Food heat preservation box for take-out delivery

A technology for incubators and foods, applied in thermal insulation containers, packaged foods, applications, etc., can solve the problems of long time consumption, increased negative reviews, and poor results, achieve good thermal insulation effect, avoid heat waste, and improve thermal insulation. effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

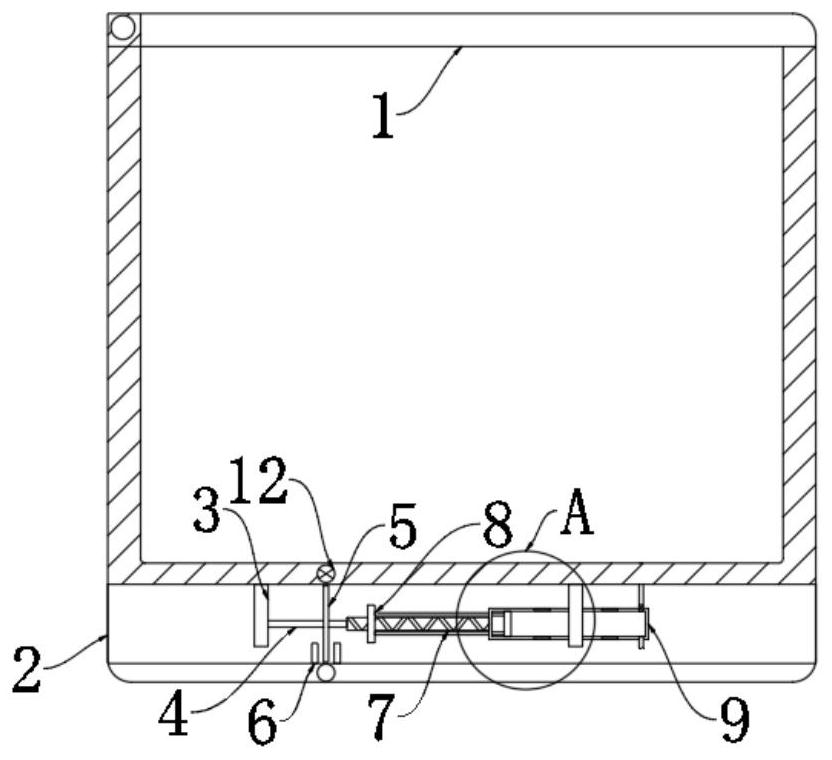

[0033] refer to Figure 1-3 , a food insulation box for takeaway distribution, comprising a box body 1, the lower end of the box body 1 is provided with an air duct 2;

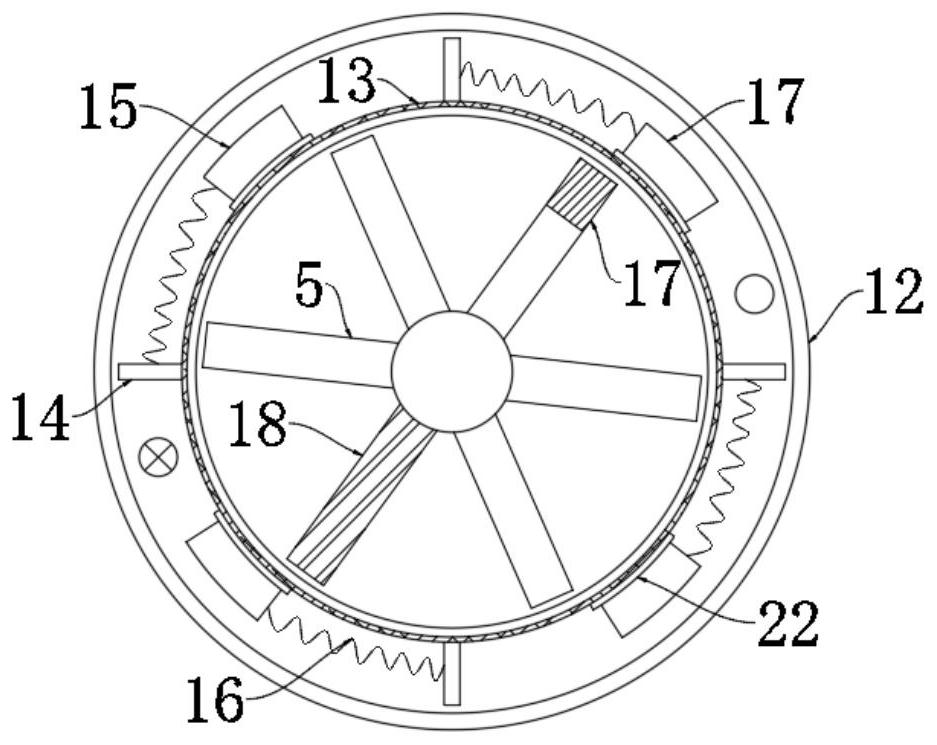

[0034] Two mounting plates 3 are fixedly connected in the air channel 2, and a transmission rod 4 is rotatably connected to the left mounting plate 3, and a plurality of obliquely arranged blades 5 are fixedly connected to the transmission rod 4;

[0035] The inner bottom of the air duct 2 is fixedly connected with a pair of first magnets 6 with opposite magnetic properties, and a plurality of blades 5 pass through the middle of the pair of first magnets 6;

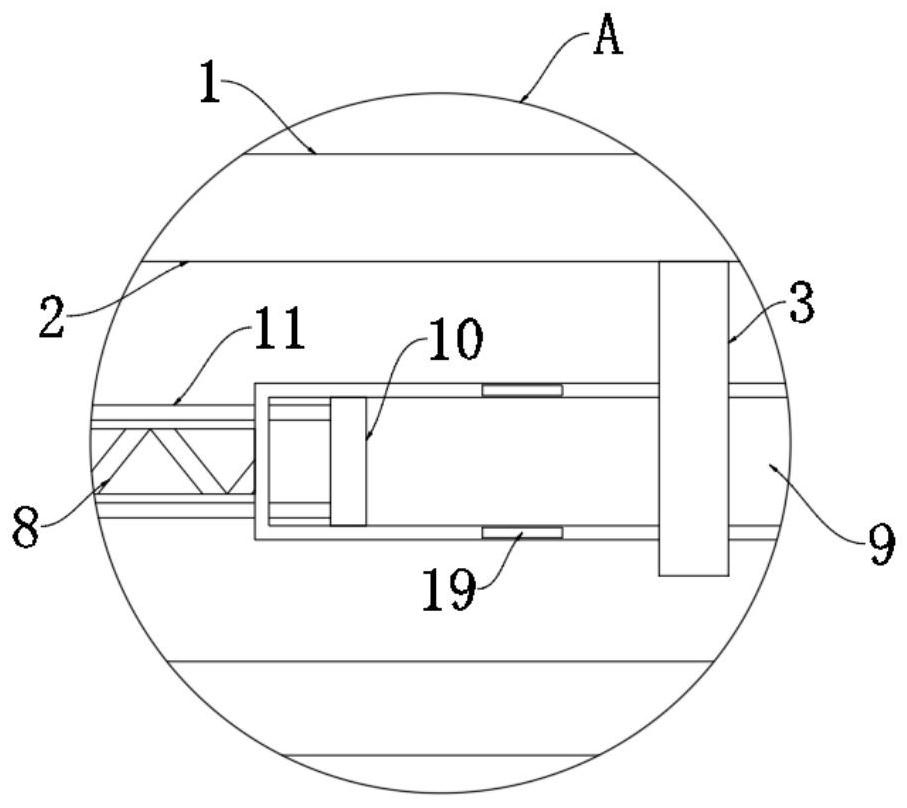

[0036] The right end of the transmission rod 4 is fixedly connected with a reciprocating lead screw 7, and the reciprocating lead screw 7 is provided with a lead screw nut 8 matched therewith;

[0037] The mounting plate 3 at the right end is provided with an air storage tank 9, the air storage tank 9 is sealed and slidably connected with a sliding plug ...

Embodiment 2

[0047] refer to Figure 4 , a food incubator for takeaway distribution, the left and right walls of the box body 1 are provided with cavities 20, and the cavities 20 are filled with phase change materials 21.

[0048] The filling height of the phase change material 21 is one-third of the height of the cavity 20, and the deformation temperature of the phase change material 21 is 50°C.

[0049] The working principle of this embodiment is that after the hot gas enters the box body 1, the temperature inside the box body 1 is relatively high, thereby reaching the deformation temperature of the phase change material 21, where the phase change material 21 is paraffin, and its deformation temperature is 50 °C, the phase change material 21 absorbs heat and liquefies at this time. When the car stops, no hot air enters at this time, and the temperature in the box body 1 begins to drop. When it drops to the deformation temperature of the phase change material 21, the phase change material...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com