Low-cost zirconium-free white glaze suitable for sanitary ceramics and daily-use porcelain and preparation method thereof

A sanitary ceramics, low-cost technology, applied in the field of ceramics, can solve the problems of narrow melting temperature range of white glaze, yellowing of product color, easy cracking, etc., and achieve the effect of solving the narrow firing range and increasing the firing temperature range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] Further, the present invention proposes the preparation method of the low-cost zirconium-free white glaze suitable for sanitary ceramics and household porcelain, including the following specific steps:

[0030] S1) According to the calculation in parts by weight, prepare the various raw material components of the low-cost zirconium-free white glaze suitable for sanitary ceramics and daily-use porcelain, mix them evenly and add them to a ball mill for wet ball milling;

[0031] S2) Filter the glaze slurry prepared by ball milling in step S1 with a filter sieve, and further test to confirm that the particle size of the glaze slurry reaches the set standard, that is, the white glaze slurry is obtained;

[0032] S3) Using the white glaze slurry prepared in step S2, glazing the surface of the prepared ceramic dry body, the ceramic dry body is a dry body of sanitary ceramics or porcelain for daily use;

[0033] S4) The glazed ceramic dry body is fired in a kiln to obtain the ...

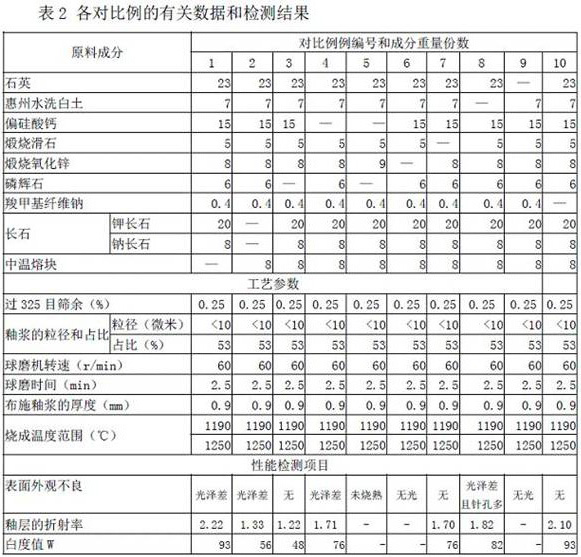

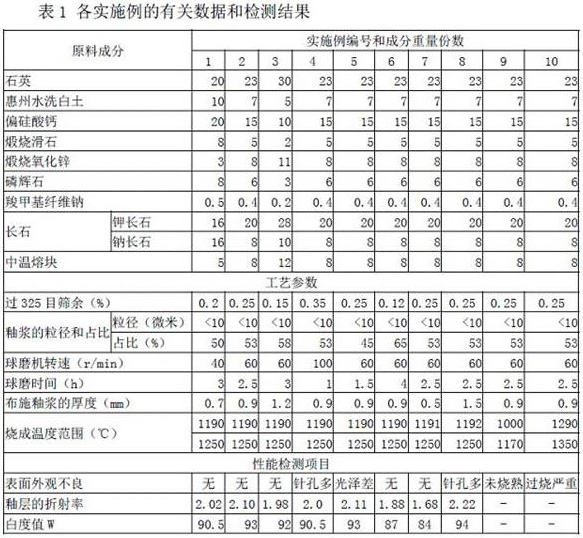

Embodiment 1-10 and comparative example 1-10

[0042] A low-cost zirconium-free white glaze suitable for sanitary ceramics and daily-use porcelain. The raw material components include: quartz, feldspar, Huizhou washed clay, calcium metasilicate, medium-temperature frit, calcined talc, calcined zinc oxide, Phosphopyroxene and additive sodium carboxymethylcellulose, wherein the feldspar includes potassium feldspar and albite; calculated by mass percentage, the chemical composition of the medium-temperature frit includes: 16.5% CaO, 4% MgO, 11.5% %Al 2 o 3 , 63% SiO 2 , 3%K 2 O and 1.5% Na 2 O.

[0043] The preparation method of the above-mentioned low-cost zirconium-free white glaze suitable for sanitary ceramics and daily-use porcelain comprises the following specific steps:

[0044] S1) According to the calculation in parts by weight, prepare the various raw material components of the low-cost zirconium-free white glaze suitable for sanitary ceramics and daily-use porcelain, mix them evenly and add them to a ball mill...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

| whiteness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com