Method for preparing high-entropy alloy through laser additive manufacturing

A high-entropy alloy and laser additive technology, applied in the directions of additive processing, additive manufacturing, and energy efficiency improvement, can solve the problem of inability to prepare functionally graded high-entropy alloys, and achieve good mechanical properties and improve mechanical properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to facilitate the understanding of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0023] The present invention provides a technical solution for manufacturing "sandwich" shaped functionally graded massive high-entropy alloys by laser additive manufacturing. Mixing, the selected powder purity is 99.99%.

[0024] The stainless steel base is polished with sandpaper, and then cleaned with ethanol to remove surface impurities and prepare for post-processing.

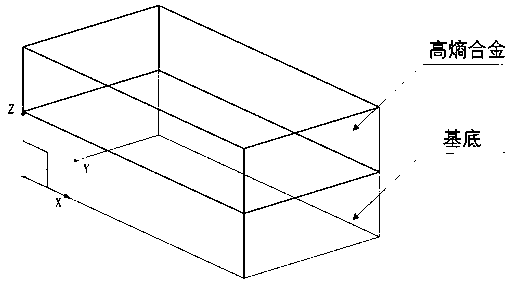

[0025] Such as figure 1 As shown, the present invention is a schematic diagram of preparing a "sandwich" shaped functionally graded bulk Fe, Co, Ni, Cr, Mn high-entropy alloy, and the metal powder is melted and solidified on the substrate to form a bulk entity.

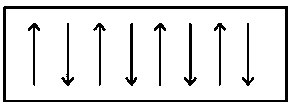

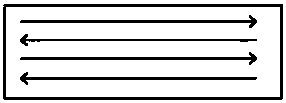

[0026] Laser additive manufacturing, such as figure 2 with image 3 As shown, the laser scanning path is divided into S-shaped scann...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| tensile yield strength | aaaaa | aaaaa |

| microhardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com