FFC glaze with high stain resistance, FFC sanitary ceramic and preparation method of FFC sanitary ceramic

A technology of sanitary ceramics and ability, applied in the field of sanitary ceramics, can solve the problems of increasing cleaning difficulty, affecting human health, and easy breeding of bacteria, etc., to improve the bonding of blank glaze, increase the range of firing temperature, and reduce the possibility of defects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0045] The present invention also provides a method for preparing the FFC sanitary ceramics of the above-mentioned high antifouling ability FFC glaze, comprising the following steps:

[0046] Pre-milling of frit: Weigh the frit according to the ratio, and pre-mill the frit with the formula amount;

[0047] Ball milling: Weigh other raw materials except the frit according to the ratio, mix the other raw materials in the formula amount with the ball-milled frit obtained in the frit pre-milling step, and then add water to ball mill to obtain the glaze slurry. Among them, the addition of water The amount is 40-45% of the total weight of raw materials;

[0048] Sieving and removing iron: the glaze slurry obtained by the ball mill is sieved with 160-200 mesh and iron is removed;

[0049] Glazing: glaze the body of sanitary ceramics, the thickness of the glaze layer is 0.8-1.2mm;

[0050] Drying: The glazed sanitary ceramics are first dried in a drying room at 50°C, and then transf...

Embodiment 4

[0069] In Example 4, the amount of water added is 45% of the total amount of raw materials, the thickness of the glaze layer after 180-mesh sieving and de-iron glazing is 0.8mm, and the firing temperature is 1205°C.

Embodiment 5

[0070] In Example 5, the amount of water added is 42% of the total amount of raw materials, the thickness of the glaze layer after 160-mesh sieving and de-iron glazing is 1.2mm, and the firing temperature is 1220°C.

[0071]

[0072] Wherein, the frit includes the following components in parts by weight: 66%SiO 2 , 4%Al 2 o 3 , 8%CaO, 12%Na 2 O, 1.0%MgO, 7.8%B 2 o 3 . The content of potassium oxide in the potassium feldspar is 10%; the content of sodium oxide in the albite feldspar is 7%; the content of magnesium oxide in the calcined talc is 30%.

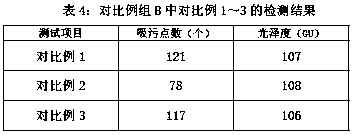

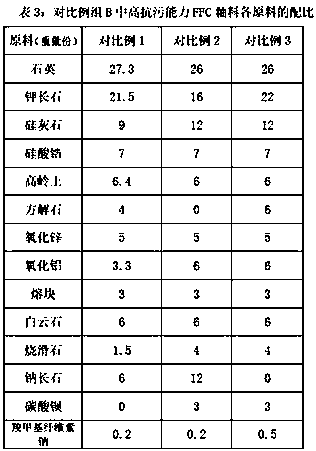

[0073] The sanitary ceramic plates were prepared by using the high anti-fouling ability FFC glazes with different raw material formulations in the above Table 1 and the above preparation method, and the sanitary ceramic plates and the sanitary ceramic samples of the prior art were subjected to the dirt absorption test and gloss test.

[0074] The test method of the stain absorption test is: apply red ink or blue ink on a 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Gloss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com