has the excellent mechanical properties. The austenitic stainless steel metal type flux-cored wire for additive manufacturing can be used for additive manufacturing of complex parts in the fields of national defense, energy, petroleum, chemical engineering, aerospace and bioengineering.

Owner:XIAN UNIV OF TECH

Argon-arc welding for austenitic stainless steel using water cooling welding method

The invention discloses a water-cooling argon-arc welding method for welding austenitic stainless steel, which is characterized in that: after finishing backing welding at the welding seam of a workpiece, the back of the welding seam is cooled with cold water when filling and cover-welding is carrying out for the welding seem. The invention solves the problems that high welding stress and poor corrosion resistance exist in the prior austenitic stainless steel welding and ensures that the welding seam of the austenitic stainless steel has fine metal crystal grains, uniform structure and small residual welding stress. The invention can not only obtain ideal welding joints but also improve the productive efficiency of welding.

Owner:普瑞特机械制造股份有限公司

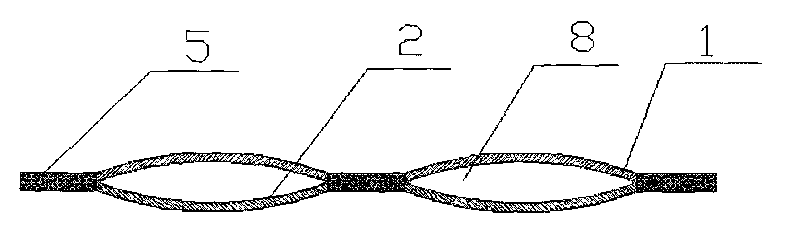

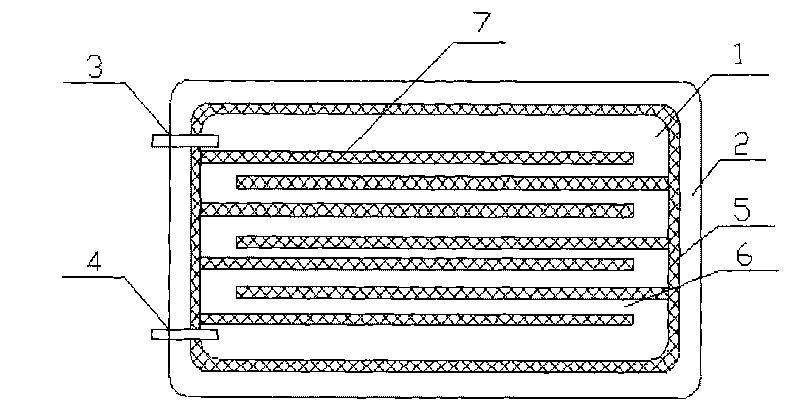

Stainless steel snakelike flow channel cold plate and processing molding method thereof

InactiveCN101691977AReduce pollutionLow soldering temperatureShaping toolsArc welding apparatusElectrical resistance and conductanceCold plate

The invention discloses a stainless steel snakelike flow channel cold plate and a processing molding method thereof. The snakelike flow channel cold plate adopts a stainless steel plate and consists of a stainless steel upper plate, a stainless steel lower plate, an inlet pipe and an outlet pipe, wherein the two stainless steel plates are overlapped and connected by a water-cooling resistance welding method; the inlet pipe and the outlet pipe are inserted in the upper end and the lower end between the two stainless steel plates and are connected with the stainless steel snakelike flow channel cold plate by using an electric arc welding method; and then the snakelike flow channel cold plate is finally molded through a mould and high-pressure bulging technology.

Owner:CHONGQING UNIV

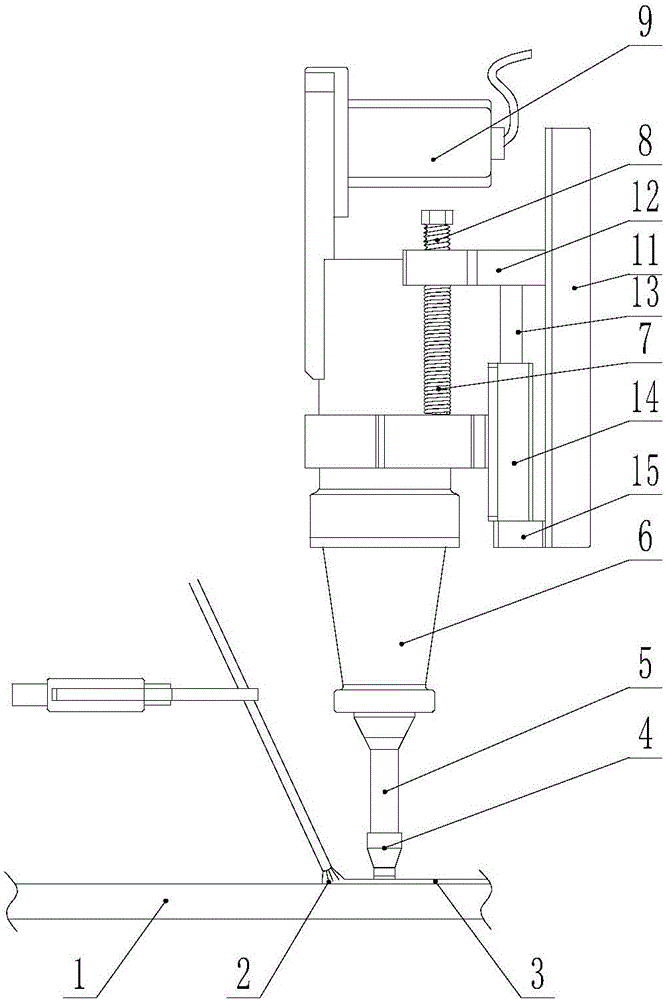

Welding seam tracking sensor capable of controlling electric arcs through electric and magnetic fields

ActiveCN107008999AReduce welding residual stressLow costWelding accessoriesPhase differenceWelding power supply

The invention discloses a welding seam tracking sensor capable of controlling electric arcs through an electric field and a magnetic field. The sensor belongs to a welding seam tracking system composed of a welding power source, a welding seam tracking real-time adjusting mechanism, a wire feeder, a Hall sensor, and the like. The sensor mainly comprises an electric field excitation power source, a magnetic field excitation power source, three pairs of polar plates used for generating the electric field, a magnetic induction coil used for generating the magnetic field, and the like. According to the welding seam tracking sensor, after a welding gun achieves arc striking, the electric field excitation power source transmits voltage of certain alternate frequency and phase difference to the three pairs of polar plates, polarity of the three pairs of polar plates is alternately changed, and the magnetic field excitation power source enables the magnetic induction coil to generate the constant longitudinal magnetic field; the electric field conveniently controls the electric arcs to rotate and swing under the situation that the magnetic field focuses on electric arc shape, so that welding seams are scanned; electric arc information is extracted through the Hall sensor, welding seam tracking deviation is processed and judged through the welding seam tracking real-time adjusting mechanism, and welding routes and welding parameters are adjusted, so that the welding seams are automatically tracked; and the magnetic field can stir a molten pool, residual stress of the welding seams is reduced, and welding quality of the welding seams is improved.

Owner:XIANGTAN UNIV

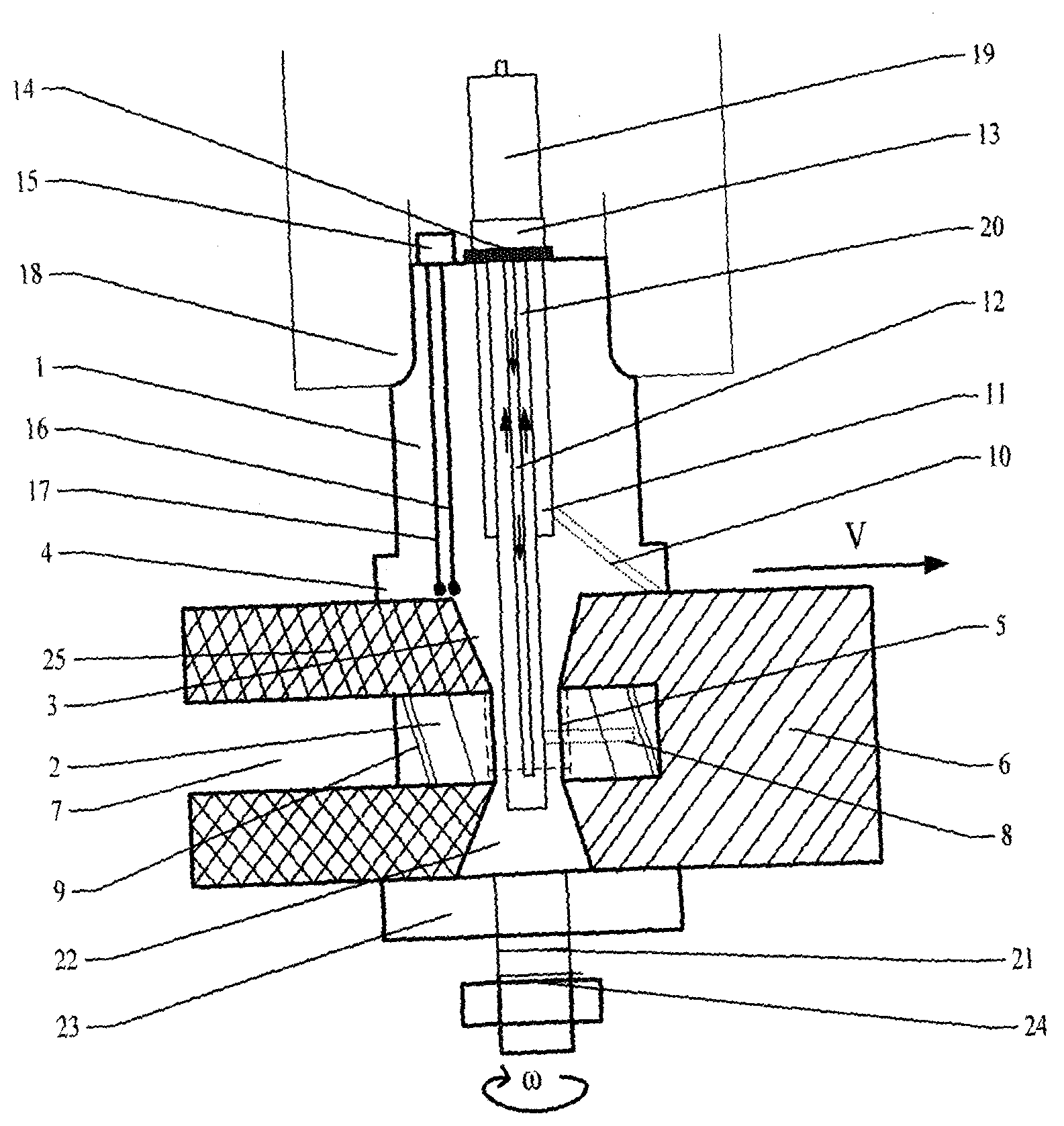

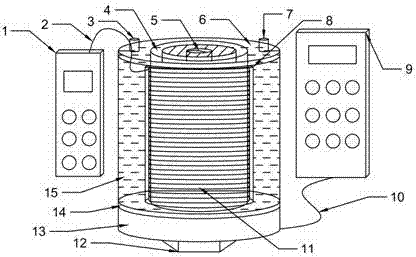

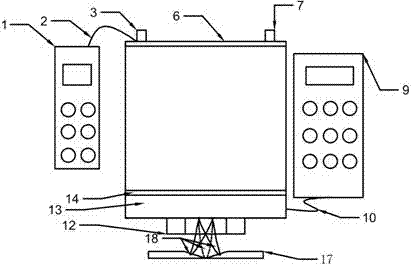

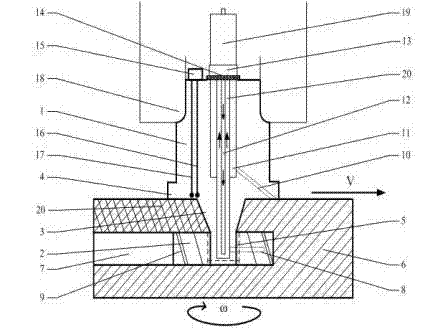

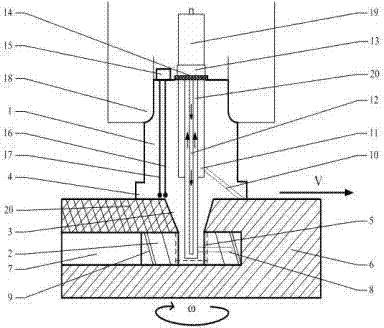

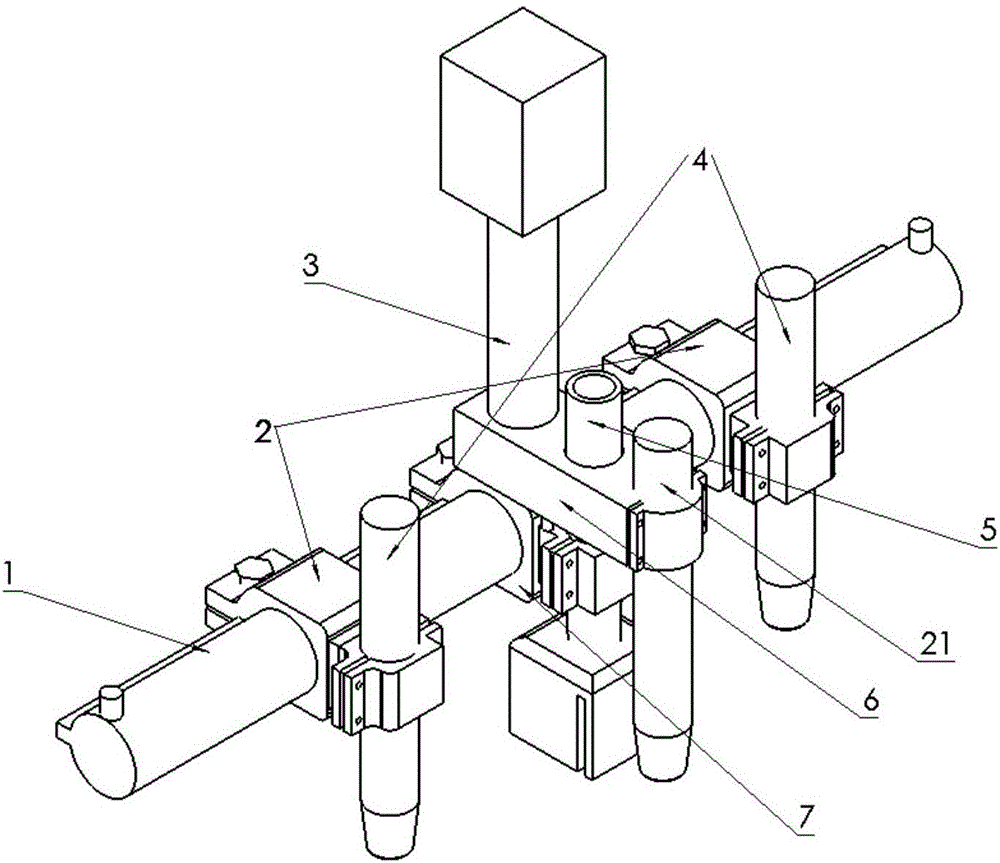

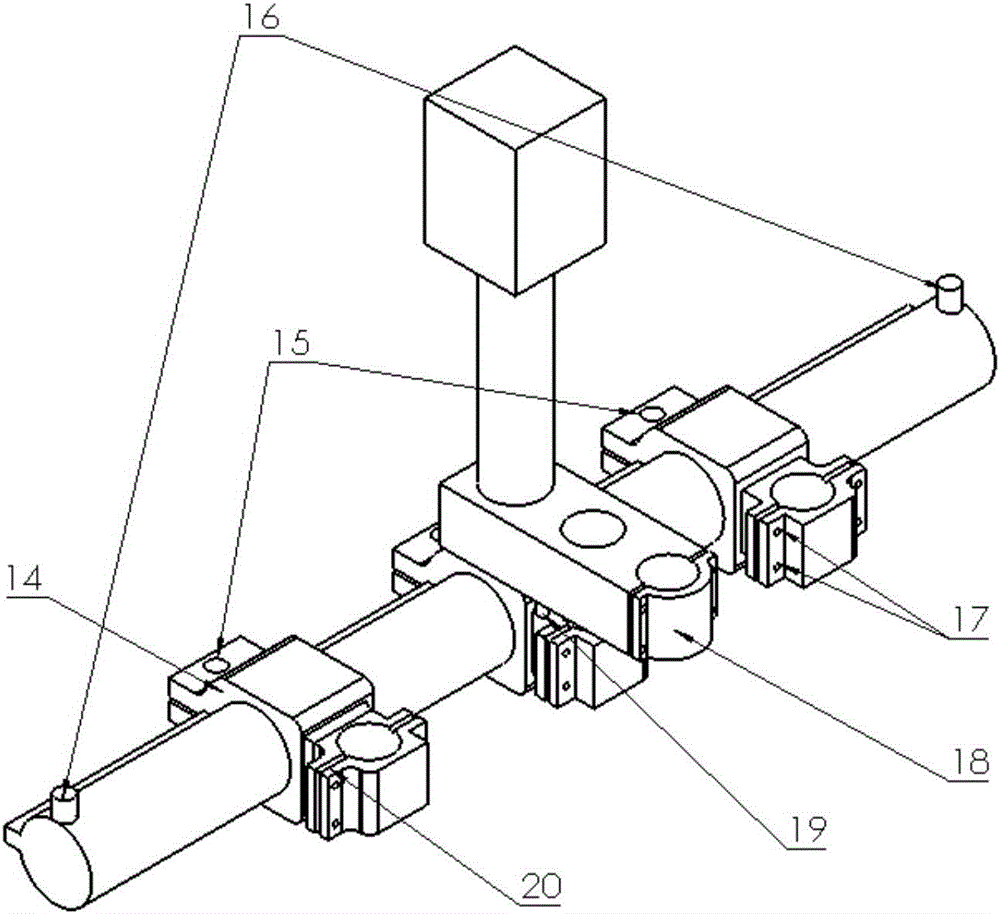

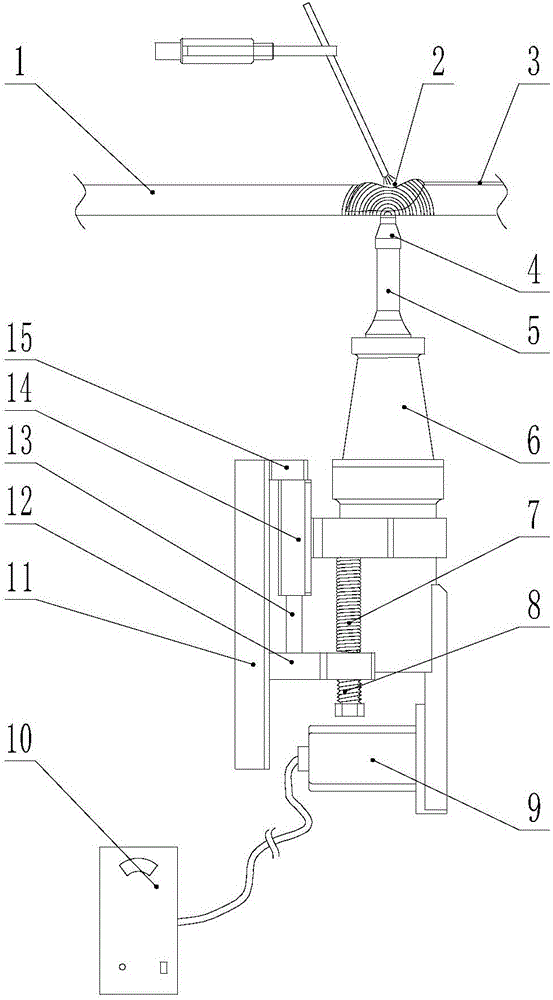

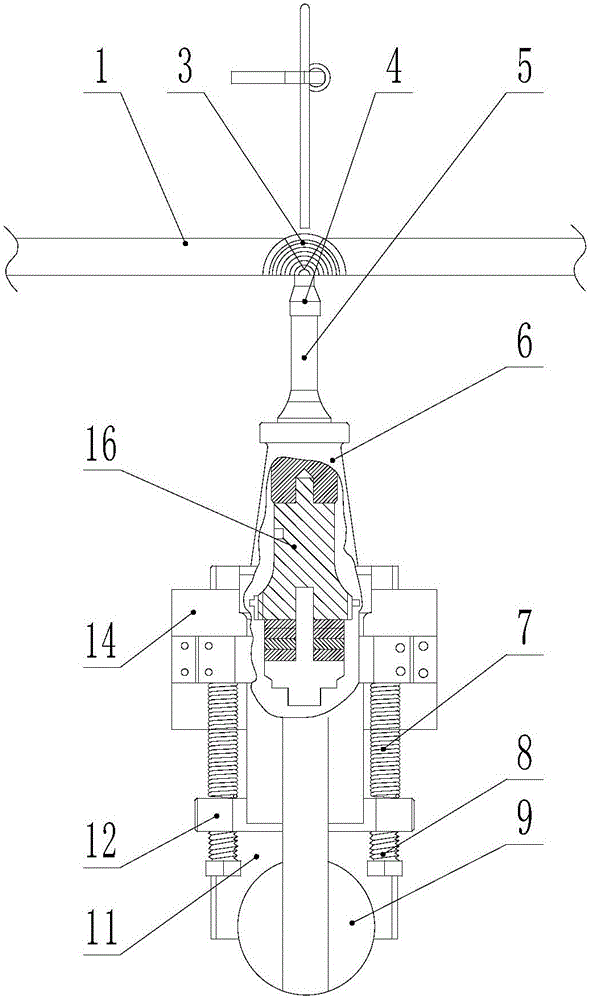

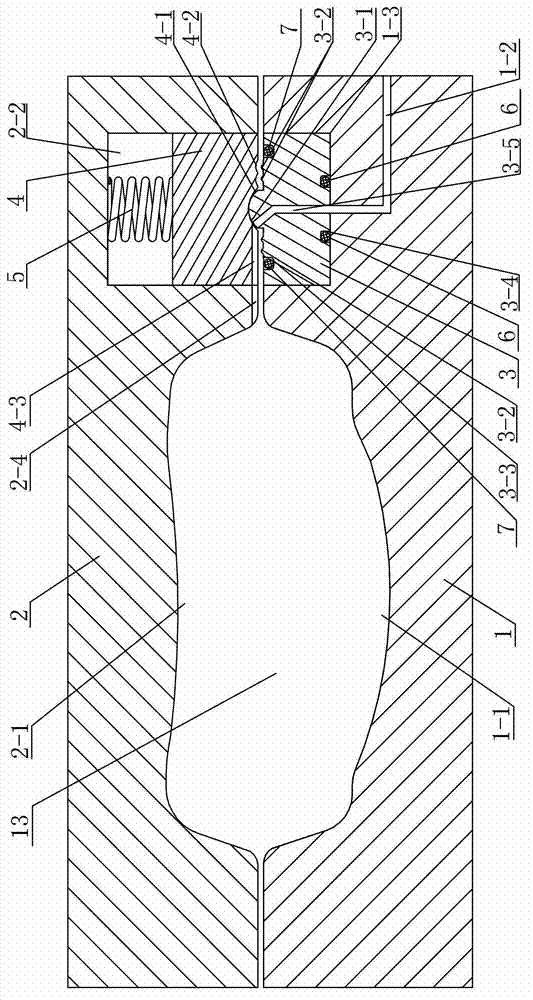

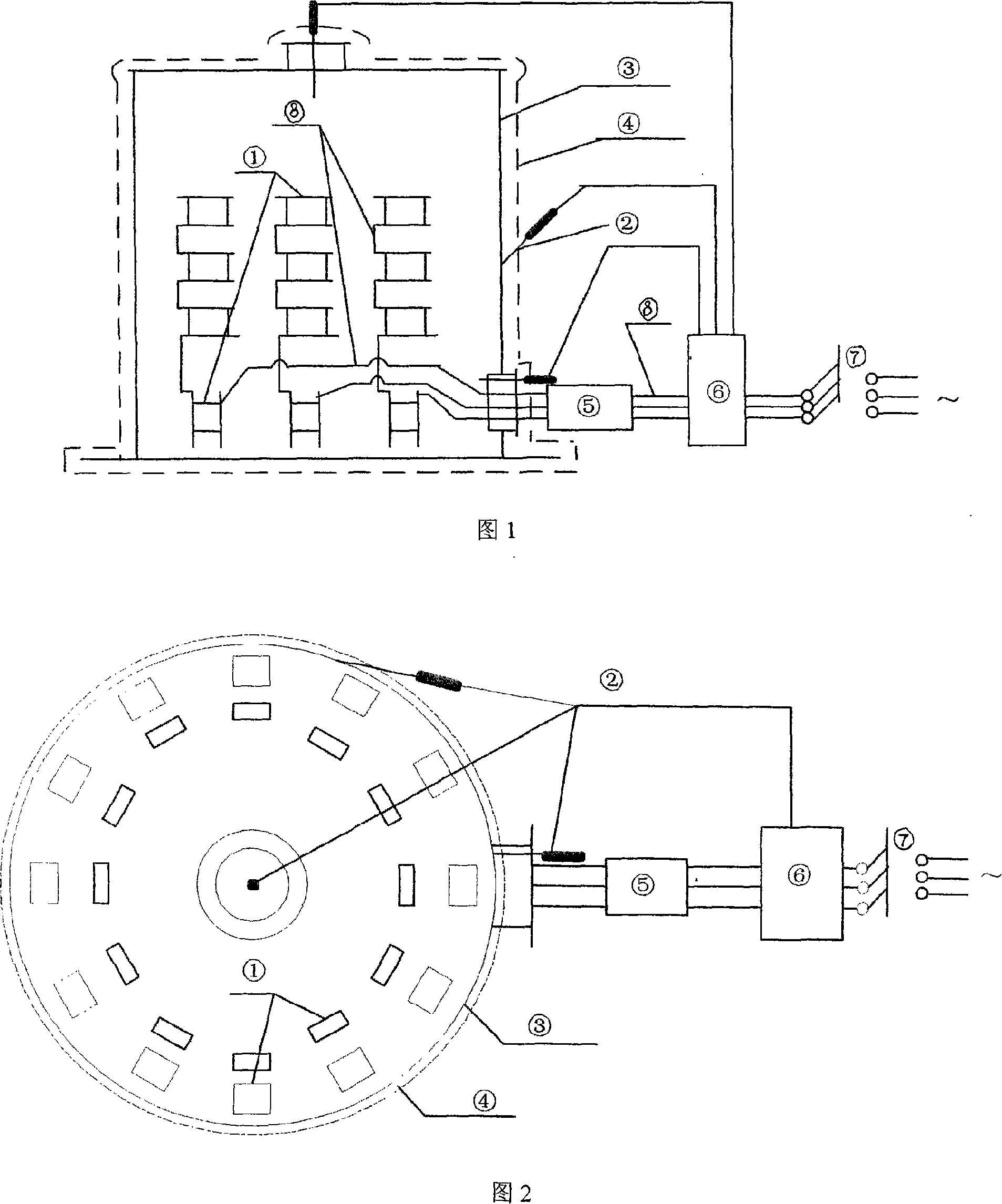

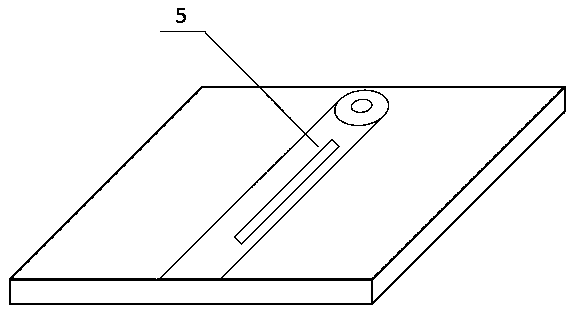

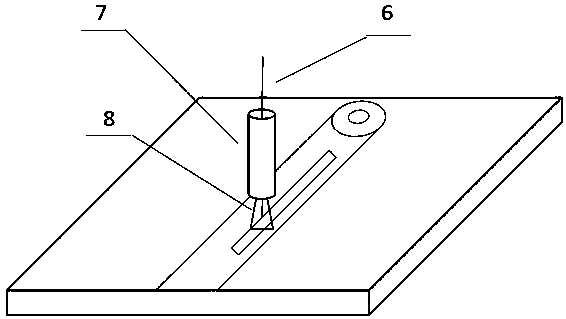

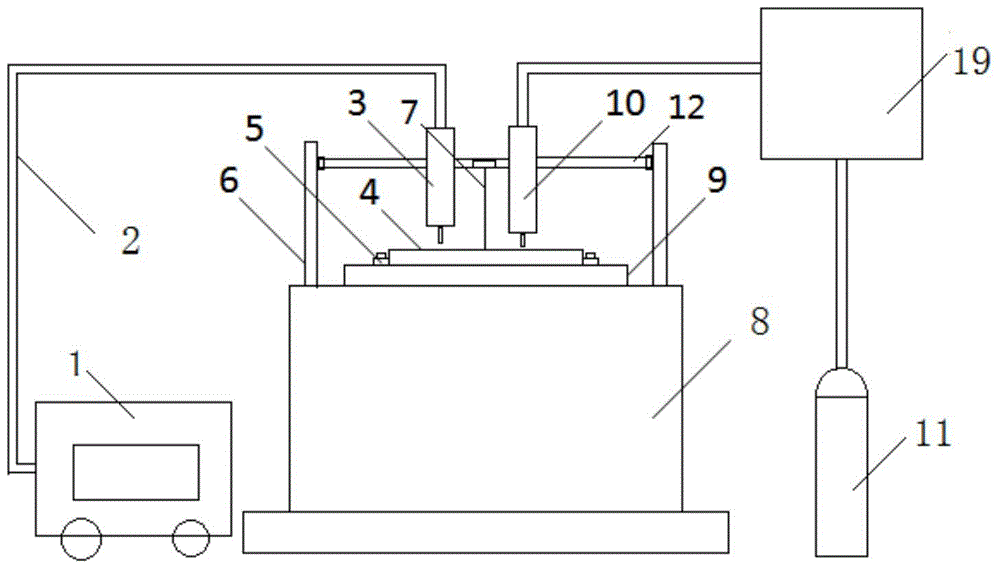

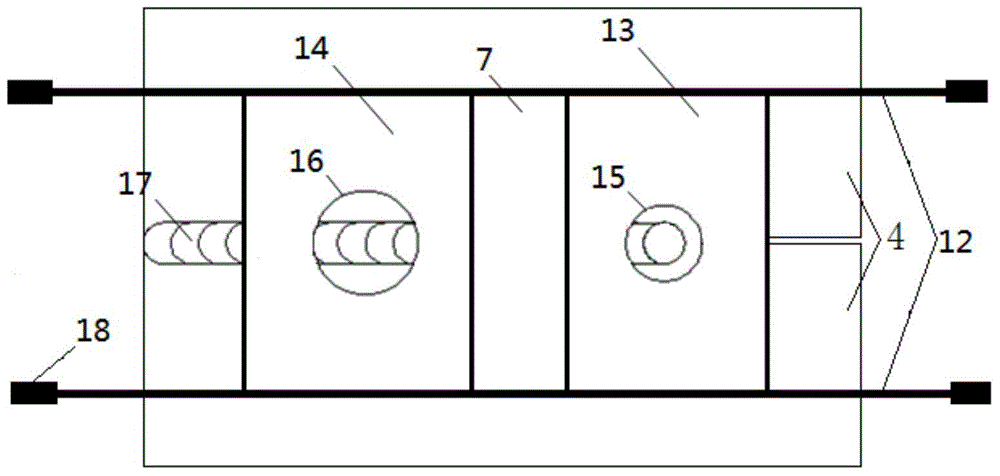

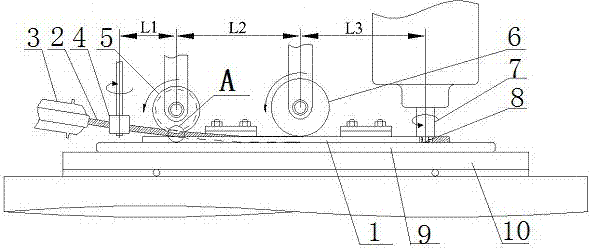

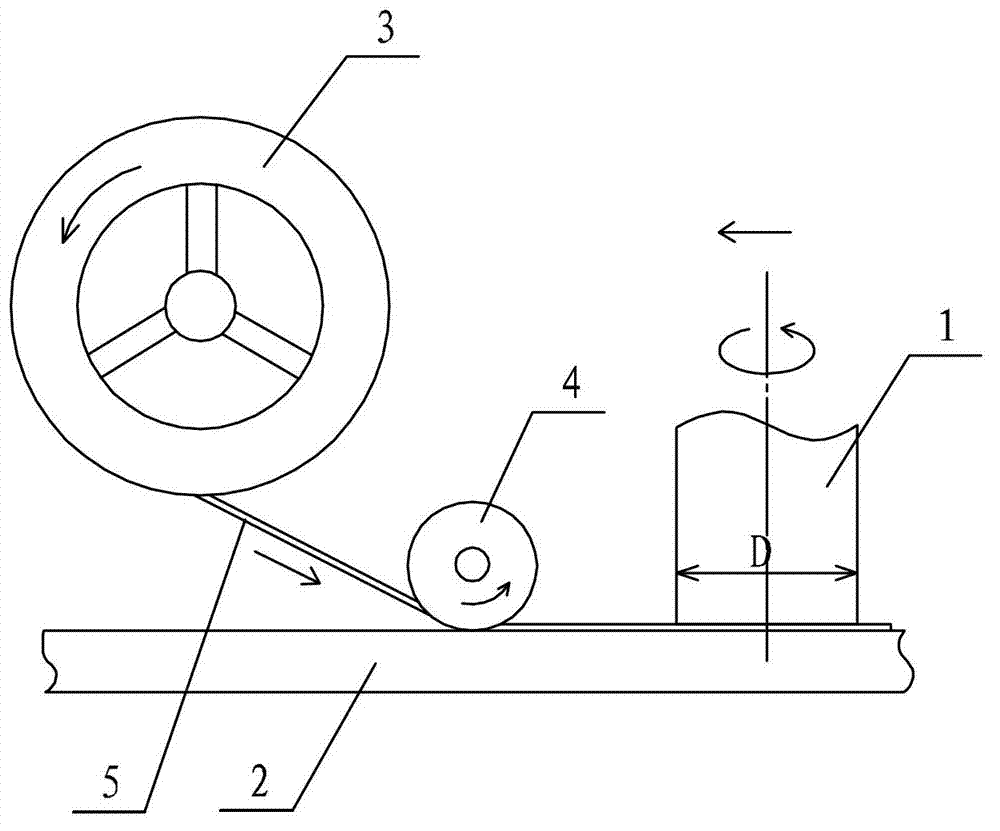

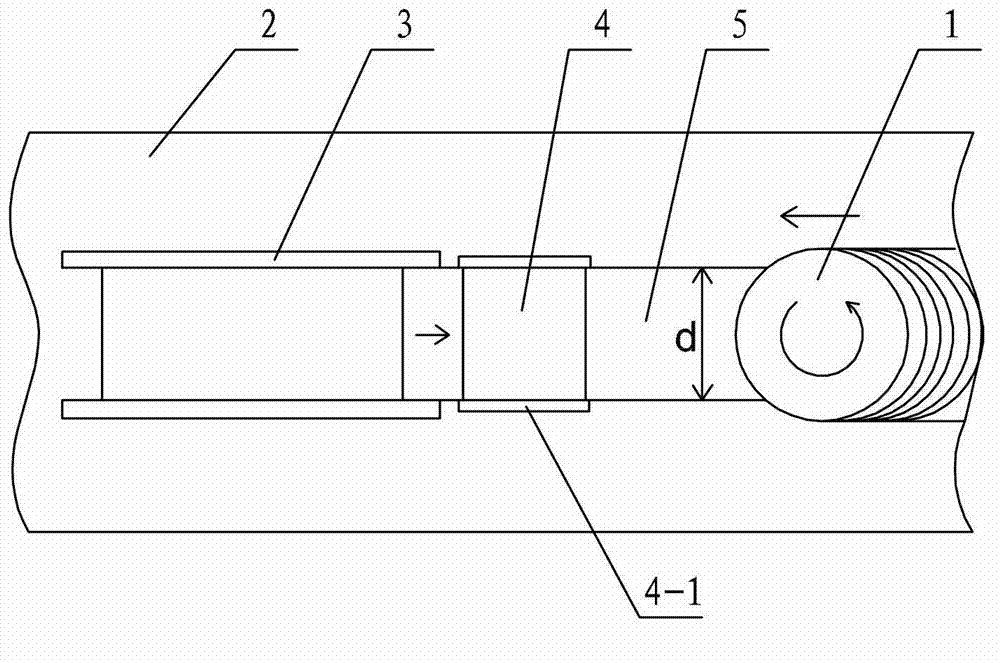

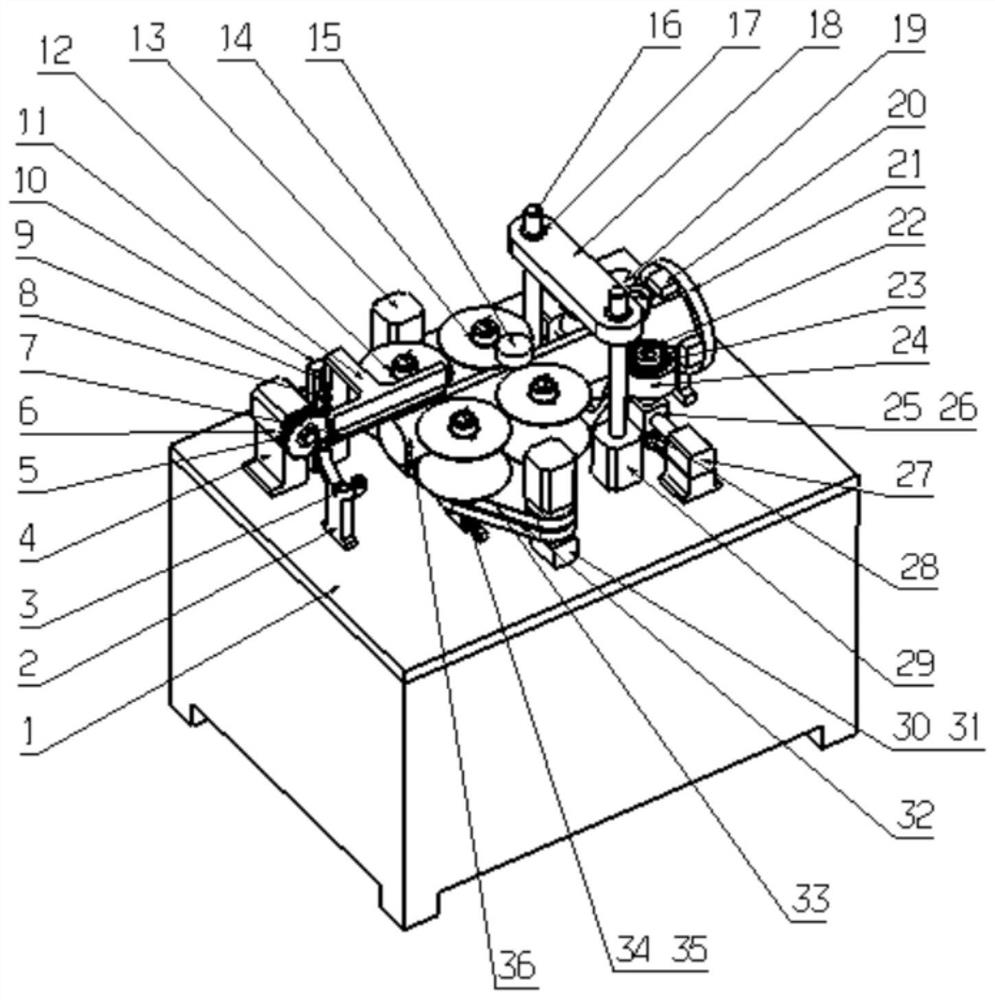

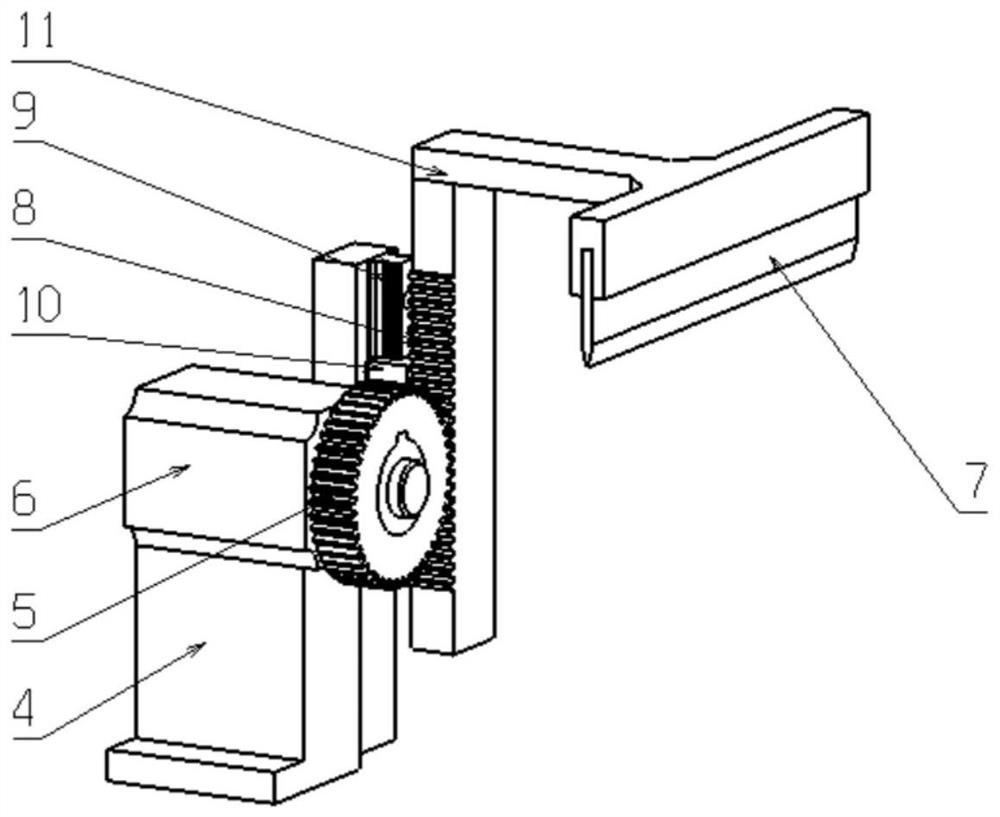

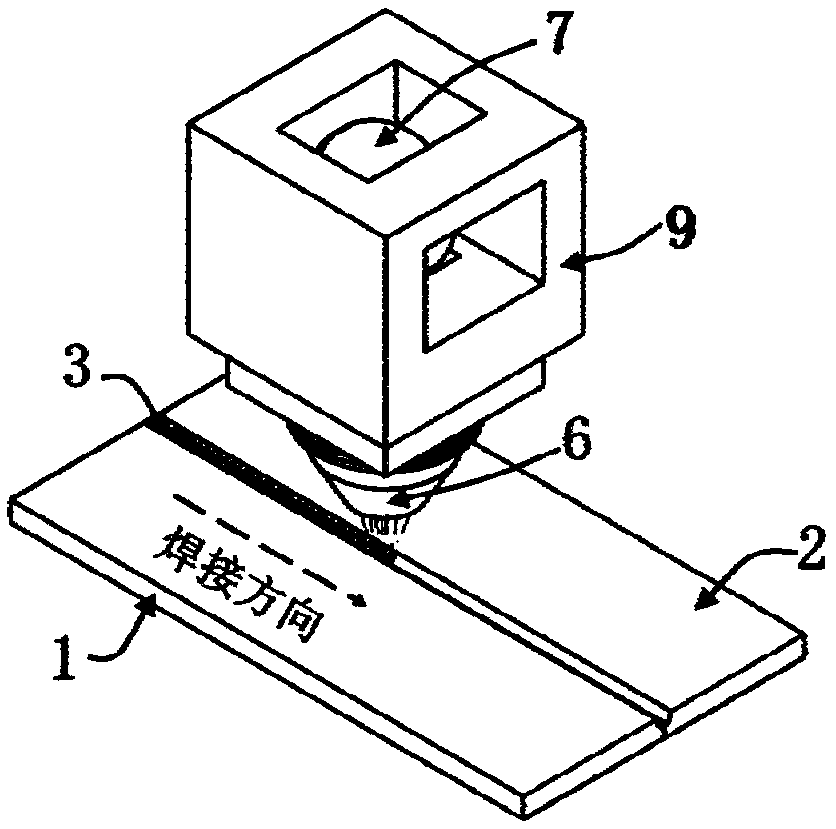

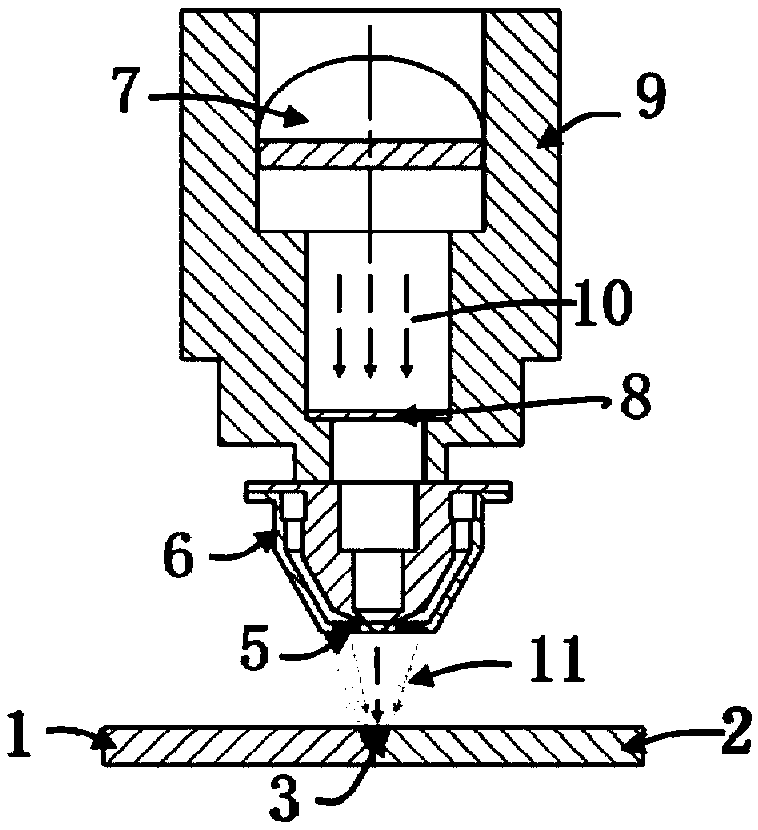

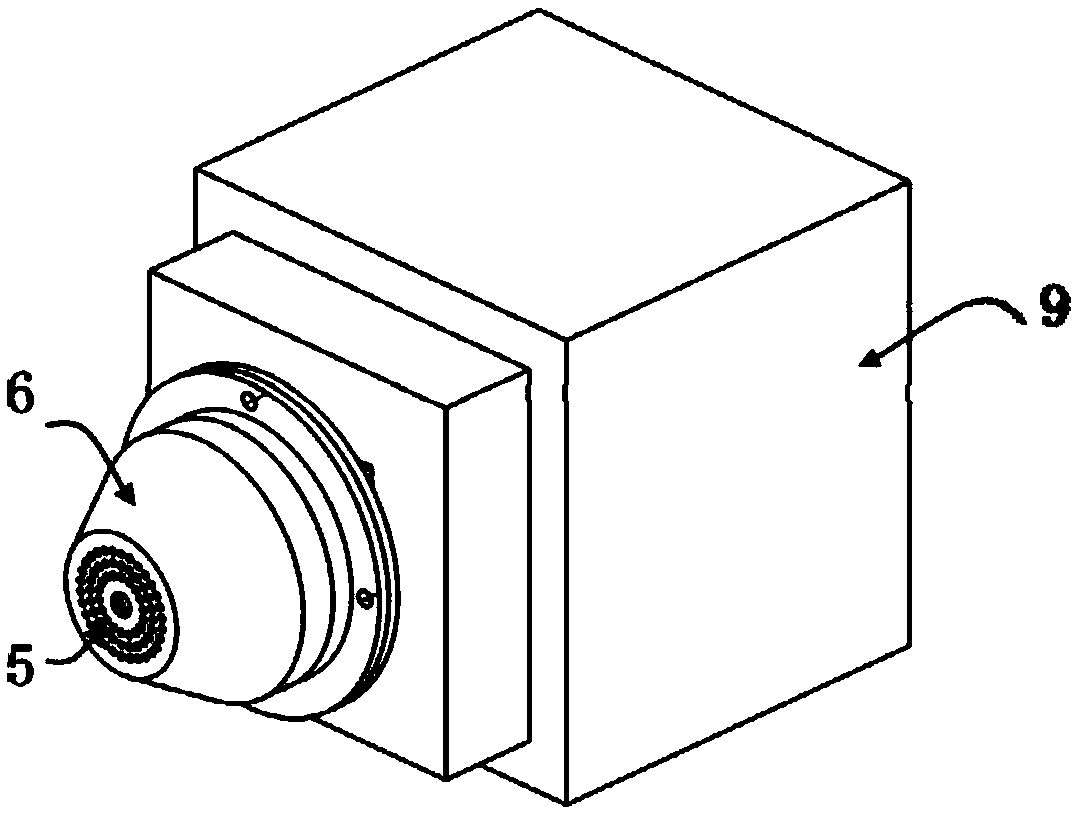

Cutting-stirring friction-welding combined machining equipment and manufacturing method thereof

ActiveCN102501074AEfficient coolingAvoid glitchesOther manufacturing equipments/toolsMaintainance and safety accessoriesTemperature sensingSensing system

The invention discloses cutting-stirring friction-welding combined machining equipment and a manufacturing method thereof. The cutting-stirring friction-welding combined machining equipment integrates a milling system or a cutting system, a stirring friction-welding system, a forced cooling system, a gas protection system, a temperature sensing system, a pressure sensing system, a milling liquid supply system and a non-sensing system. The invention provides a united or combined machining device which can carry out milling or cutting and stirring friction-welding in parallel simultaneously and a method thereof. The cutting-stirring friction-welding combined machining equipment has the functions of temperature control, gas protection, pressure detection, cooling liquid production, milling head replacement and dual-shaft shoulder self-supporting. According to the manufacturing method of the cutting-stirring friction-welding combined machining equipment, the manufacturing processes are reduced and the machining cost is saved. The limitation of the conventional mechanical machining technology is broken through, and a new method and a new idea about the mechanical manufacturing and machining are formed. The cutting-stirring friction-welding combined machining equipment and the manufacturing method in the invention have wide engineering applications to the heating industry, the air conditioning industry, the ice making industry, the freshness retaining industry, the pharmacy industry, the construction industry, the aquatic product industry and the food industry.

Owner:罗键

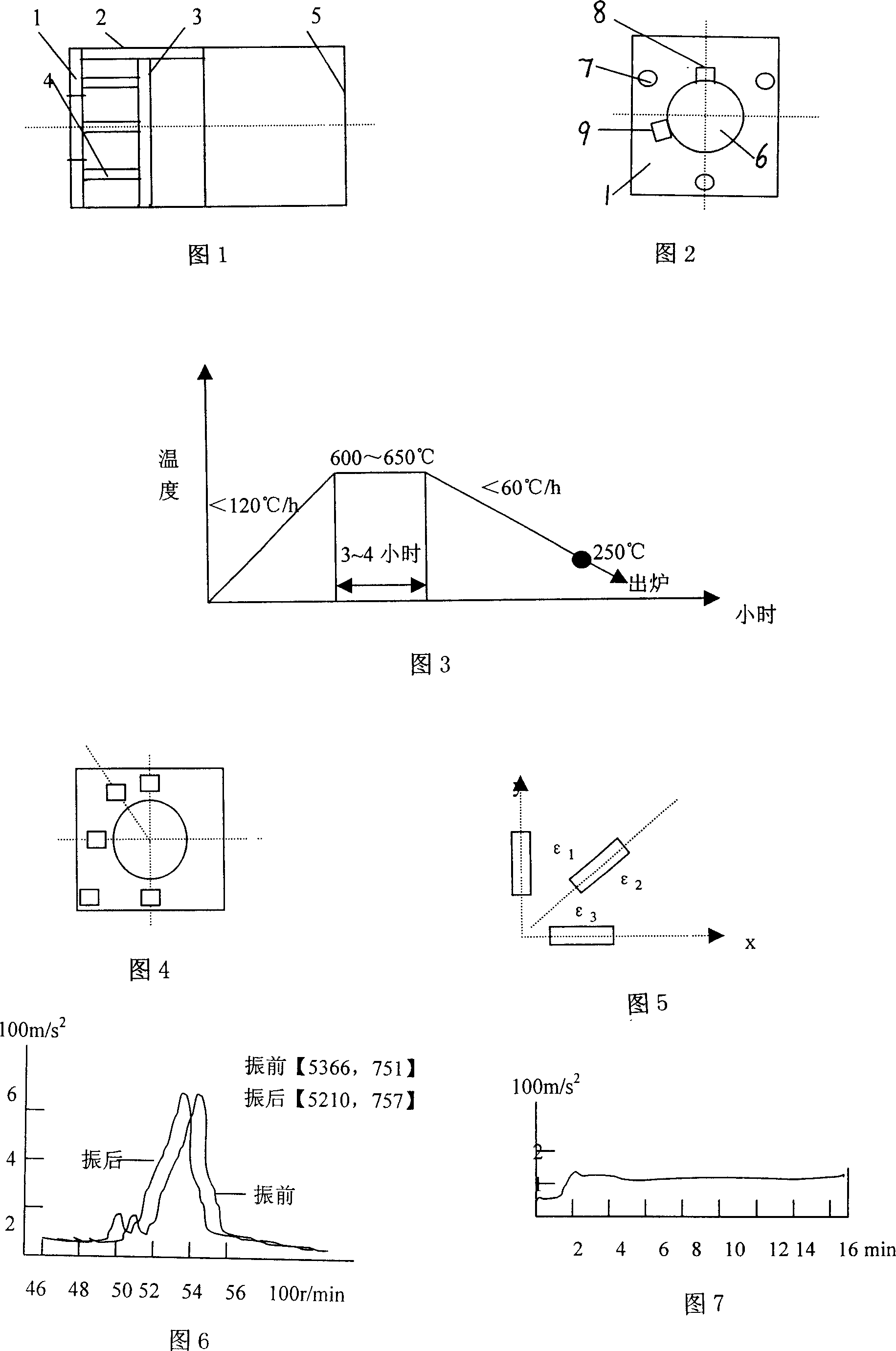

Technique for reducing residual stress of motor bed plate in welded structure

InactiveCN101003850AReduce welding residual stressReduce stressProcess efficiency improvementWelding residual stressEngineering

This invention provides a process for lowering residual stress of welding motor base by using vibrational aging. The process comprises: utilizing three points uniformly distributed on the same circumference as the supporting points, setting rubber gaskets on the supporting points, uniformly fixing the outer wall plates of the welding motor base onto the rubber gaskets, and performing vibrational aging for vibrational aging for 0.5-1 h. The vibrational aging utilizes the crossed point between the perpendicular bisector of two supporting points and the round hole on the outer wall plate as the exciting point, and the point 1 / 3 hole circumference distant from the exciting point as the detecting point. The exciting force is 1 / 3 of the working stress. The method utilizes vibrational aging as a substitute for traditional heat aging to lower residual stress of welding motor base. Through selection of appropriate exciting force as well as exciting point position, the method can realize optimal exciting effect. The method has such advantages as flexible operation, good stress-lowering effect, high efficiency, low energy consumption, and no pollution.

Owner:SHANDONG QILU ELECTRIC MOTOR MFG

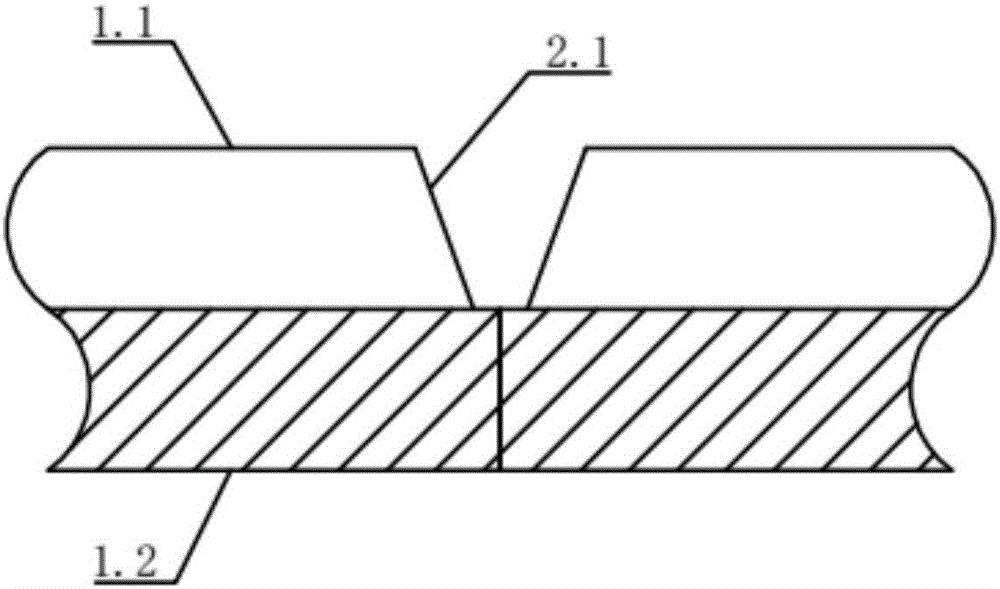

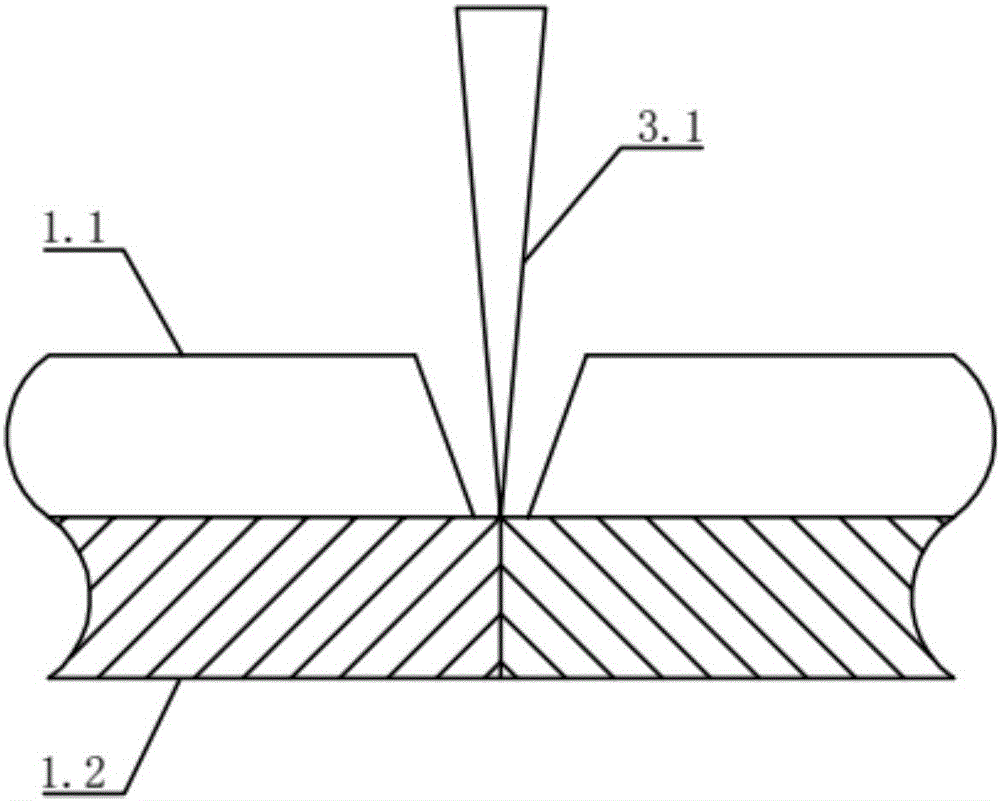

One-sided welding double-sided molding welding method for titanium steel composite pipe

ActiveCN106425104AGood for fusion transitionLow costWelding/cutting media/materialsWelding/soldering/cutting articlesAlloyTitanium

The invention provides a one-sided welding double-sided molding welding method which is suitable for welding a titanium steel composite pipe. The one-sided welding double-sided molding welding method aims at solving the problems that in existing titanium steel composite pipe welding, operation of the welding process is complicated, the accumulated heat input is large, it is necessary to prepare special welding consumables, and the welding efficiency is low. The one-sided welding double-sided molding welding method for the titanium steel composite pipe comprises the following steps that (1), a flat bottom groove with a blunt edge is machined at the pipe end of the titanium steel composite pipe to be welded; (2), a welding area is cleaned; (3), a titanium alloy layer of the titanium steel composite pipe is welded through a laser welding method; (4), acetone is used as a binder so that evenly-mixed transition layer metal powder can be made into paste, the groove bottom is evenly welded, pressing is conducted, and drying is conducted; and (5), transition layer metal is molten through laser energy, the transition layer is formed firstly, and then filling of the steel metal layer is conducted through electric arc welding. By the adoption of the method, one-sided welding double-sided molding welding of the titanium steel composite pipe is achieved, and the welding quality of the titanium steel composite pipe is improved.

Owner:SOUTHWEST JIAOTONG UNIV

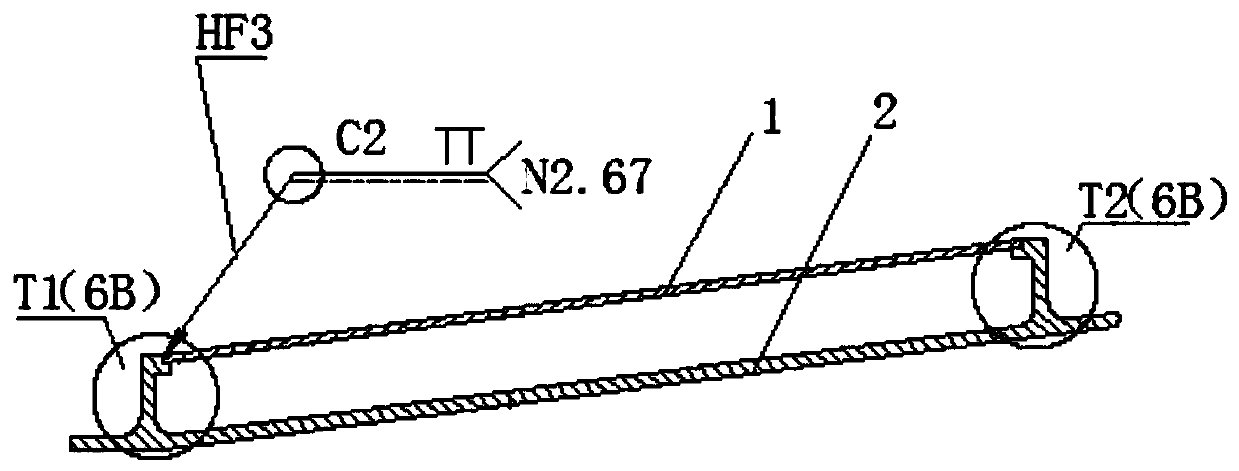

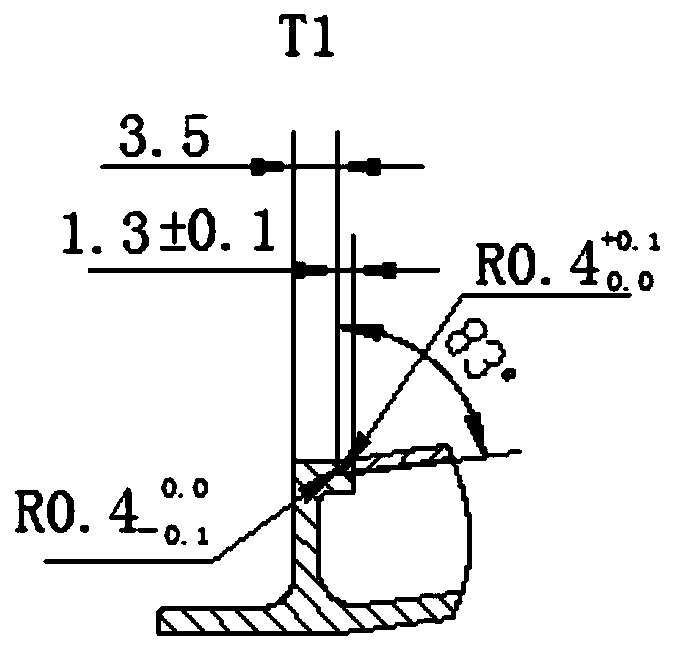

Device and method for controlling welding stress and deformation by combining heating with welding and chilling

ActiveCN106425148AIncrease space volumeReduce welding residual stressWelding/cutting auxillary devicesAuxillary welding devicesSupporting systemWelding residual stress

The invention discloses a device and a method for controlling welding stress and deformation by combining heating with welding and chilling. The device comprises a supporting system as well as an automatic travelling device, a welding system, a heating system and a cooling system which are connected with the supporting system. A welding seam high-temperature region is cooled, and near weld zones at the two sides are heated, so that dynamic multi-stretching effect is generated; requirements on constraints of a clamp are avoided, and welding is carried out under a non-constraint condition, so that control on welding residual stress and deformation is realized to carry out welding under a non-support condition, and relatively great space volume is not occupied.

Owner:JIAMUSI UNIVERSITY +1

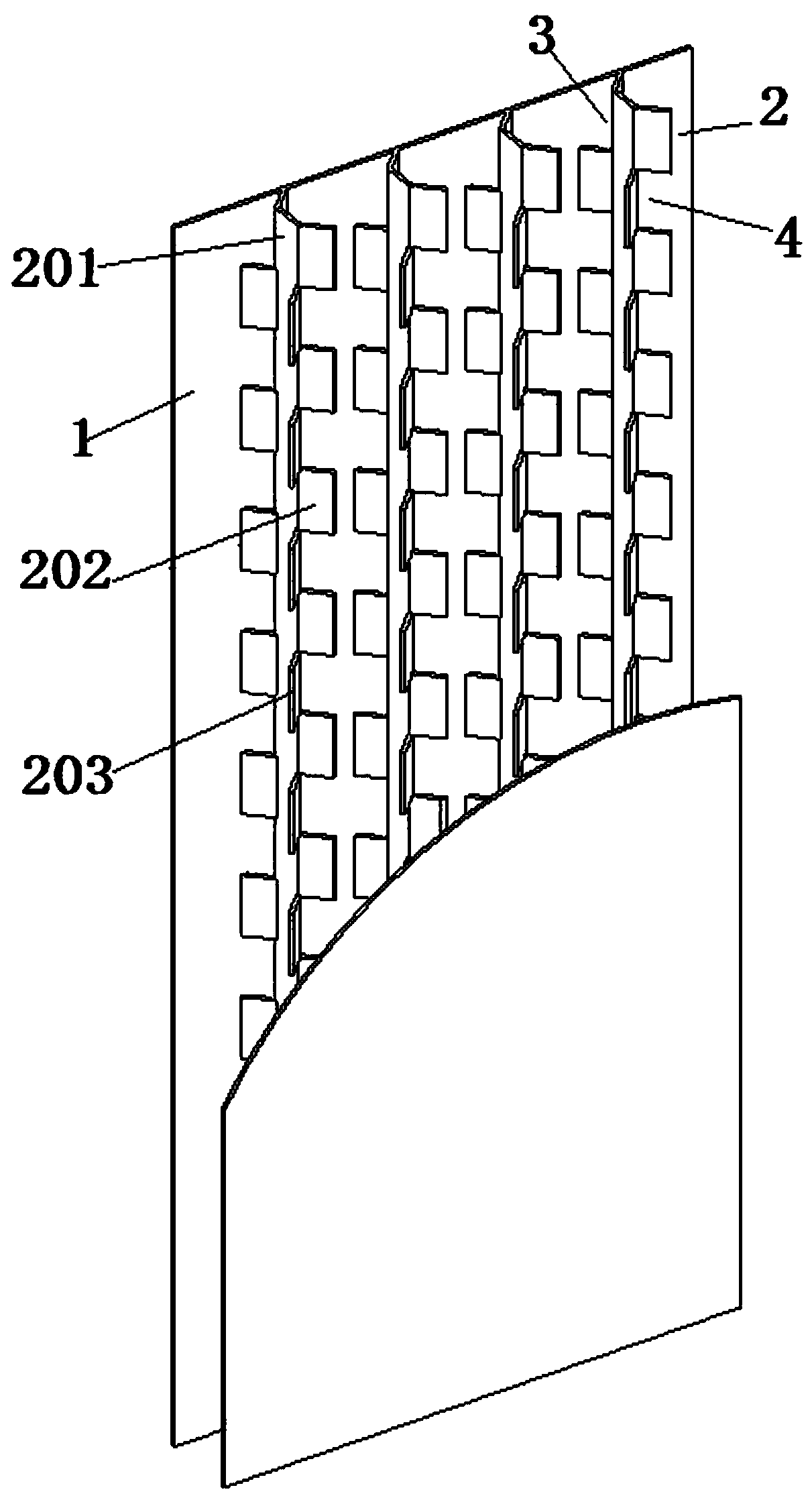

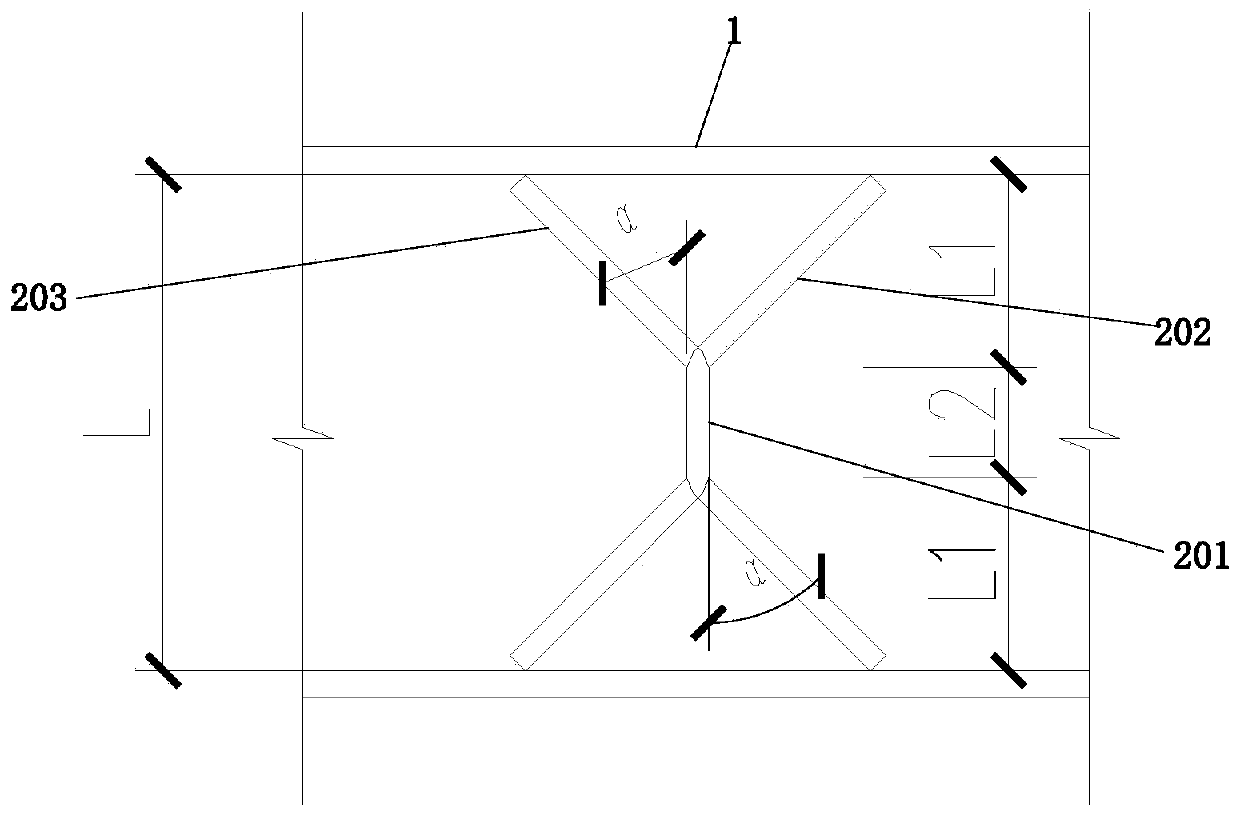

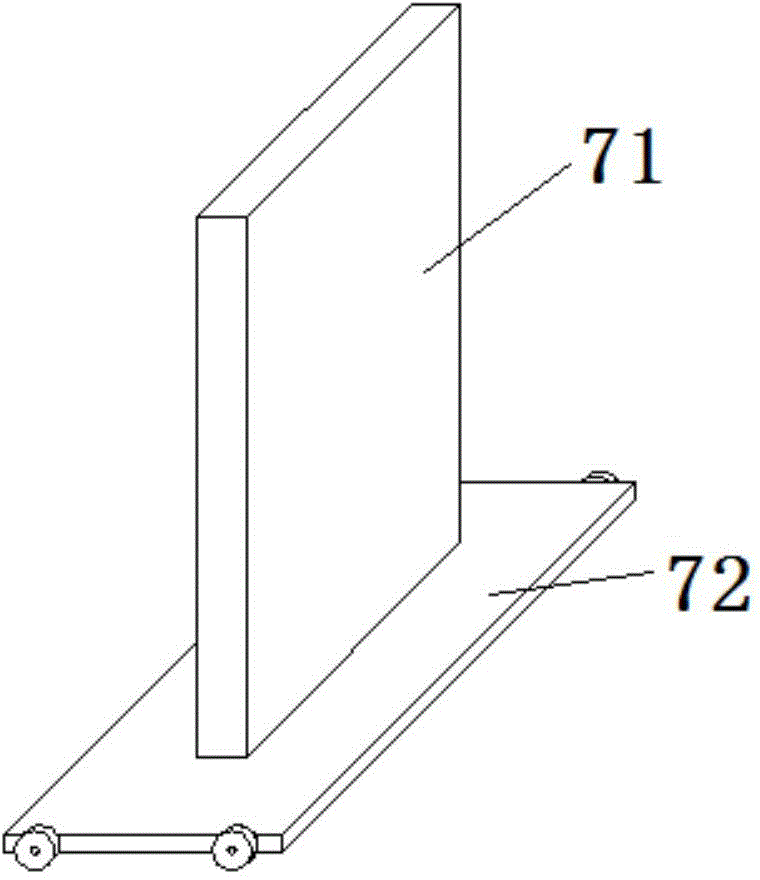

Steel plate combined shear wall capable of achieving connection through crossed bending type partition board and preparing method

PendingCN110469043AImprove stabilityEasy to moveConstruction materialWallsEngineeringSteel plate shear wall

The invention discloses a steel plate combined shear wall capable of achieving connection through a crossed bending type partition board and a preparing method. The wall comprises two parallel external package steel plates, the crossed bending type partition board is arranged between the two external package steel plates, and a first opening and a second opening which are alternatively distributedup and down are formed between the crossed bending type partition board and the external package steel plates. According to the steel plate combined shear wall, the quality of the steel plate combined shear wall can be effectively improved, and the whole stress property of the steel plate shear wall is improved.

Owner:THE ARCHITECTURAL DESIGN & RES INST OF ZHEJIANG UNIV

Ultrasonic vibration assisted welding method

ActiveCN105728930AIncrease the number ofInhibition of grain growthNon-electric welding apparatusMetalCrystal

The invention relates to the field of welding and in particular relates to an ultrasonic vibration assisted welding method. The method comprises the following steps: in a welding process of fusion welding, providing an ultrasonic vibration force through an ultrasonic excitation vibration device; introducing ultrasonic frequency stress wave into a welding fusion tank; finally, transmitting vibration to a welding part. With the adoption of the configuration, the quantity of crystal nucleuses can be effectively increased, the size of crystal grains is prevented from growing, dendritic crystals are crushed and a crystal shape is changed, so that condensed welding line metal crystal grains are thinned; gas, impurities and the like in the fusion tank are prompted to rapidly float up, and defects of air pores and slag adding are reduced; welding residual stress and welding deformation are reduced; components are more uniform so that a welding line metal structure is improved; a fusion region becomes narrow and is uniformly transited, and non-fusion defects are reduced; comprehensive mechanical properties of welding lines are improved through the effects above.

Owner:ACADEMY OF ARMORED FORCES ENG PLA

Metal material, process and product for welding LNG ultralow-temperature stainless steel

InactiveCN110576273AImprove plasticityImprove toughnessArc welding apparatusWelding/cutting media/materialsWelding residual stressMetallic materials

The invention provides a metal material process and product for welding LNG ultralow-temperature stainless steel. The components and structure of a welding material are designed to make sure that thecontent of ferrite in a weld joint is low and the proportion of residual ferrite is reduced to be equal to or less than 1.0%; during welding, a stainless steel twisted welding wire is adopted, argon arc welding is adopted for bottoming, face filling is achieved through argon arc welding or submerged arc welding, the process parameters for welding are controlled to make sure that the energy of thewelding wire is equal to or less than 13KJ / cm, and meanwhile, the formula of a welding protective gas is set; and high-frequency vibration is conducted to assisting in welding to optimize the weldingquality. By the adoption of the metal material process and product for welding the LNG ultralow-temperature stainless steel, the plasticity and tenacity of weld joint metal are obviously improved, welding residual stress is greatly reduced, and the welding efficiency is improved.

Owner:WUHAN RUNZHIDA PETROCHEM EQUIP CO LTD

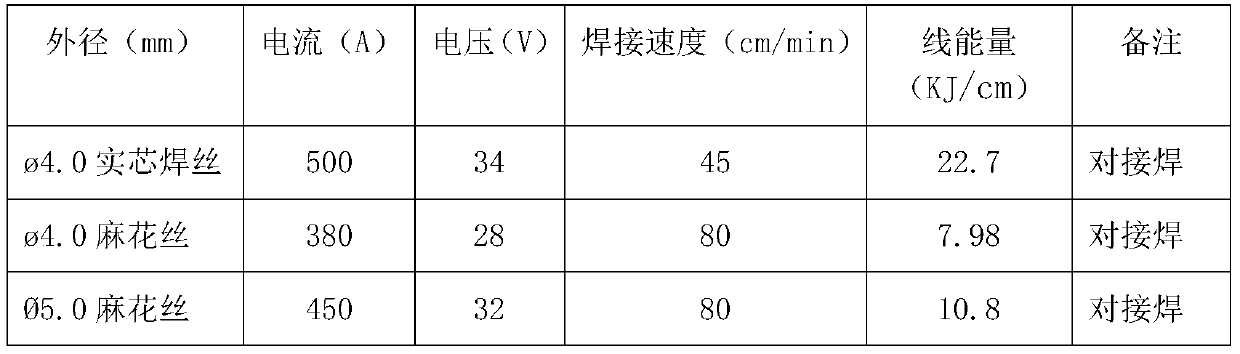

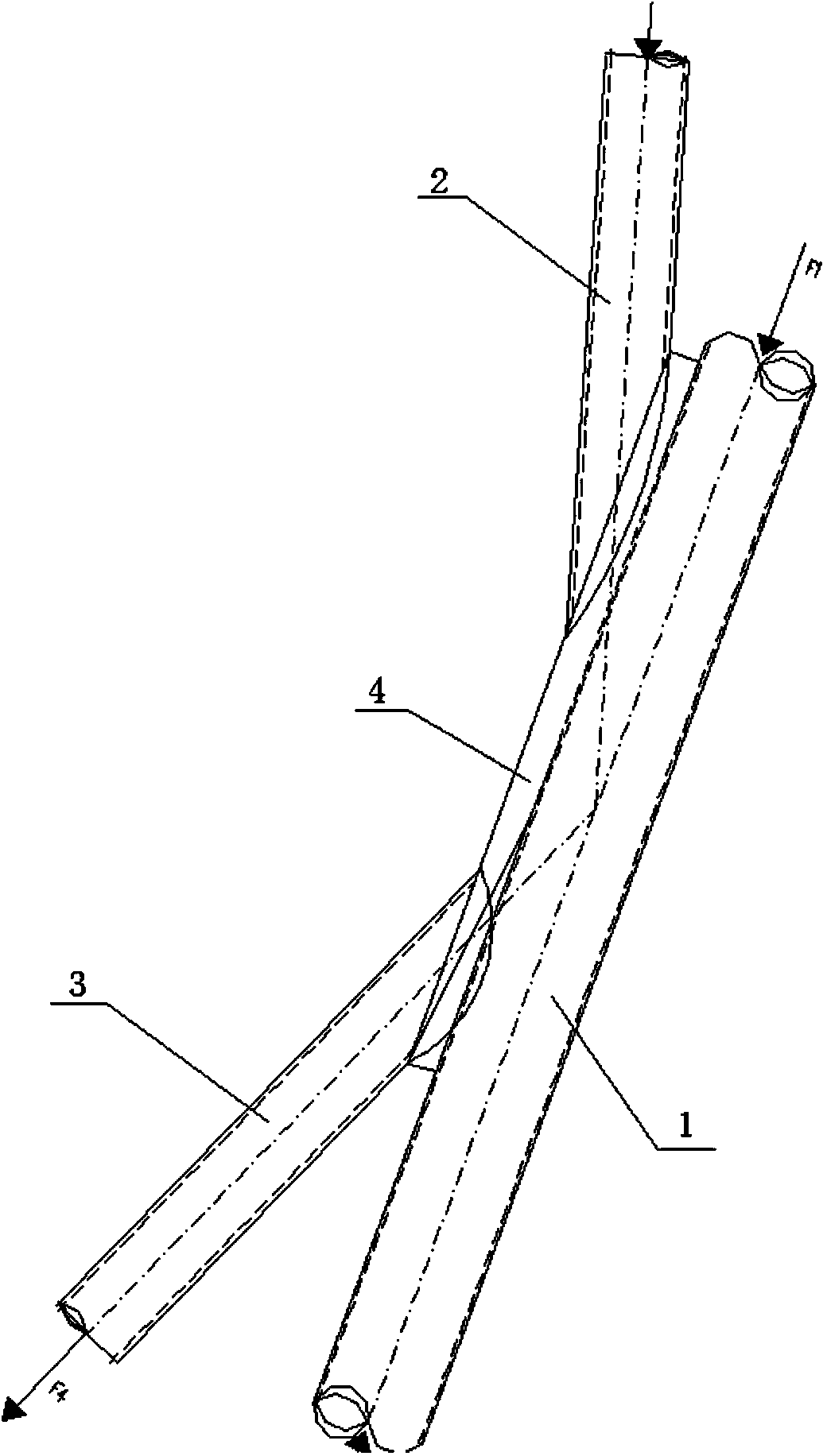

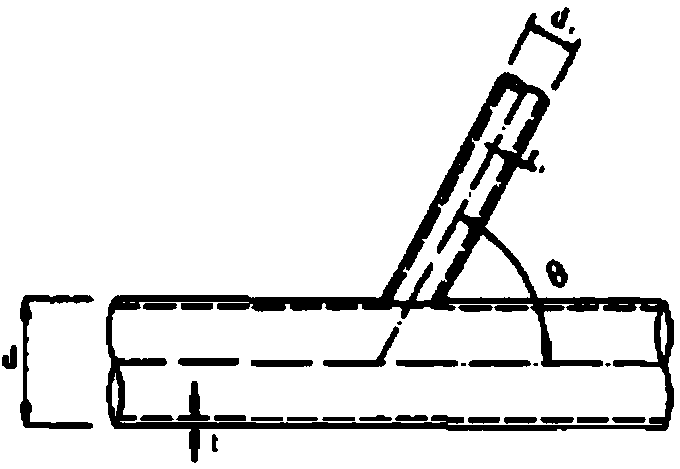

Steel tube joint

ActiveCN103806543ASolve the problem that the included angle is too smallImprove the forceBuilding constructionsMetallurgyStressed state

The invention provides a steel tube joint. The steel tube joint comprises a main tube and branch tubes. The axes of the branch tubes intersect with the axis of the main tube. The main tube and the branch tubes are all steel tubes. The steel tube joint is characterized in that a base plate is arranged between the main tube and the branch tubes. Compared with the prior art, the steel tube joint is more reasonable in structural arrangement, overcomes defects of a traditional tubular joint, improves welding conditions of welding joints and obviously improves bearing capacity and stress states.

Owner:STATE GRID CORP OF CHINA +1

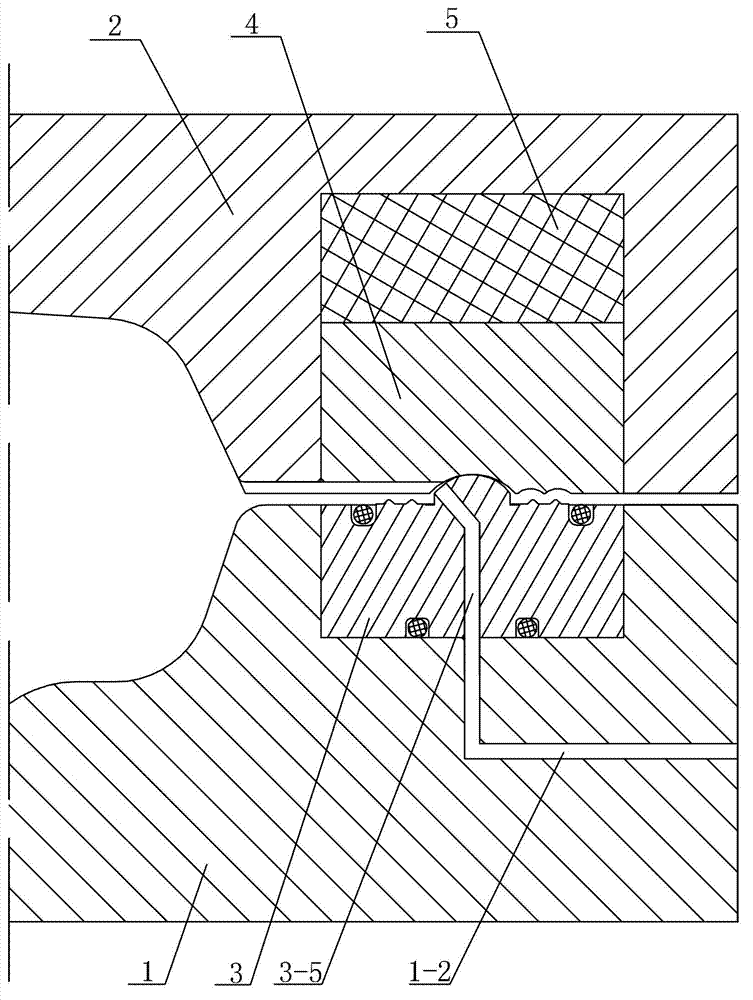

Device and method for hydraulic forming of cavity part with complex curved surface

InactiveCN102806261AReduce wall thicknessSolve welding deformationWelding residual stressDeep drawing

The invention discloses a device and a method for hydraulic forming of a cavity part with a complex curved surface, and relates to a device and a method for forming metal plates. The device and the method solve the problem of large welding deformation and welding residual stress in the prior art for stamping and deep drawing of parts with complex curved surfaces and also solve problems that in the initial forming stage, double plate blanks need to be pressed by high mold clamping force to guarantee sealing of liquid at a liquid charging opening, so that the plate blanks at two ends of a cavity are difficult to flow into the cavity of a mold when a cavity part with a complex curved surface is formed, the wall thickness of the part is reduced due to high expansion deformation, and the part is difficult to form by the existing double-plate hydraulic forming technology. The device comprises an upper mold, a lower mold, a lower liquid charge insert, an upper liquid charge insert, an elastic component, a first sealing ring and a second sealing ring, the elastic component and the upper liquid charge insert are sequentially arranged in an upper groove from top to bottom, the lower liquid charge insert is arranged in a lower groove, and the second sealing ring is mounted in a second sealing groove. The device and the method are used for forming of the cavity part with the complex curved surface.

Owner:HARBIN INST OF TECH

Heat treating method for large-scale device integral anneal

InactiveCN101148689ASolve the problem of annealing heat treatmentReduce welding residual stressFurnace typesHeat treatment process controlTemperature controlStress relieving

The heat treatment process for annealing large apparatus integrally includes the following steps: 1. arranging heating plates inside the large apparatus; 2. connecting the heating plates through a interface converter to a temperature control system comprising temperature control box and temperature measuring thermocouples; 3. coating the outside of the apparatus with heat insulating material; and 4. heating homogeneously in the controlled temperature raising rate, maintaining for required time, lowering the temperature slowly to anneal and eliminate stress and powering off. The present invention is suitable for annealing large apparatus integrally.

Owner:贵阳白云铝工业设备制造厂

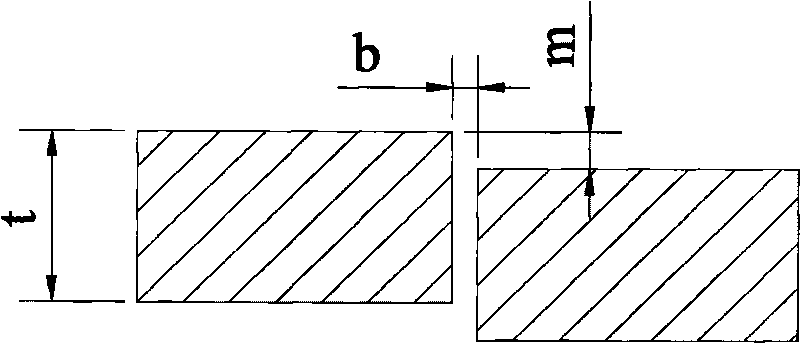

Plasma-arc welding method of cupronickel with thickness of 2-20 mm

InactiveCN101758326AImprove quality and efficiencyIncrease productivityArc welding apparatusPlasma welding apparatusCupronickelPass rate

The invention relates to a plasma-arc welding method of cupronickel with the thickness of 2-20 mm, comprising the following steps of: measuring divided edge reference dimension and adopting a welding mode; setting parameters before welding; and setting process parameters in a welding process, wherein a divided edge includes an I-shaped divided edge and a U-shaped divided edge; the welding mode includes downward welding and horizontal welding or vertical welding; the process parameters in the welding process are set by selecting different welding currents, welding voltages, welding speeds and wire feed speeds according to different thicknesses of the cupronickel plates; protective gases are all pure argon; plasma gas flow rate is not less than 3-10 L / min; and welding gun gas flow rate is not less than 15-25 L / min. The invention has the advantages of stable welding process, high welding efficiency and welding seam qualification rate and good welding seam quality and outstanding economic benefit, and can effectively enhance the welding quality and the production efficiency of cupronickel materials.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

Repair method for welding defects of large-size friction stir welding

InactiveCN108788504AEliminate stomataEliminate defects such as cracksWelding apparatusWeld seamEngineering

The invention discloses a repair method for welding defects of large-size friction stir welding. The repair method comprises the following steps of: (1) forming an open groove in a welding defect position of the friction stir welding; (2) filling and welding the open groove by adopting a fusion welding method which can add a filling material; (3) welding a fusion welding process repair welding region by adopting pullback type friction stir welding, wherein a welding tool moves in the welding direction of the last friction stir welding step; the welding tool moves forwards again after the repair welding region is welded; and meanwhile a stirring needle is gradually pulled back; and (4) after the stirring needle is pulled back, stopping the welding tool for 1-5 seconds and starting to lift up the welding tool to obtain a repair welded joint which is good in surface formation, excellent in mechanical properties and free of keyholes in surface so as to finish the repair welding. The repairmethod for the welding defects of large-size friction stir welding disclosed by the invention is high in process stability, economic efficiency and operability, and remarkably improves the mechanicalproperties of a repair welding seam; and the repair welded joint is good in surface formation and free of keyholes.

Owner:NANJING ZHONGCHE PUZHEN URBAN RAIL VEHICLE CO LTD

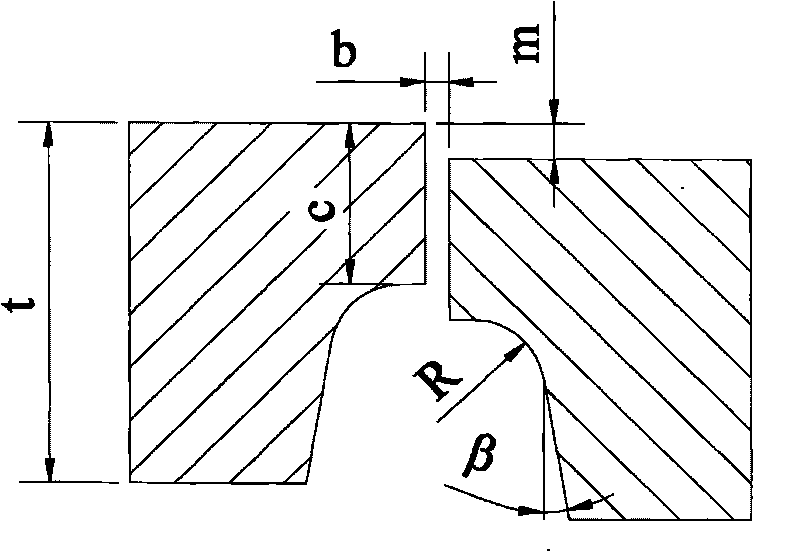

Welding device for preventing welding hot cracking and deformation

ActiveCN104785905AEnables unsupported weldingGuaranteed stabilityWelding accessoriesDry iceWeld seam

Provided is a welding device for preventing welding hot cracking and deformation. A workbench is provided with a fixing device used for positioning an aluminum alloy board. A welding device and a cooling device are arranged around the workbench. The welding device comprises a tungsten electrode argon arc welding machine, a welding gun and an argon gas bottle which are connected through pipelines; the cooling device comprises a spraying gun and a dry ice ejector which are connected through a pipeline; the fixing device comprises a layer board where the aluminum alloy board is placed; fixing blocks for positioning the aluminum alloy board are arranged around the layer board; a sliding rail is erected above the layer board and is parallel with a welding seam of the aluminum alloy board; a welding gun sliding block and a spraying gun sliding block are arranged on the sliding rail in a sliding mode; a baffle portion capable of sliding along the sliding rail is arranged between the welding gun sliding block and the spraying gun sliding block; the welding gun and the spraying gun are fixed on the welding gun sliding block and the spraying gun sliding block respectively; a muzzle of the welding gun and a muzzle of the spraying gun are aligned with the welding seam. Non-support welding of the aluminum alloy board is achieved, and stability of the welding structure is ensured.

Owner:常州瑞鼎汽车科技有限公司

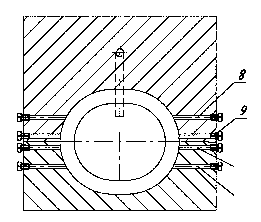

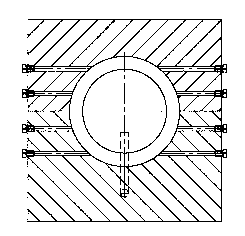

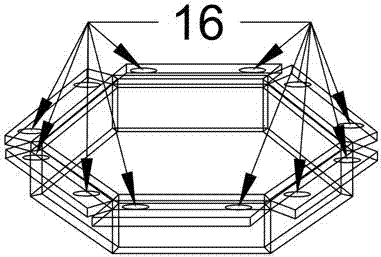

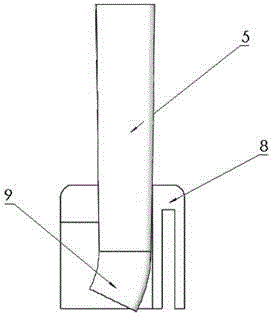

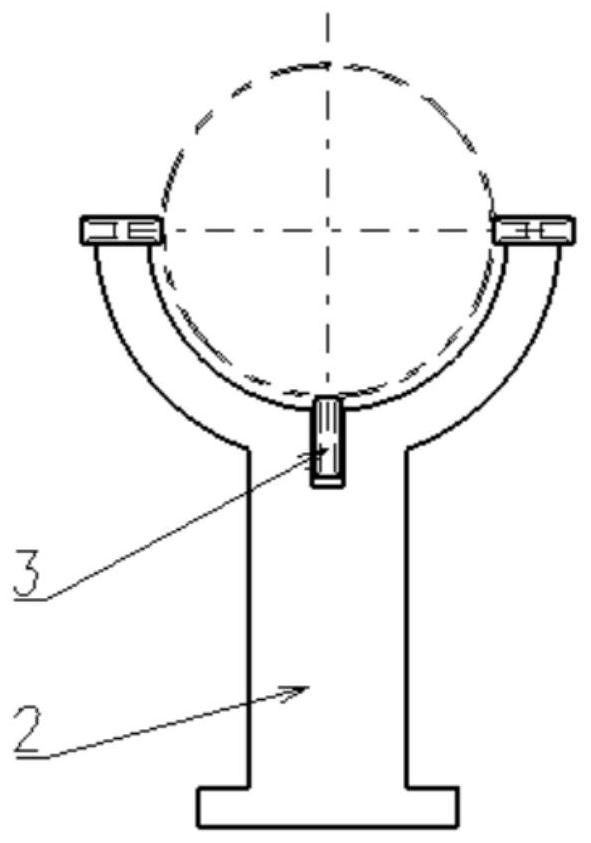

Electron beam welding method of thin-walled casing gas-collecting hood structure

ActiveCN110977170AHigh welding power densityImprove power densityLaser beam welding apparatusWelding residual stressEngineering

The invention provides an electron beam welding method of a thin-walled casing gas-collecting hood structure, and belongs to the technical field of gas-collecting hood welding. The electron beam welding method comprises the following steps of: step 1, designing a welding structure; step 2, performing the single-piece processing of a gas-collecting hood 1; and step 3, welding the gas-collecting hood 1. A gas-collecting hood heat shaping fixture in step 2. 6 comprises a tire 5, a pressure ring 6, pins 7, wedge blocks 8, and a hanger 9, wherein the hanger 9 is welded on the inner surface of the tire 5; the pressure ring 6 is arranged on the top of the tire 5; the wedge blocks 8 are uniformly arranged on the top of the pressure ring 6 in the circumferential direction and are in one-to-one correspondence with through holes of the pressure ring 6; and the pins 7 sequentially pass through the wedge blocks 8 and the pressure ring 6 to fix the pressure ring 6 and the tire 5. The electron beam welding method reduces the welding residual stress and the welding deformation, and improves the quality of parts through the design of the welding structure, the design and process improvement of thegas-collecting hood heat shaping fixture, and the improvement of the welding process.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

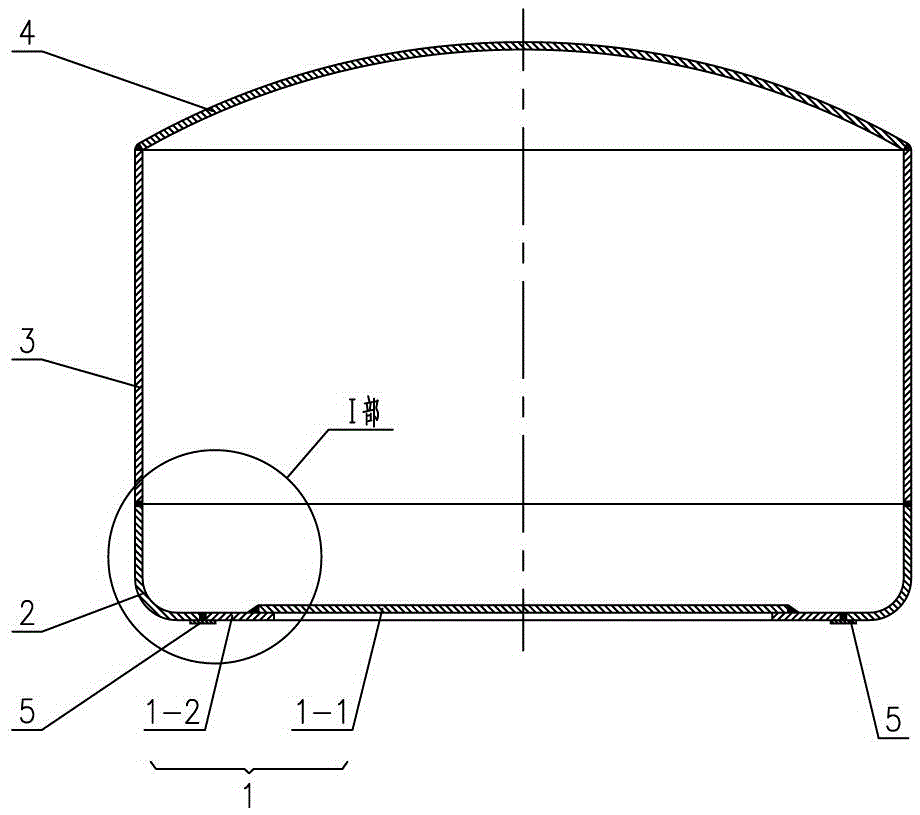

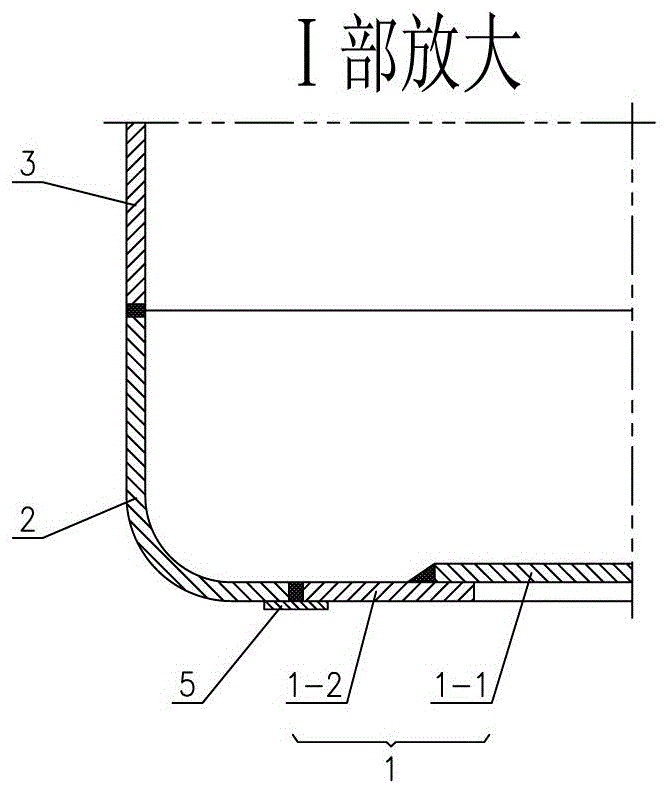

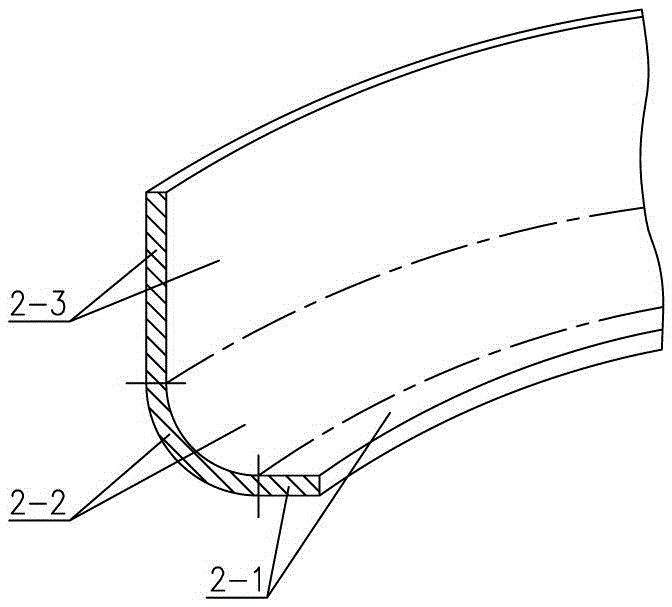

Large steel welded vertical oil tank

ActiveCN105600205AReduce edge stressEliminate welding residual stressLarge containersSafe operationWaste management

The invention provides a large steel welded vertical oil tank. The large steel welded vertical oil tank is provided with a tank bottom, a tank wall and a tank top. A transition connecting ring is arranged between the tank bottom and the tank wall and provided with an annular bottom section, an arc-shaped transition section and a vertical cylindrical section. The tank bottom is connected with the annular bottom section of the transition connecting ring in a welded mode. The tank wall is connected with the vertical cylindrical section of the transition connecting ring in a welded mode. The tank top can be a fixed top and can also be an outwards-floating top. The large steel welded vertical oil tank has the advantages that T-shaped joints of a tank wall and a tank bottom of an existing large oil tank and large fillet welds on the joints are omitted, main danger points of the whole oil tank are eliminated, and safe operation of the large oil tank is guaranteed, wherein the transition position between the tank wall and the tank bottom is not prone to low-cycle fatigue damage, an attachment weld of the transition portion between the tank wall and the tank bottom is not prone to tearing damage, the anti-seismic property of the large oil tank is greatly improved, and the anti-seismic property of the large oil tank is good.

Owner:JIANGSU CHEM EQUIP MFG & INSTALLATION CO LTD

Automatic wire-feeding friction stir welding method for butt joint of dissimilar metal materials

ActiveCN107414283AReduce frictional heatReduce thicknessWelding/soldering/cutting articlesNon-electric welding apparatusButt jointChemical compound

The invention discloses an automatic wire-feeding friction stir welding method for butt joint of dissimilar metal materials. The automatic wire-feeding friction stir welding method comprises the following steps that 1, welding pieces are in butt joint with each other and are clamped, an interval is formed between the welding pieces, strip-shaped welding wires are led out from a wire-feeding gun, a straightening wheel set, a pre-buried wheel and a leveling wheel are sequentially placed on the interval, the strip-shaped welding wires are straightened through the straightening wheel set, then obliquely downwards fed into the interval through the pre-buried wheel and later leveled through the leveling wheel, and the ends of the strip-shaped welding wires are arranged under a stirring head; 2, a welding machine is started, the stirring head starts vertical downwards feeding, later a stirring needle is pressed into the interval where the strip-shaped welding wires are stored, welding is started, and in the welding process, the wire-feeding speed keeps consistent with the welding speed; and 3, the stirring head is lifted, then wire feeding is stopped, and the strip-shaped welding wires are cut off. According to the automatic wire-feeding friction stir welding method for butt joint of the dissimilar metal materials, generation of chemical compounds between metal can be reduced, the interface temperature is decreased, the residual stress is reduced, a welding joint is prevented from generating holes, and the mechanical property and the welding efficiency of welding connectors are improved.

Owner:CHONGQING UNIV OF TECH

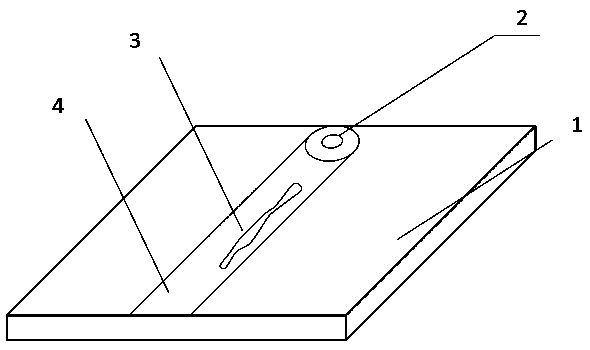

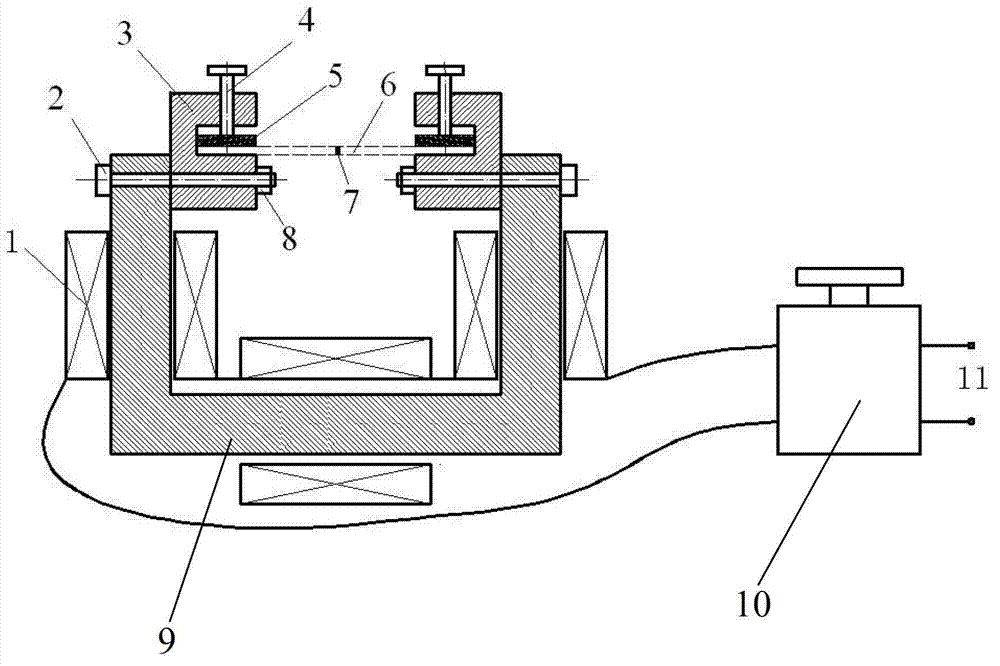

Method and device for improving formability of tailor-welded steel plate

InactiveCN102925660AGood formabilityReduce welding residual stressFurnace typesHeat treatment furnacesSheet steelWelding residual stress

The invention relates to a method and a device for improving the formability of a tailor-welded steel plate. The method is characterized in that a tailor-welded steel plate after welding is placed in a low-frequency alternating magnetic field to be subjected to magnetic field destressing treatment, the treatment time is 20 s to 300 s, the magnetic induction intensity of the low-frequency alternating magnetic field ensures that all base metals of the tailor-welded steel plate can reach a magnetic saturation state, the frequency of the low-frequency alternating magnetic field is 0.2 Hz to 10 Hz, and the welding direction of the tailor-welded steel plate is perpendicular to the direction of the low-frequency alternating magnetic field. The device comprises an iron core (9), an excitation coil winding (1), a variable velocity variable frequency (VVVF) device (10), an alternating current power supply (11) and a clamp (3) used for clamping the tailor-welded steel plate (6). Through the application of the method and the device, the welding residual stress of the tailor-welded steel plate can be reduced effectively, the formability of the tailor-welded steel plate is improved, the advantages of energy conservation and environmental protection are achieved, and meanwhile, various bad consequences caused by traditional high temperature tempering and destressing manners can be avoided.

Owner:WUHAN UNIV OF TECH

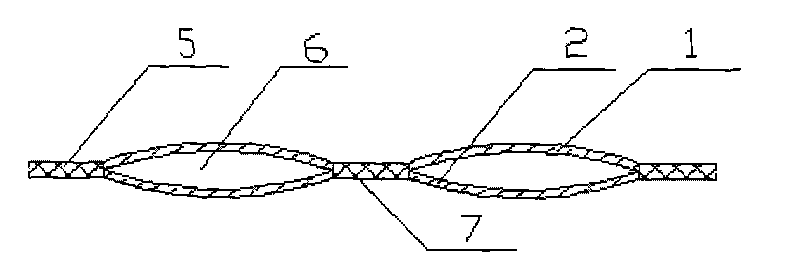

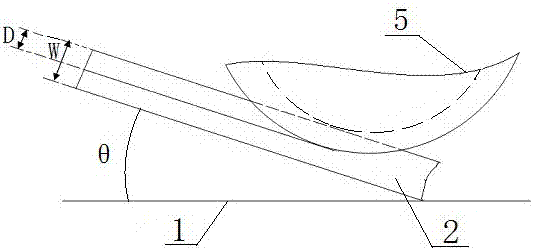

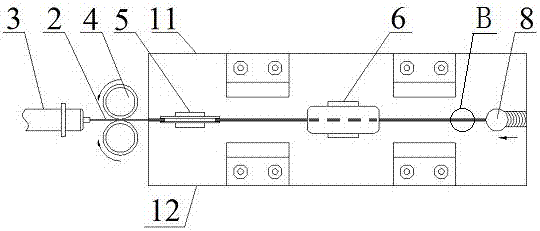

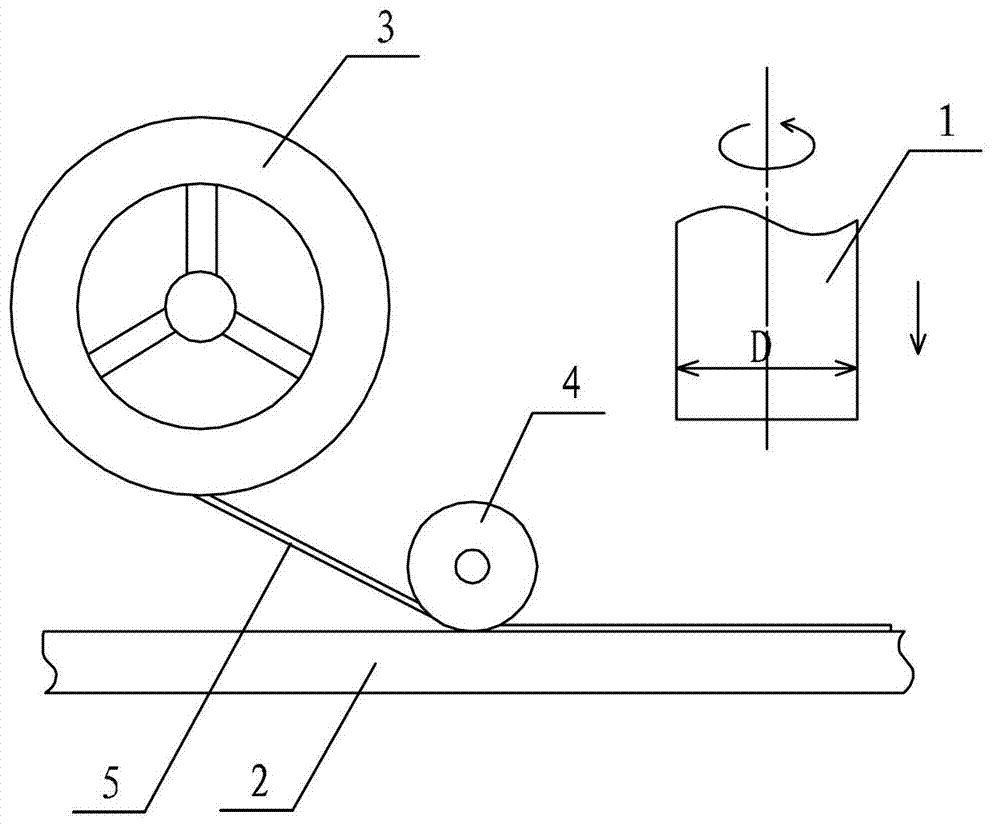

Strap-shaped welding wire filling-in type stirring friction treatment method

InactiveCN103170726ALow dilution rateChange surface propertiesNon-electric welding apparatusBand shapeEngineering

The invention relates to a strap-shaped welding wire filling-in type stirring friction treatment method, relates to a filling-in type stirring friction treatment method, and aims at solving the problem that generally high-energy beam powder bead welding can only be conducted under gas protection or even under vacuum condition. The method comprises the following steps of: firstly, pretreatment preparation, namely, a wire feeding wheel and a positioning guide wheel are fixed on a main shaft of a welding machine, a material to be treated is clamped, a strap-shaped welding wire is put under the positioning guide wheel, the positioning guide wheel is tightly adhered to the surface of the material to be treated, the strap-shaped welding wire is fixed on the surface of the material to be treated, and the end part of the strap-shaped welding wire is put just below a needleless welding tool; secondly, stirring friction treatment, namely, the welding machine is started, the needleless welding tool starts to vertically feed downwards, the shaft shoulder of the needleless welding tool is contacted with the end part of the strap-shaped welding wire and is gradually compressed into the upper surface of the material to be treated, and the strap-shaped welding wire is subjected to bead welding on the surface of the material to be treated by using the stirring and fogging and pressing functions of the shaft shoulder; and thirdly, after-welding settlement, namely, the welding wire is cut off by using a pair of cutting nippers, the residual welding material and overlap are removed by using a steel wire brush. The method is applied to stirring friction treatment.

Owner:HARBIN INST OF TECH

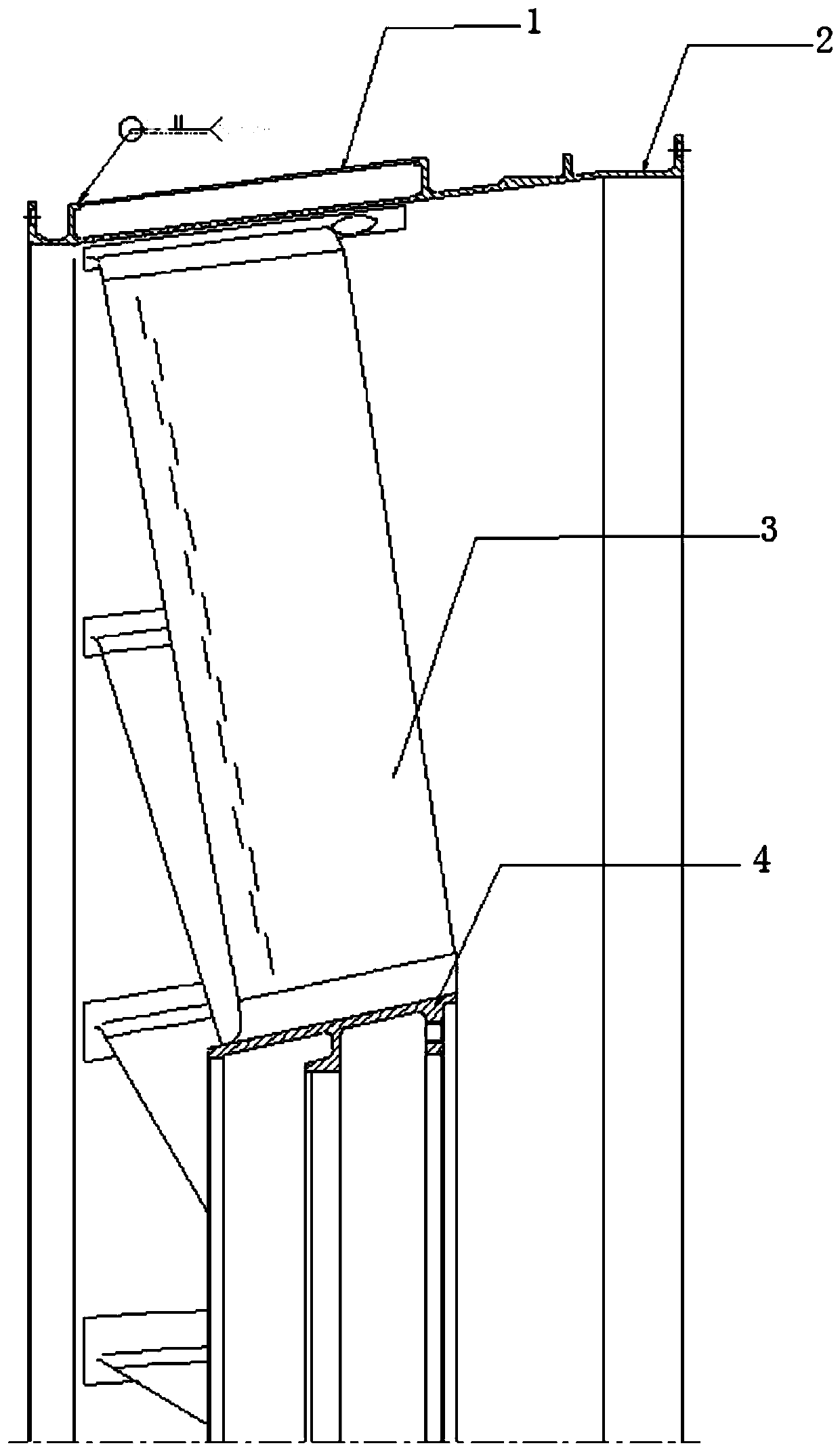

Laser welding longitudinal seam joint guiding, preheating and distressing dynamic correction device for thin-walled cylinder

ActiveCN112247381AMeet relative position accuracy requirementsWarm up evenlyFurnace typesMetal working apparatusWelding residual stressEngineering

The invention discloses a laser welding longitudinal seam joint guiding, preheating and distressing dynamic correction device and method for a thin-walled cylinder, and belongs to the technical fieldof laser welding. The device comprises a supporting mechanism, a longitudinal joint centering and guiding mechanism, double-side self-preheating feeding mechanisms, destressing correction mechanisms and a size detection structure. A blade-shaped guiding body of the device is embedded into the open cylinder, a longitudinal connector is automatically centered and guided, the guiding body is gradually separated from the connector along with opposite movement and enclasping of heating and enclasping wheels on the two sides, centering and guiding of the longitudinal connector are completed, weldingdefects are effectively avoided, the welding quality is improved, and the equipment configuration and investment cost is reduced. Uniform preheating and longitudinal feeding of the cylinder are completed through self-rotation of the heating and enclasping wheels on the two sides; the cylinder is subjected to rolling correction through circumferential high-temperature correction wheels, and meanwhile, the welding residual stress is eliminated; and laser sensors are used for detecting the size of the cylinder in real time, a circumferential shape correcting die is synchronously adjusted, and the problem of welding deformation of the thin-walled cylinder is solved.

Owner:CHANGCHUN UNIV OF SCI & TECH

Laser welding device with cooling system and welding method thereof

ActiveCN110834149AAvoid growing upReduce softeningWelding/soldering/cutting articlesLaser beam welding apparatusSpray coolingLaser soldering

The invention relates to a laser welding device with a cooling system and a welding method thereof. The laser welding device with the cooling system comprises a laser welding system, wherein the laserwelding system welds a workpiece so as to form a welding joint or a welding point. The laser welding device with the cooling system further comprises a liquid spray mist cooling system, wherein the liquid spray mist cooling system is provided with one or multiple nozzles, the nozzles are arranged on the periphery of the welding system, the nozzles face the weld joint or the weld point, and the liquid spray mist cooling system generates liquid spray mist through high pressure and sprays the liquid spray mist out through the nozzles so as to cool the weld joint or the weld point before weldingor in the welding process. By adding the liquid spray mist cooling system and using the liquid spray mist to precool or rapidly cool the weld joint, the laser welding device with the cooling system can improve cooling speed of the weld joint, then reduces softening of the weld joint, improves strength of the weld joint, reduces residual stress and residual deformation of the weld joint, and improves weld quality.

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com