Tin plating solution for copper electronic material as well as preparation method and application method of tin plating solution

A technology of electronic materials and application methods, applied in the field of electroless plating, can solve the problems of easy plating of terminals, affecting conductivity, low damage and so on, and achieving the effects of easy degradation, low porosity, and high production stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

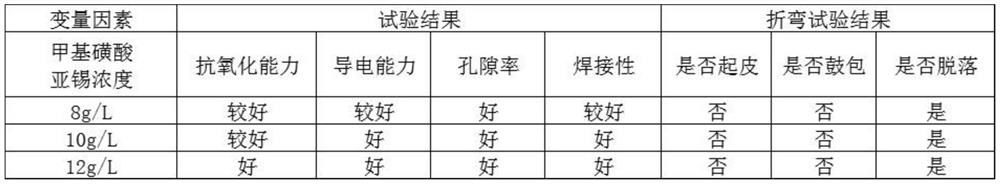

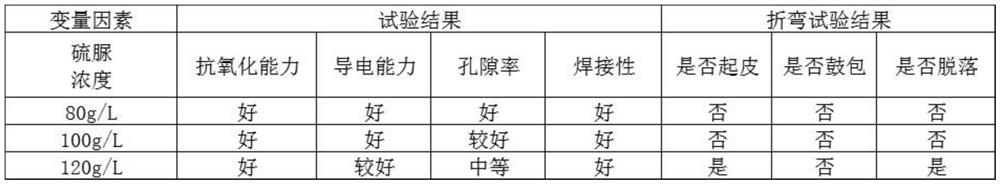

Embodiment 1

[0036] The formula of electroless tin plating solution is: 8g / L stannous methanesulfonate, 60g / L thiourea, 1g / L silver methanesulfonate, 4g / L EDTA, 104ml / L methanesulfonic acid , 66ml / L reducing agent, 0.25g / L auxiliary brightener (other additives are not shown one by one);

[0037] The process conditions of the electroless tin plating solution are as follows: the temperature of the plating solution is 35±2° C., the pH value is 1.0, the electroless plating time is 15 minutes, and the loading amount of the plating solution is 1.2 dm2 / L.

Embodiment 2

[0039] The formula of electroless tin plating solution is: 10g / L stannous methanesulfonate, 60g / L thiourea, 1g / L silver methanesulfonate, 4g / L EDTA, 104ml / L methanesulfonic acid , 66ml / L reducing agent, 0.25g / L auxiliary brightener (other additives are not shown one by one);

[0040] The process conditions of the electroless tin plating solution are as follows: the temperature of the plating solution is 35±2° C., the pH value is 1.0, the electroless plating time is 15 minutes, and the loading amount of the plating solution is 1.2 dm2 / L.

Embodiment 3

[0042] The formula of electroless tin plating solution is: 12g / L stannous methanesulfonate, 60g / L thiourea, 1g / L silver methanesulfonate, 4g / L EDTA, 104ml / L methanesulfonic acid , 66ml / L reducing agent, 0.25g / L auxiliary brightener (other additives are not shown one by one);

[0043] The process conditions of the electroless tin plating solution are as follows: the temperature of the plating solution is 35±2° C., the pH value is 1.0, the electroless plating time is 15 minutes, and the loading amount of the plating solution is 1.2 dm2 / L.

[0044] The thickness of the electroless plating layer in Example 1 is 0.83 μm, the appearance is silver white, the mass percentage of tin is 93.4 wt %, and the porosity is less than 4 pieces / 6cm 2 . In the tin-lead alloy whose flux is 25% rosin isopropanol and the solder is 60% tin + 40% lead, the wetting time is less than 3s, and the solderability is better. After passivation treatment, after being placed in the atmosphere for 3 months, th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com