Anaerobic reactor of horizontal flow fixed bed

An anaerobic reactor and fixed bed technology, which is applied in the field of anaerobic reactors, can solve problems such as inability to keep warm, easy sludge sedimentation, and increased reactor space, and achieve strong impact load resistance, high treatment efficiency, and load big effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

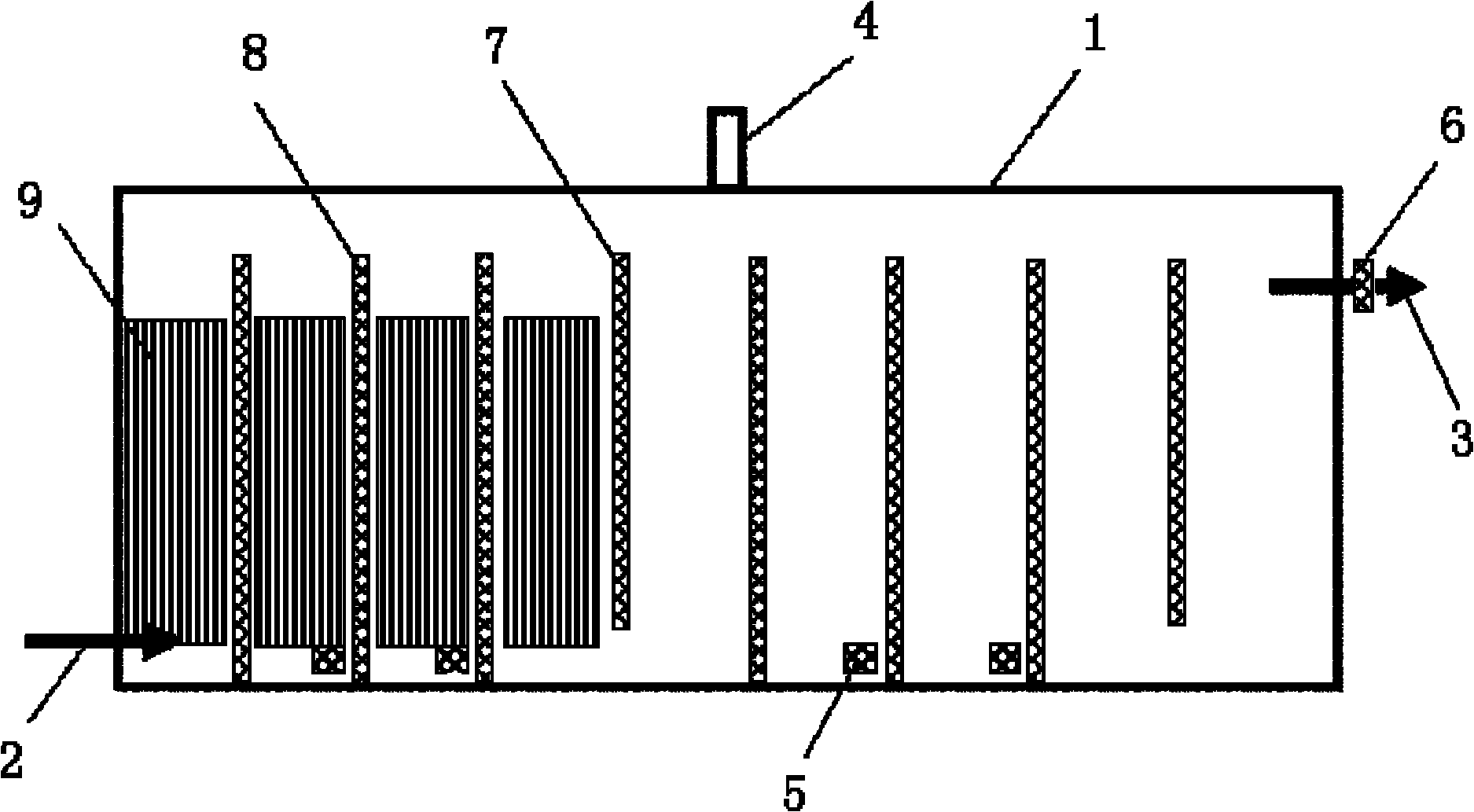

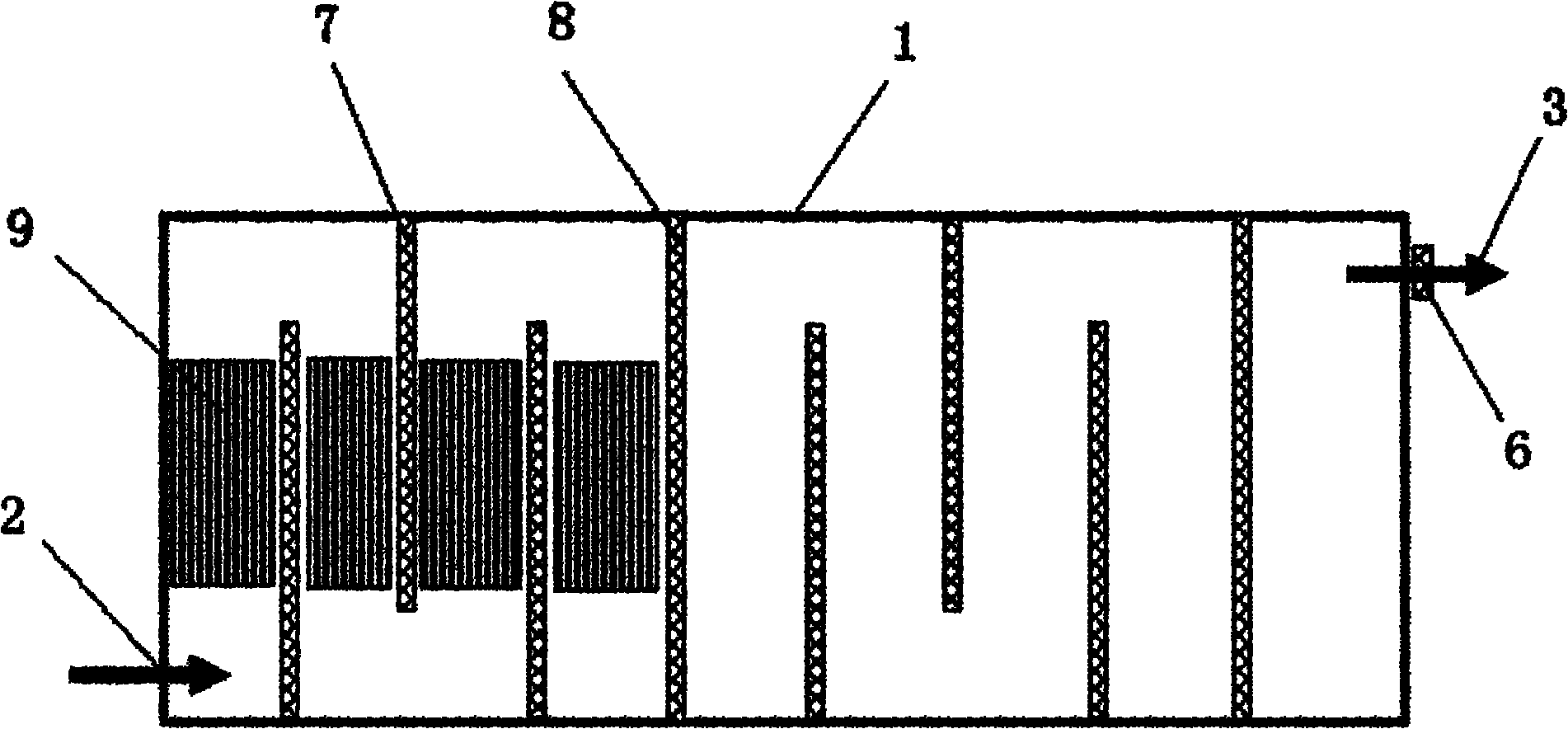

[0018] Such as figure 1 , figure 2 As shown, the present invention includes a casing 1 with a top cover, the two ends of the casing 1 are respectively provided with a feed port 2 and a discharge port 3, the top of the casing 1 is provided with a gas collection pipeline 4, and the bottom of the casing 1 is provided with a plurality of slag discharge Mouth 5. A filter screen 6 is provided at the discharge port 3 and the slag discharge port 5, and a plurality of vertical partition baffles 7 and diversion baffles 8 are provided inside the shell 1 along the water flow direction, and the partitions on the side close to the feed port 2 A fixed membrane carrier assembly 9 is arranged between the plates 7 .

[0019] In the above embodiments, the housing 1 can adopt a rectangular structure or other horizontal structures, so that it can be conveniently place...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com