A kind of pretreatment method of low-silver-lead alloy surface

A lead alloy and pretreatment technology, applied in the field of metal surface treatment, can solve problems such as high risk, and achieve the effect of simple composition, convenient preparation, and wide range of process parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

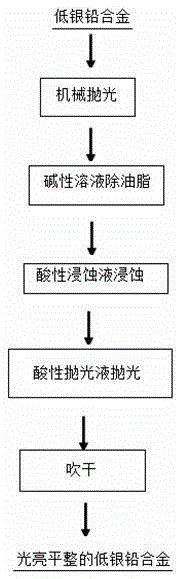

[0020] Such as figure 1 Shown, the pretreatment method of this low-silver-lead alloy surface, its concrete steps are as follows:

[0021] (1) First, mechanically polish the surface of the low-silver-lead alloy. After polishing, wash it twice with deionized water. The mass percentage of silver in the low-silver-lead alloy is 0.3%. The surface of the low-silver-lead alloy is smooth;

[0022] (2) Put the low-silver-lead alloy treated in step (1) into an alkaline solution, degrease at 60°C for 5 minutes, and then wash it twice with deionized water. The components of the alkaline solution It is sodium hydroxide, trisodium phosphate, sodium silicate and distilled water. The ratio of the mass of sodium hydroxide to the volume of distilled water is 15:1g / L, and the ratio of the mass of trisodium phosphate to the volume of distilled water is 20:1g / L , the ratio of the mass of sodium silicate to the volume of distilled water is 5:1g / L;

[0023] (3) Put the low-silver-lead alloy treat...

Embodiment 2

[0026] Such as figure 1 Shown, the pretreatment method of this low-silver-lead alloy surface, its concrete steps are as follows:

[0027] (1) First, mechanically polish the surface of the low-silver-lead alloy. After polishing, wash it twice with deionized water. The mass percentage of silver in the low-silver-lead alloy is 1.0%. The mechanical polishing is scraping, and the degree of mechanical polishing is up to The surface of silver-lead alloy is smooth;

[0028] (2) Put the low-silver-lead alloy treated in step (1) into an alkaline solution, degrease at 80°C for 10 minutes, and then wash it twice with deionized water. The components of the alkaline solution It is sodium hydroxide, trisodium phosphate, sodium silicate and distilled water, wherein the ratio of the mass of sodium hydroxide to the volume of distilled water is 25:1g / L, and the ratio of the mass of trisodium phosphate to the volume of distilled water is 30:1g / L L, the ratio of the mass of sodium silicate to th...

Embodiment 3

[0032] Such as figure 1 Shown, the pretreatment method of this low-silver-lead alloy surface, its concrete steps are as follows:

[0033] (1) First, mechanically polish the surface of the low-silver-lead alloy. After the polishing is completed, wash it twice with deionized water. The mass percentage of silver in the low-silver-lead alloy is 0.5%. The mechanical polishing is grinding, and the degree of mechanical polishing is until low The surface of silver-lead alloy is smooth;

[0034] (2) Put the low-silver-lead alloy treated in step (1) into an alkaline solution, remove grease for 8 minutes at a temperature of 70°C, and then wash it twice with deionized water. The components of the alkaline solution It is sodium hydroxide, trisodium phosphate, sodium silicate and distilled water. The ratio of the mass of sodium hydroxide to the volume of distilled water is 20:1g / L, and the ratio of the mass of trisodium phosphate to the volume of distilled water is 25:1g / L , the ratio of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com