A welding method for obtaining amorphous joints for fesib amorphous strips

A technology of amorphous strip material and welding method, which is applied in the field of amorphous material and welding, can solve the problems of difficult welding of FeSiB amorphous strip material and limited application, and achieves wide range of process parameters, strong adaptability, and simple welding tooling Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

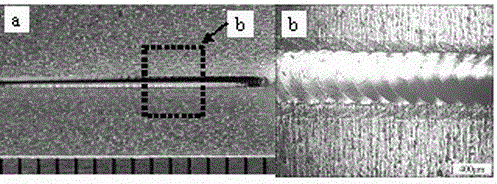

[0031] Embodiment: welding process of the present invention is as follows:

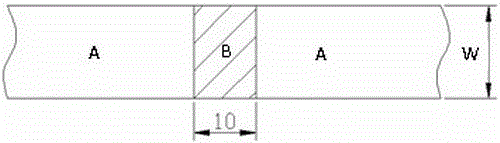

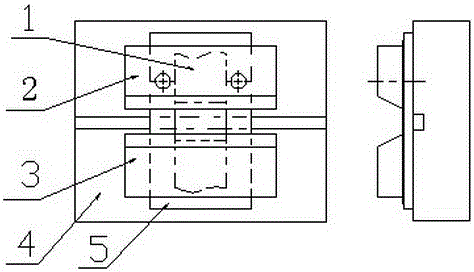

[0032] Welding equipment: L80 Nd:YAG pulsed laser welding machine from Italy SISMA company, the spot diameter is Φ0.3mm, the surface is focused, the welding speed is 0.3m / min, the argon gas flow rate is 8L / min, and the pulse power P and pulse width are changed T, pulse frequency F.

[0033] 1. Preparation stage before welding

[0034] According to the characteristics of the welding fixture, the size of the iron-based amorphous alloy sample is 40mm×15mm×25μm. The surface of the welded sample was polished with sandpaper to remove the surface oxide layer and stains, and then cleaned with absolute ethanol and dried to prevent rust. Before laser welding, preheat the welding machine for 20 minutes, and deflect the laser beam by 5 o Obliquely incident on the surface of the sample, the plasma is suppressed by side-blowing argon shielding gas with a purity of 99.9%, and the welding pool is protected. The si...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com