Austenitic stainless steel argon tungsten-arc welding active agent and preparation method and application thereof

A technology of austenitic stainless steel and argon tungsten arc welding, applied in arc welding equipment, welding equipment, welding equipment, etc., to achieve the effect of reducing welding, accelerating flow, and tightening conductive channels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0023] The present invention also provides a preparation method of the austenitic stainless steel tungsten argon arc welding activator described in the above technical solution, comprising the following steps:

[0024] SiO 2 Powder, TiO 2 Powder, Cr 2 o 3 powder, NiO powder, MnO powder, CuO powder and B2 o 3 The powders are mixed to obtain the austenitic stainless steel tungsten argon arc welding activator.

[0025] The present invention has no special limitation on the mixing method, and a mixing method well known to those skilled in the art can be used, specifically, such as stirring.

[0026] The present invention preferably adopts the grinding method well-known to those skilled in the art to SiO 2 Powder, TiO 2 Powder, Cr 2 o 3 powder, NiO powder, MnO powder, CuO powder and B 2 o 3 The powder was ground to 200 mesh powder.

[0027] The present invention also provides the application of the austenitic stainless steel tungsten arc welding activator described in th...

Embodiment 1

[0035] An austenitic stainless steel tungsten argon arc welding activator, comprising the following components in percentage by weight: 35% SiO 2 Powder, 26%TiO 2 Powder, 13%Cr 2 o 3 powder, 8% NiO powder, 4% MnO powder, 8% CuO powder and 6% B 2 o 3 powder. Of which SiO 2 Powder, TiO 2 Powder, Cr 2 o 3 powder, NiO powder, MnO powder, CuO powder and B 2 o 3 The particle size of the powder is 200 mesh.

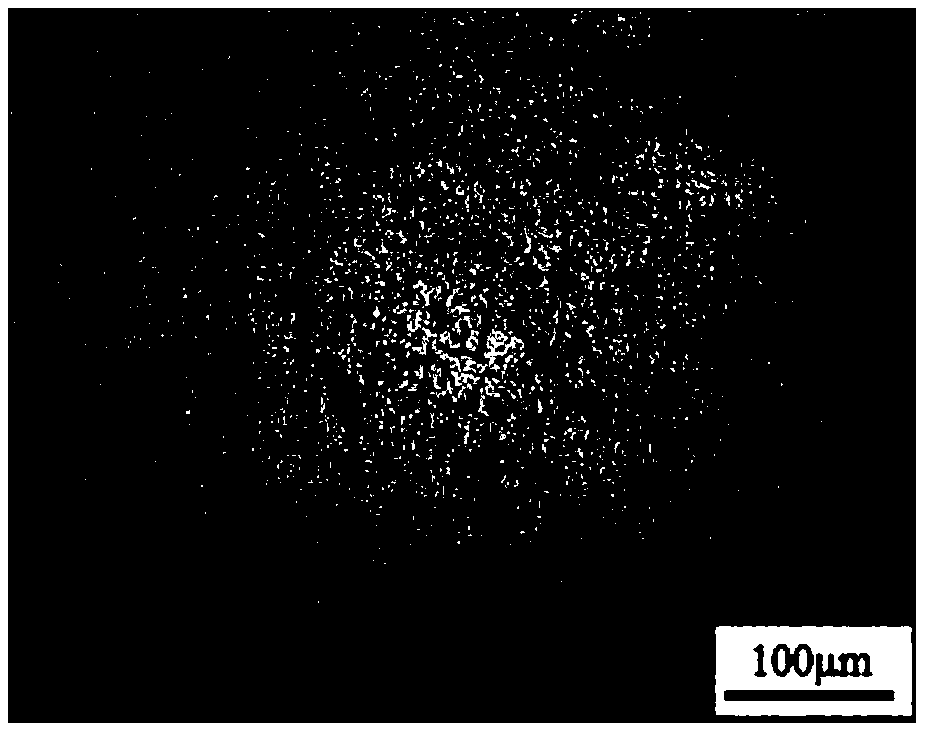

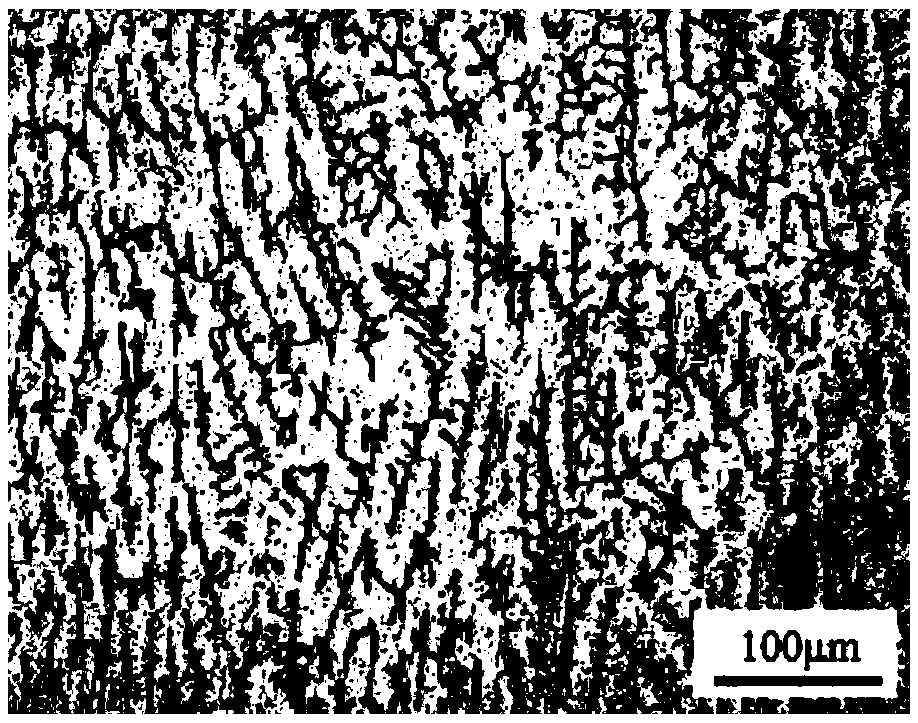

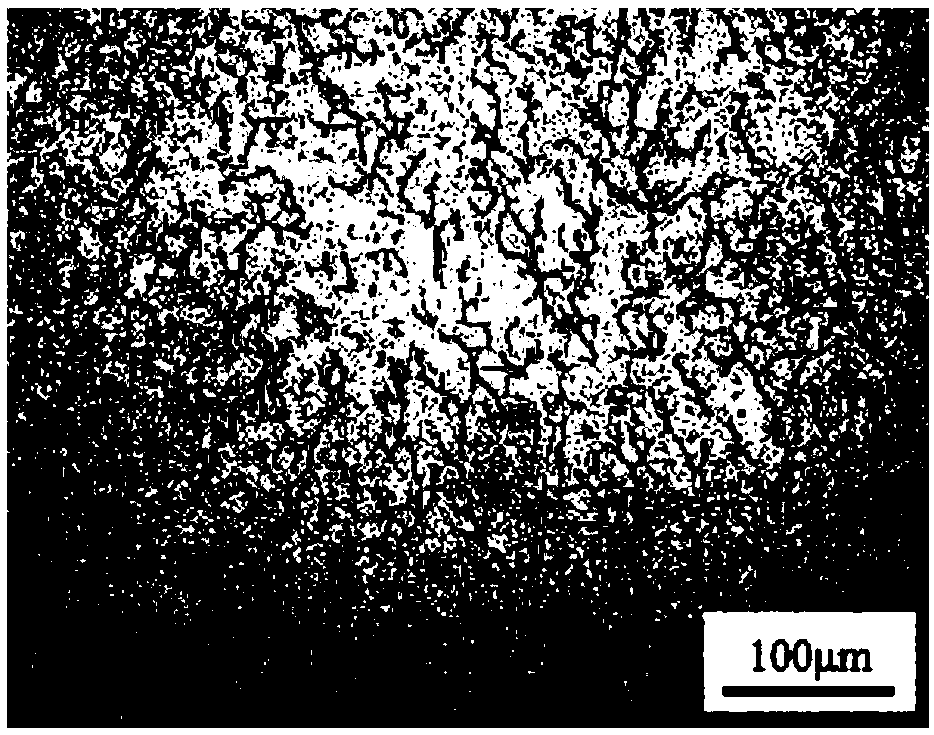

[0036] Weigh the material according to the above ratio, and then use acetone to make a paste for later use. Before welding, clean the surface of the stainless steel plate with sandpaper, and then use acetone and alcohol to scrub the surface of the plate. During the test, use a brush to evenly coat the active agent on the left and right sides of the area to be welded by 10mm. The coating thickness can cover the metal surface. After the acetone volatilizes, perform A-TIG welding. Welding 20mm 304 austenitic stainless steel, it was found that TIG welding without adding ...

Embodiment 2

[0047] An austenitic stainless steel tungsten argon arc welding activator, comprising the following components in weight percentage: 36% SiO 2 Powder, 27%TiO 2 Powder, 12%Cr 2 o 3 powder, 7% NiO powder, 4% MnO powder, 7% CuO powder and 7% B 2 o 3 powder. Of which SiO 2 Powder, TiO 2 Powder, Cr 2 o 3 powder, NiO powder, MnO powder, CuO powder and B 2 o 3 The particle size of the powder is 200 mesh.

[0048] Weigh the material according to the above ratio, and then use acetone to make a paste for later use. Before welding, clean the surface of the stainless steel plate with sandpaper, and then use acetone and alcohol to scrub the surface of the plate. During the test, use a brush to evenly coat the active agent on the left and right sides of the area to be welded by 10mm. The coating thickness can cover the metal surface. After the acetone volatilizes, perform A-TIG welding. The 20mm 304 austenitic stainless steel is welded, and the activator of Example 2 is used for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com