Preparation method of matt antifouling dry granular glaze and glaze slip, tile and preparation method thereof

A dry-grain glaze and antifouling technology, applied in the field of ceramics, can solve the problems of low surface gloss and rough surface texture, and achieve the effect of low gloss, good antifouling effect and good compactness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

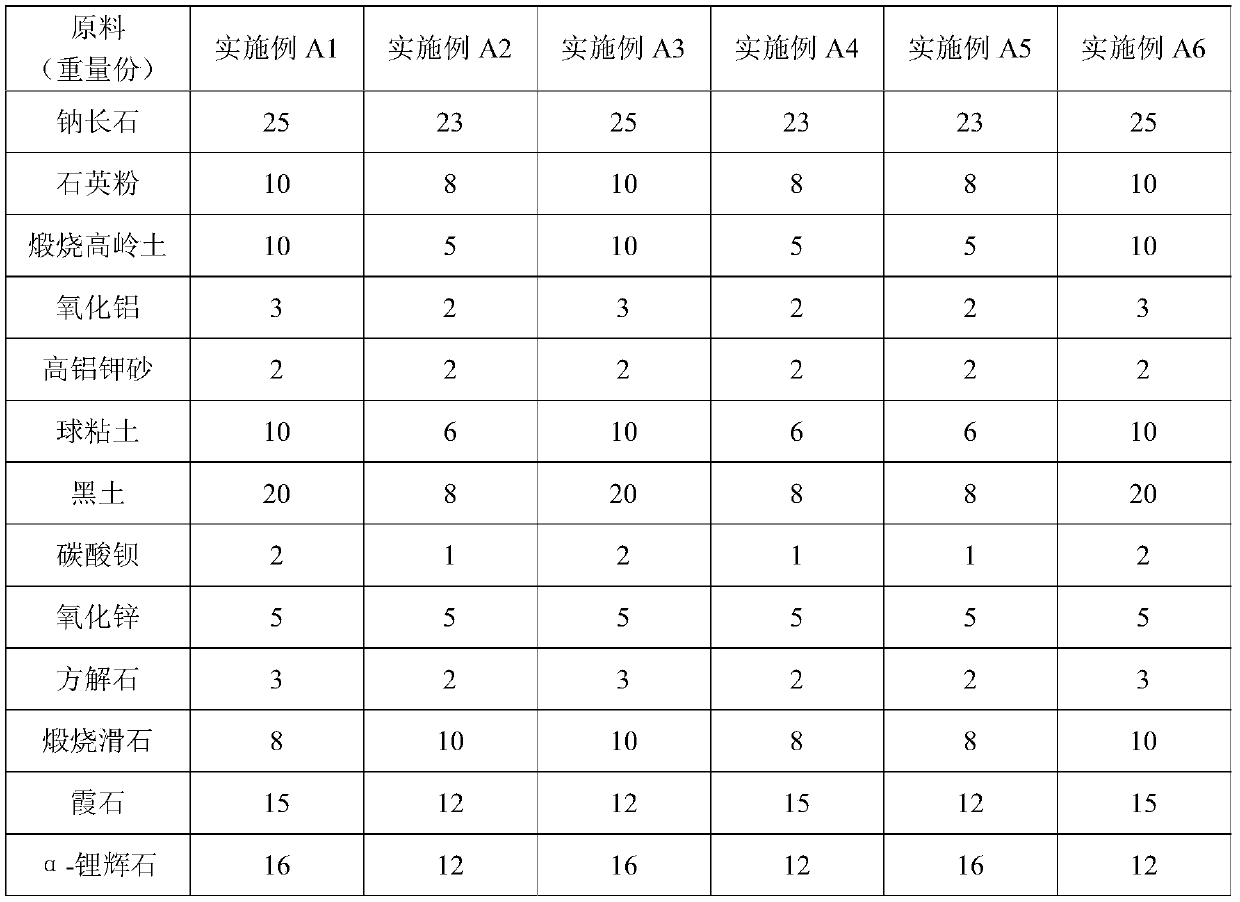

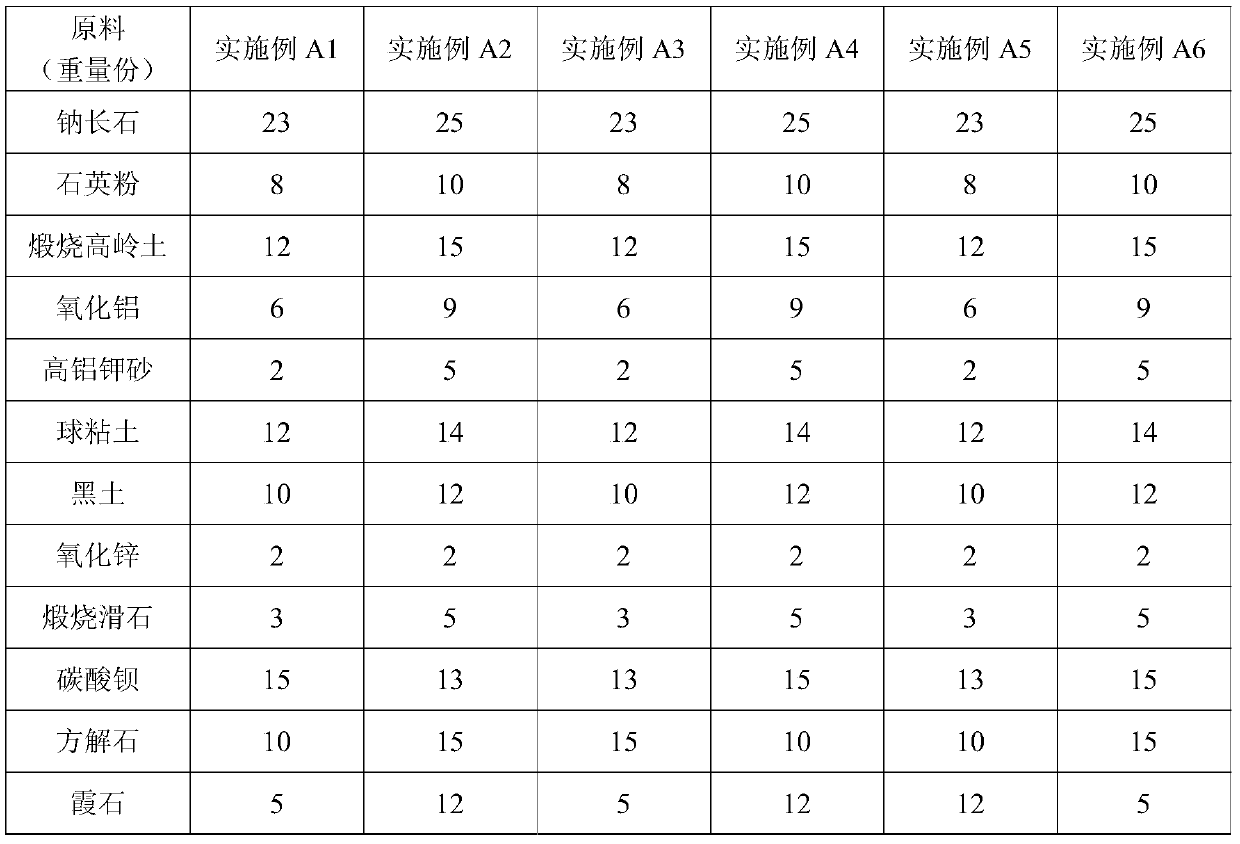

[0058] The method for preparing the glaze slurry of the above-mentioned matte antifouling dry granule glaze comprises the following steps:

[0059] (1), adding the raw materials of glaze A into a ball mill according to the ratio, mixing sodium hydroxymethyl cellulose, sodium tripolyphosphate and water into the ball mill for ball milling, and obtaining glaze A;

[0060] (2), adding the raw materials of glaze B into a ball mill according to the ratio, mixing sodium hydroxymethyl cellulose, sodium tripolyphosphate and water into a ball mill for ball milling, and obtaining glaze B;

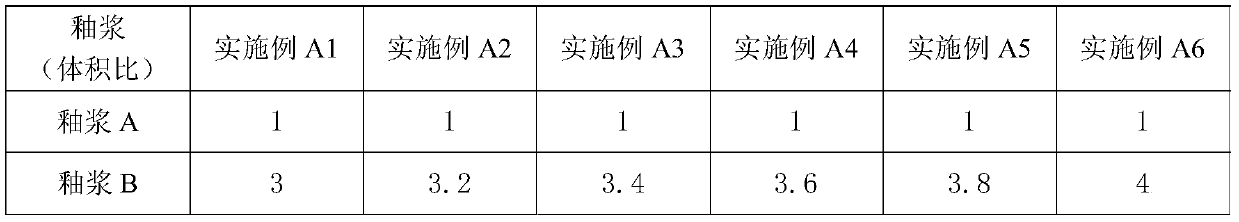

[0061] (3) Mix glaze slurry A and glaze slurry B at a volume ratio of 1: (3-4) to obtain glaze slurry C, which is the glaze slurry of the matte antifouling glaze, and it is forbidden to ball-mill the glaze slurry C again;

[0062] (4) Mix glaze A and high-temperature frit evenly to obtain glaze D. It is forbidden to ball-mill glaze D again. The weight ratio of glaze A to high-temperature frit in glaze...

Embodiment

[0096] Example group B is matte antifouling dry grain tiles

[0097] The matt antifouling dry grain ceramic tile of embodiment B1-B6 comprises the brick layer, the first glaze layer and the second glaze layer arranged in sequence from bottom to top, and the first glaze layer is prepared by one of embodiment A1-A6 glaze slurry C Fired and fired, the second glaze layer is fired from the glaze slurry D prepared in one of the embodiments A1-A6; the matte anti-fouling dry grain tile surface gloss is 2 to 3 degrees , The brick surface has a grainy feeling of sand and gravel. The preparation method of this matte antifouling dry grain tile is as follows:

[0098] (1), prepare adobe;

[0099] (2) Spread the glaze slurry C on the surface of the brick adobe, and the amount of glaze applied is 500-670g / m 2 ;

[0100] (3) Apply the glaze slurry D on the glaze slurry C of the brick adobe, and the glaze amount is 224-300g / m 2 ;

[0101] (4) Dry the adobe covered with glaze slurry C, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| gloss | aaaaa | aaaaa |

| gloss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com