Patents

Literature

58 results about "Surface enamel" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

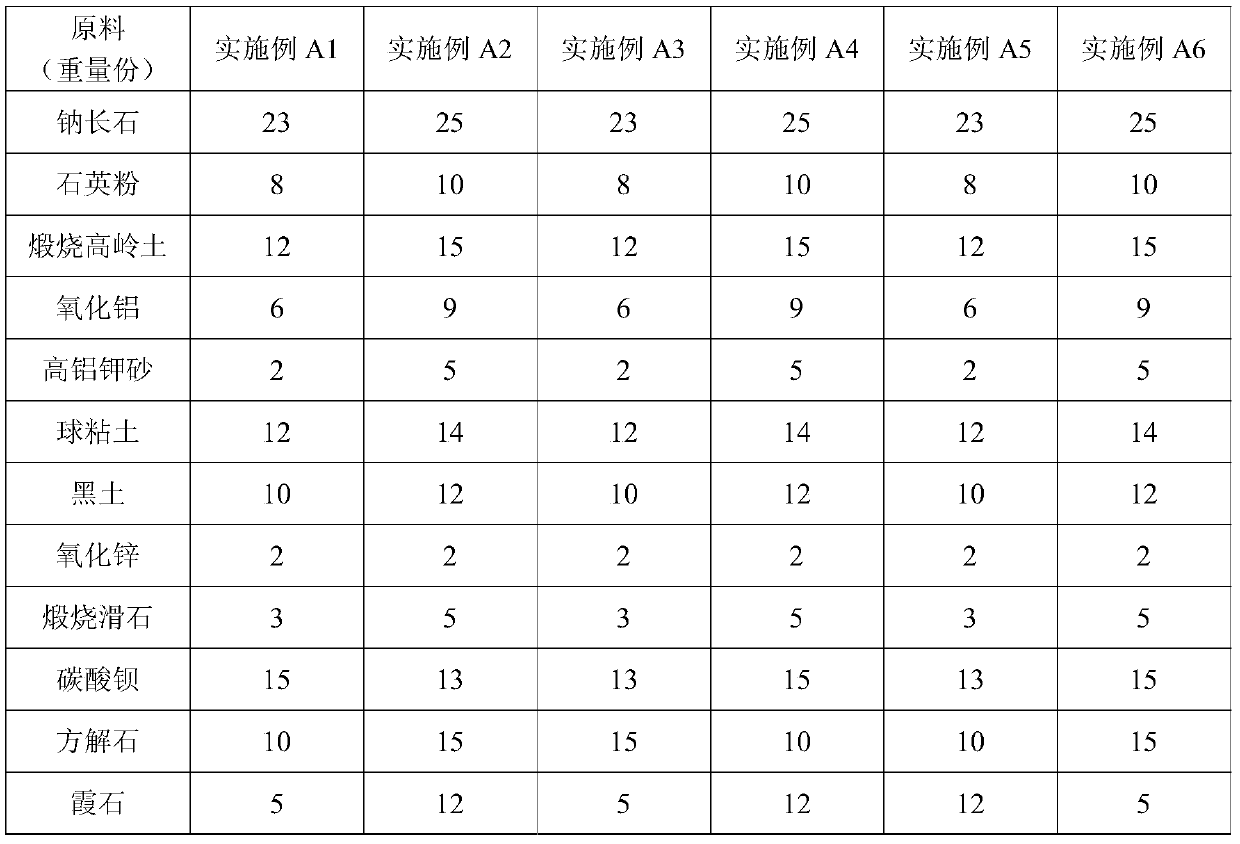

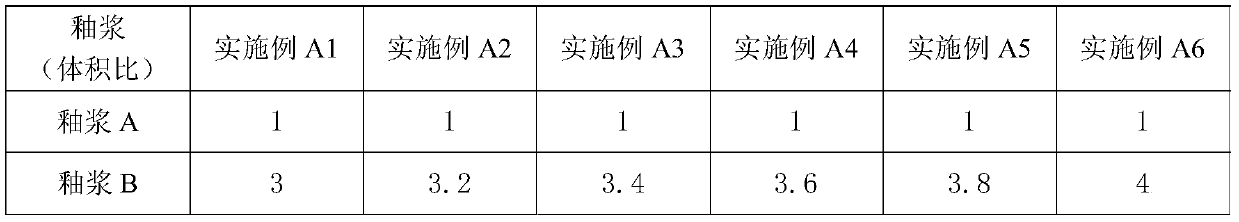

Stereo-positioning effect dry granule complete-polished ceramic brick and preparation method thereof

PendingCN110396005AImprove flatnessImprove the three-dimensional effectPigmenting treatmentIrregular area designBrickDesign pattern

The invention provides a stereo-positioning effect dry granule complete-polished ceramic brick and a preparation method thereof. The stereo-positioning effect dry granule complete-polished ceramic brick comprises a blank body, a surface enamel layer, an ink-jet printing pattern layer, a colorful dry granule layer and a transparent dry granule layer from bottom to top. According to the brick, the colorful dry granule layer and the transparent dry granule layer are combined as a dual dry granule layer, a high-flatness enamel surface can be obtained after the transparent dry granule layer is sintered and polished, a colorful dry granule enamel has an overlapping suspension effect in the enamel surface, and then a dry granule enamel pottery ceramic brick which is capable of sufficiently embodying color layers and texture effects of designed patterns, is good in stereoscopic effect, glittering and translucent in transparency, fine in texture and bright in color can be produced.

Owner:MONALISA GRP CO LTD

Preparation method of matt antifouling dry granular glaze and glaze slip, tile and preparation method thereof

The invention discloses a matt antifouling dry granular glaze. The matt antifouling dry granular glaze comprises a glaze C used for forming a first enamel layer and a glaze D used for forming a secondenamel layer, the glaze C is formed by combining a glaze A and a glaze B, and the glaze D is formed by mixing the glaze A and a high-temperature frit; the raw materials of the glaze A make a liquid phase locally generated when the glaze is at 950-1050 DEG C; the glaze B adjusts formation of a glass phase by utilizing barium carbonate, calcite and zirconia. Correspondingly, the invention further discloses a preparation method of the glaze, a matt antifouling dry granular tile and a preparation method thereof. The matt antifouling dry granular tile is an archaized brick, a surface enamel layeris composed of the first enamel layer formed by the glaze C and the second enamel layer formed by the glaze D, the first enamel layer has the advantages of low glossiness and good compactness, the second enamel layer has the advantage of good compactness, so that the enamel layer of the archaized brick has the advantages of low glossiness and good antifouling performance on the whole, and the subsidence sandstone granular sensation of the enamel layer of the archaized brick can improve the archaized effect of the archaized brick.

Owner:FOSHAN DONGPENG CERAMIC +2

Preparation method of enamel plates

The invention discloses a preparation method of enamel plates, which includes the following steps of A, pretreating a steel plate; B, preparing enamel materials: (i) preparing ground enamel powder and (ii) preparing surface enamel powder; C, spraying prepared ground enamel powder to the surface of the pretreated steel plate uniformly by a coating spraying gun; D, disposing an enamel plate with the ground enamel powder at the temperature ranging from 700 DEG C to 740 DEG C and baking and drying for 2 to 3 minutes so as to form the enamel plate with ground enamel; E, spraying the prepared surface enamel powder to the enamel plate with the ground enamel uniformly by the coating spraying gun so as to form the enamel plate with the surface enamel powder; and F, disposing the enamel plate with the surface enamel powder at the temperature ranging from 680 DEG C to 720 DEG C and baking and drying for 2 to 5 minutes. The preparation method is simple, low in cost and fine in operation, and the enamel plate prepared by the preparation method has the advantages of no chalk powder pollution, cleanness and sanitation, excellent visual effect, durability and wear resistance, long service life and the like, is not easy to be peeled off and can be widely used as writing plates.

Owner:何玉良

Tooth enamel rejuvenating toothpaste

InactiveUS20050084461A1Reduced tendency to pick up stainHard surfaceCosmetic preparationsToilet preparationsTooth enamelToothpaste

An oral composition is provided which is effective for mineralization of surface enamel comprising a first part containing a partially water soluble calcium salt and a second part containing a fluoride salt and a bicarbonate salt. The oral composition can be a toothpaste and wherein the second part preferably contains sufficient bicarbonate salt to provide a fresh, clean feeling to the oral cavity.

Owner:CHURCH & DWIGHT CO INC

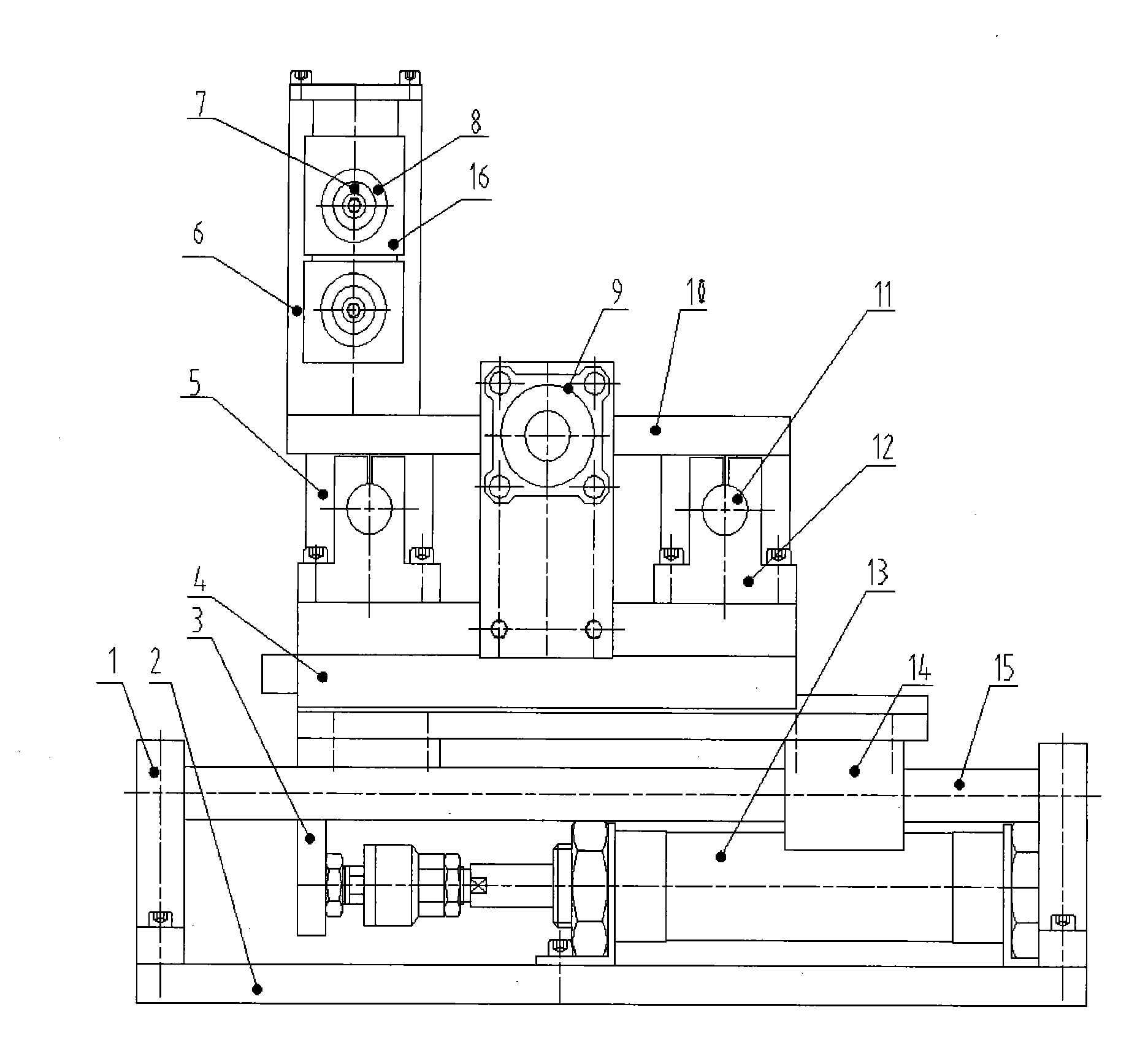

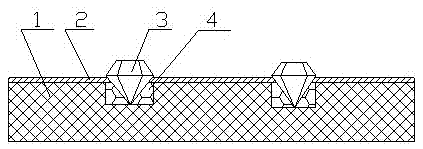

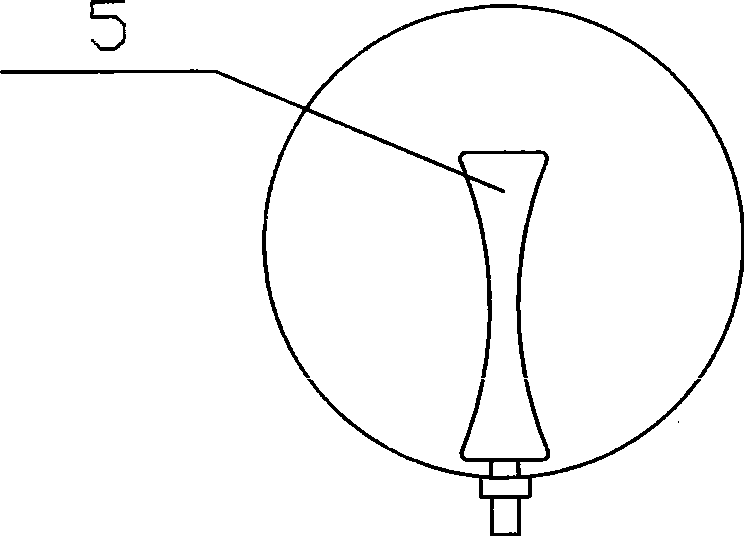

Enamel removing device for enamelled wire

InactiveCN101656391AGuaranteed peeling effectSimple structureLine/current collector detailsApparatus for removing/armouring cablesLacquerMechanical equipment

The invention belongs to electrical mechanical equipment, and particularly relates to a surface enamel removing device on a crimping machine of a wiring terminal for stator lead. The device is characterized in that a base plate is provided with a vertical moving mechanism, a transverse moving mechanism which is arranged on an intermediate fixed plate of the vertical moving mechanism, and an enamelremoving mechanism which is arranged on an upper fixed plate of the transverse moving mechanism. The device has the advantages of simple structure, good enamel removing effect, high manufacturing efficiency and long service life.

Owner:LONGKOU ZHONGJI ELECTRICAL MACHINERY

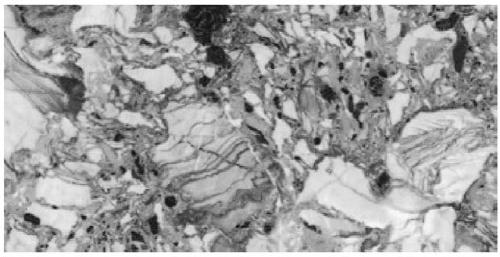

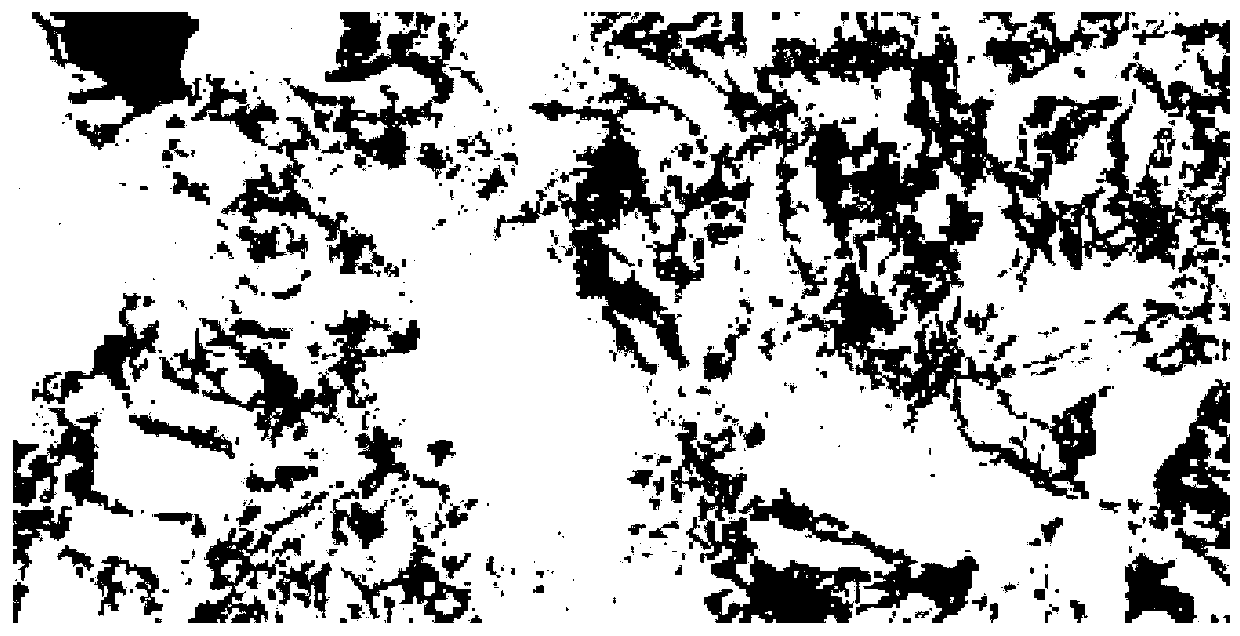

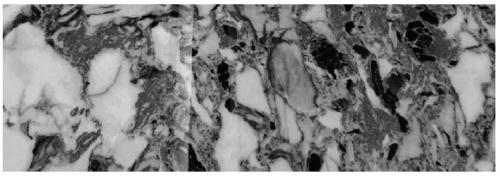

Ceramic tile made of simulated sandstone and preparation process of ceramic tile

The invention discloses a ceramic tile made of simulated sandstone and a preparation process of the ceramic tile. The ceramic tile comprises a ceramic tile green body and an enamel layer on the surface of the ceramic tile green body. The ceramic tile is characterized in that stone-shaped stripes and ink jet coarse sandstone patterns are printed on the surface of the enamel layer, the enamel layer sequentially comprises a bottom enamel layer, a surface enamel layer, a first-time dot enamel layer, a second-time dot enamel layer, a protection enamel layer and a dry granular enamel layer, an area of the first-time dot enamel layer accounts for 95-99.9% that of the surface of the ceramic tile, and an area of the second-time dot enamel layer accounts for 70-90% of that of the ceramic tile. Processes of repeated enameling and distributing, drum, ink jet, dry granule distributing and single-roller letterpress printing are adopted, multilayer texture and multilayer enamel color are formed, and an effect like natural real sandstone formed by nature is completely realized.

Owner:白刚

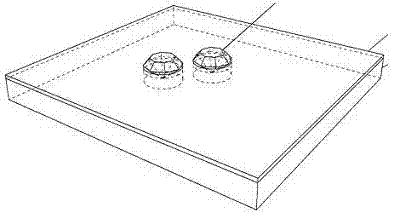

Mobile phone shell with crystals and diamonds embedded in colored patterns and manufacturing method thereof

InactiveCN102361485AImprove consumption levelTransparentDecorative surface effectsSpecial ornamental structuresComputer Aided DesignManufacturing technology

The invention relates to a mobile phone shell with crystals and diamonds embedded in colored patterns and a manufacturing method thereof, wherein ornaments such as the crystals, the diamonds and the like are embedded on the surface of the mobile phone shell with the colored patterns, the surface of the mobile phone shell is a colored pattern surface, holes are formed in the colored pattern surface, and solid crystals or the diamonds and precious stones are embedded in the holes. The mobile phone shell and the manufacturing method thereof have the advantages that: 1, the aim of manufacturing any colored drawing pattern on the mobile phone shell or the surface of a protective shell is fulfilled by adopting a computer-aided design technique and a manufacturing technique; 2, the solid crystals or the diamond and the precious stones are embedded on the colored pattern surface on the surface of the mobile phone shell, and the crystals, the diamonds and the precious stones embedded in the colored patterns are like shining stars, therefore, the consumption level of a mobile phone is improved, and the demands of specific people are satisfied; and 3, with the adoption of the design of a colored pattern surface enamel layer, the colored patterns have the advantages of permeability, glossiness, abrasion resistance and strong adhesive force.

Owner:ZHEJIANG FUCHUNJIANG MOBILE COMM TECH

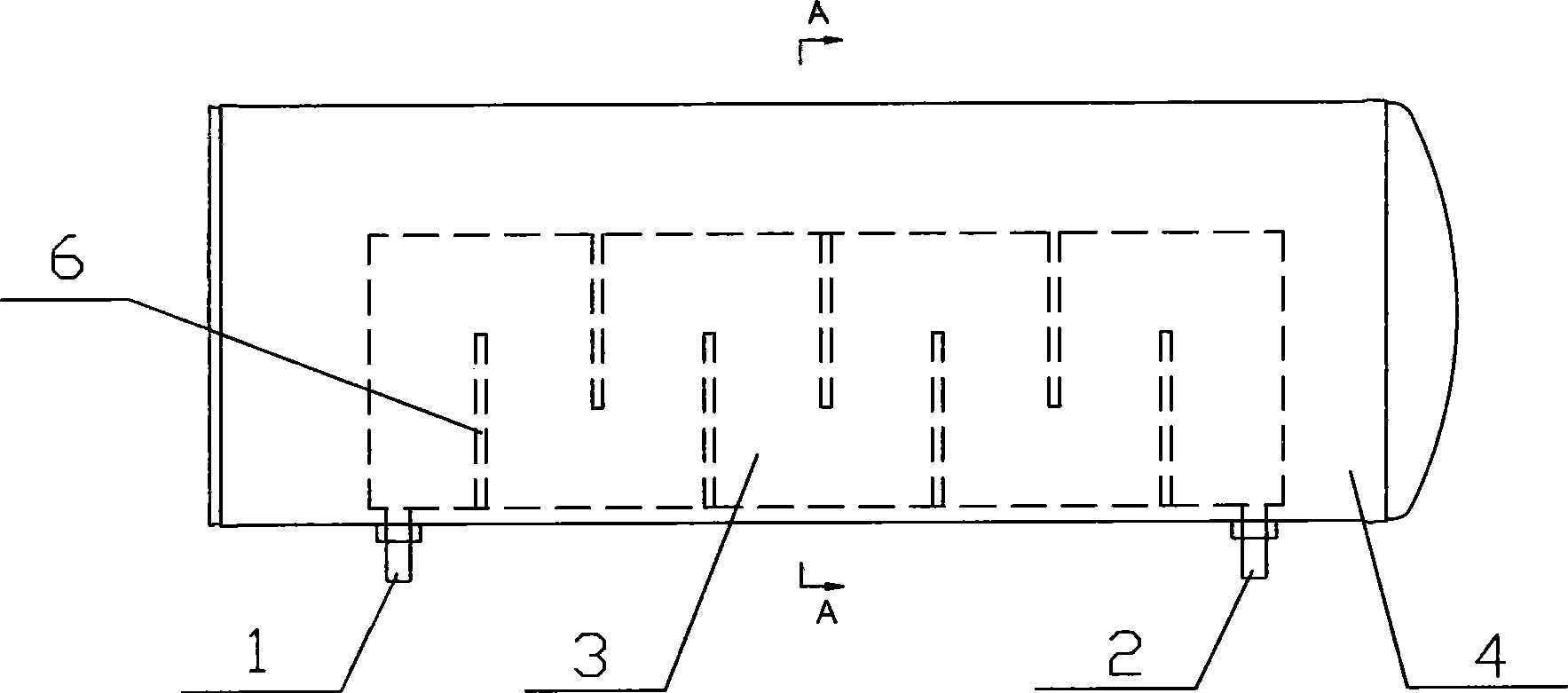

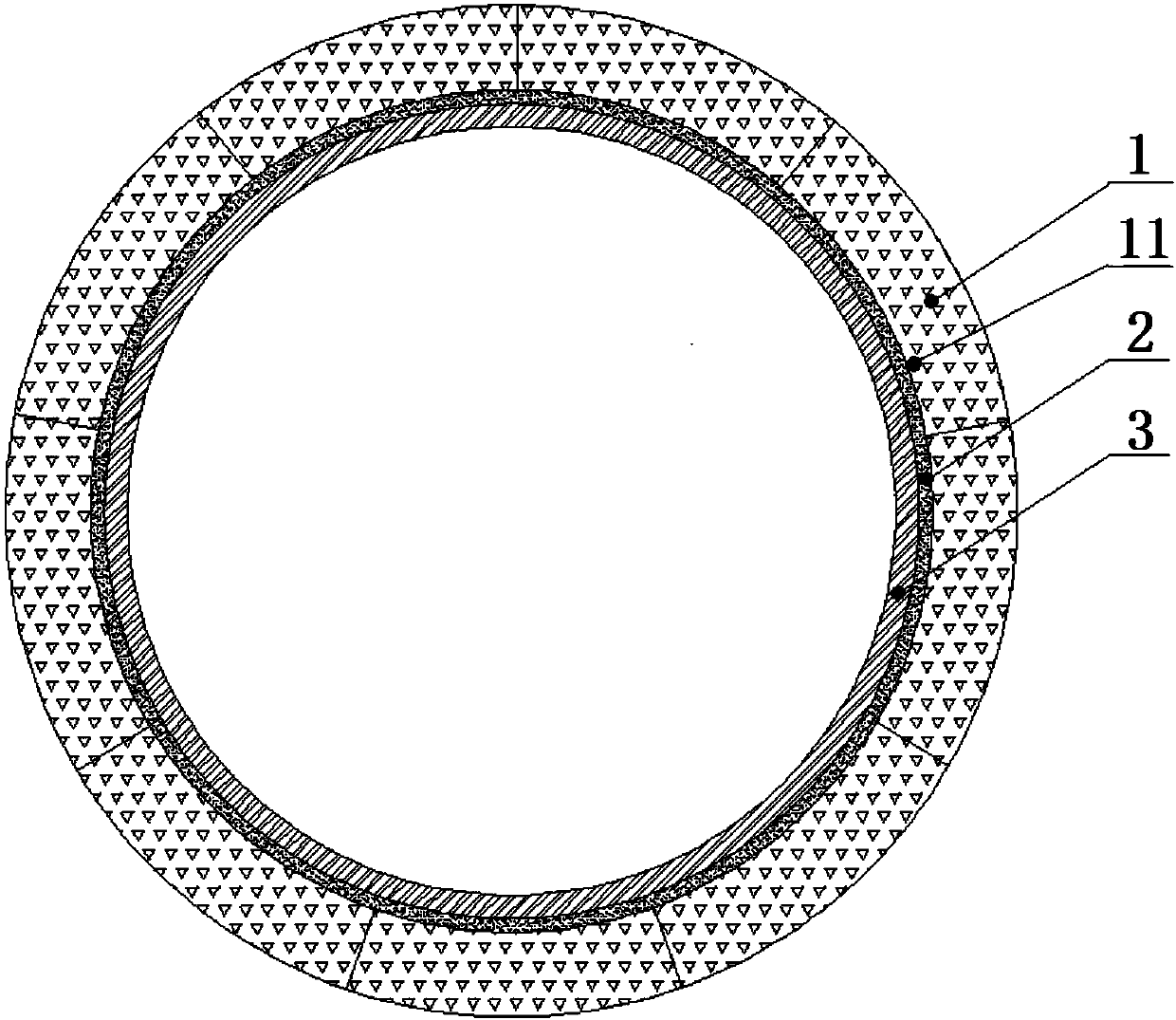

Solar water box with steady flow big heat-exchange surface porcelain enamel heat-exchanging liner

InactiveCN101457995AReduce volumeControl flowSolar heat devicesSolar thermal energy generationSolar waterEngineering

The invention discloses a solar energy water tank with a steady flow large heat-transfer surface enamel heat exchanging liner, comprising medium circulating interfaces (1, 2), a heat exchanger (3) and a liner main body (4). The heat exchanger (3) is long and narrow dolioform structure, a section (5) of which is dolioform. A stiffener (6) which is distributed in an up and down staggered way can be arranged in the heat exchanger (3). With the structure adopted, the long and narrow dolioform heat exchanger reduces the volume occupied in the water tank, enlarges the relative heat exchanging surface area and can ensure the heat exchanging effect. The stiffener which is distributed in the heat exchanger in the up and down staggered way improves the pressure bearing capacity and can control the flowing of water to be stable.

Owner:JIANGSU GMO HI TECH

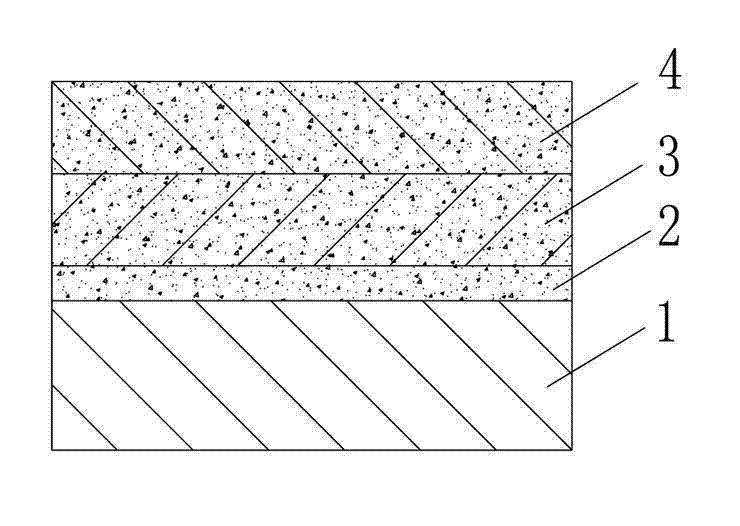

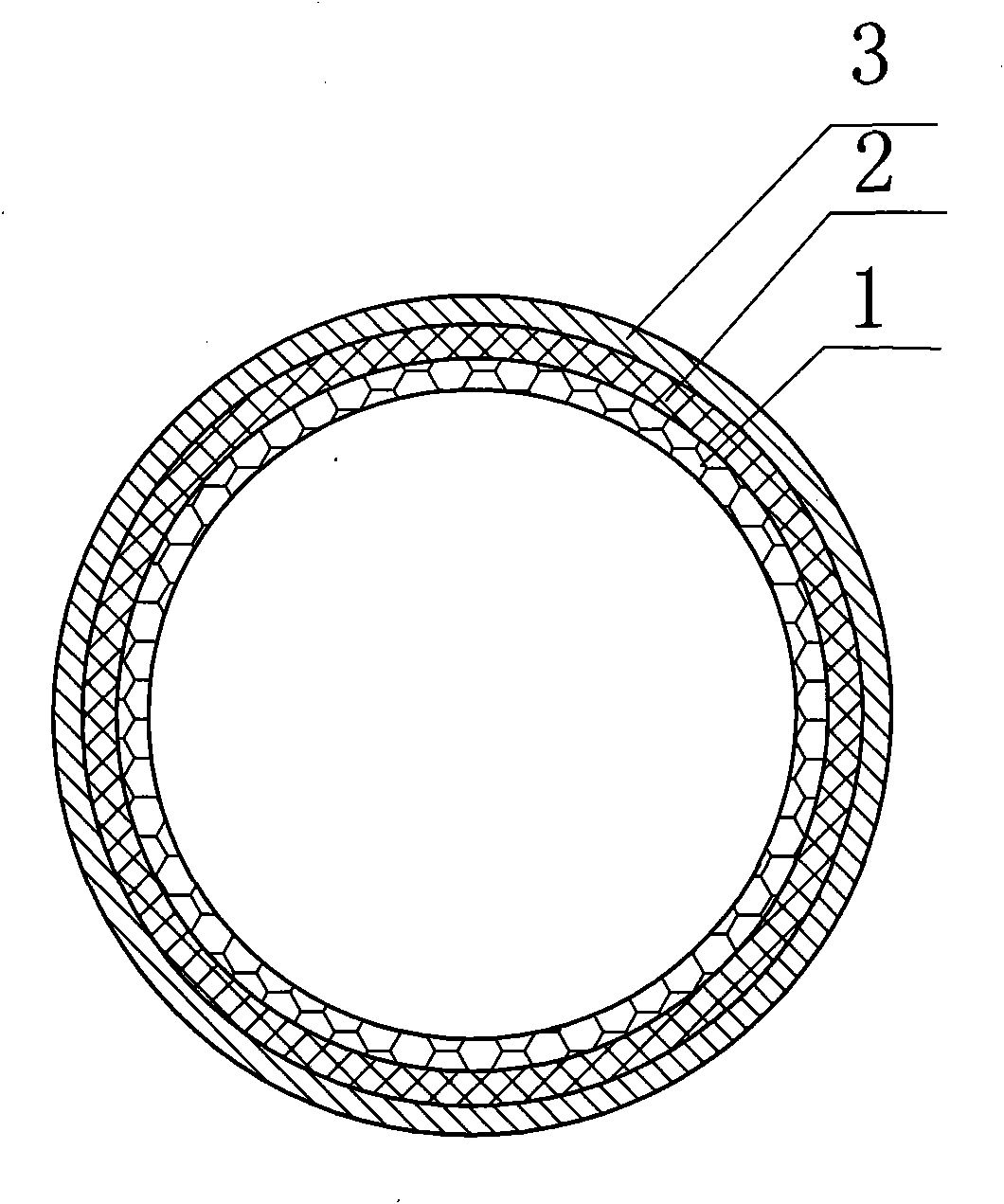

Film structure of 316L alloy steel surface enamel coating

InactiveCN104496181AExcellent adhesionAccelerated corrosionMetal layered productsSurface layerFilm structure

The invention discloses a film structure of a 316L alloy steel surface enamel coating. The film structure of the 316L alloy steel surface enamel coating is mainly characterized in that a 316L alloy steel substrate (1), a reconstruction shallow surface layer (2), an intermediate layer (3) and a surface layer (4) forms a four-layer complex enamel film, and components of an enamel material for the intermediate layer (3) and the surface layer (4) and weight percentage of each component are also disclosed. The film structure of the 316L alloy steel surface enamel coating has the characteristics of reasoned and advanced structure, good corrosion resistance, strong friction pull and the like, and the obtained 316L alloy steel surface enamel coating part can be widely applied to various fields.

Owner:常州宣纳尔新能源科技有限公司

Corundum mullite brick for high-temperaturehigh sulfur petroleum cokecalcining furnace

The invention discloses a corundum mullite brick for a high-temperature high sulfur petroleum coke calcining furnace, belonging to the technical field of high-temperature calcining equipment. The corundum mullite brick comprises a surface enamel layer and an internal brick body, and is characterized in that the brick body is prepared by taking mullite as particle materials and taking mullite powder, fused white corundum powder, andalusite, sillimanite and Suzhou clays as fine powder materials; modified alpha-aluminum oxide powder is added, and the total mass ratio of the particle materials to the fine powder materials is 25-45 to 22-54. A high-temperature stable crystalline phase in the internal structure of the brick body comprises mullite (3Al2O3.2SiO2) and corundum; a working surface at whichthe brick is in direct contact with petroleum is coated with a special high-temperature glaze with high abrasion resistance and high corrosion resistance, and a dense permeable layerof the glaze on the surface of the brick body reaches about 5mm. According to the brick body structure, the erosion resistance capability of the high sulfur petroleum coke on a tank type calcining furnace in the high-temperature calcining process is improved, and the abrasion capability of the tank body in the high sulfur petroleum coke calcining process is improved at the same time.

Owner:SHANDONG WANQIAO GROUP

Heating pipe surface enamel dry firing process

The invention provides a heating pipe surface enamel dry firing process. The surface of a heating pipe is subjected to enamel dry firing processing through the process steps of washing, drying, enamel soaking, baking, sintering and attached glaze washing. An electric heater is optimized in the enamel process, only the enamel needs to be changed into the dry firing electrification process, the problems of a cold area, scaling and corrosion of a pipe body and the like during working of the heating pipe in water for a long time can be solved effectively, and the service life of products is prolonged.

Owner:WUHU HENGMEI ELECTRIC HEATING APPLIANCE

Environment-friendly polyurethane surface lacquer enamel

InactiveCN1844280AGood weather resistanceGood gloss and color retentionPolyurea/polyurethane coatingsLacquerDistillation

The invention discloses an environment-friendly polyurethane surface enamel comprising the following raw materials (by weight percent): hydroxy acrylic resin 40-60%, biuret 10-20%, non-metal pigment 15-30%, butyl acetate 5-15%, and low distillation range aromatic solvent 3-10%.

Owner:SUZHOU TAIHU ELECTRIC ADVANCED MATERIAL CO LTD

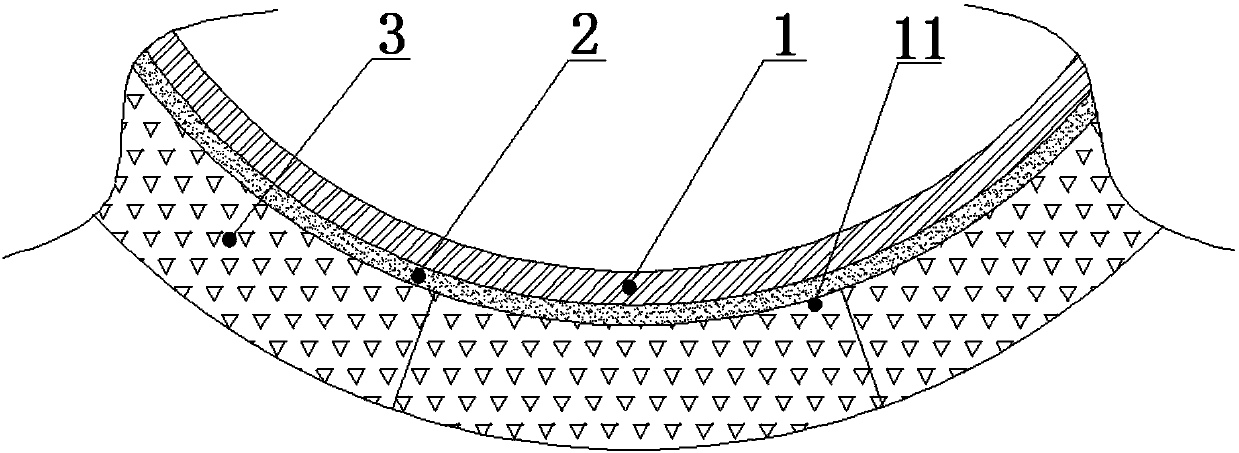

Anti-corrosion anti-seepage layer and manufacturing method thereof

PendingCN107859142AImprove waterproof performanceImprove anti-seepage effectUnderground chambersAnti-corrosive paintsCoated surfaceSurface layer

The invention relates to an anti-corrosion anti-seepage layer and a manufacturing method thereof. The anti-corrosion anti-seepage layer comprises a bottom layer used for being attached to a member anda face layer used for being attached to the bottom layer, a bottom layer material for forming the bottom layer comprises an MMA waterproof material, and a face layer material for forming the face layer comprises porcelain glaze. The anti-corrosion anti-seepage layer is high in corrosion resistance and seepage resistance, easy to manufacture and low in cost and can be used as a tunnel lining structure. The manufacturing method comprises the steps of coating the bottom layer material, wherein the bottom layer material coats a base face of the anti-corrosion anti-seepage layer to be formed of the member to form the bottom layer attached to the member; coating the face layer material, wherein the face layer material costs the bottom layer to form the face layer attached to the bottom layer. By means of the method, the anti-corrosion anti-seepage layer which is high in corrosion resistance and seepage resistance, easy to manufacture and low in cost and can be used as the tunnel lining structure can be manufactured.

Owner:JSTI GRP CO LTD

Preparation process of enamel graphite cookware and enamel graphite cookware

The invention discloses a preparation process of enamel graphite cookware. The preparation process comprises the following steps: (1) processing graphite into a graphite cookware green body; (2), coating a binder on the surface of the graphite cookware green body uniformly, and then performing high temperature sintering so as to form an intermediate bonding layer on the surface of the graphite cookware green body; and (3), enameling the surface of the intermediate bonding layer so as to obtain the enamel graphite cookware, wherein the binder in the step (2) is a mixed solution which is obtained through uniform mixing of titanium powder or silicon powder or mixed powder of titanium powder and silicon powder, high-purity alcohol, phenolic resin and graphite powder at a mass ratio of 3:4:2:1.The enameling process is applied to the graphite cookware, an enamel layer is formed on the surface of the graphite cookware, and the surface strength of the graphite cookware is improved, so that asurface protective layer is formed, and damage of metal cookware to the graphite cookware is avoided during cooking.

Owner:PINGDINGSHAN XINRUIDA NEW MATERIAL TECH CO LTD

Metal surface enamel layer, processing technology of interface thereof and use of technique

InactiveCN101775600AImprove bindingHigh bonding strengthMolten spray coatingMetal layered productsHot TemperatureMetal

The invention relates to a metal surface enamel layer, processing technology of an interface thereof and the use of the technology. The metal enamel has a high sintering temperature and short time which is within 3 to 8 minutes; and the conventional sintering process has difficulties in realizing the metal enamel and requires high cost. The processing technology comprises surface processing and enamel processing, wherein in the surface processing, surfaces of metal material products are processed by adopting electric arc spraying or oxyacetylene spraying; and in the enamel processing, an electric induction heating method is adopted for high-temperature sintering at the temperature of between 850 and 1,100 DEG C for 3 to 8 minutes. The processing technology is applied to enamel products of the surfaces of metal materials.

Owner:刘荣祥 +1

Projection blackboard, and producing process thereof

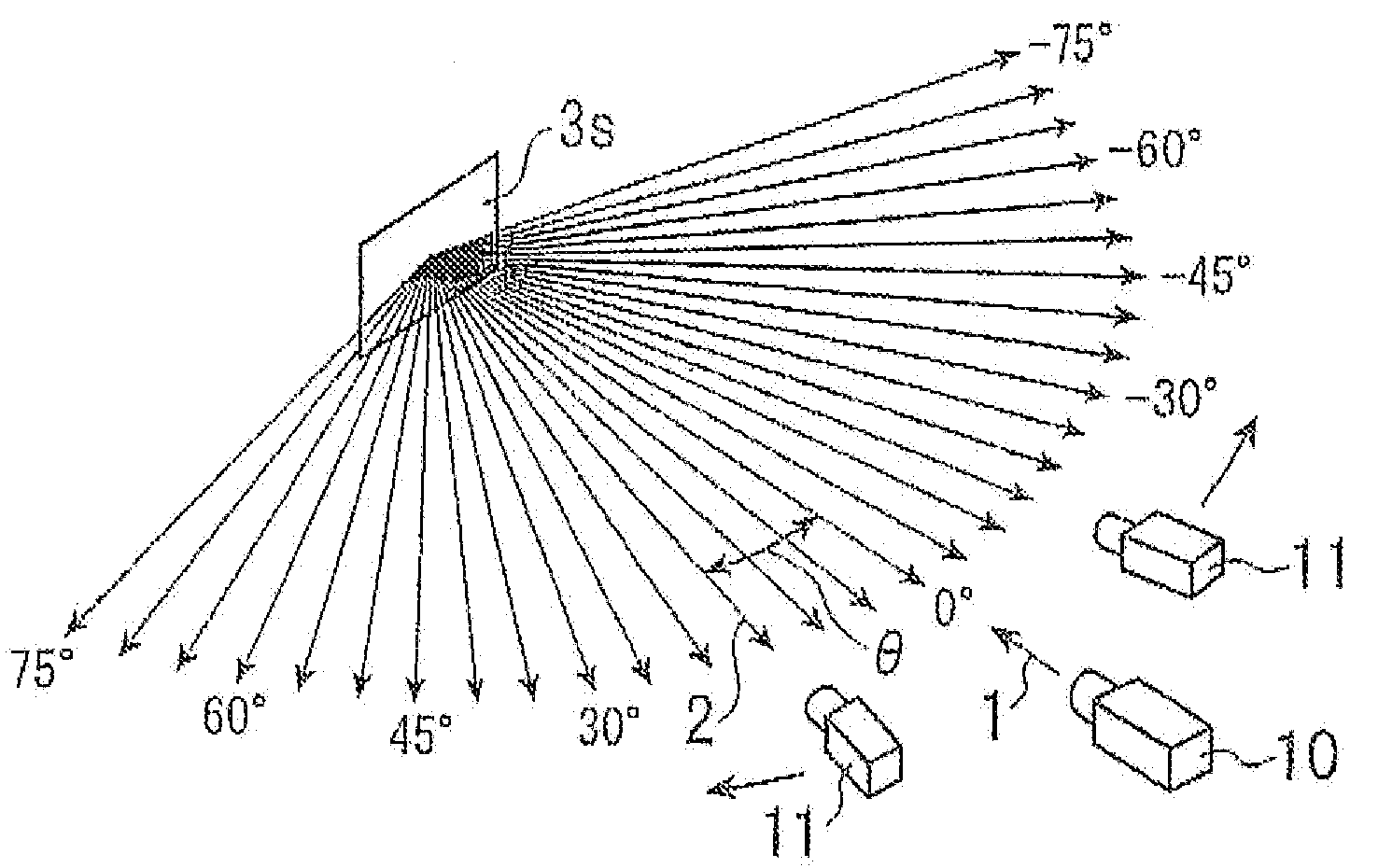

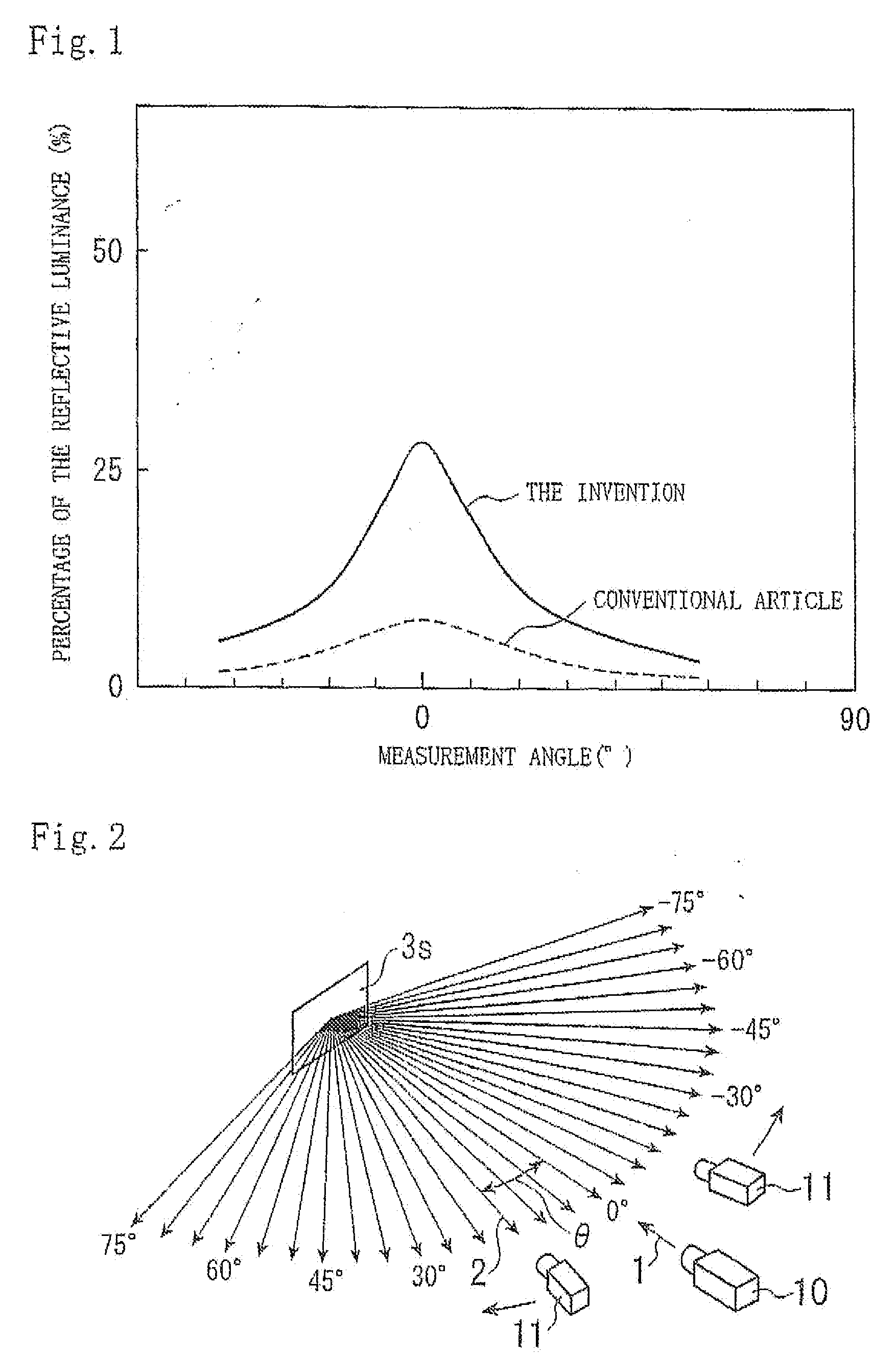

Problem Provided are a projection blackboard having both of an excellent blackboard function and an excellent screen function, and a process for producing the same.Solving means The surface enamel layer that is an outermost layer of the enamel layers is formed by using a enameling upper glaze wherein at least titanium oxide coated particles, or a titanium oxide glaze together therewith is blended into a transparent mat glaze, so as to render the layer an enamel layer having a predetermined color tone, a surface characteristic that the Rz is from 5 to 25 μm and a reflective characteristic that the peak gain is 0.28 or more, or having these properties and a glossiness Gs (75°) of 1 to 30%. This makes it possible to produce a blackboard excellent in both of blackboard function and screen function. The titanium oxide coated particles are preferably particles wherein surfaces of mica particles are coated with titanium oxide. The metallic substrate is preferably a cold-rolled steel sheet, an aluminum plated steel sheet, or a Zn-Al alloy plated steel sheet.

Owner:JFE METAL PROD & ENG INC

Preparation method of enamel plates

The invention discloses a preparation method of enamel plates, which includes the following steps of A, pretreating a steel plate; B, preparing enamel materials: (i) preparing ground enamel powder and (ii) preparing surface enamel powder; C, spraying prepared ground enamel powder to the surface of the pretreated steel plate uniformly by a coating spraying gun; D, disposing an enamel plate with the ground enamel powder at the temperature ranging from 700 DEG C to 740 DEG C and baking and drying for 2 to 3 minutes so as to form the enamel plate with ground enamel; E, spraying the prepared surface enamel powder to the enamel plate with the ground enamel uniformly by the coating spraying gun so as to form the enamel plate with the surface enamel powder; and F, disposing the enamel plate with the surface enamel powder at the temperature ranging from 680 DEG C to 720 DEG C and baking and drying for 2 to 5 minutes. The preparation method is simple, low in cost and fine in operation, and the enamel plate prepared by the preparation method has the advantages of no chalk powder pollution, cleanness and sanitation, excellent visual effect, durability and wear resistance, long service life and the like, is not easy to be peeled off and can be widely used as writing plates.

Owner:何玉良

Heating sheet and preparation method and application thereof

PendingCN110101123AAchieve feverReduce manufacturing difficultyTobacco devicesInsulation layerHeating effect

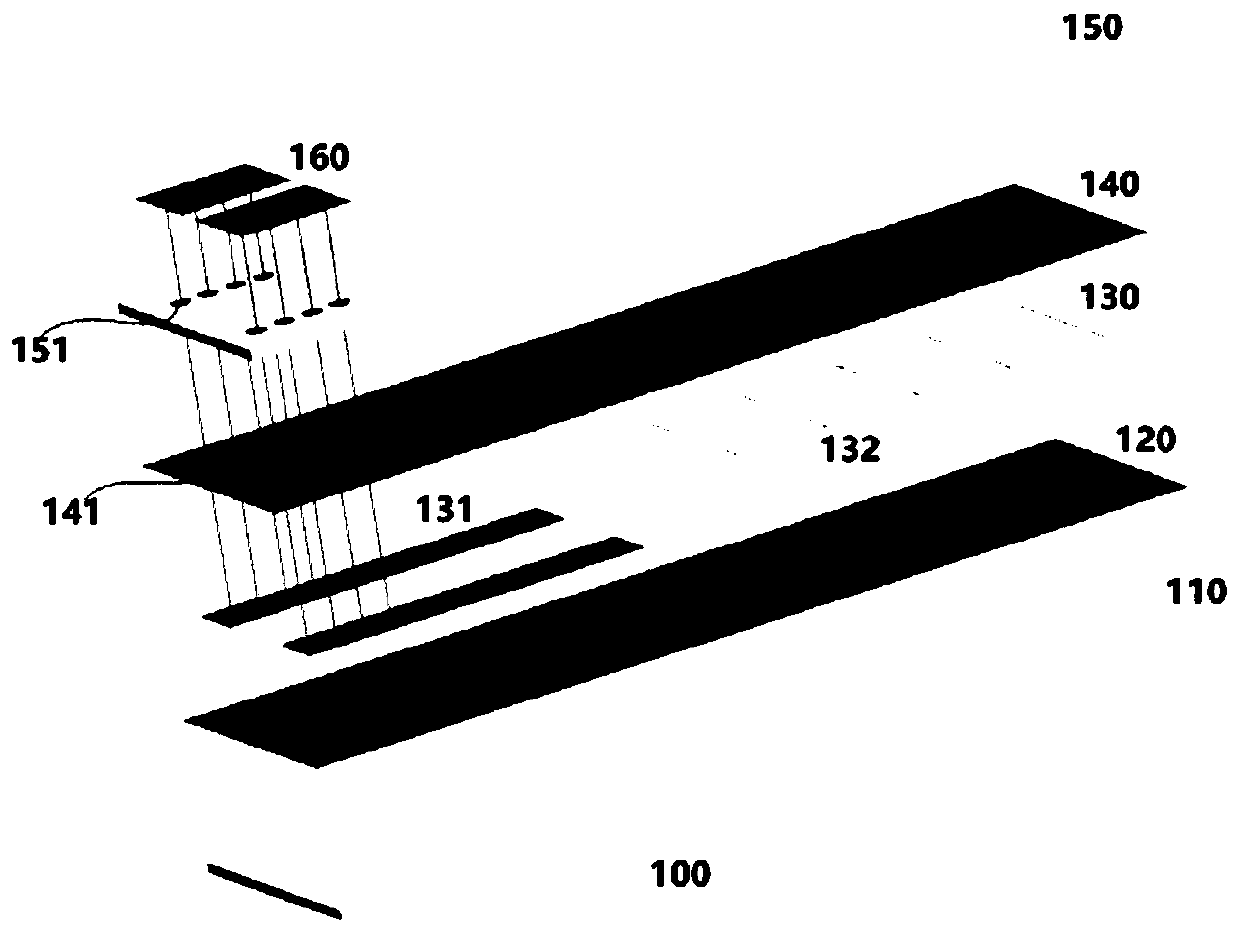

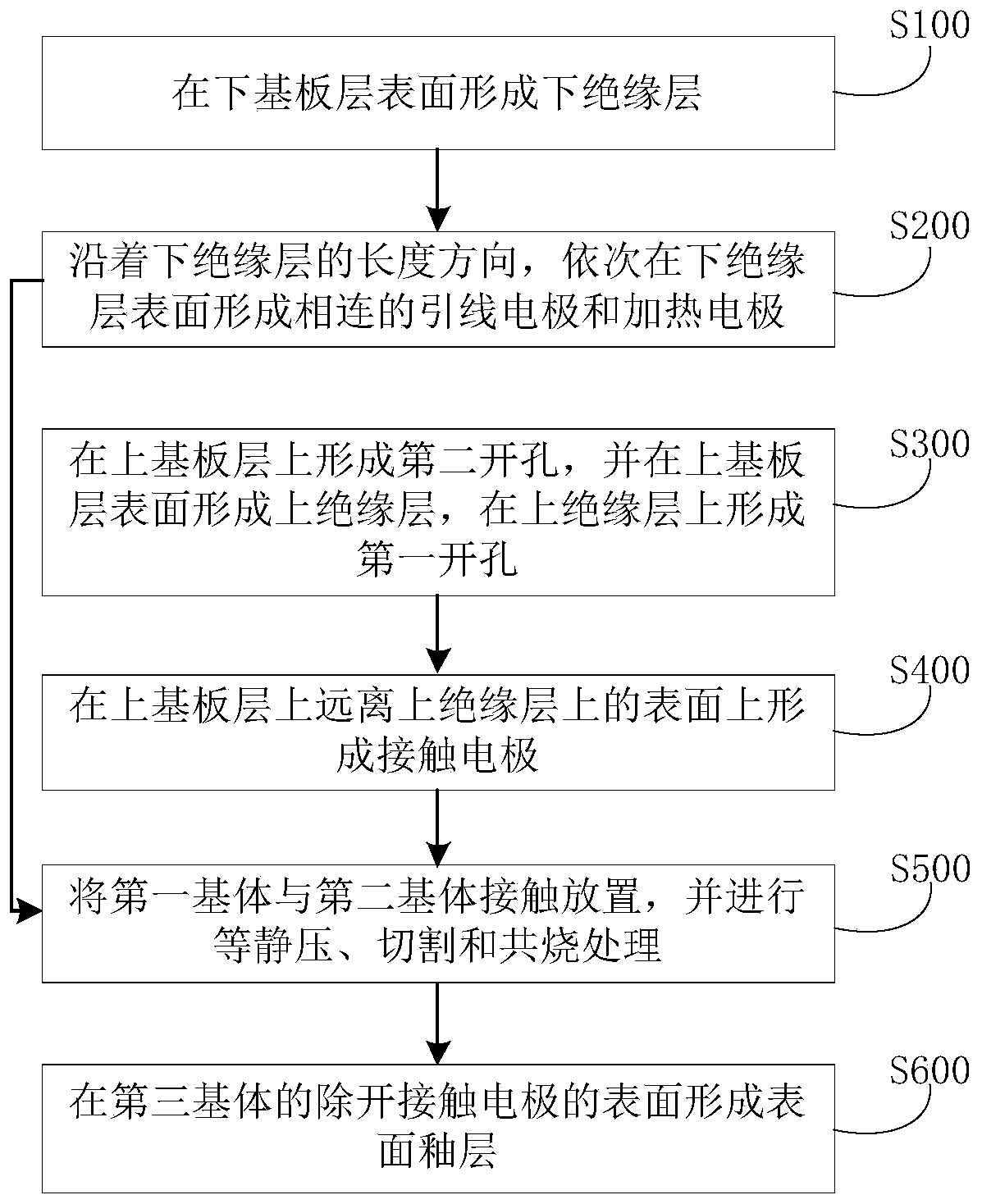

The invention discloses a heating sheet and a preparation method and application thereof. The heating sheet comprises a base body and a surface enamel layer. The base body comprises a lower substratelayer, a lower insulation layer, electrodes, an upper insulation layer, an upper substrate layer and a contact electrode, and the lower insulation layer is arranged on the lower substrate layer; the electrodes are arranged on the lower insulation layer and comprise the lead electrode and the heating electrode which are connected; the upper insulation layer is arranged on the electrodes, and a first open hole is formed in the upper insulation layer; the upper substrate layer is arranged on the upper insulation layer, and a second open hole is formed in the upper substrate layer and connected with the first open hole; the contact electrode is arranged on the upper substrate layer and electrically connected with the lead electrode through the second open hole and the first open hole in sequence; the surface enamel layer is arranged to surround the outer surface of the base body and does not cover the contact electrode. The heating sheet is low in preparation difficulty, long in service life and high in efficiency and has a good heating effect.

Owner:SHENZHEN TAOTAO TECH CO LTD

Ceramic cleaning agent and preparation method thereof

InactiveCN103865696AGood decontamination effectNot easily affected by temperatureSurface-active non-soap compounds and soap mixture detergentsActive agentAromatic agent

The invention discloses a ceramic cleaning agent and a preparation method thereof. The ceramic cleaning agent is composed of industrial alcohol, glycol, a cation activator, an amphoteric surfactant, sodium ortho-cyclohexanediaminetetraacetate, citric acid, bromothymol blue, an aromatic and softened deionized water according to a certain weight percentage. The preparation method comprises the following steps of at a normal temperature, adding softened deionized water into a container, then adding industrial alcohol and glycol into the container, carrying out stirring for full mixing, adding other raw materials into the solution, carrying out full stirring until the raw materials are completely dissolved, and putting the solution into a pot, a bottle or a bag. The ceramic cleaning agent has good cleaning effects, can clean old and stubborn stains on the ceramic surface, is not influenced by a temperature easily, has no corrosivity, does not damage surface enamel and ceramic body of ceramic and realizes good ceramic surface brightness after cleaning. Cleaning waste water of the ceramic cleaning agent does not pollute the environment. The ceramic cleaning agent is a novel environmentally-friendly product and has effects of sterilization, disinfection and peculiar smell removal. The preparation method has simple processes and a moderate cost and can be popularized.

Owner:智福春

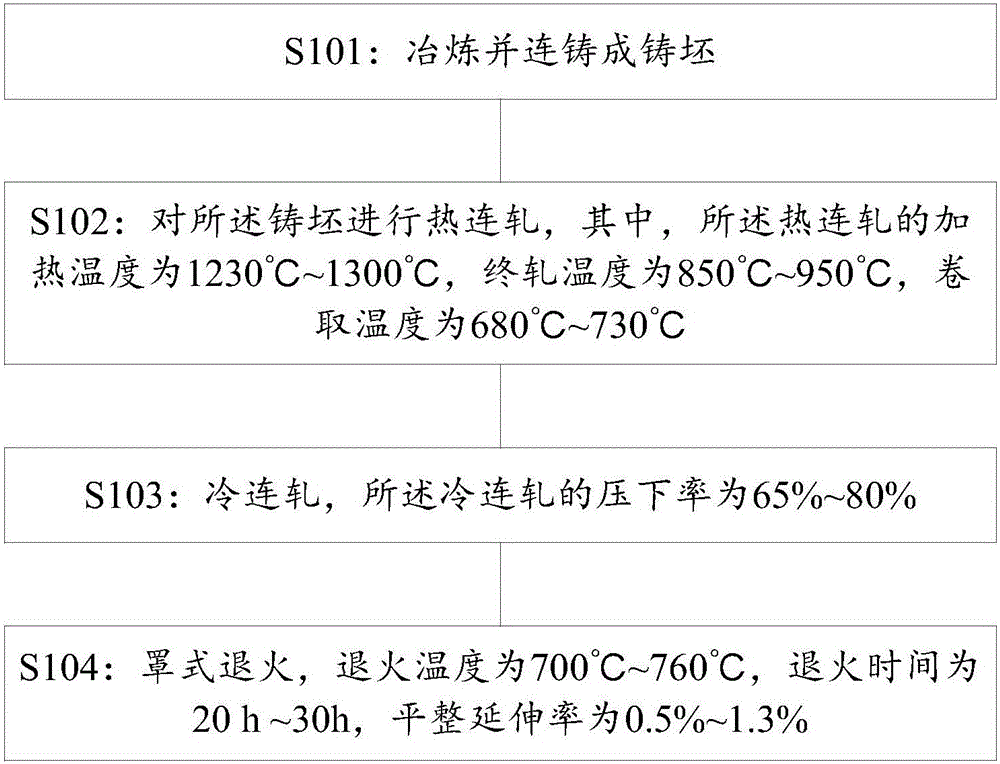

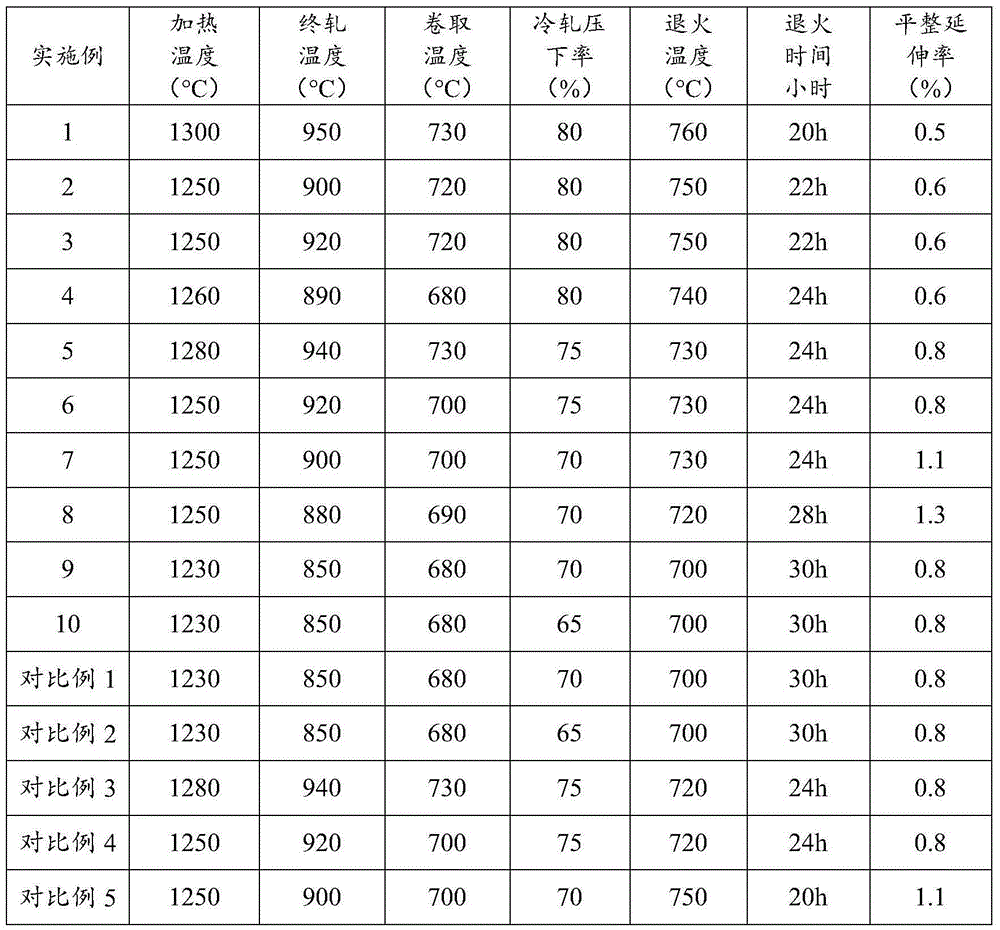

Production method of hot-rolled acid washing steel plate for 250 MPa-grade single-surface enamel

The invention relates to the field of hot-rolled acid washing plates, in particular to a production method of a hot-rolled acid washing steel plate for a 250 MPa-grade single-surface enamel. Accordingto percentage by weight, the hot-rolled acid washing plate comprises the following alloy components: 0.01-0.05% of C, Si not more than 0.05%, 0.10-0.30% of Mn, P not more than 0.020%, S not more than0.015%, 0.015-0.040% of Als, 0.035-0.050% of Ti, N not more than 0.0050%, and the balance of iron and inevitable impurities; and a cast blank is put in a heating furnace for heating to 1180-1280 DEGC, is rolled in a section of 900-1100 DEG C, and is laminarly cooled to 600-700 DEG C for winding, acid washing and oiling. The performances of the hot-rolled acid washing plate are adopted to satisfythe yield strength of not less than 250 MPa and the percentage elongation of not less than 28%; and such problems as weaker scale explosion resistance of a hot-rolled acid washing plate produced by the prior art and higher production cost and weak quality stability of special enamel steel are solved.

Owner:BENGANG STEEL PLATES

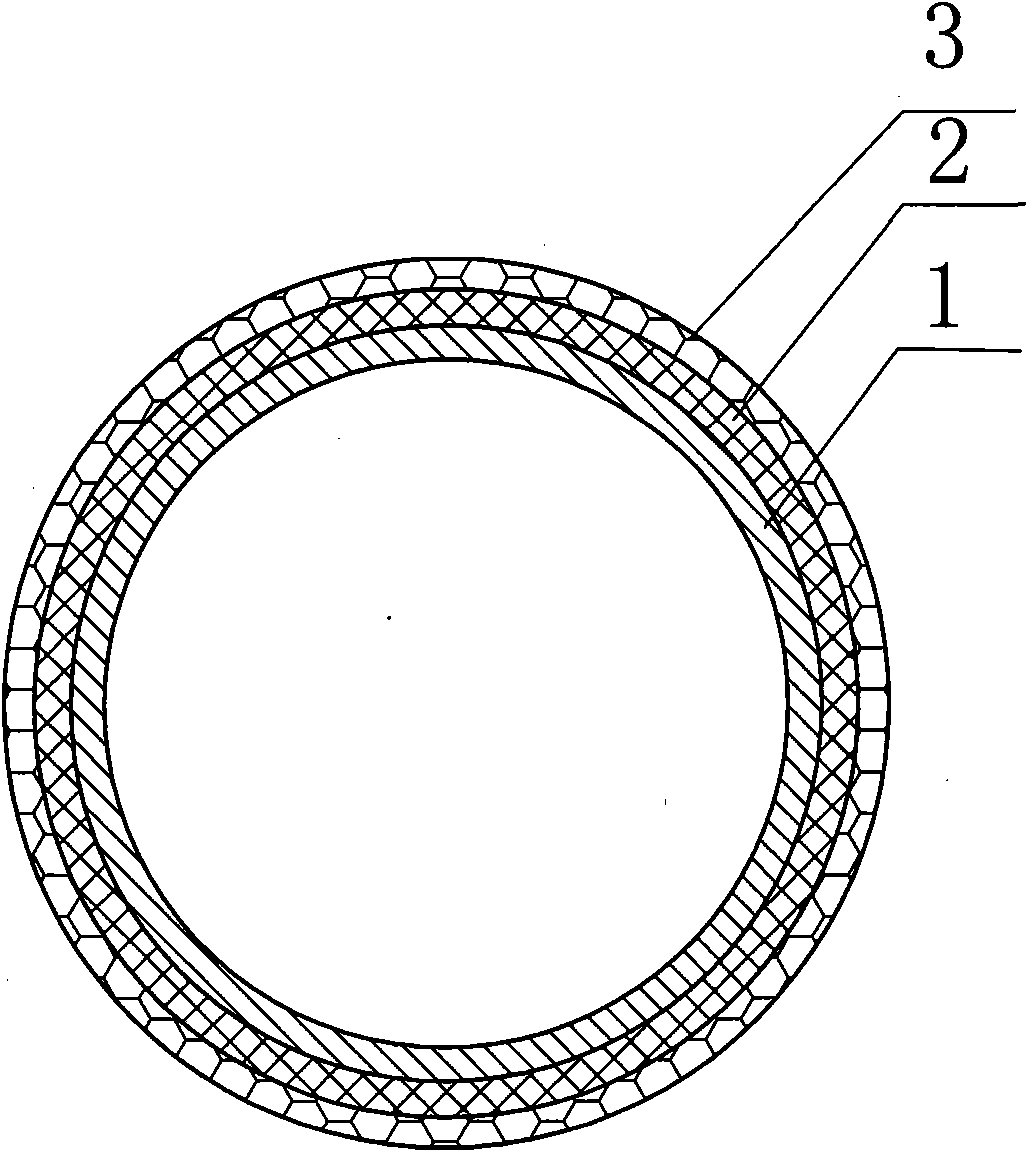

Making method of porcelain enamel radiator

InactiveCN101653904ASolve the problem of aging deteriorationIncrease productivityRecreationMetallurgy

The invention discloses a making method of a porcelain enamel radiator, which is characterized in that a steel pipe is used as a parent material; after being sprayed and coated with enamel, the innerpipe wall and the outer pipe wall of the steel pipe are sintered at high temperature to form the porcelain enamel radiator. The concrete technical process is as follows: washing, preparing base enameland surface enamel, coating the base enamel, drying, coating the surface enamel, sintering and cooling to make the product. The making method is suitable for producing porcelain enamel radiators in batch and has the advantages of simplicity, practicality and high production efficiency. A produced porcelain enamel pipe resists acid and alkali, and the radiators with different colors for appearances are produced, thereby solving the aging and deteriorating problem of the radiators; and the service life of the product is prolonged to 3 to 5 times of that of an ordinary radiator. The porcelain enamel radiator is suitably used for office buildings, schools, recreation places and families.

Owner:王福安

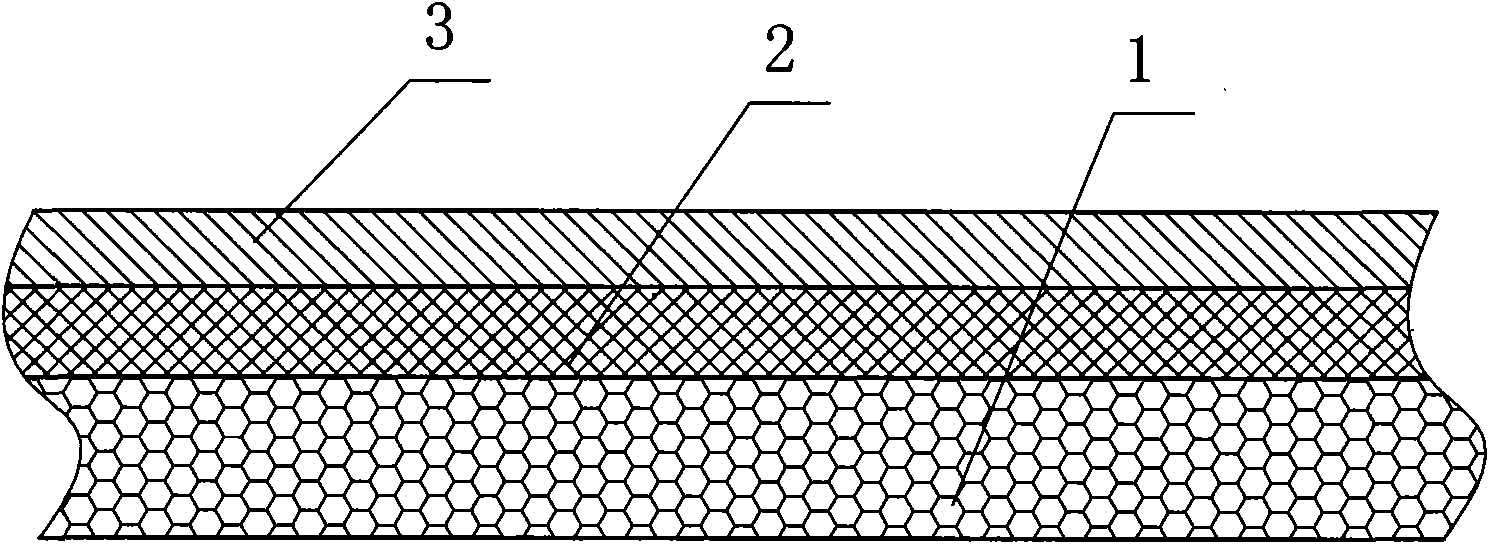

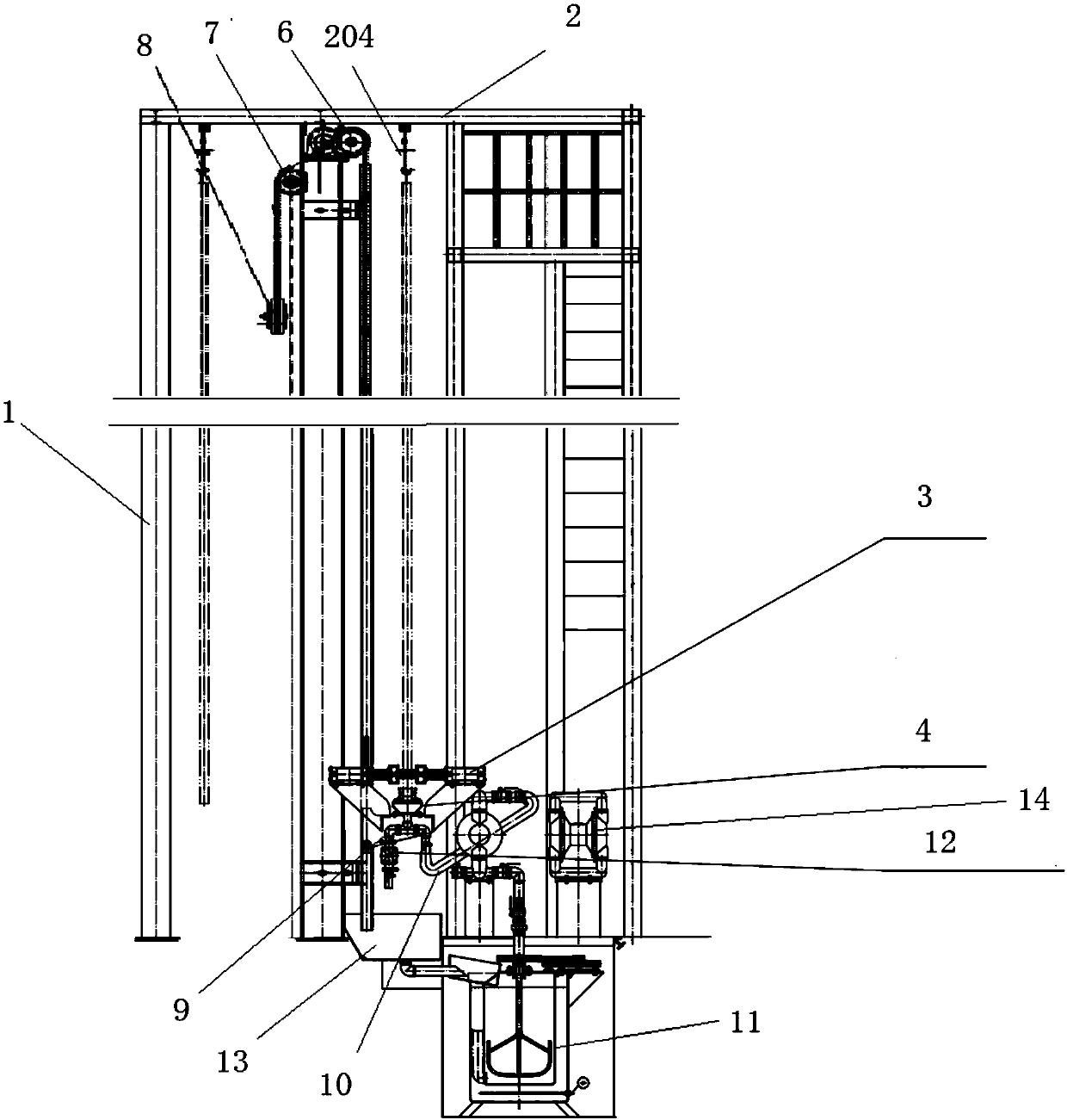

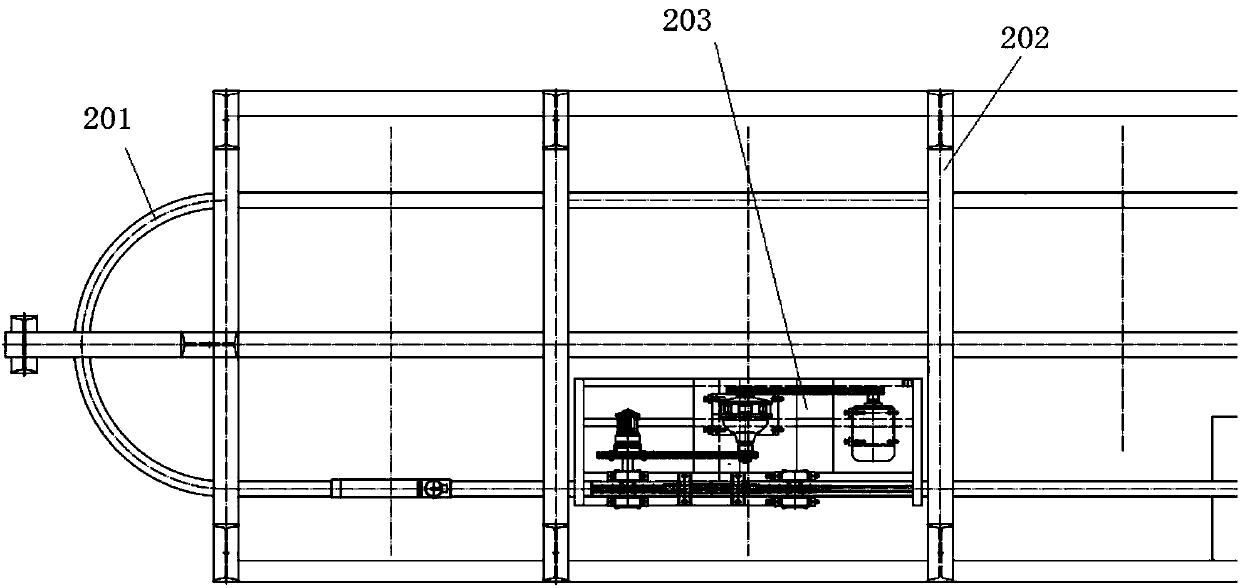

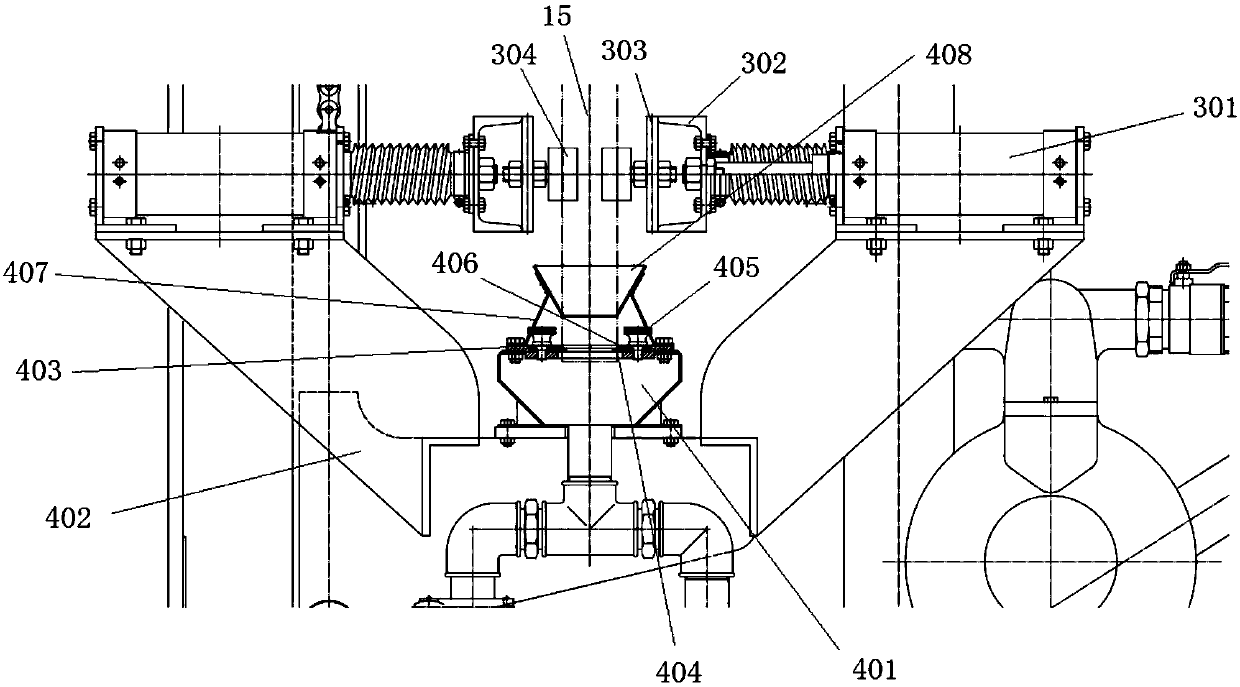

Air preheater enamel pipe inner surface enameling device and working method

ActiveCN107761097ARealization of automatic slurry supplyIncrease productivityIndirect carbon-dioxide mitigationAir preheaterMetallurgy

The invention relates to an air preheater enamel pipe inner surface enameling device and a working method. The enameling device comprises a rack, a delivery mechanism, a clamping mechanism and an enameling mechanism, wherein the delivery mechanism, the clamping mechanism and the enameling mechanism are fixed to the rack; the delivery mechanism is fixed to the top end of the rack and used for hanging and moving a pipe to be enameled; the clamping mechanism is used for clamping the pipe wall of the pipe; the enameling mechanism is connected with an enameling driving device and is driven to moveup and down along the rack by the enameling driving device; the enameling mechanism is provided with a glaze tank. In the enameling process, the enameling mechanism moves the bottom end of the pipe tobe enameled along the rack, the pipe to be enameled is inserted into the glaze tank, and the glaze tank and an inner cavity of the pipe to be enameled form a closed space through a sealing component;under the action of a slurry feed system, glaze goes into the closed space to conduct immersion type enameling on the pipe to be enameled. The air preheater enamel pipe inner surface enameling deviceprovided by the invention is high in automation degree, the production efficiency is improved, and the labor intensity is reduced.

Owner:山东中琦环保设备制造有限公司

Steel for enamel heat transfer element having corrosion resistance and manufacturing method thereof

The invention discloses steel for an enamel heat transfer element having corrosion resistance and a manufacturing method thereof. The steel comprises the following chemical components in percentage by weight: not more than 0.010% of C, 0.40-0.60% of Mn, not more than 0.10% of Si, not more than 0.02% of P, not more than 0.02% of S, 0.02-0.06% of Als, 0.20-0.40% of Cu, 0.70-1.10% of Cr, 0.04-0.10% of Sb, 0.02-0.05% of Ti, 0.01-0.03% of Nb, 0.01-0.03% of Ni, and the balance of Fe and inevitable impurities. As such elements as Cu, Cr, Ni, Sb and Ti are added to the steel, the metal corrosion potential is deviated to a passivation area, a compact protective film is easy to be formed on the surface, the steel is excellent in corrosion resistance in a smoke environment, and the corrosion resistance is obviously better than that of a general low-carbon steel plate; and as the contents of C and Si in the steel are reduced and such proper alloy elements as Nb and Ti are added in the steel, the microstructure is reasonably controlled, the enamel coating quality of the steel plate is effectively improved, the steel plate can be applied to the surface enamel coating production, and such surface defect problems as enamel scale explosion, foaming and pinholes easily generated in traditional acid-resistant steel are solved.

Owner:武汉钢铁有限公司

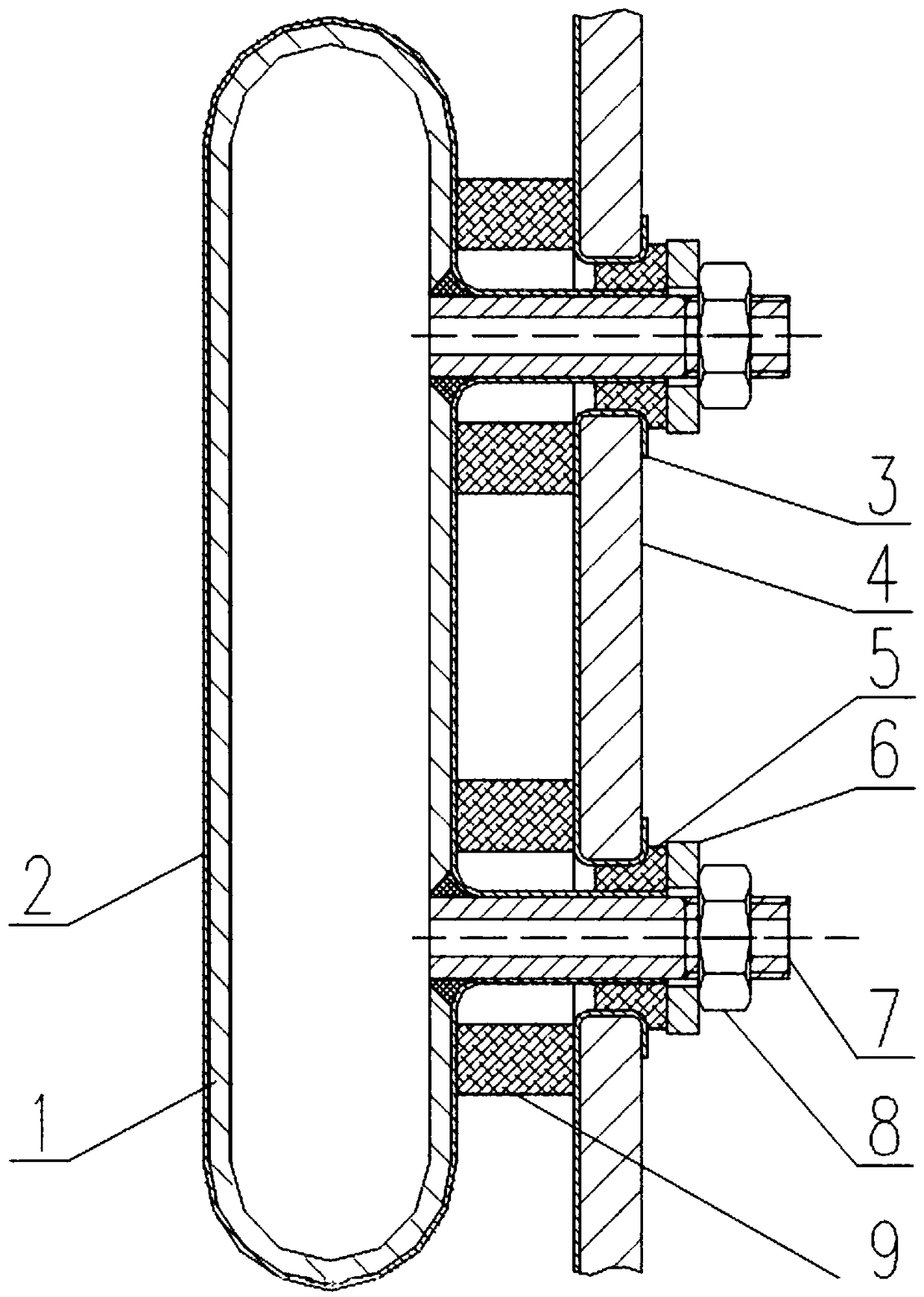

Enamel kettle stirring baffle structure

PendingCN108619991AImprove mixing efficiencySimple structureTransportation and packagingMixer accessoriesEngineeringSurface enamel

The invention discloses an enamel kettle stirring baffle structure and belongs to the technical field of enamel kettle agitating. The enamel kettle stirring baffle structure comprises a hollow baffleand at least one supporting pipe disposed on the baffle. The surfaces of the baffle and the supporting pipe are coated with baffle and supporting pipe surface enamel. The baffle is installed on the cylinder of the enamel kettle through the supporting pipe. The surface of the inner wall of the cylinder is provided with cylinder surface enamel. A positioning block sleeves the supporting pipe betweenthe cylinder and the baffle. After the positioning block sleeves the supporting pipe, the supporting pipe stretches out of the cylinder. The extending end of the supporting pipe is orderly sleeved bya filler and a pressing ring. The enamel kettle stirring baffle structure solves the problem that the enamel kettle without a baffle cannot realize the stirring under the full baffle condition, has asimple structure, is easy to arranged and greatly improves the mixing efficiency of the enamel kettle.

Owner:NANJING ZHENGYUAN ENAMEL EQUIP MFG

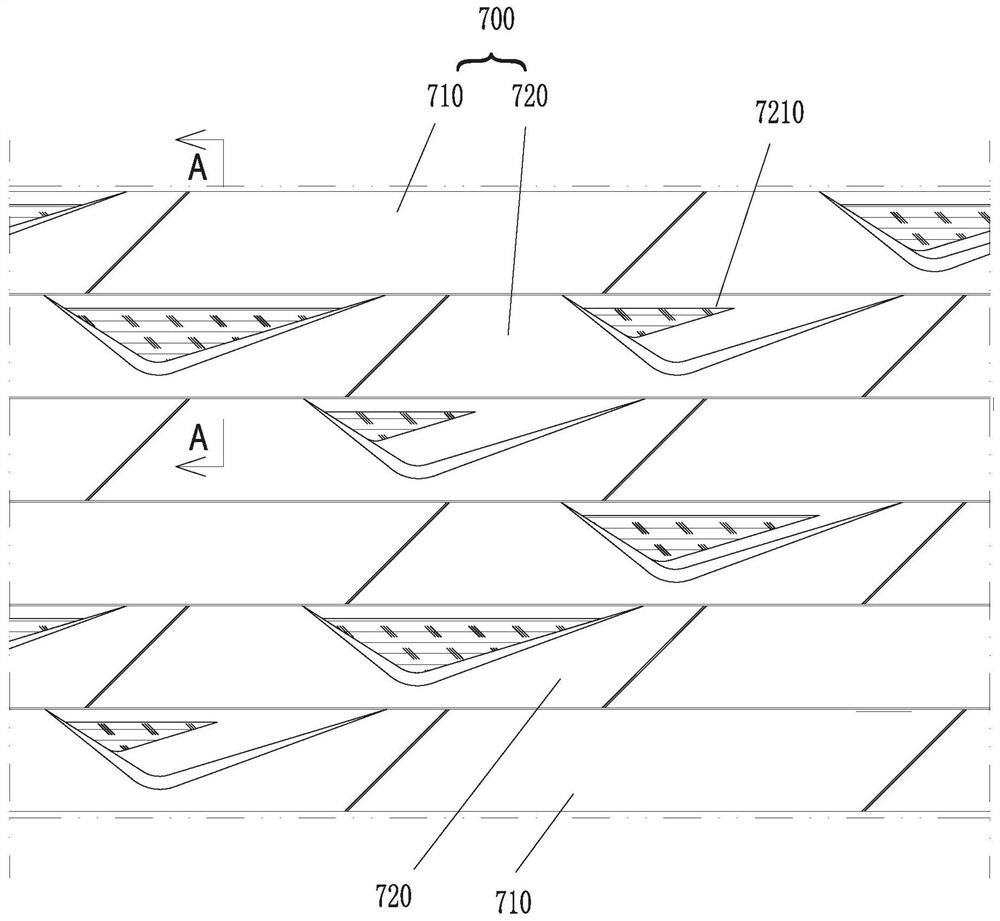

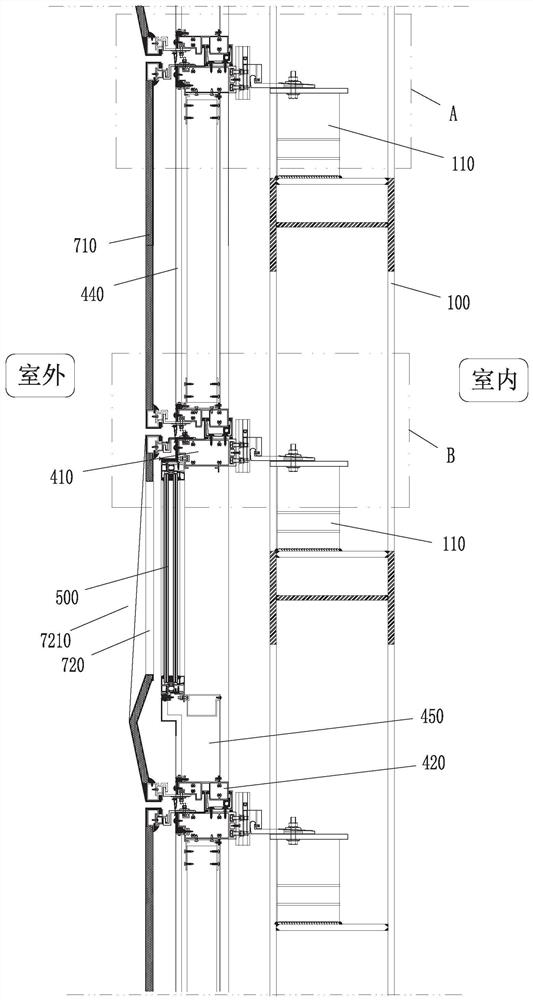

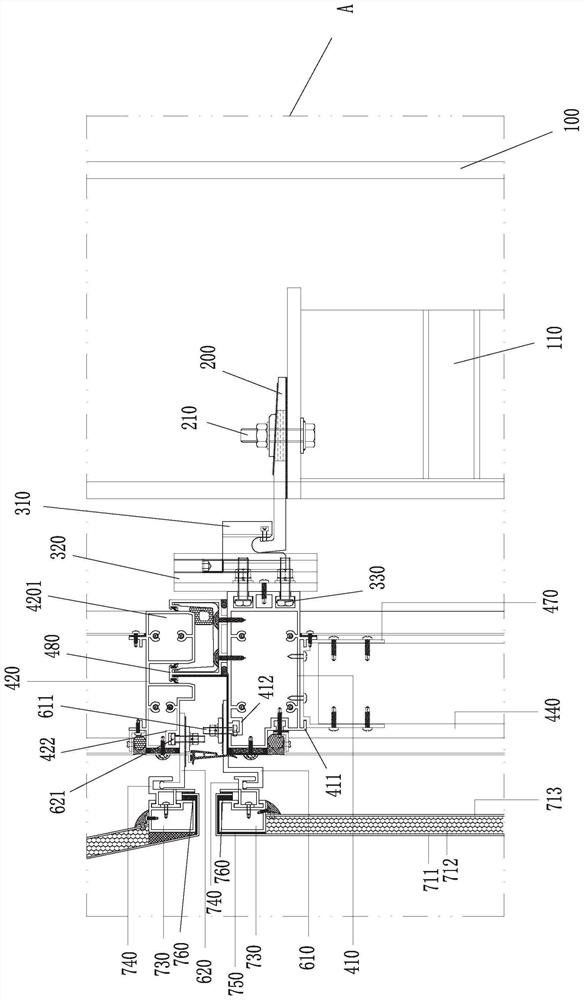

Super-large special-shaped curved surface enamel plate modeling unit type curtain wall system

ActiveCN112575933AStable structureEasy to processWallsGlass pane fixingComposite plateMechanical engineering

The invention discloses a super-large special-shaped curved surface enamel plate modeling unit type curtain wall system. The system comprises a plurality of unit frames hung on a main body structure,wherein every two horizontally-adjacent unit frames are connected in an inserted mode, every two vertically-adjacent unit frames are connected in an inserted mode, an enamel composite plate is correspondingly hung on the outer face of each unit frame, the unit frames and the enamel composite plates are matched in shape and are parallelogram-shaped, the enamel composite plates are arranged in a staggered manner, the enamel composite plates comprise totally-enclosed enamel composite plates and windowed enamel composite plates, glass panels are mounted on the unit frames corresponding to the windowed enamel composite plates, and the glass panels are opposite to window holes in the windowed enamel composite plates. According to the system, the requirement that the special-shaped super-large-size enamel plate with the curved surface effect serves as an outer decorative plate is met, construction is convenient and fast, the installation precision is easy to control, and the construction quality is guaranteed.

Owner:SHANGHAI JANGHO CURTAIN WALL SYST ENG +2

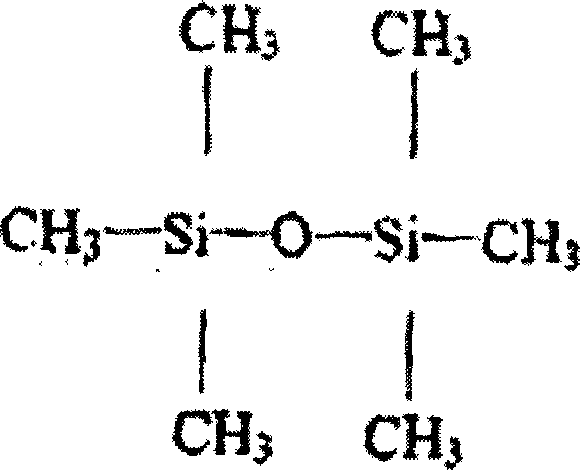

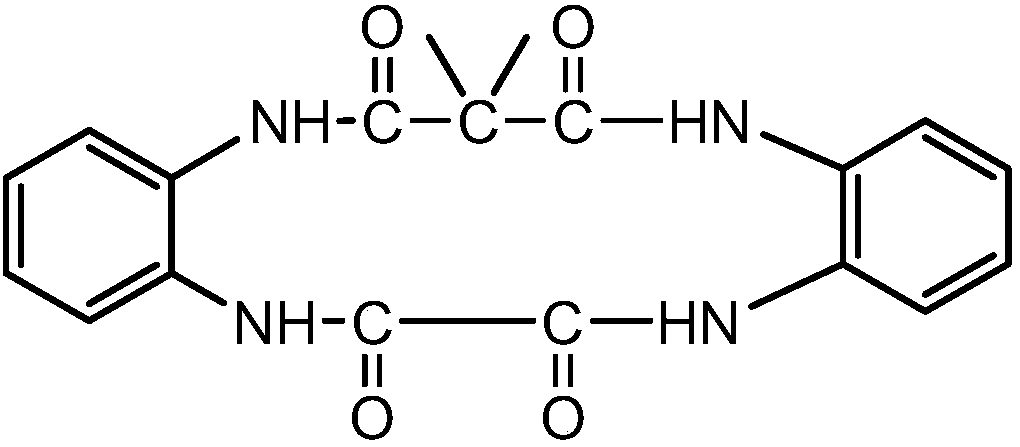

Antiskid brick and preparation method thereof

The application provides an antiskid brick and a preparation method thereof. The antiskid brick comprises a green body, a base enamel layer, a surface enamel layer and an antiskid enamel layer; the base enamel layer is arranged between the green body and the surface enamel layer, the surface enamel layer is arranged between the base enamel layer and the antiskid enamel layer; base enamel used forthe base enamel layer contains a base enamel additive; the base enamel additive is a toluene solution of a compound A, with the mass concentration of 1-2%; the structure formula of the compound A is as shown as follows; surface enamel used for the surface enamel layer contains a surface enamel additive, and the surface enamel additive is a mixture of tungsten oxide, molybdenum oxide and nickel oxide; antiskid enamel used for the antiskid enamel layer contains antiskid enamel additives, and the antiskid enamel additives are sodium chloride, aluminum chloride, aluminum sulfate and aluminum potassium sulfate dodecahydrate. The preparation method of the antiskid brick comprises the following steps: forming the green body, sprinkling base enamel, sprinkling surface enamel, performing inkjet printing, spraying antiskid enamel, baking, and performing post-treatment to obtain a finished product. According to the antiskid brick and the preparation method provided by the application, the obtained antiskid brick is good in antiskid performance, high in breaking strength and good in thermal shock resistance.

Owner:FOSHAN SHI WAN YING BRAND CERAMICS CO LTD

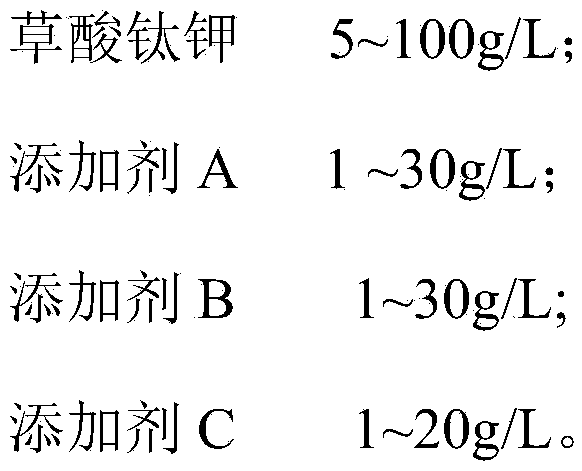

Ceramic anode oxidation solution and ceramic anode oxidation process

InactiveCN105369321AExpand the range of surface decoration colorsBeautiful surface enamelAnodisationWeather resistanceTitanium

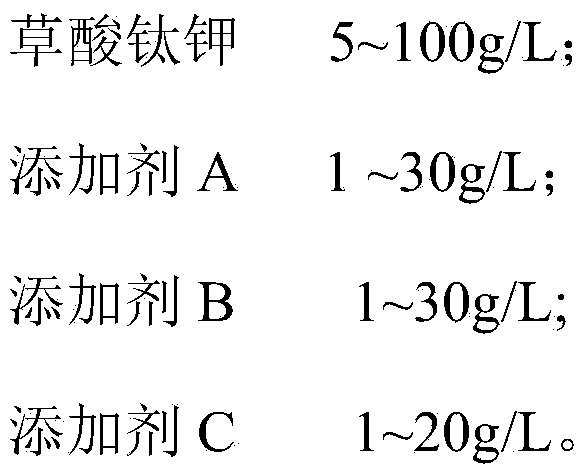

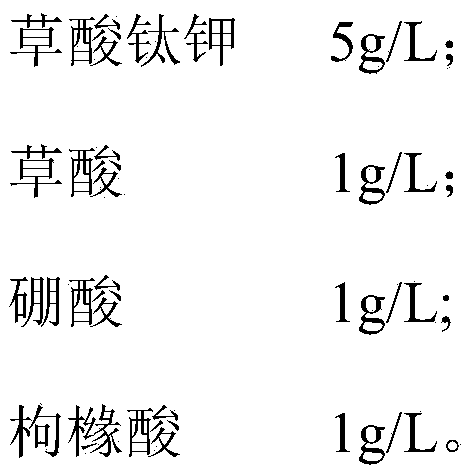

The invention relates to the technical field of anode oxidation solution formulas and anode oxidation processes, in particular to a ceramic anode oxidation solution and a ceramic anode oxidation process. The ceramic anode oxidation solution per liter comprises, by mass concentration, 5-100 g of titanium potassium oxalate, 1-30 g of additives A, 1-30 g of additives B and 1-20 g of additives C. The ceramic anode oxidation process comprises the steps that firstly, aluminum alloy materials to be subjected to ceramic anode oxidation are put in a reaction tank filled with the ceramic anode oxidation solution; and then the ceramic anode oxidation solution is heated to be at 15-60 DEG C, the voltage of 20-120 V is introduced, oxidation is conducted for 15-80 min, and the ceramic anode oxidation step is finished. The film thickness generated by a ceramic anode is in a tree root shape, the ceramic anode has incomparable hardness advantages compared with an ordinary anode, the surface color decoration range of an aluminum alloy ceramic oxidation film is enlarged, and the beautiful surface enamel sense is kept. Meanwhile, the ceramic anode has the firm and color appearance meeting different decorative requirements, and has good abrasion resistance, corrosion resistance and weather resistance properties in the use process, the process conditions are simple, and implementation is convenient.

Owner:HUIZHOU ZEHONG TECH CO LTD

Zinc oxide resistor sheet with high side flashover voltage

InactiveCN106876064AIncrease the flashover voltage along the surfaceIncrease the difficultyVaristor coresOvervoltage protection resistorsHigh resistanceWave shape

The invention discloses a zinc oxide resistor with high side flashover voltage, which comprises a zinc oxide resistor body, the outer surface of the zinc oxide resistor body is coated with a high resistance layer and a surface glaze layer in sequence, and the zinc oxide resistor The outer surface is wavy, and the extension direction of the wavy zinc oxide resistance sheet wave is consistent with the thickness direction of the zinc oxide resistance sheet. The invention has the advantages of simple structure, easy manufacture, low production cost, good flashover performance along the surface, high impact resistance of large current and the like.

Owner:QINGDAO XIANGZHI ELECTRONICS TECH CO LTD

Preparation method of aluminum alloy car instrument panel surface enamel

InactiveCN107881543AImprove oxidation resistanceAccelerated corrosionSurface reaction electrolytic coatingElectrolysisPotassium

The invention discloses a preparation method of aluminum alloy car instrument panel surface enamel. The preparation method comprises the following steps that (1), the aluminum alloy car instrument panel surface formed through preparation is placed into an electrolytic bath after being subjected to decontamination and grease removal treatment for anodic oxidation treatment; (2), silicon oxide, titanium oxide, sodium oxide, potassium oxide, zirconium oxide, potassium fluoborate, vanadium oxide and water are added into a planetary ball mill and subjected to ball milling treatment for 100-120 min,and then enamel glaze is obtained; and (3), the prepared enamel glaze prepared in the step (2) is sprayed on the aluminum alloy car instrument panel surface treated in the step (1), the sprayed aluminum alloy car instrument panel surface is placed into a drying oven to be dried and subjected to high-temperature sintering, and a finished product is prepared. According to the preparation method ofthe aluminum alloy car instrument panel surface enamel, operation is easy, the cost is low, the surface of a prepared aluminum alloy car instrument panel has excellent oxidation resistance and corrosion resistance, the instrument panel is high in glossiness and fashion sense, and the quality of the instrument panel is greatly improved.

Owner:马鞍山市东方仪表有限公司

Preparation method for surface enameled preheating electric heating tube assembly

InactiveCN106413153AWill not affect normal workImprove efficiencyHeating element shapesElectrical resistance and conductanceHydrate decomposition

The invention relates to a preparation method for a surface enameled preheating electric heating tube assembly. The method comprises the steps of 1), winding a resistance wire of a preset length, fixing the resistance wire on a magnesium oxide tube base, and fixedly sleeving two ends of the resistance wire on the wire mounting positions of two lead bars, thereby obtaining a resistance wire assembly; 2), arranging the resistance wire assembly in a metal tube; 3), shrinking the electric heating tube assembly according to a preset size by employing a tube shrinking machine; 4), pre-starting the electric heating tube assembly shrunk in the step 3) and closing the electric heating assembly for high-temperature processing; and 5), sealing the electric heating assembly after the high-temperature processing in the step 4). According to the method, the electric heating tube is pre-started for preheating; hydrate in magnesium oxide powder is decomposed by employing heat generated by the resistance wire itself, then the high-temperature processing is carried out, so water in the magnesium oxide powder is eliminated completely, and the normal working of the electric heating tube will not be influenced.

Owner:扬中市华荣电器设备有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com