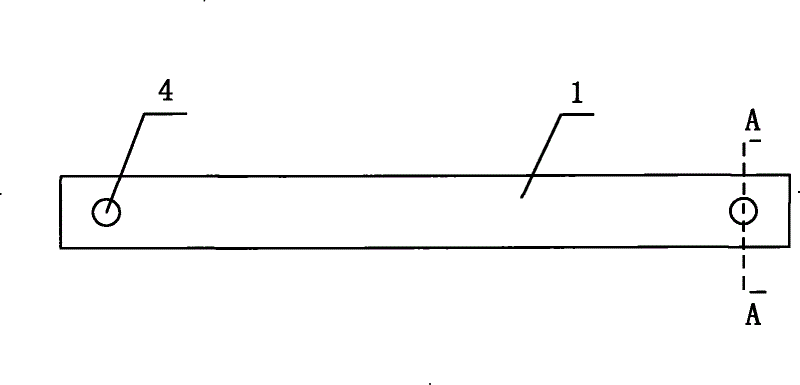

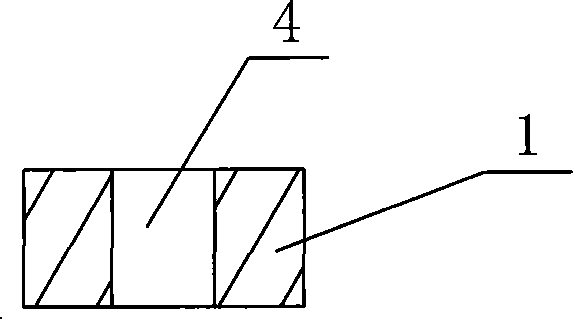

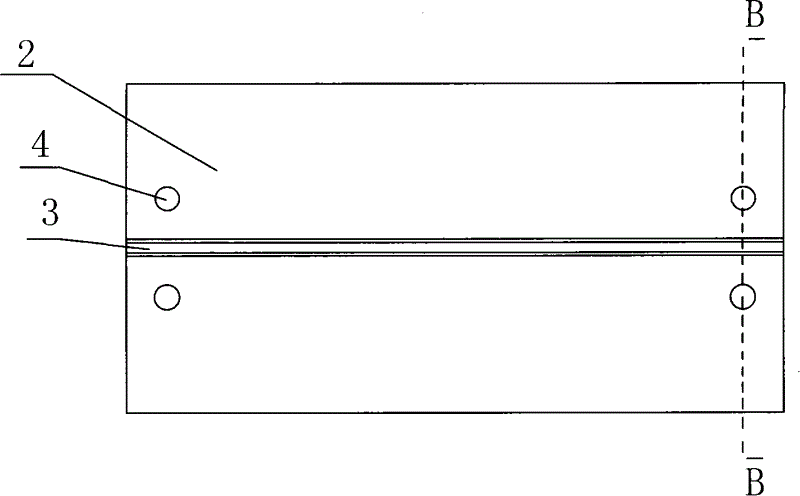

Electro-beam welding method of niobium alloy and titanium alloy thick plate

A technology of electron beam welding and niobium alloy, which is applied in the direction of electron beam welding equipment, welding equipment, welding equipment, etc., can solve the problems of plate warping and deformation, and achieve the effect of solving warping deformation, reducing weight and good use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0034] The process steps of the electron beam welding method for niobium alloy and titanium alloy thick plates described in this embodiment are substantially the same as those in the first preferred embodiment. However, the Nb521 alloy with a thickness of 7.4 mm and a length of 300 mm was butt-welded with a TC4 alloy. Similarly, first use the same method to process the welding surfaces of the two weldments, and finally process the welding surfaces of the two weldments into a smooth surface with a roughness Ra≤1.6μm and perpendicular to the adjacent surfaces of the plates; after that, Prepare acid solution for pickling, the difference is that the acid solution for pickling Nb521 niobium alloy thick plate is made of HF, HNO 3 and H 2 O is mixed and prepared at a volume ratio of 1:5:10; and the acid solution for pickling TC4 titanium alloy thick plates is composed of HF, HNO 3 and H 2 O is prepared by mixing with a volume ratio of 1:5:10. The pickling reaction time is 10 minu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com