Repair method for welding defects of large-size friction stir welding

A friction stir welding and welding defect technology, applied in welding equipment, metal processing equipment, manufacturing tools, etc., can solve the problems of welding defect repair, lack of material at welding defect positions, etc., to improve weld formation, reduce workload, process The effect of high stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

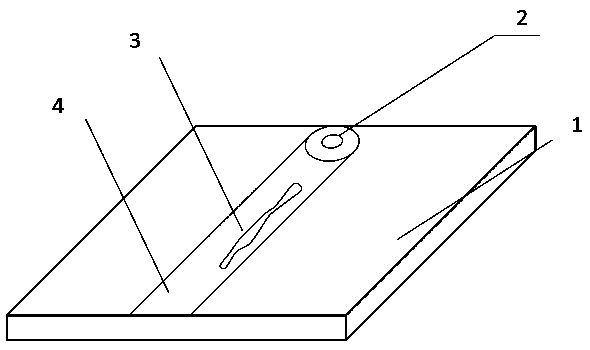

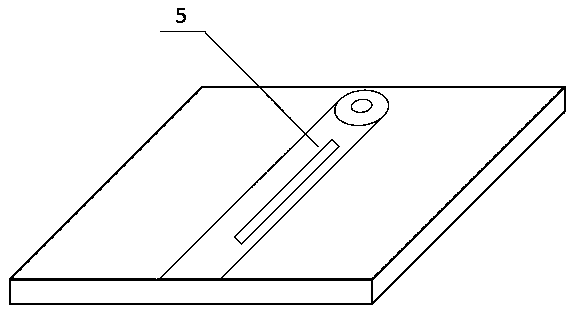

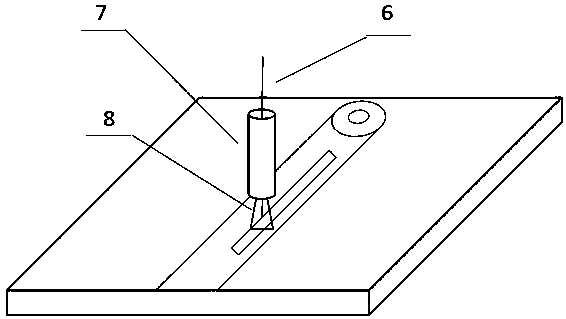

[0029] refer to Figure 1 to Figure 4 , a method for repairing welding defects of large-scale friction stir welding, which is realized by the following steps:

[0030] Step 1: Process the weld area where the large-size welding defect 3 left over by friction stir welding is processed, and process a V-shaped opening groove 5, the width of the opening groove 5 is 2 to 3 mm larger than the width of the welding defect 3, and the depth of the opening groove 5 is The depth of the opening groove 5 is 1~2mm greater than the depth of the welding defect 3, and the length of the opening groove 5 is 3~5mm longer than the length of the welding defect 3; after the opening groove is processed, the large-size welding defect 3 disappears and is invisible.

[0031] Step 2, use MIG welding to weld and fill the area where the open slot 5 processed in step 1 is located, and the welding torch 7 is perpendicular to the surface of the workpiece. After the welding is completed, the open slot 5 is compl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com