Method for deep penetration laser welding of plate under assistance of ultrasound

A deep-penetration welding and ultrasonic-assisted technology, applied in laser welding equipment, welding equipment, welding/welding/cutting items, etc., can solve problems such as root leakage and narrow range of welding process parameters, so as to improve compactness and improve air hole defects , The effect of broadening the range of process parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The following will be combined with the attached Figure 1-6 Specific embodiments of the present invention will be described in detail.

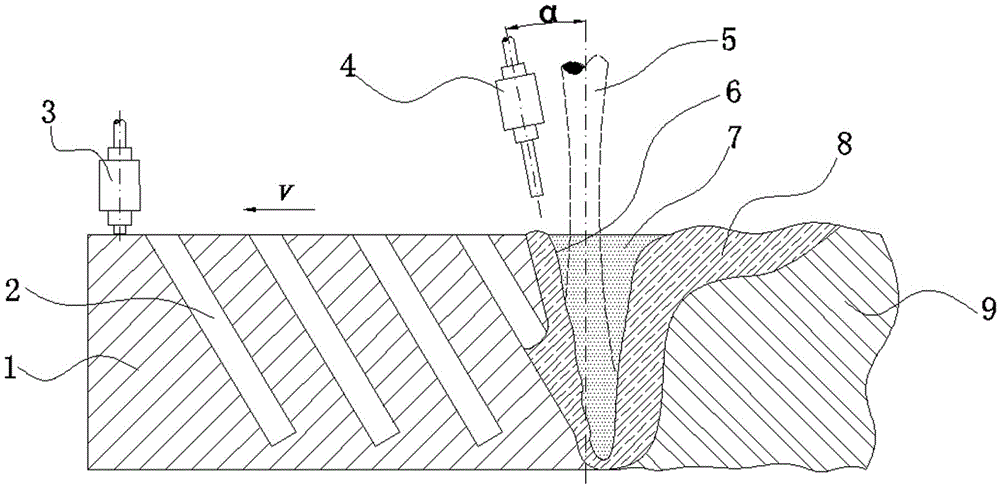

[0035] Such as figure 1 As shown, the welding workpiece is a large structural plate with a thickness exceeding 12 mm. The laser beam is vertically incident on the upper surface of the workpiece to achieve deep penetration welding, and at the same time, ultrasonic vibration is applied to the workpiece to be welded and the molten pool area to achieve high-quality connections of ultrasonic-assisted laser deep penetration welding of large-thickness flat butt joints.

[0036] In this embodiment, the method for ultrasonic-assisted laser deep penetration welding of plates includes the following steps.

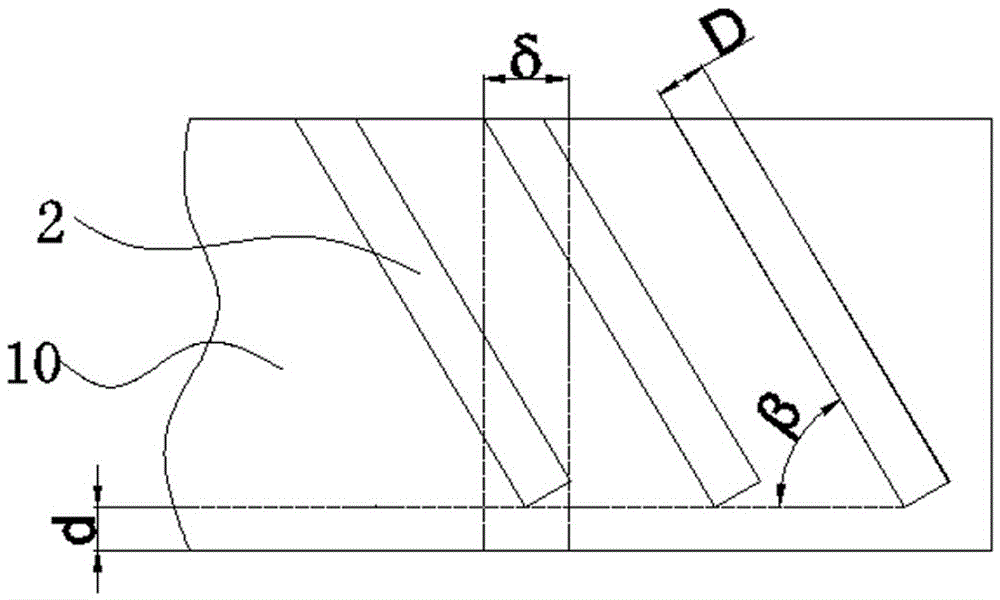

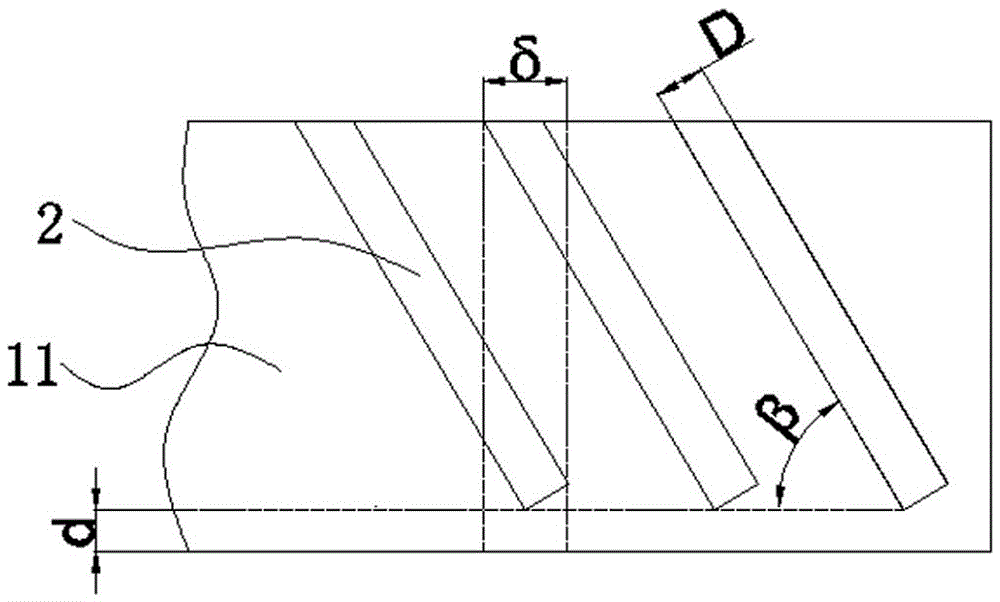

[0037] Step 1: The first base material 10 and the second base material 11 are processed to form butt end faces, and a series of inclined semicircular grooves 2 are processed on the butt end faces, and the upper and lower surfaces and butt j...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com