Heating sheet and preparation method and application thereof

A heating sheet and heating electrode technology, which is applied in the field of electronic cigarettes, can solve the problems of difficulty in ensuring product consistency, affecting product flexural strength, and prone to fragmentation, and achieves the goals of reducing preparation difficulty, improving use adaptability, and prolonging service life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

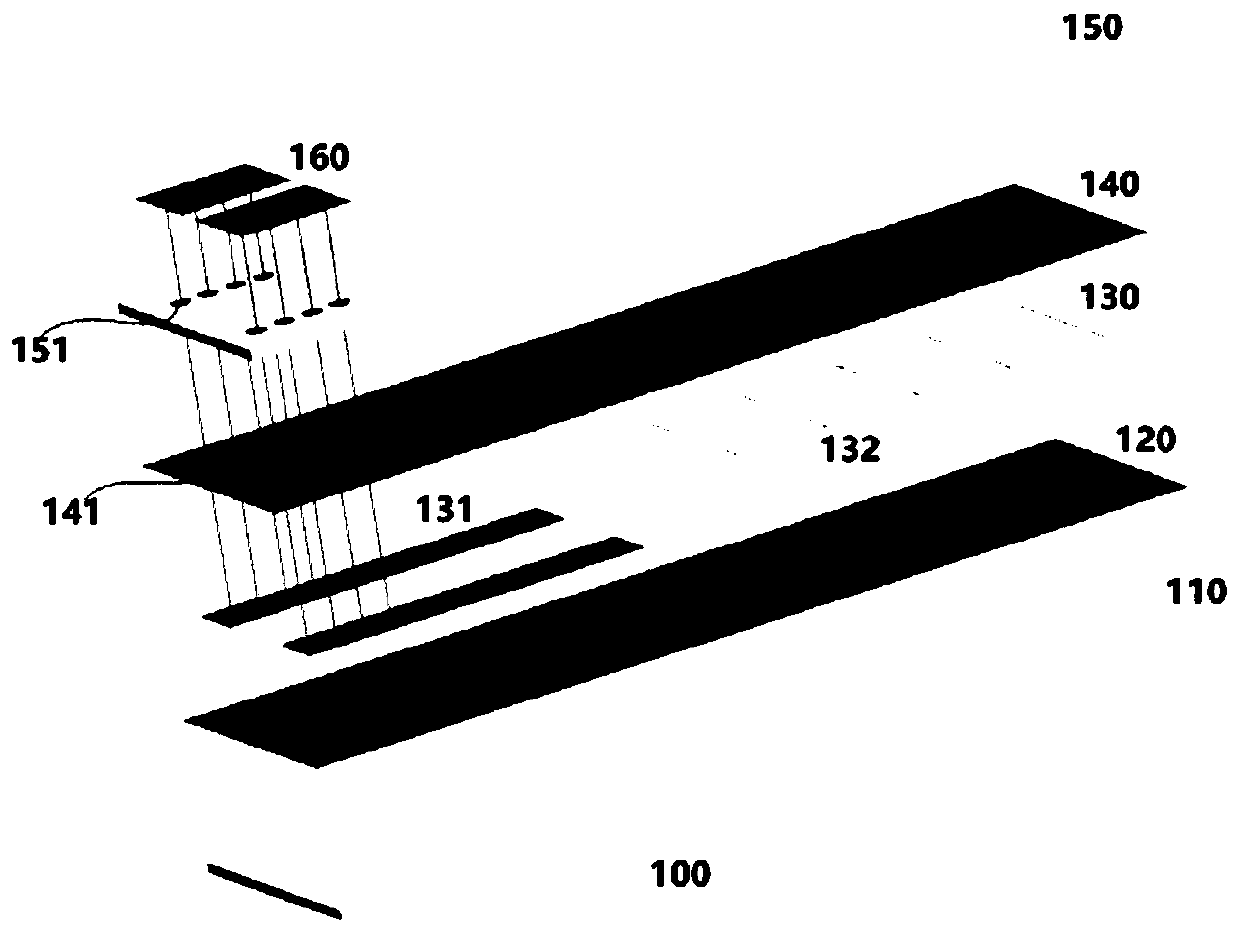

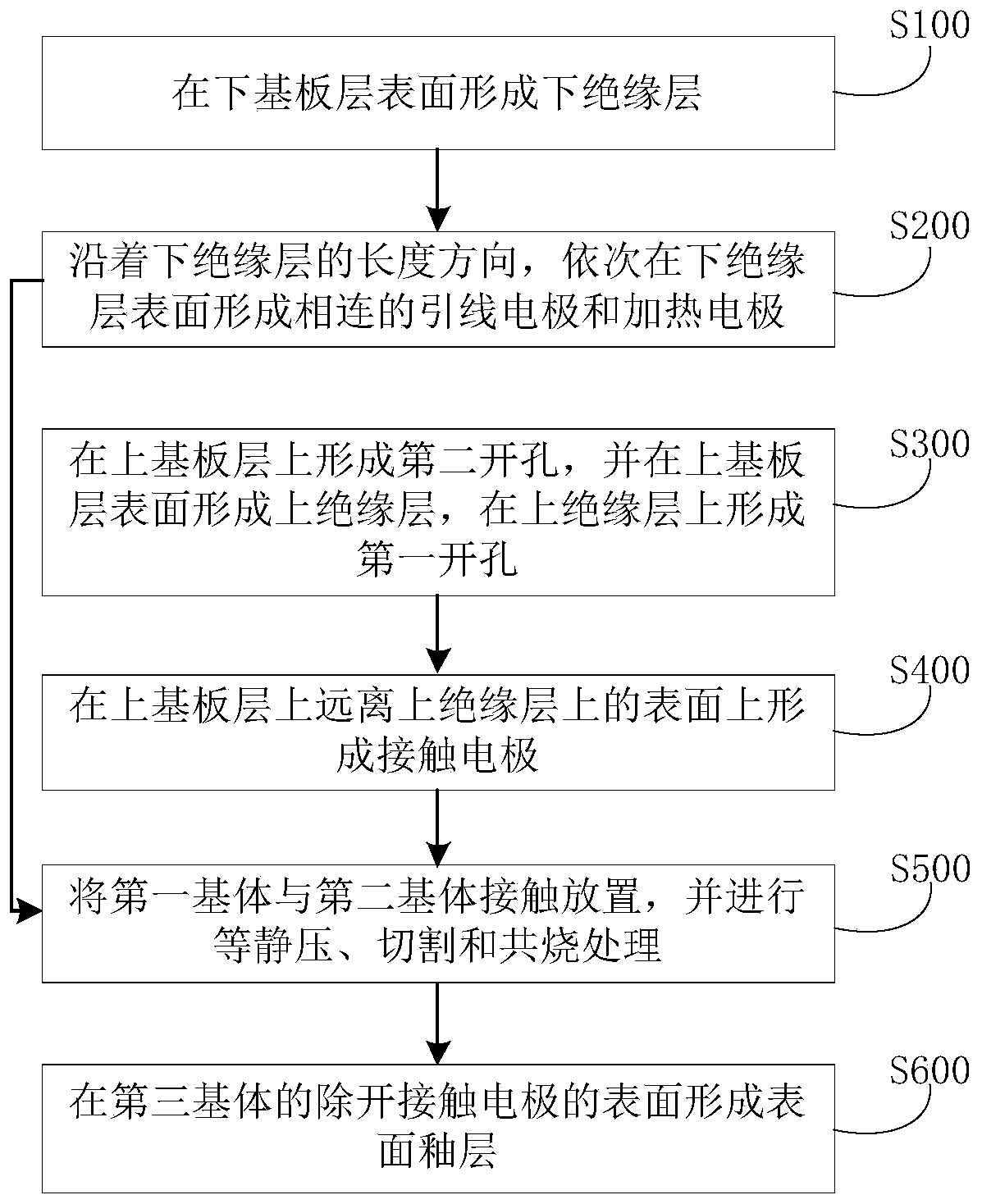

[0084] According to the method for preparing a heating sheet according to an embodiment of the present invention, the upper insulating layer and the lower insulating layer can respectively prevent the upper substrate layer and the lower substrate layer from generating ionic conductance at high temperature, thereby avoiding electrode disconnection; the heating electrode can realize heating of the heating sheet, The calorific value of the heating electrode can be controlled by controlling the resistance value of the heating electrode; both the lead electrode and the contact electrode have low resistance, the lead electrode can energize the heating electrode, and the contact electrode can be used for welding the external electrode lead, and has the same characteristics as the external electrode lead. Very low contact resistance, and the contact electrode is set above the upper substrate layer, and connected to the lead electrode through the second opening and the first opening, ins...

Embodiment 1

[0089] On the surface of the lower substrate layer made of YSZ with 2wt% yttrium oxide content, an aluminum oxide lower insulating layer is formed by screen printing; along the length direction of the lower insulating layer, lead electrodes made of platinum are sequentially formed on the surface of the lower insulating layer. and a heating electrode to obtain the first substrate; a second opening is formed on the upper substrate layer made of YSZ with a yttrium oxide content of 2wt%, and an upper insulating layer of aluminum oxide is formed on the surface of the upper substrate layer by screen printing, and the upper insulating layer is formed on the upper substrate layer. The first opening is formed on the layer, the number of the first opening and the second opening are consistent and the positions in the vertical direction are one-to-one; on the surface of the upper substrate layer away from the upper insulating layer, a material is formed by screen printing. The contact ele...

Embodiment 2

[0095] On the surface of the lower substrate layer made of YSZ with yttrium oxide content of 3wt%, an aluminum oxide lower insulating layer is formed by screen printing; along the length direction of the lower insulating layer, lead electrodes connected by platinum are formed on the surface of the lower insulating layer in turn. and a heating electrode to obtain the first substrate; a second opening is formed on the upper substrate layer made of YSZ3 with a yttrium oxide content of 3wt%, and an upper insulating layer of aluminum oxide is formed on the surface of the upper substrate layer by screen printing, and the upper insulating layer is formed on the upper substrate layer. The first opening is formed on the layer, the number of the first opening and the second opening are consistent and the positions in the vertical direction are one-to-one; on the surface of the upper substrate layer away from the upper insulating layer, a material is formed by screen printing. The contact...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com