Patents

Literature

86results about How to "Eliminate microcracks" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

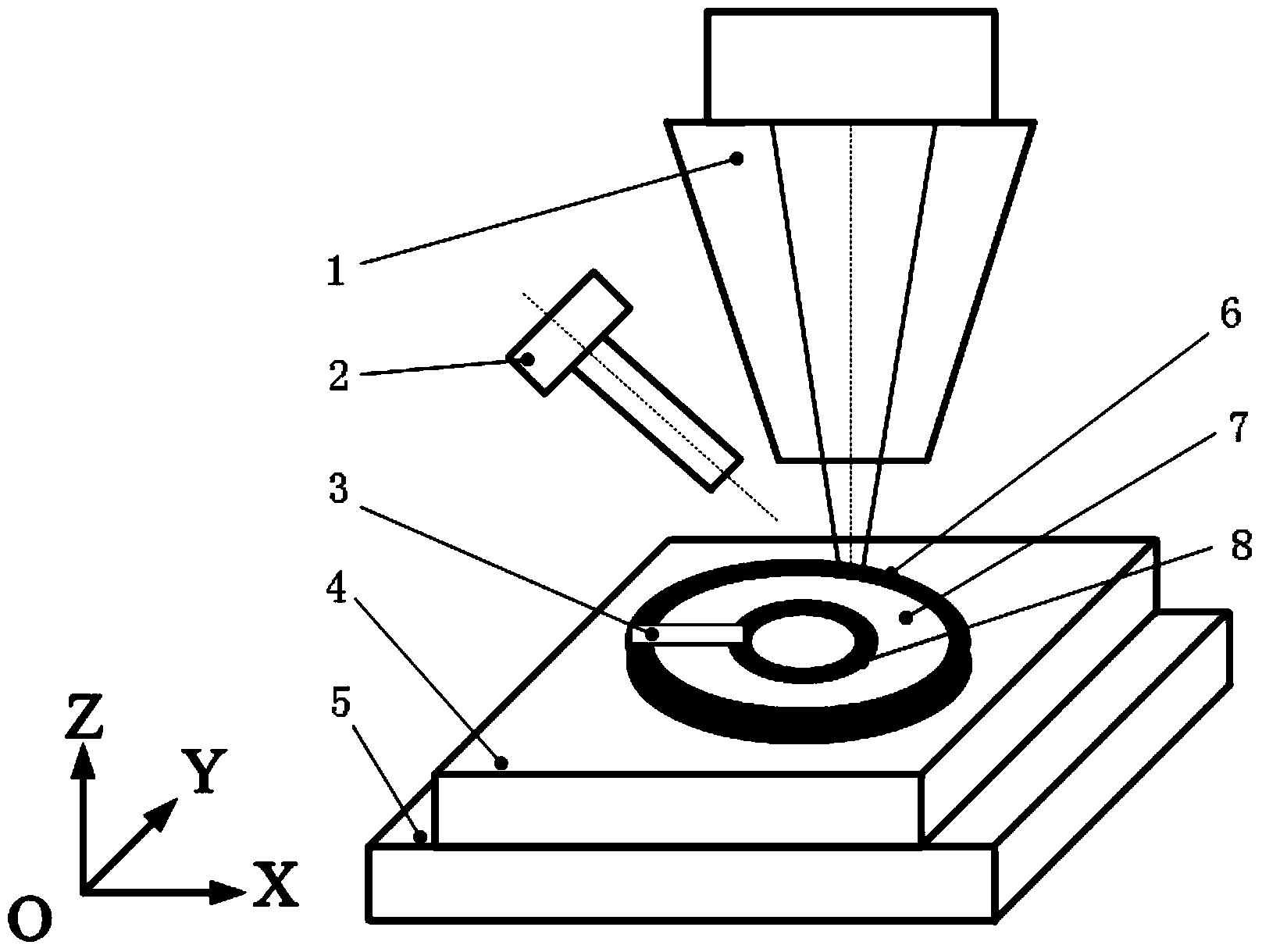

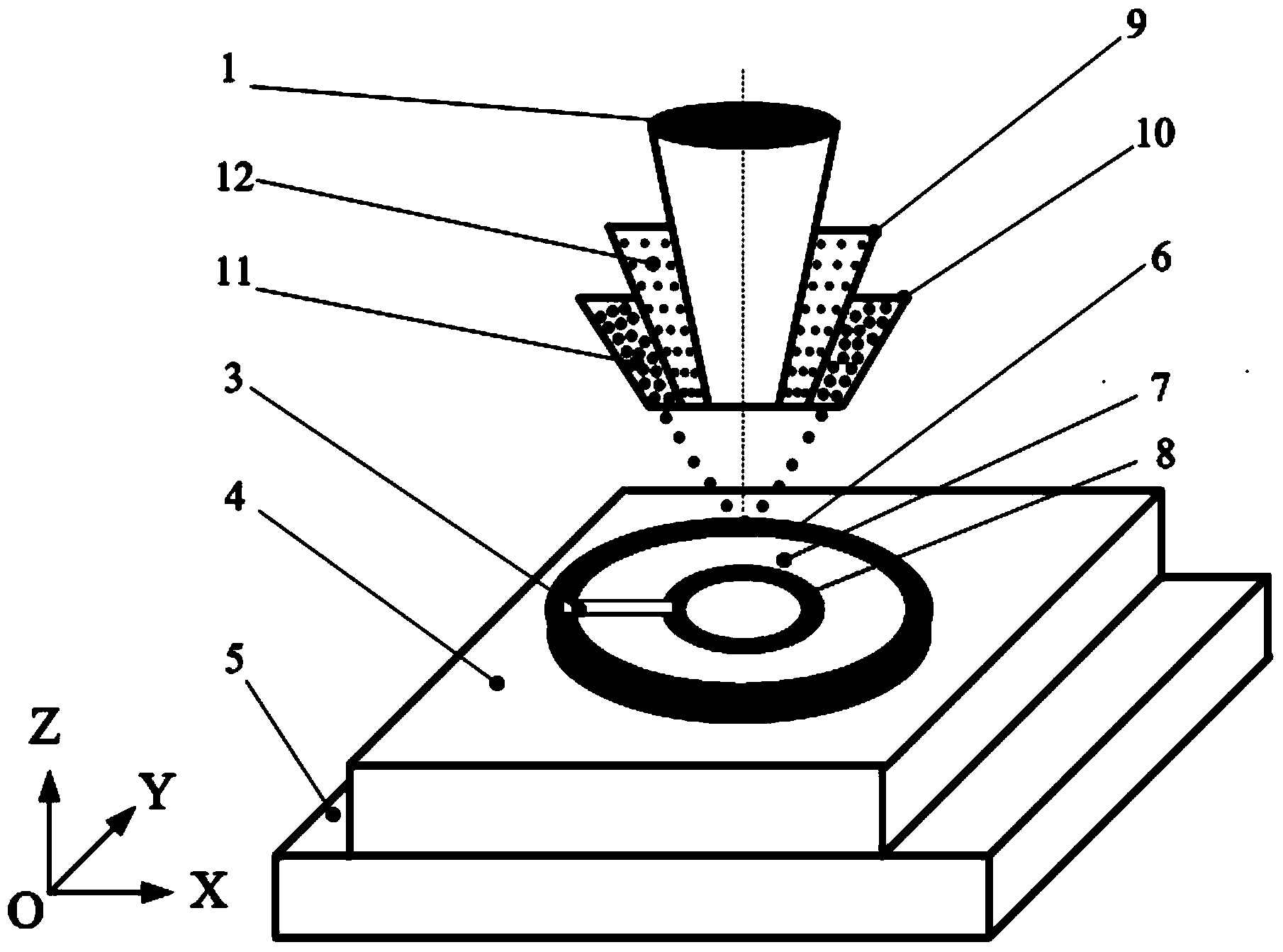

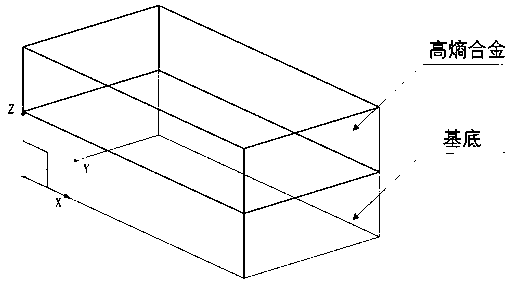

Metal 3D printer based on interlayer shock processing process and printing method thereof

The invention discloses a technique for improving the mechanical performance of a printed piece through shock processing in the process of metal part 3D printing. The technique is characterized in that shock processing is conducted on the upper surfaces of cladding layers after a certain number of layers are cladded, so that defects such as cavities, looseness and microcracks in the cladding layers are eliminated, and the density of a formed part is improved; in the shock processing process, heating and reasonable partitioned technology planning are conducted on the cladding layers, the shock processing angle can be changed according to different areas on the same layer and the change of the number of the layers, and therefore it is guaranteed that the density and the mechanical performance are improved, stress concentration is prevented, and the forming precision of the metal 3D printed part is ensured.

Owner:XI'AN INST OF OPTICS & FINE MECHANICS - CHINESE ACAD OF SCI

Deep cooling treatment method of high speed steel tool

InactiveCN1718774AIncrease the number of precipitatesEvenly distributedFurnace typesHeat treatment furnacesQuenchingHeat treated

A deep cooling method for treating the cutting tool made of high-speed steel in order to elongate its service life includes such steps as quenching, tempering, precooling, deep cooling in liquefied N2 at -185--196 deg.C , holding the temp for a certain time calculated by an equation, recovering its temp to room temp and heating it in boiling water for 60 min. For the large cutting tool, said steps can be performed 2-3 times.

Owner:大连理工模具研究所有限公司

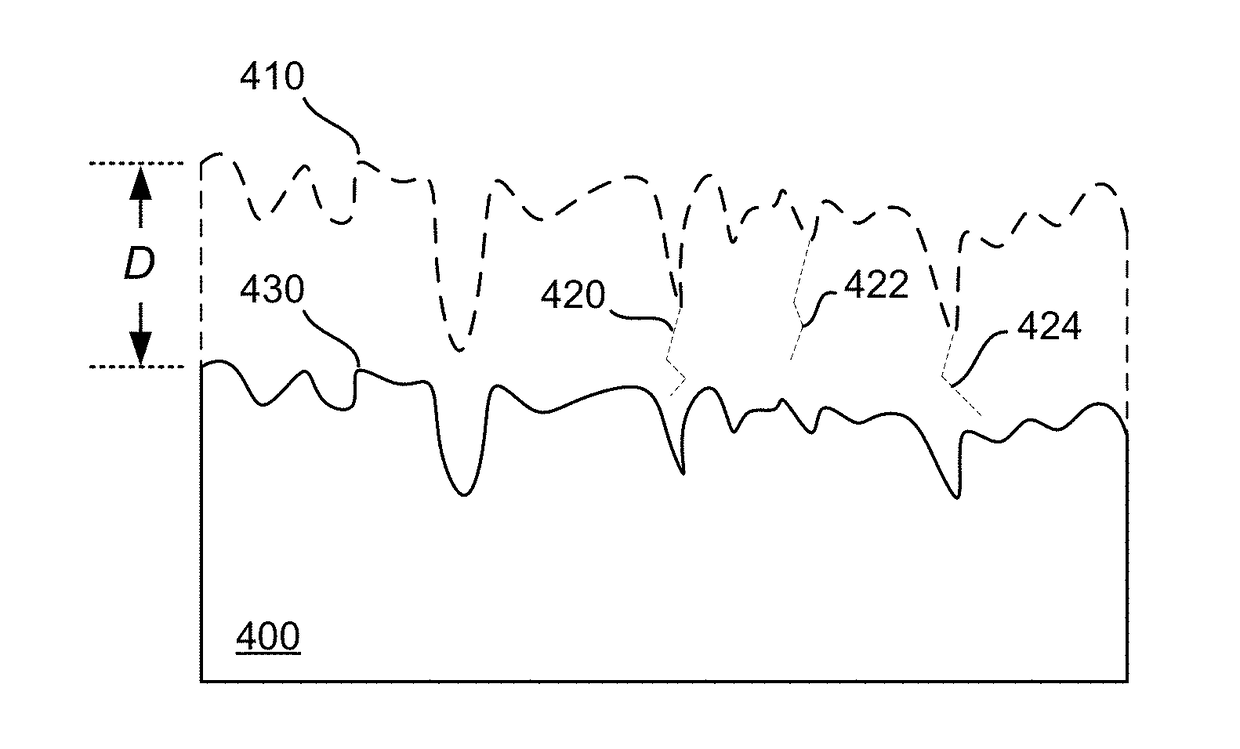

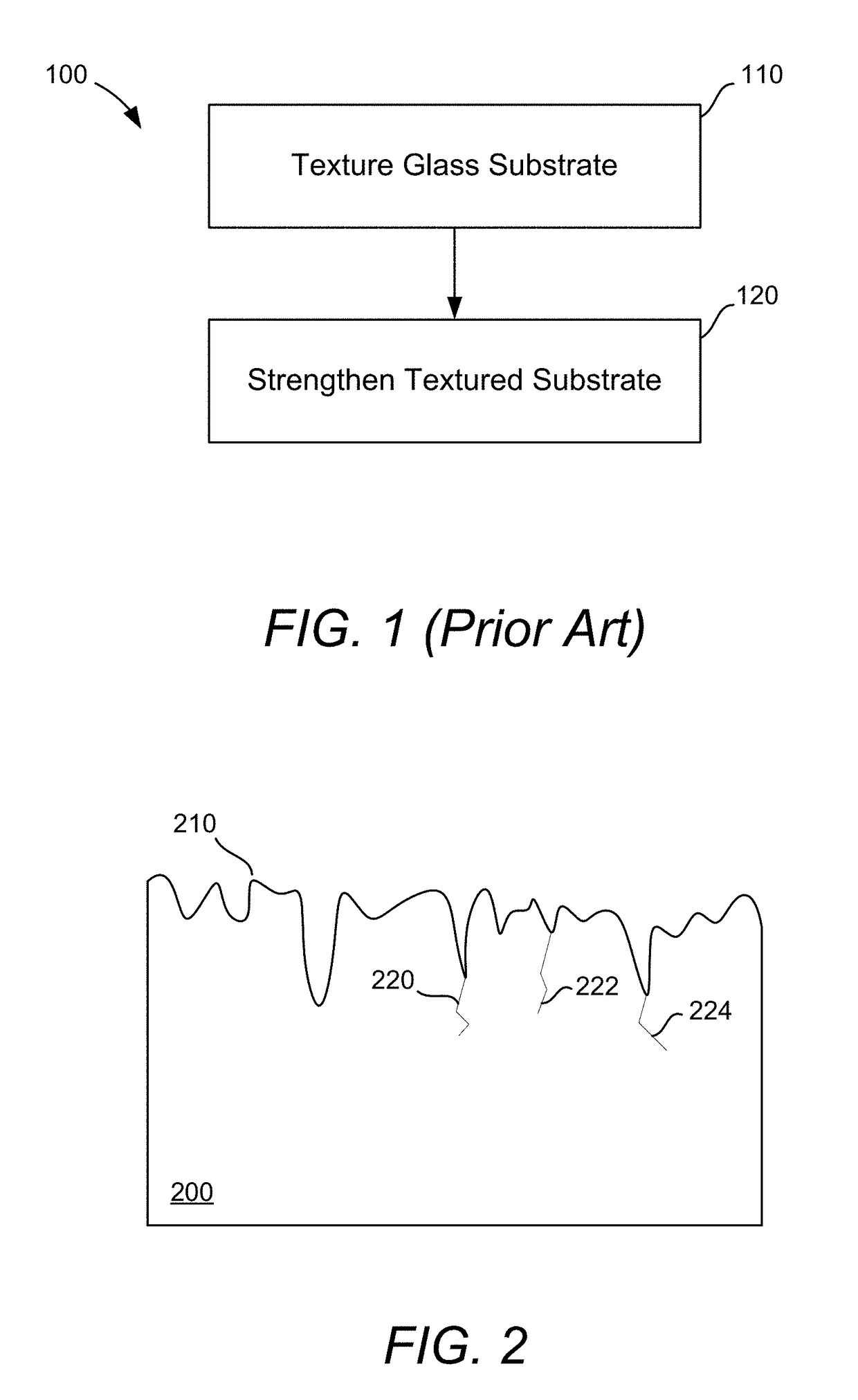

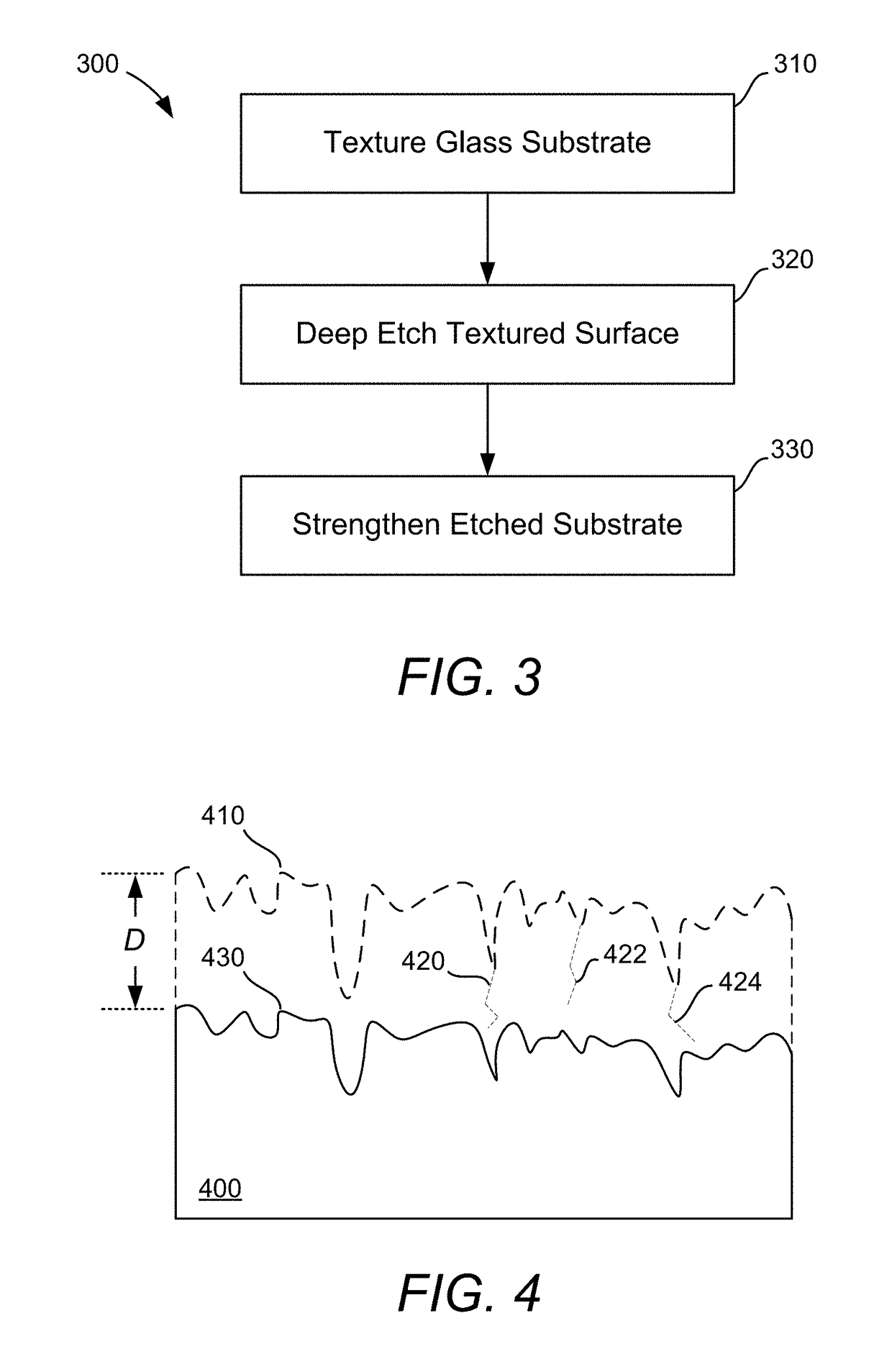

Process for forming textured glass component with high bending strength

InactiveUS20180086662A1Delay transitionImprove bending strengthCoatingsMicro fractureMaterials science

A method of processing a glass substrate including texturing the glass substrate to form a textured surface that includes a plurality of micro fractures extending from the textured surface into the substrate. And, thereafter, chemically etching the textured surface of the glass substrate to a depth sufficient to remove the micro fractures. The glass substrate can then be chemically strengthened after the etching step.

Owner:APPLE INC

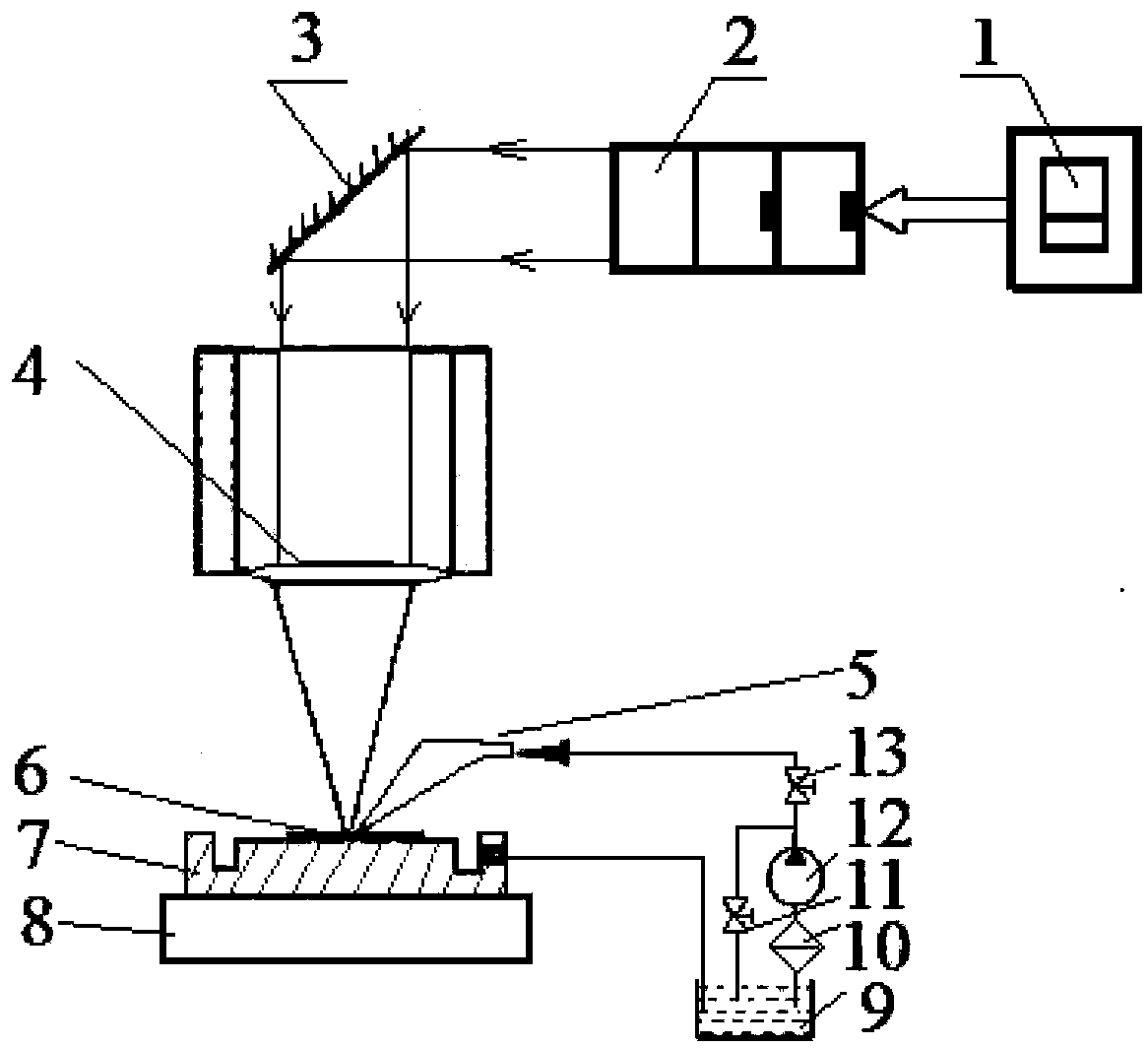

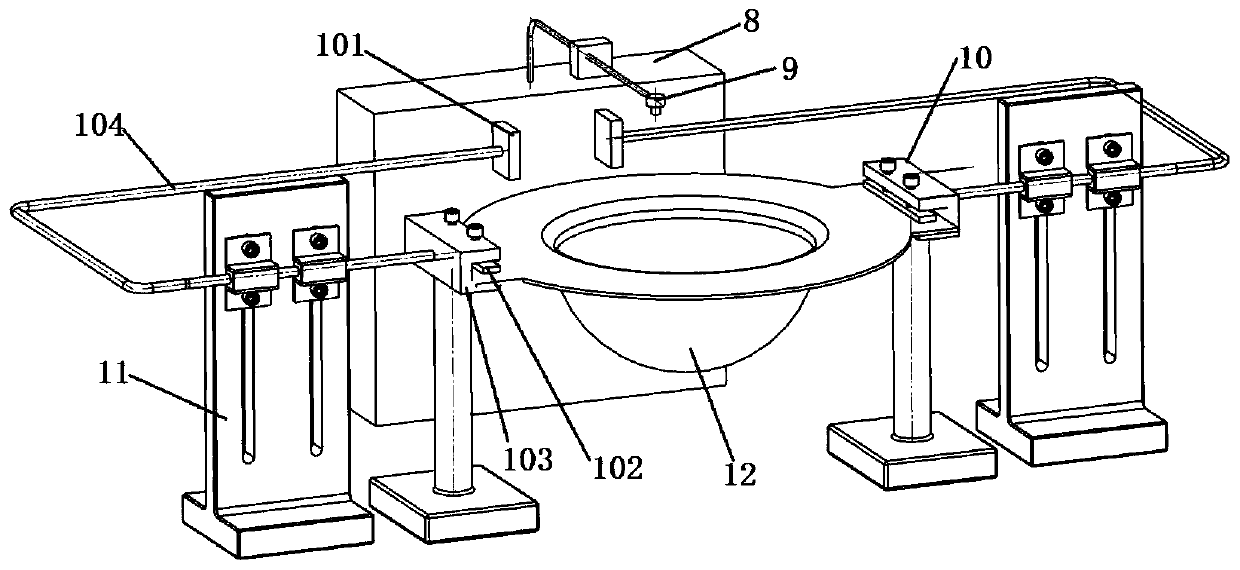

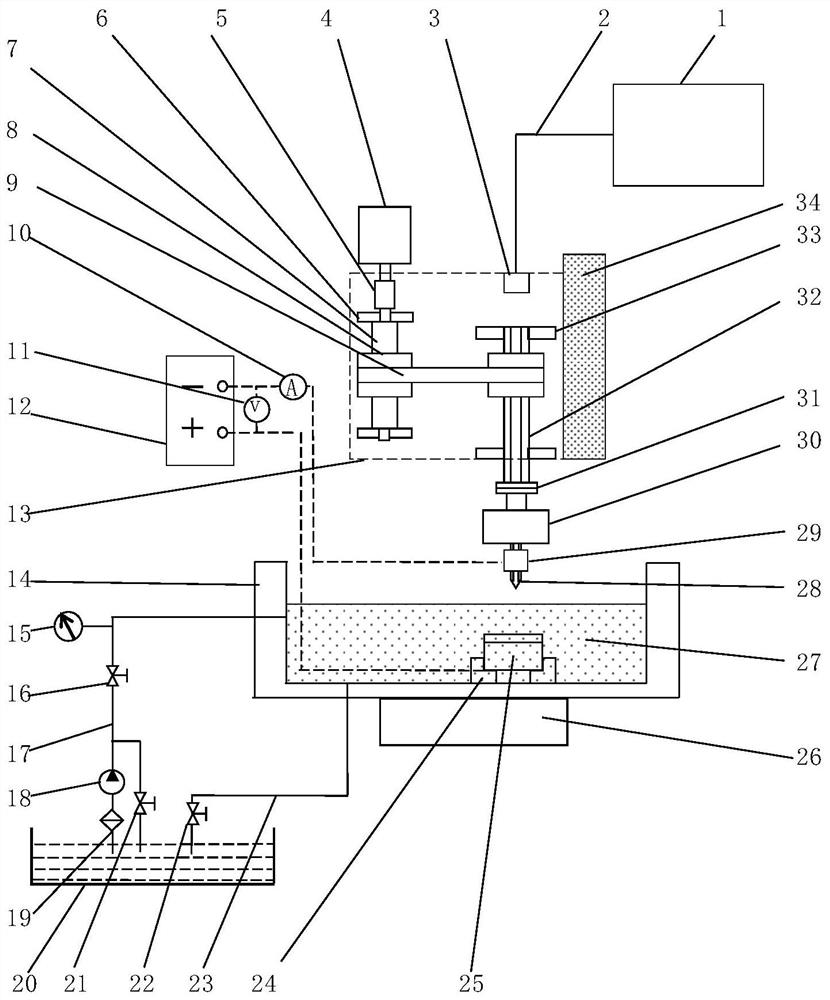

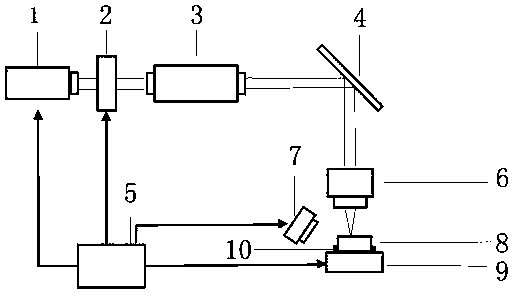

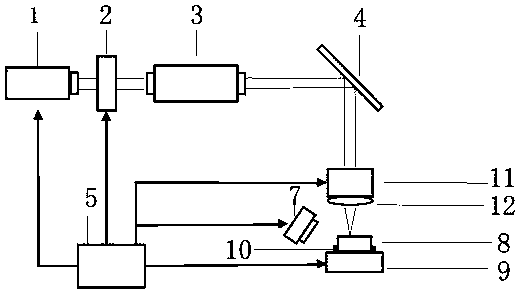

Method and system for scribing brittle ultrathin piece by water jet and laser

InactiveCN103358028AEliminate thermal effectsEliminate residual stress and micro-cracksLaser beam welding apparatusPhysicsSpray nozzle

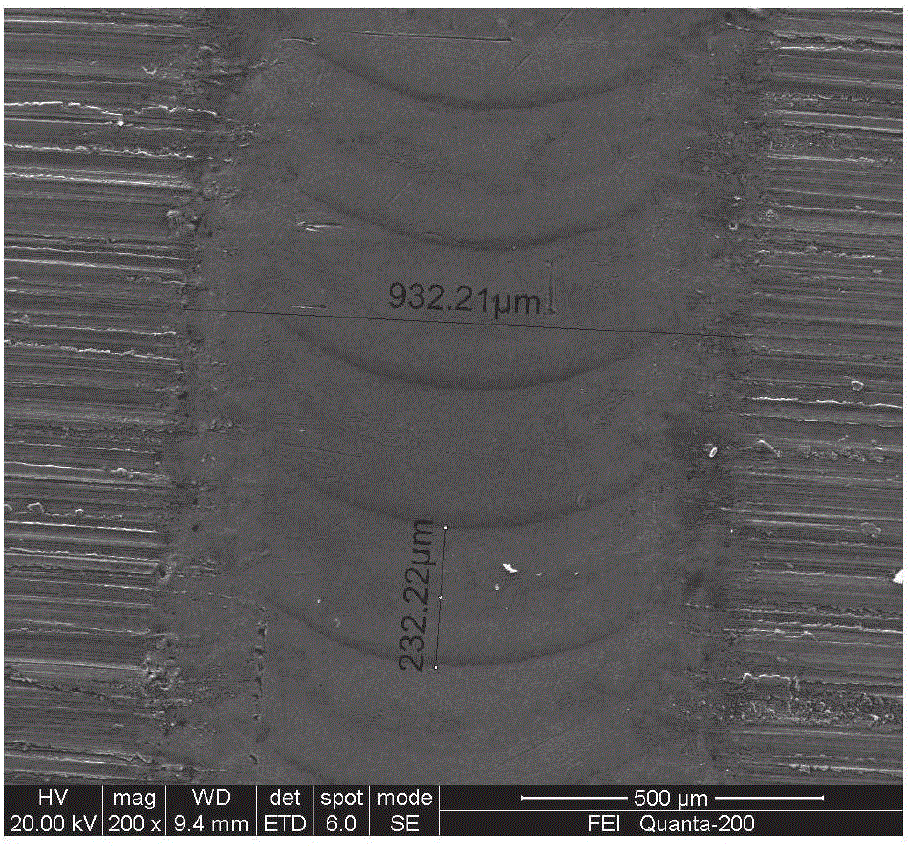

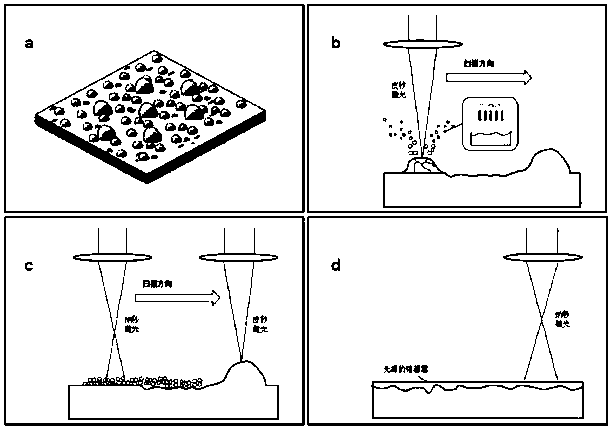

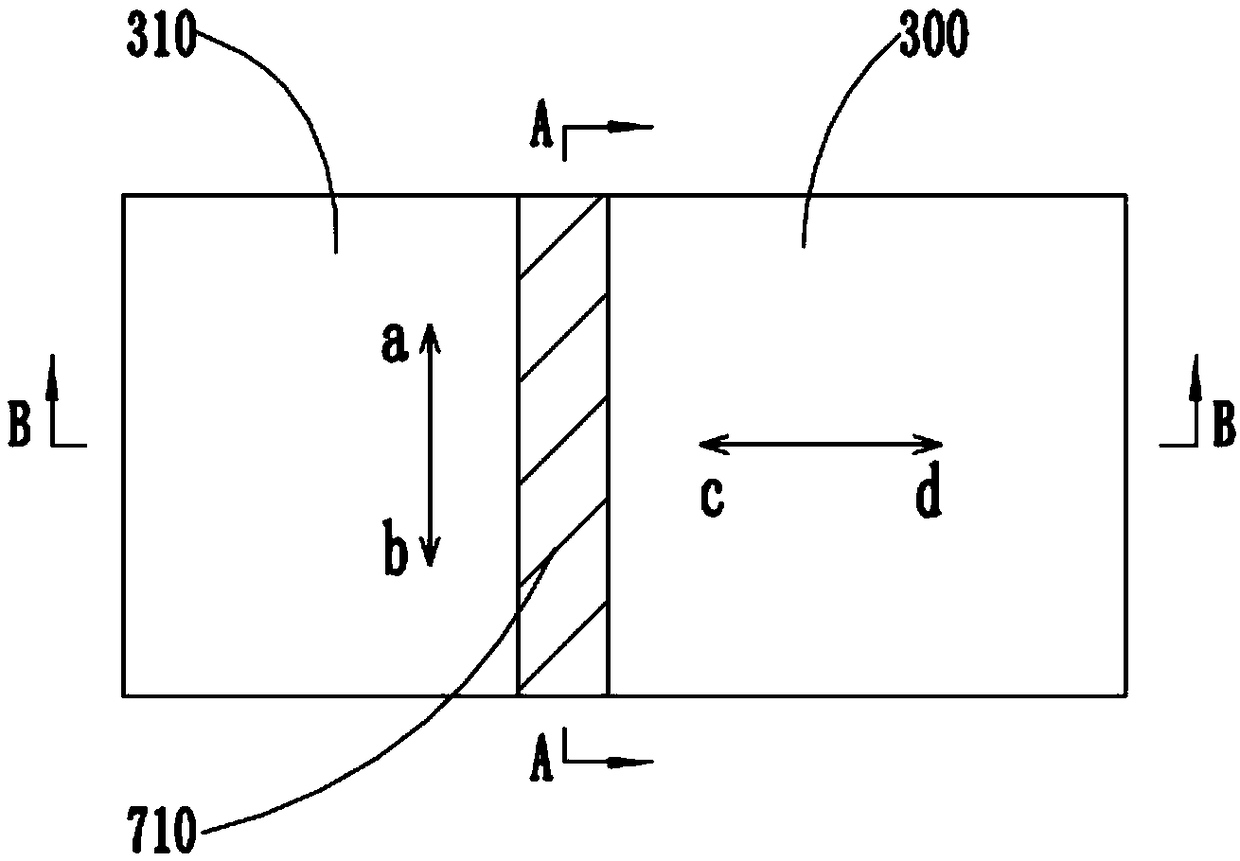

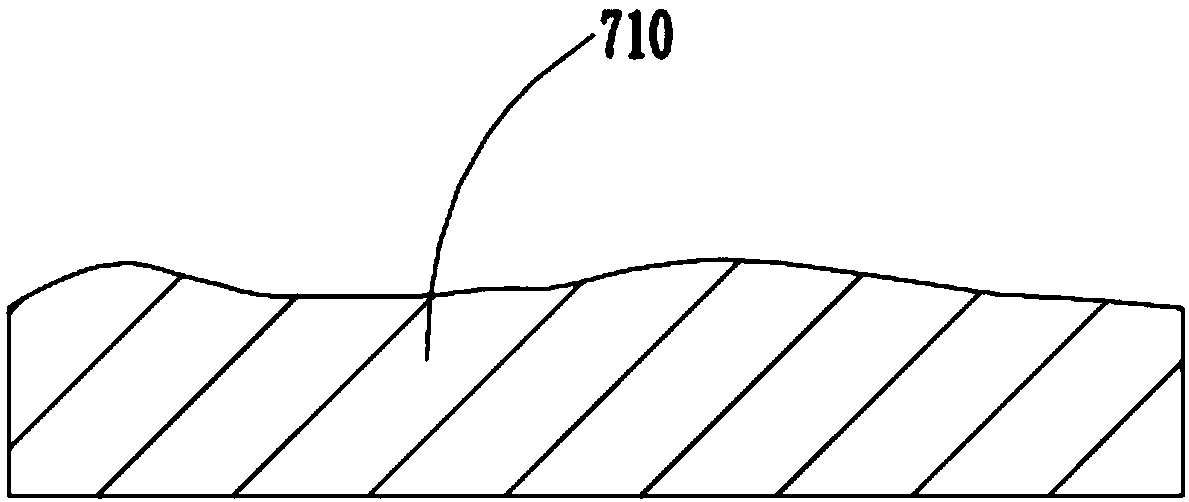

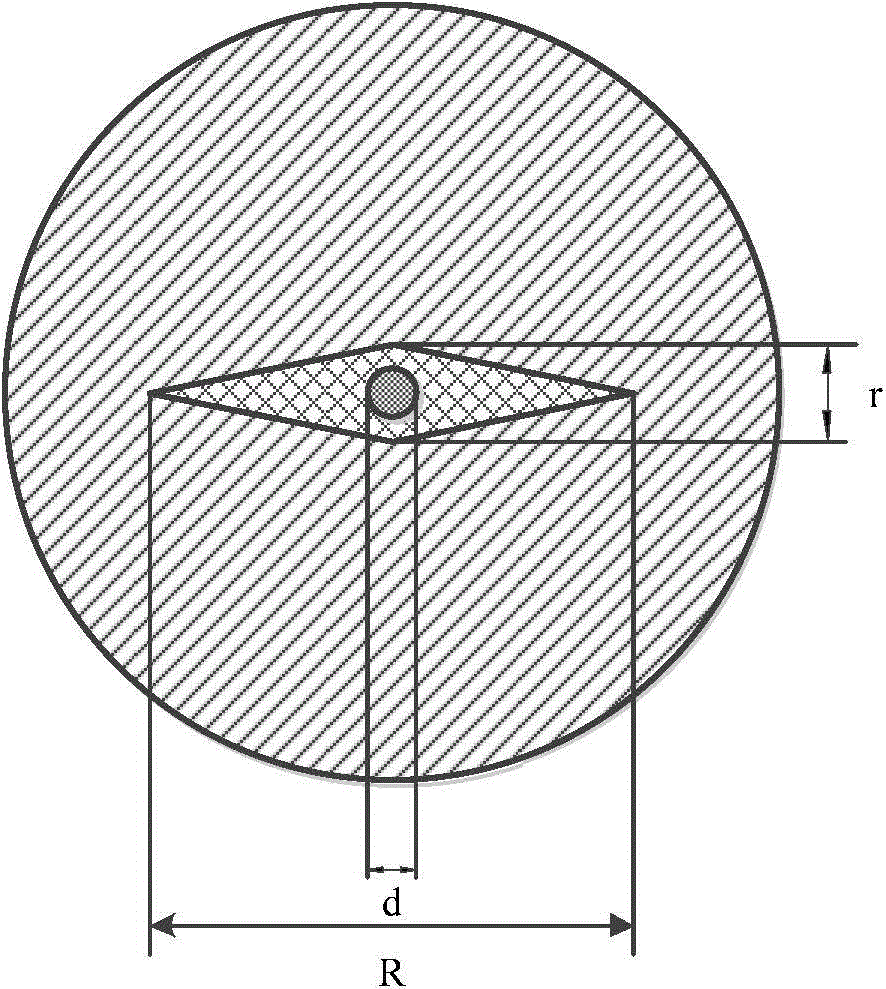

The invention discloses a method and system for scribing a brittle ultrathin piece by a water jet and laser. According to the method, a laser beam penetrates through a water jet beam to focus on the surface of a workpiece; the distance between the center of the jet point, on the surface of the workpiece, of the water jet beam and the center of the focus point, on the surface of the workpiece, of the laser beam is equal to or smaller than 1-2.5 times the radius of the focus point, on the surface of the workpiece, of the laser beam. The distance between an intersection point I and an intersection point II is equal to or smaller than 1-2.5 times the radius of the focus point of the laser beam, wherein the intersection point I is the intersection point of the surface of the workpiece and the water jet beam generated by the jet nozzle of the system, and the intersection point II is the intersection point of the surface of the workpiece and the laser beam. The longitudinal center line of the jet nozzle coincides with the center line of the laser beam. A workbench is provided with a working cavity filled with water; a water layer with a thickness of 0.5-1.5 mm is arranged on the surface of the workpiece on the top surface of a boss at the top of the workbench; the overflow port of the working cavity is connected to a water tank; a water pump is used for pumping water in the water tank into the jet nozzle to generate the water jet. According to the invention, the laser is used for laser ablating and scribing, and the water jet beam is used for cooling and washing a processed area, so that the effect that a processed surface is free from recast layers, residual stress and micro cracks is achieved; the processing efficiency is improved.

Owner:GUILIN UNIV OF ELECTRONIC TECH

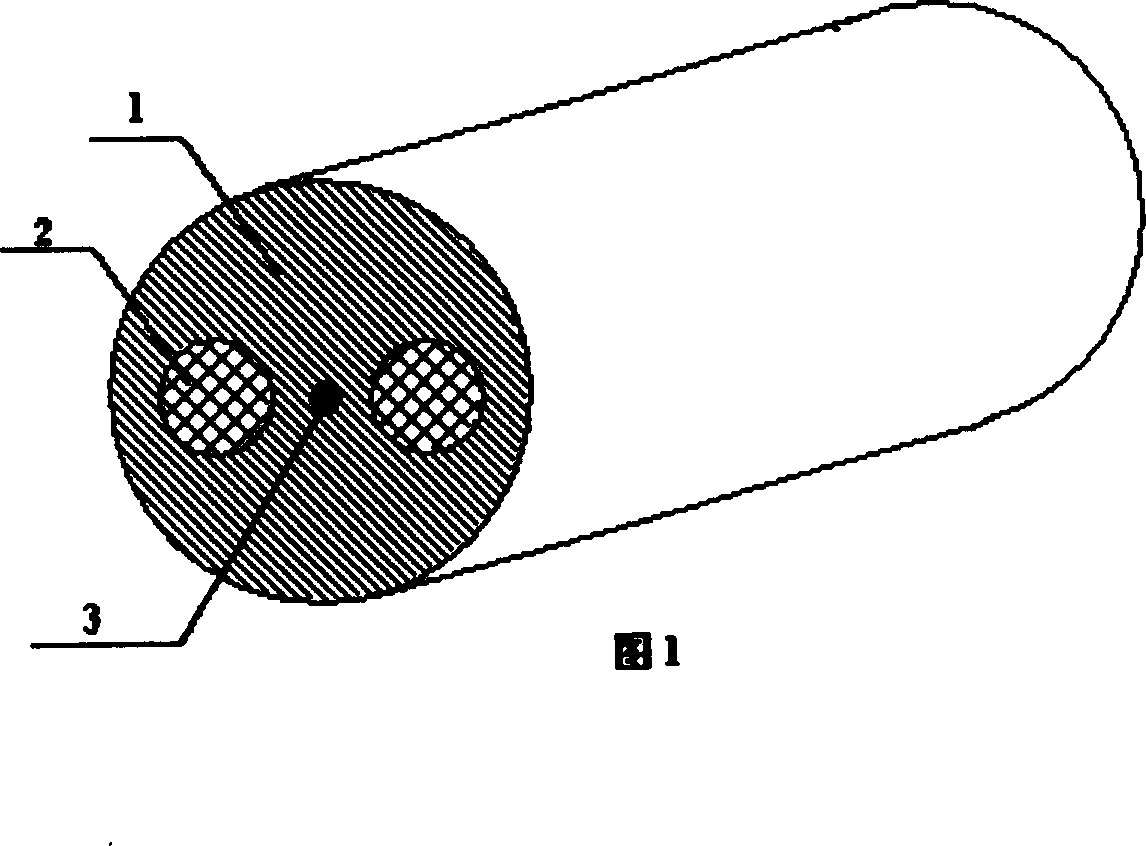

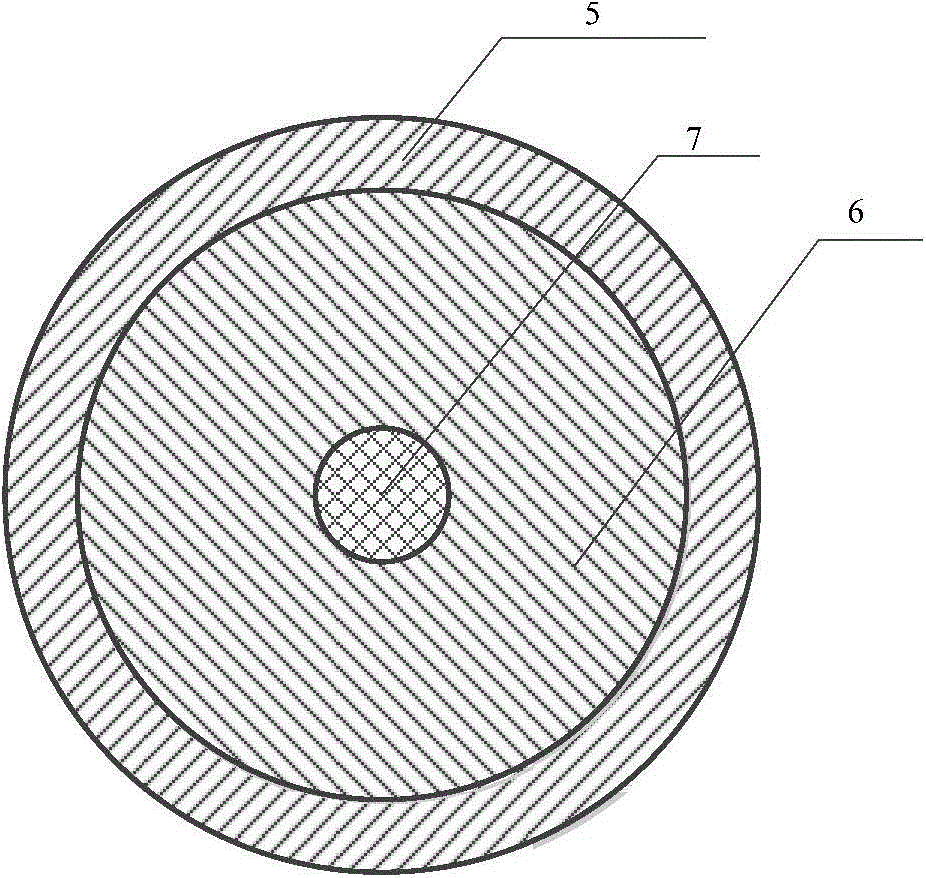

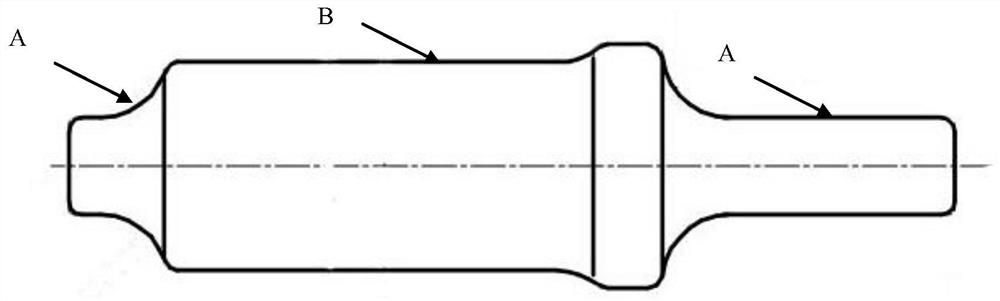

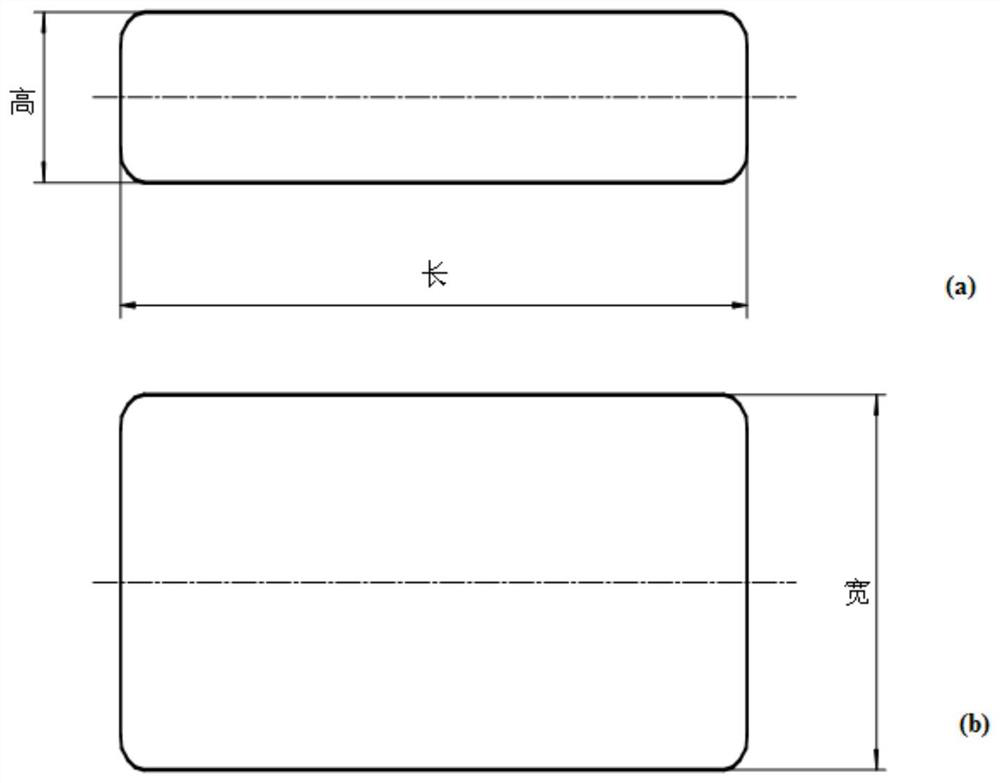

Method for producing polarization maintaining optical fibre

ActiveCN1557754AReduce processing stressReduce residual stressGlass making apparatusOptical light guidesPolarization-maintaining optical fiberEngineering

The making process of circular polarization maintaining fiber includes deposition process to make core rod and stress rod with preserved coating, machining mechanically the matched sides of the core rod and the stress rod to reach the matching interval requirement, machining mechanically the inner hole of quartz casing for fitting the combined cross section of the core rod and the stress rod, setting the machined core rod and stress rod into the quartz casing for matching tightly to constitute prefabricated rod for circular polarization maintaining fiber, drawing, cleaning, and re-drawing to form fiber. The making process has high precision, high product quality and powerful adaptability, and is suitable for mass producing circular polarization maintaining fiber product.

Owner:YANGTZE OPTICAL FIBRE & CABLE CO LTD

High-counter-pressure casting method for high-tensile and high-density aluminum silicon alloy

InactiveCN101569924AImprove micro-shrinkage feeding capacityImprove mechanical propertiesHigh densitySilicon alloy

The invention provides a high-counter-pressure casting method for a high-tensile and heavy aluminum silicon alloy, which relates to a counter-pressure casting method for the high-tensile and high-density aluminum silicon alloy. The invention solves the problem that the conventional counter-pressure casting technology cannot meet the requirement of producing castings with high mechanical properties and high density due to the limit on the density and internal quality increase of the castings. The invention has the following main steps of: regulating a counter-pressure casting machine to an operating bearing pressure of 3.0 MPa, preparing aluminum silicon alloy, controlling the temperature of the fusant after thinning and modification at 720 DEG C to 740 DEG C, and carrying out the liquid lifting, mold filling, pressurization, pressure maintaining and pressure relief of high-counter-pressure casting with the counter-pressure casting machine. The invention obviously eliminates internal pinholes, micro-shrinkage porosity and tiny cracks in the castings, and enhances the mechanical properties and density of the castings; because of small thermal resistance between the fusant and the mold wall, the setting rate of the castings accelerates, and the setting structure is obviously thinned, thereby further enhancing the mechanical properties of the castings. The method is especially suitable for the cast form of large-sized complex thin-wall parts.

Owner:HARBIN INST OF TECH

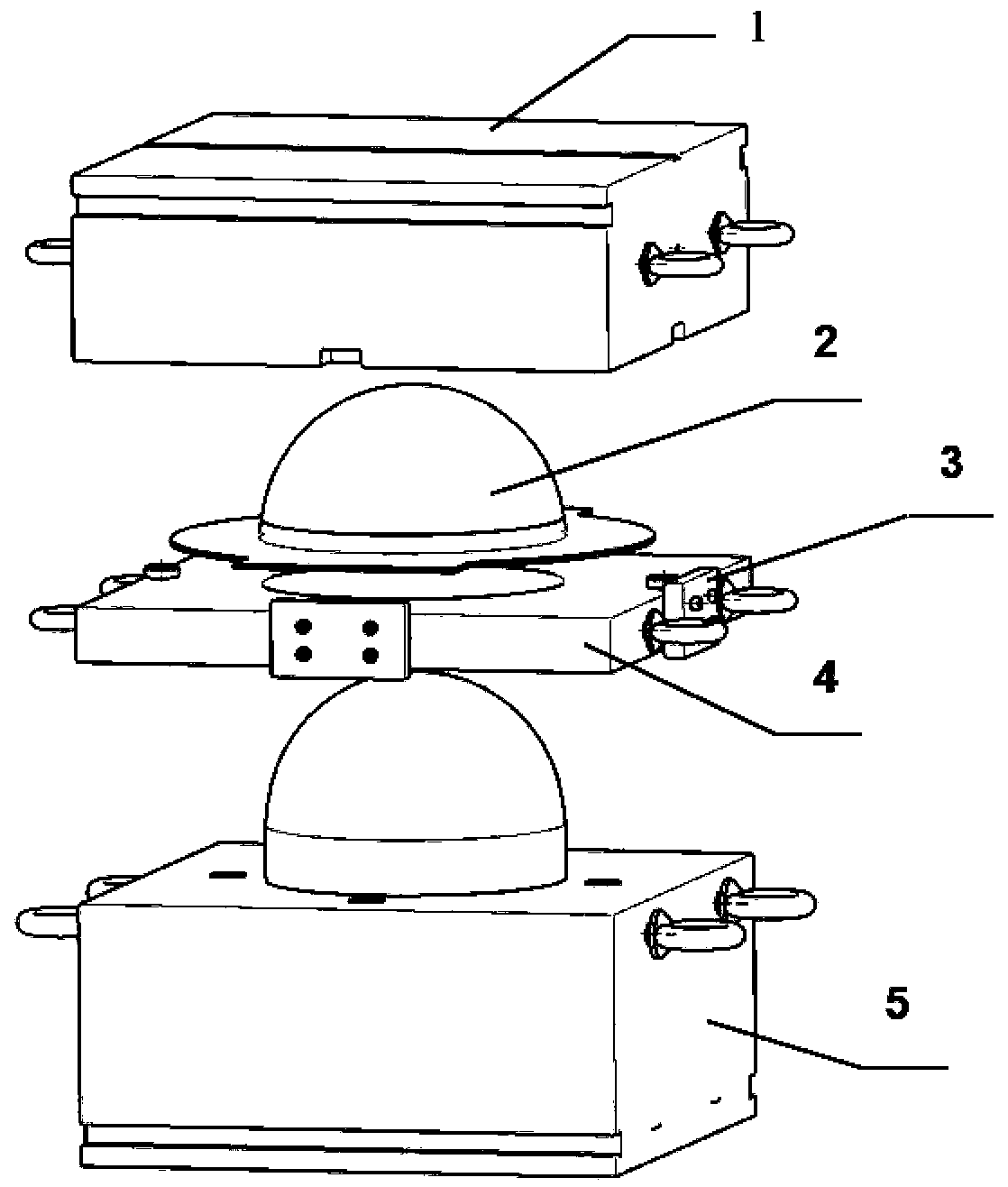

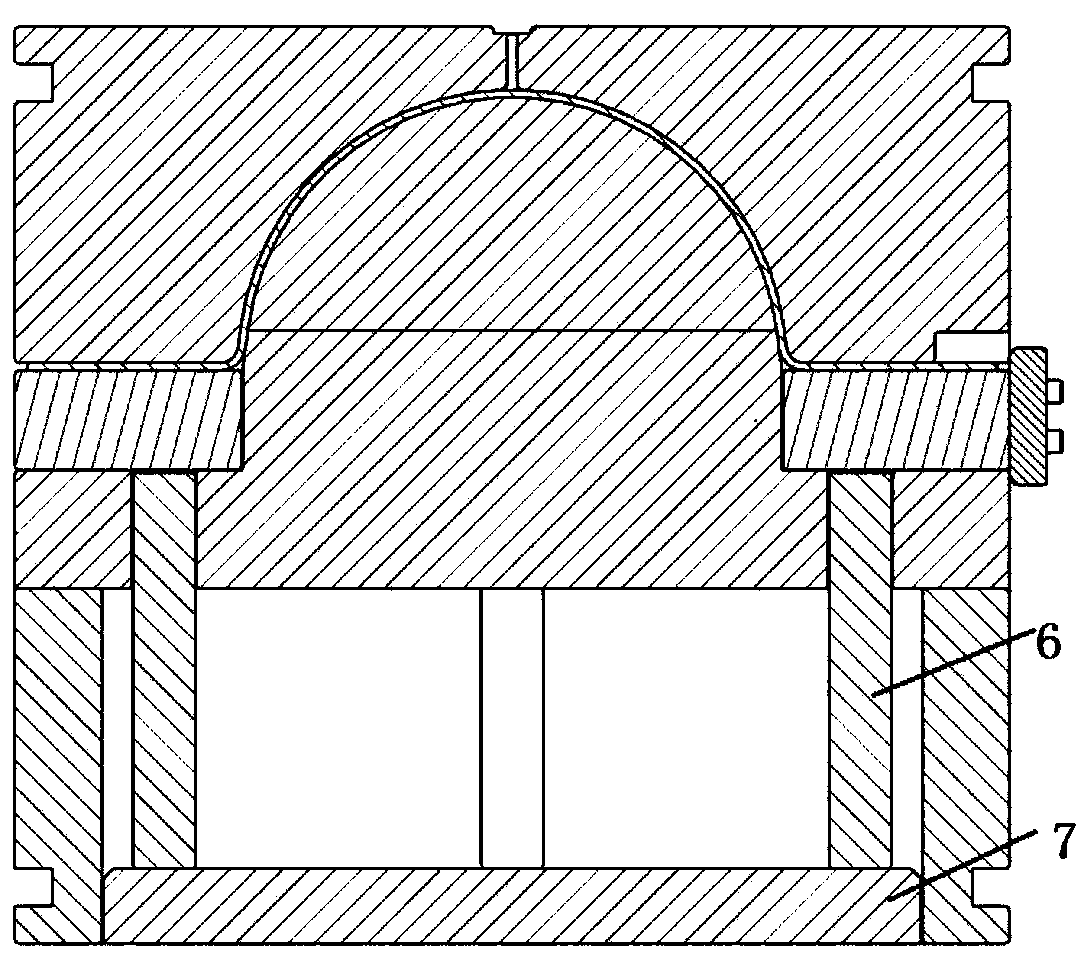

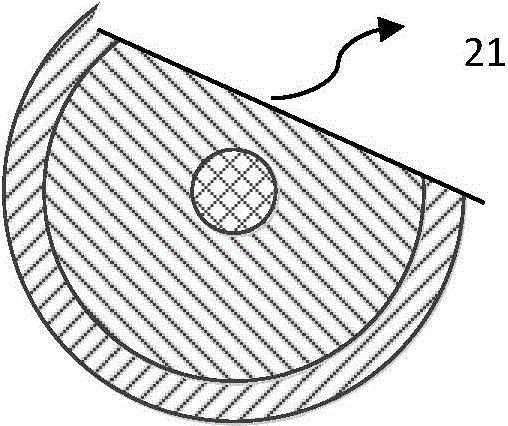

Forming mold for semi-spherical components and multi-pass forming method

ActiveCN110479843AAchieving Precise FormingBreak through the bottleneck of forming technologyShaping toolsDiameter ratioSpherical shaped

The invention discloses a forming mold for semi-spherical components and a multi-pass forming method, belongs to the technical field of semi-sphere formation, and solves the problems of corrugation and cracking in deep drawing formation of high-height-diameter-ratio semi-spherical components, difficult control of deep drawing process parameters and weaker wall thickness uniformity in the prior art. The forming mold comprises a concave mold, a convex mold, a blank holder and a positioning plate; the concave mold and the convex mold are used for forming the semi-spherical components; the blank holder is arranged between the concave mold and the convex mold, and is matched with the concave mold to tightly press blanks to prevent corrugations of the blanks in the forming process; the blank holder is provided with a positioning plate; and the positioning plate is used for positioning an upper mold and a lower mold. The forming mold and the forming method are suitable for formation of high-height-diameter-ratio semi-spherical components.

Owner:BEIJING HANGXING MACHINERY MFG CO LTD

Combined machining method for blade air film holes and device thereof

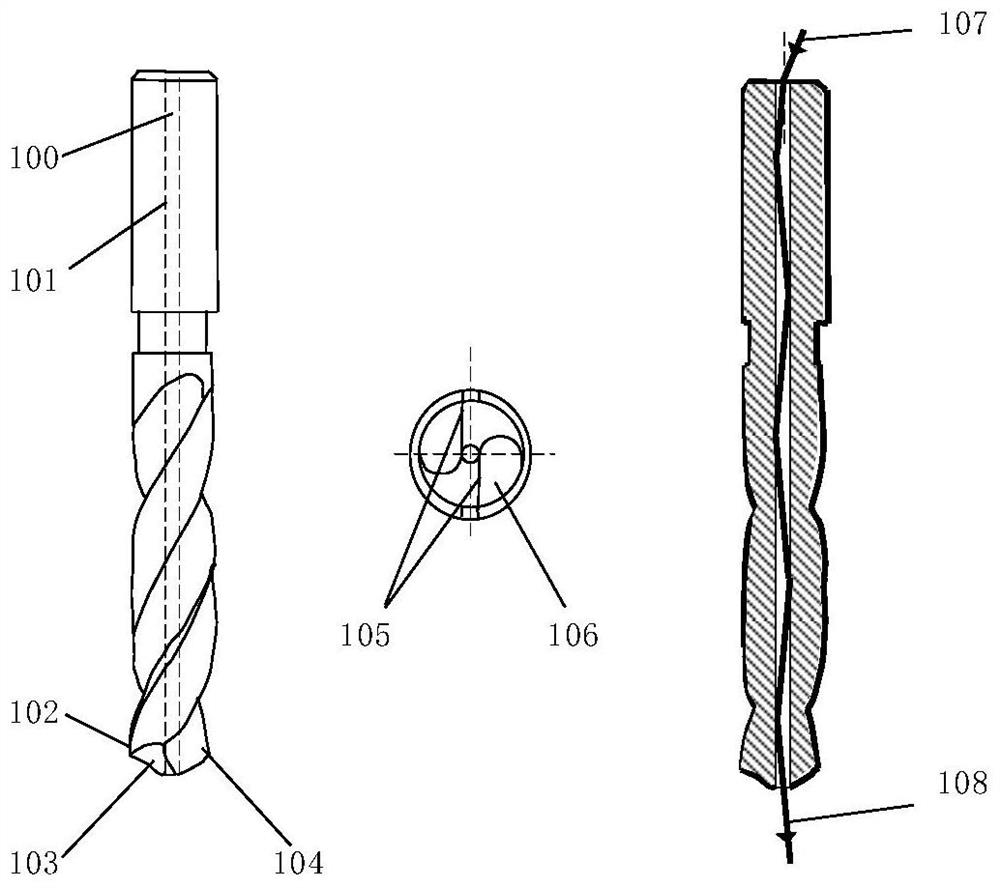

ActiveCN112171184AReduce drilling difficultyImprove drilling efficiencyMetal working apparatusElectrolytic agentHeat-affected zone

The invention discloses a combined machining method for blade air film holes and a device thereof, and relates to the field of non-traditional machining. The combined machining method comprises the steps that the air film holes with the needed size are rapidly drilled in a thermal barrier coating high-temperature alloy matrix through laser heating auxiliary drilling; secondly, a drill bit rotatingat a high speed serves as a cathode, blades serve as an anode, the drill bit moves up and down, online electrolysis aftertreatment is conducted on part of the air film holes of the metal matrix, andthe defects of residual stress, a heat affected zone and the like in the drilling process are eliminated; and meanwhile, tiny abrasive particles are suspended in the electrolyte, tiny impact scratching is conducted on the hole wall under the driving of the drill bit rotating at a high speed, the similar grinding and polishing effect is achieved, and the quality of the whole inner wall of the air film holes including the thermal barrier coating is further improved. The method is simple and easy to implement, laser transmission is not affected by the surrounding environment, the environmental adaptability is high, repeated tool setting is not needed, and the defects that the thermal barrier coating cannot be machined through a conventional electric machining method, the single crystal alloylaser machining efficiency is low, and thermal damage is likely to be generated are overcome.

Owner:JIANGSU UNIV

GH3230 nickel-based high-temperature alloy material, method for eliminating selective laser melting forming microcracks and application of GH3230 nickel-based high-temperature alloy material

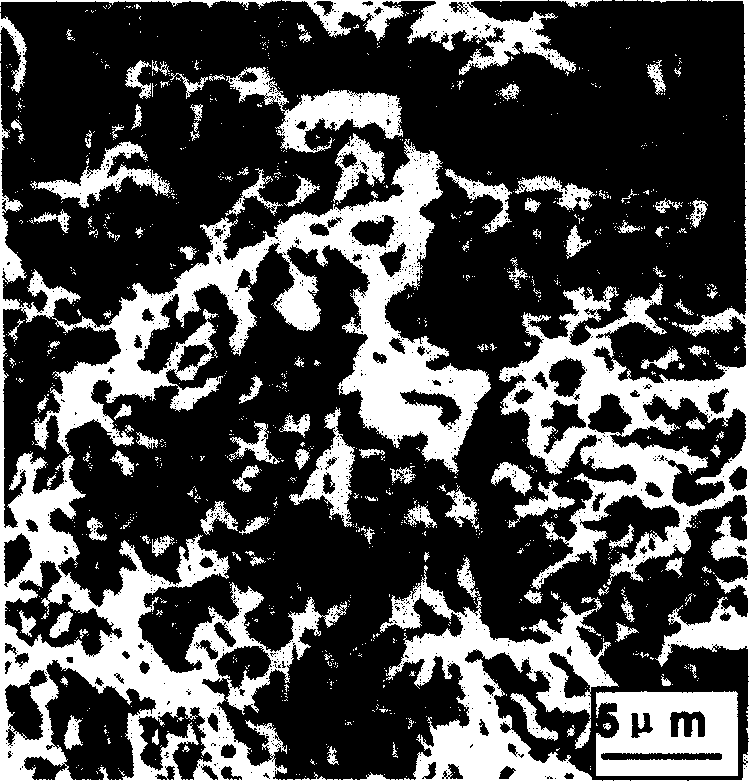

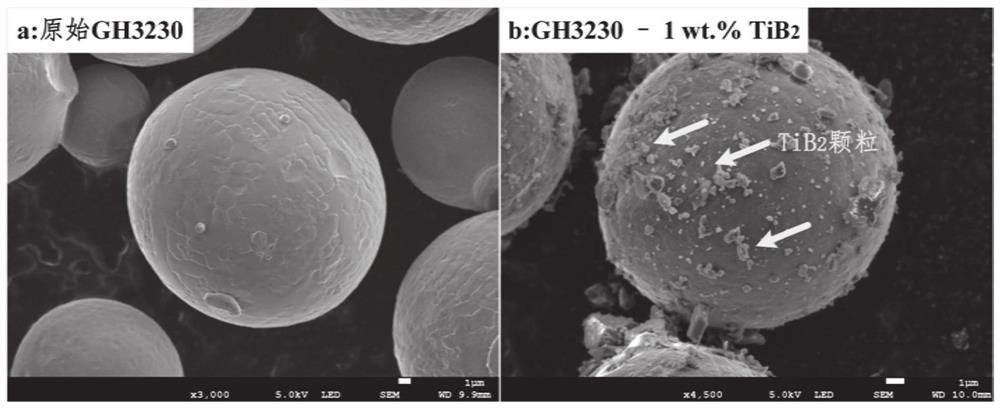

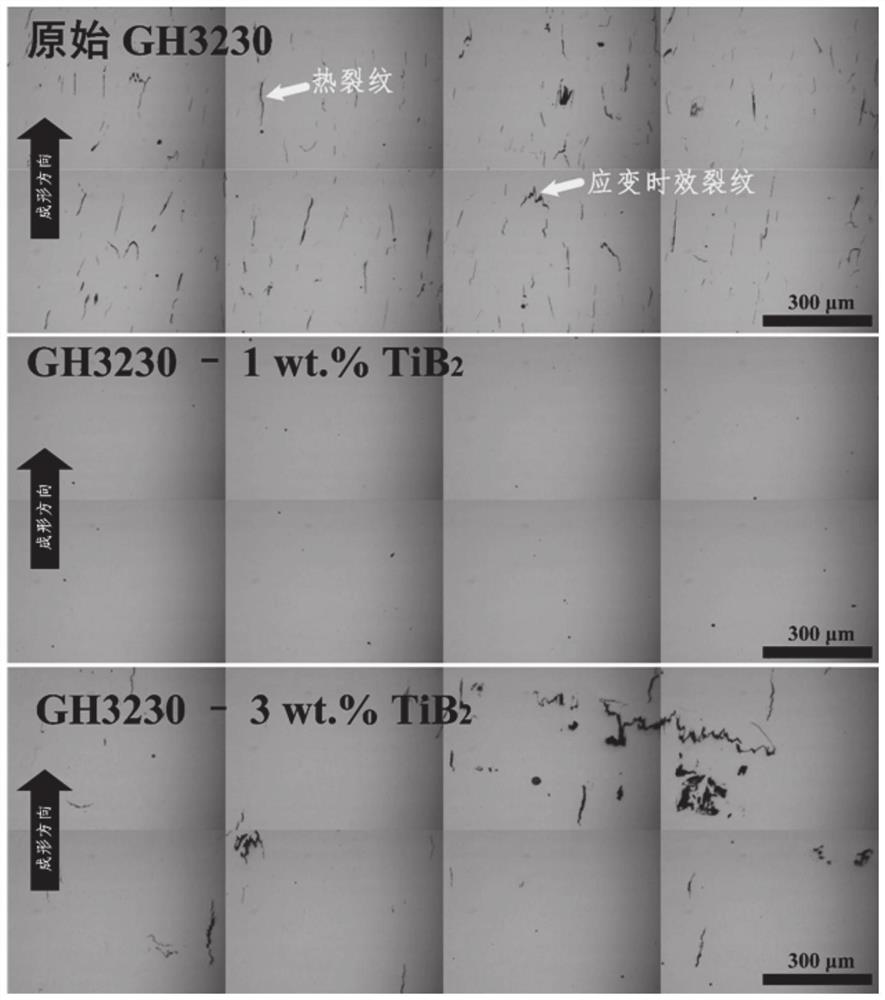

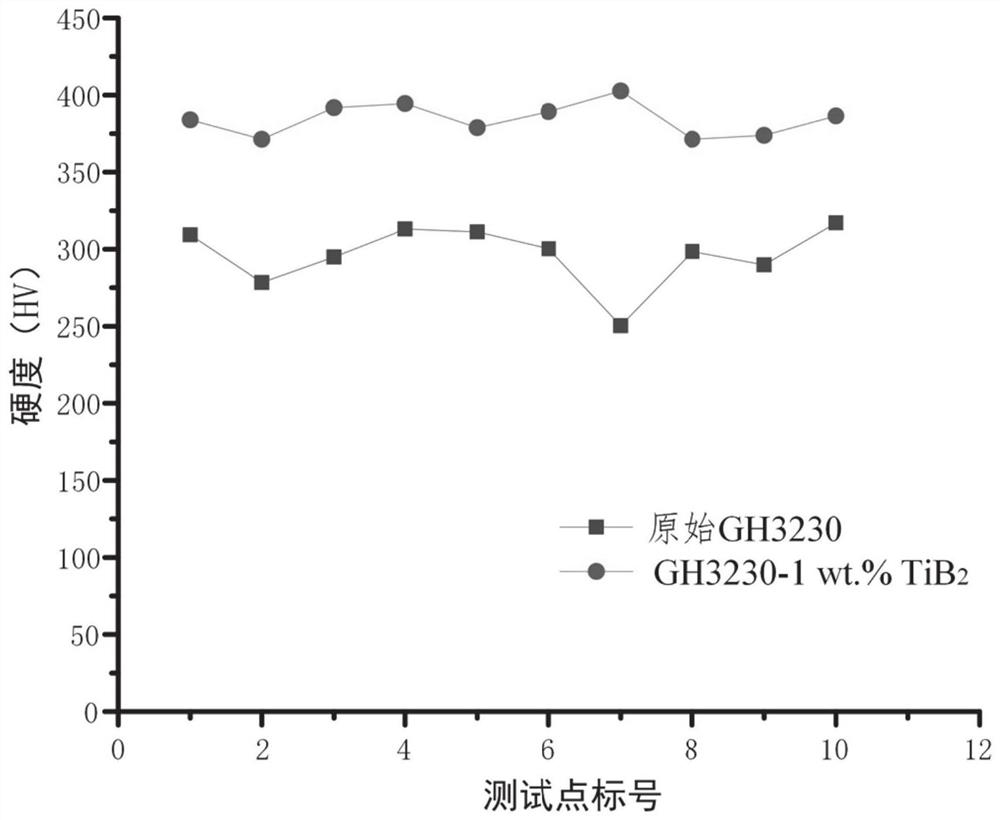

ActiveCN113061782AEliminate microcracksImprove carrying capacityAdditive manufacturing apparatusSelective laser meltingCrazing

The invention relates to the technical field of alloy preparation, and particularly provides a GH3230 nickel-based high-temperature alloy material, a method for eliminating selective laser melting forming microcracks and application of the GH3230 nickel-based high-temperature alloy material. GH3230 powder is prepared from the following elements in percentage by mass: 0.05-0.15% of C, 20-24% of Cr, less than 5% of Co, 13-15% of W, 1-3% of Mo, 0.2-0.5% of Al, less than 0.1% of Ti, less than 3% of Fe, 0.005-0.05% of La, less than 0.015% of B, 0.25-0.75% of Si, 0.3-1% of Mn, less than 0.015% of S, less than 0.03% of P, less than 0.5% of Cu, and the balance of Ni element and inevitable impurities. TiB2 powder is further included, and the mass of the TiB2 powder accounts for 0.5%-1.5% of the mass of the GH3230 alloy powder. According to the method disclosed by the invention, the microcracks in the GH3230 alloy manufactured by the SLM process can be eliminated, so that the mechanical property of a GH3230 forming component is remarkably improved.

Owner:中航迈特增材科技(北京)有限公司

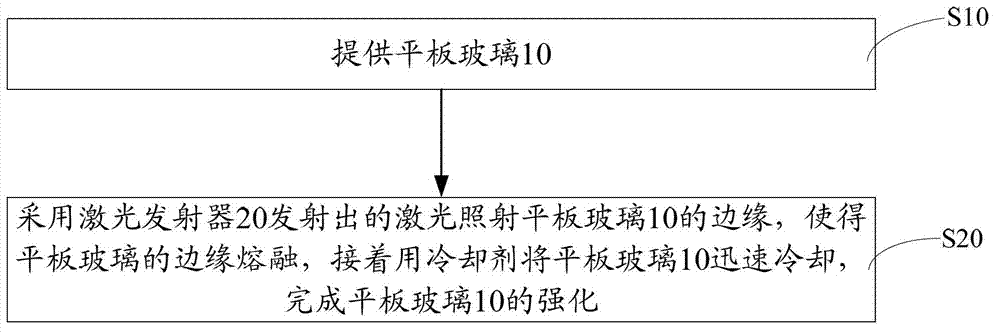

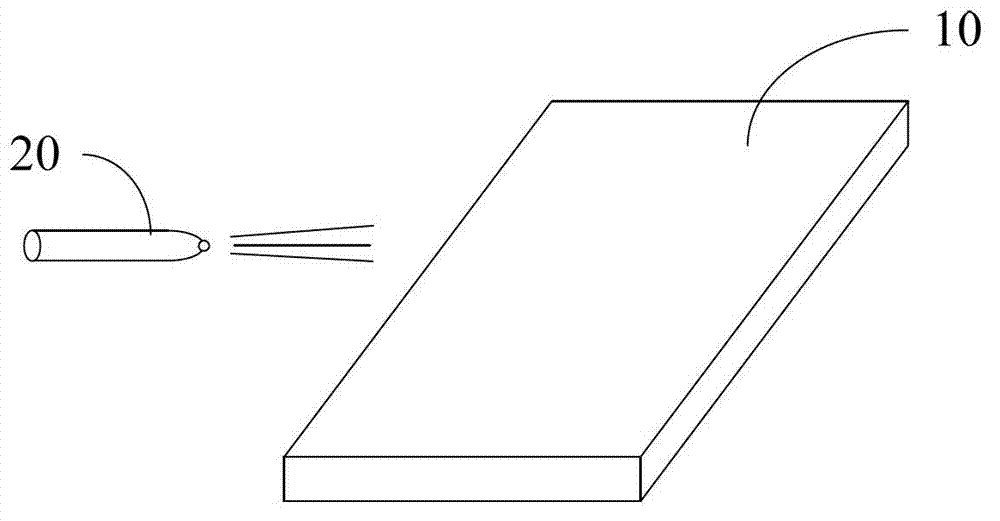

Reinforcing method for plate glass

The invention discloses a reinforcing method for plate glass. The reinforcing method comprises the following steps of: providing the plate glass; and illuminating the edge of the plate glass by utilizing laser emitted by a laser emitter, fusing the edge of the plate glass, and then quickly cooling the plate glass by utilizing a cooling agent, so as to finish the reinforcing of the plate glass. According to the reinforcing method for the plate glass, the laser is utilized to illuminate the edge of the plate glass, so that the edge of the plate glass is fused, and micro-cracks, collapse points and collapse sides generated at the edge of the plate glass are eliminated; and HF (hydrogen fluoride) is not used in the reinforcing method, so that the pollution is relatively low.

Owner:YICHANG NANBO DISPLAY

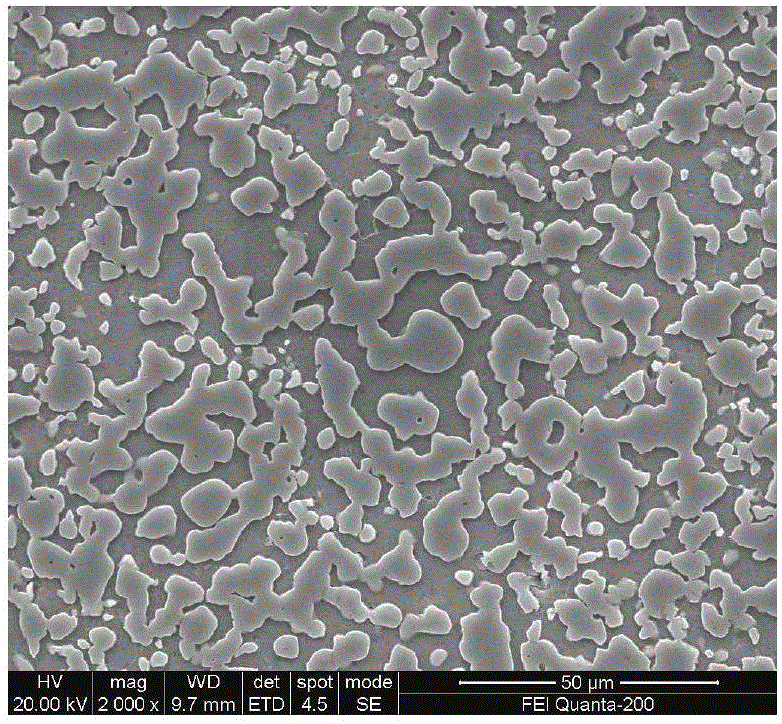

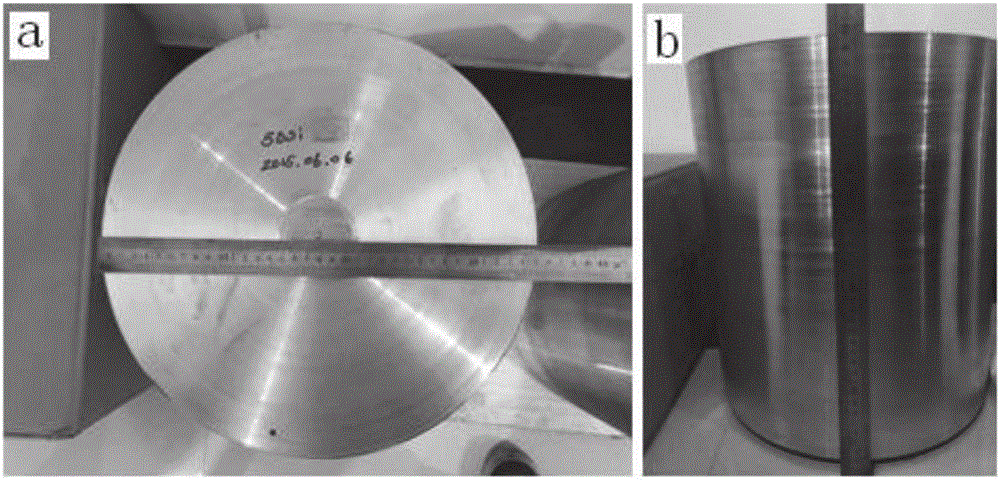

Alloying-element-strengthened high-silicon aluminum composite and preparation method thereof

The invention provides a preparation method of an alloying-element-strengthened high-silicon aluminum composite and belongs to the technical field of material preparation. The preparation method is particularly suitable for preparation of electronic packaging material. The designed alloying-element-strengthened high-silicon aluminum composite comprises, by mass percent, 48.0%-52.0% of silicon, 0.5%-4.0% of X and the balance aluminum. The X is copper and / or magnesium. The preparation method of the alloying-element-strengthened high-silicon aluminum composite comprises the steps that a silicon source, an aluminum source and an X source are prepared according to the designed components, the prepared silicon source, the prepared aluminum source and the prepared X source are smelted, and then a melt is obtained; and atomized spray deposition is conducted on the obtained melt, so that a deposition preform is obtained, hot isostatic pressing treatment is conducted on the deposition preform, and then a finished product is obtained, wherein during hot pressing pressure treatment, the temperature is controlled to be 520-600 DEG C, and the pressure is controlled to be 150-200 MPa. The designed composite has the advantages of being excellent in comprehensive performance, outstanding in mechanical property, low in preparation cost and the like and is suitable for large-scale industrial production.

Owner:CENT SOUTH UNIV

Technological method for composite asynchronous polishing of ceramics using picosecond-nanosecond laser

ActiveCN109514076AAchieve initial flatteningEliminate microcracksWelding/soldering/cutting articlesLaser beam welding apparatusPicosecond laserMicro nano

The invention discloses a technological method for composite asynchronous polishing of ceramics using picosecond-nanosecond laser. The technological method comprises the steps of firstly, irradiatingthe ceramic surface to be machined through picosecond laser along a certain scanning trace, and removing micro protrusions of the ceramic surface, so that the preliminary flattening is achieved; meanwhile, generating a large number of micro-nano particles by using a removal mechanism for the electronic state of ceramic materials through picosecond laser, wherein the micro-nano particles exist at adjacent space areas of the irradiated ceramic surface; starting a low power nanosecond laser according to the preset time for tracing the scanning path of the picosecond laser, and irradiating and fusing the micro-nano particles uniformly distributed on the ceramic surface; and finally forming a compact and smooth fine-grain melted layer so that the polishing effect is achieved. According to the technological method, original pore cracks of the ceramic materials are repaired, and the shortcomings that a heat affected zone generated by traditional laser polishing is large and the material surface is liable to generate micro-cracks and pores are overcome; and low removal amount, high efficiency and accuracy and submicron-level fine polishing of the ceramic materials is achieved.

Owner:BEIJING UNIV OF TECH

Treatment process for 2.5D mobile phone glass

InactiveCN107759065AEliminate microcracksEliminate gapsLamination ancillary operationsLaminationScreen printingEngineering

The invention relates to the technical field of mobile phone glass processing, in particular to a treatment process of 2.5D mobile phone glass. The treatment process comprises the following steps: (a)cleaning 2.5D glass and then drying; (b) carrying out enhanced treatment on the edge of the 2.5D glass; (c) cutting to the required size and then carrying out edging treatment; (d) carrying out toughening treatment on the edged 2.5D glass; (e) carrying out silk screen printing on the toughened 2.5D glass; (f) baking the 2.5D glass subjected to silk screen printing; and (g) carrying out coating treatment on the surface of the 2.5D glass. Compared with the prior art, the treatment process disclosed by the invention has the advantages that the edge of the 2.5D glass is subjected to the enhancedtreatment, so that microcracks on the edge, clearances between the edges, broken edges and the like are eliminated. By adopting the steps, the integral strength of the 2.5D glass can be greatly improved, and the service life is prolonged. The treatment process disclosed by the invention is simple in treatment step and easy to operate and can better meet the batch production demand.

Owner:萍乡星弛光电科技有限公司

Method for preparing high-entropy alloy through laser additive manufacturing

InactiveCN109317671AHigh functional gradientImprove defectsAdditive manufacturing apparatusIncreasing energy efficiencyLaser processingHigh entropy alloys

The invention relates to a method for preparing a high-entropy alloy through laser additive manufacturing. The method comprises the following steps that A, grinding, washing and drying of substrates are carried out, and the substrates are preheated; B, prepared high-entropy alloy powder is subjected to ball milling treatment and is stirred evenly to be subjected to deposition; C, according to theperformance requirements of bulk high-entropy alloy components, laser processing parameters for machining each deposition layer is pre-designed; D, according to the preset laser processing parametersof each layer, the surfaces of the substrates are subjected to layer-by-layer variable parameter laser additive manufacturing; and E, after processing is carried out, prepared bulk alloy components are slowly cooled to room temperature, a wire cutting method is used for separating the additive manufacturing components from the substrate, and then hot isostatic pressing is carried out. By means ofthe method, while the molded piece performance is met, the production cycle is shortened, cost is reduced, and large-scale parts in complicated shapes can be prepared.

Owner:JIANGSU UNIV

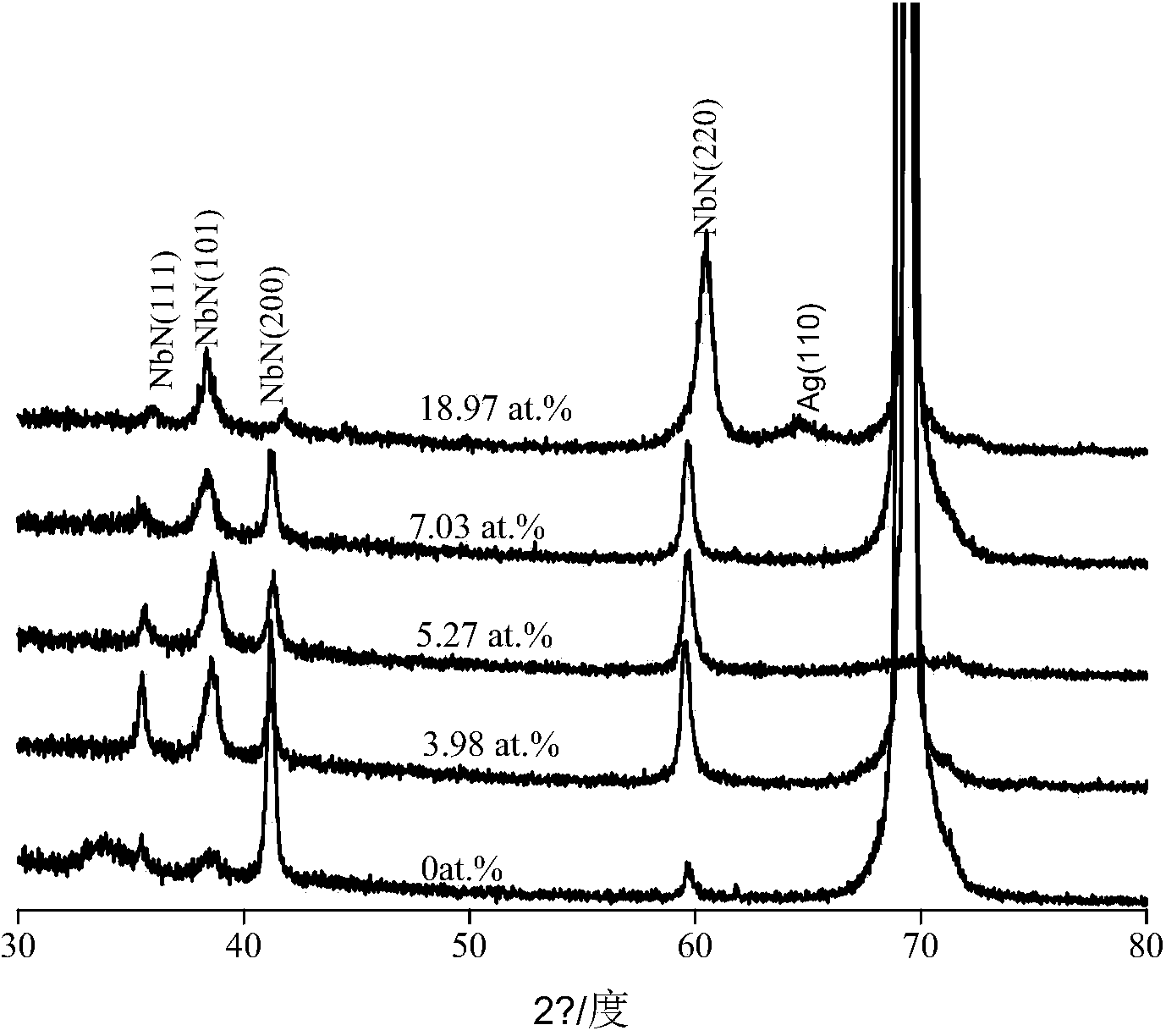

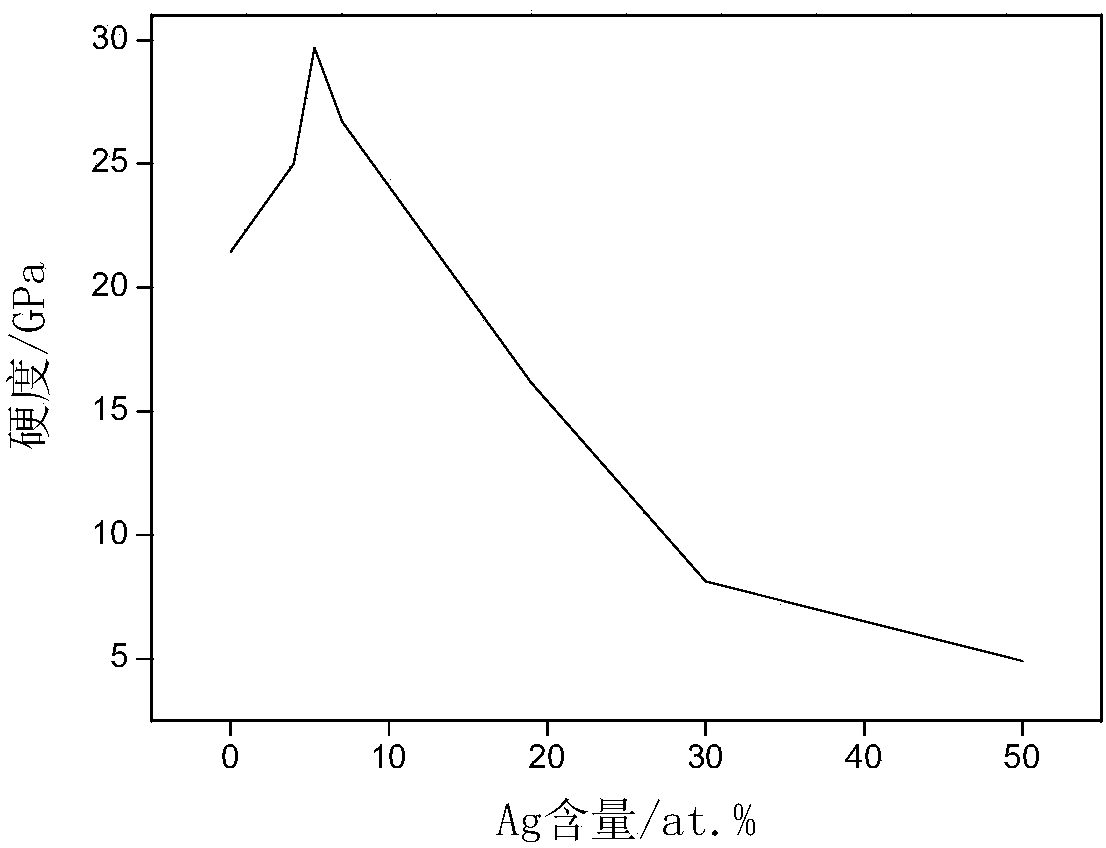

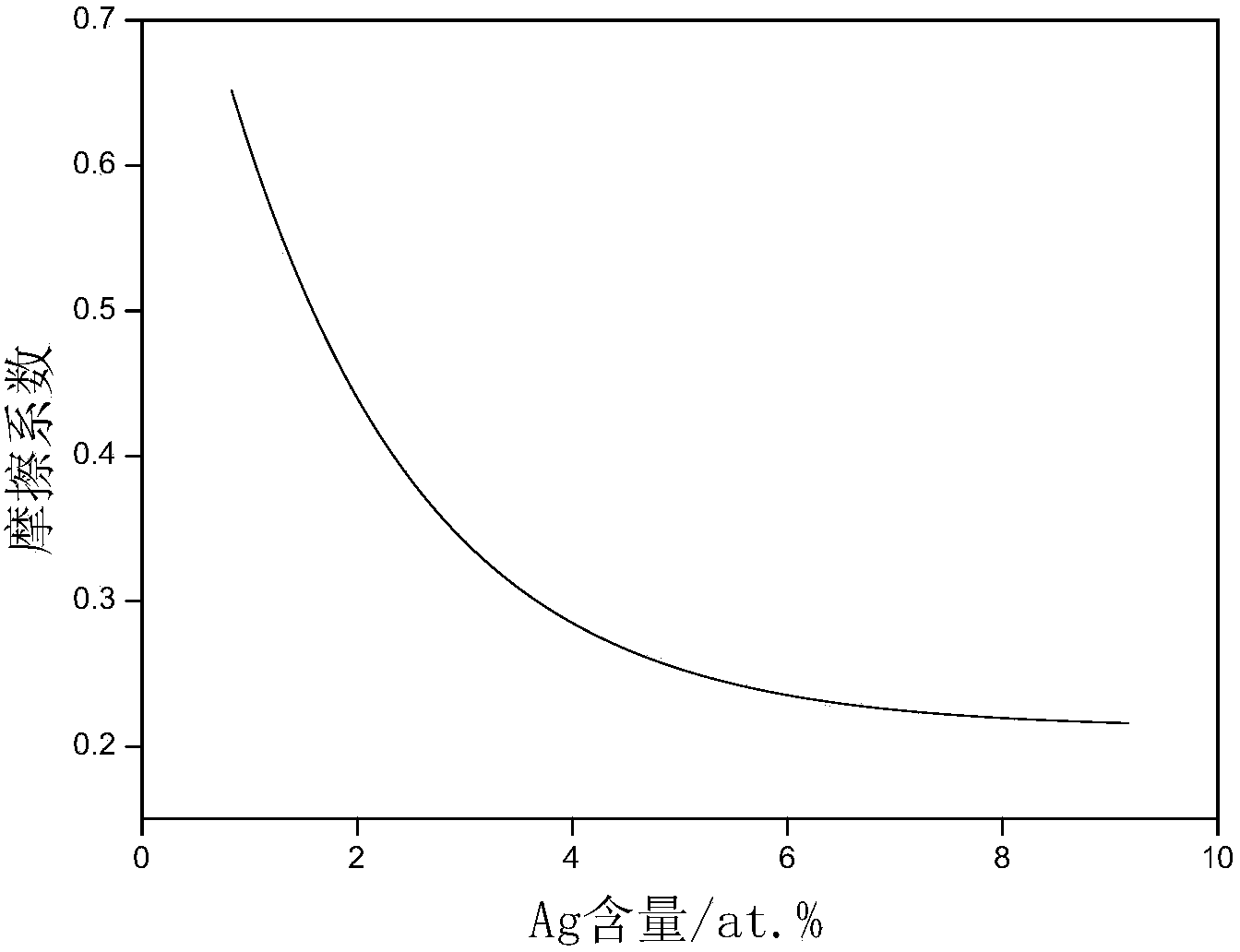

NbN-Ag hard thin film and preparation method thereof

InactiveCN104032269AImprove plasticityHigh hardnessVacuum evaporation coatingSputtering coatingRadio frequencyArgon flow

The invention relates to an NbN-Ag hard thin film and a preparation method thereof. The NbN-Ag hard thin film is characterized in that the molecular formula thereof is NbN-Ag; the thickness is 1-5 microns; the content of Ag is 0-50 at.%, and is greater than 0; a high-purity Nb target and a Ag target are used as targets; the NbN-Ag hard thin film is obtained by depositing the targets on a hard alloy or ceramic matrix through a double-target confocal radio-frequency response method; in the deposition, the vacuum degree is lower than 3.0*10-3 Pa; the deposition is performed using argon to start arcing and using nitrogen as reaction gas; the sputtering pressure is 0.3 Pa; the nitrogen-argon flow ratio is 10: (1-10); the sputtering power of the Nb target is 100-500 W; and the sputtering power of the Ag target is 0-150 W. The preparation method has high production efficiency; and the obtained thin film has high hardness and excellent friction and wear resistance, and can be used as a high-speed dry cut structural hard thin film.

Owner:JIANGSU UNIV OF SCI & TECH

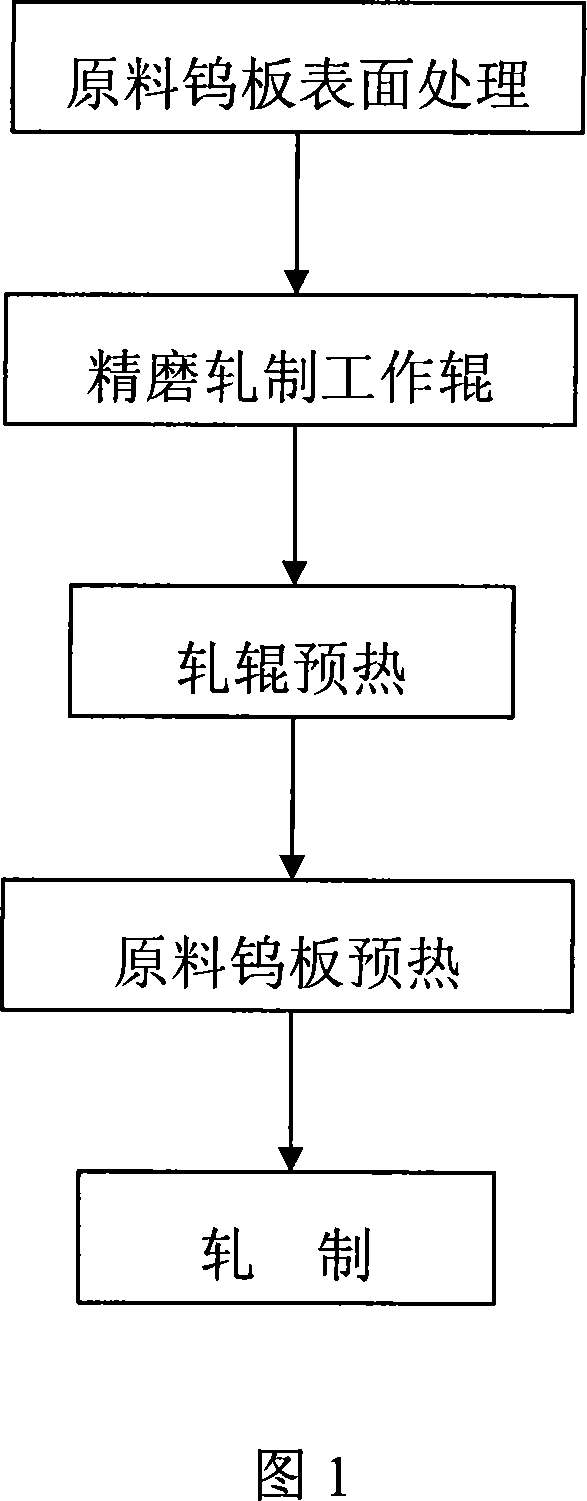

Method for rolling small-coarseness high-light thin wolfram sheet

ActiveCN101181717AImprove plasticityDecontaminationRoll force/gap control deviceTemperature control deviceSurface roughnessTungsten

The invention relates to a rolling method of small-roughness high-gross thin tungsten sheet, pertaining to the rolling method of thin tungsten sheet. The method of the invention is characterized in that: a. surface processing of tungsten board material: the surface of tungsten board is regrinded, electrolyte of 1% NaOH + 4% K2CO3 + 4% KClO3 + H2O is adopted to polish the tungsten board for 10 to 30min; b. a regrinding and rolling roller with roughness smaller than 0.1Mum is used; c. the preheating temperature of the roller is 100 to 150 DEG C; d. the preheating temperature of the tungsten board material is 100 to 200 DEG C; e. surface processed and preheated tungsten board is directly rolled on a preheated four-roll or six-roll rolling machine, with the total processing rate controlled between 20 to 30 percent, rolling force 40T to 100T. The method of the invention can prepare thin tungsten sheets with uniform and bright surface and the surface roughness is smaller than 0.15Mum.

Owner:WESTERN METAL MATERIAL

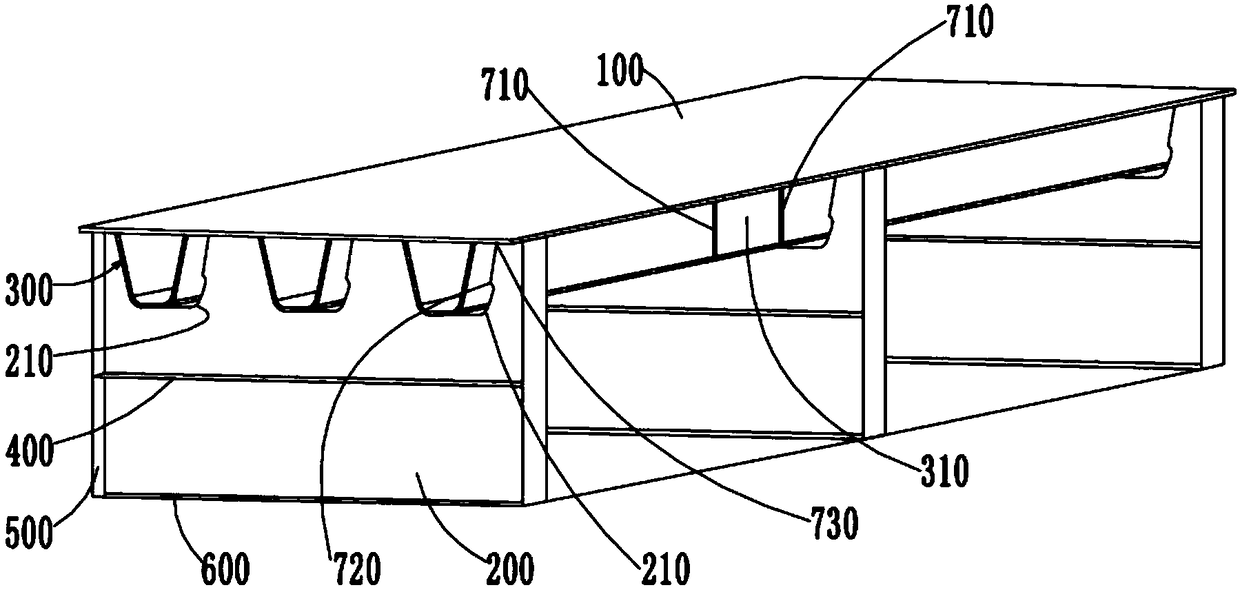

Preventive maintenance method for fatigue crack of steel box girder and steel box girder

ActiveCN109024317AReduce maintenance costsExtend working lifeBridge erection/assemblyBridge strengtheningCrazingMetallurgy

The invention provides a preventive maintenance method for fatigue cracks of steel box girders and a steel box girder, which relates to the technical field of maintenance of steel box girders and is designed to solve the problem of poor effect of existing repair methods for cracks of steel box girders. The preventive maintenance method for fatigue cracks of the steel box girder is used for curingthe welding seam of the steel box girder, comprising the following steps of: polishing the surface of the welding seam to be flush; Grinding is carried out in the direction of coating cracking on theweld to eliminate microcracks on the weld. The steel box girder is cured by the precautionary maintenance method of the fatigue crack of the steel box girder. The invention provides a preventive maintenance method for fatigue cracks of a steel box girder and the purpose that the steel box girder is used for realizing accumulative damage to a metal surface and elimination of small cracks before thecrack extends over a large area, thereby greatly improving the fatigue resistance at the welding seam of the existing steel box girder.

Owner:ZHEJIANG JIAOGONG HIGHWAY MANTAINANCE

Mortar for decorating external wall

The invention discloses a natural aeolian sand mortar for decorating an external wall, which is mixed by the following components in parts by weight: 10-20 of ordinary portland cement, 2-3 of slaked lime, 3-5 of lightweight aggregate, 71-84 of heavy aggregate (aeolian sand), 1.0 of complex additive, wherein the lightweight aggregate is an inorganic vitrified hollow micropore material; the heavy aggregate is the aeolian sand; the preferred fineness of the inorganic vitrified hollow micropore material is 80-100 mesh, the weight content of the aeolian sand with 50-70 mesh preferred fineness is more than 90 percent, and the rest aeolian sand has more than 100-mesh fineness. The invention has the advantages that the mortar has prominent stereo texture, endurance and stability, light weight, saved energy and good crack- resistant and anti-drop properties, and exhibits natural and rich European style customs decoration effect; and the mortar also has good smear workability and simple process, and is suitable for mechanization construction. The construction method is as follows: the mortar is diluted by adding water based on 30-50 percent of the mortar by weight, mechanical agitation or hand stirring is carried out to be evenly mixed to reach a proper viscosity for mechanical spray or hand construction.

Owner:SHENZHEN GRANDLAND DECORATION GROUP

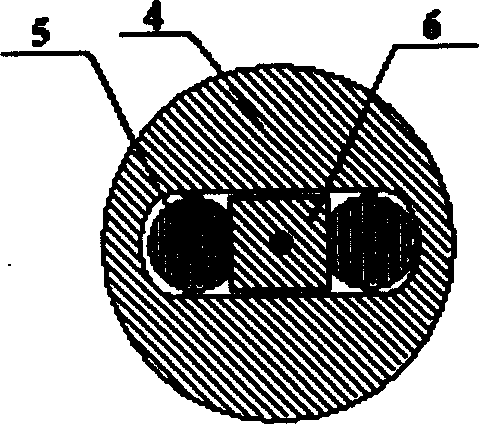

Diamond cladded polarization maintaining optical fiber and manufacturing method thereof

ActiveCN105985014AStrong process scalabilityGood process scalabilityGlass making apparatusOptical fibre with polarisationBatch productionCore (optical fiber)

The invention discloses a diamond cladded polarization maintaining optical fiber and a manufacturing method thereof. The manufacturing method comprises the following steps that a chemical vapor deposition method is adopted to manufacture a core stress integrated rod, wherein the core stress integrated rod comprises a core layer, a stress layer and an outer cladding layer; the core stress integrated rod is machined to make a cross section diamond; a target rod with a diamond cross section is manufactured and is put inside a quartz glass sleeve, an outer spraying process is adopted to conduct deposition on the quartz glass sleeve, the target rod is removed to form a pure quartz glass diamond inner-hole sleeve after the deposition process is completed; the core stress integrated rod with the diamond cross section is placed in the pure quartz glass diamond inner-hole sleeve to form a polarization maintaining optical fiber perform, the olarization maintaining optical fiber perform is subjected to drawing to form the diamond cladded polarization maintaining optical fiber. The polarization maintaining optical fiber I good in process performance and product quality, high in manufacturing precision and finished product rate, good in machining adaptability and suitable for batch production.

Owner:武汉长盈通光电技术股份有限公司

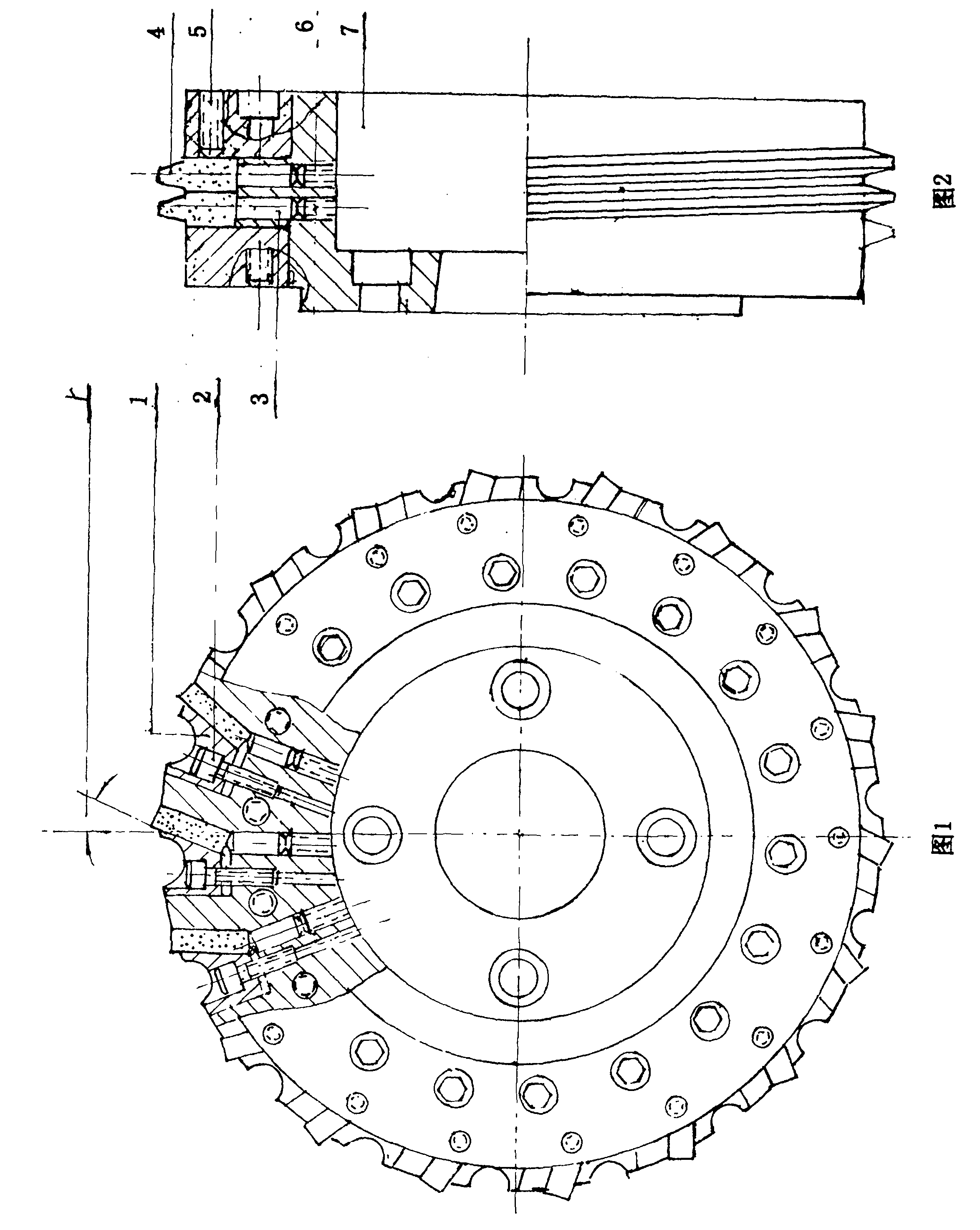

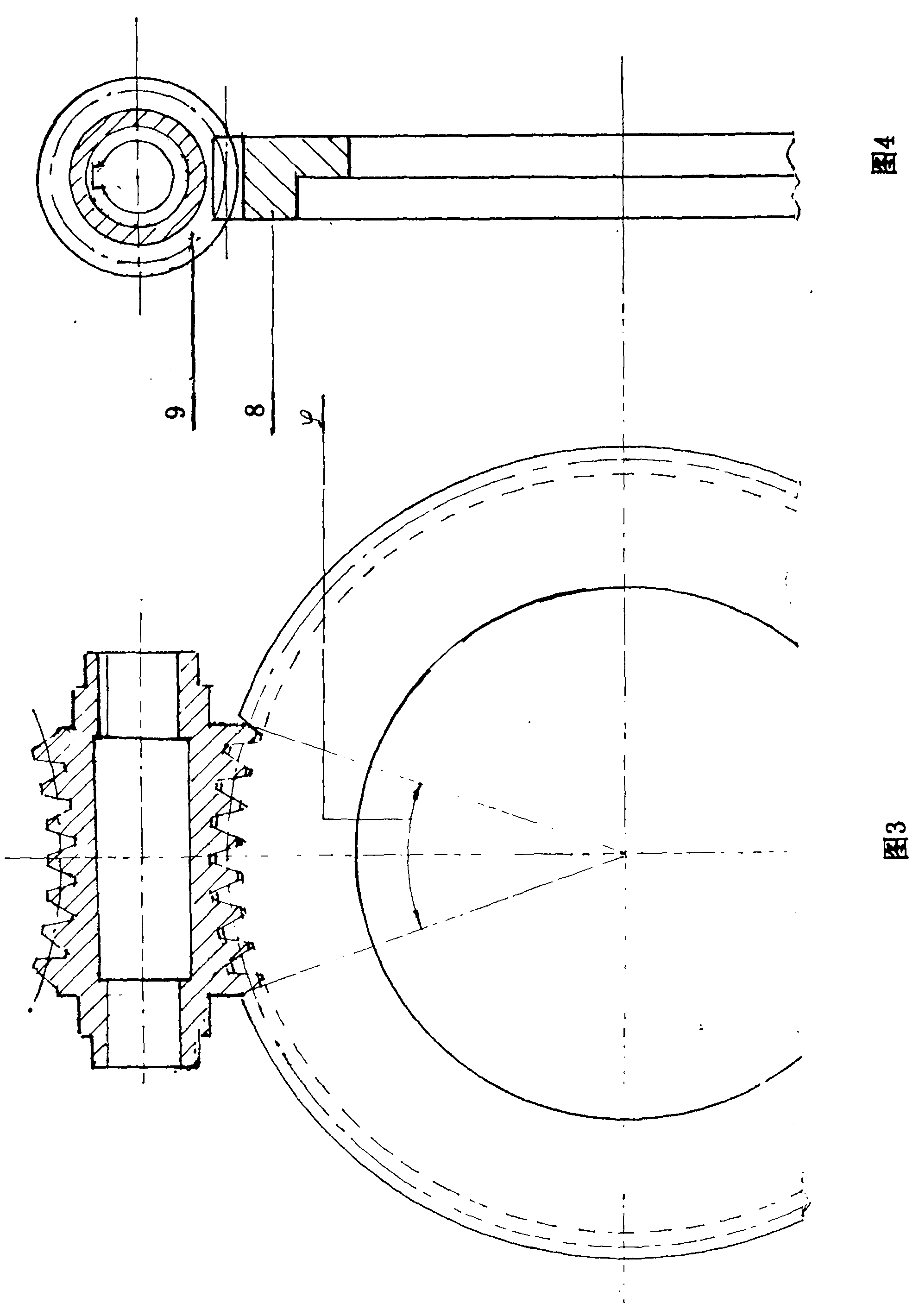

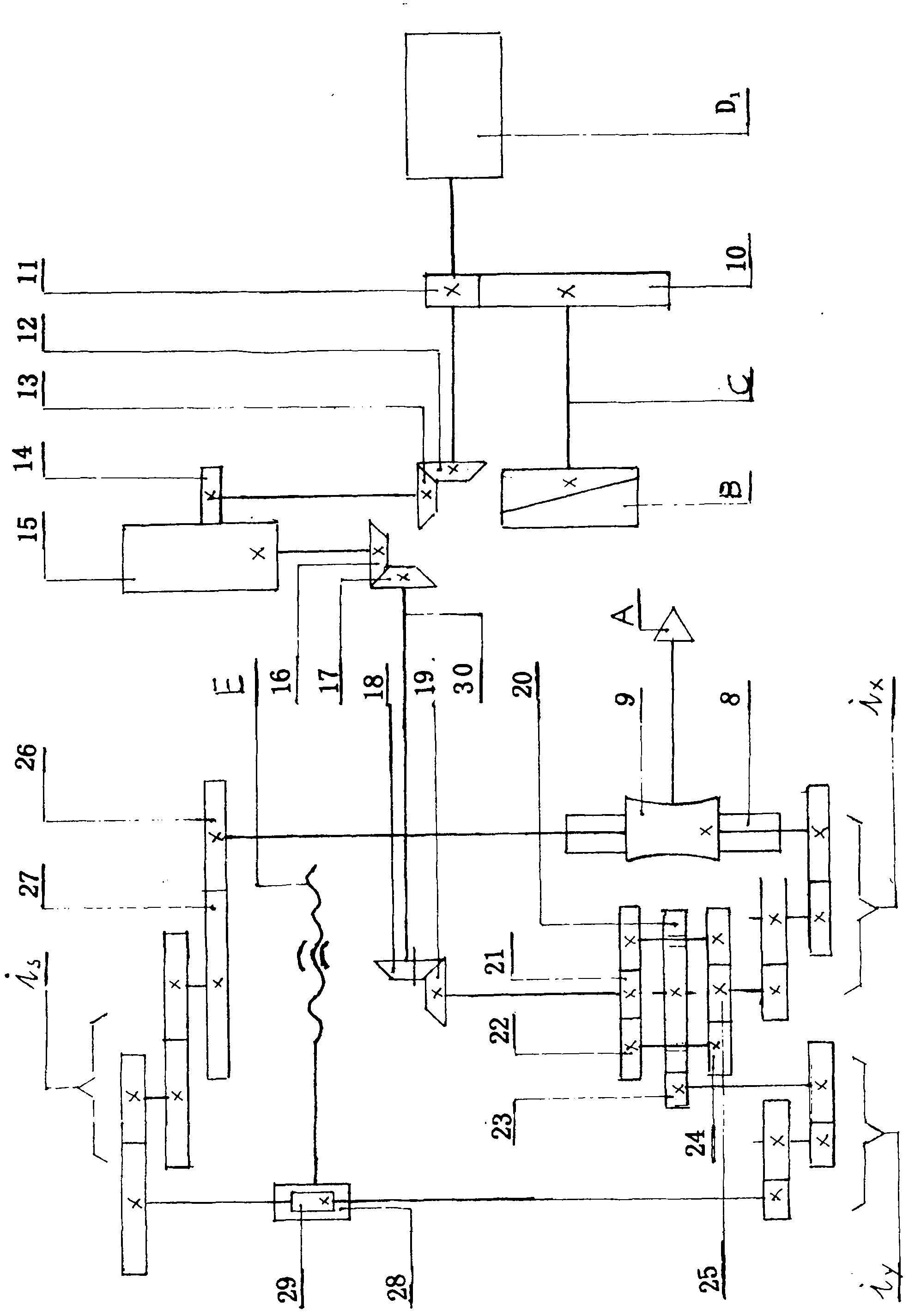

Hard-surface gear hobbing processing device

The invention discloses a hard-surface gear processing device, in particular to a hard-surface gear hobbing processing device which comprises a cutter and a hard-surface gear hobbing machine and is characterized in that the cutter adopts a hard-surface gear hobbing plate, a main motion transmission chain is shortened to a limit by the hard-surface gear hobbing machine, a working main shaft of the hard-surface gear hobbing machine is in a horizontal structure, and a dividing mechanism of the hard-surface gear hobbing machine comprises a plane worm wheel and a plane enveloped worm gear. In the hard-surface gear processing device, the hard-surface gear processing cutter has reliable operation, simple use and low cost, a hard-surface gear hobbing processing lathe has high rigidity and efficiency, eliminates the deformation of the quenched gear, reduces noise, provides an economic technology for processing the quenched gear, eliminates fine crackles on the gear surface of the quenched gear, and improves the anti-fatigue performance of the gear so as to prolong the service life of the gear.

Owner:岑益南

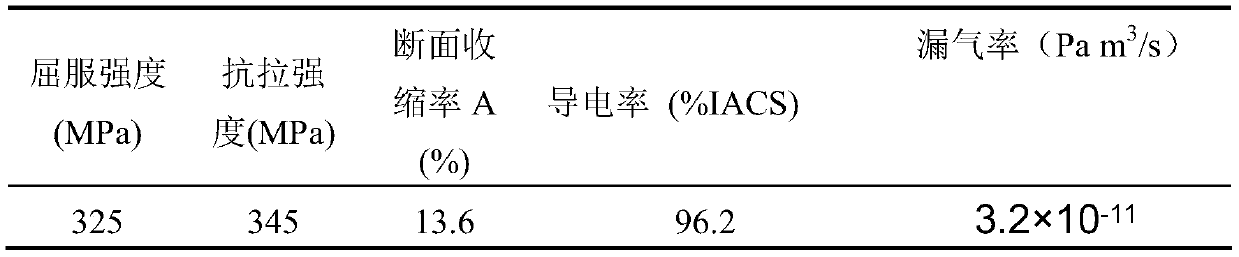

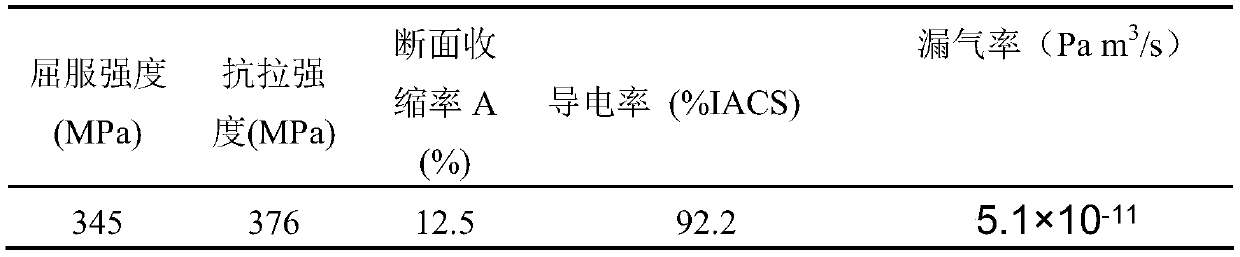

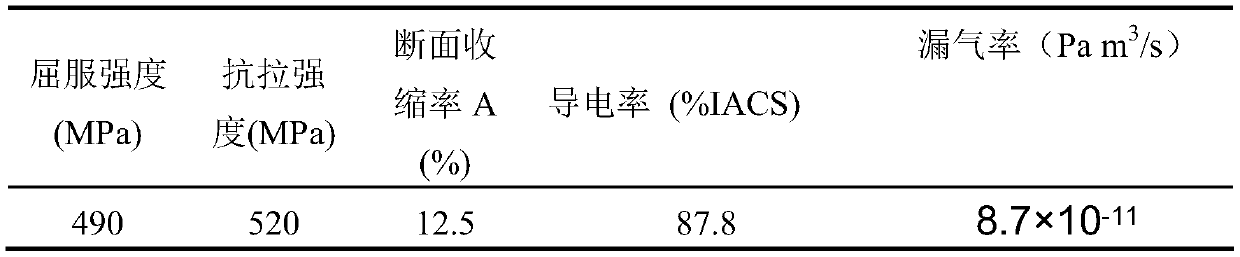

High-air-tightness low-free-oxygen-content nano disperse copper alloy and short-process preparation technology

ActiveCN109897982AReduced free oxygen contentPlay the role of diffusion strengtheningTransportation and packagingMetal-working apparatusInternal oxidationHigh dimensional

The invention discloses a high-air-tightness low-free-oxygen-content nano disperse copper alloy and a short-process preparation technology, and wherein the alloy components comprise Al2O3, Ca and La.The preparation technology is made by the following steps that preparing Cu-Al2O3 alloy powder by adopting an internal oxidation method, and then mixing the Cu-Al2O3 alloy powder with Cu-Ca-La alloy powder, wrap covering the mixed powder under the protection of argon, carrying out hot extrusion at 900-920 DEG C and then rotary forging, after rotary forging, the wrap covering is vacuumized to be less than or equal to 10<-3>Pa, the wrap covering is sealed and is placed in a nitrogen atmosphere with the temperature of 450-550 DEG Cand the pressure intensity of 40-60 Mpa for 3-5 hours. According to the preparation technology disclosed by the invention, the secondary solid reduction of Ca and La is utilized, so that residual free oxygen is effectively removed and the dispersion strengthening effect is achieved, and finally the high density is obtained through vacuum medium-temperature creep deformation. The disperse copper prepared by the invention has the advantages that low free oxygen content (<= 15ppm), high dimensional stability and good air tightness after hydrogen annealing, good in gas tightness, the gas leakage rate is less than or equal to 1.0*10<-10> Pa.m<3> / s, the preparation technology is suitable for industrial production and can be used as a variety of sealing device materials such as an electric vacuum shell sealing device and a novel energy automobile high-voltagedirect-current relay.

Owner:湖南高创科惟新材料股份有限公司

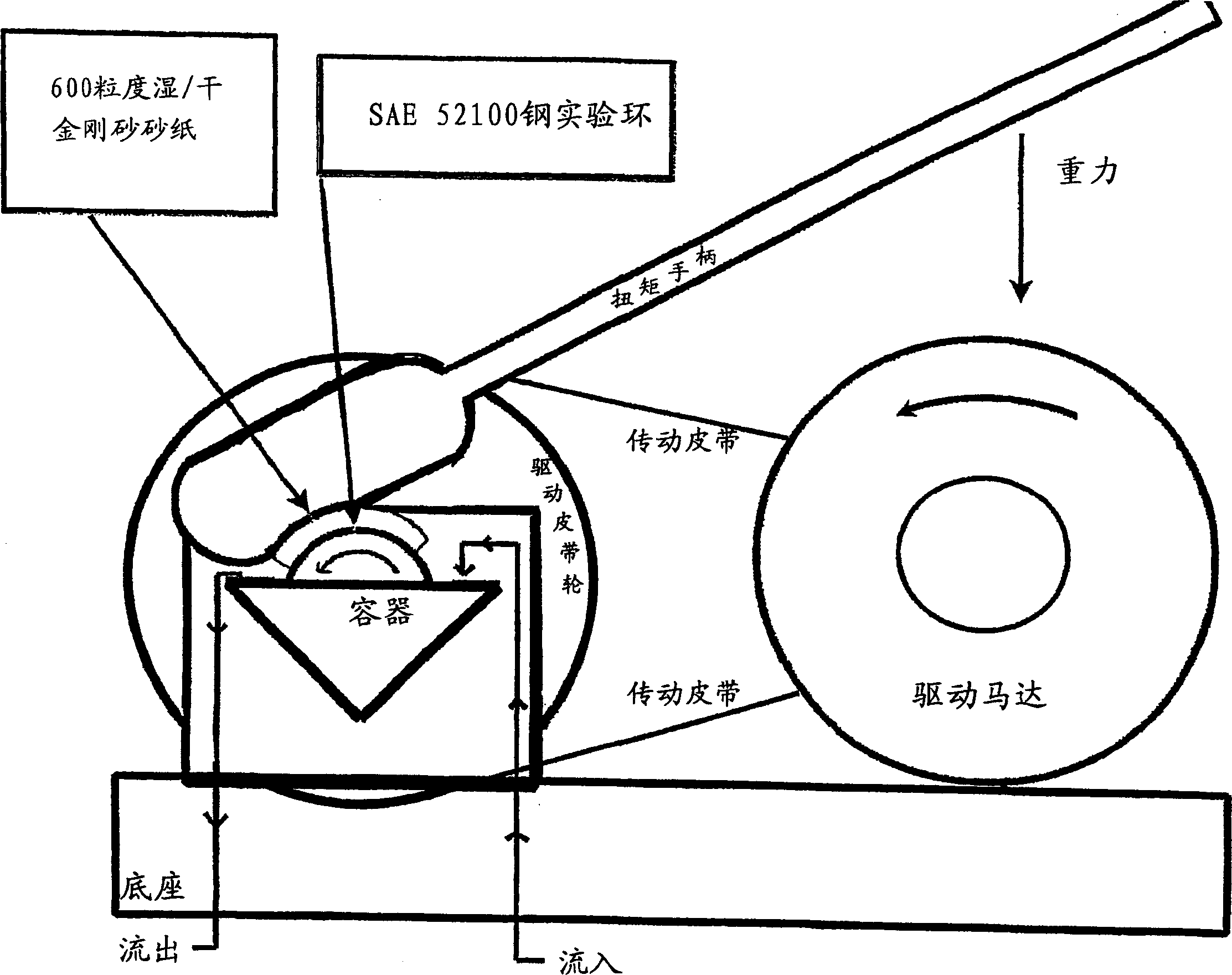

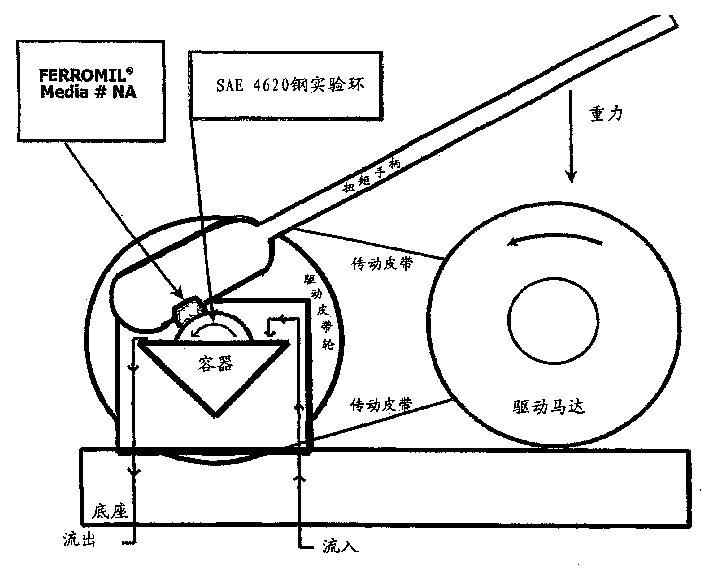

Chemical mechanical machining and surface finishing

InactiveCN1491146AReduce wearEliminate temperingRevolution surface grinding machinesLapping machinesSurface finishRelative motion

Owner:REM TECHNOLOGY INC

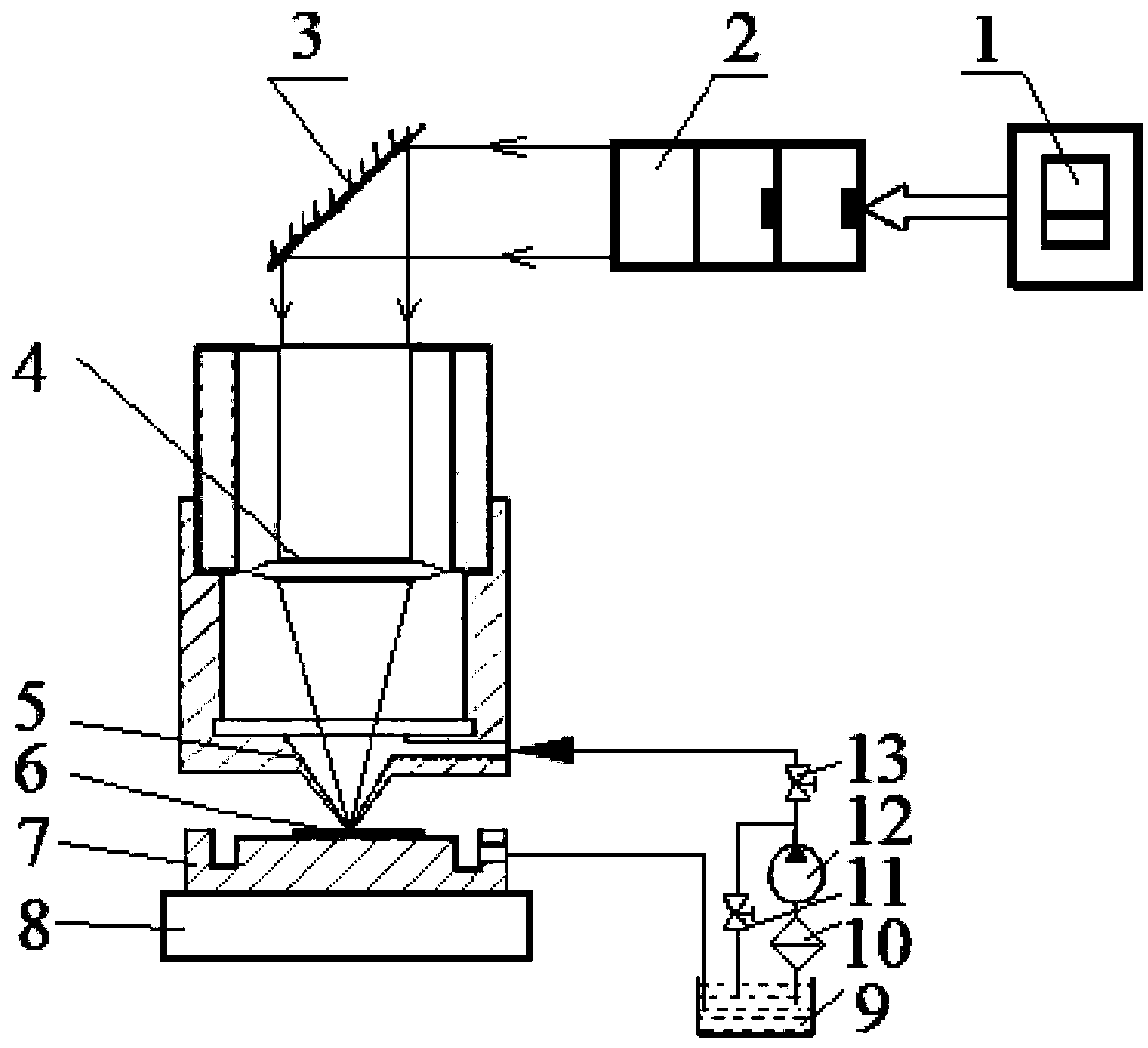

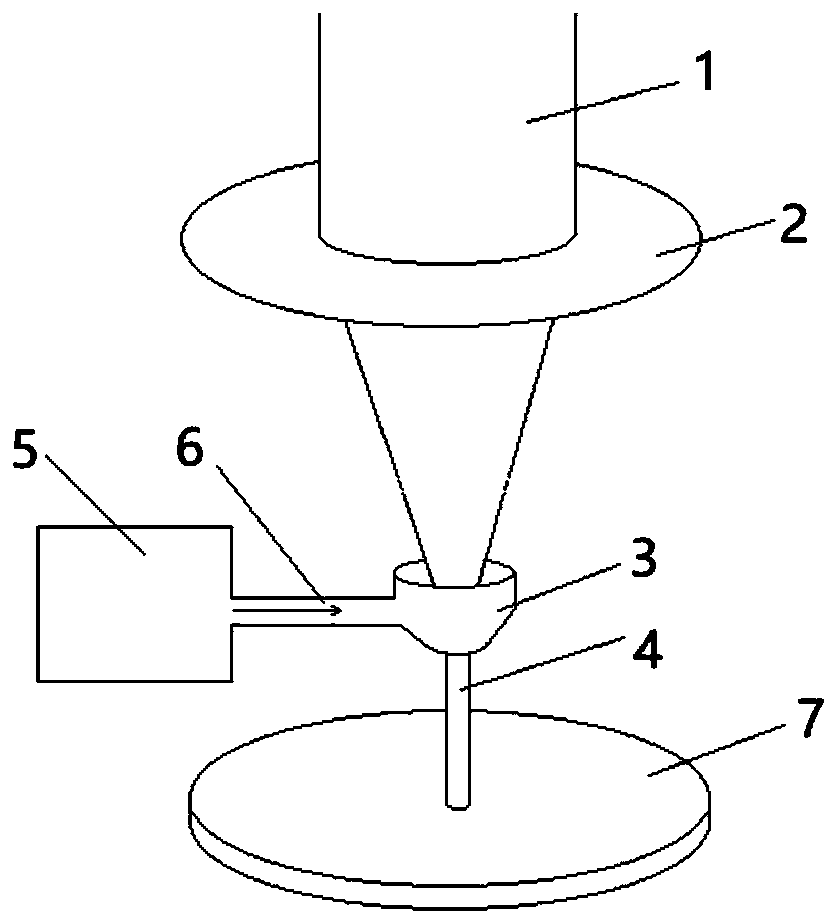

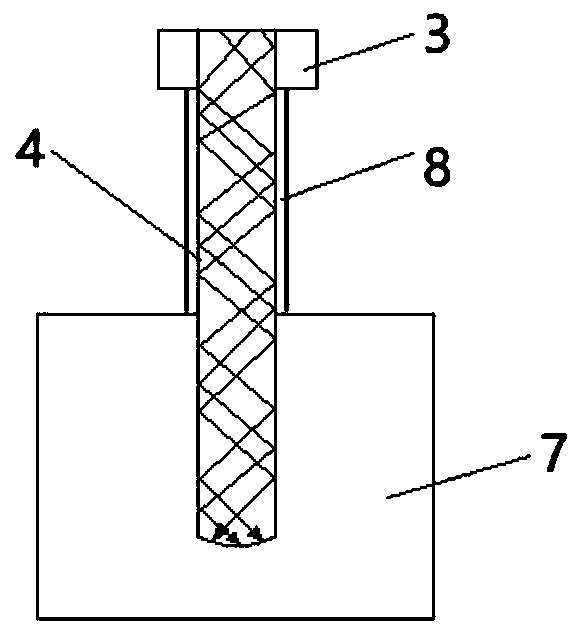

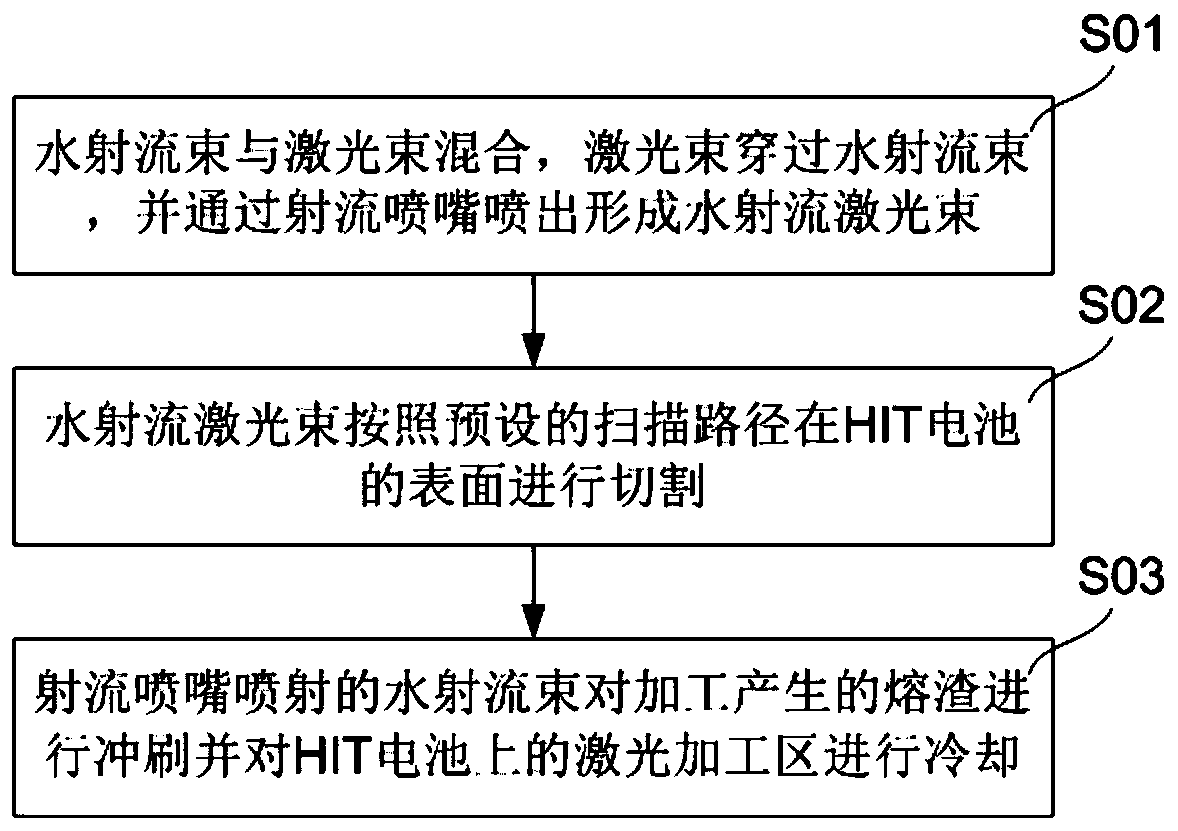

Low-temperature cutting method and device suitable for HIT battery

ActiveCN110788483AReduce performanceReduce depositionLaser beam welding apparatusLaser processingJet flow

The invention provides a low-temperature cutting method and device suitable for an HIT battery. The method comprises the steps that a water jet flow beam and a laser beam are mixed, the laser beam penetrates through the water jet flow beam, and is sprayed out through a jet flow nozzle, and a water jet flow laser beam is formed; the water jet flow laser beam carries out cutting on the surface of the HIT battery according to the preset scanning path; and the water jet flow beam sprayed out of the jet flow nozzle carries out washing on molten slag generated by machining, and the laser machining area on the HIT battery is cooled. The efficiency losses of cutting to the HIT battery can be greatly reduced, through the high-speed water jet flow beam, the laser machining area is cooled, washing iscarried out, a re-casting layer is reduced, and the surface and the cross section of the HIT battery obtained after cutting are free of casting layer, hot stress and micro cracks.

Owner:上海润势科技有限公司

Process for drying biscuit of ceramic, metallic ceramic material

The invention relates to a ceramics or metal ceramics material biscuit drying method the feature is that repeats the process of drying by wet airí¬microwave heatingí¬drying by wet air for ten times under certain temperature and relative humidity until the semi-drying biscuit containing 5-20% water forming; repeating the process of wet airí¬microwave heatingí¬drying by wet air for thirty times under certain temperature and relative humidity until the semi-drying biscuit containing 5% water. The invention realizes the equally decreasing the water distributing in biscuit. It is easy to operate and low cost.

Owner:HEFEI UNIV

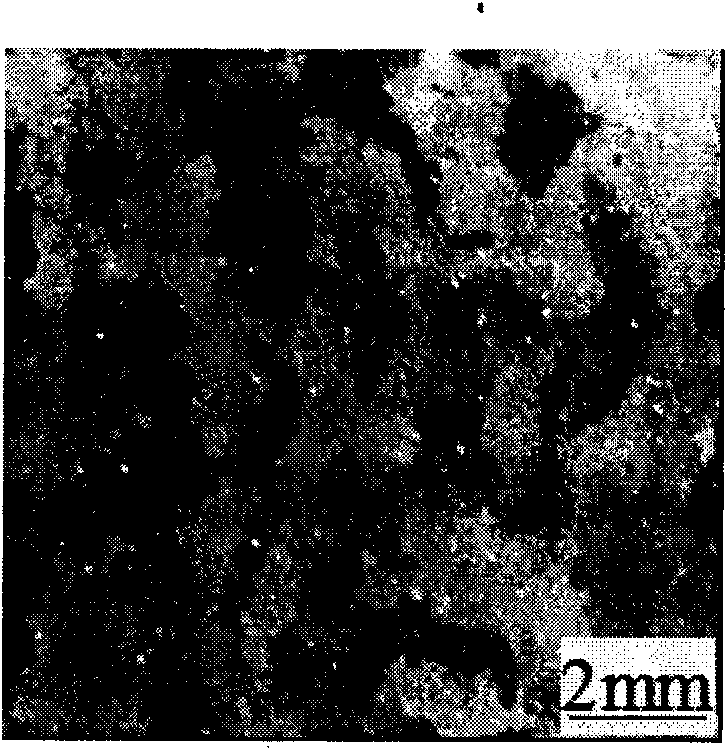

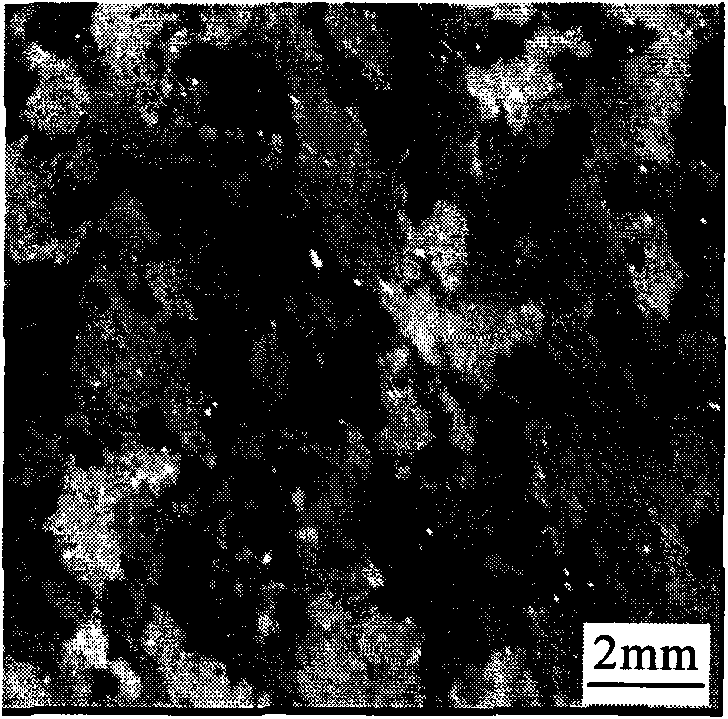

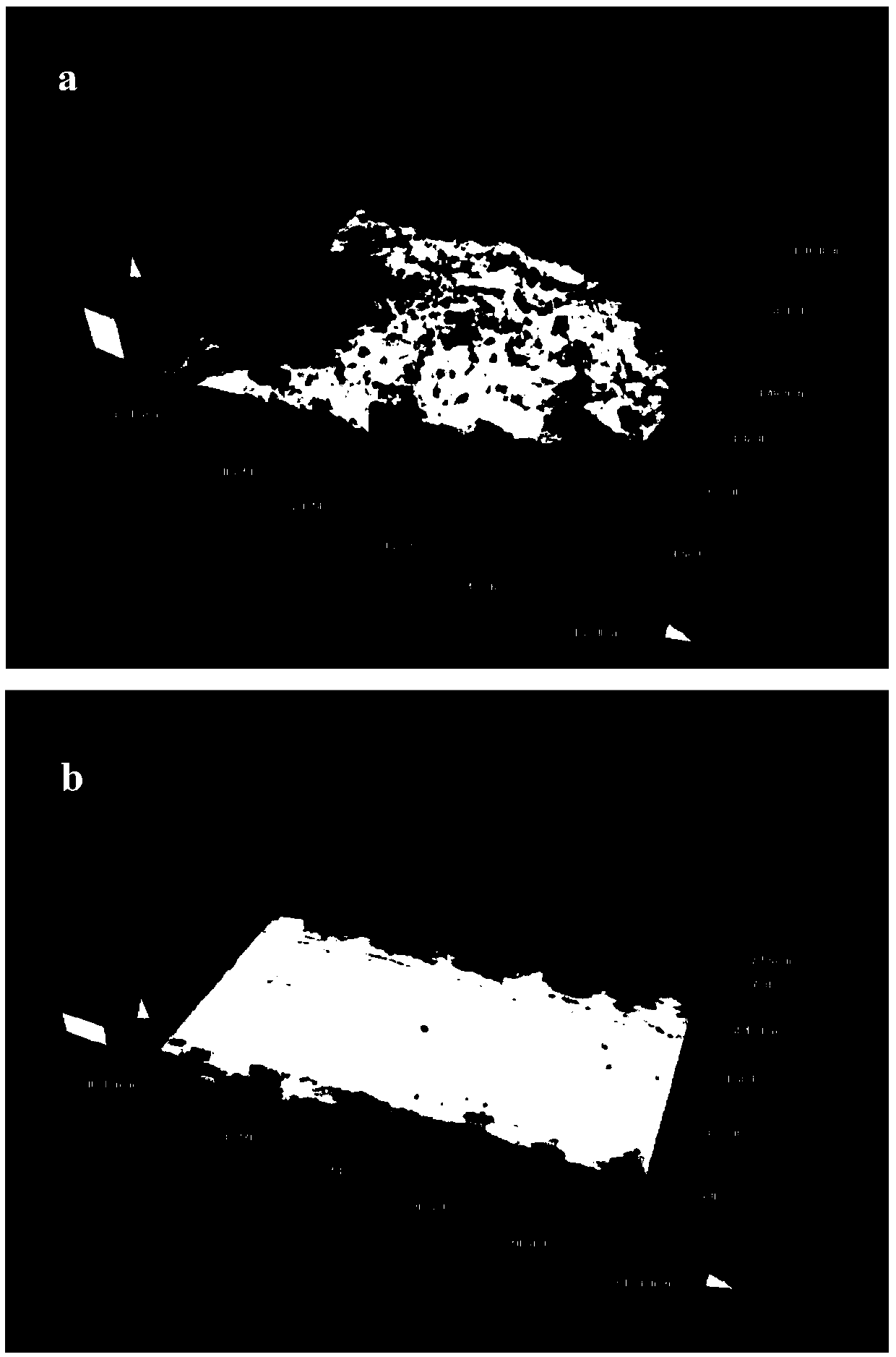

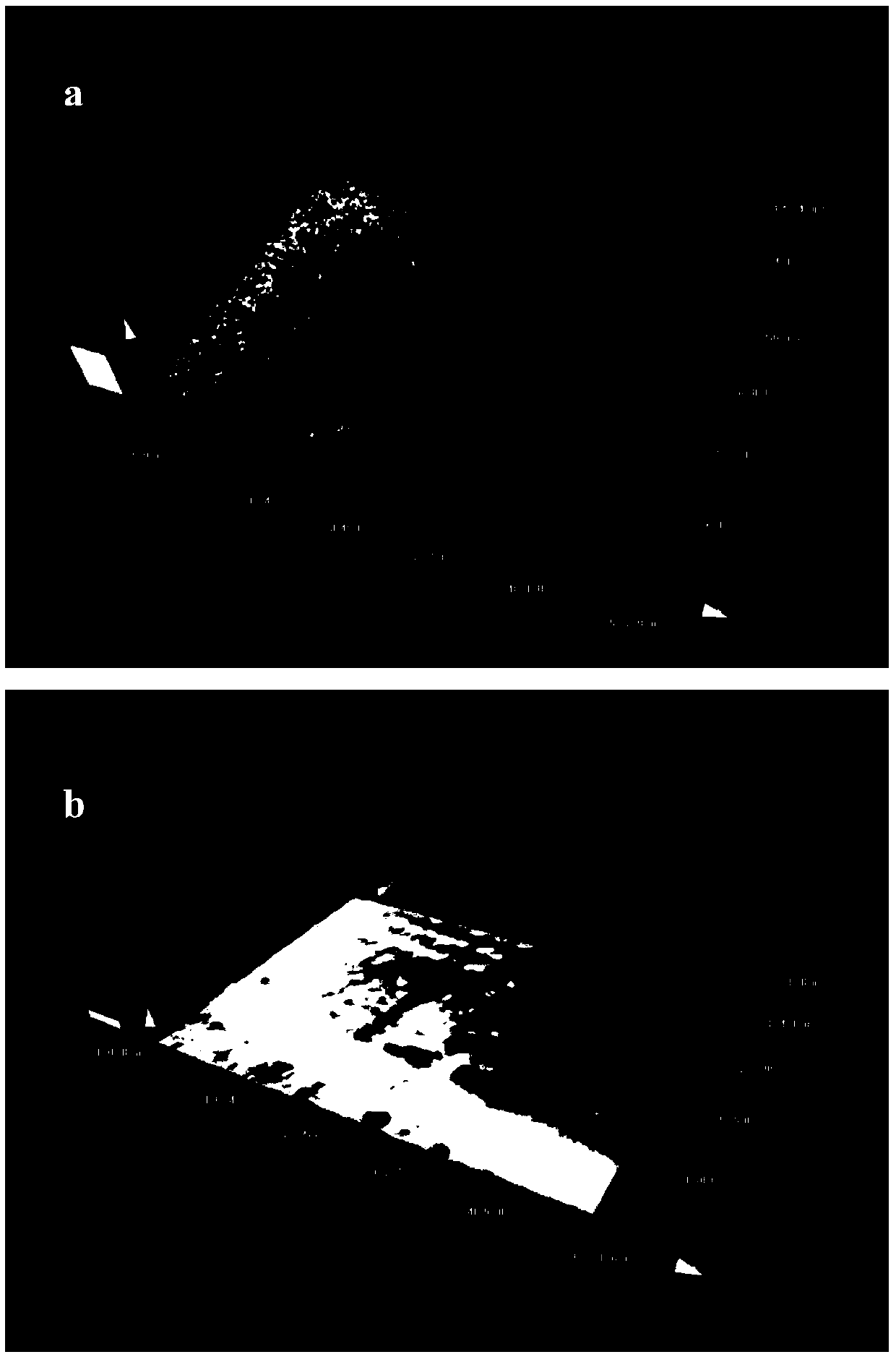

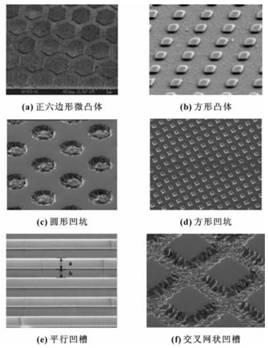

Laser machining method and system of surface composite micro-structure of nodular cast iron material

InactiveCN111571004AImprove friction and wear performanceEliminate microcracksCleaning using liquidsLaser beam welding apparatusCrazingAssembly line

The invention provides a laser machining method and system of a surface composite micro-structure of a nodular cast iron material and belongs to the technical field of laser machining. The laser machining method and system utilize the feature that spherulitic graphite is randomly and evenly distributed in cast iron, and obtain micro-pit arrays in distribution of multiple diameters and depths through ablation of the spherulitic graphite; by adjusting the laser parameters, the micro-pit distribution of the ideal dimension proportion is obtained; and meanwhile, by means of the feature of a laserremelting technology, a surface of a lower roughness is obtained on the peripheral region of the micro-pits, and micro-cracks, scratches and other defects on the original material surface are eliminated. The laser machining method can achieve continuous one-time machining of the composite micro-structure surface, and eliminates the original scratches, micro-cracks and other defects of the materialduring machining at the same time. The prepared composite micro-structure surface has a low friction coefficient and high anti-wear performance. The laser machining method and system of the surface composite micro-structure of the nodular cast iron material has the features of being high in efficiency and low in cost and can achieve assembly line production.

Owner:SHANDONG UNIV OF TECH

Surface modification method of ceramic cutting tool

The invention relates to a surface modification method of a ceramic cutting tool. According to the method, an MEVVA implantation technique is adopted to carry out surface modification on a cleaned cutting tool, wherein implanted ions are any three, four or five kinds of titanium, zirconium, chromium, molybdenum and tungsten ions. After ion implanted modification, the mechanical properties of the ceramic cutting tool are remarkably improved, and the life of the ceramic cutting tool is prolonged, so that the ceramic cutting tool is applicable to the machining of high-hardness and high-strength materials.

Owner:WUXI CHENGBO SCI & TECH DEV

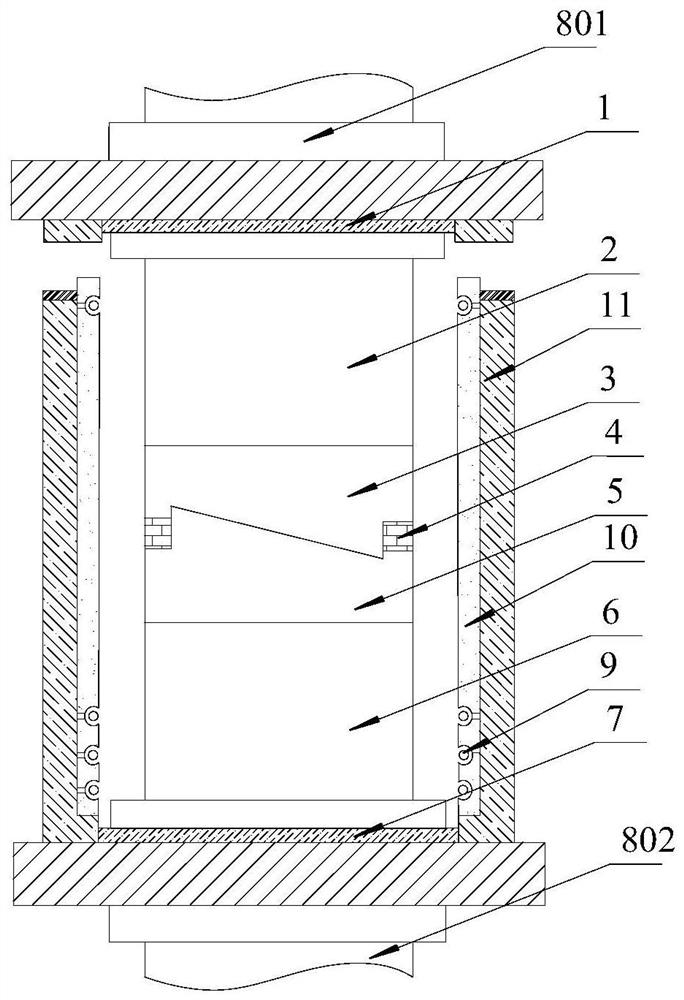

TiAl-based alloy stator blade isothermal forming manufacturing method and device thereof

InactiveCN112122523ARealize forgingReduce consumptionFurnace typesForging/hammering/pressing machinesIsothermal forgingMachining

The invention discloses a TiAl-based alloy stator blade isothermal forming manufacturing method and a device thereof, and belongs to the field of isothermal forming manufacturing methods. The method comprises the steps of machining blank manufacturing, isothermal pre-forging, isothermal final forging and heat treatment. The invention further provides a TiAl-based alloy stator blade isothermal forming device. Compared with a commonly-adopted machining mode that a square blank is extruded and then machined into a part, and due to the fact that the extruded square blank is not deformed, the structure and the performance of a prepared stator blade cannot meet the design requirements, according to the method provided by the invention, blade forging forming is achieved through machining blank manufacturing and isothermal forming, and then the blank is machined into a part. Due to the fact that a TiAl-based alloy is large in deformation resistance and poor in shaping, a common forming methodcannot be achieved, so that the blank manufacturing process is a major problem needing to be solved. According to the method, turning is adopted for blank manufacturing, the blank shape is close to the shape of a final forging, isothermal forging forming is adopted, and uniform deformation of all parts of a blade is achieved, so that the structure and the performance of the blade forging are greatly improved.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

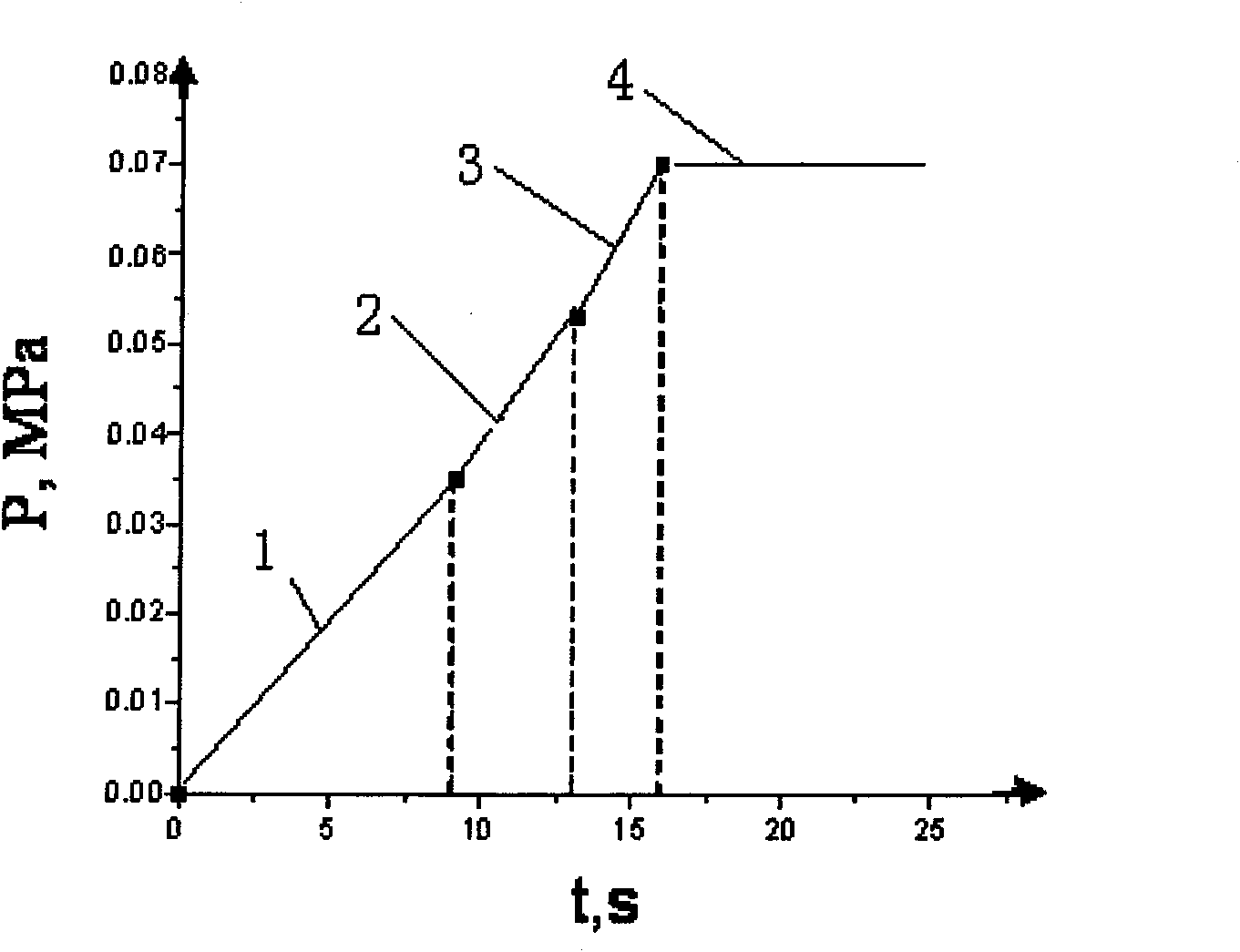

Heat treatment method for hot-dip aluminized coating

InactiveCN104233156AEliminate microcracksHot-dipping/immersion processesTemperature controlWater vapor

The invention discloses a heat treatment method for a hot-dip aluminized coating and relates to a treatment method for an alloy coating. The invention provides a method for converting a hot-dip aluminized coating on the surface of a titanium alloy to a titanium-aluminum protective coating under the conditions of program temperature control and control of a heat treatment atmosphere, wherein the control of the heat treatment atmosphere comprises two situations, one situation is that heat treatment is performed on the hot-dip aluminized coating under vacuum conditions, and the other situation is that the heat treatment is performed on the hot-dip aluminized coating under the conditions of removing water vapor in a system. The program temperature control refers to regulation of the temperature on the part on which the hot-dip aluminized coating is located according to a certain order. Through the method, when the hot-dip aluminized coating on the surface of the titanium alloy is converted to the titanium-aluminum protective coating, the continuous and complete state can be kept, common microcracks in the titanium-aluminum coating are eliminated and the titanium alloy can be further effectively protected.

Owner:SHENYANG INSTITUTE OF CHEMICAL TECHNOLOGY

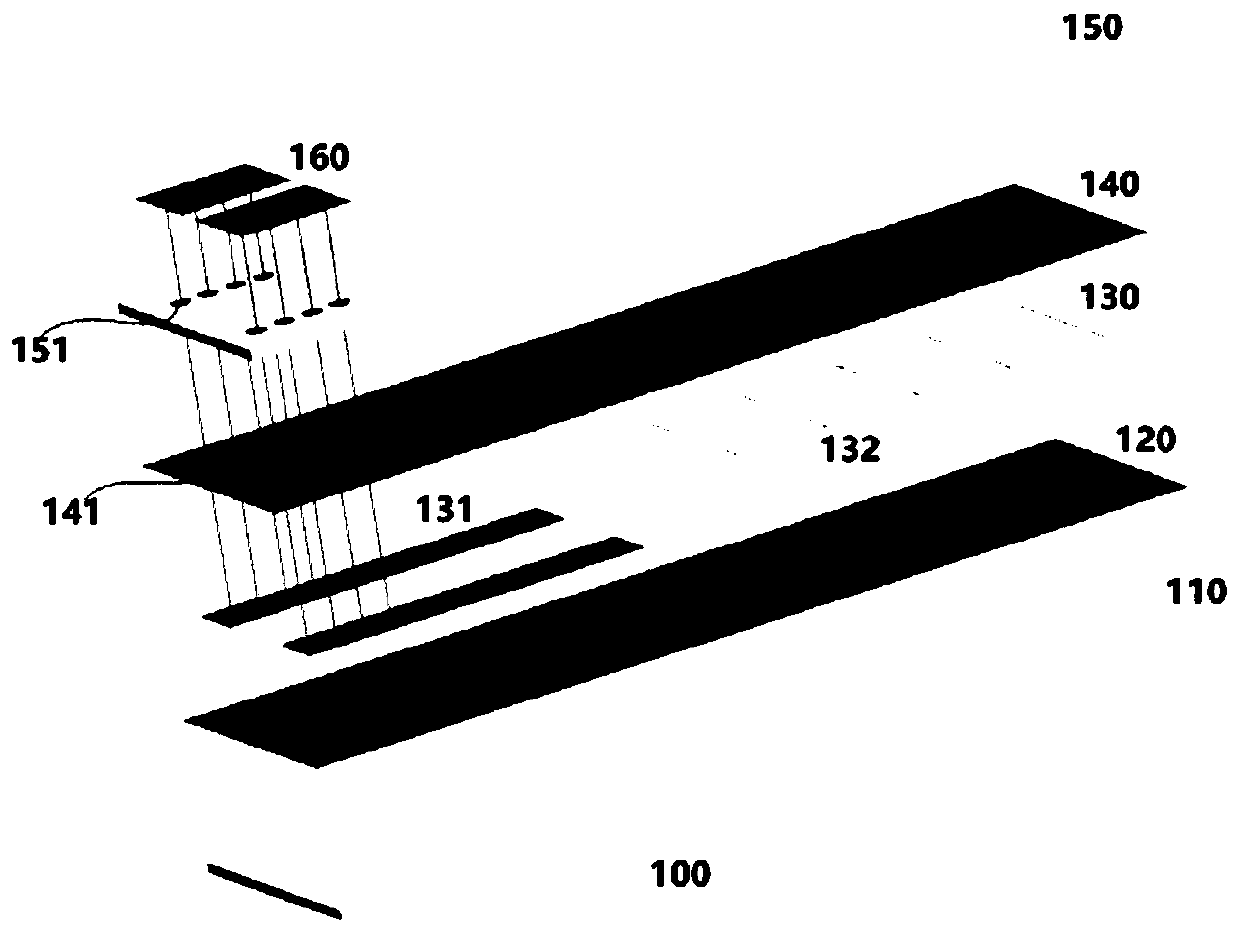

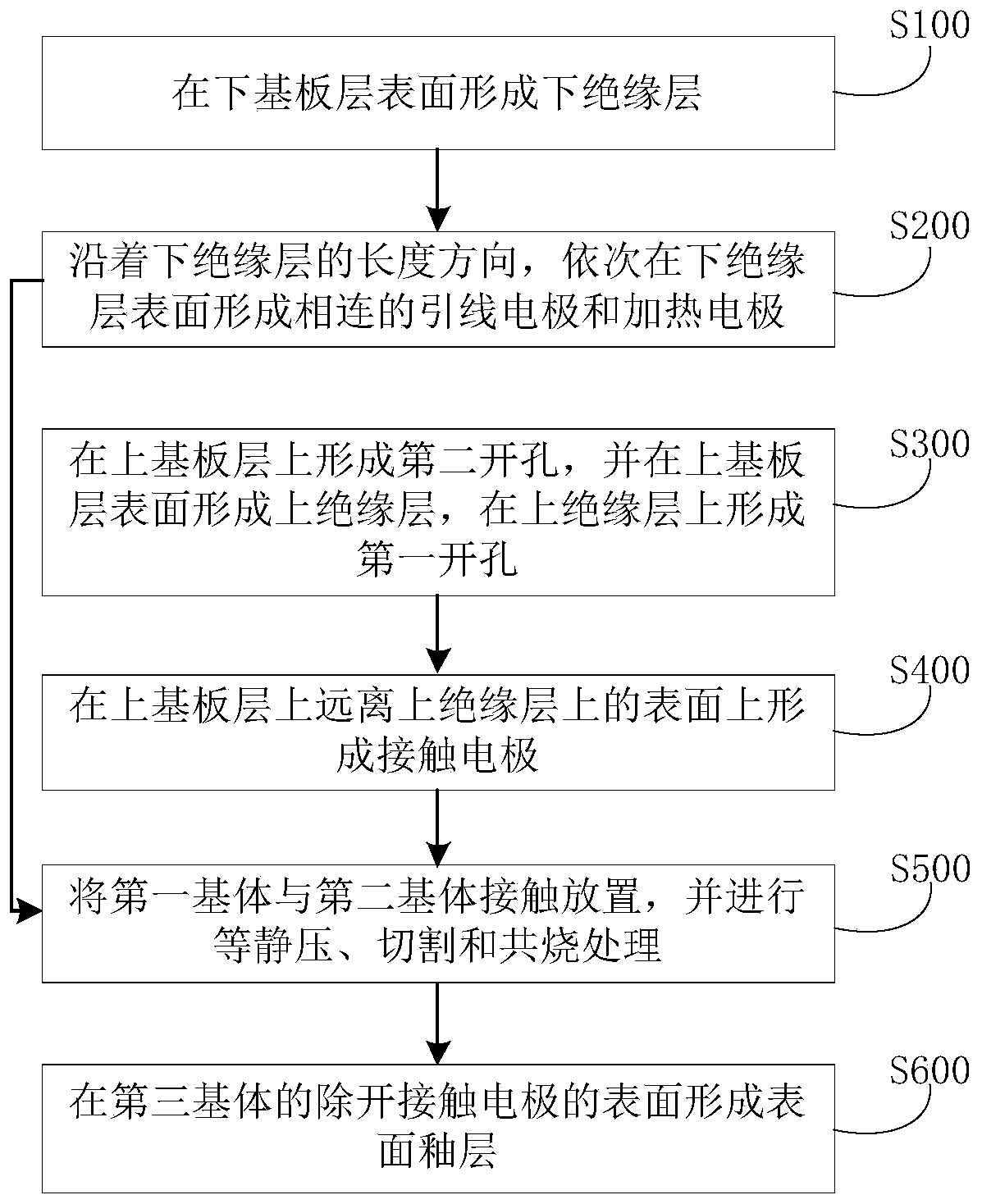

Heating sheet and preparation method and application thereof

PendingCN110101123AAchieve feverReduce manufacturing difficultyTobacco devicesInsulation layerHeating effect

The invention discloses a heating sheet and a preparation method and application thereof. The heating sheet comprises a base body and a surface enamel layer. The base body comprises a lower substratelayer, a lower insulation layer, electrodes, an upper insulation layer, an upper substrate layer and a contact electrode, and the lower insulation layer is arranged on the lower substrate layer; the electrodes are arranged on the lower insulation layer and comprise the lead electrode and the heating electrode which are connected; the upper insulation layer is arranged on the electrodes, and a first open hole is formed in the upper insulation layer; the upper substrate layer is arranged on the upper insulation layer, and a second open hole is formed in the upper substrate layer and connected with the first open hole; the contact electrode is arranged on the upper substrate layer and electrically connected with the lead electrode through the second open hole and the first open hole in sequence; the surface enamel layer is arranged to surround the outer surface of the base body and does not cover the contact electrode. The heating sheet is low in preparation difficulty, long in service life and high in efficiency and has a good heating effect.

Owner:SHENZHEN TAOTAO TECH CO LTD

Preparation process of foldable flexible glass

PendingCN114380510AReduce defectsSimple processGlass severing apparatusGlass tempering apparatusMaterial consumptionLaser cutting

The invention discloses a preparation process of foldable flexible glass. The process of combining two times of chemical thinning with laser cutting and chemical tempering is adopted. The method specifically comprises the steps of first-time chemical thinning, laser cutting, second-time chemical thinning and chemical tempering. Wherein the second-time chemical thinning adopts a vertical soaking method to thin the glass, and meanwhile, defects generated on the edge of the glass after laser cutting are eliminated. According to the preparation process, repeated dispensing and lamination treatment are not needed, so that the process is simplified, the material consumption is reduced, the straight-through yield of the flexible glass with the thickness of less than or equal to 0.05 mm can be effectively improved, and the production cost is reduced.

Owner:凯盛科技股份有限公司 +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com