IGBT module packaging welding method and packaging welding structure

A module packaging and welding structure technology, applied in the direction of electrical components, electrical solid devices, circuits, etc., can solve the problems of lowering the level of application development, difficulty in packaging, and inducing system risks, so as to improve the performance and reliability of operation, reduce the The difficulty and cost of packaging, and the effect of automatic welding alignment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described in detail in conjunction with the accompanying drawings and specific embodiments.

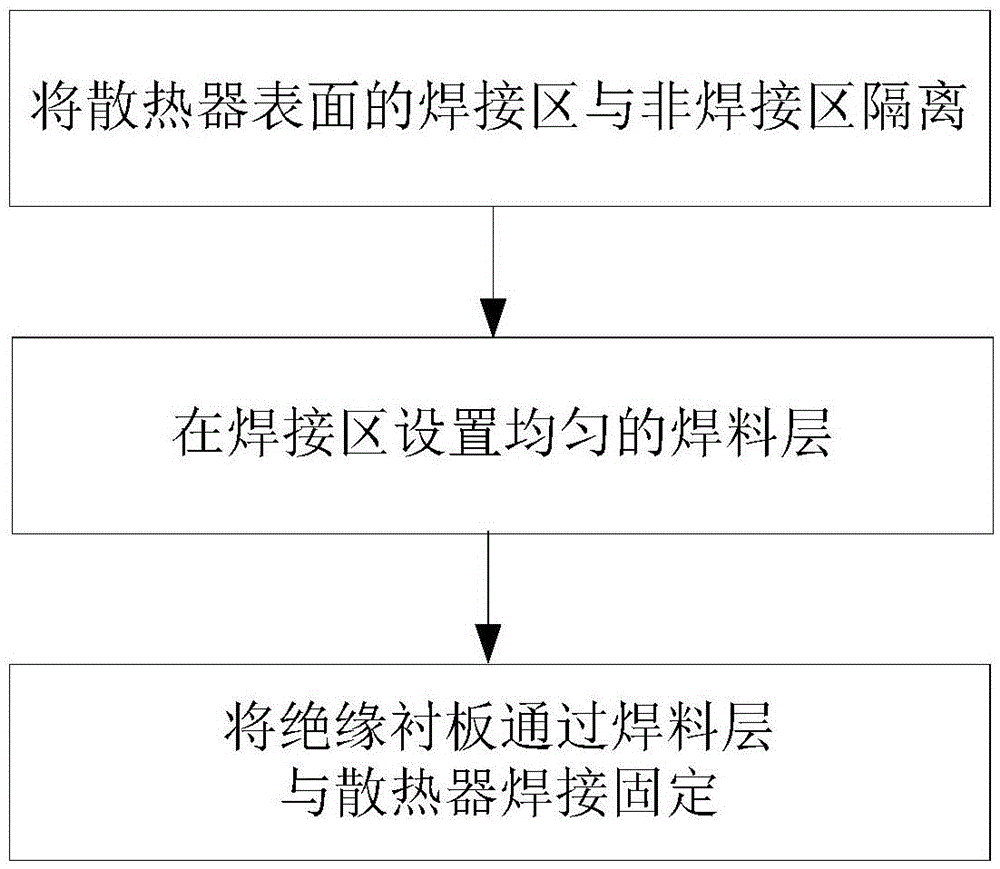

[0030] like figure 1 As shown, the IGBT module package welding method of the present embodiment includes the following steps:

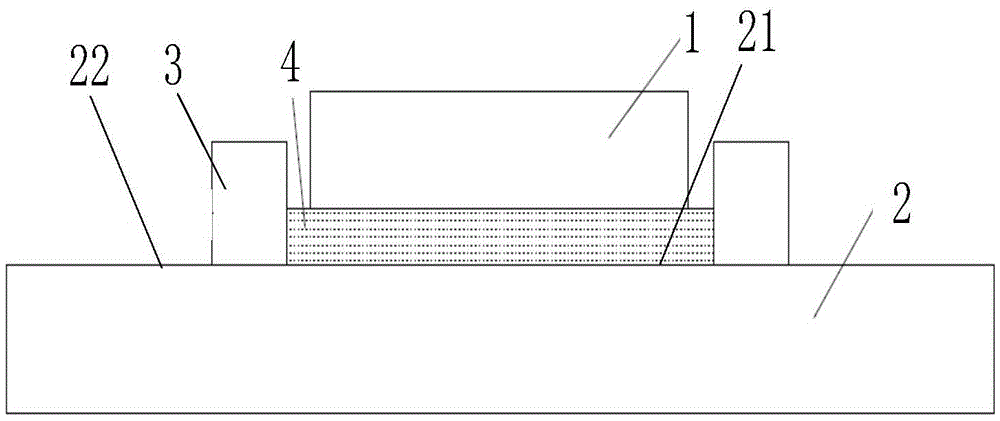

[0031] Step 1): Isolate the welding area 21 on the surface of the radiator 2 from the non-welding area 22;

[0032] Step 2): setting a uniform solder layer 4 on the welding area 21; Step 3): welding and fixing the insulating liner 1 to the heat sink 2 through the solder layer 4 .

[0033] The present invention isolates the welding area 21 and the non-welding area 22 on the surface of the radiator 2, avoids the overflow of solder, makes the insulating lining board 1 reliably welded in the welding area 21 during welding, and realizes the automatic welding alignment of the insulating lining board 1, In addition, the insulating liner 1 is directly welded and packaged by solder, which simplifies the package structure,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com